Bolt With Stopper Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for bolt with stopper

In today’s interconnected global economy, sourcing high-quality components like the bolt with stopper can present significant challenges for B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. The complexity of navigating supplier networks, ensuring compliance with international standards, and managing costs can hinder procurement efficiency. This guide is designed to equip international buyers with the essential knowledge needed to make informed purchasing decisions regarding bolts with stoppers.

We delve into various types of stopper bolts, examining their specific applications in machinery, automotive, and manufacturing sectors. Additionally, we provide insights into the importance of supplier vetting, highlighting key factors such as material quality, manufacturing processes, and certifications that guarantee product reliability. Understanding pricing structures and market trends is also critical, as it enables buyers to negotiate effectively and optimize their procurement strategies.

By leveraging this comprehensive guide, B2B buyers will gain a strategic advantage in sourcing bolts with stoppers that meet their operational requirements. Our aim is to empower your decision-making process, ensuring that you can confidently navigate the complexities of the global market and secure the best products for your business needs. Whether you’re in Vietnam, Brazil, or any other market, this resource is tailored to support your specific procurement challenges.

Understanding bolt with stopper Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Stopper Bolt | Fixed length, typically made from stainless steel | Automotive, manufacturing | Pros: Cost-effective, widely available. Cons: Limited adjustability. |

| Adjustable Stopper Bolt | Features adjustable length for precise positioning | Machinery, robotics | Pros: Customizable for specific applications. Cons: May require additional tools for adjustment. |

| Shoulder Type Stopper Bolt | Includes a shoulder to limit movement, often with a bumper | Construction, heavy machinery | Pros: Enhances safety by preventing over-travel. Cons: Bulkier design may limit space. |

| Hex Socket Head Stopper Bolt | Hexagonal socket for easy installation and removal | Industrial equipment, assembly lines | Pros: Facilitates quick maintenance. Cons: Requires specific tools for use. |

| Low Repulsion Urethane Stopper Bolt | Made with specialized urethane for reduced impact | Sensitive machinery, electronics | Pros: Protects delicate components from damage. Cons: Higher cost compared to standard materials. |

What Are the Characteristics of Standard Stopper Bolts?

Standard stopper bolts are typically constructed from durable materials like stainless steel, making them suitable for various environments, including automotive and manufacturing sectors. They are designed to provide a fixed length, which is ideal for applications where exact positioning is not critical. When purchasing, buyers should consider their specific application requirements, as the lack of adjustability may not meet all operational needs.

How Do Adjustable Stopper Bolts Enhance Flexibility?

Adjustable stopper bolts allow for customization in length, enabling precise positioning within machinery and robotics applications. This feature is particularly beneficial in dynamic environments where operational parameters may change. Buyers should evaluate the ease of adjustment, as some variations may require additional tools or expertise, potentially impacting maintenance efficiency.

What Makes Shoulder Type Stopper Bolts Unique?

Shoulder type stopper bolts are distinguished by their shoulder feature, which prevents over-travel and enhances safety in construction and heavy machinery applications. These bolts often come with a bumper to absorb impact, making them ideal for high-stress environments. Buyers should consider the space constraints of their applications, as the bulkier design may not be suitable for all setups.

Why Choose Hex Socket Head Stopper Bolts for Industrial Applications?

Hex socket head stopper bolts are designed for quick installation and removal, making them a preferred choice in industrial equipment and assembly lines. Their unique hexagonal shape allows for efficient maintenance, which can reduce downtime. Buyers must ensure they have the appropriate tools for installation, as this can affect overall operational efficiency.

How Do Low Repulsion Urethane Stopper Bolts Protect Sensitive Machinery?

Low repulsion urethane stopper bolts are crafted with specialized materials that minimize impact, making them ideal for protecting delicate components in sensitive machinery and electronics. Their ability to absorb shock can prevent damage and enhance the longevity of equipment. While they offer significant benefits, buyers should be prepared for a higher upfront cost compared to standard materials, weighing long-term savings against initial investments.

Key Industrial Applications of bolt with stopper

| Industry/Sector | Specific Application of bolt with stopper | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Used in assembly lines to limit the movement of components | Ensures precision in assembly, reducing error rates | Material specifications (e.g., stainless steel), thread sizes |

| Manufacturing | Employed in machinery to restrict motion of moving parts | Enhances safety by preventing over-travel of components | Load capacity, durability, and compliance with industry standards |

| Construction | Utilized in scaffolding to secure structural elements | Increases stability and safety in construction environments | Compliance with local regulations, weather resistance |

| Food and Beverage | Applied in canning machines to control can transfer | Improves efficiency and consistency in production processes | Hygiene standards, corrosion resistance, and material safety |

| Material Handling | Used in conveyor systems to stop items at designated points | Streamlines operations and minimizes product loss | Compatibility with existing systems, adjustability, and ease of maintenance |

How is the bolt with stopper used in the automotive industry?

In the automotive sector, bolts with stoppers are integral to assembly lines, where they are used to limit the movement of various components during the manufacturing process. This precise positioning helps to ensure that parts fit correctly, thereby minimizing errors and enhancing overall efficiency. Buyers in this industry should consider the specific material requirements, such as stainless steel for corrosion resistance, and the appropriate thread sizes to match their assembly needs.

What are the applications of bolt with stopper in manufacturing?

In manufacturing environments, bolts with stoppers are critical for machinery that requires restricted movement of parts. These fasteners prevent components from exceeding their designated travel limits, which not only enhances safety but also reduces wear and tear on machinery. For international buyers, it’s essential to focus on load capacities and the durability of the materials, as well as compliance with local safety and operational standards.

How does the construction industry benefit from using bolts with stoppers?

In the construction industry, bolts with stoppers are commonly used in scaffolding systems to secure structural elements and prevent unintended movement. This application increases stability and safety, protecting workers and ensuring the integrity of the structure. Buyers should prioritize sourcing bolts that meet local regulations and standards, particularly regarding load-bearing capacities and weather resistance, which are vital for outdoor use.

What role do bolts with stoppers play in the food and beverage sector?

Within the food and beverage industry, bolts with stoppers are utilized in canning machines to control the transfer of cans along production lines. This application is crucial for maintaining production efficiency and consistency, ensuring that cans are filled and sealed accurately. Buyers must consider hygiene standards, as well as the corrosion resistance of materials used, to ensure compliance with food safety regulations.

How are bolts with stoppers used in material handling applications?

In material handling, bolts with stoppers are essential components in conveyor systems, allowing for the precise stopping of items at designated points. This functionality streamlines operations, reduces the risk of product loss, and enhances workflow efficiency. Buyers should evaluate compatibility with existing systems, adjustability for operational flexibility, and ease of maintenance when sourcing these fasteners.

3 Common User Pain Points for ‘bolt with stopper’ & Their Solutions

Scenario 1: Difficulty in Sourcing the Right Specifications

The Problem: Many B2B buyers encounter challenges when sourcing stopper bolts that meet specific application requirements. This can stem from a lack of clarity in product specifications, such as thread size, material type, and length. For instance, a manufacturer in South America may need a stopper bolt with a unique thread size for their machinery but finds limited availability in local suppliers. This not only leads to production delays but can also incur higher costs due to emergency sourcing.

The Solution: To effectively source the right stopper bolts, buyers should begin by conducting thorough research on their specific needs. This includes understanding the machinery or equipment where the bolts will be used and noting the exact specifications required, such as thread pitch (e.g., M12x1.75), length (e.g., 70mm), and material (e.g., 304 stainless steel). Once these details are established, buyers can leverage international suppliers who specialize in custom fasteners. Utilizing platforms like MISUMI or Wild Goose Parts allows buyers to filter products based on their precise specifications, ensuring they find the correct stopper bolts without delay. Additionally, establishing relationships with reliable suppliers who can provide technical assistance and rapid prototyping can further streamline the sourcing process.

Scenario 2: Issues with Product Compatibility Across Equipment

The Problem: Another common issue faced by B2B buyers is ensuring that stopper bolts are compatible with existing machinery. A construction company in the Middle East may purchase bolts that fit their specifications but later discover that the threads do not align with their equipment. This oversight can lead to significant downtime and costly rework.

The Solution: To mitigate compatibility issues, it is crucial to perform a compatibility assessment before purchasing stopper bolts. Buyers should collaborate closely with their engineering teams to gather detailed drawings and specifications of the machinery. Additionally, requesting samples or conducting trials before bulk purchasing can help verify that the bolts function as intended. Engaging with suppliers who provide technical support and can assist in compatibility checks is also beneficial. By establishing clear communication with suppliers about the specific application and requesting guidance on suitable products, buyers can avoid the pitfalls of mismatched components.

Scenario 3: Performance Concerns Under Variable Conditions

The Problem: B2B buyers often face performance concerns regarding stopper bolts, especially when used in environments with fluctuating temperatures or exposure to corrosive substances. For example, a beverage manufacturing plant in Brazil might require bolts that can withstand high humidity and chemical exposure. If the wrong materials are chosen, this could lead to premature wear and failure, impacting operational efficiency.

The Solution: To address performance concerns, buyers should prioritize selecting stopper bolts made from materials specifically designed for their operating conditions. Conducting a thorough analysis of the environmental factors at play is essential. For humid or corrosive environments, opting for bolts made from corrosion-resistant materials like 304 stainless steel or specialized coatings can enhance durability. Furthermore, buyers can consult with suppliers about their product’s performance in various conditions, ensuring they choose bolts that will maintain integrity over time. Implementing a regular maintenance schedule to inspect and replace worn components can also extend the life of the equipment and reduce downtime, ultimately leading to more consistent operational performance.

Strategic Material Selection Guide for bolt with stopper

What are the Key Properties of Common Materials for Bolt with Stopper?

When selecting materials for bolts with stoppers, it’s crucial to understand the unique properties of each material and how they impact performance. Here, we analyze four common materials: stainless steel, carbon steel, alloy steel, and plastic. Each material has its advantages and disadvantages, which can significantly influence their suitability for various applications.

How Does Stainless Steel Perform in Bolt with Stopper Applications?

Key Properties: Stainless steel, particularly grades like 304 and 316, offers excellent corrosion resistance and high tensile strength. It can withstand temperatures up to 800°F (427°C) and is suitable for various environments, including those with moisture and chemicals.

Pros & Cons: The primary advantage of stainless steel is its durability and resistance to rust, making it ideal for outdoor applications or in humid environments. However, it tends to be more expensive than other materials, which could impact budget-sensitive projects. Manufacturing complexity is moderate, as stainless steel requires specific machining techniques.

Impact on Application: Stainless steel bolts with stoppers are compatible with a wide range of media, including water, oils, and various chemicals, making them versatile for different industries.

Considerations for International Buyers: Compliance with international standards like ASTM A276 and DIN 17440 is essential. Buyers should also consider the availability of stainless steel in their regions, as supply chain issues may arise in less developed markets.

What Role Does Carbon Steel Play in Bolt with Stopper Manufacturing?

Key Properties: Carbon steel is known for its high strength and hardness, making it suitable for heavy-duty applications. However, it lacks corrosion resistance unless treated with coatings.

Pros & Cons: The main advantage of carbon steel is its cost-effectiveness, making it a popular choice for budget-conscious projects. Its high strength-to-weight ratio is beneficial for applications requiring robust performance. On the downside, untreated carbon steel can rust easily, limiting its use in outdoor or humid environments.

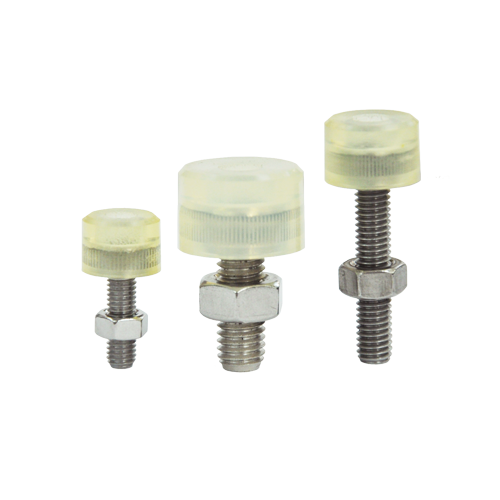

Illustrative image related to bolt with stopper

Impact on Application: Carbon steel bolts with stoppers are ideal for applications where high strength is required, such as construction and heavy machinery. However, they may not be suitable for environments where exposure to moisture is a concern.

Considerations for International Buyers: Buyers should be aware of the need for protective coatings to enhance corrosion resistance. Compliance with standards such as ASTM A307 is also critical for ensuring quality and safety.

Why Choose Alloy Steel for Bolt with Stopper Applications?

Key Properties: Alloy steel combines various elements to enhance specific properties, such as strength, hardness, and wear resistance. It can withstand high temperatures and pressures, making it suitable for demanding applications.

Pros & Cons: The key advantage of alloy steel is its exceptional strength and durability, which make it ideal for high-stress environments. However, it is generally more expensive than carbon steel and may require specialized machining processes, increasing manufacturing complexity.

Impact on Application: Alloy steel bolts with stoppers are often used in automotive and aerospace applications, where performance and reliability are critical. They can handle various media, including oils and fuels.

Illustrative image related to bolt with stopper

Considerations for International Buyers: Compliance with standards like ASTM A193 and JIS G3101 is essential for ensuring the quality and reliability of alloy steel components. Buyers should also consider the availability of alloy steel in their regions.

What Are the Benefits of Using Plastic in Bolt with Stopper Applications?

Key Properties: Plastic materials, such as nylon or polycarbonate, offer lightweight and corrosion-resistant options. They can withstand moderate temperatures and are often used in non-metallic applications.

Pros & Cons: The primary advantage of plastic is its low cost and lightweight nature, making it suitable for applications where weight savings are crucial. However, plastic bolts may not offer the same strength as metal counterparts, limiting their use in heavy-duty applications.

Impact on Application: Plastic bolts with stoppers are ideal for applications in electronics or where corrosion resistance is paramount, such as in marine environments. They are not suitable for high-stress applications.

Considerations for International Buyers: Buyers should ensure that the plastic materials meet relevant standards, such as ASTM D638 for tensile properties. Availability may vary by region, impacting sourcing decisions.

Summary Table of Material Selection for Bolt with Stopper

| Material | Typical Use Case for bolt with stopper | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Marine, chemical processing | Excellent corrosion resistance | Higher cost | High |

| Carbon Steel | Construction, heavy machinery | Cost-effective and strong | Prone to rust without coatings | Low |

| Alloy Steel | Automotive, aerospace | Exceptional strength and durability | Higher manufacturing complexity | Med |

| Plastic | Electronics, marine applications | Lightweight and corrosion-resistant | Limited strength for heavy-duty | Low |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of various materials for bolts with stoppers, aiding in informed decision-making for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for bolt with stopper

What Are the Key Stages in the Manufacturing Process of a Bolt with Stopper?

The manufacturing of a bolt with stopper involves several critical stages that ensure both functionality and quality. These stages include material preparation, forming, assembly, and finishing, each employing specific techniques to meet industry standards and customer requirements.

How Is Material Prepared for Bolt Manufacturing?

The first step in the manufacturing process is material preparation. Typically, stainless steel, particularly grade 304, is chosen for its strength and corrosion resistance. The raw material is sourced from reputable suppliers to ensure quality. Before processing, the material undergoes inspection to verify its compliance with specifications. This includes checking for material composition and any visible defects.

What Forming Techniques Are Used in Bolt Production?

Once the material is prepared, the next phase is forming. This stage typically employs techniques such as cold forging and machining. Cold forging is favored for its efficiency and ability to produce high-strength components with excellent surface finishes. The process involves shaping the metal at room temperature, which enhances its structural integrity. Following forging, machining processes like threading and drilling are utilized to create precise dimensions and features, such as the M12x1.75 thread seen in stopper bolts.

Illustrative image related to bolt with stopper

How Are Bolt Components Assembled?

After forming, the assembly stage begins. For bolts with stoppers, this involves integrating the stopper material—often urethane—into the final product. The assembly may require additional fastening techniques to ensure the components are securely attached. This stage is crucial as it directly impacts the bolt’s operational reliability in its intended application, such as in can transfer units in beverage systems.

What Finishing Processes Enhance the Durability of Bolts?

The final manufacturing stage is finishing, which includes processes such as surface treatment, coating, and polishing. Surface treatments like passivation help to enhance corrosion resistance, while coatings may provide additional protection or aesthetic appeal. Polishing improves the surface finish, ensuring that the bolt operates smoothly and minimizes wear on the connected components.

What Quality Assurance Practices Are Essential in Bolt Manufacturing?

Quality assurance (QA) is a vital aspect of the manufacturing process, ensuring that products meet both international and industry-specific standards. For bolts with stoppers, adherence to standards such as ISO 9001 is critical. This standard outlines requirements for a quality management system that can enhance customer satisfaction and streamline processes.

Which International Standards Should B2B Buyers Consider?

B2B buyers should be aware of various international standards that govern product quality. ISO 9001 is a foundational standard that applies to all manufacturing sectors, while additional certifications may be relevant depending on the industry. For example, CE marking indicates compliance with European safety standards, while the API (American Petroleum Institute) certification is crucial for components used in the oil and gas sector. Understanding these standards helps buyers assess the reliability of potential suppliers.

How Are Quality Control Checkpoints Implemented?

Quality control (QC) checkpoints are integrated throughout the manufacturing process. Incoming Quality Control (IQC) checks the quality of raw materials upon arrival. In-Process Quality Control (IPQC) monitors production processes, ensuring that each stage meets predefined specifications. Finally, Final Quality Control (FQC) examines the finished products before shipment, verifying that they meet all quality standards and customer specifications.

Illustrative image related to bolt with stopper

What Common Testing Methods Are Used to Verify Bolt Quality?

Several testing methods are employed to ensure the quality of bolts with stoppers. These include:

- Tensile Testing: Measures the strength and ductility of the material.

- Hardness Testing: Assesses the material’s resistance to deformation.

- Dimensional Inspection: Ensures that the bolt meets specified size and threading requirements.

- Non-Destructive Testing (NDT): Techniques such as ultrasonic or magnetic particle testing may be used to detect internal defects without damaging the product.

How Can B2B Buyers Verify Supplier Quality Assurance?

When sourcing bolts with stoppers, B2B buyers can take several steps to verify supplier quality assurance:

- Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes and quality control measures firsthand.

- Quality Reports: Requesting detailed QC reports can provide insights into the supplier’s testing methods and results.

- Third-party Inspections: Engaging independent inspection agencies can offer an unbiased assessment of the supplier’s quality control practices.

What Are the Quality Control Nuances for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control. Variations in local regulations and standards can affect product compliance. Additionally, language barriers and cultural differences may pose challenges in communication. To mitigate these risks, buyers should establish clear specifications and expectations upfront and consider using standardized documentation to facilitate smoother transactions.

By understanding the manufacturing processes and quality assurance practices involved in the production of bolts with stoppers, B2B buyers can make informed decisions that enhance their supply chain reliability and product performance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bolt with stopper’

In the competitive landscape of B2B procurement, acquiring the right components like bolts with stoppers can significantly impact operational efficiency. This guide serves as a practical checklist for international buyers looking to source these essential fasteners, ensuring a seamless purchasing process.

Illustrative image related to bolt with stopper

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the bolt with stopper. This includes dimensions, materials, and any specific performance criteria that your application demands.

– Material Considerations: Common materials include stainless steel and urethane, which offer durability and resistance to corrosion.

– Dimensions and Thread Types: Specify thread sizes (e.g., M12x1.75) and lengths to avoid compatibility issues.

Step 2: Research Potential Suppliers

Investigate suppliers who specialize in manufacturing bolts with stoppers. Look for companies with a proven track record in your industry and region.

– Industry Experience: Suppliers with experience in your specific application (e.g., automotive, construction) are likely to offer better insights and product recommendations.

– Market Presence: Consider suppliers who are well-established in regions like Africa, South America, the Middle East, and Europe.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, verify their certifications and compliance with international standards. This is crucial for ensuring product quality and safety.

– ISO Certification: Look for suppliers with ISO certifications relevant to manufacturing processes.

– Material Certifications: Ensure that materials used meet necessary industry standards for safety and performance.

Step 4: Request Product Samples

Always request samples before placing a bulk order. This allows you to assess the quality and suitability of the bolt with stopper for your specific needs.

– Quality Assessment: Inspect the samples for material integrity, thread precision, and overall finish.

– Testing Compatibility: Test samples in your application to verify performance under real-world conditions.

Illustrative image related to bolt with stopper

Step 5: Compare Pricing and Terms

Once you have narrowed down your options, compare pricing structures and payment terms from different suppliers.

– Bulk Discounts: Inquire about discounts for larger orders or long-term contracts, which can significantly reduce costs.

– Payment Flexibility: Evaluate payment terms that can accommodate your cash flow, such as net 30 or net 60 options.

Step 6: Check Lead Times and Delivery Options

Understand the lead times and delivery options offered by your selected suppliers. Timely delivery is critical in maintaining your production schedules.

– Shipping Methods: Discuss available shipping options, including air freight for urgent needs or sea freight for cost savings.

– Order Tracking: Ensure the supplier provides tracking information to monitor the shipment status.

Step 7: Establish a Communication Protocol

Set up a clear communication protocol with your chosen supplier to facilitate ongoing dialogue throughout the procurement process.

– Regular Updates: Establish a schedule for updates on order status, potential delays, or changes in product specifications.

– Feedback Mechanism: Create a feedback loop for addressing issues or concerns quickly, ensuring a smooth partnership.

By following this checklist, international B2B buyers can effectively navigate the sourcing process for bolts with stoppers, ensuring they procure high-quality components that meet their operational needs.

Comprehensive Cost and Pricing Analysis for bolt with stopper Sourcing

What Are the Key Cost Components in Sourcing Bolt with Stopper?

When sourcing bolts with stoppers, understanding the cost structure is crucial for effective budgeting and procurement. The primary cost components include:

-

Materials: The choice of materials significantly impacts the cost. Common materials for bolts include stainless steel, alloy steel, and various polymers for stoppers. For instance, 304 stainless steel is a popular option due to its durability and resistance to corrosion, but it may come at a premium compared to other materials.

-

Labor: Labor costs can vary based on the region and the complexity of manufacturing. Skilled labor is often required for precision machining and assembly, especially for custom specifications. Buyers should consider the local labor market conditions when assessing overall costs.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment maintenance. Overhead costs can vary significantly by region, affecting the final price of the bolts.

-

Tooling: Custom tooling may be necessary for specific designs or high-volume orders, which can add to the initial investment. The cost of tooling is often amortized over larger production runs, making it more economical for bulk orders.

-

Quality Control (QC): Ensuring the bolts meet industry standards is essential, especially in sectors like automotive or aerospace. QC processes can add to the cost but are necessary to mitigate risks associated with product failure.

-

Logistics: Shipping and handling costs can fluctuate based on distance, shipping methods, and the chosen Incoterms. For international buyers, understanding these logistics costs is vital to calculate the total landed cost accurately.

-

Margin: Suppliers typically add a margin to cover their costs and profit. This margin can vary based on the supplier’s market position, brand reputation, and the competitive landscape.

What Influences Pricing for Bolt with Stopper?

Several factors influence the pricing of bolts with stoppers:

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes generally lead to lower per-unit costs due to economies of scale. Suppliers often offer discounts for bulk orders, making it beneficial for buyers to consolidate their purchases.

-

Specifications and Customization: Custom designs or specifications can lead to increased costs due to the need for specialized tooling and manufacturing processes. Buyers should clarify their requirements upfront to avoid unexpected expenses.

-

Material Quality and Certifications: The quality of materials and any required certifications (e.g., ISO, ASTM) can significantly affect pricing. Higher-quality materials or those with specific certifications may incur higher costs but can lead to improved performance and longevity.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more but often provide better quality assurance and customer support.

-

Incoterms: The choice of Incoterms determines the responsibilities of buyers and sellers regarding shipping and logistics. For instance, FOB (Free on Board) may lead to lower shipping costs for buyers, while CIF (Cost, Insurance, and Freight) may include more comprehensive shipping services but at a higher price.

What Tips Can Help Buyers Negotiate Better Pricing?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, several negotiation strategies can enhance cost-efficiency:

-

Understand Total Cost of Ownership (TCO): Beyond the initial purchase price, consider long-term costs such as maintenance, replacement, and potential downtime. Investing in higher-quality bolts may lead to savings in the long run.

-

Leverage Volume Discounts: Consolidating orders can provide leverage in negotiations. Discuss potential discounts based on projected order volumes or long-term contracts.

-

Compare Multiple Suppliers: Engage with various suppliers to gather quotes and insights into pricing structures. This competitive approach can lead to better deals.

-

Clarify Specifications Early: Being clear about your needs from the outset minimizes the risk of costly adjustments later in the process.

-

Educate Yourself on Local Market Dynamics: Understanding the local economic conditions, tariffs, and regulations can provide insights into pricing variations and help in negotiations.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always consult with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing bolt with stopper With Other Solutions

When evaluating mechanical fasteners and positioning components, B2B buyers often encounter a variety of solutions tailored to specific applications. One such product is the bolt with stopper, commonly used to control movement in machinery. However, there are alternative solutions that can also achieve similar objectives. This section provides a comparative analysis of the bolt with stopper against two viable alternatives: the adjustable stop and the pneumatic cylinder.

Illustrative image related to bolt with stopper

| Comparison Aspect | Bolt With Stopper | Adjustable Stop | Pneumatic Cylinder |

|---|---|---|---|

| Performance | Reliable for fixed positioning | Offers flexibility in stopping points | High-speed actuation and precise control |

| Cost | Moderate cost, generally affordable | Generally lower cost | Higher initial investment |

| Ease of Implementation | Simple installation | Easy to adjust, requires minimal tools | Requires more complex setup and integration |

| Maintenance | Low maintenance, durable materials | Requires occasional recalibration | Regular maintenance needed for optimal performance |

| Best Use Case | Fixed applications in manufacturing | Variable applications, such as assembly lines | Automated systems requiring quick adjustments |

What Are the Pros and Cons of Using an Adjustable Stop as an Alternative?

Adjustable stops are mechanical devices that can be set to limit the movement of components in a system. They are often made from durable materials and can be adjusted easily to meet specific operational needs. The primary advantage of adjustable stops is their flexibility; they allow for quick changes to stopping points, making them ideal for applications where production processes may vary. However, the need for occasional recalibration can lead to downtime, which may not be suitable for high-volume manufacturing environments.

How Does a Pneumatic Cylinder Compare to a Bolt with Stopper?

Pneumatic cylinders utilize compressed air to create linear motion, providing a high degree of control and speed in operations. They are particularly advantageous in environments where rapid actuation is necessary, such as in automated assembly lines or robotic applications. The ability to control movement with precision makes pneumatic cylinders a strong alternative. However, they often come with higher costs and require more complex installation and maintenance procedures, which may not be feasible for all businesses, especially smaller operations with limited resources.

Conclusion: How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the right mechanical fastener or positioning component depends on various factors, including the specific application, budget constraints, and the operational requirements of the business. For applications requiring fixed positioning and low maintenance, the bolt with stopper remains an excellent choice. However, if flexibility and quick adjustments are paramount, adjustable stops may be more suitable. On the other hand, for high-speed automation tasks that demand precise control, pneumatic cylinders could be the best investment, despite their higher costs and maintenance needs. B2B buyers should carefully assess their unique requirements and operational contexts to make an informed decision that aligns with their strategic goals.

Illustrative image related to bolt with stopper

Essential Technical Properties and Trade Terminology for bolt with stopper

Understanding the essential technical properties and trade terminology related to bolts with stoppers is crucial for B2B buyers, especially in industries where precision and reliability are paramount. This guide outlines critical specifications and commonly used terms to enhance your purchasing decisions.

What are the Key Technical Properties of a Bolt with Stopper?

-

Material Grade

– The material used in bolts with stoppers significantly affects their strength and durability. Common materials include stainless steel (e.g., 304 or 316) and alloy steel. Stainless steel offers excellent corrosion resistance, making it suitable for outdoor or wet environments. Understanding material grades helps ensure that the selected bolts meet the specific environmental and mechanical demands of your application. -

Thread Specifications

– Threads on a bolt determine how it engages with nuts or other components. Key specifications include thread diameter (e.g., M12), pitch (distance between threads), and length (e.g., 70mm). These factors influence the bolt’s load-bearing capacity and ease of installation. Accurate thread specifications are vital for ensuring compatibility with existing machinery or fixtures, reducing downtime and potential failures. -

Stopper Material

– The material used for the stopper, often polyurethane or rubber, impacts the bolt’s performance in limiting movement. Urethane stoppers provide flexibility and reduce impact, while harder materials may offer increased durability. Selecting the right stopper material is essential for applications requiring precise control over movement, such as conveyor systems and automated machinery. -

Tolerance Levels

– Tolerance refers to the allowable variation in dimensions and is critical for ensuring that bolts fit correctly within their designated assemblies. Tight tolerances may be necessary in high-precision applications, while looser tolerances may suffice in less critical settings. Understanding tolerance levels helps in avoiding assembly issues and ensuring operational efficiency. -

Load Capacity

– This specification indicates the maximum load that a bolt can safely bear without failure. It is influenced by the bolt’s material, diameter, and design. Knowing the load capacity is crucial for ensuring that the selected bolts can withstand the operational stresses of your application, thereby preventing equipment failure and enhancing safety.

What are Common Trade Terms Related to Bolts with Stoppers?

-

OEM (Original Equipment Manufacturer)

– OEM refers to companies that produce parts that are used in the manufacturing of other products. In the context of bolts with stoppers, purchasing from an OEM ensures that the components meet specific standards and are compatible with existing equipment. This is particularly important for maintaining warranties and product integrity. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for budgeting and inventory management. For B2B buyers, negotiating MOQ can lead to cost savings, especially when planning large-scale projects or ongoing maintenance. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting pricing and terms for specific products. When sourcing bolts with stoppers, issuing an RFQ allows buyers to compare options and negotiate better deals. This process is vital for ensuring cost-effectiveness and quality in procurement. -

Incoterms (International Commercial Terms)

– Incoterms define the responsibilities of buyers and sellers in international transactions. They specify who is responsible for shipping, insurance, and tariffs. Understanding Incoterms is crucial for B2B buyers operating across borders, as it affects pricing and delivery timelines. -

Lead Time

– Lead time refers to the time it takes from placing an order to receiving the product. In industries where downtime can be costly, knowing the lead time for bolts with stoppers is vital for effective project planning and inventory management. -

Certification Standards

– Certification standards, such as ISO or ASTM, ensure that products meet specific quality and safety benchmarks. For bolts with stoppers, certification is an assurance of reliability and performance, which is particularly important in sectors like automotive and construction.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and product reliability.

Navigating Market Dynamics and Sourcing Trends in the bolt with stopper Sector

What Are the Key Drivers and Trends Influencing the Bolt with Stopper Market?

The global bolt with stopper market is experiencing significant growth, driven by the increasing demand for reliable fastening solutions across various industries, including automotive, manufacturing, and construction. Key trends influencing this market include the rise of automation in manufacturing processes, which necessitates precise and durable fastening components. Additionally, advancements in materials science are leading to the development of high-performance bolts with enhanced corrosion resistance and strength, appealing to international buyers who prioritize quality and longevity.

In regions such as Africa, South America, the Middle East, and Europe, the market dynamics are further shaped by regional economic growth and infrastructure development projects. For instance, Brazil’s focus on expanding its manufacturing base and Vietnam’s rise as a manufacturing hub are creating new opportunities for suppliers of bolts with stoppers. B2B buyers in these regions are increasingly leveraging e-procurement platforms and digital marketplaces to source these components more efficiently, facilitating faster turnaround times and better pricing.

Moreover, the integration of Industry 4.0 technologies is allowing manufacturers to streamline their supply chains and enhance traceability, which is crucial for maintaining quality standards. As competition intensifies, international buyers are looking for suppliers who can provide not only competitive pricing but also innovative solutions that address their specific operational challenges.

How Is Sustainability Shaping the Sourcing of Bolt with Stopper Products?

Sustainability is becoming an essential consideration for B2B buyers in the bolt with stopper sector. The environmental impact of manufacturing processes, including resource depletion and waste generation, is prompting companies to seek suppliers who prioritize sustainable practices. This shift is particularly relevant in regions such as Europe, where regulatory frameworks and consumer expectations are increasingly aligned with sustainability goals.

Ethical sourcing is vital for building resilient supply chains. Buyers are increasingly favoring suppliers who demonstrate transparency in their sourcing practices, including the use of recycled materials and adherence to international labor standards. Certifications such as ISO 14001 (Environmental Management) and ISO 9001 (Quality Management) are gaining traction among buyers looking for assurance that their suppliers are committed to sustainable operations.

The use of ‘green’ materials, such as eco-friendly urethane for stoppers and corrosion-resistant coatings, is also becoming a focal point for manufacturers aiming to reduce their environmental footprint. By prioritizing sustainability and ethical sourcing, B2B buyers can not only enhance their brand reputation but also contribute to a more sustainable industrial ecosystem.

What Is the Historical Context of Bolt with Stopper Development?

The evolution of the bolt with stopper dates back to the early industrial era when mechanical fasteners were essential for ensuring the stability and safety of machinery. Initially, these components were made from basic metals, but as technology advanced, the introduction of high-strength alloys and corrosion-resistant materials transformed their functionality and applications.

Over the decades, the design of bolts with stoppers has also evolved, with innovations such as adjustable positioning and improved thread designs enhancing their usability in various industrial contexts. Today, these components are integral to automated systems and complex machinery, reflecting a significant advancement from their rudimentary origins. This historical progression underscores the importance of continuous innovation in meeting the demands of modern manufacturing and construction practices.

In summary, understanding the market dynamics and sourcing trends in the bolt with stopper sector is crucial for international B2B buyers. By focusing on sustainability, ethical sourcing, and technological advancements, buyers can make informed decisions that align with their operational goals and values.

Frequently Asked Questions (FAQs) for B2B Buyers of bolt with stopper

-

1. How do I choose the right bolt with stopper for my application?

Selecting the appropriate bolt with stopper depends on several factors, including the specific application, load requirements, and environmental conditions. Consider the material composition; stainless steel offers excellent corrosion resistance, while urethane stoppers provide durability and shock absorption. Additionally, assess thread specifications, such as diameter and pitch, to ensure compatibility with your machinery. It’s advisable to consult with manufacturers or suppliers to understand the best options tailored to your operational needs. -

2. What are the common applications for bolts with stoppers in industrial settings?

Bolts with stoppers are widely used in various industrial applications, including automotive assembly, machinery, and material handling systems. They serve to limit the movement of moving parts, ensuring safety and operational efficiency. Common uses include securing conveyor belts, stabilizing machinery, and positioning components in automated systems. Their versatility makes them essential in sectors like manufacturing, construction, and packaging. -

3. What customization options are available for bolts with stoppers?

Many manufacturers offer customization options for bolts with stoppers, including variations in size, material, and thread type. You can often specify the length, diameter, and even the type of stopper material to match your specific requirements. Additionally, some suppliers provide options for special coatings or treatments for enhanced durability. When discussing customization, be clear about your application’s needs to ensure the best fit. -

4. What is the minimum order quantity (MOQ) for bolts with stoppers?

The minimum order quantity (MOQ) for bolts with stoppers can vary significantly between suppliers. Typically, MOQs range from 100 to 1,000 units, depending on the manufacturer and the degree of customization required. Larger orders may lead to discounts, while smaller orders might incur higher per-unit costs. Always verify MOQ policies with your supplier to plan your procurement effectively. -

5. How do I vet suppliers when sourcing bolts with stoppers internationally?

To vet suppliers effectively, start by checking their certifications, such as ISO or other industry-specific standards, which indicate quality compliance. Review customer testimonials and case studies to gauge their reliability and service quality. Additionally, consider visiting their facilities if feasible, or request product samples for quality assessment. Engaging with previous clients can provide insights into the supplier’s performance and customer service. -

6. What are the payment terms commonly offered for international orders of bolts with stoppers?

Payment terms for international orders vary by supplier but often include options like advance payment, letter of credit, or net payment terms (e.g., net 30 or net 60 days). Some suppliers may require a deposit upfront, especially for custom orders. It’s essential to clarify payment options and any associated fees, such as currency conversion or transaction fees, before finalizing the order. -

7. How can I ensure quality assurance (QA) for bolts with stoppers?

To ensure quality assurance, request detailed product specifications and certifications from your supplier, including material properties and manufacturing processes. Implement a quality control plan that includes inspections at various stages of production. Additionally, consider third-party quality audits or testing to verify compliance with industry standards. Establishing a clear communication channel with your supplier regarding QA processes can help prevent issues before they arise. -

8. What logistics considerations should I keep in mind when importing bolts with stoppers?

When importing bolts with stoppers, factor in shipping methods, lead times, and customs regulations. Choose a reliable logistics partner familiar with international shipping to navigate customs clearance efficiently. Be aware of potential import duties and tariffs that may apply to your shipment. Additionally, ensure that your order includes proper documentation, such as invoices and packing lists, to facilitate a smooth import process.

Top 4 Bolt With Stopper Manufacturers & Suppliers List

1. McMaster – Stopper Bolts

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Stopper Bolts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. MISUMI – Stopper Bolts

Domain: us.misumi-ec.com

Registered: 2007 (18 years)

Introduction: Stopper Bolts are mechanical fasteners designed to limit movement or travel within a system, used in machinery, equipment, and fixtures to prevent parts from exceeding predetermined positions. They are essential for maintaining safety and stability in various applications, including automotive, manufacturing, and construction. Key features include:

– Types: Shoulder Type with Bumper, Hex Socket H…

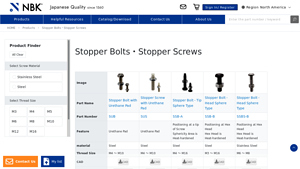

3. NBK America – Stopper Bolts and Screws

Domain: nbk1560.com

Registered: 2000 (25 years)

Introduction: Stopper Bolts and Stopper Screws from NBK America LLC include various types with features such as urethane pads, heat-hardened areas, and fine pitch screws. Key specifications include:

– Materials: Steel and Stainless Steel (SUS316L, SUS420J2)

– Thread Sizes: M3 to M16

– Part Numbers: SUB, SSB, SSBS, SAN, SPM, SPML, SPMJ, etc.

– Features: Positioning capabilities, corrosion resistance, quenchi…

4. AndyMark – Rubber Stopper for FTC Game Set

Domain: andymark.com

Registered: 1999 (26 years)

Introduction: This company, AndyMark – Rubber Stopper for FTC Game Set, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for bolt with stopper

In conclusion, effective strategic sourcing of bolts with stoppers is vital for businesses across diverse sectors, including manufacturing, automotive, and construction. By prioritizing quality, material specifications, and the adaptability of these components, buyers can ensure enhanced operational efficiency and safety within their machinery and equipment. The insights presented in this guide underscore the importance of selecting reliable suppliers who can meet specific requirements, including lead times and cost-effectiveness.

As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe navigate their sourcing strategies, it is imperative to leverage data-driven decision-making. Engaging with suppliers who offer customization options and robust support can significantly enhance supply chain resilience and performance.

Illustrative image related to bolt with stopper

Looking ahead, the demand for high-quality bolts with stoppers is expected to rise as industries focus on automation and precision. We encourage buyers to adopt proactive sourcing strategies, explore innovative suppliers, and invest in long-term partnerships that foster mutual growth. By doing so, businesses can position themselves advantageously in the competitive landscape, ensuring they remain at the forefront of industry advancements.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.