Boiler Components: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for boiler components

In the rapidly evolving global market, sourcing reliable boiler components can present a formidable challenge for B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe. As industries increasingly rely on efficient heating systems, understanding the intricate components of boilers—from burners and heat exchangers to economizers and control systems—becomes essential. This guide serves as a comprehensive resource, offering insights into various types of boiler components, their applications across different sectors, and critical factors for supplier vetting.

Navigating this complex landscape requires more than just basic knowledge; it demands a strategic approach to purchasing. This guide empowers international B2B buyers by detailing essential considerations such as cost analysis, compatibility with existing systems, and the importance of regulatory compliance. By addressing these key areas, we aim to equip decision-makers with the knowledge needed to make informed purchasing choices that enhance operational efficiency and ensure compliance with local standards.

Whether you are in Nigeria seeking durable components for industrial boilers or in Saudi Arabia evaluating options for commercial heating systems, this guide provides the insights necessary to navigate the diverse global market for boiler components effectively. Prepare to enhance your procurement strategies and optimize your heating solutions with the knowledge contained within these pages.

Understanding boiler components Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Burner | Mixes fuel and air for combustion; crucial for heat input | Industrial heating, power generation | Pros: Efficient heat generation; customizable. Cons: Requires regular maintenance; can be costly. |

| Heat Exchanger | Transfers heat between fluids without mixing | HVAC systems, industrial processes | Pros: High efficiency; reduces energy costs. Cons: Potential for fouling; initial installation costs. |

| Circulator Pump | Moves heated water to distribution points | Hydronic heating systems | Pros: Ensures consistent heating; energy-efficient. Cons: Can fail without warning; requires maintenance. |

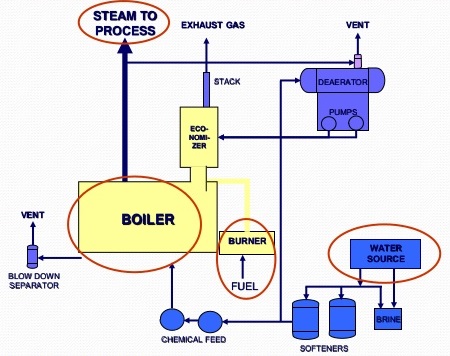

| Economizer | Recovers heat from exhaust gases | Power plants, industrial boilers | Pros: Increases overall efficiency; reduces fuel consumption. Cons: Requires space; initial investment can be high. |

| Expansion Tank | Absorbs excess pressure in the system | Steam and hot water systems | Pros: Enhances safety; protects boiler integrity. Cons: Limited lifespan; requires monitoring. |

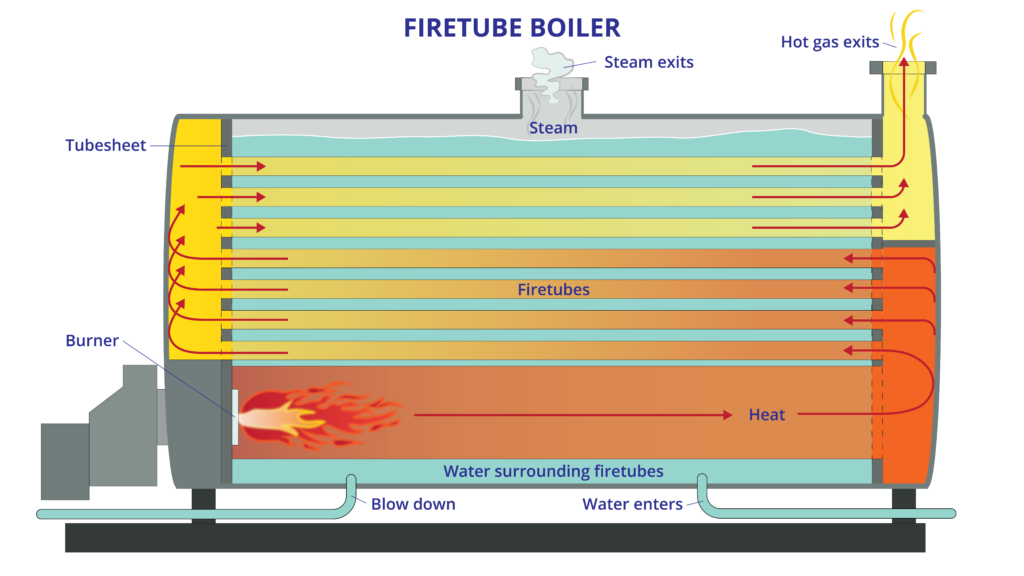

What Are the Key Characteristics of Burners in Boiler Systems?

Burners are essential components in boiler systems, responsible for the combustion process that generates heat. They mix fuel with air and ignite it, producing the necessary thermal energy. Burners vary in design, including gas, oil, and dual-fuel options, making them versatile for different industrial applications. For B2B buyers, considerations include the type of fuel available, efficiency ratings, and the specific heating requirements of their operations. Regular maintenance is crucial to ensure optimal performance and safety.

How Do Heat Exchangers Enhance Boiler Efficiency?

Heat exchangers are designed to transfer heat from one fluid to another without allowing them to mix. They are pivotal in maximizing energy efficiency in various applications, including HVAC systems and industrial processes. For B2B buyers, the selection of heat exchangers should focus on materials, design, and the specific heat transfer needs of their operations. While they can significantly reduce energy costs, buyers must also consider potential fouling and the need for regular cleaning to maintain efficiency.

Why Are Circulator Pumps Vital for Hydronic Heating Systems?

Circulator pumps play a critical role in hydronic heating systems by ensuring the movement of heated water to various distribution points, such as radiators or underfloor heating. Their efficiency directly impacts the overall performance of the heating system. Buyers should look for pumps that offer energy efficiency, reliability, and ease of maintenance. However, it is important to note that these pumps can fail unexpectedly, so having a maintenance plan in place is essential for uninterrupted operation.

What Benefits Do Economizers Offer in Boiler Systems?

Economizers are devices that recover waste heat from exhaust gases, enhancing the overall efficiency of boiler systems. They are commonly used in power plants and industrial boilers to reduce fuel consumption and operating costs. For B2B buyers, the advantages of economizers include improved energy efficiency and lower emissions. However, they require adequate space for installation and may involve a significant initial investment, which must be factored into the overall budget.

How Do Expansion Tanks Contribute to Boiler Safety?

Expansion tanks are designed to absorb excess pressure in steam and hot water systems, helping to maintain safe operating conditions. They are crucial for protecting boiler integrity and preventing potential hazards. B2B buyers should consider the size and type of expansion tank that best fits their system’s requirements. While they enhance safety, expansion tanks have a limited lifespan and require regular monitoring to ensure they function correctly, making proactive maintenance a key consideration for buyers.

Key Industrial Applications of boiler components

| Industry/Sector | Specific Application of Boiler Components | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Use of heat exchangers in process heating | Increases efficiency of production processes | Ensure compatibility with existing systems and local regulations |

| Food and Beverage | Steam generation for sterilization and cooking | Enhances product quality and safety | Look for components that meet food safety standards |

| Oil & Gas | Burners for fuel processing and energy recovery | Improves energy efficiency and reduces operational costs | Consider durability and performance under high-pressure conditions |

| Textile Industry | Circulator pumps for dyeing and finishing processes | Ensures consistent temperature control | Evaluate pump capacity and reliability for continuous operation |

| Power Generation | Economizers and superheaters for improving thermal efficiency | Reduces fuel consumption and emissions | Source high-quality materials that withstand extreme conditions |

How Are Boiler Components Applied Across Key Industries?

In the Manufacturing Sector

Boiler components, particularly heat exchangers, are critical in manufacturing processes where heat is required for production. These components facilitate efficient heat transfer, ensuring that materials are processed at optimal temperatures. For international buyers, especially in emerging markets, sourcing heat exchangers that comply with local industrial standards is essential to maintain productivity and safety. Additionally, understanding the compatibility of these components with existing systems can prevent costly downtimes.

In the Food and Beverage Industry

The food and beverage sector heavily relies on steam generation from boilers for sterilization and cooking. This application is crucial for ensuring product quality and safety, as proper temperature control is vital for eliminating pathogens. Buyers in regions like Africa and South America should prioritize sourcing boiler components that meet stringent food safety regulations. Furthermore, investing in reliable components can lead to long-term cost savings by reducing maintenance and operational disruptions.

In Oil & Gas Operations

Burners used in the oil and gas industry are essential for processing fuels and recovering energy. These components enhance energy efficiency, which is increasingly important as companies aim to reduce operational costs and environmental impact. Buyers should focus on sourcing durable burners designed to withstand high-pressure conditions typical in this sector. Furthermore, understanding local regulations regarding emissions can guide the selection of compliant components, ensuring both operational efficiency and regulatory adherence.

In the Textile Industry

In textile manufacturing, circulator pumps are vital for dyeing and finishing processes, where consistent temperature control is necessary. These pumps ensure that hot water is circulated effectively, leading to uniform dyeing results. Buyers should consider the capacity and reliability of these pumps, particularly in regions with fluctuating energy supplies. Sourcing pumps that can operate efficiently in local conditions will enhance production quality and reduce waste.

In Power Generation

Economizers and superheaters play a pivotal role in enhancing the thermal efficiency of power generation systems. By recovering waste heat and increasing steam temperature without raising pressure, these components significantly reduce fuel consumption and emissions. For international buyers, sourcing high-quality materials that can endure extreme conditions is crucial. Additionally, understanding the specific thermal dynamics of their systems can help buyers select the right components for optimal performance and sustainability.

3 Common User Pain Points for ‘boiler components’ & Their Solutions

Scenario 1: Challenges with Burner Efficiency and Fuel Consumption

The Problem: Many B2B buyers face the challenge of inefficient burners, which can lead to excessive fuel consumption and increased operational costs. This inefficiency often stems from poor maintenance, suboptimal fuel-air mixture settings, or the use of incompatible fuel types. Businesses in regions with fluctuating fuel quality, like parts of Africa and South America, may find their burners struggling to maintain efficiency, leading to higher operational costs and decreased reliability.

The Solution: To address burner efficiency, it’s essential to implement a regular maintenance schedule that includes cleaning and calibrating the burner. Buyers should work closely with manufacturers or experienced technicians to ensure that the burner is appropriately tuned to the specific fuel being used. Additionally, investing in advanced control systems can help optimize the fuel-air mixture in real-time, adapting to variations in fuel quality. Conducting regular performance assessments and utilizing data analytics can also highlight inefficiencies and guide necessary adjustments, ultimately leading to significant cost savings over time.

Scenario 2: Heat Exchanger Performance Issues

The Problem: A common pain point for B2B buyers involves the performance of heat exchangers, which can degrade due to scale buildup, corrosion, or improper sizing. This degradation not only affects heating efficiency but can also lead to increased downtime and costly repairs. Buyers in industrial sectors, particularly in the Middle East where water quality may vary, often find that their heat exchangers are underperforming, resulting in wasted energy and increased maintenance costs.

The Solution: To ensure optimal heat exchanger performance, buyers should prioritize the selection of high-quality materials that can withstand local water conditions. Regular inspections and cleaning should be scheduled to prevent scale buildup and corrosion. Implementing water treatment solutions can also mitigate these issues, prolonging the lifespan of the heat exchanger. Moreover, accurate sizing during the initial design phase is crucial; consulting with engineering experts can help ensure that the heat exchanger is appropriately sized for the specific application, enhancing overall system efficiency.

Scenario 3: Control System Failures Leading to Safety Hazards

The Problem: Control system failures can pose significant safety hazards in boiler operations. Many B2B buyers encounter issues with outdated control systems that fail to regulate pressure and temperature effectively, leading to unsafe operating conditions. This is particularly critical in regions with stringent safety regulations, such as Europe, where non-compliance can result in severe penalties and operational shutdowns.

The Solution: To mitigate risks associated with control system failures, buyers should invest in modern, automated control systems that feature advanced safety protocols. It’s vital to conduct thorough training for staff on the proper use of these systems and establish a routine maintenance program to ensure all components are functioning correctly. Additionally, integrating predictive maintenance technologies can help identify potential failures before they occur, allowing for timely interventions. Collaborating with manufacturers who offer robust support and training can further enhance the reliability and safety of boiler operations, ensuring compliance with local regulations and safeguarding personnel.

Strategic Material Selection Guide for boiler components

What Are the Key Materials Used in Boiler Components?

When selecting materials for boiler components, it is crucial to understand their properties, advantages, disadvantages, and their impact on application performance. Here, we analyze four common materials used in boiler construction: Carbon Steel, Stainless Steel, Cast Iron, and Copper. Each material has unique characteristics that can influence the efficiency, safety, and longevity of boiler systems.

How Does Carbon Steel Perform in Boiler Applications?

Carbon steel is widely used for various boiler components due to its excellent strength and cost-effectiveness. It typically has a high-temperature and pressure rating, making it suitable for high-stress environments. However, carbon steel is prone to corrosion, especially in humid or high-oxygen environments, which can lead to premature failure.

Pros: Carbon steel is durable and relatively inexpensive, making it a popular choice for many applications. Its manufacturing processes are well-established, allowing for easy sourcing and fabrication.

Cons: The primary drawback is its susceptibility to corrosion, necessitating protective coatings or regular maintenance. Additionally, it may not be suitable for applications involving corrosive media.

Impact on Application: Carbon steel is compatible with water and steam but may require additional treatment in corrosive environments.

Considerations for International Buyers: Buyers should ensure compliance with relevant standards such as ASTM A106 or DIN 17175. In regions like Africa and the Middle East, where humidity can be high, additional corrosion-resistant measures may be necessary.

What Advantages Does Stainless Steel Offer for Boiler Components?

Stainless steel is renowned for its corrosion resistance and strength, making it an excellent choice for boiler components exposed to harsh conditions. It can withstand high temperatures and pressures, making it suitable for both water and steam applications.

Pros: The primary advantage of stainless steel is its durability and resistance to corrosion, which extends the lifespan of boiler components. It requires less maintenance compared to carbon steel.

Cons: The cost of stainless steel is significantly higher than carbon steel, which may impact budget considerations for large-scale projects. Its manufacturing complexity can also lead to longer lead times.

Impact on Application: Stainless steel is compatible with a wide range of media, including corrosive fluids, making it ideal for diverse applications.

Considerations for International Buyers: Compliance with standards such as ASTM A312 or JIS G4304 is essential. Buyers in Europe may prefer stainless steel for its longevity and reduced maintenance needs.

Why Is Cast Iron a Traditional Choice for Boiler Components?

Cast iron has been a traditional material for boiler components, particularly in older systems. It offers excellent heat retention and can withstand high temperatures, making it suitable for heat exchangers and combustion chambers.

Pros: Cast iron is durable and has excellent thermal conductivity, which enhances energy efficiency. It is also relatively inexpensive compared to stainless steel.

Cons: Cast iron is brittle, which can lead to cracking under stress. It is also heavier than other materials, which may complicate installation and transportation.

Impact on Application: Cast iron is best suited for low-pressure applications and is compatible with water and steam but may not perform well in highly corrosive environments.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM A48. In regions with high thermal demands, cast iron may still be favored despite its limitations.

How Does Copper Compare for Boiler Component Use?

Copper is often used in specific boiler components, particularly heat exchangers, due to its excellent thermal conductivity. It is capable of transferring heat efficiently, which enhances the overall performance of the boiler system.

Pros: The primary advantage of copper is its superior thermal conductivity, which can lead to improved energy efficiency. It is also resistant to corrosion, particularly in water applications.

Cons: Copper is more expensive than carbon steel and can be less durable under high-pressure conditions. It is also susceptible to certain types of corrosion, such as pitting.

Impact on Application: Copper is ideal for heating applications and is compatible with water but may not be suitable for steam applications due to pressure limitations.

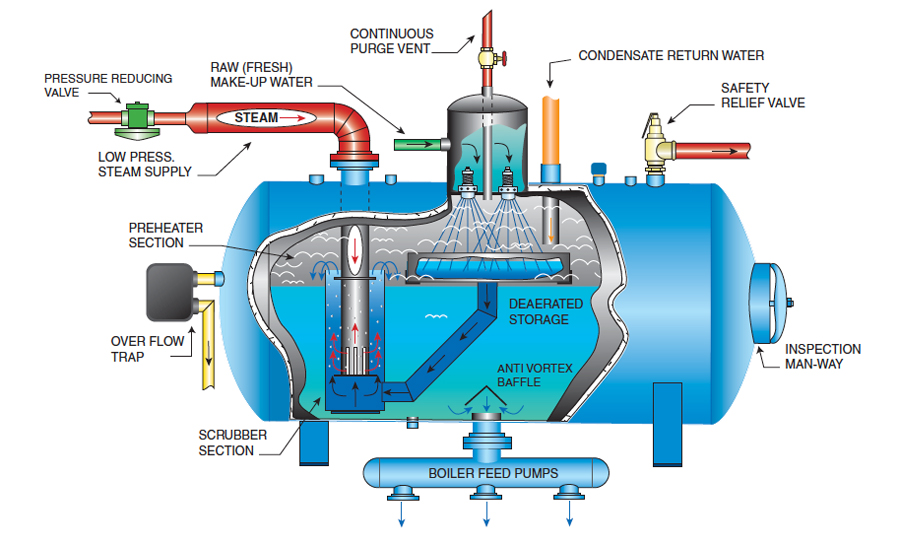

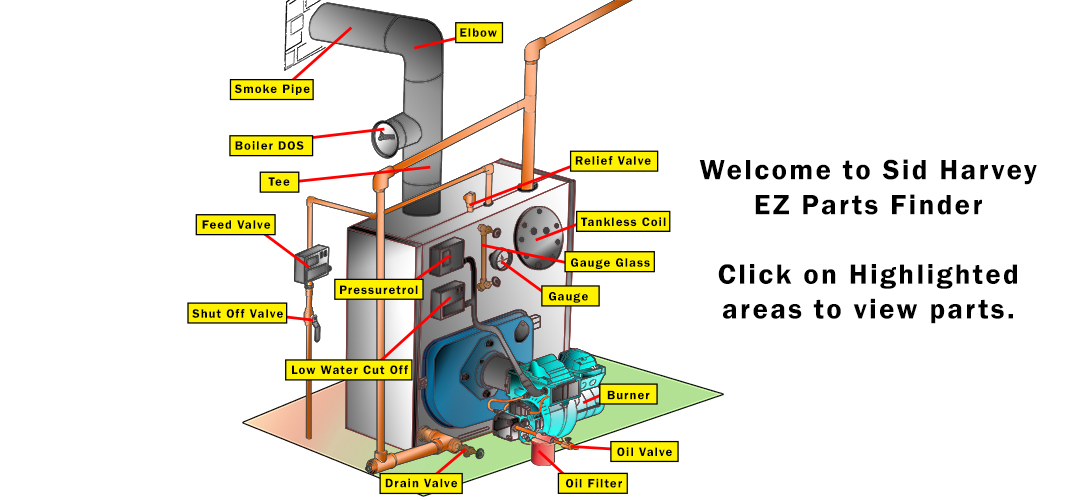

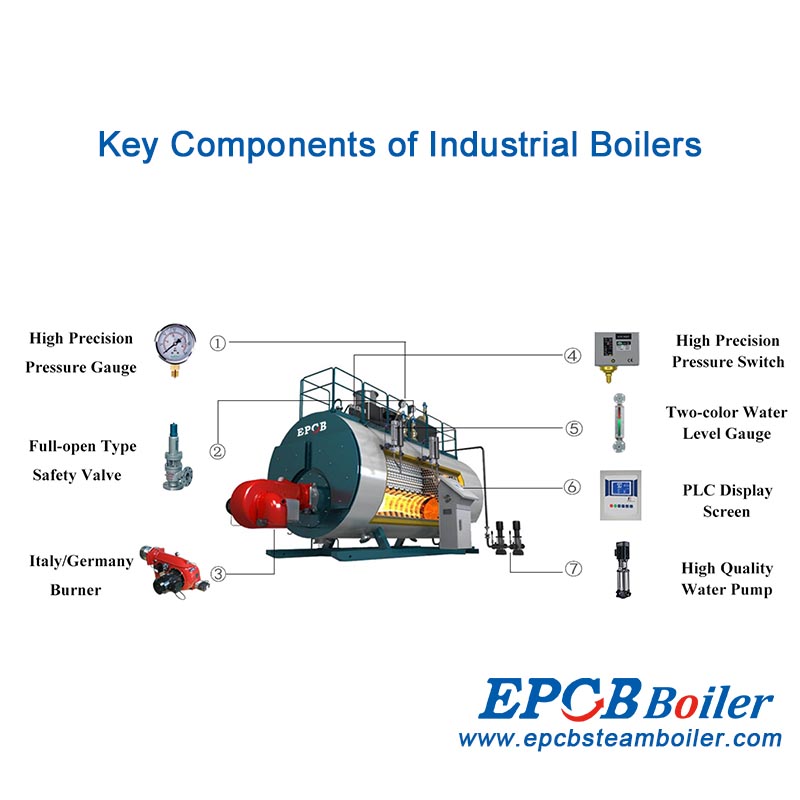

Illustrative image related to boiler components

Considerations for International Buyers: Compliance with standards like ASTM B280 is crucial. In regions like South America, where energy efficiency is a priority, copper may be preferred despite its higher cost.

Summary of Material Selection for Boiler Components

| Material | Typical Use Case for boiler components | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Pressure vessels, piping | Cost-effective and durable | Prone to corrosion | Medium |

| Stainless Steel | Heat exchangers, high-pressure systems | Corrosion-resistant and durable | Higher cost and manufacturing complexity | High |

| Cast Iron | Combustion chambers, heat exchangers | Excellent heat retention | Brittle and heavy | Medium |

| Copper | Heat exchangers | Superior thermal conductivity | Expensive and pressure limitations | High |

This guide aims to provide B2B buyers with actionable insights into material selection for boiler components, ensuring informed decisions that align with their operational needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for boiler components

What Are the Key Stages in the Manufacturing Process of Boiler Components?

The manufacturing process for boiler components is intricate, involving several critical stages that ensure the final product meets stringent performance and safety standards. Understanding these stages is vital for B2B buyers seeking reliable suppliers.

1. Material Preparation

The first step in manufacturing boiler components is material preparation. High-quality materials, such as carbon steel, stainless steel, and specialized alloys, are selected based on the component’s function and the operating conditions of the boiler.

Materials undergo rigorous testing to confirm their mechanical properties, corrosion resistance, and heat tolerance. This step may also include the treatment of materials to enhance their durability, such as heat treatment or surface hardening. For international buyers, verifying the material certifications and compliance with standards like ASTM or ISO is essential to ensure the components will withstand operational demands.

2. Forming Techniques Used in Boiler Component Manufacturing

Once materials are prepared, various forming techniques are employed to shape them into the required components. Common methods include:

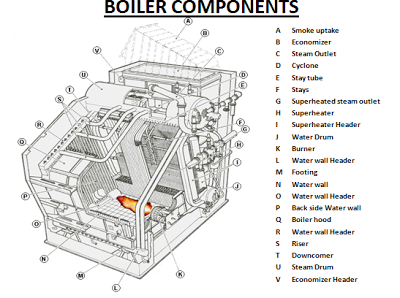

Illustrative image related to boiler components

-

Casting: This technique is often used for complex shapes, such as the combustion chamber or heat exchanger parts. Molten metal is poured into molds, allowing for intricate designs that meet specific thermal and structural requirements.

-

Machining: Precision machining is critical for components like valves and fittings. CNC (Computer Numerical Control) machines ensure high accuracy in dimensions and tolerances, which is crucial for components that must fit together seamlessly.

-

Welding: For assembling larger components, welding techniques are used to join different parts. This includes TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding, which provide strong, durable joints that can withstand high pressures and temperatures.

3. Assembly of Boiler Components

Following the forming processes, assembly is the next crucial stage. This involves the integration of various components, such as burners, heat exchangers, and controls.

Assembly requires skilled technicians who understand the operational dynamics of boiler systems. They must adhere to strict assembly protocols to ensure that each component functions harmoniously. During this stage, all components are inspected for fit and alignment, and adjustments are made as necessary.

4. Finishing Processes for Boiler Components

Finishing processes enhance both the aesthetic and functional qualities of boiler components. This may involve:

-

Surface Treatment: Coatings or finishes are applied to protect against corrosion and wear. Common treatments include galvanization, powder coating, and painting.

-

Final Machining: This step ensures that all surfaces meet specified tolerances and that any necessary threads or connections are accurately prepared for assembly.

-

Quality Testing: Before moving to the quality assurance stage, components undergo preliminary testing to check for defects or inconsistencies.

How Is Quality Assurance Implemented in Boiler Component Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that boiler components meet international safety and performance standards.

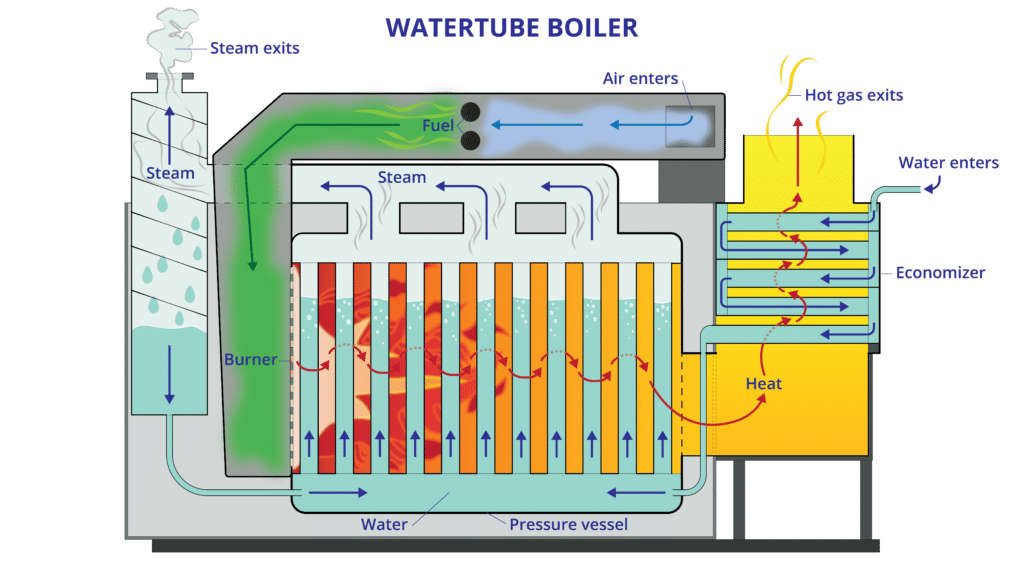

Illustrative image related to boiler components

Relevant International Standards for Quality Assurance

B2B buyers should be familiar with several international standards that govern the quality of boiler components:

-

ISO 9001: This standard specifies requirements for a quality management system (QMS). Compliance with ISO 9001 indicates that a manufacturer consistently meets customer and regulatory requirements.

-

CE Marking: In Europe, CE marking signifies compliance with health, safety, and environmental protection standards for products sold within the European Economic Area.

-

API Standards: For manufacturers producing components used in the oil and gas industries, adherence to American Petroleum Institute (API) standards ensures that products meet rigorous industry specifications.

What Are the Quality Control Checkpoints in Boiler Component Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to catch defects early and ensure compliance with standards. Common checkpoints include:

-

Incoming Quality Control (IQC): Raw materials are inspected upon arrival to verify that they meet specified standards and certifications.

-

In-Process Quality Control (IPQC): During manufacturing, components are continuously monitored for adherence to specifications. This includes checking dimensions, weld integrity, and surface finishes.

-

Final Quality Control (FQC): Once assembly is complete, a comprehensive final inspection is conducted. This may involve functional testing, pressure testing, and visual inspections to ensure that all components operate correctly and safely.

How Can B2B Buyers Verify Supplier Quality Assurance?

Verifying the quality assurance practices of suppliers is crucial for B2B buyers, especially in international markets. Here are some effective strategies:

-

Conduct Supplier Audits: Regular audits of potential suppliers can provide insights into their manufacturing processes, quality control measures, and compliance with international standards.

-

Request Quality Assurance Documentation: Buyers should ask for documentation such as ISO certificates, CE marking certificates, and test reports. These documents validate the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the manufacturing process and product quality. This is especially useful when sourcing from regions with varying standards.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate specific nuances related to quality control that can vary by region:

-

Cultural Differences in Quality Standards: Different regions may have varying perceptions of quality. Understanding local standards and expectations is essential for ensuring that products meet the buyer’s requirements.

-

Regulatory Compliance: Importing boiler components often involves compliance with local regulations, which may differ significantly from those in the supplier’s country. Buyers should be informed about these regulations to avoid complications.

-

Language Barriers: Communication challenges can affect the clarity of quality expectations. Establishing clear, written specifications and maintaining open lines of communication can mitigate misunderstandings.

By comprehensively understanding the manufacturing processes and quality assurance measures involved in boiler component production, B2B buyers can make informed decisions and select reliable suppliers that meet their operational needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘boiler components’

In the rapidly evolving field of boiler technology, sourcing the right components is crucial for operational efficiency and safety. This guide aims to equip B2B buyers with a clear, actionable checklist for procuring essential boiler components, ensuring that you make informed decisions that meet both technical specifications and regulatory standards.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline your technical requirements. This includes the type of boiler system (e.g., steam or hot water), capacity, and specific component needs such as burners, heat exchangers, and controls. A detailed specification document will help you communicate effectively with suppliers and ensure that you receive components that meet your operational demands.

Step 2: Research Regulatory Compliance

Understanding local and international regulations is vital when sourcing boiler components. Different regions, particularly in Africa, South America, the Middle East, and Europe, have specific safety and environmental standards. Ensure that the components you are considering comply with these regulations to avoid legal issues and ensure safe operation.

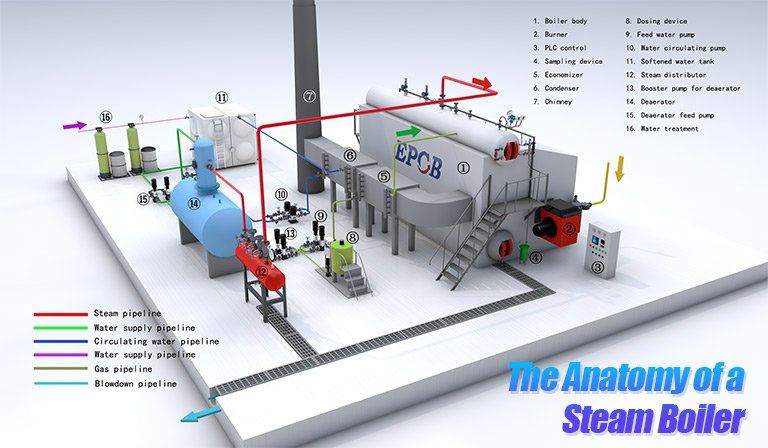

Illustrative image related to boiler components

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, thoroughly vet potential suppliers. Look for established manufacturers with a track record in the industry. Request company profiles, certifications, and references from previous clients, especially those in similar industries or regions. This step minimizes risks associated with quality and reliability.

- Check for Quality Assurance: Look for suppliers who adhere to recognized quality standards, such as ISO certifications.

- Assess Product Range: A supplier with a diverse product line can offer valuable insights and solutions tailored to your needs.

Step 4: Request Samples or Technical Data

When evaluating suppliers, requesting samples or technical data sheets is essential. This allows you to assess the quality of the components firsthand and ensures they meet your specifications. Technical data sheets should include information on materials, performance metrics, and installation guidelines.

Step 5: Compare Pricing and Payment Terms

Once you have shortlisted potential suppliers, compare their pricing structures and payment terms. While cost is a significant factor, consider the total cost of ownership, which includes maintenance, warranty, and potential downtime. Negotiate payment terms that align with your cash flow needs while ensuring that you do not compromise on quality.

Step 6: Assess After-Sales Support and Service

Evaluate the after-sales support offered by your chosen supplier. Reliable suppliers should provide comprehensive support, including installation guidance, maintenance services, and readily available spare parts. Strong after-sales support can enhance the longevity and efficiency of your boiler system.

Illustrative image related to boiler components

Step 7: Finalize Contracts with Clear Terms

Once you’ve selected a supplier, finalize the contract with clear terms regarding delivery timelines, warranties, and service agreements. Ensure that all specifications and compliance requirements are documented to protect your interests. A well-structured contract will help mitigate risks and foster a successful partnership.

By following this step-by-step checklist, B2B buyers can ensure a strategic approach to sourcing boiler components, aligning technical needs with supplier capabilities while adhering to regulatory standards.

Comprehensive Cost and Pricing Analysis for boiler components Sourcing

Understanding the cost structure and pricing dynamics of boiler components is essential for international B2B buyers, especially those operating in regions like Africa, South America, the Middle East, and Europe. This analysis delves into the various cost components, price influencers, and offers actionable tips for buyers to optimize their purchasing decisions.

What Are the Key Cost Components in Boiler Components Sourcing?

When evaluating the total cost of boiler components, several key cost components come into play:

-

Materials: The choice of materials significantly impacts the overall cost. High-quality materials such as stainless steel or specialized alloys for heat exchangers and burners tend to be more expensive but offer better durability and performance.

-

Labor: Labor costs vary by region and the complexity of the component. Skilled labor is essential for manufacturing intricate parts, and countries with higher labor costs may drive up prices.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and equipment depreciation. Manufacturers often spread these costs across their production volume, influencing the price per unit.

-

Tooling: Initial tooling costs for specialized components can be substantial. These costs are typically amortized over the expected production volume, affecting pricing for lower volume orders.

-

Quality Control (QC): Rigorous QC processes ensure that components meet safety and performance standards. The costs associated with these processes are factored into the final pricing.

-

Logistics: Transportation and shipping costs can vary widely, especially for international buyers. Factors such as shipping routes, tariffs, and local customs regulations can add to the expense.

-

Margin: Suppliers apply a profit margin to cover their operational costs and risks. This margin can vary based on market conditions and competition.

How Do Volume and Specifications Affect Boiler Component Pricing?

Volume/MOQ (Minimum Order Quantity): Pricing often benefits from economies of scale. Higher order volumes can lead to lower per-unit costs, making it advantageous for buyers to consolidate orders when possible.

Specifications and Customization: Custom components tailored to specific applications can significantly impact pricing. Customized designs may require additional engineering time and specialized materials, thus increasing costs.

Quality and Certifications: Components that meet international quality standards (e.g., ISO certifications) may come at a premium. Buyers should weigh the long-term benefits of investing in certified products against initial costs.

Supplier Factors: The reputation and reliability of suppliers also play a role in pricing. Established suppliers may charge higher prices due to their experience and quality assurance processes, while emerging manufacturers may offer lower prices to gain market share.

Incoterms: Understanding Incoterms is crucial for international transactions. Terms like CIF (Cost, Insurance, and Freight) or FOB (Free on Board) can affect the total landed cost of components, impacting budget planning.

What Tips Can Help Buyers Optimize Boiler Component Costs?

-

Negotiate Pricing: Always approach suppliers with room for negotiation. Establishing long-term relationships can lead to better pricing terms over time.

-

Focus on Total Cost of Ownership (TCO): Evaluate components not just based on initial purchase price but also consider maintenance, durability, and energy efficiency. A higher upfront cost may lead to lower operational costs in the long run.

-

Leverage Local Knowledge: For buyers in Africa, South America, the Middle East, and Europe, understanding local market conditions, regulations, and supplier landscapes can provide leverage in negotiations.

-

Request Multiple Quotes: Don’t settle for the first quote. Requesting multiple quotes from different suppliers can provide insight into market pricing and help in negotiating better deals.

-

Understand Pricing Nuances: Be aware of seasonal fluctuations in pricing and supply chain disruptions that may affect availability and cost. Timing your orders can lead to significant savings.

Disclaimer on Indicative Prices

Prices for boiler components can fluctuate based on market conditions, material availability, and other external factors. Therefore, it is advisable for buyers to conduct thorough research and obtain up-to-date quotes directly from suppliers to ensure accurate budgeting.

Alternatives Analysis: Comparing boiler components With Other Solutions

Understanding Alternatives to Boiler Components

In the industrial landscape, selecting the right heating solution is crucial for operational efficiency and cost-effectiveness. While traditional boiler components have been the backbone of heating systems, alternative technologies are emerging that may offer enhanced performance or reduced costs. This analysis will compare boiler components against two viable alternatives: heat pumps and electric resistance heaters.

Comparison Table

| Comparison Aspect | Boiler Components | Heat Pumps | Electric Resistance Heaters |

|---|---|---|---|

| Performance | High efficiency with proper maintenance | Very efficient; can provide heating and cooling | Less efficient; heat loss is significant |

| Cost | Initial investment can be high | Moderate initial cost; lower operating costs | Low initial cost; high operational costs |

| Ease of Implementation | Requires skilled installation and setup | Installation can be complex; requires expertise | Simple installation; minimal training needed |

| Maintenance | Regular maintenance required for longevity | Moderate maintenance; check refrigerant levels | Low maintenance; generally straightforward |

| Best Use Case | Large-scale industrial applications | Ideal for moderate climates; residential and commercial use | Suitable for small spaces or supplemental heating |

Detailed Breakdown of Alternatives

Heat Pumps: Are They Worth the Investment?

Heat pumps work by transferring heat from one place to another, making them a highly efficient option for both heating and cooling. They can significantly lower energy costs over time, especially in moderate climates where the temperature doesn’t drop too low. However, they require a more complex installation and depend on external temperatures for efficiency. In colder regions, their performance may decline, leading to potential supplementary heating needs.

Illustrative image related to boiler components

Electric Resistance Heaters: A Cost-Effective Short-Term Solution?

Electric resistance heaters are straightforward devices that convert electricity directly into heat. They are easy to install and require minimal maintenance, making them appealing for small-scale operations or as temporary heating solutions. However, they are less energy-efficient compared to boilers and heat pumps, leading to higher operational costs in the long run. Electric resistance heaters are best suited for smaller applications or areas where heat demand is intermittent.

Conclusion: How to Choose the Right Heating Solution

When selecting a heating solution, B2B buyers must consider various factors such as performance needs, budget constraints, and the specific application environment. Boiler components may be the ideal choice for large industrial operations requiring high efficiency and robust performance. However, in scenarios where installation simplicity and lower initial costs are paramount, heat pumps or electric resistance heaters may provide better value. Assessing the unique requirements of your operation will ensure the best investment in heating technology, aligning with both short-term needs and long-term operational goals.

Essential Technical Properties and Trade Terminology for boiler components

What are the Key Technical Properties of Boiler Components?

When sourcing boiler components, understanding their technical properties is crucial for ensuring reliability, efficiency, and safety. Here are some essential specifications to consider:

1. Material Grade

The material grade refers to the type of material used in the construction of boiler components, such as stainless steel, carbon steel, or cast iron. Each material has unique properties affecting durability, corrosion resistance, and heat transfer efficiency. For instance, stainless steel is often preferred for its resistance to oxidation and high temperatures, making it ideal for components exposed to harsh environments.

2. Tolerance Levels

Tolerance levels define the acceptable limits of variation in the dimensions of a component. Precise tolerances are critical in boiler systems, where even minor deviations can lead to inefficiencies or failures. For example, the tolerance of a heat exchanger’s tubes must be tightly controlled to ensure optimal heat transfer and prevent leaks.

3. Pressure Rating

Pressure ratings indicate the maximum pressure a component can safely withstand. This specification is particularly important for parts like valves and pipes, which must handle high-pressure steam or hot water. Understanding the pressure rating helps in selecting components that will operate safely under specific system conditions, reducing the risk of catastrophic failures.

4. Thermal Conductivity

Thermal conductivity measures a material’s ability to conduct heat. Components like heat exchangers benefit from high thermal conductivity, as they need to transfer heat efficiently between fluids. In B2B procurement, choosing materials with appropriate thermal properties can significantly impact energy efficiency and operational costs.

5. Corrosion Resistance

Corrosion resistance is a vital property for boiler components, particularly those exposed to moisture and high temperatures. Materials with high corrosion resistance, such as certain alloys or treated steels, extend the lifespan of boiler systems, thereby reducing maintenance costs and downtime.

6. Coating and Finish

The coating and finish of components can enhance their durability and performance. For example, protective coatings can prevent rust and corrosion, while polished finishes may improve heat transfer in heat exchangers. Specifying the right coatings is essential for maximizing the lifespan and efficiency of boiler parts.

What are Common Trade Terms in the Boiler Industry?

Understanding industry jargon can streamline communication and negotiations with suppliers. Here are some common terms to be familiar with:

Illustrative image related to boiler components

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the boiler industry, sourcing from OEMs can ensure that the components are made to the original specifications, which is crucial for maintaining warranty and reliability.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. In the context of boiler components, understanding MOQ can help buyers plan their inventory and budget effectively, avoiding excess costs associated with over-ordering.

3. RFQ (Request for Quotation)

An RFQ is a standard business process where buyers invite suppliers to submit price quotes for specific products or services. In the boiler sector, issuing an RFQ allows businesses to compare prices and terms from different vendors, ensuring competitive pricing and quality.

4. Incoterms (International Commercial Terms)

Incoterms are international rules that define the responsibilities of buyers and sellers regarding the delivery of goods. For international B2B transactions involving boiler components, clarity on Incoterms helps prevent misunderstandings related to shipping, insurance, and liability.

5. Lead Time

Lead time refers to the amount of time it takes for a supplier to deliver products after an order is placed. In the boiler industry, understanding lead times is crucial for project planning and ensuring that installations or repairs are completed on schedule.

6. Certification Standards

Certification standards are established criteria that products must meet to be considered safe and reliable. For boiler components, compliance with standards such as ASME (American Society of Mechanical Engineers) or ISO (International Organization for Standardization) is often required to ensure quality and safety in operation.

By familiarizing yourself with these technical properties and trade terms, you can make informed decisions when purchasing boiler components, ultimately enhancing operational efficiency and safety.

Navigating Market Dynamics and Sourcing Trends in the boiler components Sector

What Are the Key Market Trends Influencing the Boiler Components Sector?

The boiler components market is currently experiencing significant shifts driven by various global factors. Increasing energy demands, particularly in emerging markets like Nigeria and Saudi Arabia, are pushing the need for efficient and reliable boiler systems. Additionally, the rise in industrial activities across Africa and South America is contributing to the growing demand for advanced boiler components, such as burners, heat exchangers, and economizers.

Emerging technologies such as IoT (Internet of Things) and AI (Artificial Intelligence) are transforming the sourcing landscape. These technologies enable predictive maintenance, enhancing the operational efficiency of boiler systems. For B2B buyers, this means a shift towards suppliers who offer smart components capable of integrating with existing systems to provide real-time data and analytics. Furthermore, automation in manufacturing processes is reducing lead times and improving customization options, which is particularly appealing for international buyers looking to tailor solutions to specific regional needs.

Illustrative image related to boiler components

Another crucial trend is the focus on energy efficiency and sustainability. With stricter regulations on emissions and energy consumption, buyers are increasingly seeking components that comply with these standards. As a result, suppliers who can demonstrate compliance with international regulations and provide energy-efficient solutions are likely to gain a competitive edge.

How Are Sustainability and Ethical Sourcing Impacting Boiler Components Procurement?

Sustainability and ethical sourcing have become paramount considerations for B2B buyers in the boiler components sector. The environmental impact of boiler operations, including greenhouse gas emissions and resource depletion, necessitates a shift towards more sustainable practices. Buyers are increasingly prioritizing suppliers who can provide components manufactured with environmentally friendly materials and processes.

Ethical supply chains are crucial in ensuring that the components sourced do not contribute to environmental degradation or social injustices. This is particularly important in regions like Africa and South America, where sourcing practices can significantly impact local communities and ecosystems. As such, B2B buyers are encouraged to engage with suppliers who possess certifications like ISO 14001 for environmental management and other ‘green’ certifications that validate their commitment to sustainability.

Additionally, the adoption of ‘green’ materials in manufacturing boiler components—such as recycled metals and bio-based insulation—can significantly reduce the carbon footprint of boiler systems. Buyers should look for suppliers that offer these sustainable options, as they not only align with global sustainability goals but can also provide long-term cost savings through improved energy efficiency.

What Is the Historical Context of Boiler Components Development?

The evolution of boiler components dates back to the Industrial Revolution, when the need for steam power catalyzed innovations in boiler design and functionality. Early boilers were simple in design, primarily focusing on efficiency and reliability. Over the decades, as industrial processes became more complex, so too did the components within boilers.

Advancements in material science led to the development of more durable and heat-resistant materials, enabling the construction of high-efficiency heat exchangers and burners. The late 20th century saw a shift towards automation and digitalization, with the introduction of advanced controls and monitoring systems that enhanced operational efficiency and safety.

In recent years, the focus has shifted to sustainability, prompting manufacturers to innovate with eco-friendly materials and energy-efficient designs. This historical trajectory highlights the ongoing importance of innovation in the boiler components sector, making it essential for B2B buyers to stay informed about the latest trends and technologies to make informed purchasing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of boiler components

-

How do I solve supply chain disruptions when sourcing boiler components?

Supply chain disruptions can significantly impact the procurement of boiler components. To mitigate this risk, establish relationships with multiple suppliers across different regions. Diversifying your supply sources can provide alternatives in case of delays. Additionally, consider implementing inventory management strategies that allow for buffer stock of critical components. Regular communication with suppliers about potential delays and market conditions can also help in planning ahead and minimizing disruptions. -

What is the best type of boiler component for high-efficiency systems?

When seeking high-efficiency boiler components, prioritize heat exchangers and economizers. A high-efficiency heat exchanger maximizes heat transfer while minimizing energy loss. Economizers capture waste heat from exhaust gases, improving overall efficiency. Additionally, opt for components made from durable materials such as stainless steel or copper, which can withstand high temperatures and corrosive environments. Collaborating with suppliers who specialize in energy-efficient technologies can also yield the best results for your system. -

What certifications should I look for when sourcing boiler components internationally?

When sourcing boiler components, ensure that suppliers hold relevant international certifications, such as ISO 9001 for quality management and ASME (American Society of Mechanical Engineers) certifications for pressure vessels. Additionally, check for compliance with local regulations and safety standards in your region, as these can vary widely. Certifications specific to environmental standards, like ISO 14001, may also be valuable, particularly in markets focused on sustainability. -

How can I customize boiler components to meet specific operational needs?

Customization of boiler components often involves working closely with manufacturers to specify unique requirements. Start by detailing your operational parameters, such as pressure, temperature, and capacity needs. Many suppliers offer customization options, including material choice, size, and design modifications. Engage in collaborative design sessions with engineers from the manufacturer to ensure the final product aligns with your specifications while maintaining compliance with safety and efficiency standards. -

What are the typical minimum order quantities (MOQs) for boiler components?

Minimum order quantities for boiler components can vary significantly depending on the supplier and the type of components. Generally, MOQs may range from a few units for standard parts to hundreds for specialized components. It’s advisable to discuss your specific needs with suppliers to explore flexibility in MOQs, especially if you are testing a new product or entering a new market. Suppliers may also offer bulk purchase discounts, making larger orders more economical. -

What payment terms are common in international boiler component transactions?

Common payment terms in international transactions for boiler components typically include options like letter of credit (LC), advance payment, or payment upon delivery. Many suppliers may require a deposit upfront, especially for customized orders. Ensure that you negotiate clear payment terms that protect your interests while facilitating smooth transactions. Consider using escrow services for high-value orders to safeguard against non-delivery or quality issues. -

How do I ensure quality assurance for boiler components sourced internationally?

To ensure quality assurance, implement a rigorous supplier vetting process that includes checking references, certifications, and past performance. Request samples or prototypes before placing larger orders to assess quality firsthand. Additionally, consider third-party inspection services to verify that components meet your specifications and industry standards before shipment. Establishing a quality agreement with your supplier can also help ensure consistent product quality. -

What logistics considerations should I keep in mind when importing boiler components?

Logistics play a crucial role in the timely delivery of boiler components. Consider factors such as shipping methods, lead times, and customs regulations in your country. Collaborate with freight forwarders who specialize in industrial equipment to navigate these complexities efficiently. Additionally, factor in potential delays due to customs clearance and plan for them in your procurement timeline. Proper documentation and compliance with import regulations are essential to avoid costly delays.

Top 7 Boiler Components Manufacturers & Suppliers List

1. Powerhouse Combustion – Key Boiler Components

Domain: powerhouse-combustion.com

Registered: 2011 (14 years)

Introduction: The main components of a boiler include: 1. Burner: Responsible for mixing air with fuel for combustion, providing heat input. Operates based on signals from thermostats to produce heat. 2. Combustion Chamber: The area where the fuel/air mix burns, typically made of cast iron, reaching high temperatures. 3. Heat Exchanger: Allows heat exchange between two fluids (usually water and gas) without mix…

2. Burner Combustion – Steam Boiler Solutions

Domain: burnercombustion.com

Registered: 2004 (21 years)

Introduction: Steam boilers are essential for various industrial applications, providing efficient heat generation. Key components include burners, combustion chambers, heat exchangers, feedwater systems, and control systems. They operate by igniting fuel to create steam through heat transfer to water. Types of steam boilers include fire-tube, water-tube, and electric boilers. Fire-tube boilers are compact and …

3. Savree – Watertube Boilers

Domain: savree.com

Registered: 2017 (8 years)

Introduction: Watertube boilers convert water into steam using heat from burning fuels, primarily used in power stations. Key components include: 1. Steam Drum: Cylindrical vessel at the top that collects steam and contains internal components like cyclone separators and scrubbers. 2. Mud Drum: Positioned at the bottom to collect sediment and impurities. 3. Water Tubes: Carry water before it turns to steam; cat…

4. Chardon Labs – Key Components of Main Steam Boiler

Domain: chardonlabs.com

Registered: 1997 (28 years)

Introduction: The main steam boiler consists of several key components:

1. **Burner** – Creates combustion based on thermostat signals, adjusting fuel flow as needed.

2. **Tubes** – Internal components that heat water to produce steam, available in water-tube or fire-tube designs.

3. **Pressure Vessel** – Holds high temperature and high-pressure gases.

4. **Combustion Chamber** – Where fuel burning occurs, …

5. Cleaver-Brooks – Steam Boilers

Domain: cleaverbrooks.com

Registered: 1998 (27 years)

Introduction: Steam Boilers: Advanced solutions for industrial and commercial use, designed for efficiency and reliability. Types include Firetube Boilers, Watertube Boilers, Electric and Electrode Boilers. Essential components include Pressure Vessel, Burner System, Control Systems, Heat Transfer Mechanisms, and Water Treatment Solutions. Accessories include Economizers, Deaerators, Blowdown Separators, Feedwa…

6. Hurst Boiler – Replacement Parts and Services

Domain: hurstboiler.com

Registered: 1998 (27 years)

Introduction: Hurst Boiler Parts and Service offers a wide range of replacement parts and services for various boiler systems. Key product details include: 1. **Forced Draft Burner Parts**: Includes components from brands like Beckett, Industrial Combustion, Gordon Piatt, and Power Flame. Parts include motors, blower wheels, electrodes, transformers, ignition & control components, air flow switches, oil pumps, …

7. Byju’s – Boiler Overview

Domain: byjus.com

Registered: 2013 (12 years)

Introduction: A boiler is a closed vessel used to heat liquid, usually water, or generate vapor or steam under pressure through the combustion of fossil fuels. Key components include: 1. Boiler Mountings: Water level indicator, pressure gauge, safety valve, stop valve, blow off cock, feed check valve, and grate. 2. Boiler Accessories: Feed pump, super heater, economizer, and air preheater. The working principle…

Strategic Sourcing Conclusion and Outlook for boiler components

In today’s competitive landscape, strategic sourcing of boiler components is essential for ensuring operational efficiency and long-term sustainability. By investing in quality components such as burners, heat exchangers, and control systems, businesses can enhance performance and reduce maintenance costs. Understanding the diverse components of boiler systems allows buyers to make informed decisions that align with their specific operational needs.

International buyers, particularly in regions like Africa, South America, the Middle East, and Europe, must prioritize partnerships with reliable suppliers who can deliver not only quality products but also ongoing support and expertise. As markets evolve, leveraging technology and data analytics will further optimize sourcing strategies, enabling firms to adapt to changing demands and regulatory requirements.

Looking ahead, the focus should be on innovation and sustainability within the boiler component market. By embracing advancements in technology and sustainable practices, businesses can position themselves as leaders in their respective industries. Therefore, as you evaluate your sourcing strategies, consider reaching out to trusted suppliers who can help you navigate this complex landscape and drive value for your organization.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.