Boba Machine: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for boba machine

In the rapidly evolving landscape of the global beverage market, sourcing the right boba machine can pose significant challenges for international B2B buyers. Whether you’re a burgeoning bubble tea shop in Brazil or an established café in Germany, the need for high-quality, reliable equipment is paramount to your success. This comprehensive guide delves into the multifaceted world of boba machines, offering insights into various types, applications, and the critical factors to consider when selecting a supplier.

Our exploration covers essential topics such as the diverse functionalities of boba machines—from automatic brewers and tapioca pearl cookers to cup sealers and shaking machines—ensuring that you understand how each can enhance your operational efficiency. We’ll also provide guidance on vetting suppliers, analyzing costs, and understanding the latest market trends, equipping you with the knowledge needed to make informed purchasing decisions.

Designed specifically for B2B buyers across Africa, South America, the Middle East, and Europe, this guide aims to empower you to navigate the complexities of the boba machine market confidently. By leveraging the insights shared here, you can streamline your procurement process, optimize your bubble tea offerings, and ultimately drive growth in your business.

Understanding boba machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Automatic Boba Machines | High-level automation, multiple functionalities, digital controls | High-volume bubble tea shops, franchises | Pros: Speed and consistency; Cons: Higher initial investment. |

| Boba Tea Brewers | Programmable brewing times and temperatures | Establishing tea bases, quality control | Pros: Consistent flavor; Cons: May require training. |

| Tapioca Pearl Cookers | Automated cooking, maintains ideal temperature and texture | Essential for boba-focused businesses | Pros: Saves time; Cons: Limited to pearl cooking. |

| Cup Sealing Machines | Efficient sealing with various automation levels | Takeaway-focused shops | Pros: Spill-free transport; Cons: Initial setup time. |

| Shaking Machines | Automates mixing for uniform distribution of ingredients | Essential for consistency in customer experience | Pros: Improved taste uniformity; Cons: Maintenance required. |

What Are Automatic Boba Machines and Their Benefits for B2B Buyers?

Automatic boba machines represent the pinnacle of efficiency in bubble tea preparation. These machines integrate multiple functionalities such as ingredient dispensing, mixing, and sometimes even self-cleaning, making them ideal for high-volume settings like franchises or busy tea shops. When considering an automatic machine, B2B buyers should evaluate factors such as speed, ease of use, and the potential return on investment, as these machines can significantly reduce labor costs while enhancing service speed.

How Do Boba Tea Brewers Ensure Consistent Quality?

Boba tea brewers are specialized equipment designed to perfect the tea base, which is vital for creating flavorful bubble tea. These machines allow for precise control over brewing times and temperatures, ensuring that each batch maintains the desired flavor profile. For B2B buyers, investing in a quality boba tea brewer can lead to improved product consistency, which is essential for customer satisfaction and brand loyalty. Consider the machine’s programmability and ease of operation when making a purchase.

Why Are Tapioca Pearl Cookers Essential for Boba Businesses?

Tapioca pearl cookers play a critical role in ensuring that the pearls used in bubble tea are cooked to perfection. These machines automate the cooking process, maintaining optimal temperature and agitation, which is crucial for achieving the chewy texture that customers expect. For businesses focused on boba, investing in a tapioca pearl cooker can save significant time and labor, leading to more efficient operations. Buyers should consider the cooker’s capacity and ease of cleaning when evaluating options.

What Role Do Cup Sealing Machines Play in Takeaway Services?

Cup sealing machines are essential for bubble tea shops that prioritize takeaway service. These machines efficiently seal cups with a protective film, preventing spills and maintaining the drink’s temperature during transport. B2B buyers should assess the machine’s sealing speed and automation level based on their shop’s demand. While these machines enhance customer experience, it’s important to consider the initial setup time and training required for staff.

How Do Shaking Machines Improve Customer Experience?

Shaking machines are designed to automate the mixing of bubble tea ingredients, ensuring a consistent blend of tea, milk, and flavorings. This uniformity is key to delivering a satisfying customer experience, as it directly impacts the taste of the drink. For B2B buyers, investing in a shaking machine can streamline operations and reduce inconsistencies. However, potential buyers should also consider the maintenance requirements and the space needed for installation, as these factors can influence operational efficiency.

Key Industrial Applications of boba machine

| Industry/Sector | Specific Application of boba machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Automated Bubble Tea Production | Increases efficiency and reduces labor costs | Machine capacity, automation level, and maintenance requirements |

| Retail | Customizable Boba Kiosks | Attracts customers with quick service and variety | Space requirements, power supply, and payment options |

| Hospitality | Boba Beverage Services for Events | Enhances guest experience and offers unique options | Equipment size, transportability, and setup time |

| Franchise Operations | Consistent Product Quality Across Locations | Ensures brand consistency and customer satisfaction | Training support, warranty, and spare parts availability |

| Health and Wellness | Nutritional Boba Options in Cafés and Juice Bars | Expands menu diversity and caters to health trends | Ingredient compatibility, machine versatility, and ease of cleaning |

How is a Boba Machine Used in the Food and Beverage Industry?

In the food and beverage sector, boba machines streamline the bubble tea production process. They automate tasks such as brewing tea, cooking tapioca pearls, and sealing cups, which significantly enhances operational efficiency. This is particularly beneficial in high-demand environments where time is of the essence. For international buyers, considerations should include the machine’s capacity to handle peak hours and its compatibility with local ingredient supplies.

What Role Do Boba Machines Play in Retail?

Retailers are increasingly adopting boba machines to create customizable boba kiosks. These setups allow customers to personalize their drinks, enhancing the overall shopping experience. Quick service is essential in retail, and a boba machine can produce drinks in under two minutes, attracting more foot traffic. Buyers should assess the machine’s space requirements and ensure it can integrate with existing payment systems, especially in diverse markets like Africa and South America.

How Can Boba Machines Enhance Hospitality Services?

In the hospitality industry, boba machines provide unique beverage options for events and catering services. By offering bubble tea, hotels and event planners can elevate guest experiences and differentiate their services. The versatility of these machines allows for easy transport and setup, making them ideal for various venues. Buyers should consider the equipment’s portability and the time needed for setup to ensure seamless service at events.

Why Are Boba Machines Important for Franchise Operations?

Franchise operations benefit from boba machines by ensuring product consistency across multiple locations. These machines help maintain the same flavor profiles and quality standards, which is crucial for brand integrity. For franchise buyers, it’s essential to evaluate the manufacturer’s training support and warranty options, as these factors can significantly influence operational success across various regions, including Europe and the Middle East.

How Do Boba Machines Cater to Health and Wellness Trends?

With the growing demand for healthier beverage options, boba machines can be used to create nutritional boba drinks in cafés and juice bars. This allows businesses to cater to health-conscious customers by offering alternatives like fruit-infused teas or low-calorie sweeteners. Buyers should ensure that the machine can accommodate various ingredients and is easy to clean, which is vital for maintaining hygiene standards in health-focused establishments.

3 Common User Pain Points for ‘boba machine’ & Their Solutions

Scenario 1: Struggling with Consistency in Drink Quality

The Problem: One of the most significant challenges faced by B2B buyers in the bubble tea industry is maintaining consistency in drink quality. Inconsistent brewing times, varying temperatures, and uneven mixing can lead to a subpar product that frustrates customers and damages brand reputation. For new shops, this inconsistency can stem from manual processes that lack precision, while established businesses may struggle to replicate popular recipes as staff members change or new equipment is introduced.

The Solution: To overcome this issue, investing in high-quality, automated boba machines is essential. These machines often include programmable brewing functions that allow you to set precise temperatures and brewing times for different tea varieties, ensuring each batch is consistent. For instance, using a dedicated boba tea brewer can significantly improve the quality of your tea base by managing steeping conditions effectively. Additionally, integrating machines with automated mixers or shakers guarantees that all ingredients are uniformly blended, thereby enhancing the overall flavor profile. For businesses in regions like Africa and South America, where consistency can be a challenge due to varying ingredient quality, sourcing machines from reputable suppliers that offer training and support can also help streamline operations and ensure staff are well-equipped to use the equipment effectively.

Scenario 2: High Operational Costs and Labor Challenges

The Problem: Many bubble tea shops, particularly in competitive markets, face escalating operational costs, primarily due to labor expenses. Hiring and training staff to prepare complex drinks can be time-consuming and costly. Moreover, high turnover rates mean that shops frequently lose trained employees, leading to inconsistent service and increased training costs. In regions like the Middle East and Europe, where labor laws can complicate staffing strategies, this issue is particularly pressing.

The Solution: To mitigate labor-related costs, consider investing in fully automated boba machines that can streamline drink preparation. Machines like Bobacino’s robotic boba bar can produce drinks in under two minutes with minimal human intervention. By automating tasks such as ingredient dispensing, shaking, and sealing, you can reduce the need for a large staff while maintaining high service standards. Moreover, many automated systems come equipped with user-friendly interfaces, allowing new staff to operate them quickly with minimal training. For B2B buyers in Europe, where labor costs are higher, this investment not only improves efficiency but can also result in substantial long-term savings, enabling you to redirect funds toward marketing and product development.

Scenario 3: Limited Space and Equipment Versatility

The Problem: Boba machine buyers often operate in environments where space is at a premium. In urban settings or smaller venues, accommodating all necessary equipment—such as brewers, sealers, and mixers—can be a logistical nightmare. This can lead to inefficient workflows and a chaotic work environment, ultimately affecting customer service and satisfaction.

The Solution: To address space constraints, opt for multi-functional boba machines that combine several operations into one unit. For example, machines that can brew tea, cook tapioca pearls, and seal cups can significantly reduce the footprint of your equipment setup. When selecting equipment, look for options that are designed with compact dimensions while still delivering high throughput. Additionally, consider mobile solutions that can be easily relocated or stored when not in use. For businesses in South America and Africa, where shop layouts may vary significantly, consulting with suppliers who offer customizable solutions can lead to tailored setups that optimize both space and workflow. Such strategic investments not only enhance operational efficiency but also create a more pleasant working environment, allowing staff to focus on delivering exceptional customer service.

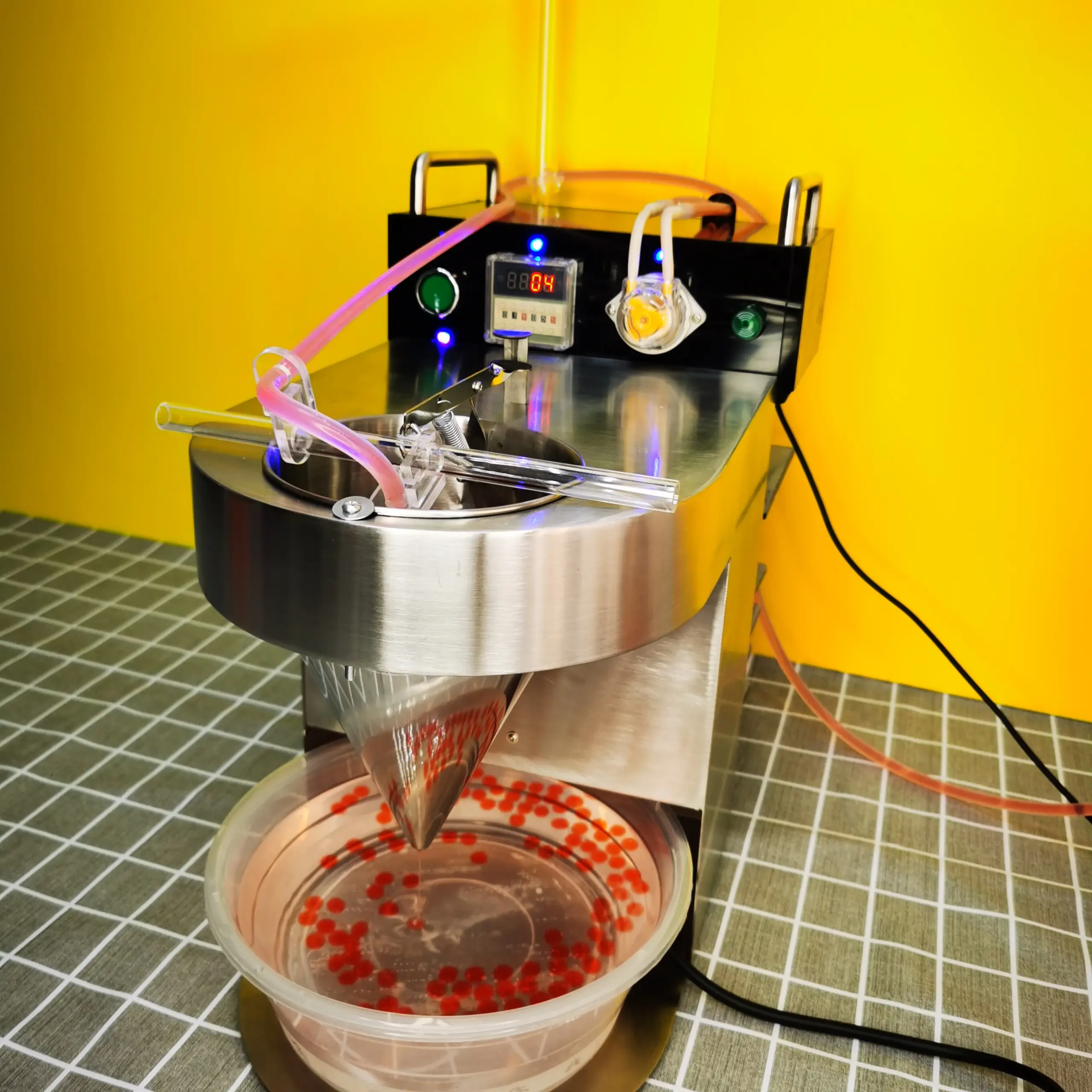

Illustrative image related to boba machine

Strategic Material Selection Guide for boba machine

What Are the Key Materials Used in Boba Machines?

When selecting materials for boba machines, it is crucial to consider their properties, advantages, and limitations. The choice of material directly impacts the machine’s performance, durability, and compliance with international standards. Below, we analyze four common materials used in boba machines: stainless steel, food-grade plastics, aluminum, and glass.

How Does Stainless Steel Benefit Boba Machine Manufacturing?

Stainless steel is a popular choice for boba machines due to its excellent corrosion resistance and durability. It can withstand high temperatures and pressures, making it suitable for brewing tea and cooking tapioca pearls. The material is easy to clean and maintain, ensuring hygiene in food preparation environments.

Pros: Stainless steel is highly durable, resistant to rust and staining, and can handle thermal shock. It also complies with various international food safety standards.

Cons: The initial cost of stainless steel can be higher compared to other materials. Additionally, it may require more complex manufacturing processes, which can increase lead times.

Impact on Application: Stainless steel is compatible with hot liquids and can maintain the integrity of the boba machine under various operating conditions.

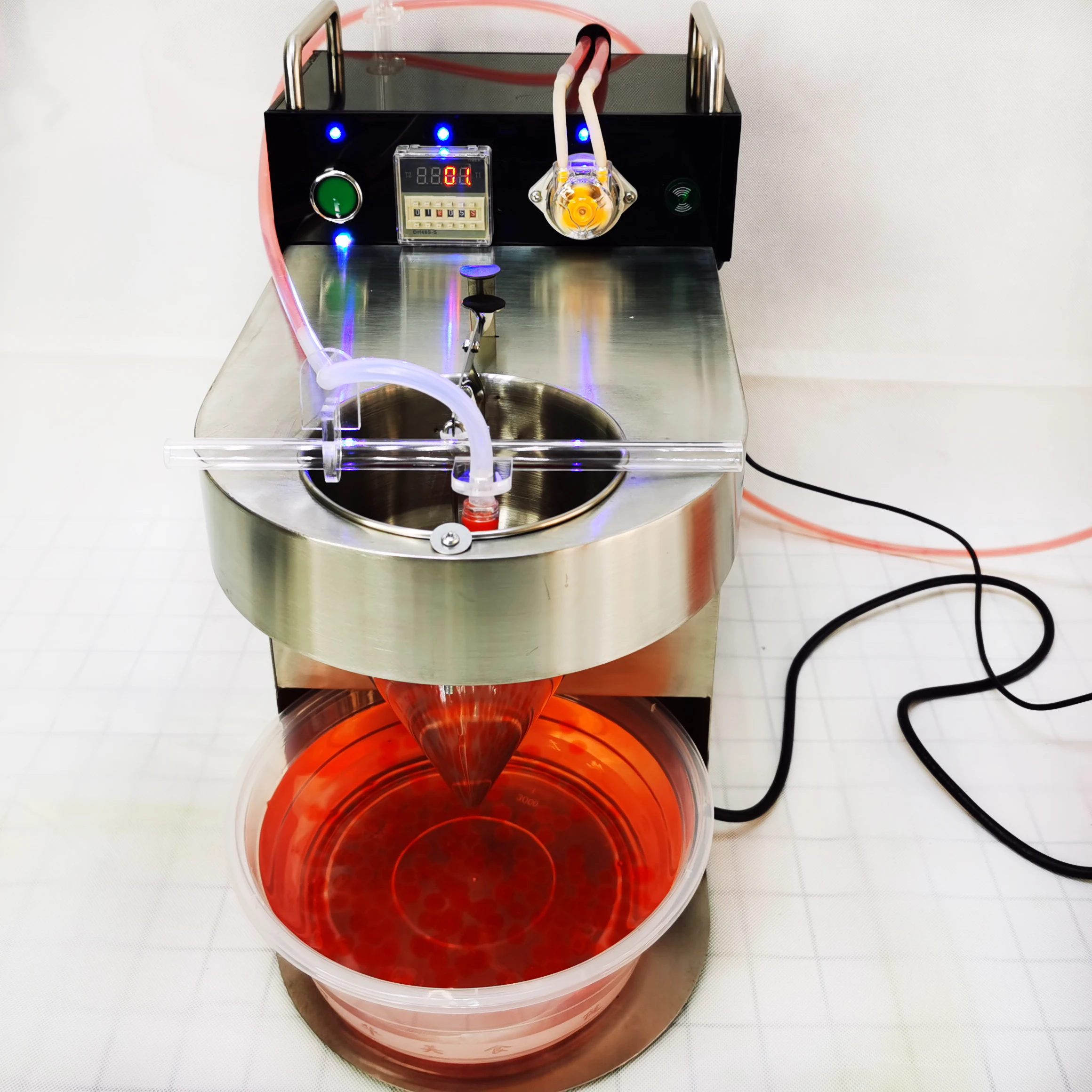

Illustrative image related to boba machine

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure that the stainless steel used meets standards such as ASTM A240 for corrosion resistance. Compliance with local food safety regulations is also essential.

What Role Does Food-Grade Plastic Play in Boba Machines?

Food-grade plastics are often used for components like cup sealing machines and ingredient dispensers. These materials are lightweight and can be molded into complex shapes, making them suitable for intricate designs.

Pros: Food-grade plastics are cost-effective and versatile, allowing for various designs and functionalities. They are also resistant to many chemicals, which is beneficial for handling different flavors and syrups.

Cons: While generally durable, food-grade plastics may not withstand high temperatures as well as metals, potentially leading to deformation over time.

Impact on Application: These plastics are ideal for cold applications and are often used in components that do not come into direct contact with hot liquids.

Considerations for International Buyers: Compliance with standards like FDA and EU regulations on food contact materials is crucial. Buyers should also consider the availability of specific plastic types in their regions.

Why Is Aluminum Used in Boba Machine Components?

Aluminum is another common material used in boba machines, particularly for structural components and heat exchangers. It is lightweight and has good thermal conductivity, making it ideal for applications that require quick heat transfer.

Pros: Aluminum is relatively inexpensive and easy to machine. Its lightweight nature makes it easier to transport and install.

Cons: Aluminum is less corrosion-resistant than stainless steel and may require protective coatings to prevent oxidation, especially in humid environments.

Impact on Application: Aluminum is suitable for applications where weight is a concern, but care must be taken to ensure that it is protected from corrosive elements.

Considerations for International Buyers: Buyers should ensure that the aluminum used meets standards such as ASTM B221 for structural applications. In regions with high humidity, additional protective measures may be necessary.

How Does Glass Contribute to Boba Machine Design?

Glass is primarily used in boba machines for display purposes, such as in beverage dispensers. It provides a clear view of the product, enhancing customer engagement.

Pros: Glass is non-reactive and does not leach chemicals, ensuring the quality of the beverage remains intact. It also offers aesthetic appeal.

Cons: Glass is fragile and can break easily, posing a safety risk in busy environments. It is also heavier than other materials.

Impact on Application: Glass is ideal for showcasing products but may not be suitable for high-impact areas of the machine.

Considerations for International Buyers: Compliance with safety standards for food contact materials is essential. Buyers should also consider the logistics of transporting glass components.

Summary Table of Material Selection for Boba Machines

| Material | Typical Use Case for boba machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Brewing and cooking components | High durability and corrosion resistance | Higher initial cost | High |

| Food-Grade Plastic | Cup sealing and ingredient dispensers | Cost-effective and versatile | Limited heat resistance | Low |

| Aluminum | Structural components and heat exchangers | Lightweight and good thermal conductivity | Less corrosion-resistant | Medium |

| Glass | Beverage dispensers | Non-reactive and aesthetically pleasing | Fragile and heavy | Medium |

This analysis provides a comprehensive overview of materials used in boba machines, helping international B2B buyers make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for boba machine

What Are the Main Stages of Manufacturing Boba Machines?

The manufacturing of boba machines involves several critical stages, each designed to ensure that the final product meets high standards of quality and functionality. Understanding these stages can help B2B buyers assess the reliability of their suppliers.

Material Preparation: Sourcing and Quality Control

The first step in the manufacturing process is material preparation, which entails sourcing high-quality raw materials. Common materials used in boba machines include stainless steel, food-grade plastics, and electronic components. Suppliers often perform preliminary quality checks to verify that materials meet industry standards, such as FDA and CE certifications.

B2B buyers should inquire about the supplier’s sourcing policies and whether they have established relationships with reputable material vendors. Additionally, obtaining certificates of compliance can provide assurance regarding the quality of materials used in production.

Forming: Utilizing Advanced Manufacturing Techniques

Once the materials are prepared, the next stage is forming, which typically involves cutting, molding, and machining the components of the boba machine. Techniques such as CNC machining and injection molding are often employed for precision and efficiency.

CNC machining allows for intricate designs and tight tolerances, ensuring that parts fit together seamlessly. Injection molding, on the other hand, is ideal for producing plastic components at scale. B2B buyers should look for suppliers who utilize state-of-the-art equipment and have experience in producing food-grade machinery to guarantee the safety and reliability of their products.

Assembly: Ensuring Functional Integration

After the individual components are formed, they undergo assembly. This stage involves integrating the various parts, such as the brewing system, dispensing mechanisms, and sealing units. Automated assembly lines are commonly employed to enhance efficiency and accuracy, which is essential for high-volume production.

Illustrative image related to boba machine

Quality assurance checkpoints during assembly, such as in-process quality control (IPQC), are vital to identify any defects early in the manufacturing process. B2B buyers should ask suppliers about their assembly techniques and whether they utilize automated systems to minimize human error.

Finishing: Final Touches and Surface Treatments

The finishing stage includes surface treatments, painting, and final inspections. Surface treatments, such as electro-polishing, improve the hygiene and aesthetic appeal of stainless steel components, making them suitable for food service environments.

Final inspections ensure that all components function correctly and meet design specifications. B2B buyers should request information on the finishing processes employed by suppliers and whether they conduct functional testing to verify the machine’s performance before shipping.

What Quality Assurance Standards Are Relevant for Boba Machines?

Quality assurance is critical in the manufacturing of boba machines, as these products must comply with various international and industry-specific standards. Understanding these standards is essential for B2B buyers aiming to ensure the reliability and safety of their equipment.

Which International Standards Should B2B Buyers Be Aware Of?

One of the most recognized international quality management standards is ISO 9001, which outlines criteria for an effective quality management system (QMS). Suppliers who are ISO 9001 certified demonstrate a commitment to consistent quality and continuous improvement.

Additionally, compliance with food safety standards, such as those outlined by the FDA in the United States and CE marking in Europe, is crucial for any equipment used in food preparation. Buyers should verify that their suppliers meet these standards, as non-compliance can lead to serious legal and operational risks.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integral throughout the manufacturing process. Key checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): Conducted during the manufacturing process, this checkpoint identifies defects early, minimizing waste and rework.

-

Final Quality Control (FQC): A comprehensive inspection of the finished product to confirm that it meets all specifications and functional requirements.

B2B buyers should inquire about the specific QC measures implemented by suppliers and whether they maintain detailed documentation of these checks.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers adhere to rigorous quality control standards, B2B buyers can take several proactive steps.

What Methods Can Buyers Use to Assess Supplier Quality?

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate a supplier’s manufacturing processes, quality management systems, and compliance with international standards.

-

Requesting Quality Reports: Suppliers should be willing to provide detailed quality reports, including results from IQC, IPQC, and FQC. These documents serve as evidence of the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging independent third-party inspectors can provide an unbiased assessment of the manufacturing processes and product quality. This step is particularly important for international buyers who may not have the resources to conduct in-person audits.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing boba machines internationally, buyers from regions such as Africa, South America, the Middle East, and Europe must be aware of specific nuances that can affect quality control.

How Do Regulatory Differences Impact Quality Assurance?

Regulatory requirements can vary significantly by region. For instance, compliance with CE marking is mandatory for products sold in the European Union, while other regions may have different safety and quality certifications. B2B buyers should familiarize themselves with local regulations and ensure that suppliers can demonstrate compliance.

What Should Buyers Consider Regarding After-Sales Support?

After-sales support is another crucial aspect of quality assurance. B2B buyers should inquire about warranty terms, availability of spare parts, and the supplier’s commitment to ongoing maintenance and technical support. This is especially important in regions where access to technical expertise may be limited.

In summary, understanding the manufacturing processes and quality assurance protocols for boba machines empowers B2B buyers to make informed purchasing decisions. By focusing on supplier credibility, compliance with international standards, and the robustness of quality control measures, businesses can enhance their operational efficiency and customer satisfaction in the competitive bubble tea market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘boba machine’

To assist B2B buyers in procuring the right boba machine for their bubble tea business, this practical sourcing guide outlines key steps to ensure a successful purchase. Each step is designed to help you evaluate options, assess suppliers, and make informed decisions that align with your operational needs.

Step 1: Define Your Technical Specifications

Before exploring the market, clearly outline the technical requirements of the boba machine you need. Consider factors such as production capacity, machine type (e.g., automatic, manual), and specific functionalities (like brewing, shaking, sealing). This clarity will help streamline your search and ensure that the machine meets your operational demands.

Step 2: Research and Compare Different Machine Types

Understanding the various types of boba machines available is essential. Look into:

– Automatic Boba Machines: Ideal for high-volume settings and offer multiple functions in one unit.

– Boba Tea Brewers: Focused on brewing the perfect tea base, crucial for quality.

– Cup Sealing Machines: Necessary for takeaway services to prevent spills.

By comparing these options, you can select the best fit for your business model and customer expectations.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, conduct thorough research on potential suppliers. Request:

– Company profiles: Understand their market presence and expertise.

– Case studies: Learn how their machines have benefited similar businesses.

– References: Speak with other buyers to gauge their experiences. This step is vital to ensure you are dealing with reputable suppliers who can provide reliable support.

Step 4: Verify Supplier Certifications and Warranty

Check for necessary certifications that validate the safety and quality of the machines, such as NSF or CE certifications. Additionally, review the warranty terms offered by the supplier. A robust warranty and customer support can save you from unexpected costs and downtime, ensuring peace of mind with your investment.

Step 5: Request Demonstrations or Samples

Whenever possible, request live demonstrations or samples of the boba machine in action. Observing the machine’s performance will help you assess its speed, efficiency, and ease of use. If applicable, ask for a trial period to evaluate how it integrates with your existing operations before making a final decision.

Step 6: Assess Total Cost of Ownership

Beyond the initial purchase price, consider the total cost of ownership, which includes maintenance, operation costs, and potential upgrades. Calculate expected ROI based on projected sales and efficiency gains. This holistic view will ensure that your investment is sustainable and financially viable in the long run.

Step 7: Finalize Your Purchase and Plan for Integration

Once you have selected a supplier and machine, finalize the purchase and plan for integration into your operations. Coordinate with your team for training on the new equipment to maximize its benefits. Ensure that you have a plan in place for managing any disruptions during the transition, allowing for a smooth implementation into your bubble tea business.

Illustrative image related to boba machine

By following these steps, B2B buyers can confidently navigate the procurement process for boba machines, ensuring they select the right equipment that supports their business goals and enhances customer satisfaction.

Comprehensive Cost and Pricing Analysis for boba machine Sourcing

What Are the Key Cost Components in Boba Machine Sourcing?

When sourcing boba machines, international B2B buyers must understand the various cost components that contribute to the final pricing. The primary cost factors include:

-

Materials: The quality of materials used in manufacturing boba machines significantly impacts the overall cost. Stainless steel, food-grade plastics, and electronic components are common materials. High-quality materials often result in better durability and performance, which can justify a higher price.

-

Labor: Labor costs vary by region and influence the pricing structure. Countries with lower labor costs may offer more competitive pricing but may compromise on quality. Conversely, manufacturers in regions with higher labor costs typically invest in skilled labor, which can enhance product quality but may raise prices.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can minimize overhead costs, allowing suppliers to offer more competitive prices.

-

Tooling: Custom tooling can be a significant upfront cost, especially for bespoke machine designs. Buyers should consider whether they need standard machines or custom solutions, as custom tooling can inflate initial costs.

-

Quality Control (QC): Ensuring quality through rigorous testing and compliance with international standards adds to the cost. Machines that meet specific certifications (e.g., NSF, CE) may command a higher price but offer peace of mind regarding safety and reliability.

-

Logistics: Shipping costs depend on the machine size, weight, and distance from the supplier. International buyers should also factor in customs duties and taxes, which can vary significantly by region.

-

Margin: Suppliers will include a profit margin in their pricing, which varies based on their business model and market competition. Understanding the typical margins in the boba machine market can help buyers gauge fair pricing.

What Influences the Pricing of Boba Machines?

Several factors can influence the pricing of boba machines beyond the basic cost components:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk often leads to discounts. Suppliers may have a MOQ that can affect the overall cost. Buyers should assess their demand and budget to negotiate better terms.

-

Specifications and Customization: Machines with advanced features or tailored specifications tend to be more expensive. Buyers should evaluate whether they need specific functionalities or if standard models suffice for their operations.

-

Quality and Certifications: Machines that meet higher quality standards or possess certifications may come at a premium. However, investing in certified equipment can save costs in the long run by reducing maintenance issues and increasing customer satisfaction.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their brand value and proven track record, while newer entrants may offer lower prices to gain market share.

-

Incoterms: The shipping terms agreed upon can significantly affect the total cost. Understanding Incoterms (e.g., FOB, CIF) is essential for international buyers, as they determine who bears the shipping costs and risks.

How Can Buyers Optimize Costs and Negotiate Effectively?

To maximize cost efficiency when sourcing boba machines, buyers should consider the following tips:

-

Negotiate: Engage suppliers in discussions about pricing, especially for bulk orders. Highlighting long-term partnership potential can lead to better deals.

-

Total Cost of Ownership (TCO): Beyond initial purchase prices, consider the TCO, including maintenance, operational costs, and potential downtime. Investing in higher-quality machines may yield lower TCO over time.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe must be aware of currency fluctuations, import tariffs, and trade agreements that can affect pricing. It’s advisable to conduct thorough market research to understand local conditions and negotiate effectively.

Disclaimer on Indicative Prices

Pricing for boba machines can vary widely based on specifications, supplier, and market conditions. The figures mentioned in this guide are indicative and should be confirmed with suppliers to ensure accuracy and relevancy to specific purchasing contexts.

Alternatives Analysis: Comparing boba machine With Other Solutions

In the dynamic world of bubble tea businesses, selecting the right equipment is crucial for maintaining quality and efficiency. While boba machines offer specialized functions for preparing bubble tea, there are alternative solutions that also serve similar purposes. This analysis explores these alternatives, providing insights that can aid B2B buyers in making informed decisions.

| Comparison Aspect | Boba Machine | Automated Boba Kiosk | Manual Preparation Method |

|---|---|---|---|

| Performance | High efficiency; consistent quality | Fast service; customizable drinks | Variable; depends on staff skill |

| Cost | $1,000 – $2,000 per unit | $50,000 per unit; $500/month | Low initial investment |

| Ease of Implementation | Moderate; requires training | High; plug-and-play setup | High; familiar processes |

| Maintenance | Regular cleaning; part replacements | Minimal; 30 minutes/day | Moderate; depends on equipment |

| Best Use Case | High-volume shops needing consistency | Locations with high foot traffic | Small shops or mobile vendors |

What Are the Pros and Cons of Automated Boba Kiosks?

Automated boba kiosks, such as those offered by Bobacino, represent a significant leap in bubble tea service. These kiosks can produce drinks in under two minutes with minimal human intervention, which is ideal for high-traffic areas. The upfront cost, however, can be a barrier for some businesses, with units priced around $50,000 and ongoing operational costs. They require minimal maintenance, making them attractive for operators focused on efficiency and quick service. However, they may lack the personal touch that some customers appreciate in traditional shops.

How Does Manual Preparation Compare?

The manual preparation method relies heavily on trained staff to create bubble tea, offering a more personalized experience. This approach typically has a low initial investment, making it accessible for smaller businesses or those just starting out. However, the quality and consistency of drinks can vary significantly based on the skill level of the staff, which may lead to customer dissatisfaction. Additionally, manual methods can be time-consuming, particularly during peak hours, potentially impacting service speed.

Conclusion: How Can B2B Buyers Choose the Right Solution?

When considering the best option for a bubble tea business, B2B buyers should evaluate their specific needs, including budget, service speed, and customer experience. Boba machines are excellent for businesses prioritizing consistency and efficiency, while automated kiosks suit high-traffic locations with a focus on rapid service. Conversely, manual preparation may work well for smaller operations that value personalized service and have a limited budget. By aligning equipment choices with business goals, buyers can enhance their operational efficiency and customer satisfaction in the competitive bubble tea market.

Essential Technical Properties and Trade Terminology for boba machine

What Are the Key Technical Properties of Boba Machines?

Understanding the essential technical properties of boba machines is crucial for B2B buyers aiming to enhance their bubble tea business. Here are some critical specifications that should be considered:

-

Material Grade

The material used in boba machines, often stainless steel or food-grade plastic, is vital for durability and hygiene. Stainless steel is preferred for its resistance to corrosion and ease of cleaning, ensuring compliance with food safety regulations. For B2B buyers, selecting machines made from high-quality materials reduces maintenance costs and extends the lifespan of the equipment. -

Production Capacity

The production capacity of a boba machine refers to the number of drinks it can prepare per hour. For example, high-capacity machines can serve over 200 drinks in a short time, making them suitable for high-traffic establishments. This metric is essential for businesses in regions with growing bubble tea demand, as it influences service speed and customer satisfaction. -

Power Consumption

The energy efficiency of a boba machine is indicated by its power consumption, typically measured in watts. Machines that consume less power while maintaining high performance can significantly reduce operational costs. For B2B buyers, understanding power requirements is essential for budgeting and ensuring compliance with local electrical standards. -

Automation Level

Boba machines vary in automation from fully manual to highly automated units. Fully automated machines can brew tea, cook tapioca pearls, and seal cups, minimizing labor costs and maximizing consistency. Buyers should assess their operational needs to determine the right level of automation that balances efficiency and capital investment. -

Safety Compliance

Compliance with safety standards, such as NSF or CE certifications, indicates that a boba machine meets international food safety and sanitation guidelines. For B2B buyers, investing in compliant equipment protects their business from potential legal issues and enhances brand reputation among health-conscious consumers.

What Are Common Trade Terms Used in the Boba Machine Industry?

Familiarity with industry terminology is crucial for navigating the purchasing process effectively. Here are some common trade terms relevant to boba machines:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce equipment that is marketed by another company under its brand name. For B2B buyers, understanding OEM relationships can help in sourcing machines that meet specific quality and performance standards while potentially offering better pricing. -

MOQ (Minimum Order Quantity)

MOQ is the smallest amount of a product that a supplier is willing to sell. This term is significant for B2B buyers as it affects inventory management and initial investment. Knowing the MOQ helps businesses align their purchasing strategy with their sales forecasts. -

RFQ (Request for Quotation)

An RFQ is a document that businesses send to suppliers to request pricing information for specific products or services. For buyers, issuing an RFQ is a critical step in the procurement process, enabling them to compare quotes and negotiate better terms. -

Incoterms (International Commercial Terms)

Incoterms are a set of internationally recognized rules that define the responsibilities of buyers and sellers regarding the delivery of goods. Understanding these terms helps B2B buyers clarify shipping costs, risk levels, and delivery responsibilities, which is vital for international transactions. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until the product is delivered. For B2B buyers, knowing the lead time is essential for planning inventory and ensuring that their supply chain remains efficient, especially in regions where demand for bubble tea is rising rapidly.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance their bubble tea operations and contribute to long-term success in the market.

Illustrative image related to boba machine

Navigating Market Dynamics and Sourcing Trends in the boba machine Sector

What Are the Current Market Dynamics and Key Trends in the Boba Machine Sector?

The boba machine sector is experiencing rapid growth driven by an increasing global demand for bubble tea. Factors such as rising consumer interest in diverse beverage options and the proliferation of bubble tea shops worldwide are propelling this trend. In particular, markets in Africa, South America, the Middle East, and Europe are witnessing a surge in boba shop openings, with Brazil and Germany leading the charge. This expansion is not just about quantity; it also emphasizes quality and efficiency, making advanced boba machines essential for shop owners to stay competitive.

Emerging technologies are reshaping the boba machine landscape. Automation is a key trend, with robotic solutions like Bobacino offering quick service and high volume production. These innovations enable shops to reduce labor costs and improve service times, appealing to a tech-savvy consumer base. Additionally, the integration of smart features, such as digital interfaces for drink customization, is becoming increasingly common, enhancing customer engagement and operational efficiency.

International buyers must also consider the sourcing dynamics. As demand grows, so does the importance of reliable suppliers who can provide high-quality machines with robust warranties and support. B2B buyers should prioritize vendors that offer comprehensive training and after-sales support to ensure seamless integration of new equipment into their operations.

Illustrative image related to boba machine

How Important Is Sustainability and Ethical Sourcing in the Boba Machine Sector?

Sustainability is becoming a critical concern for businesses across all sectors, and the boba machine industry is no exception. The environmental impact of manufacturing processes, particularly in the plastic components of boba machines, necessitates a shift towards greener practices. B2B buyers should look for suppliers that prioritize sustainable materials and energy-efficient manufacturing processes to minimize their ecological footprint.

Ethical sourcing is equally vital. Establishing an ethical supply chain not only enhances brand reputation but also meets the increasing consumer demand for transparency and responsibility in business practices. Boba machine manufacturers that utilize certified green materials and adhere to ethical labor practices can foster trust with their B2B clients. Certifications such as ISO 14001 (Environmental Management) and Fair Trade can serve as indicators of a manufacturer’s commitment to sustainability.

Investing in sustainable and ethically sourced boba machines can lead to long-term cost savings and resilience against regulatory pressures. Buyers are encouraged to evaluate potential suppliers based on their sustainability credentials and certifications, ensuring alignment with their own corporate social responsibility goals.

What Has Been the Evolution of Boba Machines Over Time?

The evolution of boba machines reflects the growing complexity and sophistication of the bubble tea industry. Initially, bubble tea was prepared manually, requiring significant labor and time. However, as the popularity of bubble tea surged, so did the demand for more efficient production methods. Early boba machines primarily focused on brewing tea and cooking tapioca pearls, but advancements have led to the creation of fully automated systems capable of handling multiple tasks, including ingredient dispensing and drink sealing.

This transformation mirrors broader technological advancements in food service and automation. Today’s boba machines not only enhance operational efficiency but also ensure consistency and quality in product offerings, a critical factor in customer satisfaction. As the market continues to evolve, ongoing innovations will likely further streamline operations, catering to the ever-increasing demands of consumers and business owners alike.

Illustrative image related to boba machine

In summary, understanding the market dynamics, prioritizing sustainability, and recognizing the evolution of boba machines are crucial for B2B buyers looking to invest in this thriving sector. With the right insights and strategic sourcing, businesses can position themselves for success in the competitive bubble tea landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of boba machine

-

How do I solve issues with inconsistent bubble tea quality using a boba machine?

To address inconsistent bubble tea quality, investing in a high-quality boba machine is crucial. Look for machines that automate key processes such as brewing tea, cooking tapioca pearls, and mixing drinks. These machines ensure precise control over temperature, timing, and ingredient ratios, which leads to uniformity in taste and texture. Additionally, regular maintenance and calibration of the machine can further enhance performance, ensuring that every drink meets customer expectations consistently. -

What is the best type of boba machine for a small bubble tea shop?

For a small bubble tea shop, a semi-automatic boba machine may be the best choice. These machines provide a balance between automation and manual control, allowing for flexibility in drink preparation while still speeding up service times. Look for features such as a built-in tea brewer and a cup sealing mechanism to streamline operations. This setup not only enhances efficiency but also helps maintain product quality, crucial for attracting and retaining customers. -

What factors should I consider when vetting boba machine suppliers?

When vetting boba machine suppliers, consider their experience in the industry, customer reviews, and the range of products offered. Ensure they provide warranties and after-sales support, including training and maintenance services. Additionally, verify their compliance with international safety and quality standards, especially if you are importing machines into regions like Africa or South America. A supplier with a solid reputation and responsive customer service can significantly impact your business’s success. -

Are there customization options available for boba machines?

Yes, many manufacturers offer customization options for boba machines to meet specific business needs. This can include tailored configurations for ingredient dispensing, unique branding on the machine, or adjustments in size and capacity. When discussing customization with suppliers, clearly outline your requirements, such as volume needs or specific functionalities. This ensures that the machine you purchase aligns perfectly with your operational workflow and enhances your brand identity. -

What is the minimum order quantity (MOQ) for boba machines?

The minimum order quantity for boba machines can vary significantly between suppliers. Some may offer individual units, while others might have a MOQ of 5 to 10 machines, particularly for wholesale pricing. It’s advisable to communicate directly with potential suppliers to understand their MOQ policies and inquire about any potential discounts for larger orders. This can help you strategize your purchasing plan according to your budget and business scale. -

What payment terms can I expect when purchasing boba machines internationally?

Payment terms for international purchases of boba machines typically include options like a deposit (often 30-50%) upfront, with the balance due before shipping or upon delivery. Some suppliers may also offer financing options or payment through platforms like PayPal or letters of credit, especially for larger transactions. Always ensure clarity on payment terms and conditions before finalizing any agreements to avoid unexpected costs or delays in your order. -

How can I ensure quality assurance (QA) for my boba machines?

To ensure quality assurance (QA) for your boba machines, request detailed product specifications and certifications from suppliers. It’s essential to confirm that the machines meet international standards for safety and food quality. Additionally, consider asking for samples or demonstrations of the equipment before committing to a purchase. Establishing a good relationship with your supplier can also facilitate regular updates on QA practices and maintenance support. -

What logistics should I consider when importing boba machines?

When importing boba machines, consider logistics such as shipping methods, customs regulations, and delivery timelines. Choose a reliable freight forwarder who can navigate international shipping complexities and ensure your machines arrive safely and on schedule. Additionally, be aware of any import duties or taxes that may apply in your country. Planning for these factors can help avoid delays and unexpected costs, ensuring a smooth import process for your business.

Top 5 Boba Machine Manufacturers & Suppliers List

1. BubbleTeaology – Bubble Tea Machines

Domain: bubbleteaology.com

Registered: 2014 (11 years)

Introduction: Best Bubble Tea Machines and Equipment – BubbleTeaology offers a variety of bubble tea machines including: 1. Boba Tea Shaker Machine – Rated 4.80 out of 5, priced at $1,082.00. 2. Bubble Tea Sealer Machine – Rated 4.88 out of 5, starting from $1,379.00. 3. Bubble Tea Fructose Dispenser – Rated 4.80 out of 5, starting from $1,269.00. All machines come with a free training video, free shipping, a 1…

2. Bobacino – Automated Boba Bar

Domain: bobacino.co

Introduction: Bobacino is an automated boba bar featuring a robotic bobarista that serves customizable bubble tea in about 2 minutes. Key features include: 6-axis robotic arm, cup sealer, pick-up locker, QR code ordering, and a boba dispenser. It holds enough ingredients for up to 200 drinks and can handle multiple SKUs. The system is fully safety compliant (NSF-compliant) and requires daily maintenance of less…

3. Bossen – Kitchen Equipment

Domain: bossenstore.com

Introduction: This company, Bossen – Kitchen Equipment, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Cooler Depot USA – Boba Tea Equipment

Domain: coolerdepotusa.com

Registered: 2015 (10 years)

Introduction: Boba tea EQ products include various machines and equipment for making and serving boba tea. Key items include: 12L Insulated Barrel Beverage Dispenser ($79), Commercial 12L Fully Automatic Smart Tea Brewing Bucket ($189), Commercial 20L Fully Automatic Smart Tea Brewing Bucket ($219), Commercial 12L Water Boiler Milk Frothing Steam Machine ($379), Commercial 48L Dual-Temperature Milk Frothing Mac…

5. ScrapingDog – Instagram Scraping Services

Domain: instagram.com

Registered: 2004 (21 years)

Introduction: Contact us at [email protected] for scraping Instagram. Let us know how many pages you want to scrape per month.

Strategic Sourcing Conclusion and Outlook for boba machine

In the competitive landscape of the bubble tea industry, strategic sourcing of boba machines emerges as a crucial component for success. As highlighted throughout this guide, investing in high-quality, automated equipment not only enhances operational efficiency but also ensures consistency and quality in product offerings. From automatic boba machines that streamline the preparation process to specialized brewers and sealing machines, selecting the right tools can significantly improve customer satisfaction and boost profitability.

International B2B buyers from regions such as Africa, South America, the Middle East, and Europe have a unique opportunity to capitalize on the growing demand for bubble tea. By sourcing advanced boba machines, businesses can differentiate themselves in a crowded market, offering quick service and innovative beverage options that cater to diverse consumer preferences.

Looking ahead, the trend toward automation in the beverage sector is poised to continue, making it essential for operators to stay ahead of the curve. Embrace the future of bubble tea by investing in the right equipment today, ensuring not just survival but thriving in an evolving marketplace. Engage with reputable suppliers and explore the latest technologies to elevate your bubble tea business to new heights.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.