Board Pallets: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for board pallets

In the fast-evolving landscape of global logistics, sourcing high-quality board pallets presents a significant challenge for international B2B buyers. Whether you are operating in Africa, South America, the Middle East, or Europe, understanding the nuances of board pallets—ranging from reclaimed wood options to new manufacturing methods—is crucial for ensuring efficient supply chain management. This comprehensive guide aims to equip you with essential insights into the diverse types of board pallets available, their various applications across industries, and the best practices for vetting suppliers.

Navigating the market for board pallets involves more than just selecting a product; it requires a strategic approach to cost-effectiveness, sustainability, and compliance with international standards. By delving into the specifics of material sourcing, quality assessment, and logistical considerations, this guide empowers buyers to make informed purchasing decisions that align with their business goals.

As a buyer from regions like Vietnam or Brazil, you will benefit from a structured framework that highlights key factors influencing cost and performance, as well as tips for establishing reliable supplier partnerships. Armed with this knowledge, you can confidently select board pallets that meet your operational needs while also adhering to budgetary constraints and sustainability objectives. Join us as we explore the intricate world of board pallets and unlock the potential for enhanced productivity and profitability in your supply chain.

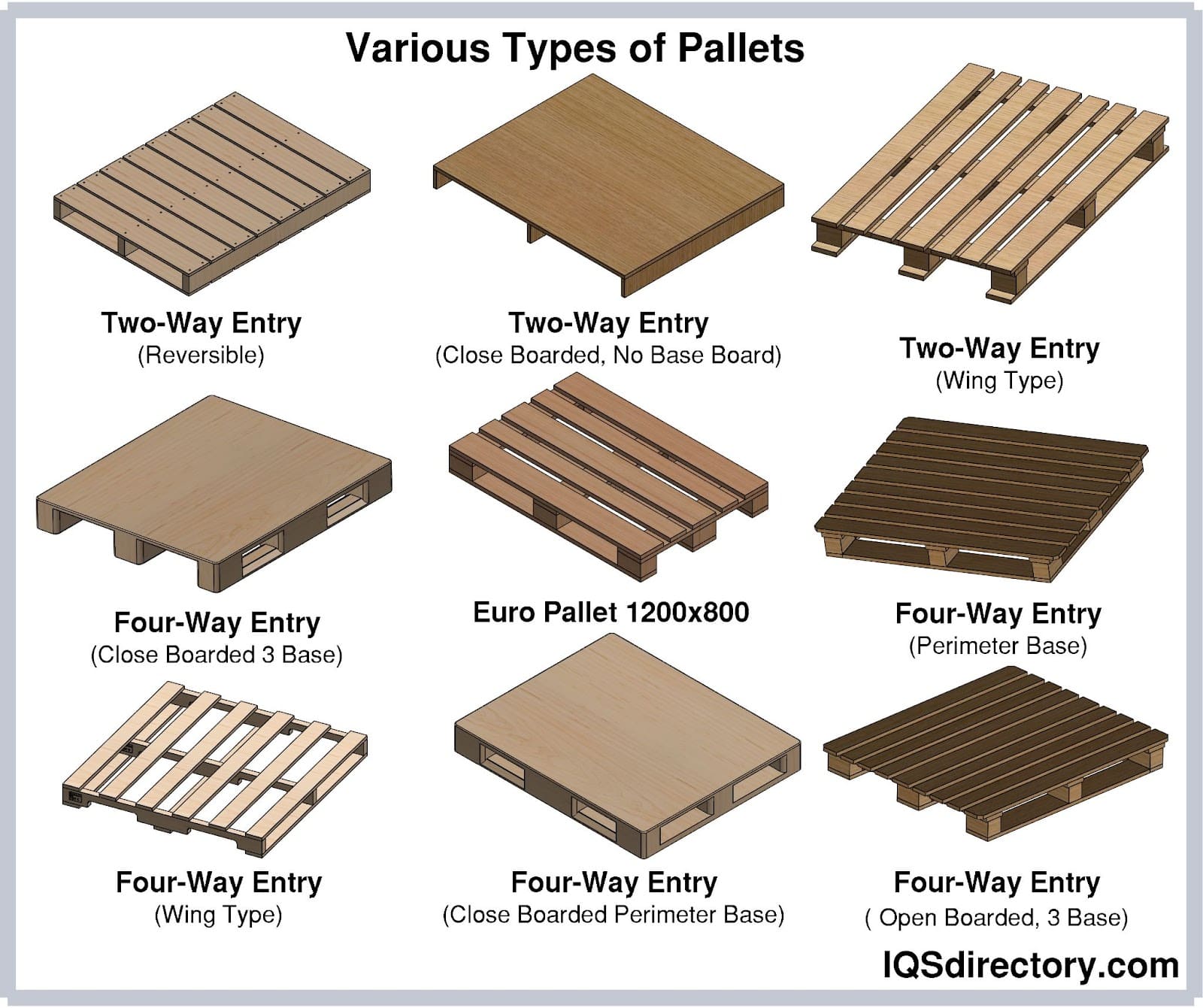

Understanding board pallets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Reclaimed Pallet Boards | Made from repurposed wood, often featuring rustic aesthetics | Interior design, furniture, crafts | Pros: Eco-friendly, unique character; Cons: Variable quality, potential for splinters |

| Heat-Treated Pallets | Treated to eliminate pests and pathogens, typically single-use | Food and beverage transport, exports | Pros: Safe for food contact, durable; Cons: Limited reuse potential, higher cost |

| Standard Wooden Pallets | Commonly manufactured from softwoods like pine or fir | General goods transportation, warehousing | Pros: Cost-effective, widely available; Cons: Less durable than hardwood options, environmental concerns |

| Plastic Pallets | Made from recycled plastic, resistant to moisture and chemicals | Pharmaceuticals, food industry, export | Pros: Lightweight, reusable, hygienic; Cons: Higher initial investment, less traditional aesthetic |

| Composite Pallets | Constructed from a blend of materials, offering enhanced durability | Heavy-duty applications, industrial goods | Pros: Strong, resistant to moisture; Cons: Heavier, may not be recyclable |

What Are Reclaimed Pallet Boards and Their B2B Suitability?

Reclaimed pallet boards are sourced from repurposed wood, often showcasing unique textures and characteristics that appeal to businesses in the interior design and craft sectors. Their rustic aesthetic makes them ideal for creating bespoke furniture and decorative accents. When purchasing, businesses should consider the variability in quality and potential imperfections, which can impact the final product’s look and feel. Buyers should ensure they source from reputable suppliers to mitigate risks associated with splinters or structural integrity.

How Do Heat-Treated Pallets Meet B2B Standards?

Heat-treated pallets are designed specifically for transporting food products, ensuring they are free from pests and pathogens. This type of pallet is particularly suitable for businesses in the food and beverage sector, as they comply with international shipping standards. When considering heat-treated pallets, buyers should evaluate the cost against the assurance of safety and compliance for food-grade applications. They offer durability but are typically single-use, which can limit their long-term value.

What Are the Advantages of Standard Wooden Pallets?

Standard wooden pallets are predominantly made from softwoods like pine or fir and are widely used across various industries for transporting goods. Their affordability and availability make them a popular choice for businesses in logistics and warehousing. However, buyers should be aware of the environmental implications associated with sourcing these pallets. While they provide a cost-effective solution, their durability may not match that of hardwood or composite alternatives, which could lead to more frequent replacements.

Why Choose Plastic Pallets for Your Business Needs?

Plastic pallets offer a modern alternative, made from recycled materials that provide resistance to moisture, chemicals, and pests. They are particularly advantageous for industries requiring high hygiene standards, such as pharmaceuticals and food processing. While the upfront investment is higher compared to wooden pallets, their reusability and lower maintenance costs can yield savings over time. Businesses should consider their specific needs, particularly in terms of weight and handling, when opting for plastic solutions.

What Benefits Do Composite Pallets Provide for Heavy-Duty Applications?

Composite pallets, made from a mixture of materials, are engineered for strength and moisture resistance, making them suitable for heavy-duty applications in industrial settings. They are ideal for businesses dealing with heavy machinery or equipment that require robust support during transport. While they offer enhanced durability, composite pallets tend to be heavier, which can affect shipping costs. Buyers should weigh the benefits of strength and longevity against the potential for increased shipping expenses.

Key Industrial Applications of board pallets

| Industry/Sector | Specific Application of board pallets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Transporting bulk food products | Ensures safe and hygienic transport of perishables | Verify heat treatment and compliance with food safety standards |

| Construction | Building materials for interior design | Provides sustainable and aesthetically pleasing materials | Check for reclaimed certifications and local availability |

| Retail and Warehousing | Display fixtures and shelving | Cost-effective solutions for in-store displays | Assess durability and load-bearing capacity |

| Agriculture | Storing and transporting agricultural goods | Reduces spoilage and ensures product integrity | Consider weather resistance and treatment against pests |

| Furniture Manufacturing | Crafting custom furniture pieces | Offers unique design opportunities with reclaimed materials | Evaluate sourcing for consistency and availability of sizes |

How Are Board Pallets Used in the Food and Beverage Industry?

In the food and beverage sector, board pallets are primarily utilized for transporting bulk food products. Their design ensures that items are moved safely, adhering to hygiene standards crucial for perishable goods. International buyers must confirm that the pallets are made from heat-treated wood, which complies with food safety regulations. This guarantees that the pallets do not harbor harmful chemicals or pests, thus protecting the integrity of the food products during transit.

What Role Do Board Pallets Play in Construction?

In construction, board pallets serve as building materials for various interior design projects, including accent walls and decorative ceilings. Their rustic appearance adds character to spaces while promoting sustainability through the use of reclaimed wood. Buyers from regions with a strong focus on eco-friendly practices should ensure that the pallets are certified reclaimed and free from chemical treatments. Additionally, they should consider the local availability and shipping logistics to minimize delays in project timelines.

How Are Board Pallets Beneficial for Retail and Warehousing?

Retailers and warehouse operators employ board pallets to create display fixtures and shelving. These pallets provide a cost-effective solution that enhances product visibility while maintaining a rustic aesthetic. For B2B buyers, it is essential to assess the durability of the pallets, ensuring they can withstand the weight of products and the rigors of a retail environment. Sourcing from reputable suppliers who offer customizable sizes can further enhance the effectiveness of these displays.

In What Ways Do Board Pallets Support Agriculture?

In agriculture, board pallets are instrumental in storing and transporting goods such as fruits and vegetables. They help reduce spoilage by ensuring that products are kept intact during transit. Buyers in this sector should focus on sourcing pallets that are treated to resist moisture and pests, as these factors can significantly impact product quality. Additionally, understanding local regulations regarding pallet materials can aid in compliance and reduce potential issues during shipping.

How Can Board Pallets Be Used in Furniture Manufacturing?

Furniture manufacturers utilize board pallets to create custom furniture pieces, leveraging the unique textures and colors of reclaimed wood. This not only provides distinctive design options but also aligns with growing consumer preferences for sustainable products. Buyers should evaluate the sourcing process to ensure consistency in wood quality and size. Establishing relationships with suppliers who can provide a steady stream of materials is crucial for maintaining production schedules and meeting market demands.

3 Common User Pain Points for ‘board pallets’ & Their Solutions

Scenario 1: Inconsistent Quality of Board Pallets Affects Production Efficiency

The Problem: A manufacturing company in South America requires a reliable supply of board pallets for transporting goods. However, they often receive pallets that vary significantly in quality, dimensions, and treatment. This inconsistency not only disrupts their supply chain but also leads to delays in production and increased costs due to additional handling and quality checks. The company struggles to maintain a smooth workflow, affecting their overall efficiency and customer satisfaction.

The Solution: To combat this issue, B2B buyers should establish clear specifications for board pallets before placing orders. This includes defining the dimensions, wood type, treatment process, and quality standards. It is crucial to partner with reputable suppliers who can provide certifications or guarantees regarding the quality of their pallets. Implementing a quality control process upon receipt of goods can also help identify issues early. Regular audits of supplier practices can ensure they meet the required standards consistently. Building long-term relationships with suppliers who understand your quality expectations can lead to better product consistency and reliability.

Scenario 2: High Costs Due to Unsuitable Board Pallet Sourcing

The Problem: A construction firm in Europe frequently faces challenges with the high costs associated with sourcing board pallets. They often resort to purchasing from multiple suppliers to meet their fluctuating demands, resulting in increased logistics expenses and administrative overhead. This piecemeal approach not only inflates costs but also complicates inventory management and project timelines.

The Solution: To reduce costs, B2B buyers should consider consolidating their pallet sourcing through a single supplier that can meet their volume requirements. By negotiating bulk purchase agreements, companies can leverage better pricing and reduce logistics costs. Additionally, exploring local suppliers can minimize shipping expenses and lead times. Implementing a just-in-time inventory system can further optimize storage costs and ensure that pallets are available when needed without overstocking. Regularly reviewing supplier contracts and market rates can also help ensure competitive pricing.

Scenario 3: Environmental Concerns Related to Board Pallet Sourcing

The Problem: An international retailer is increasingly pressured to adopt sustainable practices, particularly in their supply chain. They face difficulties finding board pallets that align with environmental standards, as many suppliers do not provide transparency regarding the sourcing and treatment of their wood products. This lack of information poses a risk to the retailer’s brand reputation and sustainability goals.

The Solution: To address environmental concerns, B2B buyers should prioritize sourcing from suppliers who offer certified sustainable board pallets, such as those that are FSC (Forest Stewardship Council) certified. This certification ensures that the wood used is sourced from responsibly managed forests. Buyers should also inquire about the supplier’s manufacturing processes, including whether they use eco-friendly treatments or recycled materials. Establishing a sustainability policy within the procurement process can guide decisions and ensure alignment with the company’s overall environmental strategy. Collaborating with suppliers who are committed to sustainability can enhance the retailer’s brand image while contributing positively to the environment.

Strategic Material Selection Guide for board pallets

What Are the Key Properties of Wood for Board Pallets?

Wood is the most commonly used material for board pallets, particularly reclaimed wood from pallets. Its key properties include a natural resistance to temperature fluctuations and pressure, making it suitable for various climates. Wood is also biodegradable, which aligns with sustainability goals. However, its susceptibility to moisture can lead to warping or decay if not properly treated. For international buyers, ensuring that the wood meets local regulations on chemical treatments and sustainability certifications is crucial.

What Are the Advantages and Disadvantages of Using Plastic for Board Pallets?

Plastic pallets are gaining popularity due to their durability and resistance to moisture and chemicals. They can withstand a wide range of temperatures, making them suitable for various applications, including food and pharmaceuticals. The primary advantage of plastic is its lightweight nature, which reduces shipping costs. However, plastic pallets can be more expensive upfront compared to wood, and they may not be as easily recyclable. For buyers in regions like Africa and South America, where recycling infrastructure may be limited, this could be a significant consideration.

How Do Metal Pallets Compare to Other Materials for Board Pallets?

Metal pallets, often made from aluminum or steel, offer exceptional durability and load-bearing capabilities. They are resistant to corrosion and can withstand harsh environmental conditions, making them ideal for heavy-duty applications. However, the cost of metal pallets is significantly higher than wood or plastic, and they can be heavier, which may increase shipping costs. For international buyers, compliance with standards such as ASTM for metal strength and safety is essential, particularly in industries like automotive and aerospace.

What Are the Specific Considerations for Composite Materials in Board Pallets?

Composite materials, which combine wood fibers with plastic, offer a balance between the benefits of both materials. They provide good moisture resistance and are less prone to splintering than wood. Composites can be engineered to meet specific performance criteria, such as temperature and load ratings. However, they can be more expensive than traditional wood pallets, and their recyclability can vary based on the composition. Buyers should consider local regulations regarding composite materials, as some regions may have stricter guidelines for their use.

Illustrative image related to board pallets

| Material | Typical Use Case for board pallets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood | General shipping and storage | Sustainable and biodegradable | Susceptible to moisture and pests | Low |

| Plastic | Food and pharmaceutical industries | Lightweight and moisture-resistant | Higher initial cost | Medium |

| Metal | Heavy-duty applications | Exceptional durability and strength | Expensive and heavier | High |

| Composite | Versatile applications | Good moisture resistance | Higher cost and variable recyclability | Medium |

This strategic material selection guide provides a comprehensive overview of the most common materials used for board pallets, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for board pallets

What Are the Main Stages in the Manufacturing Process of Board Pallets?

The manufacturing process of board pallets involves several key stages that ensure the final product meets industry standards and customer expectations. Understanding these stages can help B2B buyers make informed decisions when sourcing pallets.

Material Preparation: Sourcing and Selecting Raw Materials

The first step in the manufacturing of board pallets is the careful selection and preparation of raw materials. Most board pallets are made from reclaimed wood, which is sourced from discarded pallets and other wood products. The wood is sorted based on quality, species, and dimensions.

The preparation process often involves:

- Debarking: Removing the bark from logs to prevent pest infestations and ensure uniformity.

- Cutting: Logs are cut into manageable sizes based on the desired dimensions of the final pallet boards.

- Drying: Moisture content is reduced through air or kiln drying to enhance durability and prevent warping.

Proper material preparation is crucial as it directly impacts the quality and longevity of the pallets.

Illustrative image related to board pallets

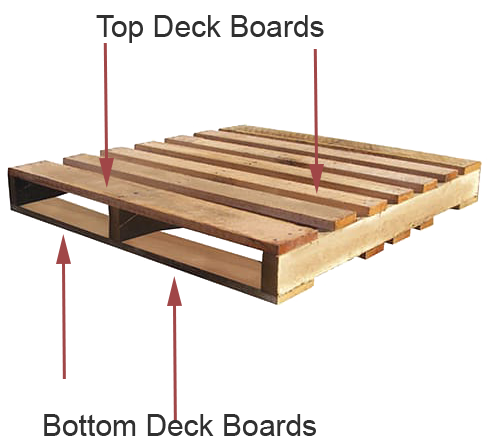

How Are Board Pallets Formed and Assembled?

Once the materials are prepared, the next phase is forming and assembling the pallets. This involves several techniques that contribute to the structural integrity of the final product.

-

Planing and Sanding: The cut boards are planed to achieve uniform thickness and sanded to create a smooth surface. This step is vital for aesthetic appeal and safety, minimizing splinters and rough edges.

-

Joining Techniques: Boards are typically joined using various methods, including:

– Nailing: Using metal fasteners to secure the boards.

– Gluing: Adhesives may be applied for added strength, particularly in laminated pallets.

– Interlocking Systems: Some designs incorporate interlocking features that enhance stability. -

Assembly Lines: Pallets are assembled on production lines where workers or machines position the boards accurately before securing them in place.

What Quality Control Measures Are Essential in Board Pallet Manufacturing?

Quality assurance is a critical aspect of board pallet manufacturing, ensuring that products meet both international standards and customer specifications.

Which International Standards Should B2B Buyers Be Aware Of?

For board pallets, several international standards govern quality, safety, and environmental considerations. Key standards include:

- ISO 9001: This standard focuses on quality management systems and is crucial for ensuring consistent production quality.

- ISPM 15: This regulation pertains to the treatment of wooden packaging materials to prevent pest transmission, especially important for international shipping.

- CE Marking: In Europe, CE marking indicates compliance with health, safety, and environmental protection standards.

B2B buyers should ensure that their suppliers are compliant with these standards to mitigate risks associated with product quality and safety.

Illustrative image related to board pallets

What Are the Common Quality Control Checkpoints?

Quality control (QC) in board pallet manufacturing typically involves several checkpoints throughout the production process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival. Factors such as moisture content, dimensions, and overall quality are assessed to ensure compliance with specifications.

-

In-Process Quality Control (IPQC): During production, quality checks are conducted at various stages, including during cutting, drying, and assembly. This helps identify defects early and allows for immediate corrective actions.

-

Final Quality Control (FQC): Once the pallets are assembled, they undergo final inspections. This may include load testing, visual inspections for defects, and ensuring compliance with labeling and packaging requirements.

How Can B2B Buyers Verify Supplier Quality Control?

When sourcing board pallets, B2B buyers should take proactive steps to verify the quality control processes of potential suppliers. Here are some strategies:

-

Supplier Audits: Conducting on-site audits can provide insights into the manufacturing practices, quality control measures, and overall operational efficiency of the supplier.

-

Requesting Quality Reports: Suppliers should provide documentation of their quality control processes, including inspection reports, compliance certifications, and any third-party testing results.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality assurance practices. These inspections can focus on various aspects, including material quality, production processes, and compliance with relevant standards.

What Are the Unique Quality Control Challenges for International B2B Buyers?

For B2B buyers in regions such as Africa, South America, the Middle East, and Europe, there are specific challenges to consider when it comes to quality control:

-

Regulatory Variations: Different countries may have varying regulations regarding wood treatment and quality standards. Understanding these differences is crucial for compliance and avoiding delays in customs.

-

Cultural Differences in Quality Expectations: Perceptions of quality can vary by region. Buyers should communicate their specific quality requirements clearly and ensure that suppliers understand and can meet those expectations.

-

Supply Chain Reliability: International logistics can introduce risks related to product damage during transportation. Buyers should discuss packaging standards and transportation methods with suppliers to mitigate these risks.

Conclusion: Ensuring Quality in Board Pallet Sourcing

Understanding the manufacturing processes and quality assurance practices associated with board pallets is essential for B2B buyers. By focusing on material preparation, assembly techniques, and quality control measures, buyers can make informed decisions that ensure the procurement of high-quality pallets. Furthermore, being proactive in verifying supplier capabilities and addressing international regulatory challenges can enhance the overall sourcing experience and reduce risks associated with product quality.

Illustrative image related to board pallets

Practical Sourcing Guide: A Step-by-Step Checklist for ‘board pallets’

To successfully procure board pallets for your business needs, a systematic approach is essential. This checklist will guide you through the critical steps to ensure you make informed decisions, prioritize quality, and foster sustainable partnerships with suppliers.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Consider the dimensions, materials (e.g., reclaimed wood or new timber), and weight capacity required for your pallets. Specificity helps avoid misunderstandings with suppliers and ensures that the pallets meet your operational needs effectively.

Step 2: Identify Potential Suppliers

Conduct thorough research to compile a list of potential suppliers. Utilize industry directories, trade shows, and online marketplaces to find reputable vendors. Focus on suppliers that specialize in board pallets and have a track record of serving businesses in your region or industry, as they will better understand your unique requirements.

Step 3: Evaluate Supplier Certifications

Before entering into any agreements, verify the certifications of potential suppliers. Look for industry standards such as ISO certifications or compliance with safety regulations relevant to your region. Certifications can indicate a supplier’s commitment to quality and sustainability, which are increasingly important in today’s market.

Step 4: Request Samples

Obtaining samples is a crucial step in assessing the quality of the board pallets. Request samples of various types, including different wood finishes and sizes, to evaluate their suitability for your projects. Pay attention to craftsmanship, durability, and any imperfections that could affect your end product.

Step 5: Compare Pricing and Terms

Once you have evaluated multiple suppliers, compare their pricing structures and terms of sale. Look beyond the initial price—consider bulk discounts, shipping costs, and payment terms. A slightly higher upfront cost might be justified by better quality or more favorable payment options.

Step 6: Check References and Reviews

Reach out to previous clients or check online reviews to gauge the reliability of your shortlisted suppliers. Understanding other buyers’ experiences can provide insights into delivery times, customer service, and overall satisfaction. This step helps mitigate risks associated with supplier selection.

Step 7: Finalize the Purchase Agreement

Once you have selected a supplier, ensure that all terms are clearly outlined in a purchase agreement. This should include delivery timelines, payment schedules, and quality assurance clauses. A well-defined contract protects both parties and minimizes potential disputes.

By following this checklist, you can streamline your sourcing process for board pallets, ensuring that you select the right suppliers and products that align with your business goals.

Comprehensive Cost and Pricing Analysis for board pallets Sourcing

What Are the Key Cost Components in Board Pallet Sourcing?

When sourcing board pallets, understanding the cost structure is crucial for effective budgeting and pricing strategy. The primary cost components include:

- Materials: The type of wood used (e.g., pine, hardwood) significantly impacts costs. Reclaimed wood may be less expensive than new lumber, but the quality and availability can vary.

- Labor: The cost of labor for cutting, treating, and finishing the pallets contributes to overall expenses. Skilled labor, particularly in regions with higher wage standards, can increase costs.

- Manufacturing Overhead: This encompasses utilities, rent, and equipment depreciation. Efficient operations can reduce overhead, leading to better pricing.

- Tooling: Specialized tools and machinery for cutting and processing wood are necessary investments. These costs are typically amortized over production volume.

- Quality Control (QC): Ensuring that pallets meet safety and quality standards incurs costs. Certification processes, particularly for food-grade pallets, can add to expenses.

- Logistics: Shipping costs, influenced by distance, volume, and transport methods, are a critical factor. International shipping may involve customs duties and tariffs, which should be factored into the total cost.

- Margin: Suppliers will typically add a margin to cover their costs and profit. Understanding industry standards for margins can aid in negotiations.

How Do Price Influencers Affect Board Pallet Sourcing?

Several factors can influence the pricing of board pallets, particularly for B2B buyers in diverse markets like Africa, South America, the Middle East, and Europe. Key influencers include:

- Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to lower per-unit prices. Suppliers may offer discounts for bulk purchases, making it essential to assess your needs accurately.

- Specifications and Customization: Custom sizes or treatments may incur additional costs. Clearly defining specifications at the outset can prevent unexpected charges later.

- Materials and Quality Certifications: Premium materials or certifications (e.g., for food safety) typically lead to higher prices. Buyers should evaluate whether these certifications are necessary for their applications.

- Supplier Factors: The supplier’s reputation, location, and operational efficiency can significantly influence pricing. It’s beneficial to source from suppliers with established quality and reliability.

- Incoterms: Understanding the terms of trade (e.g., FOB, CIF) can affect pricing. Buyers must consider who bears the shipping costs and risks, as this can influence the final landed cost.

What Are Essential Buyer Tips for Cost-Efficiency in Board Pallet Procurement?

To maximize cost-efficiency when sourcing board pallets, consider the following strategies:

- Negotiate Effectively: Engage in discussions with suppliers to negotiate better terms. Leverage volume commitments and long-term relationships to secure favorable pricing.

- Assess Total Cost of Ownership (TCO): Beyond the purchase price, evaluate the TCO, which includes logistics, handling, and potential disposal costs. This holistic view aids in identifying the best value.

- Understand Pricing Nuances for International Buyers: Different regions may have unique pricing structures due to market demand, labor costs, and material availability. Familiarize yourself with local market conditions to better navigate negotiations.

- Request Samples: Before committing to a large order, request samples to evaluate quality. This can prevent costly mistakes and ensure the product meets your specifications.

- Consider Local Suppliers: Sourcing from local suppliers can reduce logistics costs and lead times, enhancing overall supply chain efficiency.

Disclaimer on Indicative Prices

It’s important to note that prices for board pallets can fluctuate based on market conditions, material availability, and other external factors. Always consult with suppliers for the most accurate and current pricing information tailored to your specific needs.

Alternatives Analysis: Comparing board pallets With Other Solutions

Understanding Alternatives to Board Pallets in Logistics and Storage Solutions

When it comes to logistics and storage solutions, board pallets are widely recognized for their durability and versatility. However, businesses often seek alternatives that may better suit their specific needs, whether due to cost, ease of use, or performance. This analysis compares board pallets with two viable alternatives: plastic pallets and metal pallets, allowing B2B buyers to make informed decisions based on their unique operational requirements.

| Comparison Aspect | Board Pallets | Plastic Pallets | Metal Pallets |

|---|---|---|---|

| Performance | High load capacity; suitable for various goods | Resistant to moisture and chemicals; consistent in quality | Extremely durable; withstand heavy loads and harsh environments |

| Cost | Generally lower upfront cost; may require more frequent replacement | Higher initial investment; cost-effective over time due to longevity | Highest upfront cost; long-term investment with minimal maintenance |

| Ease of Implementation | Requires manual handling; availability may vary | Lightweight and easy to stack; compatible with automated systems | Heavy and less versatile in handling; requires specialized equipment |

| Maintenance | May require repairs; susceptible to moisture damage | Low maintenance; resistant to rot and pests | Minimal maintenance; corrosion-resistant options available |

| Best Use Case | Ideal for general storage and transportation needs | Best for industries requiring hygiene and moisture resistance | Suitable for heavy-duty applications in manufacturing and shipping |

In-Depth Analysis of Alternatives

What Are the Advantages and Disadvantages of Plastic Pallets?

Plastic pallets offer a modern alternative to traditional wooden options. They are lightweight, making them easier to handle and stack, which is particularly beneficial in automated warehousing systems. Plastic pallets are also resistant to moisture, chemicals, and pests, which enhances their longevity and makes them suitable for industries like food and pharmaceuticals. However, the initial cost can be significantly higher than that of board pallets, which may deter budget-conscious buyers. Despite this, their durability often leads to lower total costs over time, making them a worthwhile investment for businesses with high turnover rates.

How Do Metal Pallets Compare to Board Pallets?

Metal pallets are engineered for maximum durability and strength, making them ideal for heavy-duty applications. They can withstand extreme conditions and are resistant to fire and chemicals, making them popular in industries like manufacturing and aerospace. However, they tend to be the most expensive option upfront and may require specialized handling equipment due to their weight. While they provide excellent long-term value in terms of durability, businesses need to consider whether the high initial investment aligns with their operational needs.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the right pallet solution requires careful consideration of various factors, including the nature of the goods being transported, budget constraints, and the specific environment in which the pallets will be used. Board pallets may be ideal for businesses looking for a cost-effective solution with a broad application range, while plastic pallets serve well in hygiene-sensitive sectors. On the other hand, companies that handle heavy loads in harsh conditions may find metal pallets to be the most beneficial despite their higher costs. Ultimately, understanding the unique advantages and limitations of each option will empower B2B buyers to make informed decisions that align with their operational goals and financial strategies.

Illustrative image related to board pallets

Essential Technical Properties and Trade Terminology for board pallets

What are the Key Technical Properties of Board Pallets?

Understanding the essential technical properties of board pallets is crucial for B2B buyers. These specifications not only impact the performance of the pallets but also influence procurement decisions, cost management, and compliance with industry standards. Here are some key properties to consider:

1. Material Grade

Material grade refers to the quality of wood used in the production of board pallets. Common grades include select, standard, and industrial. Higher-grade materials typically offer greater durability, load-bearing capacity, and aesthetic appeal. For buyers, selecting the appropriate material grade is essential for ensuring the pallets meet specific application requirements, such as transporting heavy goods or maintaining a certain visual standard for retail displays.

2. Tolerance Levels

Tolerance levels indicate the permissible variations in dimensions (length, width, thickness) of the pallets. For instance, a board pallet might have a standard tolerance of ±1/8 inch in thickness. Understanding these tolerances is critical for buyers, as they affect the fitting of pallets into storage systems, compatibility with handling equipment, and overall structural integrity during transport.

3. Load Capacity

Load capacity defines the maximum weight a pallet can safely support without failing. This specification is vital for buyers to ensure that the pallets can handle the intended loads during storage and shipping. Overloading a pallet can lead to structural failure, resulting in product loss and potential safety hazards, making it essential to match pallet specifications with the expected load requirements.

Illustrative image related to board pallets

4. Treatment and Certification

Board pallets often undergo treatments such as heat treatment or chemical treatment to ensure they are pest-free and compliant with international shipping standards. Certifications like ISPM 15 are crucial for global trade, particularly when shipping to countries with strict import regulations. Buyers must verify treatment and certification to avoid delays or fines at customs.

5. Surface Finish

The surface finish of board pallets can range from raw to sanded or treated surfaces. A smoother finish may be necessary for certain applications, such as in food handling, where hygiene is paramount. For B2B buyers, understanding the surface finish helps in selecting the right pallet for specific industries, ensuring compliance with safety and quality standards.

What are Common Trade Terms Associated with Board Pallets?

In the B2B realm, familiarity with industry jargon is essential for effective communication and negotiation. Here are some common trade terms that buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are then sold under another company’s brand. In the context of board pallets, buyers might engage with OEMs to source customized pallets tailored to their specifications. Understanding OEM relationships can lead to better pricing and product alignment with business needs.

Illustrative image related to board pallets

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This term is crucial for buyers to understand as it impacts inventory management and cash flow. Knowing the MOQ helps in planning purchases to avoid excess inventory or stock shortages.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a price quote for specific products or services. For board pallets, issuing an RFQ allows buyers to compare prices, terms, and conditions from multiple suppliers, facilitating informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) clarify who is responsible for shipping costs, insurance, and risk during transit. Understanding Incoterms is critical for B2B buyers engaged in cross-border procurement of board pallets.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. For board pallets, understanding lead times is essential for effective inventory management and ensuring that production schedules are met. Buyers should always inquire about lead times to avoid delays in their supply chain.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing board pallets, ultimately leading to better procurement outcomes and enhanced operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the board pallets Sector

What Are the Key Market Dynamics and Trends Influencing the Board Pallets Sector?

The board pallets market is experiencing significant growth, driven by a combination of global supply chain demands, evolving consumer preferences, and technological advancements. Key drivers include the rise of e-commerce, which has surged the demand for efficient shipping and storage solutions. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe (including Vietnam and Brazil) seek to optimize logistics, the need for versatile and durable pallet solutions has become increasingly critical.

Emerging trends in technology are reshaping sourcing strategies. The integration of data analytics and IoT (Internet of Things) in supply chain management allows businesses to track inventory in real-time, facilitating better decision-making and reducing waste. Additionally, automated production processes are enhancing the quality and consistency of board pallets, making them more appealing to buyers who prioritize efficiency and reliability.

Furthermore, the market is witnessing a shift towards customization, with businesses looking for pallets tailored to specific dimensions and load capacities. This trend is particularly relevant for industries such as food and beverage, where compliance with safety regulations is paramount. As such, suppliers who can offer flexible solutions while maintaining quality standards are likely to gain a competitive edge.

How Is Sustainability Shaping the Sourcing of Board Pallets in B2B Transactions?

Sustainability has become a cornerstone of sourcing strategies in the board pallets sector. With increasing environmental awareness, both businesses and consumers are prioritizing eco-friendly products. The use of reclaimed wood and other sustainable materials in board pallet production not only reduces waste but also meets the growing demand for green certifications. B2B buyers are increasingly scrutinizing their supply chains, seeking partners who adhere to ethical sourcing practices.

The environmental impact of board pallets is significant, as traditional manufacturing processes can contribute to deforestation and pollution. Consequently, suppliers are adopting sustainable practices, such as using heat-treated wood instead of chemically treated alternatives, to minimize their ecological footprint. Certifications such as FSC (Forest Stewardship Council) and PEFC (Programme for the Endorsement of Forest Certification) are becoming essential for suppliers aiming to appeal to environmentally conscious buyers.

In regions like Africa and South America, where natural resources are often exploited, the emphasis on ethical sourcing is paramount. B2B buyers are increasingly favoring suppliers who can demonstrate their commitment to responsible forestry and sustainable practices, thereby ensuring that their purchasing decisions align with their corporate social responsibility goals.

How Has the Board Pallets Sector Evolved Over Time?

The evolution of the board pallets sector reflects broader changes in global trade and logistics. Initially, pallets were primarily constructed from solid wood, which limited their versatility and increased costs. However, as industries expanded and the demand for efficient shipping solutions grew, manufacturers began experimenting with alternative materials, including plywood and composite materials, which offered durability and cost-effectiveness.

The rise of the e-commerce boom in the early 21st century marked a pivotal shift in pallet design and usage. Businesses needed lightweight yet robust solutions that could accommodate rapid turnover in inventory and diverse shipping requirements. This transition prompted innovations in pallet manufacturing, such as the introduction of stackable and collapsible designs, which optimize storage space and improve logistical efficiency.

Today, the board pallets sector is characterized by a strong emphasis on sustainability, technological integration, and customization. As international markets continue to evolve, suppliers who can adapt to these changes and anticipate buyer needs will thrive in the competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of board pallets

-

1. How do I ensure the quality of board pallets when sourcing internationally?

To guarantee the quality of board pallets, conduct thorough supplier vetting. Request samples to evaluate wood quality and workmanship. Verify compliance with international standards, such as ISPM 15 for heat treatment, which ensures the pallets are pest-free. Additionally, establish clear quality assurance (QA) protocols and consider third-party inspections to validate the quality before shipment. Maintaining open communication with suppliers regarding your quality expectations can also help ensure that the pallets meet your specifications. -

2. What are the key factors to consider when choosing a supplier for board pallets?

When selecting a supplier, consider their reputation, experience in the industry, and compliance with international trade regulations. Evaluate their production capabilities, including customization options, minimum order quantities (MOQs), and lead times. It’s also essential to assess their logistics capabilities, such as shipping options and delivery times. Request references and reviews from previous clients to gain insights into their reliability and service quality. -

3. What are the typical minimum order quantities (MOQ) for board pallets?

Minimum order quantities for board pallets can vary significantly based on the supplier and the type of pallets you need. Generally, MOQs can range from as low as 100 units to several thousand. Suppliers may impose higher MOQs for customized orders or specific wood types. It’s advisable to discuss your requirements directly with potential suppliers to negotiate acceptable MOQs that align with your business needs. -

4. How do payment terms work when sourcing board pallets internationally?

Payment terms can vary widely among suppliers. Common options include upfront payment, partial payment upon order confirmation, and balance upon delivery. Some suppliers may offer credit terms for established relationships. It’s crucial to clarify payment methods, such as wire transfers or letters of credit, and ensure they are secure and reliable. Discussing payment terms upfront can help prevent misunderstandings and facilitate smoother transactions. -

5. What logistics considerations should I keep in mind when importing board pallets?

Logistics is a critical factor in importing board pallets. Ensure you understand the shipping methods available, including sea freight and air freight, and choose based on your budget and delivery timeline. Verify the supplier’s ability to handle customs documentation and compliance with regulations in your destination country. Additionally, consider potential tariffs, taxes, and the overall supply chain management to avoid unexpected delays. -

6. Can I customize board pallets to fit specific project requirements?

Yes, many suppliers offer customization options for board pallets. This can include different wood types, sizes, finishes, and even branding options. Discuss your specific project needs with the supplier to explore available customization features. Keep in mind that customized orders may have different lead times and potentially higher MOQs, so plan accordingly to ensure your project timelines are met. -

7. What are the environmental considerations when sourcing board pallets?

When sourcing board pallets, consider the sustainability of the wood used. Look for suppliers who offer reclaimed or sustainably sourced wood to minimize environmental impact. Certifications such as FSC (Forest Stewardship Council) can indicate responsible sourcing practices. Additionally, inquire about the treatment processes used to ensure that the pallets are free from harmful chemicals, which is essential for eco-conscious projects. -

8. How do I handle potential disputes with suppliers in international transactions?

To manage potential disputes effectively, establish clear contracts that outline terms, conditions, and expectations from the outset. Include clauses for dispute resolution, such as mediation or arbitration, to provide a structured approach in case issues arise. Maintain open communication throughout the process to address concerns promptly. Having a legal framework that adheres to international trade laws can also protect your interests in case of disputes.

Top 4 Board Pallets Manufacturers & Suppliers List

1. Dakota Tin – Bulk Pallet Wood for Sale

Domain: dakotatin.com

Registered: 2017 (8 years)

Introduction: Bulk Pallet Wood for Sale | Reclaimed Pallet Boards | Pallet Wood For Walls

– Regular Price: $89.00 USD

– Available Sizes: 20 Sq. Ft. ($89.00), 40 Sq. Ft. ($174.00), 60 Sq. Ft. ($260.00), 80 Sq. Ft. ($348.00), 100 Sq. Ft. ($435.00), 250 Sq. Ft. ($900.00), 500 Sq. Ft. ($1,200.00), 750 Sq. Ft. ($1,995.00), 1000 Sq. Ft. ($2,280.00), 1500 Sq. Ft. ($3,000.00), 2000 Sq. Ft. ($3,750.00)

– Dimensions: Len…

2. Stratis – 48 x 40 inch Blue Stackable Plastic Pallet

Domain: shop.snydernet.com

Registered: 1998 (27 years)

Introduction: {“Product Name”: “48 x 40 inch Blue Stackable Smooth Deck Plastic Pallet Board”, “SKU”: “TP4840PTOOS00”, “Brand”: “Stratis”, “Dimensions”: {“Length”: “48 in”, “Width”: “40 in”, “Height”: “3 in”}, “Weight”: “30 lb”, “Material”: “Linear Low-Density Polyethylene (LLDPE)”, “Color”: “Blue”, “Category”: “General Material Handling”, “Minimum Order Quantity”: “6”, “Price”: “$340.86”, “Shipping Origin”: “I…

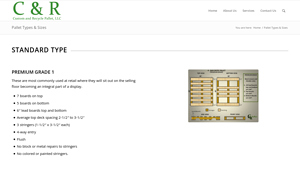

3. Custom Recycle Pallet – Premium Grade 1

Domain: customrecyclepallet.com

Registered: 2010 (15 years)

Introduction: {‘pallet_types’: [{‘type’: ‘Premium Grade 1’, ‘description’: ‘Most commonly used at retail for displays.’, ‘top_boards’: 7, ‘bottom_boards’: 5, ‘lead_boards’: ‘6″‘, ‘top_deck_spacing’: ‘2-1/2″ to 3-1/2″‘, ‘stringers’: ‘3 (1-1/2″ x 3-1/2″ each)’, ‘entry’: ‘4-way’, ‘flush’: ‘Yes’, ‘repairs’: ‘No block or metal repairs to stringers’, ‘colored_stringers’: ‘No’}, {‘type’: ‘Grade 1’, ‘description’: ‘Use…

4. RDU Pallets – Reclaimed Wood Pallet Boards

Domain: rdupallets.com

Registered: 2020 (5 years)

Introduction: Reclaimed Wood Pallet Boards for Sale

– Sizes Available: 12 inch, 18 inch, 24 inch, 30 inch, 36 inch (custom sizes available upon request)

– Price Range:

– 12″ Boards: $16.99 – $19.99

– 18″ Boards: $19.99 – $29.99

– 24″ Boards: $26.99 – $36.99

– 30″ Premium Boards: $31.99 – $43.99

– 36″ Boards: $34.99 – $49.99

– Shipping: FREE shipping on all small orders; bulk orders incur shipping cos…

Strategic Sourcing Conclusion and Outlook for board pallets

In navigating the complexities of sourcing board pallets, international B2B buyers can significantly enhance their operational efficiency and sustainability practices. Strategic sourcing not only ensures access to high-quality materials but also fosters long-term partnerships with suppliers, thereby streamlining logistics and reducing costs. By prioritizing reclaimed and sustainably sourced pallet wood, businesses can meet growing environmental standards while also appealing to eco-conscious consumers.

Key takeaways include understanding the importance of quality, the benefits of bulk purchasing, and the necessity of evaluating supplier reliability. Buyers should also consider the diverse applications of board pallets, from construction to creative design, thereby maximizing their investment potential.

As the global market continues to evolve, the demand for sustainable materials will only grow. International buyers, particularly in regions like Africa, South America, the Middle East, and Europe, should seize this opportunity to leverage strategic sourcing for board pallets. By aligning with forward-thinking suppliers and embracing innovative sourcing strategies, businesses can position themselves for success in an increasingly competitive landscape. Take action today to secure your supply chain and enhance your product offerings!

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to board pallets

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.