Blister Wrap: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for blister wrap

In today’s fast-paced global market, sourcing effective blister wrap solutions can be a daunting task for B2B buyers, especially those operating across diverse regions such as Africa, South America, the Middle East, and Europe. With an increasing demand for protective packaging that ensures product integrity and minimizes damage during transit, understanding the nuances of blister wrap is essential. This guide serves as an invaluable resource for international buyers, offering insights into various types of blister wrap, their applications, and the critical factors to consider when vetting suppliers.

The comprehensive scope of this guide covers everything from the different materials used in blister wrap to their specific applications across industries like pharmaceuticals, electronics, and consumer goods. Additionally, we delve into the intricacies of cost analysis and quality assurance, enabling buyers to make informed purchasing decisions that align with their operational needs and budget constraints.

By equipping B2B buyers with actionable insights and expert recommendations, this guide empowers them to navigate the complexities of the blister wrap market effectively. Whether you are based in bustling urban centers or emerging markets, understanding the landscape of blister wrap will enhance your sourcing strategy and drive successful business outcomes. With this knowledge at your fingertips, you can confidently select the right blister wrap solutions that safeguard your products and elevate your brand’s reputation in the competitive global marketplace.

Understanding blister wrap Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Blister Prevention Tape | Strong adhesive, breathable material, pre-cut strips | Sports, outdoor activities, first aid kits | Pros: Easy to apply, effective in preventing blisters. Cons: May irritate sensitive skin. |

| Hydrocolloid Blister Wrap | Gel-like properties, moisture-retentive, promotes healing | Medical, sports medicine, wound care | Pros: Promotes faster healing, reduces pain. Cons: Not suitable for heavy-duty use. |

| Foam Blister Pads | Thick cushioning, shock absorption, adhesive backing | Footwear manufacturing, outdoor gear | Pros: Provides excellent protection, comfortable. Cons: Bulkier than other options. |

| Transparent Adhesive Film | Thin, flexible, water-resistant, allows visibility of skin | Medical, cosmetic, sports | Pros: Discreet, waterproof, protects against friction. Cons: Limited durability in extreme conditions. |

| Medical Adhesive Tape | Strong adhesion, variety of sizes, latex-free options | Hospitals, clinics, sports teams | Pros: Versatile, widely available, reliable adhesion. Cons: May not be specialized for blister prevention. |

What are the Key Characteristics of Blister Prevention Tape?

Blister prevention tape is designed primarily for athletes and outdoor enthusiasts. It features a strong adhesive that adheres well to the skin while remaining breathable. Pre-cut strips make it easy to apply on common blister-prone areas. This type is particularly suitable for businesses in the sports and outdoor industries, where blister prevention is crucial for performance. When purchasing, consider the adhesive strength and skin compatibility, especially for sensitive skin types.

How Does Hydrocolloid Blister Wrap Function?

Hydrocolloid blister wraps have gel-like properties that provide a moist environment conducive to healing. They are often used in medical settings and for sports medicine due to their ability to promote faster recovery from blisters and abrasions. These wraps are ideal for B2B buyers in the healthcare sector, where effective wound care is a priority. Key considerations include the wrap’s size, moisture retention capacity, and whether it fits the intended application, as they may not withstand heavy-duty activities.

What Makes Foam Blister Pads a Good Choice?

Foam blister pads offer excellent shock absorption and cushioning, making them ideal for use in footwear manufacturing and outdoor gear. Their thicker design provides substantial protection against impact and friction. B2B buyers should evaluate the thickness and adhesive quality when considering foam pads, as they may impact the comfort and fit of footwear. While they provide great protection, their bulkiness can be a drawback for applications requiring a slimmer profile.

Why Choose Transparent Adhesive Film for Blister Protection?

Transparent adhesive films are thin and flexible, allowing visibility of the skin while providing a protective barrier. They are water-resistant and are often used in medical and cosmetic applications. This type is advantageous for B2B buyers seeking discreet protection against friction while maintaining a professional appearance. When sourcing these films, consider their durability in high-motion environments, as they may not perform as well under extreme conditions.

What are the Benefits of Medical Adhesive Tape?

Medical adhesive tape is versatile, widely available, and comes in various sizes and formulations, including latex-free options. While not specifically designed for blister prevention, it is commonly used in hospitals and clinics for general wound care and securing dressings. B2B buyers should assess the tape’s adhesive strength and suitability for different skin types. The main advantage is its availability and reliability, but it may lack the specialized properties needed for optimal blister prevention.

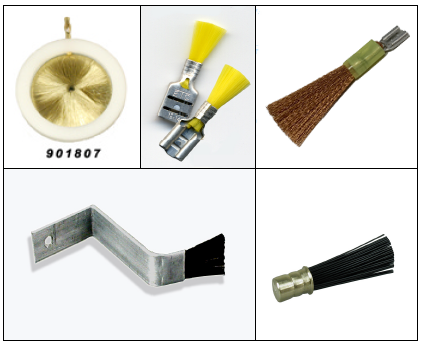

Illustrative image related to blister wrap

Key Industrial Applications of blister wrap

| Industry/Sector | Specific Application of blister wrap | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

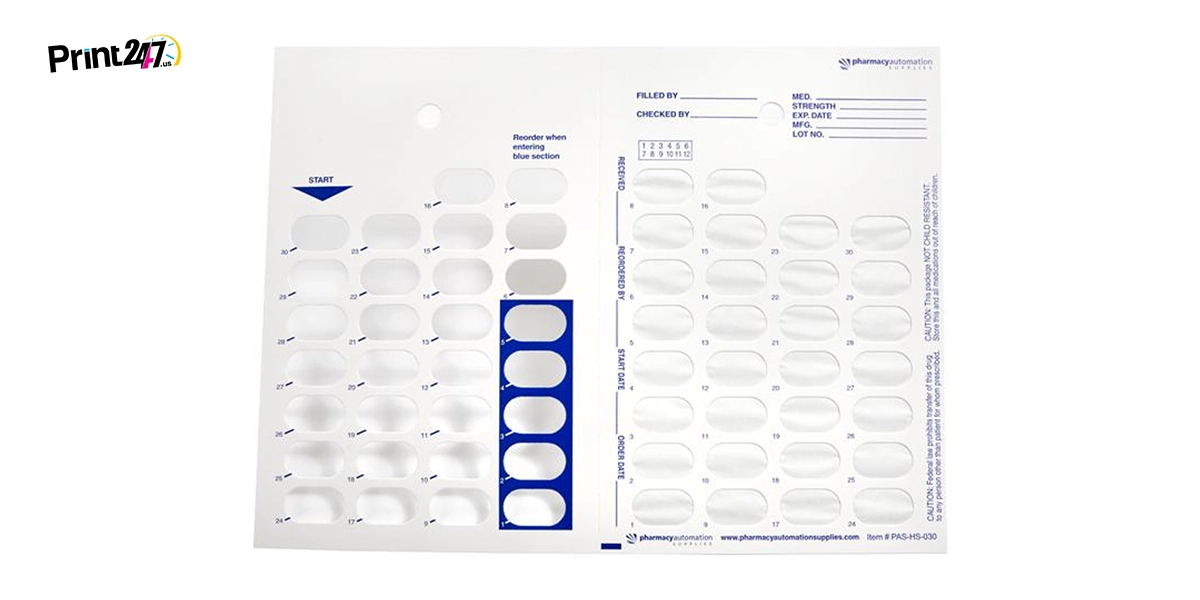

| Pharmaceutical | Packaging of tablets and capsules | Ensures product integrity and extends shelf life | Compliance with health regulations, material safety, and compatibility with contents |

| Electronics | Protection of delicate components during shipping | Reduces damage during transit, lowering return rates | Custom sizing, anti-static properties, and durability for varying climates |

| Consumer Goods | Packaging of cosmetics and personal care products | Enhances product visibility and reduces tampering | Eco-friendly materials, aesthetic appeal, and cost-effectiveness |

| Food and Beverage | Packaging of snacks and ready-to-eat meals | Maintains freshness and prevents contamination | Food-grade materials, moisture barrier properties, and compliance with food safety standards |

| Sports and Outdoor Gear | Protection of footwear and gear during transport | Minimizes wear and tear, ensuring products reach consumers intact | Lightweight options, moisture resistance, and ease of storage |

How is blister wrap utilized in the pharmaceutical industry?

In the pharmaceutical sector, blister wrap is primarily used for packaging tablets and capsules. This application is critical as it protects the integrity of the medication, preventing contamination and degradation due to environmental factors. For international buyers, especially in regions like Africa and South America, sourcing blister wrap that complies with local health regulations is vital. Additionally, the materials used must be safe for direct contact with pharmaceuticals to ensure patient safety.

What role does blister wrap play in the electronics industry?

Blister wrap serves a crucial role in the electronics industry by providing protective packaging for delicate components, such as circuit boards and connectors, during shipping. This type of packaging reduces the risk of damage from impacts and static electricity, which can lead to costly returns and replacements. International buyers from the Middle East and Europe should consider sourcing blister wrap that offers anti-static properties, as well as durability to withstand varying climatic conditions during transport.

How does blister wrap benefit the consumer goods sector?

In the consumer goods industry, blister wrap is commonly used for packaging cosmetics and personal care products. This application not only enhances the product’s visibility on retail shelves but also deters tampering, which is essential for maintaining brand integrity. For B2B buyers, especially those from Europe and South America, it is important to consider eco-friendly materials that align with sustainability goals, while also ensuring that the packaging remains cost-effective.

Illustrative image related to blister wrap

In what ways is blister wrap used in food and beverage packaging?

Blister wrap is increasingly utilized in the food and beverage sector for packaging snacks and ready-to-eat meals. This application helps to maintain product freshness and prevents contamination, which is vital for consumer safety. International buyers must ensure that the blister wrap materials used are food-grade and compliant with local food safety regulations, particularly in diverse markets like Africa and the Middle East, where food safety standards can vary significantly.

How does blister wrap protect sports and outdoor gear?

In the sports and outdoor gear industry, blister wrap is used to protect footwear and equipment during transportation. This application minimizes wear and tear, ensuring that products arrive at retail locations in pristine condition. For B2B buyers, sourcing lightweight blister wrap options that offer moisture resistance is crucial, particularly in regions with high humidity levels. Proper packaging not only enhances customer satisfaction but also reduces the likelihood of returns due to damaged goods.

3 Common User Pain Points for ‘blister wrap’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality Blister Wrap for Diverse Applications

The Problem: B2B buyers often struggle to find a reliable source of high-quality blister wrap that meets their specific needs. For example, a company in the Middle East focused on packaging pharmaceuticals may require blister wraps that not only protect delicate products but also comply with stringent regulatory standards. The inconsistency in quality and the lack of suppliers who can provide customized solutions tailored to different markets can lead to significant procurement headaches, delays in product launches, and potential financial losses.

Illustrative image related to blister wrap

The Solution: To address this issue, buyers should conduct thorough market research to identify reputable suppliers with proven track records in their industry. It’s beneficial to request samples and conduct quality assessments to ensure that the blister wrap meets necessary specifications. Buyers can also establish relationships with manufacturers that offer customization options, such as varying thicknesses and adhesive strengths, to cater to their specific product requirements. Utilizing platforms that specialize in B2B procurement can also streamline the sourcing process, connecting buyers with trusted manufacturers across different regions.

Scenario 2: Managing Inventory and Cost-Effectiveness of Blister Wrap

The Problem: Many companies face challenges in managing inventory levels of blister wrap, which can lead to excess stock or shortages. For instance, a packaging firm in Brazil might experience fluctuating demand due to seasonal variations in product sales. This variability can result in either wasted resources due to over-purchasing or missed opportunities and production delays due to insufficient stock, impacting the overall profitability of the business.

The Solution: Implementing a just-in-time (JIT) inventory management system can significantly improve inventory control for blister wrap. By forecasting demand based on historical sales data and market trends, companies can order blister wrap more accurately, reducing the risk of overstocking or running out. Collaborating with suppliers that offer flexible ordering options or rapid delivery services can also help maintain optimal inventory levels. Additionally, leveraging technology such as inventory management software can enhance visibility and tracking of stock levels, enabling timely reordering and better financial management.

Scenario 3: Ensuring User-Friendly Application of Blister Wrap

The Problem: A common pain point for businesses is the difficulty faced by employees in applying blister wrap effectively. For example, a manufacturer in Europe may find that workers are struggling with the application process, resulting in misaligned or poorly sealed packages. This not only affects the aesthetic appeal of the products but can also compromise the integrity and safety of the items within the blister pack, leading to increased returns and customer dissatisfaction.

The Solution: To enhance the application process, companies should invest in training programs that educate employees on best practices for using blister wrap. This could include hands-on workshops or instructional videos demonstrating proper techniques for cutting, sealing, and applying the wrap. Moreover, considering the use of user-friendly blister wrap products that come with pre-cut sizes or easy-peel backing can simplify the application process. Suppliers that provide comprehensive guides and support materials will also empower employees to perform their tasks more effectively, ultimately leading to improved product quality and customer satisfaction.

Strategic Material Selection Guide for blister wrap

What Are the Key Materials Used in Blister Wrap Production?

When selecting materials for blister wrap, it is essential to consider their properties, advantages, disadvantages, and suitability for specific applications. Here, we analyze four common materials used in blister wraps: PVC, PET, Polypropylene (PP), and Tyvek.

Illustrative image related to blister wrap

How Does PVC Perform as a Blister Wrap Material?

Polyvinyl Chloride (PVC) is one of the most widely used materials for blister packaging due to its excellent clarity and barrier properties. It can withstand a temperature range of -10°C to 60°C, making it suitable for a variety of products, including pharmaceuticals and consumer goods.

Pros: PVC offers good durability and is relatively inexpensive, making it a cost-effective option for mass production. It also has excellent sealing properties, which helps maintain product integrity.

Cons: However, PVC is less environmentally friendly due to its chlorine content, and its rigidity can limit its application in certain designs. Additionally, it may not be suitable for products that require high-temperature sterilization.

Impact on Application: PVC is compatible with a wide range of products but may not be ideal for those sensitive to plasticizers used in the manufacturing process.

Considerations for International Buyers: Buyers should be aware of compliance with local regulations regarding PVC usage, especially in regions like Europe, where stricter environmental regulations are in place.

What Advantages Does PET Offer for Blister Wrap?

Polyethylene Terephthalate (PET) is another popular choice for blister wraps, known for its high strength and excellent barrier properties against moisture and gases. It can handle temperatures up to 70°C, making it suitable for various applications.

Pros: PET is recyclable, which appeals to environmentally conscious consumers and businesses. It also provides superior clarity and strength compared to PVC, enhancing product visibility.

Cons: The main drawback is its higher cost compared to PVC, which may deter budget-sensitive projects. Additionally, PET can be more challenging to seal than PVC.

Impact on Application: PET is ideal for packaging food and medical products due to its high barrier properties, but it may require specific sealing equipment.

Considerations for International Buyers: Compliance with standards such as ASTM and DIN is crucial, especially in food and pharmaceutical applications, to ensure safety and quality.

Why Choose Polypropylene (PP) for Blister Wrap?

Polypropylene (PP) is known for its flexibility and resilience, making it a suitable choice for blister wraps that require bending or folding. It can withstand temperatures up to 100°C, which is beneficial for products needing sterilization.

Pros: PP is lightweight and offers good chemical resistance, making it versatile for various applications. It is also cost-effective and provides a good balance between performance and price.

Cons: However, PP may have lower clarity compared to PVC and PET, which could affect product presentation. Its sealing properties can also be less effective if not handled properly.

Impact on Application: PP is particularly effective for products that require high-temperature sterilization, such as medical devices.

Illustrative image related to blister wrap

Considerations for International Buyers: Buyers should ensure that the PP used meets local regulations and standards, especially in the medical field.

What Is the Role of Tyvek in Blister Wrap Applications?

Tyvek, a brand of flashspun high-density polyethylene fibers, is often used for its unique properties, including breathability and moisture resistance. It is suitable for applications requiring a sterile environment, such as medical packaging.

Pros: Tyvek is lightweight, durable, and resistant to tearing, making it an excellent choice for protective packaging. Its breathable nature prevents moisture buildup, which is crucial for sensitive products.

Cons: The primary limitation of Tyvek is its higher cost compared to traditional plastic materials. Additionally, it may not provide the same level of clarity as PVC or PET.

Impact on Application: Tyvek is ideal for medical and pharmaceutical applications where sterility is paramount, but its cost may limit its use for less critical products.

Considerations for International Buyers: Compliance with medical packaging standards, such as ISO 11607, is essential for Tyvek products, especially in regulated markets like Europe and North America.

Summary Table of Blister Wrap Materials

| Material | Typical Use Case for blister wrap | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Pharmaceuticals, consumer goods | Cost-effective and durable | Environmental concerns, rigidity | Low |

| PET | Food, medical products | Recyclable and high clarity | Higher cost, sealing challenges | Med |

| Polypropylene (PP) | Medical devices, flexible packaging | Lightweight and chemical resistant | Lower clarity, sealing issues | Low |

| Tyvek | Medical packaging, sterile products | Durable, breathable, moisture-resistant | Higher cost, lower clarity | High |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling informed decisions based on product requirements and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for blister wrap

What Are the Key Stages in the Manufacturing Process of Blister Wrap?

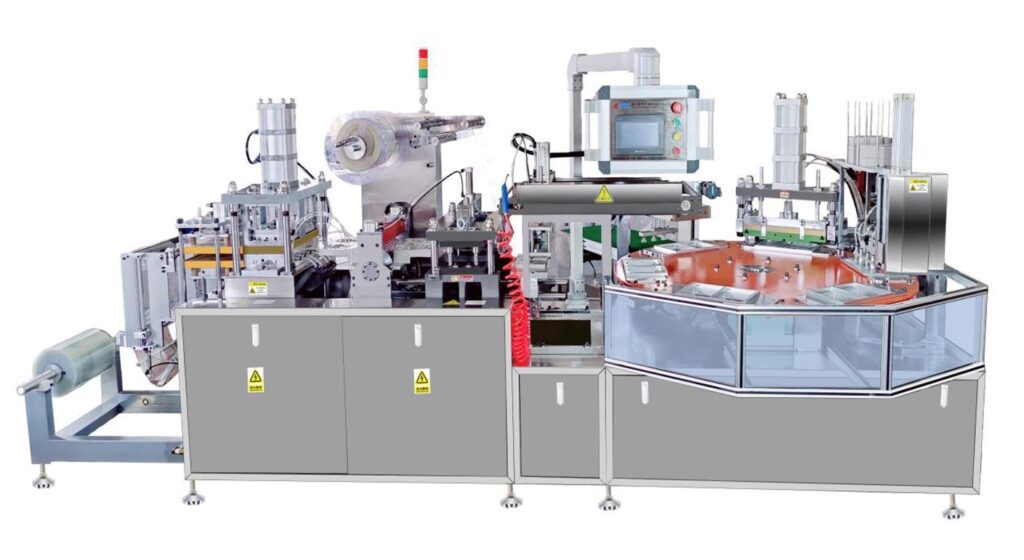

The manufacturing process of blister wrap is critical for ensuring that the final product meets the high standards required for protective packaging. The primary stages include material preparation, forming, assembly, and finishing.

Illustrative image related to blister wrap

Material Preparation: How Is Blister Wrap Material Selected and Processed?

The first stage involves selecting the appropriate materials, typically a combination of PVC, PET, or other thermoplastic materials. These materials are chosen based on their durability, flexibility, and barrier properties. Once selected, the materials undergo thorough cleaning and drying processes to eliminate any contaminants that could compromise quality.

After preparation, the materials are cut into sheets of desired dimensions and are often pre-treated to enhance adhesion properties, particularly for the adhesive layers used in blister packaging. This is crucial for maintaining the integrity of the product once it is assembled.

Forming: What Techniques Are Used to Create Blister Structures?

Forming is a pivotal stage where the prepared sheets are heated and molded into specific shapes. Techniques such as thermoforming or vacuum forming are commonly used. During thermoforming, sheets are heated until pliable and then formed over a mold to create the blister shape. This process is efficient and allows for rapid production of complex shapes, which is essential for accommodating various product types.

Illustrative image related to blister wrap

Once formed, the blisters may undergo cooling and trimming to ensure precise dimensions. This precision is essential for maintaining the quality of the packaging and ensuring it fits well with the product it is intended to protect.

Assembly: How Are Blister Packs Constructed?

The assembly stage involves combining the formed blister with a backing material, typically a card or film that provides additional support and branding space. The blister is adhered to the backing using high-quality adhesives, ensuring a secure bond that can withstand shipping and handling.

In many cases, automated machinery is used to streamline this process, allowing for high-volume production while maintaining consistency in quality. Quality checks are integrated throughout the assembly process to identify any defects early, reducing waste and ensuring customer satisfaction.

Finishing: What Final Touches Are Added Before Packaging?

The final stage of manufacturing involves several finishing processes, including printing, sealing, and packaging. Printing is often done using flexographic or digital printing techniques to add branding and product information directly onto the blister pack.

Illustrative image related to blister wrap

After printing, the packs are sealed, often using heat or pressure to create a tamper-proof closure. Finally, the finished products are packaged for distribution, ensuring they are protected during transit and ready for retail display.

What Quality Assurance Standards Are Relevant for Blister Wrap Manufacturing?

Quality assurance (QA) is essential for maintaining high manufacturing standards in blister wrap production. Several international and industry-specific standards guide this process.

How Do International Standards Like ISO 9001 Apply?

ISO 9001 is one of the most recognized quality management standards worldwide. It outlines the requirements for a quality management system (QMS) that organizations must meet to demonstrate their ability to consistently provide products that meet customer and regulatory requirements. Manufacturers of blister wrap must ensure they have robust quality control measures in place, which is often verified through regular audits.

What Industry-Specific Certifications Should B2B Buyers Look For?

In addition to ISO standards, certain industry-specific certifications may apply, such as CE marking for products sold within the European Economic Area and compliance with FDA regulations for medical packaging. Buyers should verify that their suppliers have these certifications to ensure compliance with regional regulations and quality expectations.

Illustrative image related to blister wrap

What Are the Key Quality Control Checkpoints in Blister Wrap Manufacturing?

Quality control (QC) is integral to the blister wrap manufacturing process, with multiple checkpoints throughout production.

What Are the Main QC Checkpoints to Ensure Product Quality?

-

Incoming Quality Control (IQC): This involves inspecting raw materials before they enter the production process. Materials must meet specific criteria to ensure they are suitable for use.

-

In-Process Quality Control (IPQC): During manufacturing, real-time checks are performed to monitor production processes. This includes checking temperature, pressure, and adhesion properties to ensure consistency.

-

Final Quality Control (FQC): Before packaging, final inspections are conducted to verify that the blister wraps meet all specifications. This may include visual inspections, dimensional checks, and functional testing.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verifying the quality control practices of suppliers is crucial for B2B buyers, particularly in international markets.

What Steps Can Buyers Take to Ensure Supplier Compliance?

-

Supplier Audits: Conducting on-site audits can provide valuable insights into a supplier’s manufacturing processes and quality control measures. This allows buyers to assess the adherence to international standards firsthand.

-

Requesting Quality Reports: Buyers should ask for detailed quality reports that outline the QC processes, results of inspections, and any corrective actions taken. This transparency helps build trust between parties.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control systems. This is particularly important for buyers from regions like Africa, South America, the Middle East, and Europe, where regulatory compliance may vary.

What Nuances Should International Buyers Be Aware of Regarding QC and Certifications?

B2B buyers from diverse regions may encounter specific nuances in quality control and certification requirements. For instance, regulations may differ significantly between the EU and countries in Africa or South America.

How Can Buyers Navigate These Differences?

Understanding local regulations and standards is essential. Buyers should research the specific requirements for blister wrap in their target markets, which may include additional certifications or testing procedures. Collaborating with local experts or consultants can also aid in navigating these complexities and ensuring compliance with all necessary regulations.

Conclusion

The manufacturing processes and quality assurance measures for blister wrap are vital for ensuring product effectiveness and safety. By understanding these processes, B2B buyers can make informed decisions when selecting suppliers, ensuring that they receive high-quality blister wrap that meets both their needs and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘blister wrap’

In the competitive landscape of B2B procurement, sourcing the right blister wrap is essential for ensuring product safety and integrity during shipping and handling. This guide serves as a comprehensive checklist for international buyers from regions such as Africa, South America, the Middle East, and Europe. By following these steps, you can streamline your sourcing process and make informed purchasing decisions.

Step 1: Define Your Technical Specifications

Start by determining the specific requirements for the blister wrap you need. Consider factors such as material type (PVC, PET, etc.), thickness, size, and barrier properties. This clarity will help you communicate effectively with potential suppliers and ensure the product meets your operational needs.

Step 2: Identify Supplier Capabilities

Research suppliers that specialize in blister wrap manufacturing. Look for companies with a proven track record in producing high-quality products that align with your specifications. Evaluate their production capacity, technology, and quality control processes to ensure they can meet your volume requirements consistently.

Illustrative image related to blister wrap

Step 3: Verify Supplier Certifications

Before entering into a contract, ensure that your chosen suppliers hold relevant certifications. Certifications such as ISO 9001 for quality management or specific industry-related standards can provide assurance of a supplier’s commitment to quality and compliance. This step is vital to mitigate risks associated with sourcing from unverified suppliers.

Step 4: Request Samples for Evaluation

Always request samples of the blister wrap from potential suppliers. Assess the samples for durability, flexibility, and ease of use. This practical evaluation will help you understand how well the product will perform in real-world applications, ensuring it meets your expectations before making a larger commitment.

Step 5: Review Pricing and Payment Terms

Conduct a thorough analysis of pricing structures from different suppliers. Consider not only the unit price but also any additional costs such as shipping, taxes, and potential tariffs. Understanding payment terms is equally important; negotiate favorable conditions that align with your cash flow needs.

Step 6: Discuss Lead Times and Delivery Options

Clarify lead times and delivery options with suppliers. Timeliness is crucial in B2B transactions, and understanding the supplier’s logistics capabilities can prevent delays in your production schedule. Inquire about their ability to handle urgent orders or last-minute changes.

Step 7: Establish Communication and Support Channels

Effective communication is vital for a successful partnership. Ensure that the supplier has a responsive customer support system in place. Discuss how issues will be handled, including product recalls or defects, to foster a transparent and reliable working relationship.

By following this sourcing checklist, you can enhance your procurement strategy for blister wrap and secure a reliable supply chain that meets your business needs. Each step is designed to facilitate informed decision-making and promote long-term partnerships with your suppliers.

Comprehensive Cost and Pricing Analysis for blister wrap Sourcing

What Are the Key Cost Components for Sourcing Blister Wrap?

When sourcing blister wrap, understanding the cost structure is crucial for international B2B buyers. The primary components include:

-

Materials: The type of materials used significantly impacts cost. High-quality, hypoallergenic synthetic fabrics often command a premium. Materials with advanced properties, such as breathability or moisture resistance, can lead to higher prices.

-

Labor: Labor costs can vary by region, affecting the total production cost. Countries with lower labor costs may offer competitive pricing, but it’s essential to assess the quality of workmanship, as this can influence the product’s performance.

-

Manufacturing Overhead: This includes expenses related to facility operations, utilities, and administrative costs. Efficient production processes can reduce overhead, making the product more cost-effective.

-

Tooling: Initial costs for tooling and molds are significant, especially for customized blister wraps. Buyers should consider these costs when negotiating prices, as they are often spread across production runs.

-

Quality Control (QC): Implementing strict QC processes ensures product reliability and compliance with health standards. However, these processes add to the overall cost, which should be factored into pricing.

-

Logistics: Transportation costs are critical, especially for international shipments. Factors such as distance, shipping method, and customs duties can significantly affect the final price.

-

Margin: Supplier profit margins vary widely based on market conditions and competition. Understanding typical margins in your supplier’s region can help in negotiations.

How Do Price Influencers Affect Blister Wrap Sourcing Decisions?

Several key factors influence pricing in blister wrap sourcing:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically lower the per-unit cost. Buyers should assess their needs to negotiate favorable terms, keeping in mind the balance between inventory holding costs and supplier requirements.

-

Specifications and Customization: Custom designs or specific material requirements can increase costs. Buyers should clearly define their needs to avoid unexpected expenses.

-

Quality and Certifications: Products with certifications (e.g., dermatological testing, hypoallergenic status) often come at a premium. Buyers should weigh the benefits of certifications against their budget and market needs.

-

Supplier Factors: The supplier’s reputation, production capacity, and past performance can influence pricing. Working with established suppliers may offer better reliability but could also mean higher costs.

-

Incoterms: Understanding Incoterms is essential for determining who bears the costs and risks during shipping. Buyers should negotiate favorable terms to minimize unexpected expenses.

What Are Some Buyer Tips for Cost-Efficient Sourcing of Blister Wrap?

-

Negotiation Strategies: Approach negotiations with a clear understanding of market prices and competitor offerings. Leverage volume commitments or long-term partnerships to negotiate better terms.

-

Total Cost of Ownership (TCO): Consider not just the purchase price but also associated costs such as shipping, handling, and storage. A lower upfront cost might lead to higher TCO if the quality is poor or if logistics costs are inflated.

-

Pricing Nuances for International Buyers: Buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import tariffs, and local market conditions that may affect pricing.

-

Conduct Thorough Supplier Research: Evaluate multiple suppliers to compare prices and quality. Request samples to ensure product quality meets your standards before placing large orders.

-

Stay Informed on Market Trends: Keep abreast of industry developments and material innovations that could affect pricing. Being informed can help you make strategic sourcing decisions that align with your business goals.

Disclaimer on Indicative Prices

Pricing for blister wrap can fluctuate based on various factors, including market demand, raw material costs, and supplier dynamics. The figures mentioned herein are indicative and should be verified with suppliers for accuracy in current market conditions.

Alternatives Analysis: Comparing blister wrap With Other Solutions

In the ever-evolving landscape of packaging and protection solutions, buyers must evaluate various alternatives to blister wrap. While blister wrap offers excellent cushioning and protection, several other products can serve similar purposes depending on specific needs, usage contexts, and budget considerations. This section explores alternative solutions to blister wrap, providing a detailed comparison to aid B2B buyers in making informed decisions.

Comparison Table

| Comparison Aspect | Blister Wrap | KT Health Blister Prevention Tape | Leukotape P Blister Prevention Tape |

|---|---|---|---|

| Performance | High cushioning and protection | Prevents blisters during activity | Strong adhesive for friction-prone areas |

| Cost | Moderate (price varies by size) | $10.39 per pack of 30 strips | $12.95 for standard roll (15 yd) |

| Ease of Implementation | Requires cutting and fitting | Pre-cut strips for convenience | Available in mini or standard rolls |

| Maintenance | Minimal; single-use | Single-use; no maintenance required | Single-use; no maintenance required |

| Best Use Case | General packaging and protection | Athletic use, hiking, and sports | Outdoor activities and first aid kits |

In-Depth Analysis of Alternatives

What Are the Advantages and Disadvantages of KT Health Blister Prevention Tape?

KT Health Blister Prevention Tape is designed specifically for athletes and active individuals. Its ultra-durable, flexible fabric minimizes friction and conforms well to the skin, making it an excellent choice for preventing blisters during sports activities. The pre-cut strips enhance usability, allowing users to apply the tape quickly and efficiently. However, its higher cost per use compared to traditional blister wrap may be a consideration for budget-conscious buyers. Additionally, it is primarily effective in preventing blisters rather than packaging items.

How Does Leukotape P Blister Prevention Tape Compare?

Leukotape P is another strong alternative that excels in preventing blisters, especially in high-friction areas. Known for its aggressive adhesive, it remains securely in place even during intense physical activity, making it suitable for outdoor adventures. The availability of mini rolls makes it a convenient addition to first aid kits, providing flexibility for short trips. On the downside, the adhesive’s strength can be a double-edged sword; it may cause skin irritation or damage when removed if not applied correctly. Furthermore, like KT Health tape, it is not intended for packaging but rather for protective use.

How Can B2B Buyers Choose the Right Solution?

When selecting the right solution, B2B buyers should consider their specific needs and application contexts. If the primary goal is to protect items during shipping or storage, blister wrap remains a strong contender due to its cushioning properties. For active environments where blister prevention is crucial, KT Health or Leukotape P can offer targeted protection but may not be suitable for packaging. Ultimately, the decision should factor in performance requirements, cost-effectiveness, ease of use, and the specific scenarios in which the product will be deployed. By evaluating these aspects, buyers can make informed choices that align with their operational objectives and budgets.

Essential Technical Properties and Trade Terminology for blister wrap

What Are the Key Technical Properties of Blister Wrap?

When evaluating blister wrap for packaging or protective applications, understanding its technical properties is essential for making informed purchasing decisions. Here are some critical specifications to consider:

1. Material Composition

Blister wraps are typically made from various plastic polymers, such as PVC (Polyvinyl Chloride) or PET (Polyethylene Terephthalate). The choice of material affects durability, transparency, and barrier properties. For instance, PVC is often favored for its excellent clarity and rigidity, making it ideal for displaying products, while PET is known for its superior moisture barrier, which is crucial for food and pharmaceutical applications. Selecting the right material ensures the blister wrap meets regulatory requirements and protects the integrity of the enclosed products.

2. Thickness (Gauge)

The thickness of blister wrap, measured in mils or microns, directly influences its strength and protective capabilities. A thicker gauge typically offers enhanced puncture resistance and durability, making it suitable for heavier or more fragile items. Conversely, a thinner gauge may be more cost-effective for lighter products but could compromise protection. Understanding the appropriate thickness required for your specific application can optimize both cost and performance.

3. Sealing Method

Blister wraps can be sealed through various methods, such as heat sealing or cold sealing. Heat sealing is common for creating airtight seals, essential for extending shelf life in food packaging. Cold sealing, on the other hand, uses adhesive properties to bond materials without heat, which can be beneficial for heat-sensitive products. Knowing the sealing method is vital for ensuring product safety and compliance with industry standards.

4. Barrier Properties

The barrier properties of blister wraps refer to their ability to prevent the permeation of gases, moisture, and contaminants. This is especially important in sectors like pharmaceuticals and food packaging, where product preservation is paramount. Testing for oxygen and moisture transmission rates (OTR and MVTR) can help buyers assess whether a specific blister wrap meets the necessary requirements for their products.

5. Surface Treatment

Some blister wraps undergo surface treatments to enhance adhesion for labels or printing. These treatments can improve the performance of the packaging in terms of branding and product information visibility. Understanding the surface characteristics is crucial for ensuring compatibility with printing and labeling processes.

Illustrative image related to blister wrap

What Common Trade Terminology Should B2B Buyers Know?

Navigating the world of blister wrap involves understanding key trade terms that can impact purchasing decisions:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are then sold under another company’s brand name. In the context of blister wrap, understanding OEM relationships can help buyers identify suppliers that offer customized solutions tailored to their specifications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for budgeting and inventory management, as it can affect the overall cost and availability of blister wraps. Buyers should be aware of MOQs to ensure they can meet their production needs without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing information for specific products. Crafting a comprehensive RFQ for blister wrap can streamline the procurement process and help buyers compare offers from multiple suppliers effectively.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for determining shipping costs, insurance, and risk management associated with blister wrap procurement.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. This is a critical factor for inventory planning and can significantly impact production schedules. Buyers should negotiate lead times with suppliers to align with their operational needs.

By familiarizing yourself with these technical properties and trade terms, you can make more informed decisions when sourcing blister wrap, ensuring that your packaging solutions meet industry standards and customer expectations.

Navigating Market Dynamics and Sourcing Trends in the blister wrap Sector

What are the Key Market Dynamics and Trends Influencing the Blister Wrap Sector?

The blister wrap market is experiencing significant growth driven by several global factors, including increased demand for protective packaging across various industries such as pharmaceuticals, electronics, and consumer goods. The rise of e-commerce and the need for secure shipping solutions are further propelling the market, particularly in regions like Africa, South America, the Middle East, and Europe. Emerging technologies, such as smart packaging solutions that incorporate IoT devices, are also reshaping the sector. These innovations allow for better tracking and monitoring of products during transit, which is essential for maintaining quality, especially in temperature-sensitive shipments.

Illustrative image related to blister wrap

In addition, the shift towards automation in manufacturing processes is streamlining production and reducing costs, making blister wraps more accessible to international B2B buyers. As market dynamics evolve, businesses are increasingly looking for suppliers that can offer customized solutions tailored to specific needs, such as size, material, and adhesive properties. This trend is particularly prevalent in regions like Brazil and Saudi Arabia, where local industries are growing rapidly and demand for specialized packaging solutions is on the rise.

How is Sustainability Shaping Sourcing Practices in the Blister Wrap Industry?

Sustainability and ethical sourcing are becoming critical considerations for B2B buyers in the blister wrap sector. The environmental impact of packaging materials has led to increased scrutiny from consumers and regulators alike. Businesses are now prioritizing suppliers that demonstrate a commitment to sustainable practices, including the use of recycled materials and eco-friendly production processes. Certifications such as FSC (Forest Stewardship Council) and Cradle to Cradle are gaining importance, providing assurance to buyers that the materials used are sourced responsibly.

Additionally, the demand for biodegradable and compostable blister wraps is growing, particularly in Europe, where environmental regulations are stringent. Suppliers that can provide innovative materials that reduce waste and carbon footprints are likely to gain a competitive edge in the market. This shift towards sustainability not only aligns with corporate social responsibility goals but also enhances brand reputation, making ethical sourcing a strategic advantage in the B2B landscape.

What is the Historical Context of Blister Wrap Development in B2B Markets?

The blister wrap sector has evolved significantly over the past few decades, initially gaining traction in the pharmaceutical and consumer electronics industries due to its ability to provide protection and visibility for products. Early iterations of blister packaging primarily focused on functionality, but as consumer preferences shifted towards aesthetics and sustainability, manufacturers began to innovate.

The introduction of advanced materials and adhesive technologies has improved the performance of blister wraps, making them more durable and versatile. Today, businesses are not only looking for protective solutions but also for packaging that enhances user experience and supports sustainability initiatives. This evolution reflects broader trends in the B2B market, where the emphasis has shifted from mere product protection to encompassing environmental responsibility and consumer engagement.

Overall, as international B2B buyers navigate the blister wrap sector, understanding these dynamics and trends will be essential for making informed sourcing decisions that align with their business goals and values.

Frequently Asked Questions (FAQs) for B2B Buyers of blister wrap

-

How do I solve issues with blister wrap quality during international shipping?

Ensuring the quality of blister wrap during international shipping requires working with reputable suppliers who prioritize quality assurance. Request certifications and quality control documentation to verify product standards. Additionally, consider using moisture-proof packaging to protect the blister wrap from environmental factors during transit. Conduct regular communication with your supplier to track the production process and address any concerns early. Engaging third-party inspection services can also help assess the quality before shipment. -

What is the best type of blister wrap for protecting fragile items?

The best type of blister wrap for protecting fragile items is one that combines durability and cushioning properties. Look for wraps made from high-quality polyethylene or PVC, which offer excellent impact resistance and cushioning. The thickness of the wrap also plays a crucial role; thicker materials provide better protection. Additionally, consider wraps with custom-size blisters tailored to your products, as this ensures a snug fit and minimizes movement during transit. -

What should I consider when selecting a blister wrap supplier?

When selecting a blister wrap supplier, evaluate their industry experience, product range, and customer reviews. Ensure they have a proven track record of meeting international shipping standards and compliance regulations. Request samples to assess the quality and suitability of their products for your needs. It’s also vital to discuss their production capacity and lead times to ensure they can meet your order volume requirements, especially for urgent shipments. -

What are the minimum order quantities (MOQs) for blister wrap?

Minimum order quantities (MOQs) for blister wrap can vary significantly depending on the supplier and the specific product. Typically, MOQs can range from a few hundred to several thousand units. Discuss your requirements with potential suppliers to negotiate MOQs that suit your business needs. Some suppliers may offer flexibility for first-time buyers or for larger orders, which can help you manage inventory effectively while minimizing upfront costs. -

How can I customize blister wrap for my products?

Customization options for blister wrap often include size, shape, and printing. Work closely with your supplier to specify the dimensions and blister configurations that best suit your products. Many suppliers also offer branding options, allowing you to print your logo or product information directly on the wrap. Discuss lead times for custom orders, as these may differ from standard products, and ensure that the design process includes proofing to avoid errors. -

What payment terms should I negotiate with blister wrap suppliers?

Negotiating payment terms with blister wrap suppliers is essential for managing cash flow and minimizing risk. Common payment options include upfront payments, partial payments before shipping, and payment upon delivery. Establishing a letter of credit can provide security for both parties in international transactions. Be sure to clarify any additional costs, such as shipping and customs duties, to ensure you have a comprehensive understanding of the total cost involved. -

What logistics considerations should I keep in mind when sourcing blister wrap internationally?

When sourcing blister wrap internationally, consider logistics factors such as shipping methods, transit times, and customs regulations. Collaborate with your supplier to select the most cost-effective shipping options that meet your timeline. Familiarize yourself with import duties and taxes applicable in your country to avoid unexpected expenses. Additionally, ensure that your supplier provides proper documentation, including invoices and packing lists, to facilitate smooth customs clearance. -

How can I ensure compliance with international packaging regulations for blister wrap?

To ensure compliance with international packaging regulations, stay informed about the specific requirements of the countries you are exporting to. Different regions may have regulations concerning materials, labeling, and safety standards. Work with suppliers who are knowledgeable about these regulations and can provide compliant products. Conduct regular audits of your packaging processes and consult with legal or trade experts to ensure adherence to all relevant laws and standards.

Top 3 Blister Wrap Manufacturers & Suppliers List

1. Target – Blister Tape Solutions

Domain: target.com

Registered: 1997 (28 years)

Introduction: This company, Target – Blister Tape Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. COMPEED® – Advanced Blister Care Medium

Domain: compeedusa.com

Registered: 2015 (10 years)

Introduction: COMPEED® Advanced Blister Care Medium provides medium blister cushions that absorb excess moisture and form a protective cushion for instant pain relief and optimal healing conditions. Available in pack counts of 2ct, 10ct, and 12ct. Features hydrocolloid technology with moisture-absorbing particles, thick cushioning for pressure redistribution, tapered edges to reduce friction, and waterproof, br…

3. Reddit – Leukotape P

Strategic Sourcing Conclusion and Outlook for blister wrap

In the evolving landscape of blister wrap sourcing, strategic partnerships are paramount for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. The insights gathered indicate that investing in high-quality blister prevention solutions not only enhances product integrity but also significantly reduces the risk of damage during transportation and handling. The increasing demand for reliable and effective blister wraps underlines the necessity for buyers to collaborate with reputable suppliers who prioritize product innovation and sustainability.

Moreover, understanding regional market dynamics and consumer behavior will allow businesses to tailor their sourcing strategies effectively. By leveraging data analytics and market research, companies can identify potential growth opportunities and optimize their supply chains, ensuring they remain competitive in a global marketplace.

As we look ahead, the focus on sustainability and eco-friendly materials will likely shape the future of blister wrap solutions. International buyers are encouraged to stay informed about emerging trends and technologies in the industry. By embracing these changes, businesses can not only meet customer expectations but also contribute to a more sustainable supply chain. Engaging with forward-thinking suppliers now will position your business to thrive in the dynamic landscape of blister wrap sourcing.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.