Black Sun Patch: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for black sun patch

In today’s competitive landscape, international B2B buyers face the challenge of sourcing high-quality black sun patches that resonate with their target markets. Whether for fashion, military, or cultural significance, the demand for these patches spans various sectors across Africa, South America, the Middle East, and Europe. This guide serves as a comprehensive resource, equipping buyers with insights on the different types of black sun patches available, their applications, and essential factors for supplier vetting.

From embroidered and PVC options to custom designs, understanding the nuances of black sun patches is crucial for making informed purchasing decisions. Additionally, we delve into the cost considerations and logistics involved in sourcing these products, ensuring that buyers can evaluate suppliers based on quality, reliability, and compliance with regional standards.

By offering actionable strategies and insights, this guide empowers B2B buyers to navigate the global market effectively. Whether you are based in Nigeria, Germany, or anywhere in between, you will find tailored advice that addresses your unique sourcing needs and helps enhance your product offerings. With a firm grasp of market dynamics and supplier capabilities, you can confidently position your business for success in the burgeoning patch industry.

Understanding black sun patch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PVC Black Sun Patch | Durable material, Velcro backing, various sizes | Military, outdoor gear, fashion | Pros: Weather-resistant, customizable; Cons: Limited design variations. |

| Embroidered Black Sun Patch | Traditional stitching, intricate designs | Apparel, promotional items | Pros: High-quality look, long-lasting; Cons: Higher production costs. |

| Printed Black Sun Patch | Full-color designs, polyester or cotton | Fashion, merchandise, events | Pros: Vibrant colors, versatile; Cons: Less durable than PVC or embroidered. |

| Baphomet Black Sun Patch | Unique graphic design, often associated with specific subcultures | Niche markets, collectors | Pros: Appeals to specific audiences; Cons: Limited market appeal. |

| Multi-color Black Sun Patch | Available in multiple color combinations | Fashion, team branding | Pros: Customizable for branding; Cons: May require higher minimum orders. |

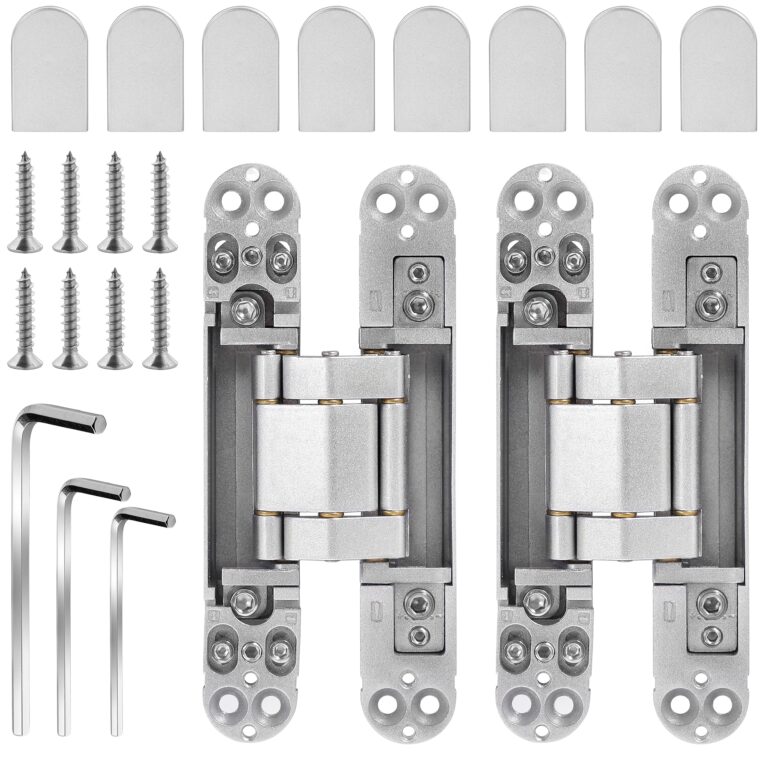

What Are the Key Characteristics of PVC Black Sun Patches?

PVC Black Sun patches are known for their durability and weather resistance, making them ideal for outdoor applications. Typically featuring Velcro backing, these patches can be easily attached and detached from various fabrics. Their availability in various sizes allows for flexibility in branding and personalization. B2B buyers should consider the longevity and customization options when selecting PVC patches for military or outdoor gear, as these factors can enhance product appeal and usability.

How Do Embroidered Black Sun Patches Stand Out?

Embroidered Black Sun patches are characterized by their intricate stitching and high-quality finish. These patches offer a premium look and feel, making them suitable for apparel and promotional items. While they tend to be more expensive than PVC alternatives, their durability and aesthetic appeal can justify the cost for businesses aiming to present a professional image. B2B buyers should weigh the benefits of quality against budget constraints when considering embroidered options.

What Advantages Do Printed Black Sun Patches Offer?

Printed Black Sun patches utilize vibrant colors and can feature complex designs, making them a popular choice for fashion and merchandise. Typically made from polyester or cotton, these patches are versatile and can be used in various applications, including events and promotional campaigns. However, their lower durability compared to PVC or embroidered patches may be a consideration for B2B buyers focused on longevity. The vibrant appearance can attract attention, making them effective for branding purposes.

Who Is the Target Market for Baphomet Black Sun Patches?

Baphomet Black Sun patches cater to niche markets and collectors, often associated with specific subcultures. Their unique graphic designs can resonate with audiences interested in alternative fashion or symbolism. B2B buyers should consider the limited market appeal of these patches, as they may not suit broader consumer bases. However, for businesses targeting specific demographics, these patches can serve as effective promotional items or collectibles.

What Are the Benefits of Multi-color Black Sun Patches?

Multi-color Black Sun patches allow for creative branding opportunities, as they can be customized to fit various team colors or brand identities. These patches can be particularly appealing for fashion lines or sports teams looking to enhance their visibility. While they offer significant customization options, buyers should be aware that they may require higher minimum order quantities, which can affect initial investment. B2B buyers should evaluate the potential return on investment when opting for multi-color designs.

Key Industrial Applications of black sun patch

| Industry/Sector | Specific Application of black sun patch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fashion & Apparel | Custom patches for clothing lines | Enhances brand identity and customer loyalty through unique designs | Quality of materials, customization options, and lead times |

| Military & Tactical | Insignia for military uniforms and tactical gear | Fosters unit cohesion and identity, crucial for morale | Compliance with military standards, durability, and sourcing from reputable suppliers |

| Promotional Products | Corporate branding and giveaways | Increases brand visibility and engagement at events | Cost-effectiveness, design versatility, and delivery timelines |

| Arts & Crafts | Decorative elements for art projects | Adds unique artistic flair, appealing to niche markets | Material quality, design complexity, and pricing flexibility |

| Cultural Events | Symbolic patches for festivals and cultural gatherings | Strengthens community identity and pride, enhancing event appeal | Cultural relevance, production scalability, and shipping logistics |

How is the black sun patch used in the fashion and apparel industry?

In the fashion and apparel sector, black sun patches serve as custom embellishments that can be sewn or ironed onto clothing items. These patches allow brands to express individuality and create a unique aesthetic, which resonates with target audiences. For international buyers, especially those in regions like Africa and South America, sourcing high-quality patches that can withstand various climates and wear is essential. Buyers should also consider customization options to align with their brand ethos and customer preferences.

What role does the black sun patch play in military and tactical applications?

In military and tactical sectors, black sun patches are often used as insignia on uniforms and gear, representing unit affiliation or personal identity. They help foster a sense of belonging and morale among personnel. Buyers in this sector must prioritize compliance with military standards for durability and functionality. Additionally, sourcing from reputable suppliers ensures that the patches meet the rigorous demands of military environments, including resistance to wear and environmental elements.

How can promotional products utilize the black sun patch effectively?

For businesses looking to enhance their promotional products, black sun patches can be an effective tool. They can be used as giveaways during events or included in merchandise, helping to increase brand visibility. International B2B buyers should focus on cost-effectiveness and design versatility when sourcing these patches. Ensuring timely delivery is also critical for aligning with promotional campaigns, particularly in fast-paced markets in Europe and the Middle East.

In what ways do arts and crafts benefit from black sun patches?

In the arts and crafts industry, black sun patches are utilized as decorative elements in various projects, adding a unique touch that appeals to creative consumers. These patches can be integrated into mixed media art or used in DIY projects. Buyers should consider material quality and design complexity to ensure that the patches meet the diverse needs of artists and crafters. Pricing flexibility is also important, especially for bulk orders targeting niche markets.

How do cultural events leverage the black sun patch?

Cultural events often utilize black sun patches to symbolize community identity and pride, enhancing the overall appeal of gatherings such as festivals. These patches can be sold as merchandise or distributed to attendees, fostering a sense of belonging. When sourcing patches for cultural applications, buyers should focus on cultural relevance and production scalability to meet demand. Additionally, understanding shipping logistics is vital to ensure timely availability for events, especially in regions with complex supply chains.

3 Common User Pain Points for ‘black sun patch’ & Their Solutions

Scenario 1: Sourcing Quality Black Sun Patches for Resale

The Problem: B2B buyers, especially those in regions like Africa and South America, often struggle to find reliable suppliers for black sun patches. The challenge lies not only in ensuring product authenticity but also in verifying the quality of materials used. Many suppliers may offer low-cost options that compromise on quality, leading to customer dissatisfaction and potential reputational damage for the buyer’s business.

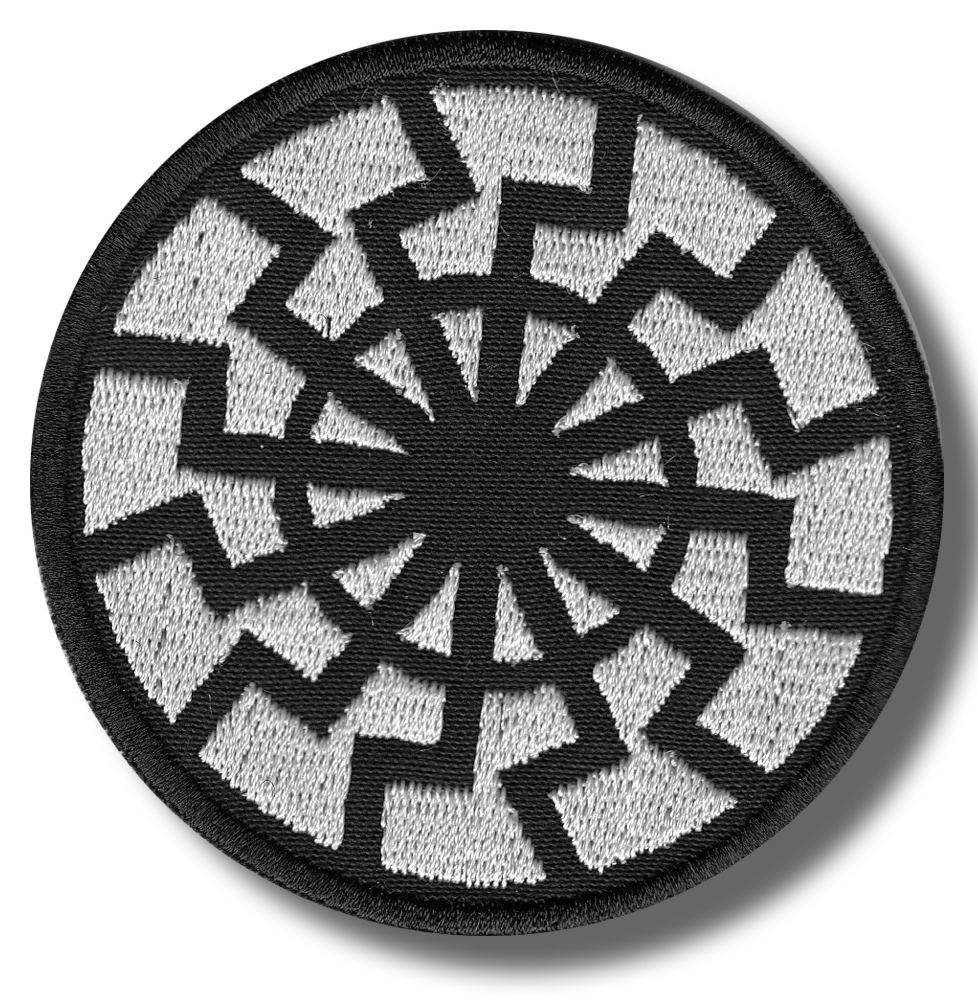

Illustrative image related to black sun patch

The Solution: To effectively source quality black sun patches, buyers should establish partnerships with reputable manufacturers known for their craftsmanship and ethical practices. Conduct thorough research on suppliers by reviewing customer testimonials and product samples. Consider utilizing platforms like Alibaba or local trade shows to connect with verified manufacturers. When placing bulk orders, request a sample batch to assess the quality of materials, such as the durability of the fabric and the precision of the embroidery or printing. Additionally, ensure that the supplier adheres to international shipping standards to avoid delays and complications.

Scenario 2: Navigating Cultural Sensitivity and Legal Compliance

The Problem: The black sun symbol can evoke strong cultural and political sentiments, especially in regions with complex histories. B2B buyers may face backlash or legal issues if they unknowingly distribute patches associated with extremist ideologies or movements. This challenge is particularly pertinent for companies in Europe and the Middle East, where regulatory scrutiny regarding symbols and branding is heightened.

The Solution: Buyers should prioritize cultural awareness and legal compliance when sourcing black sun patches. Begin by conducting a comprehensive analysis of the cultural implications of the black sun symbol in the target market. Engage with local experts or consultants who can provide insights into the cultural sensitivities surrounding the product. Furthermore, familiarize yourself with local laws regarding the sale and distribution of controversial symbols. To mitigate risks, consider diversifying your product line to include patches that celebrate positive themes, such as unity and heritage, which can appeal to broader audiences while steering clear of controversy.

Scenario 3: Ensuring Consistent Supply and Inventory Management

The Problem: B2B buyers often encounter challenges in maintaining consistent inventory levels for black sun patches, particularly when dealing with multiple suppliers across different regions. Fluctuations in supply can lead to missed sales opportunities, particularly during peak seasons or specific events that drive demand for such patches.

The Solution: To address supply chain inconsistencies, buyers should implement a proactive inventory management strategy. Begin by forecasting demand based on historical sales data and upcoming trends, such as festivals or events where black sun patches are popular. Establish agreements with multiple suppliers to create a safety net against supply chain disruptions. Additionally, utilize inventory management software that can track stock levels in real-time and alert you when reordering is necessary. By integrating these strategies, businesses can ensure they have adequate stock to meet customer demands while minimizing excess inventory that ties up capital.

Strategic Material Selection Guide for black sun patch

When selecting materials for black sun patches, several options are commonly used, each with distinct properties that affect performance, durability, and overall suitability for various applications. This guide will analyze four prevalent materials: embroidered fabric, PVC (polyvinyl chloride), rubber, and woven labels. Understanding these materials will help B2B buyers make informed decisions based on their specific needs and regional compliance requirements.

What Are the Key Properties of Embroidered Fabric for Black Sun Patches?

Embroidered fabric patches are made from threads stitched onto a fabric base. This material is known for its aesthetic appeal and versatility. Key properties include excellent durability and resistance to wear and tear, making it suitable for outdoor applications. Embroidered patches can withstand moderate temperatures but may not perform well in extreme conditions.

Pros: The main advantages of embroidered patches include their visual appeal and durability. They can be produced in various colors and designs, allowing for customization.

Cons: However, they can be more expensive to manufacture than other materials due to the labor-intensive stitching process. Additionally, they may not be as weather-resistant as synthetic options.

Illustrative image related to black sun patch

Impact on Application: Embroidered patches are ideal for clothing and accessories, particularly in markets that value craftsmanship, such as Europe and South America.

How Does PVC Perform as a Material for Black Sun Patches?

PVC patches are made from a dense polyvinyl chloride material, which provides a high level of durability and weather resistance. Key properties include resistance to moisture, UV rays, and chemicals, making them suitable for outdoor and tactical applications.

Pros: PVC patches are lightweight, easy to clean, and can be produced in various colors and designs. They also have a longer lifespan compared to fabric patches, especially in harsh environments.

Cons: The main drawback is that PVC can be less flexible than fabric, which may limit its application on garments that require a softer touch. Additionally, the manufacturing process can be more complex, impacting production costs.

Impact on Application: PVC patches are particularly popular in military and tactical markets, which are prevalent in regions like the Middle East and Africa, where durability is paramount.

What Advantages Does Rubber Offer for Black Sun Patches?

Rubber patches, often made from synthetic rubber compounds, provide excellent durability and flexibility. Key properties include high resistance to abrasion and temperature fluctuations, making them suitable for various applications.

Pros: Rubber patches are highly durable and can withstand extreme weather conditions. They are also flexible, allowing them to conform to different surfaces.

Cons: However, they can be heavier than fabric or PVC options, which may affect their application on lightweight garments. Additionally, the cost of rubber can be higher, depending on the quality of the material.

Illustrative image related to black sun patch

Impact on Application: Rubber patches are ideal for rugged outdoor gear and workwear, aligning well with the preferences of B2B buyers in industrial sectors across Africa and South America.

Why Choose Woven Labels for Black Sun Patches?

Woven labels are another option for black sun patches, made from tightly woven threads that create a flat, durable surface. Key properties include excellent detail retention and a soft feel, making them suitable for clothing applications.

Pros: Woven labels are lightweight and can be produced in high detail, allowing for intricate designs. They are also more cost-effective than embroidered patches.

Cons: On the downside, they may not offer the same level of durability as PVC or rubber patches, particularly in harsh environments.

Impact on Application: Woven labels are often used in fashion and branding applications, making them appealing to B2B buyers in Europe and South America, where brand identity is crucial.

Summary Table of Material Selection for Black Sun Patches

| Material | Typical Use Case for black sun patch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Embroidered Fabric | Clothing and accessories | Aesthetic appeal and durability | Higher manufacturing costs | Medium |

| PVC | Military and tactical applications | Weather-resistant and durable | Less flexible than fabric | Medium |

| Rubber | Outdoor gear and workwear | Highly durable and flexible | Heavier and potentially costlier | High |

| Woven Labels | Fashion and branding | High detail retention and lightweight | Less durable than PVC or rubber | Low |

This material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of various materials used in black sun patches. Understanding these factors can help inform purchasing decisions that align with regional preferences and compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for black sun patch

What Are the Key Stages in the Manufacturing Process of Black Sun Patches?

The production of black sun patches involves several critical stages, each contributing to the overall quality and appeal of the final product. Understanding these stages can help B2B buyers evaluate potential suppliers effectively.

Material Preparation: What Materials Are Used for Black Sun Patches?

The manufacturing process begins with the selection of appropriate materials. Common materials include dense polyvinyl chloride (PVC) for rubberized patches, which offers durability and weather resistance. Embroidered patches typically utilize high-quality threads and fabric, ensuring a premium look and feel. For buyers, verifying the source and specifications of these materials is crucial, as they impact both the patch’s aesthetic and functional qualities.

Illustrative image related to black sun patch

How Are Black Sun Patches Formed?

The forming stage involves several techniques, primarily dependent on the type of patch being produced. For PVC patches, processes such as injection molding are common, where heated plastic is injected into molds to create the desired shape and design. In contrast, embroidered patches are created through machine embroidery, where threads are stitched onto the fabric in intricate patterns. Buyers should inquire about the specific forming techniques used, as this can affect lead times and production costs.

What Does the Assembly Process Entail for Black Sun Patches?

Once the individual components are prepared, the assembly process begins. For PVC patches, this typically involves attaching a Velcro backing, which facilitates easy application and removal. In the case of embroidered patches, the assembly may include heat sealing or stitching on additional elements, such as borders or labels. B2B buyers should ensure that suppliers have efficient assembly practices in place to minimize defects and ensure consistency.

How Is the Finishing Stage Conducted in Black Sun Patch Manufacturing?

The finishing stage is where the patches are prepared for packaging and distribution. This may involve quality checks, trimming excess material, and applying protective coatings to enhance durability. Additionally, aesthetic considerations such as color matching and design alignment are addressed at this stage. Buyers should look for suppliers who implement robust finishing protocols to ensure that every patch meets the desired specifications before shipment.

What Quality Control Measures Are Essential for Black Sun Patch Production?

Quality assurance is crucial in the manufacturing of black sun patches to ensure they meet international standards and buyer expectations. A thorough understanding of quality control (QC) measures can help B2B buyers assess supplier reliability.

Which International Standards Should B2B Buyers Look For in Quality Assurance?

Adherence to international standards such as ISO 9001 is essential for manufacturers of black sun patches. ISO 9001 establishes a framework for quality management systems, ensuring that processes are efficient and customer-focused. Additionally, industry-specific certifications like CE marking can indicate compliance with safety and performance standards in Europe. Buyers should prioritize suppliers with these certifications to mitigate risks associated with product quality.

What Are the Key Quality Control Checkpoints in Patch Manufacturing?

Quality control is typically segmented into various checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint involves the inspection of raw materials before production begins. Buyers should ensure that suppliers have robust IQC procedures to prevent defects from the outset.

-

In-Process Quality Control (IPQC): During production, ongoing inspections help identify issues before they escalate. This includes monitoring machinery performance and ensuring that production aligns with design specifications.

-

Final Quality Control (FQC): The last checkpoint occurs after production, where finished patches are thoroughly inspected for defects, consistency, and adherence to specifications. This stage is critical for maintaining high standards.

What Common Testing Methods Are Used to Ensure Quality in Black Sun Patches?

Common testing methods for black sun patches include visual inspections, tensile strength tests, and colorfastness evaluations. Visual inspections assess the overall appearance, while tensile strength tests evaluate the durability of the materials used. Colorfastness testing ensures that colors remain vibrant and do not fade under various conditions. B2B buyers should inquire about the specific testing methods employed by suppliers to gauge their commitment to quality.

How Can B2B Buyers Verify Supplier Quality Control Practices?

Verifying a supplier’s quality control practices is essential for B2B buyers seeking to establish long-term partnerships. There are several methods to ensure that potential suppliers maintain high-quality standards.

Illustrative image related to black sun patch

What Role Do Audits and Reports Play in Supplier Quality Verification?

Conducting audits of potential suppliers can provide invaluable insights into their manufacturing processes and quality control practices. Audits may involve on-site evaluations, where buyers can assess equipment, processes, and employee training. Additionally, requesting quality assurance reports can help buyers understand how suppliers track and manage quality metrics. Regular audits and reports foster transparency and trust in the supplier relationship.

How Can Third-Party Inspections Enhance Quality Assurance for Buyers?

Engaging third-party inspection services can further validate a supplier’s quality claims. These independent inspectors evaluate the manufacturing processes, conduct random sampling of finished products, and provide unbiased assessments. This extra layer of scrutiny is particularly beneficial for international buyers, as it reduces the risks associated with cross-border transactions.

What Are the Quality Control Considerations for International Buyers in Diverse Markets?

B2B buyers from Africa, South America, the Middle East, and Europe must consider unique quality control nuances when sourcing black sun patches. Regional regulations, cultural expectations, and market preferences can influence product quality and compliance standards.

How Do Regional Regulations Affect Quality Control in Patch Manufacturing?

Different regions may have specific regulations governing product safety and quality. For instance, European buyers must be aware of CE marking requirements, while buyers from regions like Africa and South America may face varying local compliance standards. Understanding these regulations ensures that products not only meet international standards but are also suitable for local markets.

What Cultural Expectations Should Buyers Keep in Mind When Evaluating Quality?

Cultural perceptions of quality can differ significantly across regions. For example, buyers in Germany may prioritize precision and durability, while those in Nigeria may focus on vibrant aesthetics and affordability. Recognizing these preferences can guide buyers in selecting suppliers who align with their target market’s expectations, ensuring successful product acceptance.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance measures for black sun patches is vital for B2B buyers. By focusing on material selection, production techniques, and rigorous quality control practices, buyers can make informed decisions that enhance their product offerings and ensure customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘black sun patch’

When sourcing ‘black sun patches’ for your business, it is essential to follow a structured approach. This checklist will guide you through the critical steps necessary to ensure you find a reliable supplier and procure high-quality products that meet your specific requirements.

Step 1: Define Your Technical Specifications

Clearly outline the specifications for the black sun patches you intend to purchase. Consider aspects such as material (e.g., PVC, embroidered), size, color options, and design details. Having precise requirements will streamline your search and ensure that potential suppliers understand your needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers specializing in black sun patches. Utilize online marketplaces, industry directories, and trade shows to compile a list of manufacturers and distributors. Pay attention to supplier reviews and ratings to gauge their reputation and reliability.

Step 3: Evaluate Supplier Capabilities

Before committing, assess the capabilities of each supplier. Look for information on their production capacity, lead times, and quality control processes. Request samples to evaluate the quality of their products directly; this step is vital to ensure that the patches meet your standards and expectations.

Step 4: Verify Compliance and Certifications

Ensure that your chosen suppliers comply with relevant industry standards and regulations. Verify if they possess certifications that affirm their adherence to quality and ethical manufacturing practices. This is particularly important in international trade, where compliance with local and international laws can impact your business.

Step 5: Request Detailed Quotes

Once you have shortlisted potential suppliers, request detailed quotes that outline pricing, payment terms, and shipping options. Compare these quotes to assess the overall value offered, not just the price. Look for transparency in pricing to avoid hidden costs that could affect your budget.

Step 6: Discuss Customization Options

If your business requires customized patches, engage in discussions with suppliers regarding their customization capabilities. Clarify aspects such as minimum order quantities, design flexibility, and production timelines. Understanding their process will help you align your branding with the product effectively.

Step 7: Finalize Terms and Place Your Order

After selecting a supplier, negotiate and finalize the terms of your agreement, including delivery timelines, payment methods, and return policies. Ensure that all terms are documented in a contract to protect your interests. Once everything is agreed upon, place your order and maintain communication with the supplier throughout the production process to ensure timely delivery.

Illustrative image related to black sun patch

By following these steps, you can confidently navigate the procurement process for black sun patches, ensuring that your sourcing decisions are well-informed and aligned with your business goals.

Comprehensive Cost and Pricing Analysis for black sun patch Sourcing

What Are the Key Cost Components in Sourcing Black Sun Patches?

When sourcing black sun patches, various cost components contribute to the overall price structure. The primary elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of material significantly impacts cost. Common materials include polyvinyl chloride (PVC), which is durable and weather-resistant. Alternatives like embroidered fabric may increase costs due to higher material and labor expenses.

-

Labor: Labor costs vary by region and production scale. Skilled labor in countries like Germany may demand higher wages, whereas sourcing from regions with lower labor costs, such as parts of Africa or South America, could reduce expenses.

-

Manufacturing Overhead: This encompasses expenses related to the production facility, including utilities, equipment maintenance, and general administrative costs. Efficient production processes can minimize overhead and improve profitability.

-

Tooling: Initial setup costs for custom patches can be significant. This includes molds or dies for specific designs, which are essential for large-volume orders but can add to the upfront investment.

-

Quality Control: Implementing strict QC measures is vital to ensure product consistency and adherence to specifications. While this may add to the overall cost, it can prevent expensive returns and strengthen customer trust.

-

Logistics: Shipping and handling costs can vary widely based on the destination, shipping methods, and Incoterms used. For international buyers, understanding these costs is crucial for accurate budgeting.

-

Margin: Suppliers typically add a markup to cover their expenses and ensure profitability. Margins can fluctuate based on market demand and competition.

How Do Price Influencers Affect Black Sun Patch Costs?

Several factors influence the pricing of black sun patches, which international buyers must consider:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower per-unit costs due to economies of scale. Negotiating MOQs can be advantageous for buyers looking to optimize costs.

-

Specifications and Customization: Customized designs, sizes, and colors can significantly affect pricing. Buyers should clearly communicate their requirements to avoid unexpected costs.

-

Materials and Quality Certifications: Premium materials or certifications (e.g., ISO standards) can increase costs. Buyers should weigh the benefits of quality against budget constraints.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities play a crucial role in pricing. Establishing a relationship with reliable suppliers can lead to better terms and pricing.

-

Incoterms: Understanding shipping terms is essential. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears shipping costs and risks, impacting the total cost.

What Are Effective Buyer Tips for Sourcing Black Sun Patches?

To ensure a cost-effective sourcing process, buyers should consider the following strategies:

-

Negotiation: Engage suppliers in discussions about pricing and terms. Leverage bulk orders or long-term partnerships to negotiate better deals.

-

Cost-Efficiency: Analyze the Total Cost of Ownership (TCO), which includes purchase price, shipping, tariffs, and potential quality issues. This holistic view helps in selecting the best supplier.

-

Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional pricing trends and potential tariffs. Understanding local market conditions can inform better purchasing decisions.

-

Quality Assurance: Prioritize suppliers who provide transparent quality control processes. Request samples to evaluate product quality before committing to larger orders.

-

Research and Comparison: Conduct thorough market research to compare prices and specifications from multiple suppliers. This ensures that buyers receive competitive pricing and quality.

Disclaimer on Pricing

Prices for black sun patches can vary significantly based on the aforementioned factors and are subject to change due to market conditions, supplier pricing strategies, and international trade dynamics. Buyers should verify current pricing with suppliers before making purchasing decisions.

Illustrative image related to black sun patch

Alternatives Analysis: Comparing black sun patch With Other Solutions

Understanding Alternatives for Black Sun Patch Solutions

In the competitive landscape of patches and insignia, B2B buyers often seek alternatives to the ‘black sun patch’ to fulfill various branding, identification, or decorative needs. Understanding these alternatives can empower buyers to make informed decisions that align with their specific requirements and budget constraints.

Comparison Table

| Comparison Aspect | Black Sun Patch | PVC Tactical Patch | Embroidered Patch |

|---|---|---|---|

| Performance | Durable, weather-resistant material | High durability, lightweight | Premium look, softer feel |

| Cost | Moderate (€6 – €16) | Lower (≈ €5 – €10) | Higher (€10 – €20) |

| Ease of Implementation | Simple Velcro application | Easy to attach | Requires careful sewing |

| Maintenance | Low maintenance, easy to clean | Low maintenance | Requires occasional care |

| Best Use Case | Fashion and cultural statements | Military and tactical uses | Formal and decorative settings |

Detailed Breakdown of Alternatives

PVC Tactical Patch

The PVC tactical patch offers a robust alternative to the black sun patch, particularly in demanding environments. Made from dense polyvinyl chloride, these patches are designed to withstand harsh conditions and are often lighter than their fabric counterparts. Their simplicity in attachment via Velcro makes them user-friendly. However, while they are cost-effective and durable, they may lack the aesthetic appeal and softness that some buyers prefer.

Embroidered Patch

Embroidered patches represent a classic option for those seeking a premium look and feel. These patches are crafted with threads stitched into the fabric, providing a tactile experience and a polished appearance. They are often favored for formal occasions or brand representation in professional settings. The downside is their higher cost and the necessity for careful sewing or attachment, which can complicate the implementation process for some users.

Illustrative image related to black sun patch

Conclusion

When evaluating alternatives to the black sun patch, B2B buyers should consider their specific needs, including the desired performance, budget, and context of use. The PVC tactical patch is ideal for those prioritizing durability and cost-effectiveness, while embroidered patches cater to those seeking a high-quality aesthetic. By analyzing these aspects, buyers can select the most suitable patch solution that aligns with their branding or operational objectives.

Essential Technical Properties and Trade Terminology for black sun patch

What Are the Key Technical Properties of a Black Sun Patch?

When considering the procurement of black sun patches, understanding their technical properties is crucial for ensuring product quality and suitability for your specific needs. Here are several essential specifications:

-

Material Composition

Black sun patches are often made from various materials, including dense polyvinyl chloride (PVC), embroidered fabric, or woven polyester. PVC patches, known for their durability and weather resistance, are ideal for outdoor use, while embroidered patches offer a classic aesthetic and softness. Selecting the appropriate material directly affects the patch’s longevity and performance, making it vital for B2B buyers to align material choice with intended applications. -

Size and Dimensions

Common dimensions for black sun patches range from 7 cm to 30 cm in diameter. The size influences visibility and application area, whether for clothing, bags, or promotional items. For businesses, understanding size specifications is essential for ensuring compatibility with products and marketing strategies. -

Fastening Type

Most black sun patches utilize Velcro or heat-seal backing for attachment. Velcro patches allow for easy removal and reapplication, making them suitable for tactical or seasonal use. In contrast, heat-seal patches provide a more permanent solution, ideal for long-term branding. Knowing the fastening method helps businesses select patches that meet their operational needs. -

Color Variations

Black sun patches are available in multiple color combinations, such as black and white, red and black, or olive and black. Color selection can impact brand identity and market appeal, especially in diverse regions like Africa, South America, and Europe. It’s important for buyers to choose colors that resonate with their target audience while maintaining brand consistency. -

Production Tolerance

Tolerance refers to the allowable deviation in size and shape during manufacturing. High-quality patches typically have tighter tolerances, ensuring that each product meets specific standards. For B2B buyers, understanding tolerances can help manage expectations regarding product consistency and quality control. -

Customizability

Many manufacturers offer custom black sun patches, allowing businesses to incorporate unique designs, logos, or text. Customizability is essential for branding and promotional efforts, enabling companies to tailor products to their specific market segments.

What Are Common Trade Terms Related to Black Sun Patches?

Familiarizing yourself with trade terminology is critical for effective communication and negotiation in B2B transactions. Here are several key terms relevant to black sun patches:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or products that are used in another company’s end product. For black sun patches, partnering with an OEM can streamline the production process, ensuring high-quality output tailored to specific brand requirements. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for businesses to gauge inventory needs and budget constraints. For black sun patches, MOQs can vary significantly based on customization and material specifications. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for the cost of specific products or services. Submitting an RFQ for black sun patches allows buyers to compare prices and quality across different manufacturers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in the shipping process. Familiarity with Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is crucial for B2B buyers to understand shipping costs and risk management associated with importing black sun patches. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the product. For black sun patches, lead times can vary based on customization and production schedules. Knowing the lead time is essential for inventory management and planning marketing campaigns. -

Quality Assurance (QA)

QA encompasses the processes that ensure products meet specific quality standards before delivery. For black sun patches, implementing QA measures can help businesses maintain product consistency and enhance customer satisfaction.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing black sun patches, ensuring they select products that align with their strategic goals and operational requirements.

Illustrative image related to black sun patch

Navigating Market Dynamics and Sourcing Trends in the black sun patch Sector

What are the Current Trends and Market Dynamics in the Black Sun Patch Sector?

The black sun patch sector has witnessed a notable surge in demand, driven by a blend of cultural significance and fashion trends across various regions. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly interested in these products due to their unique aesthetic appeal and the subcultures they represent. In Europe, for instance, the black sun symbol has been adopted in various contexts, prompting a rise in custom patch orders that reflect regional identities and movements.

Emerging sourcing trends indicate a shift toward personalization and customization, with buyers favoring patches that resonate with their specific cultural narratives. This trend is further supported by advancements in digital printing and embroidery technologies, enabling suppliers to offer bespoke designs quickly and at scale. Moreover, the rise of e-commerce platforms has simplified the procurement process, allowing businesses to access a global marketplace, thus enhancing competition and driving innovation.

In addition, sustainability has become a focal point, with buyers increasingly prioritizing eco-friendly materials and ethical sourcing practices. Suppliers who can demonstrate a commitment to sustainable production methods and transparent supply chains are likely to gain a competitive edge in this evolving market. As the global landscape continues to change, understanding these dynamics will be critical for B2B buyers looking to capitalize on the opportunities within the black sun patch sector.

How Can Sustainability and Ethical Sourcing Influence B2B Decisions in the Black Sun Patch Market?

Sustainability is becoming a critical factor in the purchasing decisions of B2B buyers in the black sun patch sector. The environmental impact of production processes, particularly in textile manufacturing, has prompted businesses to seek out suppliers who prioritize sustainable practices. This encompasses the use of eco-friendly materials such as organic cotton, recycled polyester, and water-based inks, which minimize the carbon footprint associated with production.

Ethical sourcing is equally important, as businesses look to partner with manufacturers who adhere to fair labor practices and provide safe working conditions. Certifications such as OEKO-TEX, GOTS (Global Organic Textile Standard), and Fair Trade can serve as indicators of a supplier’s commitment to sustainability and ethical practices. By opting for suppliers with these certifications, B2B buyers can not only enhance their brand reputation but also meet the growing consumer demand for responsible sourcing.

Moreover, integrating sustainability into the supply chain can lead to cost efficiencies in the long run. For instance, using less harmful materials can reduce waste disposal costs and improve overall production efficiency. As the black sun patch sector continues to evolve, businesses that embrace sustainable and ethical sourcing will likely find themselves well-positioned to capture market share while contributing positively to environmental and social outcomes.

What is the Historical Context Behind the Black Sun Symbol in B2B Markets?

The black sun symbol has a complex history, often associated with various cultural and ideological movements. Originally rooted in ancient mythology, it has been appropriated by different groups over time, leading to its varied interpretations. In recent years, the symbol has gained prominence in subcultures, particularly within the realms of fashion and music, where it is frequently used in patches and apparel.

Illustrative image related to black sun patch

For B2B buyers, understanding the historical context of the black sun is essential. This knowledge allows for more informed sourcing decisions, particularly when dealing with suppliers who may interpret the symbol differently based on their cultural backgrounds. Additionally, recognizing the symbol’s controversial aspects can help businesses navigate the potential backlash from consumers who may associate it with extremist ideologies.

As the black sun patch sector continues to grow, acknowledging its historical significance can enhance brand storytelling and resonate with target audiences. Engaging with the symbol’s rich narrative can also open up opportunities for collaboration with artists and designers who seek to reinterpret its meaning in contemporary contexts. Thus, a nuanced understanding of the black sun’s history is invaluable for B2B buyers aiming to create authentic and meaningful connections in their markets.

Frequently Asked Questions (FAQs) for B2B Buyers of black sun patch

-

How do I choose the right supplier for black sun patches?

Selecting the right supplier is crucial for ensuring quality and reliability. Start by researching potential suppliers’ reputations, looking for reviews and testimonials from other B2B buyers. Verify their production capabilities and quality assurance processes. Request samples to assess the quality of the patches and confirm that they meet your specifications. Additionally, inquire about their compliance with international trade regulations and ethical standards to ensure a responsible partnership. -

What customization options are available for black sun patches?

Most suppliers offer a variety of customization options, including size, color, and design variations. You can often choose between materials like PVC, embroidered fabric, or Velcro-backed patches. To create a unique product that aligns with your brand, consider discussing your specific requirements with the supplier. Be prepared to provide artwork or design files if you wish to create bespoke patches, and inquire about any associated costs for customization. -

What is the typical minimum order quantity (MOQ) for black sun patches?

The MOQ can vary significantly depending on the supplier and the complexity of the design. Generally, it ranges from 50 to 500 pieces for standard designs. For customized patches, the MOQ may be higher due to setup costs. Always clarify the MOQ with your supplier during initial discussions to ensure it aligns with your purchasing needs and budget. -

How do I ensure quality control when sourcing black sun patches?

Implementing a thorough quality control process is essential. Request samples before placing a bulk order to evaluate the quality firsthand. Establish clear quality standards and communicate them to your supplier. Additionally, consider arranging for third-party inspections during production or before shipment. This proactive approach helps mitigate risks and ensures that the patches meet your specifications. -

What payment terms should I expect when sourcing black sun patches?

Payment terms can vary by supplier and typically include options like upfront payment, partial payments, or letters of credit. Many suppliers may require a deposit before production begins, with the balance due upon completion or before shipment. Ensure you discuss payment methods and terms upfront to avoid misunderstandings. Look for suppliers that offer secure payment options to protect your financial transactions. -

What shipping options are available for international orders of black sun patches?

Shipping options will depend on the supplier’s capabilities and your location. Common methods include air freight for faster delivery or sea freight for more economical shipping on larger orders. Inquire about delivery times, costs, and tracking options. Additionally, ensure the supplier can handle customs documentation and shipping regulations specific to your region to avoid delays. -

Are there any specific regulations or compliance issues for importing black sun patches?

When importing black sun patches, it’s important to be aware of regulations that may apply, such as labeling requirements, material safety standards, and customs duties. Different countries have varying import laws, particularly in regions like the EU, Africa, and South America. Consult with a trade compliance expert to ensure all products meet local regulations and avoid potential legal issues during customs clearance. -

How can I effectively communicate my needs to suppliers of black sun patches?

Clear communication is key to a successful supplier relationship. Prepare a detailed brief outlining your requirements, including design, materials, quantity, and delivery timelines. Use visual aids such as sketches or examples of desired patches to convey your vision accurately. Establish regular communication channels, whether through email, video calls, or messaging apps, to ensure ongoing dialogue and address any concerns promptly.

Top 6 Black Sun Patch Manufacturers & Suppliers List

1. Patch Shop – Baphomet Black Sun

Domain: patch-shop.com

Registered: 2009 (16 years)

Introduction: Product Name: Baphomet black sun 28×28 Cm, Price: 18.00 €; Product Name: Baphomet black sun 9×9 Cm, Price: 5.90 €; Product Name: Black sun 30×30 Cm, Price: 16.70 €; Product Name: Vytis 8×5 Cm, Price: 12.00 €; Product Name: Danko Jones 10×9 Cm, Price: 12.00 €; Product Name: Invunche 9×2 Cm, Price: 12.00 €; Product Name: One Master 3×8 Cm, Price: 12.00 €; Product Name: True Iron Will 9×2 Cm, Price: …

2. Militant – BLACK SUN PATCH

Domain: militant.zone

Introduction: {“name”:”BLACK SUN PATCH”,”price”:”400 ₴ (≈ 8.89 USD)”,”colors”:[“white-black”,”red-black”,”olive”],”material”:”dense polyvinyl chloride (rubber)”,”fastening”:”Velcro”,”diameter”:”7.5 cm (total – 8 cm)”,”sku”:”N/A”,”categories”:[“Accessories”,”Main”,”Patches”],”tags”:[“black sun”,”patch”]}

3. BLACK SUN – Patch from Ukraine

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“product_name”: “BLACK SUN Patch”, “seller”: “fromukraine2022”, “price”: “US $17.00 or Best Offer”, “condition”: “New”, “quantity_available”: 2, “shipping_cost”: “US $10.00 Standard International Shipping”, “location”: “Kyev, Ukraine”, “estimated_delivery”: “between Mon, Oct 13 and Wed, Nov 5”, “returns_policy”: “Seller does not accept returns”, “item_number”: “357280307664”, “seller_feedback”: {…

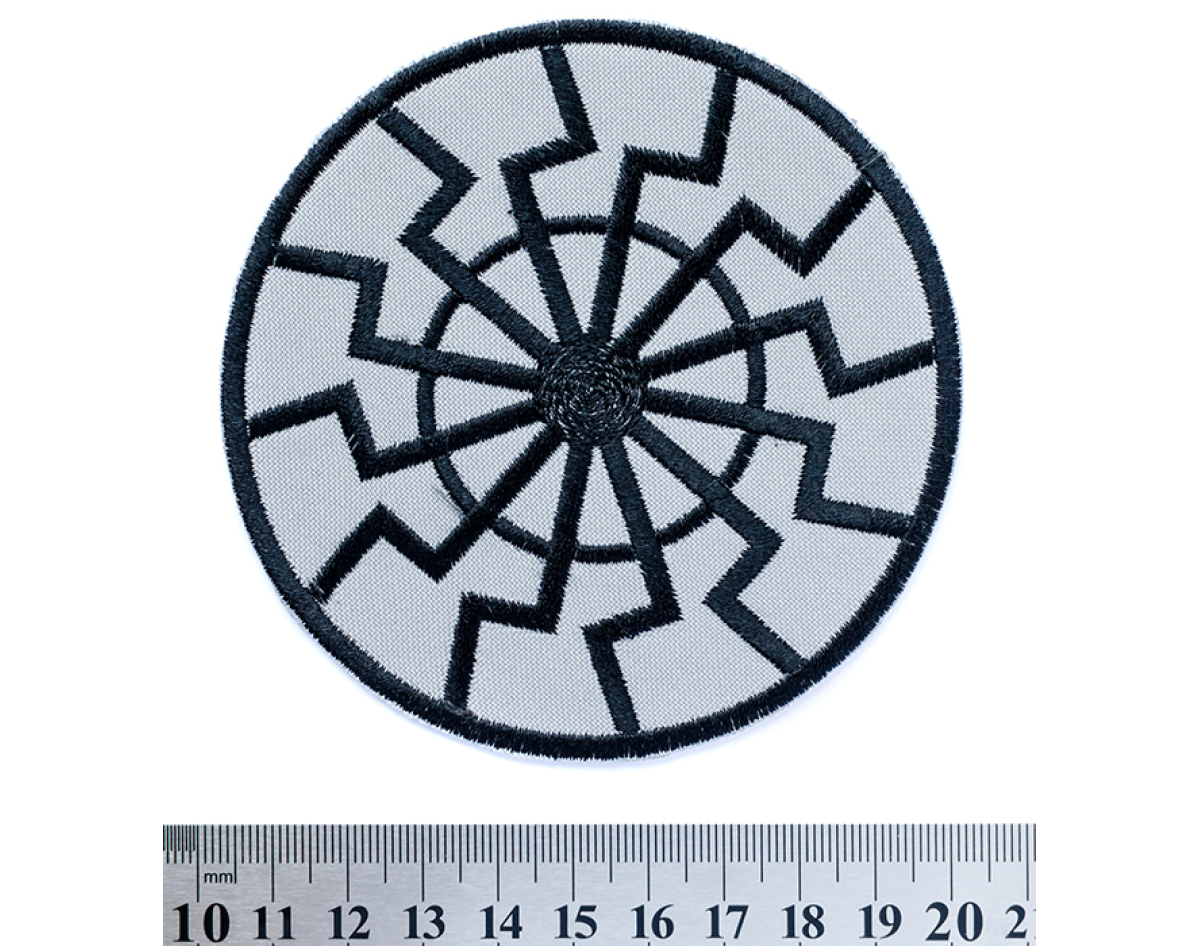

4. Spe Tactical Surplus – Black Sun Embroidered Patch

Domain: spe-tactical-surplus.com

Registered: 2018 (7 years)

Introduction: {‘name’: ‘Black Sun embroidered patch’, ‘part_number’: ‘926’, ‘price’: ‘$8.95’, ‘availability’: ‘In Stock’, ‘size’: ’70mm’, ‘color’: ‘Black/White’, ‘backing’: ‘Velcro’, ‘made_in’: ‘Ukraine’, ‘description’: ‘The Black Sun is a very ambiguous and complex symbol with several variants of meaning and origin. It is found in medieval alchemy as a metaphor for self-knowledge and is also an ancient Nordic …

5. Reddit – Ukrainian Soldier with Black Sun Patch

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Ukrainian female soldier wearing a Black Sun patch

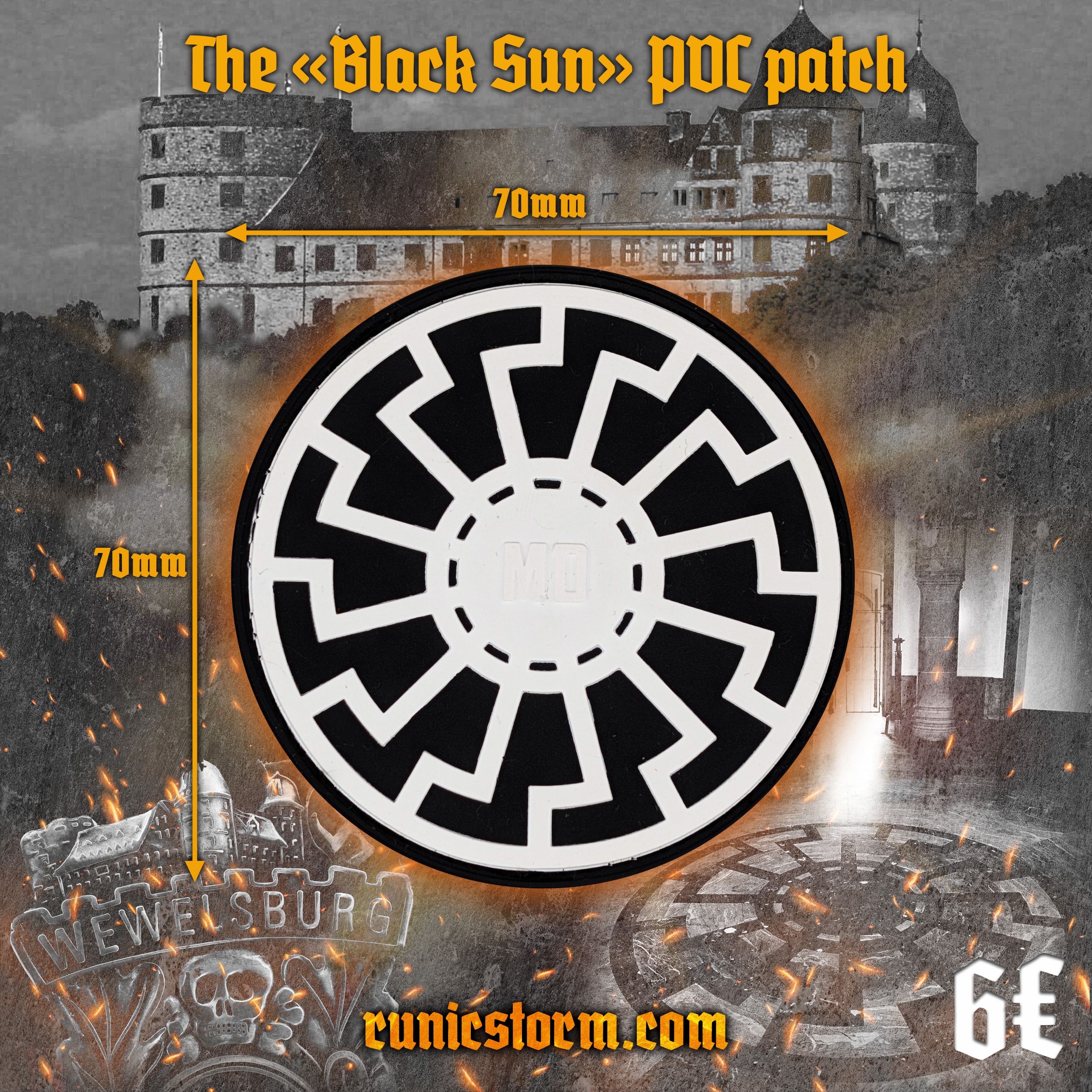

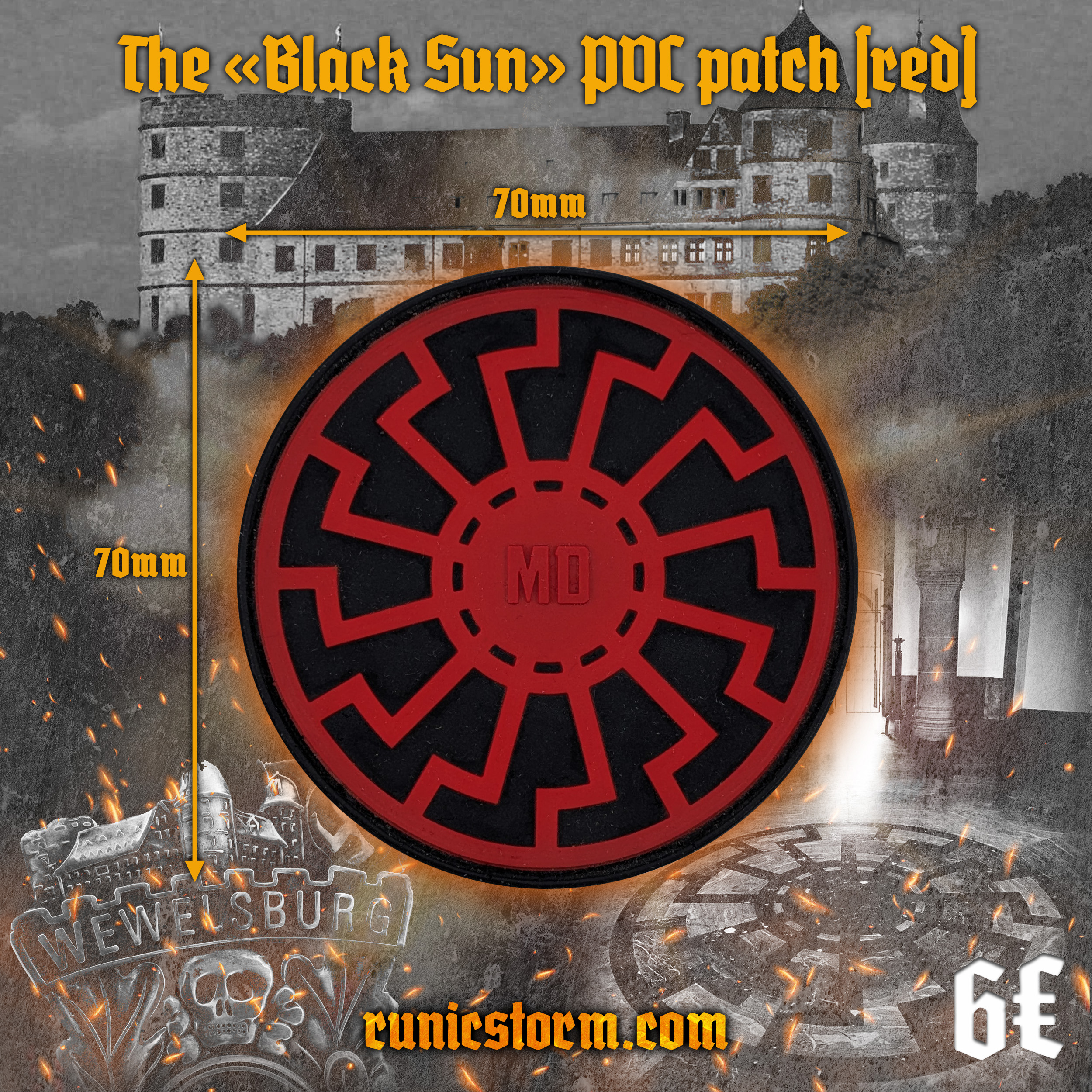

6. Runic Storm – The Black Sun PVC Patch

Domain: runicstorm.com

Registered: 2023 (2 years)

Introduction: {“product_name”: “The Black Sun PVC patch”, “price”: “€ 6.00”, “size”: “70×70 mm”, “age_restriction”: “Over 18 y.o. only”, “limited_edition”: “no”, “description”: “Embrace European Pride: Our clothing line celebrates European heritage and nationalist ideals. Crafted in Europe: Each garment is meticulously crafted in Europe, reflecting our commitment to quality and supporting local artisans. Streng…

Strategic Sourcing Conclusion and Outlook for black sun patch

In conclusion, the strategic sourcing of black sun patches offers a unique opportunity for international B2B buyers, particularly in emerging markets such as Africa, South America, the Middle East, and Europe. These patches, available in various materials and designs, cater to a diverse range of consumer preferences, from military and biker communities to those embracing cultural symbolism. By understanding the distinct product offerings and their cultural significance, buyers can better align their sourcing strategies with market demands.

The value of strategic sourcing cannot be overstated; it enhances supplier relationships, optimizes costs, and ensures product quality. As buyers navigate the complexities of the global supply chain, leveraging local suppliers while considering international partnerships can yield significant competitive advantages.

Looking ahead, the demand for black sun patches is expected to grow, fueled by increasing interest in cultural and identity-based products. We encourage B2B buyers to actively explore partnerships with reputable suppliers, embrace customization options, and stay ahead of market trends to capitalize on this burgeoning niche. By doing so, businesses can not only enhance their product offerings but also foster a deeper connection with their customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.