Bison Gear & Engineering Corp. Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for bison gear & engineering corp.

In today’s competitive landscape, international B2B buyers face the challenge of sourcing reliable and high-performance gear motors and engineering solutions, particularly from established manufacturers like Bison Gear & Engineering Corp. This comprehensive guide is designed to empower businesses across Africa, South America, the Middle East, and Europe—regions that are increasingly seeking innovative and durable motion control solutions. By delving into Bison’s extensive product range, which includes over 1,000 customizable gearmotors, motors, and reducers, buyers can gain insights into selecting the right components tailored to their specific applications.

This guide will cover essential aspects of the procurement process, including types of products available, applications across various industries such as food and beverage, transportation, and agriculture, as well as strategies for effective supplier vetting. Additionally, we will explore cost considerations, ensuring that buyers can make informed financial decisions without compromising on quality.

Ultimately, this resource equips B2B buyers with the knowledge and tools necessary to navigate the complexities of sourcing from Bison Gear & Engineering Corp., fostering partnerships that drive efficiency and innovation in their operations. With Bison’s commitment to engineering excellence and customer service, buyers can confidently integrate these advanced solutions into their projects, ensuring optimal performance and reliability.

Understanding bison gear & engineering corp. Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 200 Series Inline Parallel Shaft Gearmotors | Rugged construction, high torque output, over 1,000 standard configurations available. | Food & beverage processing, material handling. | Pros: Versatile, trusted design; Cons: May require customization for specific applications. |

| 261 Series Sanimotor | IP69K rated stainless steel shell, designed for washdown environments. | Food processing, pharmaceutical industries. | Pros: Durable and hygienic; Cons: Higher upfront cost due to specialized materials. |

| VFsync PMAC Motors | Lightweight, compact design, advanced velocity control. | Automation, robotics, and precision machinery. | Pros: Space-saving, cost-effective compared to servo motors; Cons: Might need additional integration support. |

| Hypoid Gear Motors | High torque density, quiet operation, and high efficiency. | Conveying systems, automotive applications. | Pros: Efficient and quiet; Cons: Complexity may increase installation time. |

| Washdown Gearmotors | IP69K rated for extreme washdown conditions, stainless steel. | Food processing, beverage manufacturing. | Pros: Excellent for hygiene-sensitive environments; Cons: Limited to specific applications due to washdown focus. |

What Are the Characteristics of the 200 Series Inline Parallel Shaft Gearmotors?

The 200 Series Inline Parallel Shaft Gearmotors are known for their rugged construction and high torque output, making them a preferred choice across various industries. With over 1,000 standard configurations, these gearmotors can cater to diverse applications, particularly in food and beverage processing and material handling. Buyers should consider their specific torque and speed requirements, as customization may be necessary for niche applications. Their proven reliability over decades enhances their appeal for businesses seeking consistent performance.

How Does the 261 Series Sanimotor Stand Out in Sanitary Applications?

The 261 Series Sanimotor is specially designed for sanitary applications, featuring an IP69K rated stainless steel shell that ensures durability in washdown environments. This makes it ideal for industries such as food processing and pharmaceuticals, where hygiene is paramount. While the initial investment may be higher due to its advanced materials, the long-term benefits of reduced maintenance and compliance with health regulations can justify the cost for B2B buyers.

Why Are VFsync PMAC Motors a Game Changer in Automation?

VFsync PMAC Motors offer a lightweight and compact design that provides advanced velocity control, making them suitable for high-tech automated machines. With a size advantage over traditional 3-phase induction motors, these motors allow for greater mounting versatility. Businesses focused on automation and robotics should assess their integration needs, as these motors may require additional technical support for optimal performance. Their cost-effectiveness compared to servo motors is a significant consideration for budget-conscious buyers.

What Advantages Do Hypoid Gear Motors Offer?

Hypoid Gear Motors are characterized by their high torque density, quiet operation, and efficiency, making them an excellent choice for conveying systems and automotive applications. Their design allows for compact installations while delivering robust performance. However, the complexity of these systems may lead to longer installation times, which should be factored into project timelines. Buyers seeking efficient and quiet solutions will find these motors particularly advantageous.

How Do Washdown Gearmotors Ensure Compliance in Sensitive Environments?

Washdown Gearmotors are engineered to meet the rigorous demands of hygiene-sensitive environments, featuring an IP69K rating that protects against high-pressure and high-temperature washdowns. These gearmotors are essential for food processing and beverage manufacturing, where cleanliness is critical. While their specialized design limits their use to specific applications, the benefits of maintaining stringent hygiene standards make them a worthwhile investment for businesses in these sectors.

Key Industrial Applications of bison gear & engineering corp.

| Industry/Sector | Specific Application of Bison Gear & Engineering Corp. | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Sanitation-compliant gearmotors for processing equipment | Ensures hygienic operations, reducing contamination risks | IP69K rating, stainless steel construction, and washdown capability |

| Transportation | Gear motors for conveyor systems in logistics and material handling | Enhances efficiency and reliability in transporting goods | Load capacity, torque specifications, and integration capabilities |

| Agriculture | Custom gear motors for irrigation systems | Improves water management and operational efficiency | Durability in outdoor environments, energy efficiency, and customization options |

| Automation & Robotics | High-precision motors for robotic arms and automated machinery | Increases productivity and precision in manufacturing processes | Size constraints, power requirements, and compatibility with existing systems |

| Mining & Heavy Industry | Robust gear reducers for heavy machinery | Enhances performance and longevity under extreme conditions | Load ratings, environmental resistance, and maintenance support |

How Does Bison Gear & Engineering Corp. Serve the Food & Beverage Industry?

In the food and beverage sector, Bison’s sanitation-compliant gearmotors play a critical role in ensuring that processing equipment meets stringent hygiene standards. The proprietary 261 Series Sanimotor, designed for washdown environments, helps mitigate contamination risks while maintaining operational efficiency. For international buyers, especially in regions like Africa and the Middle East, sourcing gearmotors that comply with local food safety regulations is essential. Buyers should prioritize IP69K-rated products to ensure reliability in demanding environments.

What Are the Applications of Bison Gear Motors in Transportation?

Bison gear motors are integral to conveyor systems used in logistics and material handling. They enhance the efficiency and reliability of transporting goods, crucial for businesses in fast-paced environments. For buyers in South America and Europe, understanding the load capacity and torque specifications is vital for selecting the right motor. Additionally, integration capabilities with existing systems can significantly streamline operations, making Bison a preferred partner for transportation solutions.

How Does Bison Gear Address Agricultural Needs?

In agriculture, Bison’s custom gear motors are essential for efficient irrigation systems. These motors improve water management, contributing to higher crop yields and operational efficiency. Buyers from regions like Nigeria should consider the durability of these motors in outdoor environments and their energy efficiency to optimize costs. Customization options allow for tailored solutions that meet specific agricultural demands, ensuring that operations run smoothly.

What Role Does Bison Play in Automation & Robotics?

Bison’s high-precision motors are designed for robotic arms and automated machinery, significantly increasing productivity and precision in manufacturing processes. For international buyers, particularly in Europe, the size constraints and power requirements of these motors are critical factors to evaluate. Compatibility with existing systems ensures seamless integration, making Bison an attractive choice for companies looking to enhance automation capabilities.

How Are Bison Gear Reducers Beneficial in Mining & Heavy Industry?

In mining and heavy industry, Bison’s robust gear reducers are engineered to perform under extreme conditions, enhancing both performance and longevity. These reducers are essential for heavy machinery, providing the necessary torque and load ratings to handle demanding applications. Buyers in the Middle East should prioritize environmental resistance and maintenance support when sourcing gear reducers, ensuring that their equipment remains operational in harsh environments.

3 Common User Pain Points for ‘bison gear & engineering corp.’ & Their Solutions

Scenario 1: Customization Challenges in Gearmotor Selection

The Problem: B2B buyers often encounter difficulties when selecting the right gearmotor for specific applications, especially in industries like food and beverage or transportation. With a myriad of options available, the challenge lies in not only identifying the right product specifications but also ensuring that the gearmotor will perform optimally under unique operational conditions. Buyers may worry about compatibility with existing systems, the durability of components in harsh environments, and the potential for inefficiencies that could lead to increased operational costs.

The Solution: To overcome these challenges, Bison Gear & Engineering Corp. offers a robust customization process. Buyers should engage directly with Bison’s engineering team early in the product selection phase. This collaboration allows for a detailed assessment of application requirements, including torque, speed, and environmental factors. Bison’s commitment to providing tailored solutions means that their team can recommend the appropriate gearmotor configuration or develop a custom solution that integrates seamlessly into the buyer’s existing systems. Additionally, utilizing Bison’s extensive catalog of over 1,000 standard products can help narrow down options based on proven performance in similar applications. By leveraging these resources, buyers can ensure that they choose the right gearmotor to meet their specific needs while avoiding costly trial-and-error.

Scenario 2: Integration Difficulties with Existing Systems

The Problem: Many companies struggle with integrating new gearmotors and motors into their existing production lines, particularly when transitioning from outdated or incompatible systems. This integration challenge can lead to prolonged downtime, increased labor costs, and even disruptions in production schedules. Furthermore, buyers often face uncertainty regarding the necessary modifications or support needed to ensure a smooth integration process.

The Solution: Bison Gear & Engineering Corp. provides comprehensive integration support, which is crucial for buyers facing this scenario. When procuring new gearmotors, buyers should not hesitate to consult with Bison’s technical support team. By providing information about their current systems and the desired outcomes, buyers can receive tailored guidance on installation procedures and potential modifications. Bison’s engineers can also assist in designing custom mounting solutions or recommending compatible components that streamline the integration process. Additionally, taking advantage of Bison’s rapid prototyping and performance testing services can help buyers validate the integration before full-scale implementation, ensuring that their production lines remain efficient and minimizing the risk of costly downtimes.

Scenario 3: Performance Reliability Concerns in Harsh Environments

The Problem: In sectors such as agriculture and food processing, equipment is often exposed to harsh conditions, including moisture, dust, and extreme temperatures. Buyers frequently express concerns about the reliability and longevity of gearmotors in these environments, fearing that inadequate protection could lead to premature failures and costly maintenance. These concerns are particularly pronounced in regions with challenging climates, such as parts of Africa and the Middle East.

The Solution: Bison addresses these reliability concerns by offering a range of IP69K-rated washdown gearmotors and stainless-steel components specifically designed for harsh conditions. Buyers should prioritize these products when operating in environments susceptible to moisture and contaminants. To ensure optimal performance, it is advisable to consult with Bison’s engineering team to understand the specific environmental challenges and select the most appropriate solutions. Furthermore, implementing a routine maintenance schedule and utilizing Bison’s support for operational training can help maximize the lifespan of the equipment. By proactively addressing environmental factors and leveraging Bison’s specialized products, buyers can significantly enhance their operational reliability and reduce long-term costs associated with equipment failures.

Strategic Material Selection Guide for bison gear & engineering corp.

What Are the Key Properties of Common Materials Used in Bison Gear & Engineering Corp. Products?

Bison Gear & Engineering Corp. utilizes a variety of materials in its gearmotors, motors, and reducers to ensure optimal performance across diverse applications. Below are analyses of three common materials: stainless steel, aluminum, and cast iron.

How Does Stainless Steel Enhance Product Performance?

Stainless steel is renowned for its exceptional corrosion resistance and strength, making it an ideal choice for applications in harsh environments, such as food and beverage processing. Its temperature rating can exceed 300°C, and it can withstand high pressure, which is vital for gearmotors operating in demanding conditions.

Pros: The durability of stainless steel means it has a long lifespan, reducing the need for frequent replacements. Its hygienic properties make it suitable for washdown applications, which is critical in industries where cleanliness is paramount.

Cons: The primary drawback is its cost, which is higher than other materials. Additionally, manufacturing complexity can increase due to the need for specialized tooling and processes.

Impact on Application: Stainless steel’s corrosion resistance makes it ideal for environments exposed to moisture and chemicals, ensuring the longevity of the equipment.

Considerations for International Buyers: Buyers from regions like Saudi Arabia and Nigeria should ensure compliance with local standards, such as ASTM or DIN, especially when dealing with food-grade applications.

What Advantages Does Aluminum Offer in Gearmotors?

Aluminum is a lightweight material that provides excellent strength-to-weight ratios, making it suitable for applications requiring mobility and efficiency. It typically has a temperature rating up to 150°C and is resistant to corrosion, particularly when anodized.

Pros: The lightweight nature of aluminum allows for easier handling and installation, which can reduce labor costs. It also offers good thermal conductivity, aiding in heat dissipation.

Cons: While aluminum is durable, it is not as strong as stainless steel or cast iron, making it less suitable for heavy-duty applications. Its cost is moderate, but the performance trade-offs may not justify its use in all scenarios.

Impact on Application: Aluminum is best suited for applications where weight is a critical factor, such as in transportation or robotics.

Considerations for International Buyers: Buyers in Europe may prefer aluminum due to its recyclability and lower environmental impact, aligning with EU sustainability goals.

How Does Cast Iron Compare in Terms of Durability?

Cast iron is known for its exceptional durability and ability to withstand high loads, making it a popular choice for heavy-duty gearmotors. Its temperature rating can reach around 200°C, and it offers good wear resistance.

Pros: The robustness of cast iron translates to a long operational life, making it a cost-effective option for high-load applications. Its vibration-damping properties also enhance performance in dynamic environments.

Cons: Cast iron is heavier than both stainless steel and aluminum, which can complicate installation and handling. It is also more prone to corrosion if not properly coated or maintained.

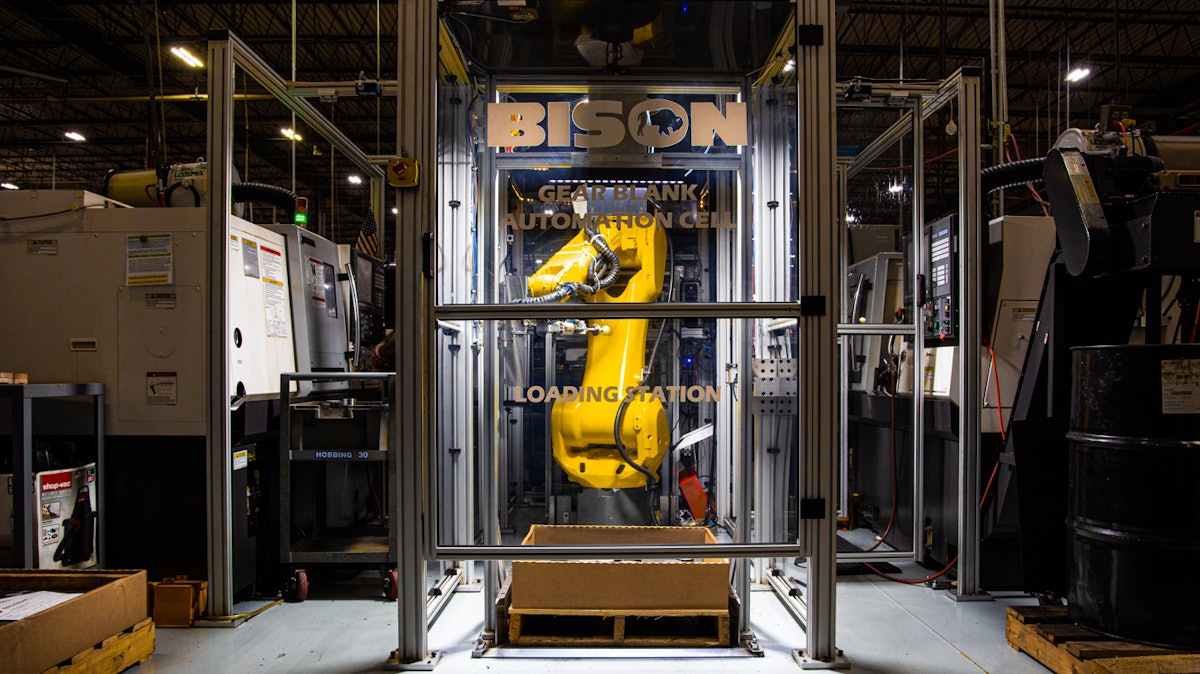

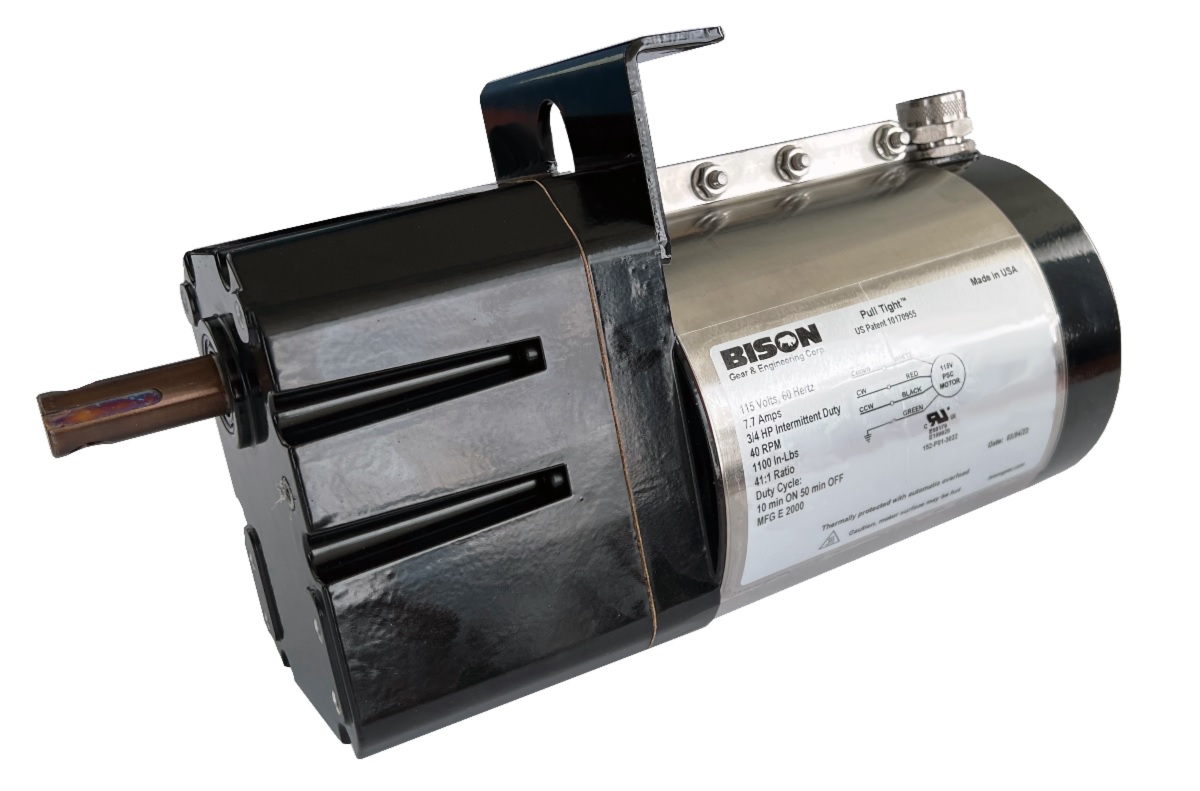

Illustrative image related to bison gear & engineering corp.

Impact on Application: Cast iron is ideal for applications in heavy machinery or industrial settings where durability and load-bearing capacity are essential.

Considerations for International Buyers: Buyers in South America and Africa should consider the availability of cast iron and the associated costs for transportation and installation, especially in remote areas.

Summary Table of Material Selection

| Material | Typical Use Case for Bison Gear & Engineering Corp. | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Food and beverage processing gearmotors | Exceptional corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Lightweight gearmotors in robotics | Lightweight and good thermal conductivity | Less strength for heavy-duty applications | Medium |

| Cast Iron | Heavy-duty industrial gearmotors | High durability and load-bearing capacity | Heavier and prone to corrosion if uncoated | Medium |

This strategic material selection guide provides international B2B buyers with critical insights into the materials used in Bison Gear & Engineering Corp. products, enabling informed decisions based on application requirements and regional considerations.

Illustrative image related to bison gear & engineering corp.

In-depth Look: Manufacturing Processes and Quality Assurance for bison gear & engineering corp.

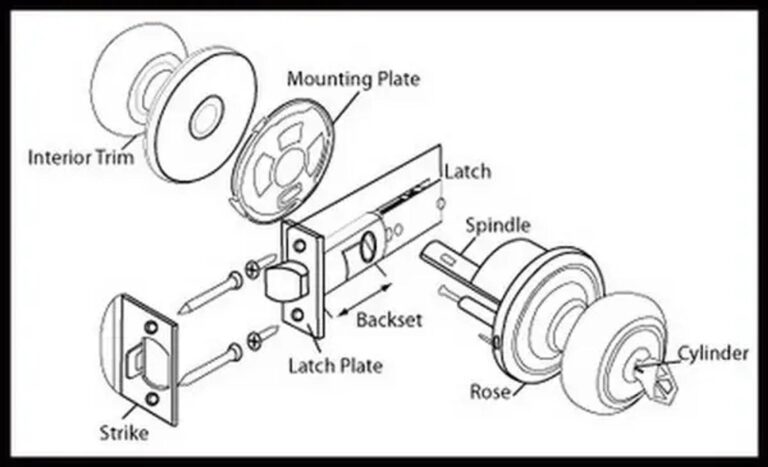

What Are the Key Stages in the Manufacturing Process of Bison Gear & Engineering Corp.?

Bison Gear & Engineering Corp. employs a rigorous manufacturing process characterized by several critical stages: material preparation, forming, assembly, and finishing. Each stage is designed to optimize efficiency and ensure the high quality of the final products.

-

Material Preparation: The manufacturing process begins with the selection of high-grade materials. Bison utilizes advanced materials such as stainless steel and various alloys that enhance durability and performance in demanding environments. The materials undergo thorough inspection to ensure they meet specific engineering standards before moving to the next stage.

-

Forming: This stage involves shaping the prepared materials into components that will form the core of the gearmotors and other products. Bison employs techniques like precision machining, casting, and forging, depending on the required specifications of each component. Advanced CNC machines are often used to ensure high accuracy and repeatability in forming processes.

-

Assembly: Once the individual components are ready, they are meticulously assembled. Skilled technicians utilize automated assembly lines and manual assembly techniques to ensure each gearmotor, reducer, or motor meets stringent design specifications. The assembly process also incorporates real-time monitoring to identify any discrepancies immediately.

-

Finishing: The final stage involves surface treatments and coatings that enhance the products’ resistance to environmental factors. Techniques such as anodizing, painting, and polishing are employed to achieve the desired finish. This not only improves aesthetics but also ensures longevity, especially in washdown environments prevalent in food and beverage industries.

How Does Bison Gear & Engineering Ensure Quality Control?

Quality assurance is a cornerstone of Bison’s manufacturing ethos. The company adheres to several international and industry-specific standards, ensuring that every product meets the highest benchmarks for quality and performance.

-

International Standards Compliance: Bison is committed to maintaining ISO 9001 certification, which signifies a robust quality management system. This certification ensures that the company consistently meets customer and regulatory requirements while enhancing customer satisfaction through effective processes.

-

Industry-Specific Standards: In addition to ISO 9001, Bison products comply with other standards relevant to specific industries. For instance, CE marking indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area (EEA). Additionally, certain products may meet API (American Petroleum Institute) standards, particularly those used in the oil and gas sector.

What Are the Key Quality Control Checkpoints in Bison’s Manufacturing Process?

Bison implements multiple quality control checkpoints throughout the manufacturing process to ensure that all products meet rigorous standards. These checkpoints include Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

-

Incoming Quality Control (IQC): Before production begins, raw materials and components undergo IQC to verify their quality and compliance with specifications. This step prevents substandard materials from entering the production line.

-

In-Process Quality Control (IPQC): During manufacturing, IPQC checks are conducted at various stages to monitor processes and identify any defects early. This proactive approach allows for immediate corrective actions, minimizing waste and ensuring consistency.

-

Final Quality Control (FQC): After assembly, every product is subjected to FQC, which includes rigorous testing and inspection. This may involve performance testing, load testing, and safety checks to ensure that the final product meets all operational requirements.

What Common Testing Methods Are Utilized by Bison Gear & Engineering?

Bison employs several common testing methods to validate the performance and reliability of its products. These methods include:

-

Performance Testing: Gearmotors and motors undergo tests to ensure they meet the specified torque, speed, and efficiency ratings. This testing simulates real-world conditions to assess performance under load.

-

Durability Testing: Products are subjected to stress tests to evaluate their durability over extended periods. This may involve simulating extreme operational conditions to assess the longevity of components.

-

Environmental Testing: For products designed for harsh environments, such as the IP69K rated gearmotors, environmental testing ensures they can withstand moisture, dust, and extreme temperatures without compromising functionality.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Here are actionable steps to ensure compliance and reliability:

-

Supplier Audits: Conducting audits of the supplier’s manufacturing facilities can provide insight into their quality management systems and practices. This can include examining their adherence to ISO certifications and other relevant standards.

-

Requesting Quality Reports: B2B buyers should request detailed quality control reports that outline the supplier’s testing methodologies, results, and any corrective actions taken. These reports can provide transparency regarding the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection agencies can offer an unbiased evaluation of the supplier’s products and processes. These agencies can verify compliance with international standards and provide certification for the products.

What Are the Quality Control Considerations for International Buyers?

International buyers should be aware of specific quality control nuances when sourcing from Bison Gear & Engineering Corp. Each region may have distinct regulatory requirements that must be met. For example:

-

Regulatory Compliance: Buyers in the European market should ensure that products meet CE marking requirements, while those in the Middle East might need to consider local certification standards.

-

Cultural and Communication Factors: Understanding cultural differences in business practices can aid in establishing effective communication regarding quality expectations. Clear specifications and agreements can help mitigate misunderstandings.

-

Post-Sales Support: Assessing the supplier’s post-sales support capabilities is essential. Buyers should ensure that the supplier offers reliable customer service, warranty options, and availability of spare parts to maintain product performance over time.

In conclusion, Bison Gear & Engineering Corp. maintains a comprehensive manufacturing and quality assurance process designed to meet the diverse needs of its international B2B clientele. By understanding these processes and quality control measures, buyers can make informed decisions that align with their operational requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bison gear & engineering corp.’

To assist B2B buyers in successfully procuring products from Bison Gear & Engineering Corp., this guide outlines essential steps to follow. Whether you’re sourcing gearmotors, motors, or custom solutions, adhering to this checklist will streamline your purchasing process and ensure you receive high-quality products tailored to your needs.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the products you need. This includes understanding the type of motor or gear reducer required, power ratings, torque specifications, and environmental conditions (e.g., washdown capabilities for food and beverage applications). Accurate specifications will help suppliers provide precise solutions that meet your operational demands.

Step 2: Research Bison’s Product Range

Familiarize yourself with Bison’s extensive product catalog, which includes over 1,000 standard gearmotors and customizable options. Identify which products align with your specifications, such as the popular 200 Series Inline Parallel Shaft Gearmotors or the IP69K rated Sanimotor for washdown applications. Understanding the product offerings will enable you to make informed decisions when discussing options with suppliers.

Step 3: Evaluate Supplier Capabilities

Assess Bison’s ability to meet your requirements by reviewing their engineering expertise and customization options. Engage with their technical team to discuss your specific needs and ensure they can provide tailored solutions. Look for evidence of their experience in your industry, such as case studies or testimonials from similar applications.

Step 4: Verify Certifications and Quality Standards

Ensure that Bison Gear & Engineering Corp. adheres to relevant industry certifications and quality standards. This includes ISO certifications and compliance with safety regulations pertinent to your region. Verification of these credentials not only guarantees product quality but also mitigates risks associated with non-compliance.

Step 5: Request Prototypes and Performance Tests

Before finalizing your order, request prototypes or samples of the products you intend to purchase. Bison’s commitment to rapid prototyping and performance testing can help you assess the suitability of their products in your applications. Evaluate how well the prototypes perform under your specific conditions and gather data to support your final decision.

Step 6: Discuss Pricing and Terms of Sale

Engage in discussions about pricing, payment terms, and delivery schedules. Understanding the total cost of ownership, including shipping and potential tariffs, is crucial for budgeting. Be sure to clarify warranty terms and support services offered by Bison to ensure you have comprehensive coverage post-purchase.

Step 7: Establish a Communication Plan

Finally, create a communication plan with your Bison representative to facilitate smooth interactions throughout the procurement process. Regular updates on production timelines, shipping schedules, and any potential issues will help maintain transparency and build a strong partnership. This proactive approach ensures that you remain informed and can address any concerns promptly.

Illustrative image related to bison gear & engineering corp.

By following this checklist, international B2B buyers can effectively navigate the sourcing process with Bison Gear & Engineering Corp., ensuring a successful procurement experience that meets their technical and operational needs.

Comprehensive Cost and Pricing Analysis for bison gear & engineering corp. Sourcing

What Are the Key Cost Components in Bison Gear & Engineering Corp. Products?

When analyzing the cost structure of Bison Gear & Engineering Corp., it’s essential to consider various components that contribute to the overall pricing of their gearmotors and related products. The main cost components include:

-

Materials: The quality and type of materials used, such as high-grade stainless steel for washdown products, significantly influence costs. Additionally, specialized components for custom solutions may also increase material costs.

-

Labor: Skilled labor is required for manufacturing and assembly processes, particularly given Bison’s focus on high-quality engineering and custom solutions. Labor costs can vary depending on the region where manufacturing occurs, impacting pricing for international buyers.

-

Manufacturing Overhead: This includes costs related to facilities, utilities, and equipment maintenance. Bison’s investment in state-of-the-art engineering labs and manufacturing flexibility also plays a role in determining overhead costs.

-

Tooling: The initial costs associated with tooling for custom designs or modifications can be substantial. This is particularly relevant for clients requiring tailored solutions to meet specific operational needs.

-

Quality Control (QC): Bison’s commitment to high standards necessitates rigorous QC processes, which contribute to overall costs. Certifications and compliance with industry standards also add to the QC expenditure.

-

Logistics: International shipping and handling can significantly affect the final price, especially for buyers from regions such as Africa, South America, and the Middle East. Understanding local import duties and regulations is crucial.

-

Margin: Bison’s pricing strategy includes a margin that reflects their brand value, engineering expertise, and market positioning. This margin can vary depending on the product line and market demand.

What Price Influencers Should Buyers Consider When Sourcing from Bison?

Several factors influence the pricing of Bison’s products, which B2B buyers should consider:

-

Volume/MOQ: Pricing is often tiered based on order volume. Larger orders may qualify for discounts, making it essential for buyers to evaluate their needs against minimum order quantities (MOQs).

-

Specifications and Customization: Customized products typically come at a premium. Buyers must weigh the benefits of tailored solutions against standard product offerings.

-

Materials: The choice of materials can affect both performance and cost. Premium materials may enhance durability but will also increase initial costs.

-

Quality and Certifications: Compliance with local and international standards can add to the cost but may be necessary for specific applications, especially in regulated industries.

-

Supplier Factors: The reliability and reputation of Bison as a supplier can impact pricing. Established suppliers with a proven track record may command higher prices but offer greater assurance of product quality and service.

-

Incoterms: Understanding the terms of shipment and delivery is crucial for international buyers. Incoterms dictate the responsibilities of buyers and sellers concerning shipping costs, insurance, and risk.

What Are the Best Negotiation Tips for International B2B Buyers?

To optimize costs when sourcing from Bison Gear & Engineering Corp., consider the following negotiation strategies:

-

Leverage Volume Discounts: If possible, consolidate orders to meet higher volume thresholds that can trigger discounts.

-

Discuss Customization Options: Engage with Bison’s engineering team to explore cost-effective solutions that meet your specifications without unnecessary customization.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the upfront costs but also the long-term savings associated with product durability, energy efficiency, and maintenance costs.

-

Understand Pricing Nuances: Familiarize yourself with the pricing structure specific to your region. Factors such as local currency fluctuations and import tariffs can significantly impact overall costs.

-

Build Relationships: Establishing a strong partnership with Bison can lead to better pricing and more favorable terms over time, especially for repeat business.

Disclaimer on Pricing Information

Prices may vary based on market conditions, customization, and specific buyer requirements. It is advisable for buyers to request formal quotes to ensure accuracy and to account for any additional factors influencing the final pricing.

Alternatives Analysis: Comparing bison gear & engineering corp. With Other Solutions

Understanding Alternatives in Power Transmission Solutions

When considering power transmission solutions, businesses must evaluate various options to find the best fit for their operational needs. Bison Gear & Engineering Corp. is a prominent player in this market, offering a range of gearmotors and related products tailored for diverse applications. However, it’s essential to compare Bison’s offerings against other viable alternatives to ensure informed decision-making. This analysis will explore two notable alternatives: SEW-Eurodrive and Nord Drivesystems, both respected manufacturers in the motion control industry.

Comparison Table

| Comparison Aspect | Bison Gear & Engineering Corp. | SEW-Eurodrive | Nord Drivesystems |

|---|---|---|---|

| Performance | High torque output, customizable solutions | Excellent torque and efficiency; extensive product range | High efficiency and reliability across various applications |

| Cost | Competitive pricing, custom solutions can increase cost | Generally higher cost; premium brand positioning | Mid-range pricing; good value for quality |

| Ease of Implementation | Strong engineering support for integration | Comprehensive training and support available | User-friendly installation with extensive documentation |

| Maintenance | Low maintenance with robust designs | Requires regular service; some parts can be costly | Easy maintenance with accessible parts and support |

| Best Use Case | Food & beverage, automation, transportation | Heavy industry, material handling | Logistics, automotive, and industrial applications |

In-Depth Look at Alternatives

What Are the Advantages and Disadvantages of SEW-Eurodrive?

SEW-Eurodrive is well-regarded for its performance and extensive range of products, making it suitable for heavy industrial applications. The company offers high torque and efficiency, often leading the market in terms of reliability. However, this comes at a cost, as their products tend to be priced higher than average. Additionally, while SEW provides excellent training and support, the need for regular maintenance can be a downside for companies seeking low-maintenance solutions.

How Does Nord Drivesystems Compare?

Nord Drivesystems is another strong alternative known for its high efficiency and reliability. Their products are particularly favored in logistics and automotive applications due to their robust design and user-friendly installation process. The pricing is generally mid-range, providing good value without compromising quality. One of the notable advantages is their commitment to easy maintenance, which can reduce long-term operational costs. However, companies may find that their product range is not as extensive as that of Bison or SEW, which could limit options in specific applications.

How Can B2B Buyers Choose the Right Solution?

When selecting the right power transmission solution, B2B buyers should consider their specific operational needs, budget constraints, and maintenance capabilities. Bison Gear & Engineering Corp. stands out for its customizable solutions and strong engineering support, making it ideal for companies with unique requirements. SEW-Eurodrive is best suited for those in heavy industries who prioritize performance and are willing to invest in premium solutions. Conversely, Nord Drivesystems offers an excellent balance of efficiency and ease of maintenance, appealing to businesses looking for reliable yet cost-effective options.

Ultimately, the choice will depend on a thorough assessment of each alternative’s strengths and weaknesses in relation to the specific demands of the buyer’s industry.

Essential Technical Properties and Trade Terminology for bison gear & engineering corp.

What Are the Key Technical Properties of Bison Gear & Engineering Products?

Understanding the technical properties of Bison Gear & Engineering products is crucial for B2B buyers in various industries. Here are some essential specifications that highlight the quality and suitability of Bison’s offerings:

-

Material Grade

– Bison gearmotors and components often utilize high-grade materials such as stainless steel (IP69K rated) for washdown applications. This material grade ensures durability and resistance to corrosion, making it ideal for industries like food and beverage where hygiene is paramount. -

Torque Output

– Torque is a critical specification that determines the power a gearmotor can deliver. Bison’s gearmotors, like the 200 Series, are known for their high torque output, allowing them to effectively handle demanding applications across various sectors. This property is vital for ensuring that machinery operates efficiently without stalling. -

Horsepower Range

– The horsepower range of Bison motors typically spans from 1/53 HP to 1.5 HP, catering to a wide array of fractional horsepower applications. This versatility allows buyers to select a motor that precisely matches their operational requirements, minimizing energy waste and enhancing performance. -

IP Rating

– The Ingress Protection (IP) rating indicates the level of protection against dust and moisture. For example, Bison’s washdown gearmotors have an IP69K rating, making them suitable for environments exposed to high-pressure water and dust. This specification is crucial for ensuring reliability and longevity in challenging conditions. -

Configuration Options

– Bison offers various gearmotor configurations, including inline parallel shaft and right-angle gearmotors. This flexibility allows B2B buyers to select products that fit their specific design and spatial constraints, facilitating seamless integration into existing systems.

What Are Common Trade Terms in the Bison Gear & Engineering Sector?

Familiarizing oneself with industry jargon is essential for effective communication and negotiation in the B2B landscape. Here are some common trade terms relevant to Bison Gear & Engineering:

Illustrative image related to bison gear & engineering corp.

-

OEM (Original Equipment Manufacturer)

– An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. For Bison, being an OEM means providing high-quality gearmotors and components that can be integrated into other manufacturers’ products, ensuring reliability and performance. -

MOQ (Minimum Order Quantity)

– MOQ refers to the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is crucial for buyers to manage inventory and budget effectively, especially when ordering customized solutions from Bison. -

RFQ (Request for Quotation)

– An RFQ is a formal process in which a buyer requests pricing and terms from suppliers for specific products. For Bison, issuing an RFQ allows potential customers to receive tailored quotes based on their unique specifications and needs. -

Incoterms (International Commercial Terms)

– Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC). They clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers involved in international transactions with Bison. -

Lead Time

– Lead time is the duration from when an order is placed until it is delivered. Understanding Bison’s lead times helps buyers plan their production schedules and manage their supply chains effectively, ensuring that projects remain on track.

By grasping these technical specifications and trade terms, B2B buyers can make informed decisions when sourcing gearmotors and engineering solutions from Bison Gear & Engineering.

Navigating Market Dynamics and Sourcing Trends in the bison gear & engineering corp. Sector

What Are the Key Market Dynamics and Trends Affecting Bison Gear & Engineering Corp.?

The global market for gear motors and engineering solutions is experiencing a significant transformation, driven by technological advancements and increasing demand across various industries. Key drivers include the automation of manufacturing processes, which has heightened the need for reliable motion control solutions. In regions such as Africa, South America, the Middle East, and Europe, industries like food and beverage, agriculture, and transportation are rapidly adopting advanced gearmotors to enhance efficiency and productivity.

Emerging technologies such as Industry 4.0 and the Internet of Things (IoT) are reshaping sourcing trends, allowing for real-time data collection and improved operational efficiency. B2B buyers are increasingly seeking suppliers who can offer customizable solutions and rapid prototyping capabilities, which are essential for meeting specific operational requirements. The integration of artificial intelligence in motion control solutions is also on the rise, enabling predictive maintenance and reducing downtime.

International buyers should be aware of fluctuating raw material costs and supply chain disruptions, which can impact sourcing strategies. As manufacturers like Bison Gear & Engineering adapt to these market dynamics, they are focusing on providing not just products but comprehensive solutions that include engineering support and integration assistance. This shift towards a solution-oriented approach is particularly appealing to B2B buyers looking for reliable partnerships in their operational frameworks.

How Is Sustainability Impacting B2B Sourcing for Bison Gear & Engineering Corp.?

Sustainability has become a pivotal consideration in the B2B landscape, influencing sourcing decisions and supplier partnerships. The environmental impact of manufacturing processes is under scrutiny, prompting companies to adopt more sustainable practices. For Bison Gear & Engineering Corp., this means prioritizing ethical supply chains and integrating ‘green’ certifications into their products.

B2B buyers are increasingly demanding transparency regarding the materials and processes used in the manufacturing of gear motors and other engineering solutions. This trend is particularly pronounced in markets where regulatory frameworks are becoming stricter regarding sustainability and environmental protection. By leveraging materials that are recyclable or made from sustainable sources, Bison can appeal to environmentally-conscious businesses.

Illustrative image related to bison gear & engineering corp.

Additionally, adopting energy-efficient technologies not only reduces the carbon footprint but also offers cost savings over time, making them more attractive to buyers. The emphasis on sustainability is not just a compliance issue; it is also a competitive differentiator that can influence purchasing decisions across various sectors.

What Is the Historical Context of Bison Gear & Engineering Corp. Relevant to Today’s Market?

Founded in 1960, Bison Gear & Engineering Corp. has a rich history of innovation in the motion control sector. Over the decades, the company has evolved from a traditional manufacturer into a leader in providing highly engineered solutions tailored to the needs of diverse industries. The acquisition by AMETEK in 2023 marked a significant milestone, allowing Bison to expand its capabilities and enhance its product offerings through greater resources and technological expertise.

This evolution reflects broader market trends where companies are increasingly required to adapt to technological advancements and changing customer needs. Bison’s commitment to engineering excellence and customer-centric solutions has established it as a trusted partner for B2B buyers seeking reliable and high-performance gear motors and engineering solutions.

The legacy of quality and innovation positions Bison favorably in a competitive landscape, enabling it to respond effectively to the demands of international buyers looking for robust, customizable, and sustainable solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of bison gear & engineering corp.

-

1. How can I determine the right gearmotor for my application?

To select the right gearmotor, consider the specific requirements of your application, such as load capacity, speed, torque, and environmental conditions. Bison Gear & Engineering offers a diverse range of products, including the 200 Series Inline Parallel Shaft Gearmotors and the 261 Series Sanimotor, which cater to various industries. Collaborating with Bison’s engineering team can also provide tailored solutions that match your unique needs, ensuring optimal performance and longevity. -

2. What customization options are available for Bison products?

Bison Gear & Engineering excels in providing customizable solutions. Buyers can work directly with Bison’s engineering team to develop products that meet specific requirements, such as size, configuration, and material specifications. This flexibility is particularly beneficial for industries with unique operational demands, such as food and beverage or automation. Discussing your needs early in the process can lead to better integration and performance of the final product. -

3. What are the minimum order quantities (MOQ) for Bison products?

Minimum order quantities can vary based on the specific product and customization requirements. Typically, Bison accommodates both small and large orders, allowing businesses to scale as needed. For precise MOQ details, it’s best to consult directly with Bison’s sales representatives, who can provide tailored information based on your project scope and urgency. -

4. What are the payment terms for international orders with Bison?

Bison Gear & Engineering offers flexible payment terms for international buyers, which can include options such as advance payment, letters of credit, or net payment terms depending on the volume and nature of the order. It’s advisable to discuss your preferred payment method with Bison’s sales team early in the negotiation process to ensure clarity and smooth transactions. -

5. How does Bison ensure quality assurance for its products?

Bison places a strong emphasis on quality assurance through rigorous testing and certification processes. Each product undergoes comprehensive performance evaluations to meet industry standards. Additionally, Bison’s engineering labs are equipped for rapid prototyping and testing, ensuring that every solution is validated for reliability and efficiency before it reaches the customer. -

6. What logistics options are available for international shipping of Bison products?

Bison Gear & Engineering offers various logistics options tailored to meet the needs of international buyers. Shipping can be arranged through multiple carriers, with options for air or sea freight depending on urgency and budget. The sales team can assist in providing shipping estimates and arranging logistics to ensure timely delivery to your location. -

7. How can I vet Bison as a reliable supplier?

To vet Bison as a supplier, consider their industry reputation, years of operation, and product offerings. Bison has been a trusted manufacturer since 1960, specializing in engineered solutions for diverse markets. Requesting customer references, reviewing case studies, and engaging with their engineering team can provide insights into their capabilities and commitment to quality. -

8. What industries benefit from Bison gearmotors and engineering solutions?

Bison Gear & Engineering serves a wide array of industries, including food and beverage, transportation, agriculture, and automation. Their products are designed for demanding applications that require precision and reliability. By leveraging Bison’s expertise, businesses in these sectors can enhance their operational efficiency and product performance through high-quality gearmotors and engineering solutions.

Top 3 Bison Gear & Engineering Corp. Manufacturers & Suppliers List

1. Bison Gear – Gearboxes & Gear Motors

Domain: motion.com

Registered: 1994 (31 years)

Introduction: This company, Bison Gear – Gearboxes & Gear Motors, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Bison Gear – Motion Control Solutions

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: Bison Gear & Engineering Corp is a leading manufacturer of highly engineered motion control solutions serving diverse markets and applications.

3. Bison Gear – Roof Racks and Accessories

Domain: bison-gear.com

Registered: 2020 (5 years)

Introduction: Product Types: Accessories, Cargo Barrier, Cargo Basket, Fridge Slider, Lamps, LED Bars, MOLLE Panels, Roof Rack, Roof Shelf, Tables. OX PRO System: Roof Racks, MOLLE Panels, Camping Table, Interior Shelves, Cargo Barrier, Door Tables, Interior Accessories, Trunk Dividers, Fridge Sliders, Exterior MOLLE Panels, Exterior Accessories, Spare Wheel Accessories, Tents & Awning Mounts, Canisters & Mount…

Strategic Sourcing Conclusion and Outlook for bison gear & engineering corp.

In today’s competitive landscape, strategic sourcing is essential for international B2B buyers seeking reliable partners in the power transmission and motion control sectors. Bison Gear & Engineering Corp. stands out with its extensive portfolio of over 1,000 customizable products, including gearmotors, motors, and reducers tailored for demanding applications across various industries such as food & beverage, agriculture, and transportation. By leveraging Bison’s engineering expertise, buyers can enhance operational efficiency and ensure optimal performance in their applications.

Bison’s recent integration into AMETEK further strengthens its capabilities, providing buyers access to advanced engineering resources and a broader range of innovative solutions. This synergy allows for accelerated time to market and customized product offerings that meet specific operational needs.

As international buyers from regions like Africa, South America, the Middle East, and Europe seek to enhance their supply chains, partnering with Bison presents a strategic advantage. Embrace the opportunity to collaborate with a trusted technology partner that not only understands your challenges but also provides tailored solutions to drive your business forward. Engage with Bison today to explore how their products can empower your operations and contribute to your success.

Illustrative image related to bison gear & engineering corp.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to bison gear & engineering corp.