Bentonville Plastics: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for bentonville plastics

In today’s competitive landscape, sourcing high-quality bentonville plastics can be a daunting challenge for international B2B buyers. Companies across diverse sectors, from packaging to automotive, increasingly rely on innovative plastic solutions to meet their production needs. However, navigating the complexities of material selection, supplier reliability, and cost efficiency can significantly impact operational success. This guide serves as a comprehensive resource, exploring various types of bentonville plastics, including injection molding, polyurethane molding, and blow molding, alongside their specific applications across industries.

As you delve into this guide, you will gain insights into effective supplier vetting processes, essential quality assurance measures, and cost considerations that can empower your purchasing decisions. Particularly for businesses in Africa, South America, the Middle East, and Europe—regions that are rapidly expanding their industrial capabilities—understanding the nuances of bentonville plastics is crucial. This guide aims to equip you with the knowledge to navigate the global market confidently, ensuring you select the right materials and partners to drive innovation and sustainability in your operations.

By leveraging the insights contained herein, you will be better positioned to make informed choices that not only enhance product quality but also contribute to your company’s long-term success in the evolving global marketplace.

Understanding bentonville plastics Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Plastic Injection Molding | High precision, mass production capability | Automotive, consumer goods, electronics | Pros: Cost-effective for large runs; high detail. Cons: Initial mold costs can be high. |

| Polyurethane Molding | Versatile, durable, and customizable | Furniture, automotive parts, insulation | Pros: Excellent flexibility and resilience. Cons: Longer cure times may delay production. |

| Rotational Molding | Produces hollow, seamless parts; suitable for large items | Storage tanks, playground equipment | Pros: Low tooling costs; great for large quantities. Cons: Limited to simpler shapes. |

| Blow Molding | Creates hollow products; fast production speeds | Bottles, containers, automotive components | Pros: Efficient for large volumes; lightweight products. Cons: Design limitations on shapes. |

| Thermoforming | Uses heat to mold sheets into various shapes | Packaging, trays, and medical devices | Pros: Cost-effective for low to medium volumes. Cons: Less durable than injection molded products. |

What Are the Characteristics and Suitability of Plastic Injection Molding?

Plastic injection molding is a highly efficient manufacturing process ideal for mass production. It allows for the creation of complex shapes with high precision, making it suitable for industries such as automotive and electronics. Buyers should consider the initial investment in mold creation, which can be significant, but the per-unit cost decreases with larger production runs, making it an economical choice for high-volume needs.

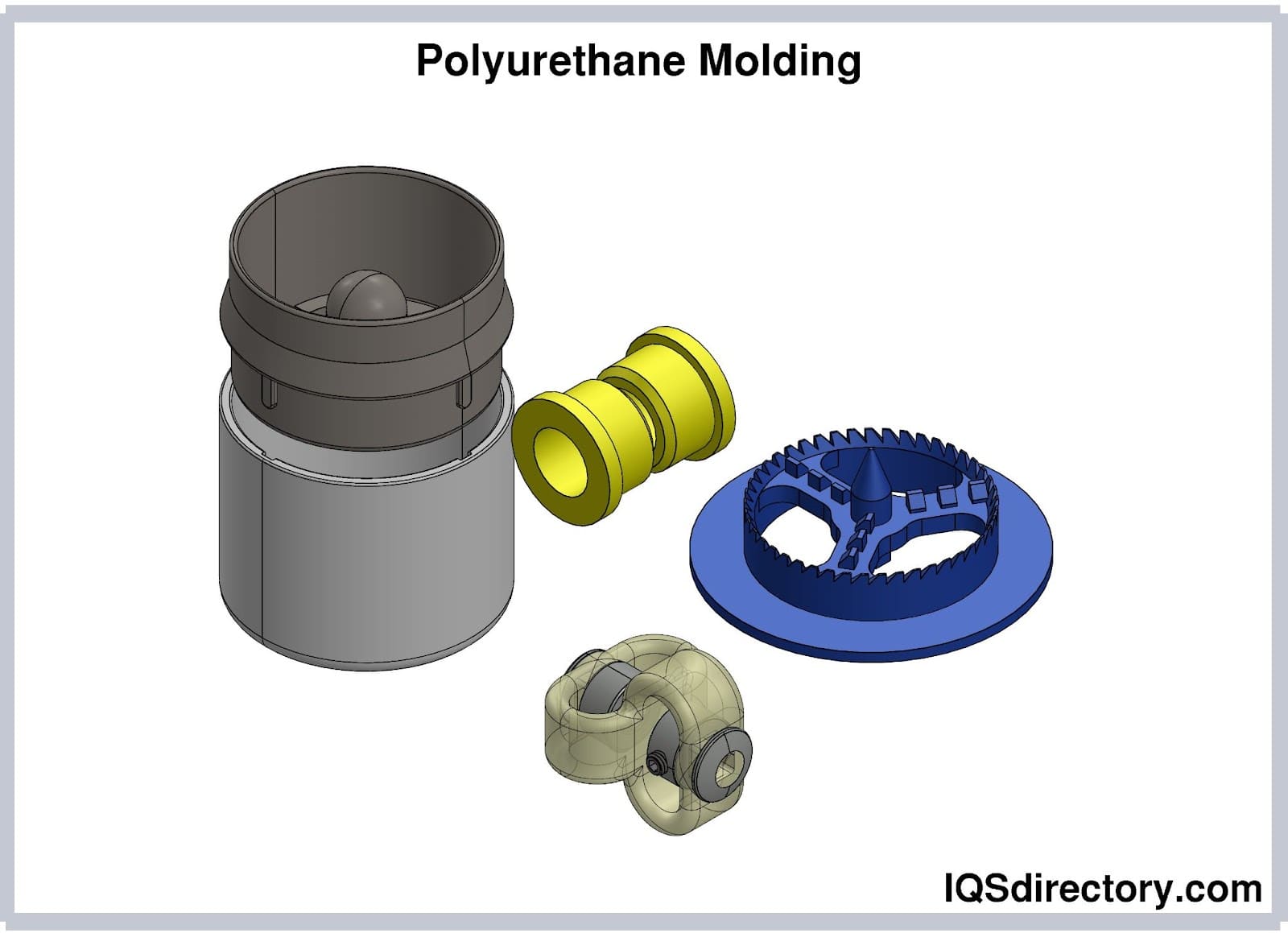

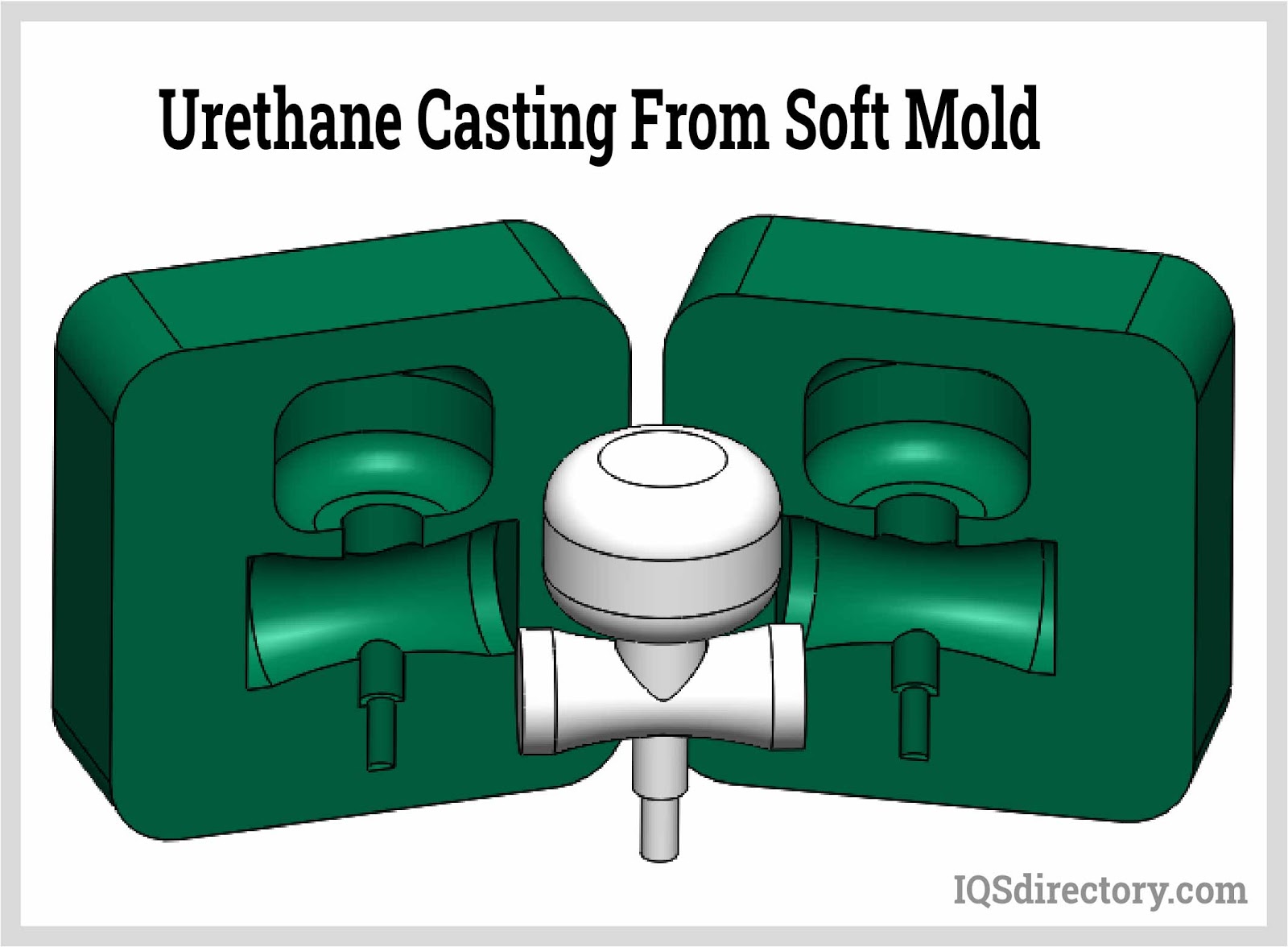

How Does Polyurethane Molding Stand Out for B2B Buyers?

Polyurethane molding is known for its versatility and durability, making it an excellent choice for applications requiring flexibility and resilience, such as furniture and automotive parts. This process can be tailored to meet specific design requirements, allowing for customized solutions. However, buyers should be aware of longer curing times, which can impact production schedules, especially when quick turnaround times are essential.

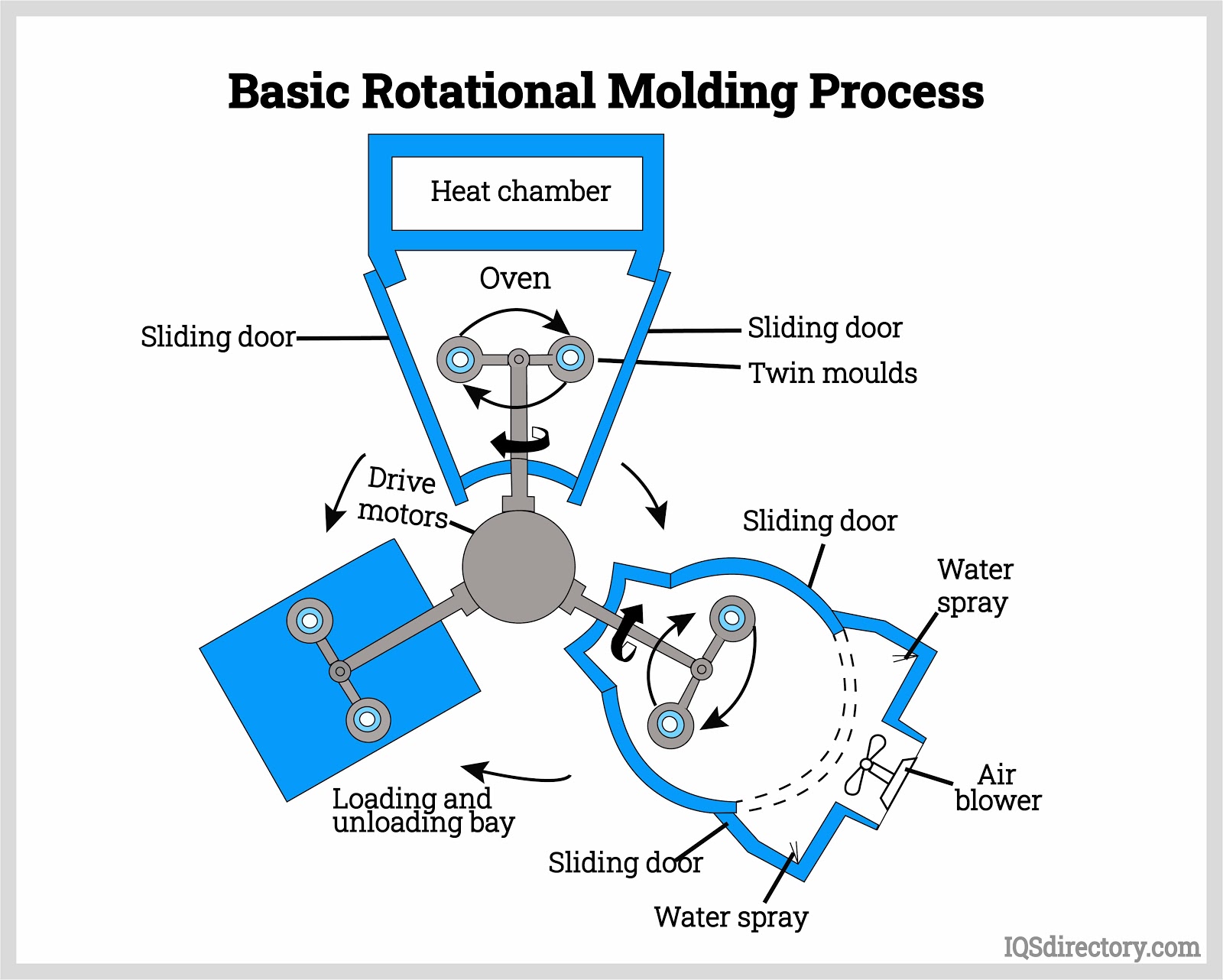

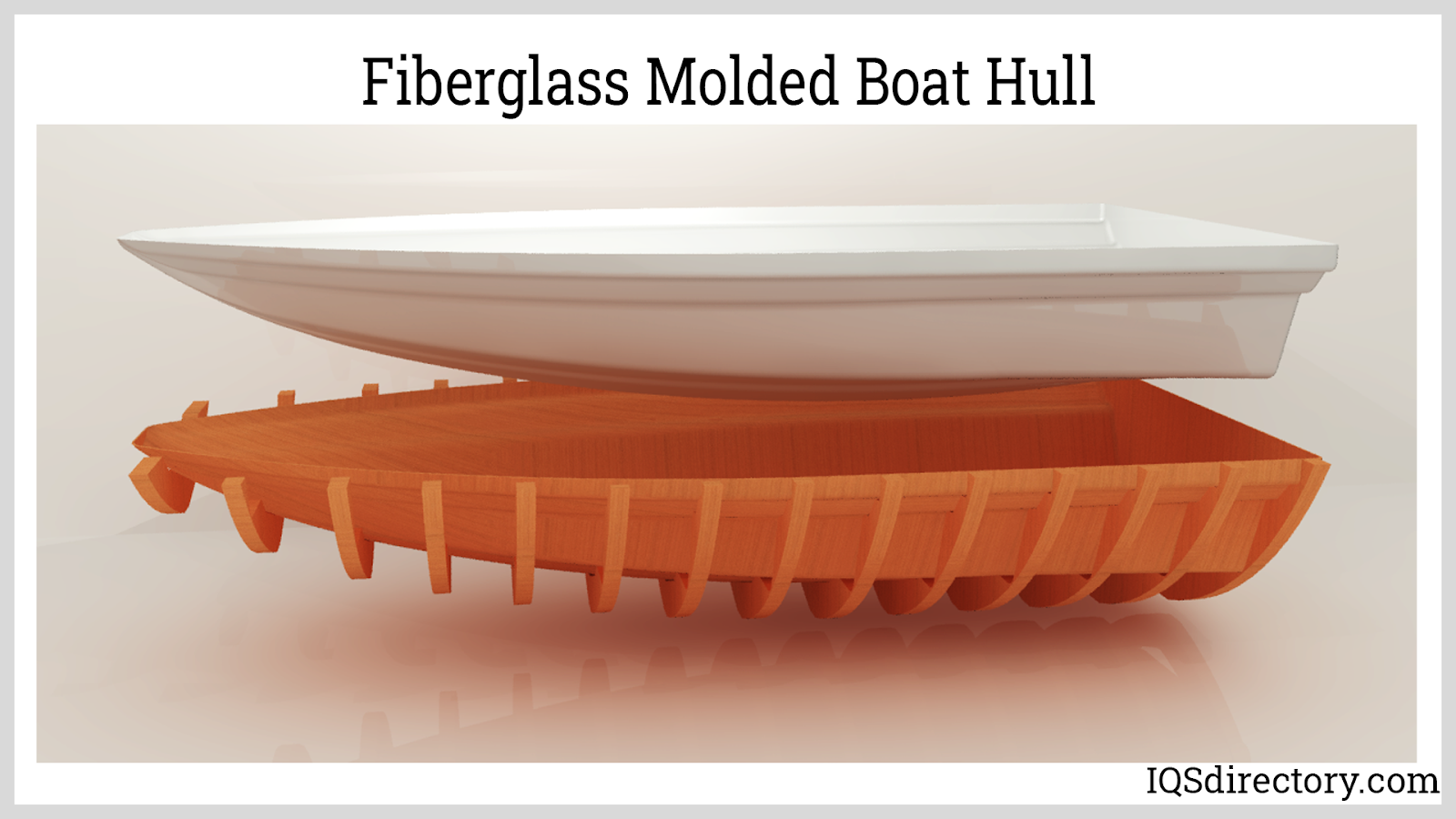

What Are the Benefits of Rotational Molding for Large Products?

Rotational molding is a unique process that produces hollow, seamless parts, making it ideal for large items such as storage tanks and playground equipment. Its low tooling costs allow manufacturers to create cost-effective products in large quantities. However, the design complexity is limited, which may not suit every application. Buyers should evaluate whether the simplicity of design aligns with their product needs.

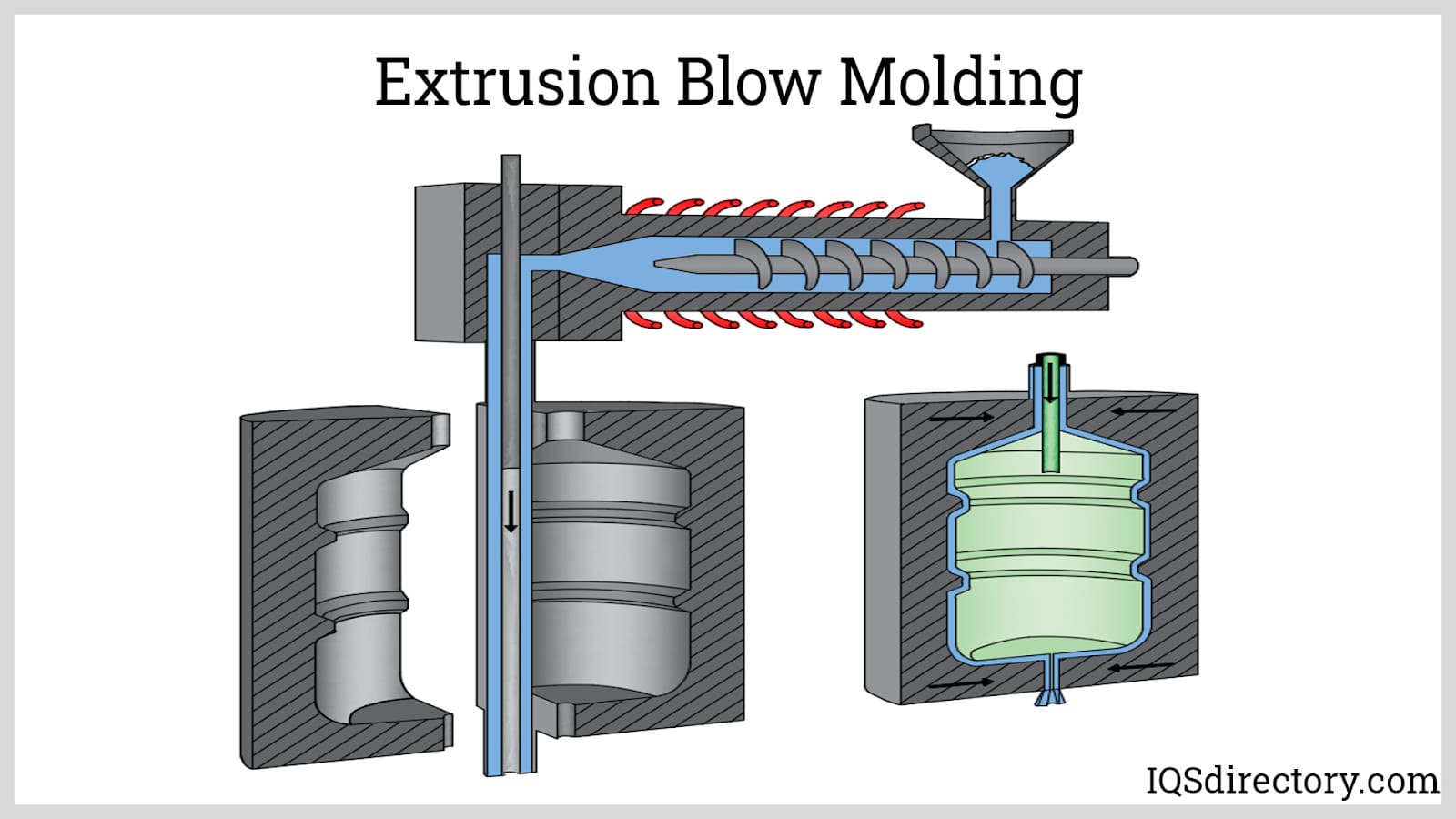

What Are the Key Features of Blow Molding for Hollow Products?

Blow molding is particularly effective for creating hollow plastic products, such as bottles and containers, at high production speeds. This method is advantageous for industries that require lightweight and durable products. While it is efficient for large volumes, buyers should note that the design options may be limited compared to other molding processes, which could affect product functionality.

Why Choose Thermoforming for Packaging Solutions?

Thermoforming is a cost-effective method for producing parts from thin plastic sheets, making it popular for applications like packaging and trays. It is particularly suitable for low to medium production volumes. While thermoformed products can be less durable than those produced through injection molding, they offer flexibility in design and rapid prototyping. Buyers should weigh the benefits of lower costs against the potential trade-offs in durability.

Key Industrial Applications of bentonville plastics

| Industry/Sector | Specific Application of Bentonville Plastics | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Packaging | Custom plastic containers and closures | Enhanced product protection and shelf appeal, tailored to specific product needs | Material compatibility, regulatory compliance, and design flexibility |

| Automotive | Plastic components for interior and exterior parts | Lightweight, durable materials that improve fuel efficiency and reduce costs | Quality assurance, supplier reliability, and lead times |

| Consumer Electronics | Injection molded housings and components | Precise fit and finish, enabling better product performance and aesthetics | Design collaboration, customization options, and testing capabilities |

| Construction | Plastic fittings and fixtures | Cost-effective solutions that withstand environmental stressors | Material specifications, durability testing, and availability |

| Medical Devices | Custom molded parts for medical equipment | Compliance with health regulations and high-performance standards | Certification processes, material safety, and scalability |

How Is Bentonville Plastics Used in Packaging Applications?

In the packaging industry, Bentonville Plastics produces custom plastic containers and closures designed to enhance product protection and shelf appeal. These solutions are crucial for international buyers, particularly in regions like Africa and South America, where packaging must withstand varying climates and transport conditions. Buyers should consider material compatibility with their products, regulatory compliance for safety, and the ability to customize designs to meet local market preferences.

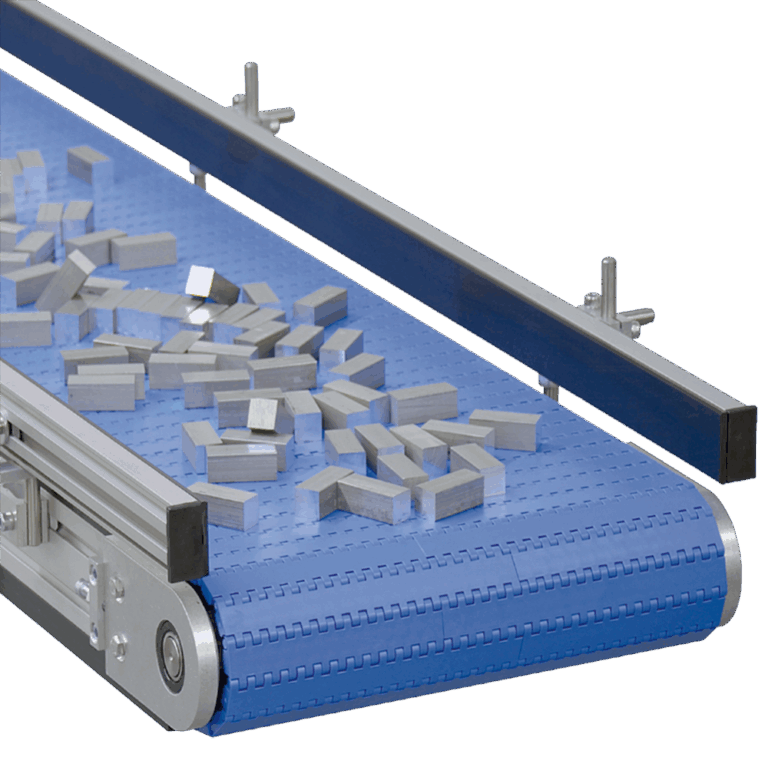

Illustrative image related to bentonville plastics

What Role Does Bentonville Plastics Play in Automotive Manufacturing?

Bentonville Plastics specializes in manufacturing lightweight plastic components for automotive applications, such as interior trim and exterior parts. These materials not only reduce vehicle weight, improving fuel efficiency, but also lower production costs. For B2B buyers in Europe and the Middle East, it’s essential to focus on quality assurance and supplier reliability, as automotive components must meet stringent safety and performance standards.

How Are Consumer Electronics Enhanced with Bentonville Plastics?

In the consumer electronics sector, Bentonville Plastics provides injection molded housings and components that ensure precise fit and finish. This attention to detail is vital for enhancing product performance and aesthetics. Buyers from regions like Brazil and Nigeria should prioritize design collaboration and customization options to align products with local consumer preferences, as well as testing capabilities to ensure durability and functionality.

What Applications Exist for Bentonville Plastics in Construction?

Bentonville Plastics manufactures a variety of plastic fittings and fixtures for the construction industry, offering cost-effective solutions that are resistant to environmental stressors. This is particularly beneficial for international buyers in harsh climates. When sourcing, businesses should focus on material specifications and durability testing to ensure longevity and reliability in construction applications, as well as the availability of products to meet project timelines.

How Does Bentonville Plastics Support Medical Device Manufacturing?

In the medical device sector, Bentonville Plastics creates custom molded parts that comply with health regulations and high-performance standards. These components are critical for ensuring the safety and efficacy of medical equipment. International buyers must be aware of certification processes and material safety standards, as well as the scalability of production to meet increasing demand for medical technologies, especially in emerging markets.

3 Common User Pain Points for ‘bentonville plastics’ & Their Solutions

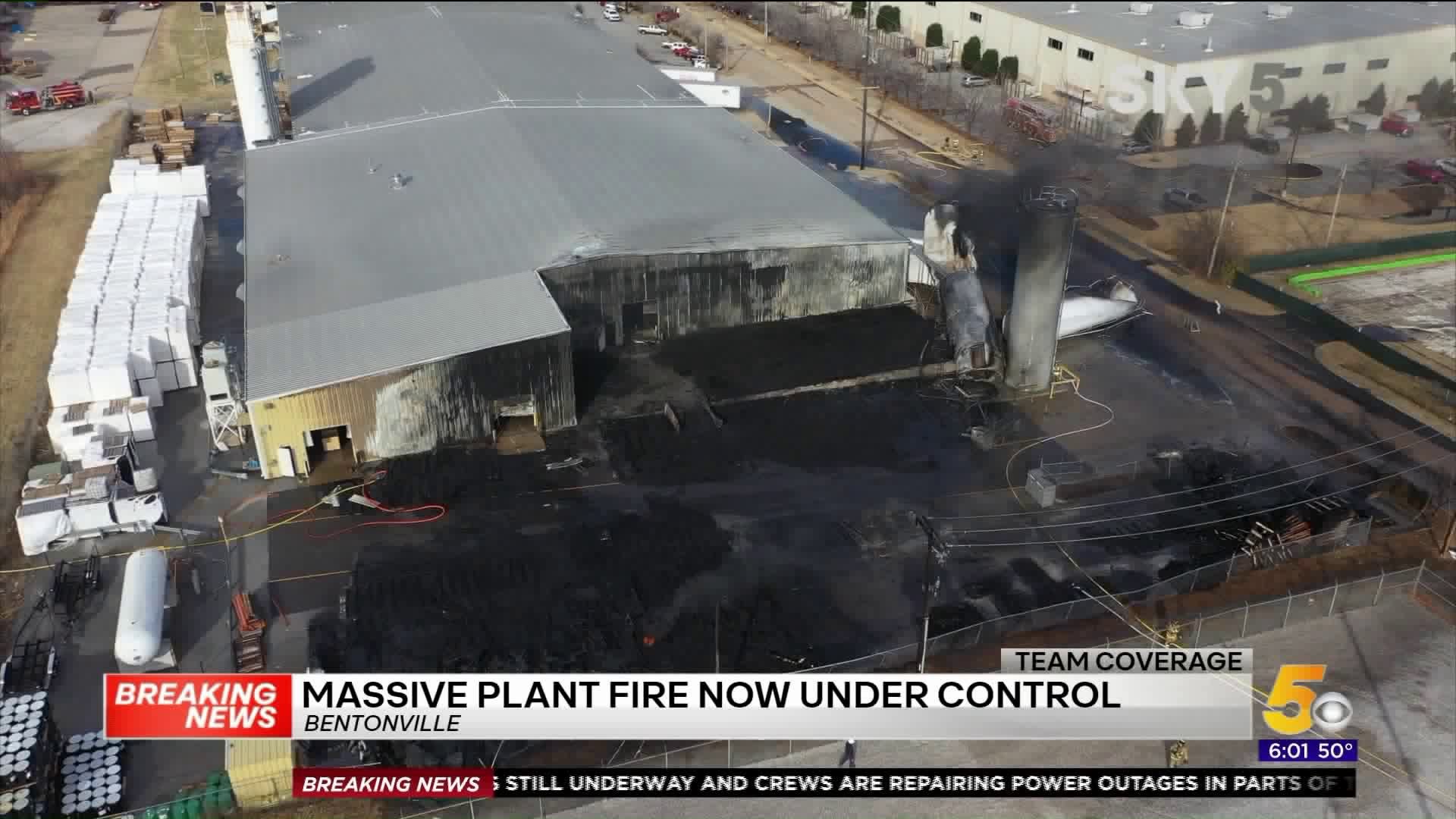

Scenario 1: Navigating Quality Assurance in Plastic Manufacturing

The Problem: B2B buyers often face challenges in ensuring the quality and consistency of plastic components, which is crucial for maintaining the integrity of their own products. Inconsistent quality can lead to production delays, increased costs, and ultimately, dissatisfied customers. For international buyers, the stakes are higher; discrepancies in product quality can result in significant financial losses and damage to reputation across diverse markets.

Illustrative image related to bentonville plastics

The Solution: To mitigate quality assurance issues, buyers should establish a robust communication channel with Bentonville Plastics. Before placing orders, engage in thorough discussions about specific quality standards and certifications relevant to your industry. Request detailed documentation of quality control processes, including material specifications and testing protocols. Additionally, consider requesting a small batch for initial testing to evaluate the product’s performance in your application. This proactive approach not only ensures that the products meet your expectations but also fosters a collaborative relationship with the manufacturer, enhancing trust and reliability.

Scenario 2: Managing Lead Times and Delivery Schedules

The Problem: International buyers often struggle with long lead times and unpredictable delivery schedules, particularly when sourcing custom plastic components from manufacturers like Bentonville Plastics. These delays can disrupt supply chains, leading to missed deadlines and potential loss of business opportunities. For companies operating in fast-paced industries, such as consumer electronics or automotive, the ability to meet tight timelines is critical.

The Solution: To effectively manage lead times, it is essential to have a clear understanding of the production capabilities and timelines of Bentonville Plastics. Buyers should inquire about the manufacturer’s capacity for handling rush orders or scaling production during peak periods. Additionally, implementing a Just-In-Time (JIT) inventory strategy can help align production schedules with your operational needs. Establishing a timeline that includes milestones for design approval, production, and shipping will provide better visibility into the process, allowing for adjustments to be made proactively. Regular check-ins and updates from the supplier can further enhance transparency and reliability in delivery schedules.

Scenario 3: Sourcing Sustainable Plastic Solutions

The Problem: With growing environmental concerns, many B2B buyers are increasingly tasked with sourcing sustainable products. However, navigating the landscape of eco-friendly plastics can be daunting, especially when trying to balance performance, cost, and environmental impact. Buyers from regions like Africa or South America may also encounter limited availability of sustainable options, complicating their sourcing efforts.

The Solution: Bentonville Plastics offers a range of sustainable solutions, particularly with their experience in recycling and using eco-friendly materials. To effectively source these options, buyers should engage in discussions about the availability of recycled and biodegradable plastics. Request samples of sustainable products and evaluate their performance in real-world applications. Moreover, consider partnering with Bentonville Plastics for custom solutions that meet specific sustainability goals, such as reduced carbon footprints or improved recyclability. By prioritizing sustainability in your procurement strategy and collaborating with the manufacturer, you can ensure that your sourcing practices align with both environmental standards and market demands.

Strategic Material Selection Guide for bentonville plastics

When selecting materials for plastic manufacturing, it is crucial for international B2B buyers to understand the properties, advantages, and limitations of various materials. This knowledge not only influences product performance but also impacts compliance with regional standards and market preferences.

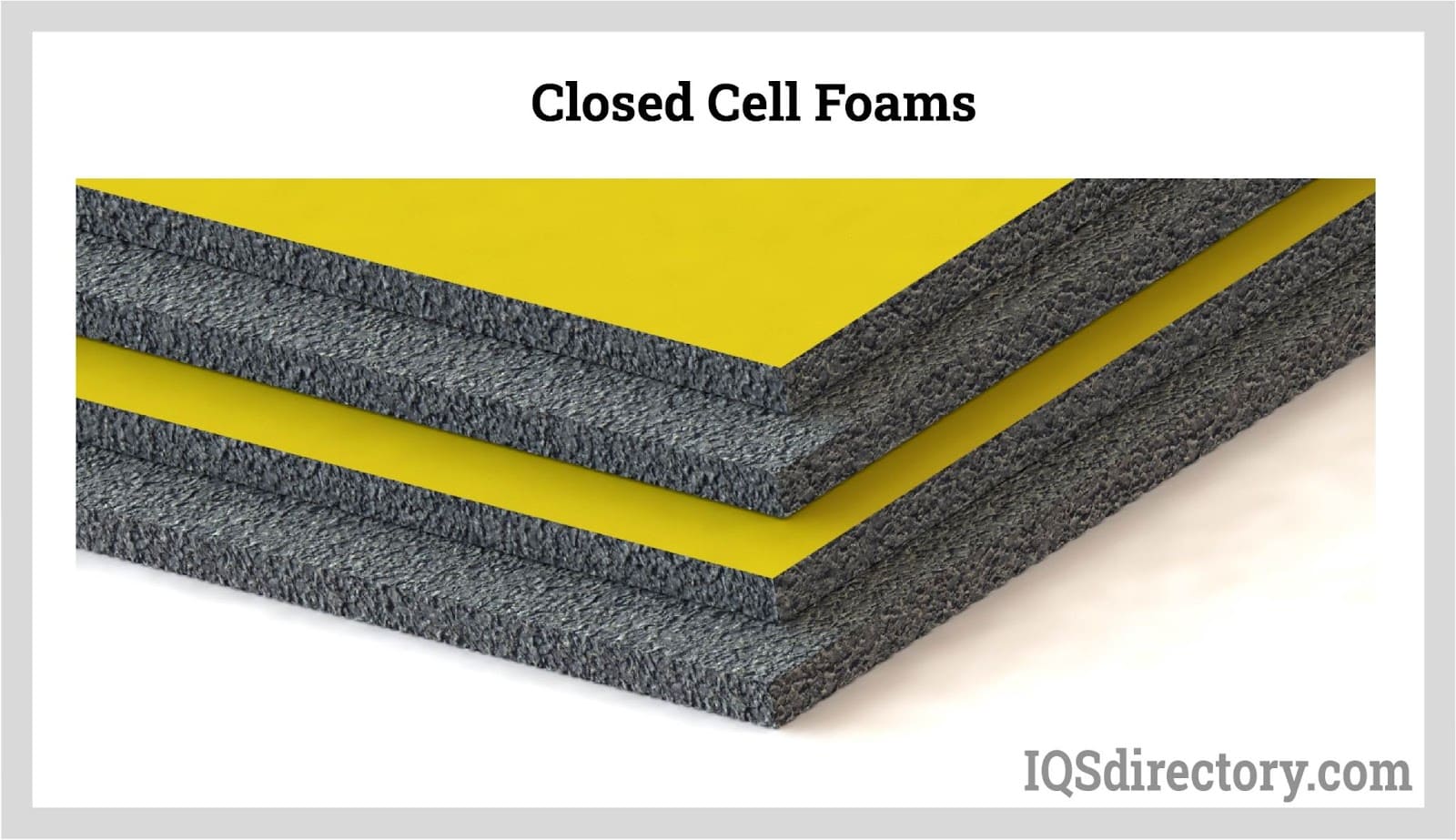

What Are the Key Properties of Polypropylene in Bentonville Plastics?

Polypropylene (PP) is a widely used thermoplastic known for its excellent chemical resistance and versatility. It has a temperature rating of up to 100°C (212°F) and demonstrates good tensile strength and flexibility. Polypropylene is resistant to fatigue, making it suitable for applications requiring repeated bending.

Pros and Cons: The advantages of polypropylene include its low cost, lightweight nature, and resistance to moisture and chemicals. However, it has lower impact resistance compared to other plastics and can become brittle at lower temperatures.

Illustrative image related to bentonville plastics

Impact on Application: Polypropylene is compatible with various media, making it ideal for packaging, automotive components, and consumer goods. Its recyclability is also a plus for environmentally conscious buyers.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with local regulations regarding plastic use and recycling. Standards such as ASTM D638 for tensile properties may be relevant.

How Does Polyethylene Compare for Bentonville Plastics Applications?

Polyethylene (PE) is another popular choice, particularly for its excellent chemical resistance and low moisture absorption. It is available in various densities, with High-Density Polyethylene (HDPE) and Low-Density Polyethylene (LDPE) being the most common. HDPE can withstand temperatures up to 120°C (248°F), while LDPE is more flexible and suitable for lower-temperature applications.

Pros and Cons: The key advantages of polyethylene include its durability, low cost, and ease of processing. However, it can be less rigid than other materials and may not perform well under high temperatures.

Illustrative image related to bentonville plastics

Impact on Application: Polyethylene is widely used for packaging, containers, and pipes. Its compatibility with food products makes it a preferred choice for packaging in the food and beverage industry.

Considerations for International Buyers: Compliance with food safety standards, such as those set by the FDA or EU regulations, is essential for buyers in Europe and the Middle East. Understanding local recycling capabilities is also crucial.

What Are the Benefits of Using Polycarbonate in Bentonville Plastics?

Polycarbonate (PC) is known for its exceptional impact resistance and optical clarity. It can withstand temperatures ranging from -40°C to 120°C (-40°F to 248°F) and is often used in applications requiring transparency and durability.

Illustrative image related to bentonville plastics

Pros and Cons: Polycarbonate’s key advantages include its high strength-to-weight ratio and resistance to UV radiation. However, it is generally more expensive than other plastics and may require specialized processing techniques.

Impact on Application: This material is ideal for applications such as safety glasses, automotive parts, and electronic housings due to its strength and clarity.

Considerations for International Buyers: Buyers should be aware of compliance with safety standards such as ANSI Z87.1 for eyewear and other relevant certifications in their respective markets.

Why Consider ABS for Bentonville Plastics Solutions?

Acrylonitrile Butadiene Styrene (ABS) is a robust thermoplastic known for its toughness and impact resistance. It can operate effectively in temperatures ranging from -20°C to 80°C (-4°F to 176°F).

Pros and Cons: ABS offers excellent machinability and is relatively easy to mold, making it suitable for complex shapes. However, it can be more expensive than polypropylene and polyethylene and is less resistant to UV light.

Illustrative image related to bentonville plastics

Impact on Application: ABS is commonly used in consumer electronics, automotive parts, and toys, where durability and aesthetic appeal are essential.

Considerations for International Buyers: Buyers should check for compliance with toy safety standards (e.g., ASTM F963) in regions like Europe and the Middle East. Understanding local market demands for aesthetics and durability can also influence material choice.

Summary Table of Material Selection for Bentonville Plastics

| Material | Typical Use Case for Bentonville Plastics | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene | Packaging, automotive components, consumer goods | Excellent chemical resistance | Lower impact resistance | Low |

| Polyethylene | Food packaging, containers, pipes | Durable and low cost | Less rigid under high temperatures | Low |

| Polycarbonate | Safety glasses, automotive parts, electronic housings | High impact resistance and clarity | More expensive and requires special processing | High |

| ABS | Consumer electronics, automotive parts, toys | Excellent machinability | Less UV resistance | Medium |

This strategic material selection guide aims to empower B2B buyers with the necessary insights to make informed decisions when sourcing plastic materials from Bentonville Plastics. Understanding these factors can enhance product performance and compliance with international standards, ultimately leading to successful business outcomes.

Illustrative image related to bentonville plastics

In-depth Look: Manufacturing Processes and Quality Assurance for bentonville plastics

What Are the Key Stages in the Manufacturing Processes at Bentonville Plastics?

Bentonville Plastics employs a comprehensive manufacturing process that ensures the production of high-quality plastic components tailored to diverse industry needs. This process can be broken down into several critical stages: material preparation, forming, assembly, and finishing.

Material Preparation: How Are Raw Materials Selected and Processed?

The manufacturing journey begins with the careful selection and preparation of raw materials. Bentonville Plastics primarily utilizes thermoplastics and polyurethane, which are known for their versatility and durability. The materials undergo rigorous screening to ensure they meet specific industry standards and customer requirements.

Once selected, the materials are processed into the desired form. This may involve granulation, where large plastic pellets are reduced to smaller sizes for easier handling and processing. Additionally, additives may be mixed in at this stage to enhance the properties of the plastic, such as UV resistance or color stability.

How Does the Forming Process Work in Plastic Manufacturing?

The forming stage is where the selected materials are transformed into finished products through various techniques, including injection molding, blow molding, and rotational molding.

-

Injection Molding: This is one of the most common methods used at Bentonville Plastics. In this process, molten plastic is injected into a precisely designed mold. After cooling, the mold is opened to reveal the finished part. This technique is particularly effective for producing high-volume, complex parts with tight tolerances.

-

Blow Molding: Used primarily for creating hollow objects, this technique involves inflating a heated plastic tube into a mold. It’s ideal for products like bottles and containers, ensuring uniform thickness and a seamless design.

-

Rotational Molding: This method is utilized for creating large, hollow items. The process involves heating a powdered resin in a mold that rotates, allowing the material to coat the mold’s interior. The result is a durable, double-walled product.

-

Thermoforming: In this technique, sheets of plastic are heated until pliable and then formed over molds. This is suitable for producing trays, packaging, and other shallow products.

-

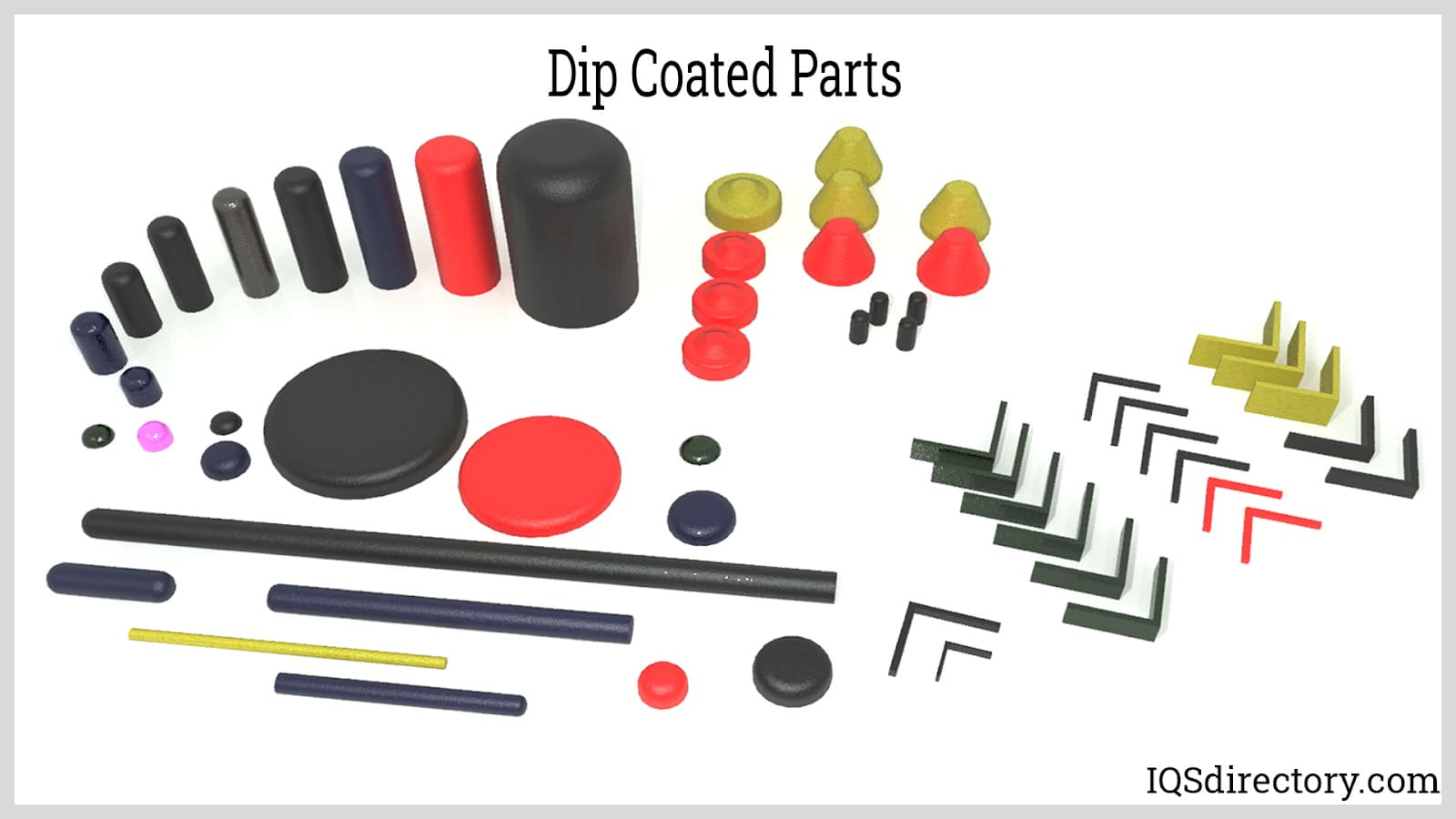

Polyurethane Molding: This process allows for the creation of flexible parts and is often used in applications requiring shock absorption or cushioning.

What Assembly Techniques Are Used for Plastic Products?

Following the forming process, assembly may be necessary for products comprising multiple components. Bentonville Plastics uses techniques such as overmolding and adhesive bonding to ensure that different parts fit together seamlessly. Overmolding combines two different materials into a single product, enhancing both functionality and aesthetics.

How Does the Finishing Process Enhance the Quality of Plastic Products?

The finishing stage involves additional treatments to enhance the product’s performance and appearance. This may include processes like trimming, sanding, and surface coating. Techniques such as plastic coating can provide protective and decorative finishes, ensuring that the end product meets both functional and aesthetic requirements.

Illustrative image related to bentonville plastics

What Quality Assurance Measures Are Implemented at Bentonville Plastics?

Bentonville Plastics is committed to maintaining high-quality standards throughout its manufacturing processes. The company adheres to international quality standards such as ISO 9001, which outlines the criteria for a quality management system. This commitment to quality is vital for B2B buyers seeking reliable suppliers.

What International Standards and Certifications Are Relevant?

For B2B buyers, understanding the certifications and standards that a manufacturer complies with is crucial. In addition to ISO 9001, industry-specific certifications such as CE marking for products sold in Europe and API standards for oil and gas components may also be applicable. These certifications indicate that products meet stringent safety, health, and environmental requirements.

How Are Quality Control Checkpoints Structured?

Quality control (QC) at Bentonville Plastics is integrated at various checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards before being used in production.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor production parameters and product quality. This proactive approach helps identify and rectify issues before they escalate.

-

Final Quality Control (FQC): Once the products are completed, they undergo rigorous testing to ensure they meet all specifications and standards before shipping.

What Testing Methods Are Commonly Used in Quality Assurance?

Bentonville Plastics employs various testing methods to assess product quality, including mechanical testing, dimensional inspections, and environmental testing. These methods help ensure that the products can withstand the intended use and comply with applicable regulations.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control practices of a potential supplier is essential. Here are several actionable steps to consider:

Illustrative image related to bentonville plastics

-

Supplier Audits: Conducting regular audits of the manufacturing facility can provide insights into the supplier’s operational processes and quality management systems.

-

Requesting Quality Reports: Buyers should request quality control reports that detail inspection results, testing methods used, and any corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance, as these organizations can provide unbiased evaluations of product quality and compliance with international standards.

What Are the Quality Control Nuances for International Buyers?

International B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control. Different markets may have varying regulatory requirements and standards, necessitating careful consideration during supplier selection.

It is also crucial to communicate clearly with suppliers about quality expectations and compliance needs from the outset. Establishing a mutual understanding can help prevent misunderstandings and ensure that products meet the buyer’s requirements.

In conclusion, Bentonville Plastics employs a meticulous approach to manufacturing and quality assurance, ensuring that B2B buyers receive reliable, high-quality products. By understanding the manufacturing processes and quality control measures in place, international buyers can make informed decisions and establish successful partnerships.

Illustrative image related to bentonville plastics

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bentonville plastics’

Introduction

This practical sourcing guide is designed to assist international B2B buyers in procuring plastic products from Bentonville Plastics. By following this step-by-step checklist, you can streamline the sourcing process, ensure quality, and establish a fruitful partnership with your supplier.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, clearly outline your technical requirements. This includes the type of plastic needed, dimensions, tolerances, and any specific industry standards that must be met. Having a well-defined specification helps suppliers understand your needs and reduces the risk of miscommunication.

- Consider the end-use application: Different industries may require specific grades of plastic that can withstand certain environmental conditions.

- Document your requirements: A detailed specification sheet can serve as a reference for both you and the supplier throughout the sourcing process.

Step 2: Research Supplier Capabilities

Investigate the manufacturing capabilities of Bentonville Plastics to ensure they align with your requirements. This includes understanding their production processes—such as injection molding, blow molding, or rotational molding—and the materials they utilize.

- Ask about production capacity: Ensure the supplier can meet your volume requirements within your timeline.

- Inquire about customization options: Determine if they can provide tailored solutions to meet unique project needs.

Step 3: Evaluate Potential Suppliers

Thoroughly vet Bentonville Plastics and other potential suppliers before making a commitment. Request company profiles, case studies, and references from buyers in your industry or region to gauge their reliability and performance.

Illustrative image related to bentonville plastics

- Review their quality control processes: A supplier’s commitment to quality assurance can significantly impact the final product.

- Check for industry certifications: Certifications like ISO 9001 can indicate a supplier’s dedication to maintaining high standards.

Step 4: Request Samples

Once you’ve narrowed down your options, request samples of the products you intend to procure. Evaluating samples allows you to assess the quality, durability, and suitability of the plastic components for your applications.

- Test the samples in real-world conditions: This helps validate that the materials will perform as expected in your specific use case.

- Provide feedback: Use this opportunity to communicate any adjustments you may need before placing a larger order.

Step 5: Negotiate Terms and Pricing

Engage in discussions regarding pricing, payment terms, and delivery schedules. Be prepared to negotiate and ensure that the terms are mutually beneficial to foster a long-term partnership.

- Understand total cost of ownership: Consider factors such as shipping, tariffs, and potential discounts for bulk orders.

- Clarify payment terms: Ensure that payment methods and timelines align with your budget and cash flow.

Step 6: Finalize the Contract

Once terms are agreed upon, draft a formal contract that outlines all specifications, pricing, delivery schedules, and quality assurances. This document serves as a legal agreement that protects both parties.

- Include clauses for dispute resolution: This can prevent misunderstandings and provide a clear path for addressing issues.

- Review the contract with legal counsel: Ensure that all terms are fair and legally binding.

Step 7: Establish Communication Protocols

Effective communication is key to a successful supplier relationship. Set up regular check-ins to discuss production updates, delivery schedules, and any potential issues that may arise.

- Use project management tools: Consider tools that facilitate collaboration and tracking of milestones.

- Maintain open lines of communication: This fosters a proactive approach to problem-solving and enhances overall partnership satisfaction.

Comprehensive Cost and Pricing Analysis for bentonville plastics Sourcing

What Are the Key Cost Components in Bentonville Plastics Sourcing?

When considering sourcing from Bentonville Plastics, it’s crucial to understand the various components that contribute to the overall cost structure. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Illustrative image related to bentonville plastics

-

Materials: The choice of resin and other raw materials is a significant factor. Prices can fluctuate based on market conditions and availability, especially for specialty plastics. For international buyers, understanding local sourcing options can mitigate costs.

-

Labor: Labor costs vary based on the complexity of the molding process and the skill level required. Regions with higher labor costs may impact pricing, so it’s important to assess the labor market in Bentonville, Arkansas, relative to your own.

-

Manufacturing Overhead: This includes costs associated with utilities, facility maintenance, and administrative expenses. A well-managed facility can result in more competitive pricing.

-

Tooling: Tooling costs are substantial, especially for custom parts. The initial investment for molds can be high, but this cost is often amortized over large production runs.

-

Quality Control (QC): Implementing rigorous QC measures ensures that products meet specifications and standards. These processes can add to the cost but are essential for maintaining product integrity.

-

Logistics: Shipping costs must be factored into the total cost, especially for international buyers. Understanding Incoterms can help manage these expenses effectively.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. This margin can vary based on competition and the buyer’s negotiation strength.

How Do Price Influencers Affect Sourcing from Bentonville Plastics?

Several factors influence pricing when sourcing from Bentonville Plastics, including volume, specifications, materials, quality certifications, and supplier considerations.

-

Volume/MOQ: Purchasing in bulk can significantly reduce per-unit costs. Minimum Order Quantities (MOQs) should be discussed upfront, as higher volumes typically lead to better pricing.

-

Specifications and Customization: Customized products often come with higher prices due to additional design and tooling requirements. Clear specifications can help streamline the design process and potentially lower costs.

-

Material Choices: The type of plastic selected can impact pricing. Standard materials are usually less expensive than specialized or high-performance options.

-

Quality and Certifications: Products that meet industry standards or come with certifications (e.g., ISO, FDA) may command a premium. Buyers should evaluate whether these certifications are necessary for their specific applications.

-

Supplier Factors: Relationship dynamics with suppliers can affect pricing. Established partnerships may lead to discounts or favorable terms, making negotiation an essential skill.

-

Incoterms: Understanding Incoterms is vital for international buyers, as they dictate the responsibilities of buyers and sellers concerning shipping costs, insurance, and risk.

What Are Some Buyer Tips for Cost Efficiency in Sourcing?

For international buyers from regions like Africa, South America, the Middle East, and Europe, here are several strategies to enhance cost efficiency when sourcing from Bentonville Plastics:

-

Negotiation: Leverage your position as a buyer to negotiate better terms. Consider long-term contracts for stability and potential discounts.

-

Total Cost of Ownership (TCO): Evaluate the total cost beyond the initial price. This includes shipping, tariffs, and potential costs associated with quality issues or delays.

-

Explore Multiple Quotes: Obtain quotes from several suppliers to compare pricing and services. This can provide leverage in negotiations and ensure competitive pricing.

-

Understand Local Regulations: Familiarize yourself with import/export regulations, tariffs, and duties applicable to your region. This knowledge can help prevent unexpected costs.

-

Focus on Quality Over Price: Sometimes, opting for a slightly higher-priced supplier that guarantees quality can save money in the long run by reducing returns and replacements.

-

Build Relationships: Developing strong relationships with suppliers can lead to better service and flexibility in pricing, especially when you become a repeat customer.

Disclaimer on Indicative Prices

Prices for products from Bentonville Plastics can vary significantly based on the aforementioned factors. It is advisable for buyers to conduct thorough market research and engage directly with suppliers for the most accurate and current pricing information tailored to their specific needs.

Illustrative image related to bentonville plastics

Alternatives Analysis: Comparing bentonville plastics With Other Solutions

Understanding Alternative Solutions to Bentonville Plastics

In the rapidly evolving landscape of plastic manufacturing, B2B buyers must evaluate various solutions to meet their specific operational needs. Bentonville Plastics is recognized for its robust offerings in plastic molding and fabrication. However, there are other viable alternatives that may suit different requirements based on performance, cost, and application. This analysis will compare Bentonville Plastics against two notable alternatives: Injection Molding Technology and Rotational Molding.

Comparison Table

| Comparison Aspect | Bentonville Plastics | Injection Molding Technology | Rotational Molding |

|---|---|---|---|

| Performance | High precision, suitable for complex designs | Excellent for mass production with high accuracy | Good for large, hollow products with less complexity |

| Cost | Competitive, varies with customization | Higher initial investment but lower per unit cost at scale | Lower setup costs, ideal for small to medium runs |

| Ease of Implementation | Requires skilled labor and custom molds | Established processes, widely understood | Simpler setup, requires less specialized labor |

| Maintenance | Regular maintenance of molds and machinery | Generally low maintenance once operational | Moderate maintenance; molds are less complex |

| Best Use Case | Custom components for varied industries | High-volume production of consistent parts | Production of large, hollow items like tanks and toys |

Detailed Breakdown of Alternatives

Injection Molding Technology

Injection molding is a widely adopted method for producing high-volume plastic parts with intricate designs. Its primary advantage lies in its ability to create consistent, high-quality products rapidly. However, the initial setup costs can be significant due to the need for custom molds, which may deter smaller businesses. Once established, the process is efficient, allowing for high production rates and cost savings on a per-unit basis. This method is best suited for companies needing large quantities of identical parts, such as automotive or consumer goods manufacturers.

Rotational Molding

Rotational molding is an alternative that excels in producing large, hollow items like storage tanks or playground equipment. The process involves heating a mold while it is rotated, allowing the plastic to coat the interior evenly. This method is cost-effective for smaller production runs and has lower initial tooling costs compared to injection molding. However, it is not as suitable for complex shapes or high-precision components. Rotational molding is ideal for businesses focused on creating large, lightweight products that require minimal structural integrity.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between Bentonville Plastics and its alternatives, B2B buyers should carefully assess their specific requirements, including production volume, complexity of design, and budget constraints. Companies needing high precision and volume may favor injection molding, while those looking for lower costs and larger products may find rotational molding more advantageous. Ultimately, understanding the strengths and limitations of each option will enable businesses to make informed decisions that align with their operational goals and market demands.

Essential Technical Properties and Trade Terminology for bentonville plastics

What Are the Essential Technical Properties of Bentonville Plastics?

When sourcing plastic components from Bentonville Plastics, understanding key technical properties is crucial for B2B buyers. Here are some critical specifications that can influence product selection and performance.

1. Material Grade

Material grade refers to the specific formulation of plastic used in manufacturing. Different grades have unique properties such as strength, flexibility, and temperature resistance. For instance, high-density polyethylene (HDPE) is known for its robustness and is often used in packaging, while acrylonitrile butadiene styrene (ABS) is favored for its impact resistance and aesthetic qualities. Selecting the right material grade ensures that the product meets industry standards and performance expectations.

2. Tolerance

Tolerance is the allowable variation in the dimensions of a part during the manufacturing process. This specification is essential for ensuring that parts fit together as intended, especially in applications requiring precise assembly. For example, tighter tolerances are crucial in aerospace components, while looser tolerances may suffice for consumer goods. Understanding tolerance levels helps buyers assess the suitability of parts for their specific applications.

3. Surface Finish

The surface finish of a plastic part affects not only its aesthetic appeal but also its functionality. Common finishes include matte, gloss, and textured surfaces, each serving different purposes. A smooth finish may be preferred for packaging to enhance visual appeal, while a textured finish could improve grip in consumer products. Buyers should consider how surface finish impacts both the end-user experience and the functionality of the product.

4. Impact Resistance

Impact resistance measures a material’s ability to withstand sudden forces without breaking. This property is particularly important in sectors like automotive and consumer electronics, where components may be subject to shock or stress. Understanding the impact resistance of plastic parts ensures that they can endure the rigors of their intended applications, leading to greater durability and customer satisfaction.

5. Chemical Resistance

Chemical resistance indicates how well a material can withstand exposure to various chemicals without degrading. This property is critical for applications in industries such as pharmaceuticals, food packaging, and automotive, where contact with harsh substances is common. Buyers must ensure that the materials used can maintain their integrity and performance when exposed to specific chemicals.

What Common Trade Terms Should B2B Buyers Know?

In addition to technical specifications, familiarity with industry jargon is vital for effective communication and negotiation. Here are some common terms relevant to Bentonville Plastics.

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of Bentonville Plastics, it signifies that the company supplies components that are integrated into larger products manufactured by other businesses. Understanding OEM relationships can help buyers assess the credibility and reliability of suppliers.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. This term is crucial for budget-conscious buyers, as it can affect overall costs and inventory management. Knowing the MOQ helps businesses plan their purchasing strategies effectively, ensuring they meet production needs without overcommitting resources.

Illustrative image related to bentonville plastics

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing for specific products or services. By issuing an RFQ to Bentonville Plastics, buyers can receive detailed quotes that facilitate comparison among potential suppliers. This process is essential for making informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They clarify aspects such as shipping costs, risk transfer, and delivery points. Familiarity with Incoterms helps buyers understand their obligations and negotiate better terms with suppliers.

5. Lead Time

Lead time refers to the duration from the initiation of an order to its delivery. Understanding lead times is essential for supply chain management, as it impacts inventory levels and production schedules. Buyers should inquire about lead times when placing orders to ensure timely delivery of critical components.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when sourcing products from Bentonville Plastics, ultimately leading to improved operational efficiency and product quality.

Illustrative image related to bentonville plastics

Navigating Market Dynamics and Sourcing Trends in the bentonville plastics Sector

What Are the Key Trends Shaping the Bentonville Plastics Market?

The Bentonville plastics sector is witnessing significant transformation driven by global market dynamics and technological advancements. A major trend is the rising demand for customized plastic solutions, as businesses increasingly seek tailored components that meet specific operational requirements. This shift is facilitated by advancements in injection molding and other manufacturing technologies, enabling rapid prototyping and production. Furthermore, the growth of e-commerce is propelling the need for innovative packaging solutions, which are essential for enhancing product protection and shelf appeal.

International B2B buyers, particularly from emerging markets in Africa, South America, the Middle East, and Europe, should also note the increasing importance of sustainable materials. The global push towards circular economies is leading manufacturers to explore biodegradable and recyclable options, which can significantly impact sourcing decisions. Additionally, the ongoing digitalization of supply chains, including the use of AI and IoT for real-time tracking and inventory management, is changing how companies engage with suppliers. Buyers should consider these technological advancements as they strategize their sourcing processes.

How Is Sustainability Influencing Sourcing Decisions in the Bentonville Plastics Sector?

Sustainability has become a cornerstone of sourcing strategies in the Bentonville plastics sector. With growing awareness of environmental issues, businesses are prioritizing ethical supply chains that minimize ecological footprints. This involves not only selecting suppliers that utilize renewable resources but also ensuring that waste is effectively managed throughout the production process.

B2B buyers should look for suppliers who are certified in sustainable practices, such as those recognized by organizations like ISO 14001 for environmental management. Furthermore, sourcing materials that are recycled or derived from bio-based sources can enhance a company’s sustainability profile. The acquisition of companies like Sable Polymer Solutions by Ecoark Holdings reflects this trend, as it integrates recycling capabilities into the supply chain, providing a circular solution for plastic materials. Engaging with suppliers committed to sustainability not only enhances corporate responsibility but can also yield long-term cost savings and brand loyalty among environmentally conscious consumers.

What Is the Historical Context of Bentonville Plastics and Its Evolution?

The Bentonville plastics sector has evolved significantly since its inception in the mid-1980s, with Bentonville Plastics, Inc. at the forefront of this transformation. Initially focused on traditional plastic molding techniques, the company has expanded its capabilities to include advanced manufacturing processes such as blow molding and rotational molding. This evolution reflects broader industry trends towards innovation and customization.

The integration of sustainable practices, particularly after the acquisition of Sable Polymer Solutions, marks a pivotal point in the sector’s development. By embracing recycling and resource recovery, Bentonville Plastics is positioning itself as a leader in sustainable plastic solutions, catering to an increasingly environmentally aware market. This historical context underscores the importance of adaptability and innovation in meeting the changing demands of international B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of bentonville plastics

-

How do I source high-quality plastic products from Bentonville Plastics?

To source high-quality plastic products from Bentonville Plastics, begin by clearly defining your specifications and requirements, including material types, product dimensions, and desired quantities. Reach out to their sales team to discuss your needs and request a quote. It’s advisable to review their product catalog and request samples for quality assessment. Establishing a direct line of communication will also facilitate any customization needs and ensure timely responses to your queries. -

What types of plastic molding processes are offered by Bentonville Plastics?

Bentonville Plastics provides a variety of plastic molding processes, including injection molding, polyurethane molding, rotational molding, thermoforming, and blow molding. Each process is tailored to meet specific design and production requirements, allowing for the creation of both intricate and large structural components. Understanding these processes will help you select the best method for your project needs, whether for packaging, components, or specialized products. -

What customization options are available for plastic products?

Bentonville Plastics offers extensive customization options, allowing you to tailor products to your specific needs. This includes variations in material types, colors, sizes, and shapes. You can also request unique designs or modifications to existing products. Collaborating closely with their design team during the early stages of development ensures that your requirements are met, enhancing product functionality and market appeal. -

What is the minimum order quantity (MOQ) for products from Bentonville Plastics?

The minimum order quantity (MOQ) at Bentonville Plastics can vary depending on the product type and complexity of the design. Generally, MOQs are established to ensure cost-effectiveness in production. It’s advisable to consult directly with their sales team for precise MOQ details tailored to your specific product requirements, especially if you are considering a large-scale or customized order. -

What payment terms can I expect when working with Bentonville Plastics?

Payment terms with Bentonville Plastics typically include options such as upfront payments, net 30, or net 60 days, depending on the order size and customer relationship. For international buyers, it’s essential to discuss payment methods that accommodate your region, such as wire transfers or letters of credit. Establishing clear terms at the outset helps avoid misunderstandings and ensures a smooth transaction process. -

How does Bentonville Plastics ensure quality assurance in its products?

Bentonville Plastics adheres to stringent quality assurance protocols throughout the manufacturing process. This includes rigorous testing of raw materials, in-process inspections, and final product evaluations to meet industry standards. They utilize advanced technologies and methodologies to ensure that every product meets your specifications and performance requirements. It’s beneficial to inquire about their quality control practices during your initial discussions. -

What logistics and shipping options are available for international orders?

Bentonville Plastics offers various logistics and shipping options for international orders, including air freight, sea freight, and courier services. The choice of shipping method often depends on your delivery timeline and budget. They can assist in arranging logistics and provide guidance on customs requirements for your specific country, ensuring that your products arrive on time and in compliance with local regulations. -

How can I evaluate Bentonville Plastics as a reliable supplier?

To evaluate Bentonville Plastics as a reliable supplier, consider reviewing their industry experience, client testimonials, and case studies showcasing successful projects. Requesting references from other international clients can provide insights into their reliability and service quality. Additionally, assess their certifications and compliance with industry standards, which can further confirm their credibility as a trusted partner in your supply chain.

Top 5 Bentonville Plastics Manufacturers & Suppliers List

1. Bentonville Plastics – Premium Plastic Molding Services

Domain: plasticmoldingmanufacturers.com

Registered: 2015 (10 years)

Introduction: Bentonville Plastics, Inc provides premium plastic molding services since 1985. They specialize in various plastic molding processes including: 1. Plastic Injection Molding – mass fabrication of plastic parts using molten plastic injected into molds. 2. Polyurethane Molding – manufacturing plastic parts using urethane polymer systems. 3. Rotational Molding – producing hollow, seamless, double-wall…

2. Bentonville Plastics – Injection Molded Solutions

Domain: injection-molded-plastics.net

Registered: 2001 (24 years)

Introduction: Bentonville Plastics, Inc. specializes in injection molded plastics products, offering a wide range of solutions for various industries and applications. Key offerings include: 1. Custom plastic components, from small intricate parts to large structural components. 2. High-quality plastic packaging solutions, including containers, bottles, caps, closures, and related components. 3. Advanced inject…

3. Sable Polymer Solutions – Recycled Resin Feedstock

Domain: talkbusiness.net

Registered: 2005 (20 years)

Introduction: Sable Polymer Solutions produces products from recycled plastics, formulating recyclable materials into resin feedstock for industrial and consumer products. The acquisition allows Ecoark to create a vertically integrated supplier of recyclable products, managing the entire lifecycle from collection to repurposing and sale.

4. Bentonville Plastics – Key Products

Domain: linkedin.com

Registered: 2002 (23 years)

Introduction: This company, Bentonville Plastics – Key Products, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Bentonville Plastics – Employee Insights

Domain: indeed.com

Registered: 1998 (27 years)

Introduction: This company, Bentonville Plastics – Employee Insights, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for bentonville plastics

In the competitive landscape of plastics manufacturing, Bentonville Plastics stands out as a leader in innovation and quality. Their extensive expertise in diverse molding techniques—ranging from injection and rotational molding to eco-friendly solutions—positions them as a reliable partner for businesses seeking tailored plastic components. For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, strategic sourcing from Bentonville Plastics offers not only high-quality products but also the opportunity to engage with a company committed to sustainability through their recent acquisition by Ecoark Holdings.

The value of strategic sourcing cannot be overstated. By leveraging Bentonville Plastics’ advanced manufacturing capabilities, businesses can enhance their product offerings while ensuring compliance with global quality standards. This partnership can also facilitate access to innovative packaging solutions that cater to varying market demands.

Looking ahead, now is the perfect time for international buyers to explore the possibilities of collaboration with Bentonville Plastics. By prioritizing sustainable practices and customer-centric solutions, Bentonville Plastics is poised to meet the evolving needs of global markets. Engage with them today to unlock the potential of your projects and drive success in your industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to bentonville plastics

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.