Belting Material: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for belting material

In the fast-paced global market, sourcing the right belting material can pose a significant challenge for B2B buyers. With an array of options ranging from PVC to specialized food-grade materials, the decision-making process can be daunting. This comprehensive guide aims to simplify that journey, providing insights into various types of belting materials, their applications across industries, and essential considerations for supplier vetting. Whether you are in Africa, South America, the Middle East, or Europe, understanding the nuances of belting materials is crucial for optimizing your operations and ensuring compliance with local regulations.

Throughout this guide, we will explore the characteristics of different belting materials, such as rubber, polyurethane, and thermoplastic options, and their specific applications in sectors like food processing, manufacturing, and logistics. Additionally, we will discuss strategies for evaluating suppliers and estimating costs, empowering you to make informed purchasing decisions. By equipping yourself with this knowledge, you can navigate the complexities of the belting material market with confidence, minimizing risks while maximizing efficiency and productivity. The insights provided herein will be invaluable as you seek to establish long-term partnerships and enhance your supply chain resilience in an increasingly interconnected world.

Understanding belting material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| PVC Conveyor Belts | Versatile, oil and chemical-resistant, moderate flexibility | General manufacturing, packaging, and distribution | Pros: Cost-effective, good abrasion resistance. Cons: Limited temperature tolerance. |

| Rubber Conveyor Belts | Highly durable, flexible, excellent impact resistance | Mining, heavy-duty industrial applications | Pros: Great for heavy loads, long lifespan. Cons: Can degrade with chemicals. |

| Thermoplastic Polyurethane (TPU) | Lightweight, wear-resistant, high elasticity | Food processing, packaging, and conveyor systems | Pros: Good for sensitive products, resistant to oils. Cons: Limited chemical resistance. |

| FDA-Approved PVC | Compliant with food safety regulations, smooth surface | Food processing and handling | Pros: Safe for direct food contact. Cons: Not suitable for high-temperature applications. |

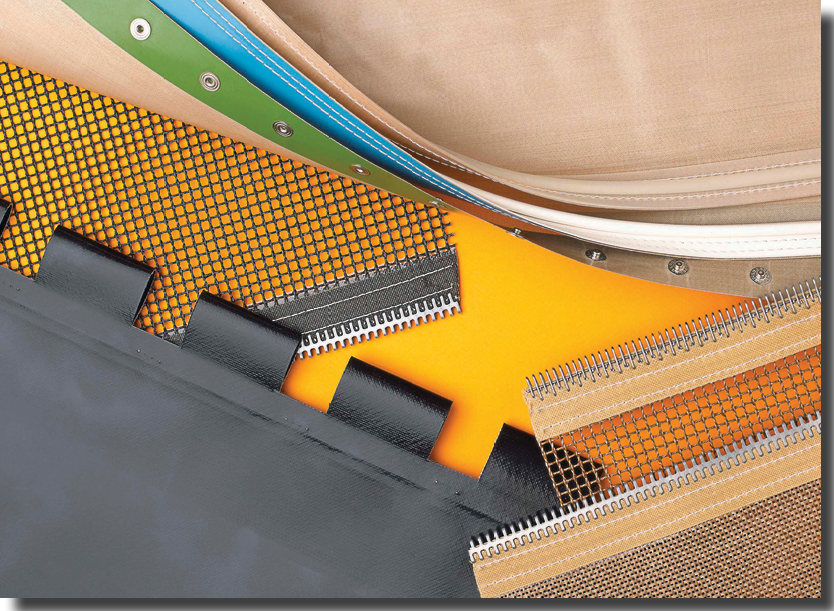

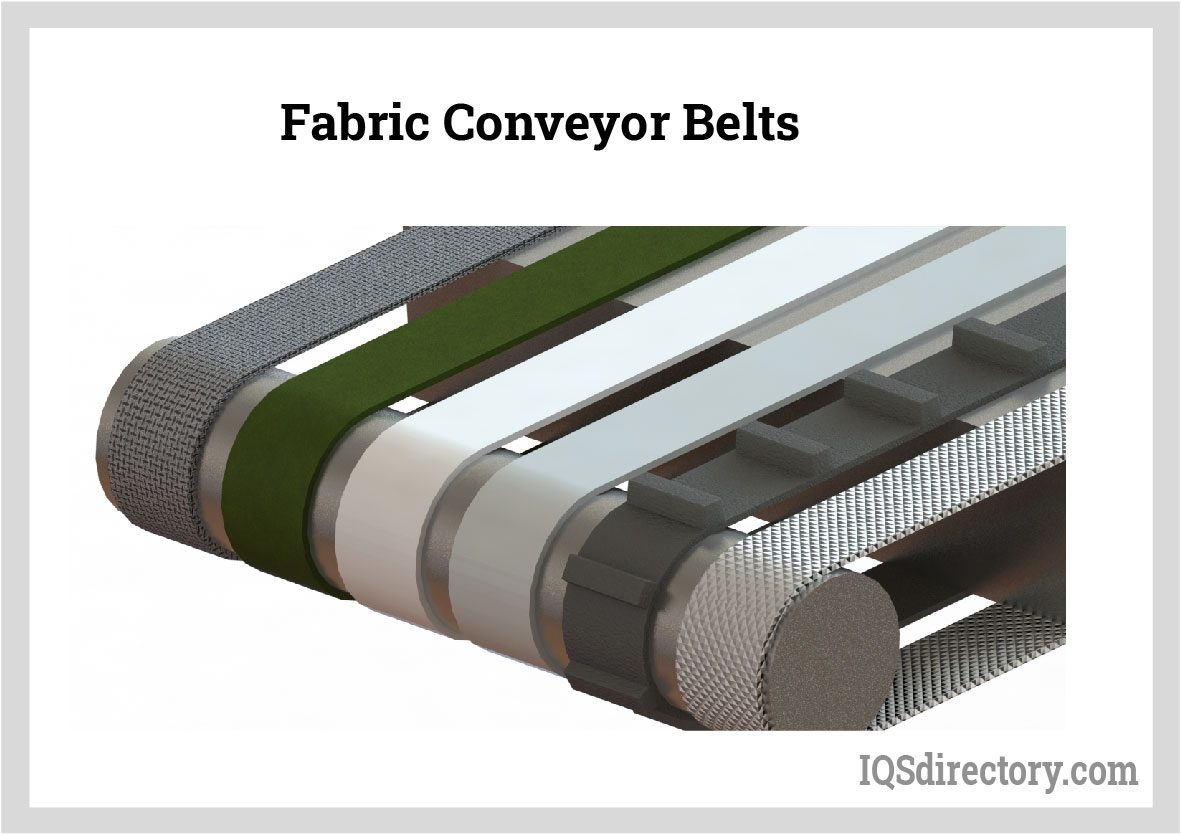

| Fabric Conveyor Belts | Made from woven materials, customizable thickness | Textile, recycling, and bulk handling | Pros: Flexible, customizable for specific needs. Cons: Generally lower durability than rubber or PVC. |

What Are the Characteristics of PVC Conveyor Belts for B2B Buyers?

PVC conveyor belts are known for their versatility and resistance to oils and chemicals, making them suitable for various applications in general manufacturing and distribution. They provide a good balance of cost and performance but have limitations in extreme temperature environments. B2B buyers should consider the specific operational conditions, as prolonged exposure to heat can compromise the material’s integrity.

Why Choose Rubber Conveyor Belts for Heavy-Duty Applications?

Rubber conveyor belts are favored in industries requiring durability and flexibility, such as mining and heavy-duty manufacturing. Their excellent impact resistance makes them ideal for transporting heavy loads. However, buyers need to be cautious of their susceptibility to chemical degradation, which can affect longevity. Understanding the specific environment and materials they will encounter is crucial for making an informed purchasing decision.

What Makes Thermoplastic Polyurethane (TPU) Belts Ideal for Sensitive Products?

Thermoplastic polyurethane (TPU) belts are lightweight and offer high elasticity, making them suitable for applications in food processing and packaging where product integrity is critical. Their resistance to oils and fats enhances their usability in environments where hygiene is paramount. However, buyers should note that while they excel in sensitivity, their chemical resistance may not match that of other materials, impacting their application scope.

How Do FDA-Approved PVC Belts Meet Food Safety Standards?

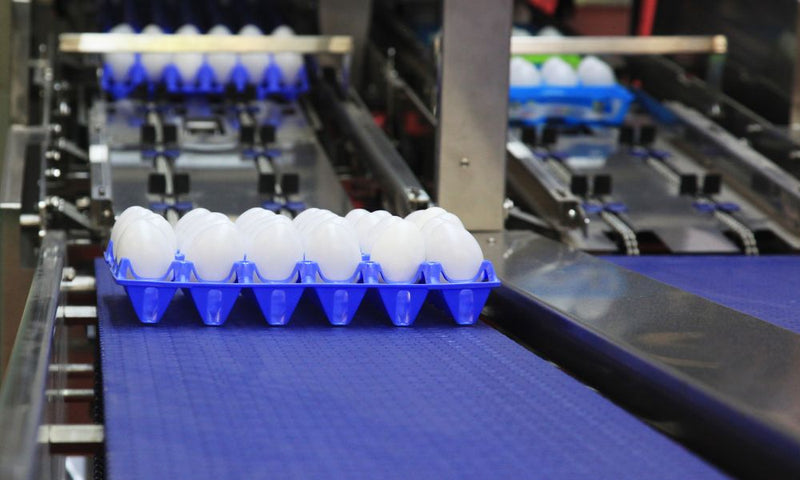

FDA-approved PVC conveyor belts are specifically designed to comply with food safety regulations, ensuring they are safe for direct contact with food products. Their smooth surface minimizes contamination risks, making them ideal for the food processing industry. However, they are not recommended for high-temperature environments, which buyers need to consider when selecting materials for their operations.

What Are the Benefits of Fabric Conveyor Belts in Custom Applications?

Fabric conveyor belts, made from woven materials, offer flexibility and customization options that can be tailored to specific industrial needs. They are commonly used in textile, recycling, and bulk handling applications. While they provide adaptability, their durability may not match that of rubber or PVC belts, which is an essential factor for buyers to evaluate based on their operational requirements.

Key Industrial Applications of belting material

| Industry/Sector | Specific Application of belting material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Conveyor systems for packaging and sorting | Ensures food safety and compliance with regulations | FDA-approved materials, resistance to cleaning agents |

| Mining and Quarrying | Transporting bulk materials like minerals and ores | Enhances operational efficiency and reduces downtime | High tensile strength, resistance to abrasion |

| Manufacturing | Assembly lines for product handling | Streamlines production processes and improves productivity | Customizable designs, compatibility with machinery |

| Agriculture | Grain handling and processing | Increases throughput and minimizes product damage | Weather-resistant materials, easy maintenance |

| Logistics and Warehousing | Automated sorting and distribution systems | Improves supply chain efficiency and reduces labor costs | Durability under heavy loads, flexibility in design |

How is Belting Material Used in Food Processing?

In the food processing industry, belting material is critical for conveyor systems that handle packaging, sorting, and transporting food products. These belts must meet stringent safety standards, such as FDA approval, to prevent contamination. Buyers need to consider materials that resist cleaning agents and can withstand the rigors of frequent sanitation processes. This ensures compliance with health regulations and maintains product integrity, especially in regions like Africa and South America where food safety standards are increasingly emphasized.

What Role Does Belting Material Play in Mining and Quarrying?

In mining and quarrying, belting material is essential for transporting bulk materials, such as minerals and ores, across various terrains. Rubber and PVC belts are commonly used due to their high tensile strength and resistance to abrasion, which are vital for handling heavy loads and rough materials. Buyers should prioritize sourcing durable belts that can withstand harsh environmental conditions, especially in regions like the Middle East where operational challenges can be significant. The right belting material can significantly enhance operational efficiency and minimize costly downtimes.

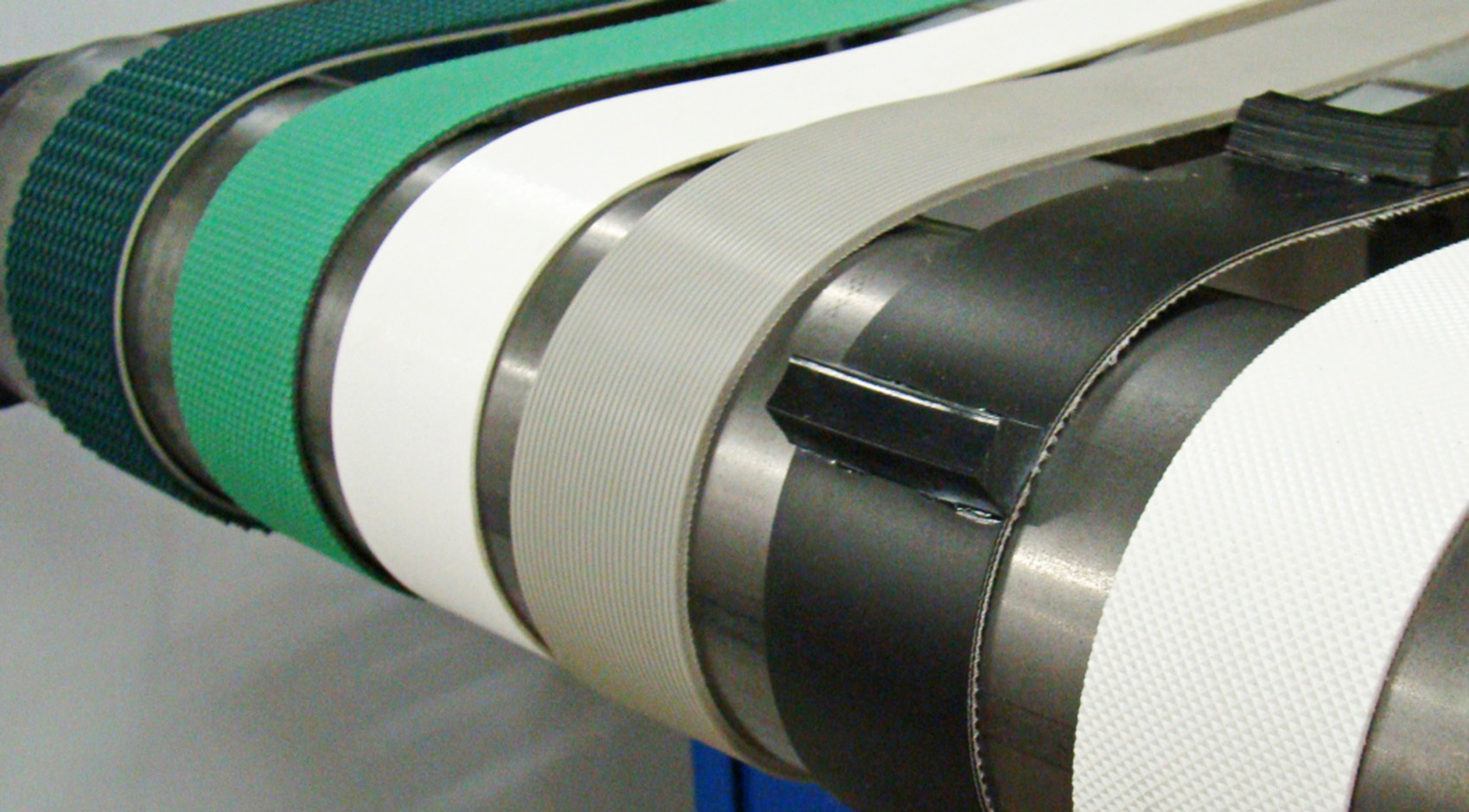

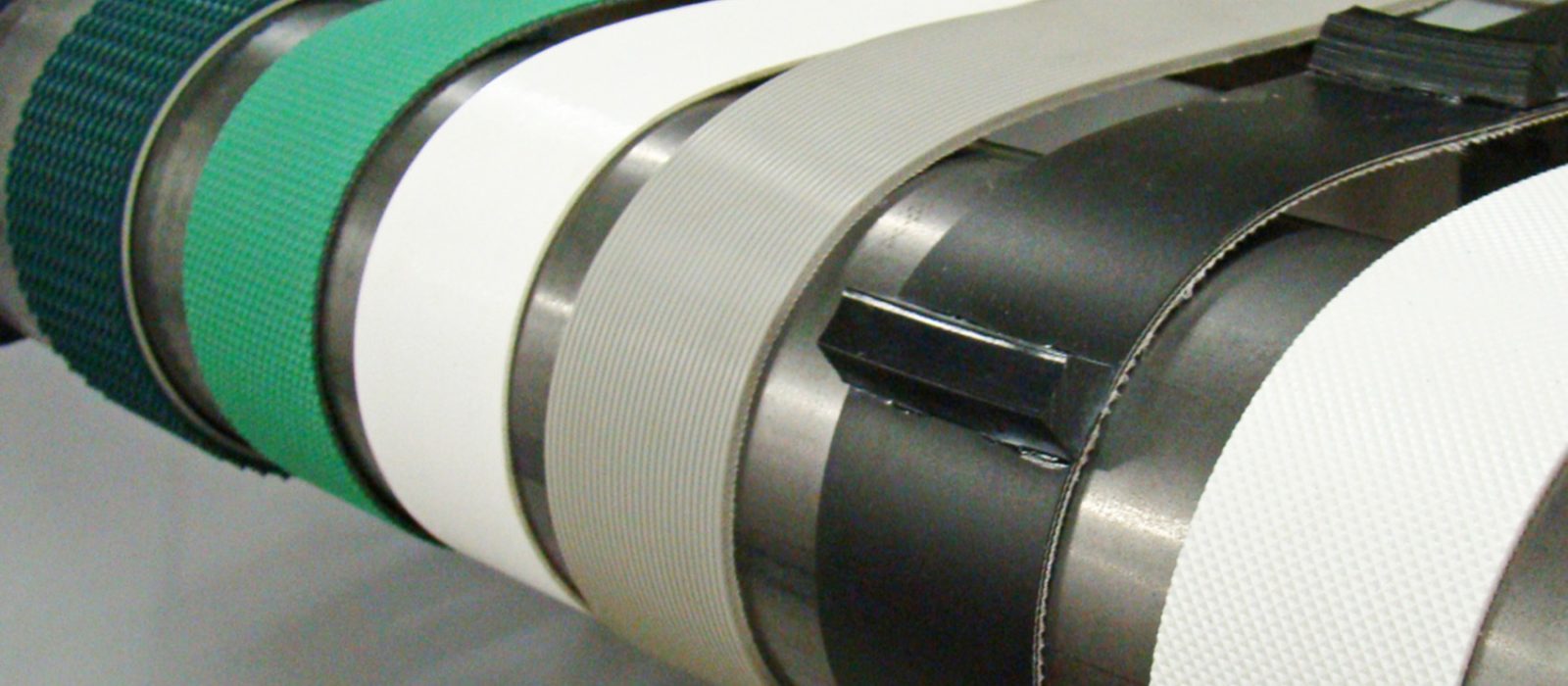

Illustrative image related to belting material

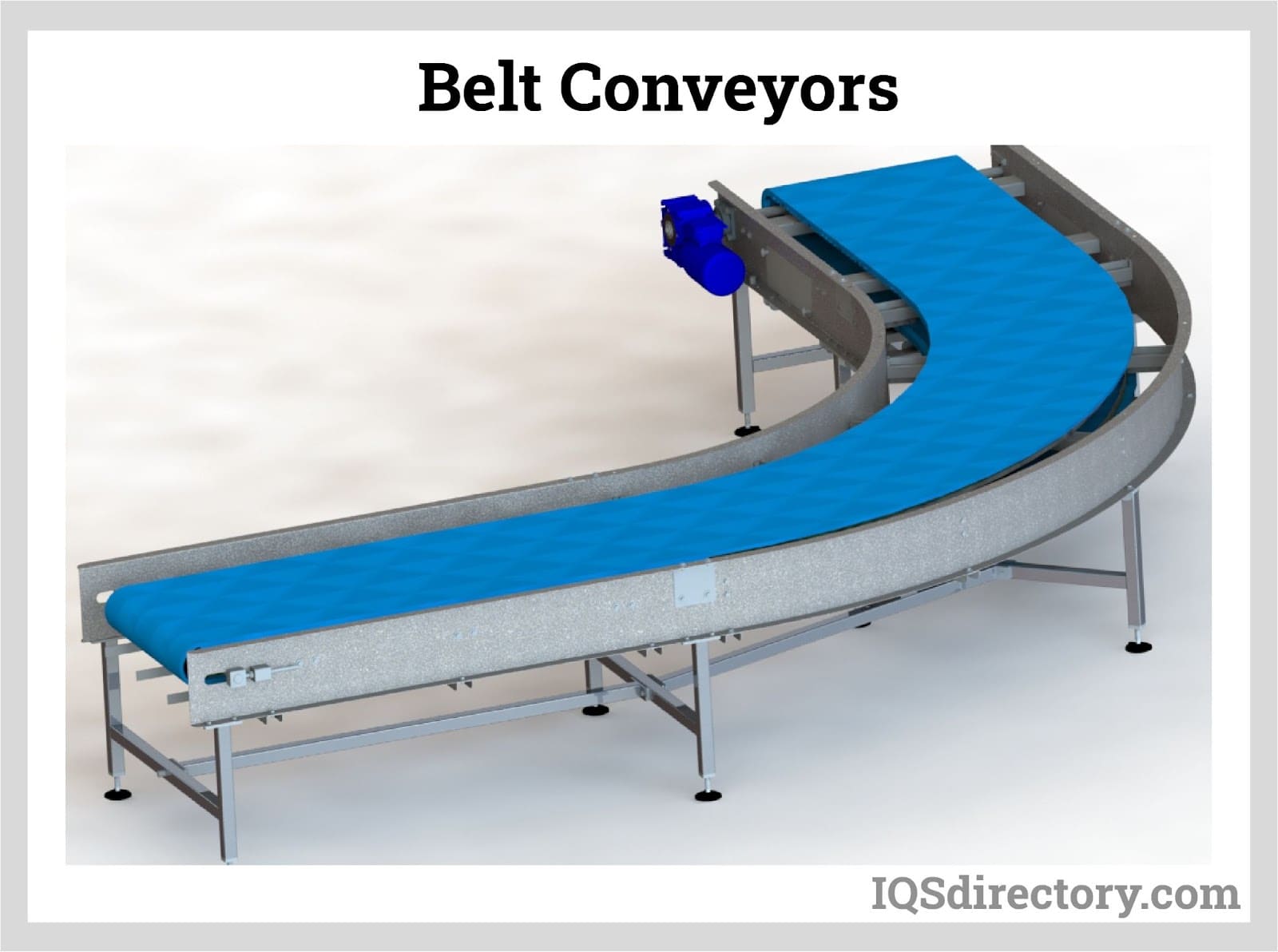

How Does Belting Material Enhance Manufacturing Processes?

Manufacturing industries rely on belting material for assembly lines and product handling systems. These belts facilitate the movement of components and finished products, streamlining operations and improving productivity. Buyers should look for customizable belt designs that fit their specific machinery and processes, ensuring compatibility. In Europe, where manufacturing standards are high, sourcing belts that meet these requirements is crucial for maintaining competitive advantage and operational efficiency.

In What Ways is Belting Material Utilized in Agriculture?

In agriculture, belting material is used for grain handling and processing applications, providing a reliable means to transport crops from fields to storage facilities. The right belts can increase throughput while minimizing damage to delicate products. Buyers must consider weather-resistant materials that can endure outdoor conditions and are easy to maintain. This is particularly important in regions like South America, where agricultural operations are extensive and diverse, requiring robust and efficient handling solutions.

How is Belting Material Important for Logistics and Warehousing?

In logistics and warehousing, belting material is integral to automated sorting and distribution systems. These conveyor belts enhance supply chain efficiency by facilitating the quick movement of goods, reducing labor costs, and minimizing human error. Buyers should focus on sourcing durable belts capable of handling heavy loads while maintaining flexibility in design to adapt to various operational layouts. This consideration is vital in fast-paced environments across Europe and Africa, where logistics efficiency is a key driver of business success.

3 Common User Pain Points for ‘belting material’ & Their Solutions

Scenario 1: Sourcing Quality Belting Materials for Harsh Environments

The Problem: B2B buyers in industries such as mining or food processing often face the challenge of sourcing belting materials that can withstand extreme conditions. For instance, belts used in mining must resist wear from abrasive materials, while those in food processing need to comply with stringent hygiene standards. When the wrong materials are selected, it can lead to premature belt failure, increased downtime, and ultimately, significant financial losses.

The Solution: To mitigate this risk, buyers should start by conducting a thorough needs assessment that evaluates the specific environmental conditions their belting materials will encounter. For harsh environments, consider sourcing materials such as rubber or thermoplastic polyurethane (TPU), which offer excellent durability and resistance to wear and tear. Engage with suppliers who specialize in your industry and can provide insights into their materials’ performance under specific conditions. Request samples and conduct tests to ensure compatibility with your operational needs. Additionally, consider investing in customized solutions that tailor the belting materials to your precise specifications, enhancing longevity and performance.

Scenario 2: Compliance with Food Safety Standards

The Problem: In the food processing industry, compliance with food safety regulations is paramount. B2B buyers often struggle to find belting materials that not only meet food safety standards but also perform effectively in production environments. A lack of suitable options can lead to contamination risks, production delays, and costly regulatory fines.

The Solution: Buyers should prioritize sourcing FDA-approved materials that are explicitly designed for food contact, such as FDA-approved PVC or specially formulated TPU. These materials are engineered to prevent contamination and withstand cleaning processes without degrading. To ensure compliance, work closely with suppliers who can provide certifications and detailed material specifications. Regularly review your suppliers’ quality assurance processes and consider conducting audits to verify their adherence to food safety standards. Collaborating with industry experts can also help you stay updated on changing regulations and new materials that may offer better performance.

Scenario 3: Managing Cost Efficiency While Maintaining Performance

The Problem: Cost management is a significant concern for B2B buyers, particularly in competitive industries where profit margins are tight. Buyers often find themselves at a crossroads between selecting cost-effective belting materials and ensuring that these materials can perform adequately for their operations. Choosing lower-cost options without thorough evaluation can lead to frequent replacements and higher long-term costs.

The Solution: To strike a balance between cost and performance, buyers should adopt a total cost of ownership (TCO) approach. This involves analyzing not only the initial purchase price but also factors such as maintenance costs, downtime, and lifespan of the belting materials. Collaborate with suppliers who can provide insights into the durability and lifespan of different materials. Engaging in bulk purchasing or long-term contracts can also yield savings. Additionally, consider investing in training for your maintenance staff to ensure proper installation and handling of the belts, which can further enhance their lifespan and performance, ultimately providing a better return on investment.

Strategic Material Selection Guide for belting material

What Are the Key Properties of Common Belting Materials?

When selecting belting materials for industrial applications, understanding the properties of various materials is essential. Here, we analyze four common materials used in belting—PVC, rubber, polyurethane, and thermoplastic polyurethane (TPU)—focusing on their performance characteristics, pros and cons, and specific considerations for international buyers.

How Does PVC Perform in Conveyor Belt Applications?

PVC, or polyvinyl chloride, is a widely used material for conveyor belts due to its versatility. It typically offers good resistance to oils, chemicals, and abrasion, making it suitable for various applications. However, PVC is not ideal for extreme temperature conditions, as high heat can compromise its structural integrity.

Pros: PVC belts are cost-effective, lightweight, and easy to manufacture. They are suitable for general-purpose applications and can be customized for specific needs.

Cons: The main limitation of PVC is its vulnerability to extreme temperatures and its reduced performance in high-stress environments. Additionally, while it is durable, it may not last as long as other materials in demanding applications.

Impact on Application: PVC belts are commonly used in food processing, packaging, and light industrial applications. However, they should not be used in environments with high heat or exposure to certain chemicals.

Considerations for International Buyers: Buyers from regions such as Africa and South America should ensure compliance with local regulations regarding material safety and environmental impact. Standards like ASTM and DIN may apply, and it is crucial to verify that the PVC used is of high quality and suitable for the intended application.

What Are the Advantages of Rubber Belting?

Rubber is another popular choice for conveyor belts, known for its flexibility and durability. It offers excellent resistance to abrasion and impact, making it ideal for heavy-duty applications.

Pros: Rubber belts are highly durable and can withstand harsh environments, making them suitable for mining, construction, and heavy manufacturing.

Illustrative image related to belting material

Cons: The primary drawback of rubber is its susceptibility to degradation when exposed to oils and chemicals. Additionally, rubber belts can be more expensive than PVC options.

Impact on Application: Rubber belts are often used in environments where heavy loads and rough handling are common. They are particularly effective in transporting bulk materials.

Considerations for International Buyers: Buyers should consider the specific rubber grades and their compliance with international standards. In regions like the Middle East, where temperatures can be high, selecting rubber that can withstand heat is essential.

How Does Polyurethane Compare as a Belting Material?

Polyurethane is known for its lightweight and wear-resistant properties, making it an excellent choice for applications requiring high elasticity and flexibility.

Pros: Polyurethane belts are ideal for long-distance conveying and sensitive products, as they minimize product damage. They also offer good resistance to oils and fats.

Cons: However, polyurethane is less resistant to high temperatures and harsh chemicals compared to other materials, which can limit its application scope.

Impact on Application: These belts are commonly used in food processing and packaging industries, where product integrity is critical.

Considerations for International Buyers: Compliance with food safety standards is crucial for buyers in the food processing sector. Materials must meet FDA or equivalent standards, especially in Europe and the Middle East.

Illustrative image related to belting material

What Are the Benefits of Thermoplastic Polyurethane (TPU) Belting?

TPU is a specialized type of polyurethane that combines the benefits of both rubber and plastic. It is known for its high resistance to wear, tear, and chemicals.

Pros: TPU belts are highly durable and can withstand a wide range of temperatures and environmental conditions. They are also suitable for food-grade applications.

Cons: The main limitation is the cost, as TPU belts tend to be more expensive than PVC and rubber options.

Impact on Application: TPU is ideal for applications requiring high performance in challenging environments, such as automotive and food processing industries.

Considerations for International Buyers: Buyers should ensure that TPU belts comply with international standards, particularly for food safety. Understanding local regulations in regions like Brazil and Saudi Arabia is vital to ensure compliance.

Summary Table of Belting Materials

| Material | Typical Use Case for belting material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Food processing, packaging | Cost-effective and versatile | Vulnerable to extreme temperatures | Low |

| Rubber | Mining, construction, heavy industry | Highly durable and abrasion-resistant | Degrades with oils and chemicals | Medium |

| Polyurethane | Food processing, sensitive products | Lightweight and flexible | Less resistant to high temperatures | Medium |

| TPU | Automotive, food processing | High durability and temperature range | Higher cost compared to PVC and rubber | High |

This strategic material selection guide serves as a comprehensive resource for international B2B buyers, providing insights into the properties, advantages, and limitations of various belting materials. Understanding these elements is crucial for making informed purchasing decisions that align with specific application needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for belting material

What Are the Main Stages of Manufacturing Belting Material?

The manufacturing process for belting material involves several critical stages that ensure the final product meets the necessary performance standards and specifications. Understanding these stages can help B2B buyers assess potential suppliers and their capabilities.

Material Preparation

The first step in the manufacturing process is the preparation of raw materials. Depending on the type of belting being produced, this may include synthetic materials like PVC, polyurethane, or rubber, as well as fabric reinforcements. Suppliers often source high-quality materials from reputable manufacturers, ensuring they possess the necessary certifications for industrial use.

Once the materials are acquired, they undergo rigorous quality checks to confirm their suitability for production. This phase includes inspecting for defects, testing for material properties (like tensile strength and elasticity), and verifying compliance with relevant industry standards.

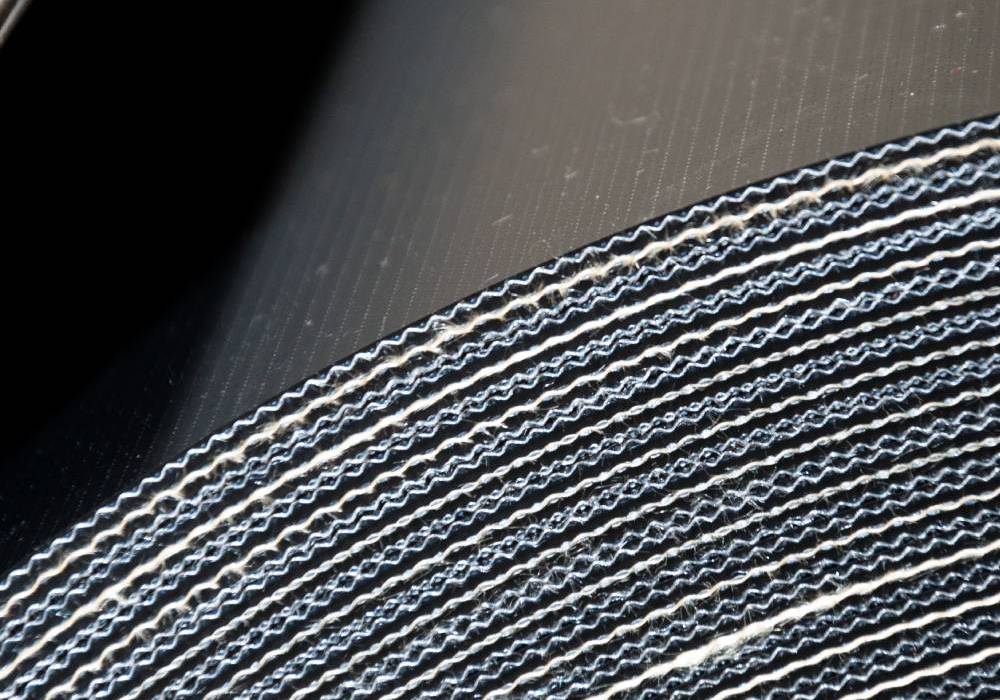

Forming the Belts

After the raw materials are prepared, the next stage is forming the belts. This process involves cutting the materials into specific shapes and sizes, which may be performed using automated machinery for precision. Techniques such as extrusion or molding may be employed, depending on the design requirements.

For fabric-reinforced belts, layers of fabric are often coated with a rubber or plastic material to enhance durability and performance. This step is crucial, as it determines the belt’s resistance to wear, chemicals, and environmental factors.

Assembly of Components

Once the belts are formed, they move to the assembly stage. Here, various components, such as fasteners, cleats, or sidewalls, are attached. This can involve sewing, bonding, or mechanical fastening techniques to ensure that the components are securely in place.

Illustrative image related to belting material

Quality at this stage is critical, as improper assembly can lead to operational failures in the field. Manufacturers should implement strict adherence to assembly protocols, utilizing skilled labor and automated systems to ensure uniformity and reliability.

Finishing Touches

The final stage in manufacturing is finishing. This includes processes such as surface treatment, where belts may be coated or treated to enhance properties like slip resistance or chemical resistance.

After finishing, the belts undergo another round of quality assurance checks to ensure that they meet all specified criteria. This may include visual inspections, dimensional checks, and performance tests to confirm that the belts will perform under the conditions they are designed for.

Illustrative image related to belting material

How Is Quality Assurance Implemented in Belting Material Manufacturing?

Quality assurance (QA) is paramount in the manufacturing of belting materials, especially for B2B buyers who require reliability and consistency in performance. Manufacturers often adhere to international standards to ensure that their products are safe and effective.

What International Standards Are Relevant for Belting Material?

Many manufacturers comply with ISO 9001, which outlines the criteria for a quality management system. This standard emphasizes continuous improvement, customer satisfaction, and the ability to consistently provide products that meet customer and regulatory requirements.

In addition to ISO 9001, industry-specific certifications such as CE (Conformité Européenne) for products sold in Europe or API (American Petroleum Institute) standards for oil and gas applications may also be relevant. These certifications help ensure that the belting materials are suitable for specific applications and meet regulatory requirements.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is integrated throughout the manufacturing process, with several checkpoints to ensure product integrity:

Illustrative image related to belting material

-

Incoming Quality Control (IQC): This initial checkpoint occurs when raw materials arrive at the manufacturing facility. Materials are inspected for compliance with specifications and tested for quality before production begins.

-

In-Process Quality Control (IPQC): Throughout the manufacturing stages, ongoing checks are performed to monitor production processes. This includes dimensional checks, material property testing, and visual inspections to ensure that any deviations are caught early.

-

Final Quality Control (FQC): Once the belts are completed, they undergo rigorous testing and inspection before shipment. This may include performance tests, load testing, and inspections for any visual defects.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are several methods to ensure that suppliers adhere to high-quality standards:

-

Supplier Audits: Conducting on-site audits can provide insights into a supplier’s manufacturing processes, quality control systems, and compliance with international standards. Audits should focus on reviewing documentation, processes, and the overall quality management system.

-

Requesting Quality Assurance Reports: Buyers should request detailed QA reports that outline the testing methods used, results obtained, and any certifications achieved. This documentation can be vital in assessing a supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s products and processes. These services can perform random inspections and tests, ensuring that the products meet the required specifications before they are shipped.

What Nuances Should International Buyers Consider Regarding Quality Control?

International buyers must be aware of specific nuances that may affect quality control when sourcing belting materials. Differences in regulatory standards, material availability, and manufacturing practices can lead to variations in product quality.

For example, suppliers in different regions may adhere to varying safety and quality standards. Buyers should familiarize themselves with local regulations and ensure that their suppliers comply with both international and region-specific requirements.

Additionally, cultural differences may influence communication and expectations regarding quality. Establishing clear quality expectations upfront and maintaining open lines of communication throughout the manufacturing process can help mitigate potential misunderstandings.

Illustrative image related to belting material

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance practices in belting material production is essential for B2B buyers. By focusing on these aspects, buyers can make informed decisions, ensuring they source high-quality materials that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘belting material’

To effectively procure belting material, B2B buyers must navigate various factors that influence their purchasing decisions. This guide provides a structured checklist to streamline the sourcing process, ensuring you make informed and strategic choices tailored to your operational needs.

Step 1: Define Your Technical Specifications

Clearly outlining your technical requirements is the foundation of successful sourcing. Identify the specific characteristics needed for your application, such as material type (e.g., PVC, rubber, or polyurethane), thickness, tensile strength, and any industry-specific certifications (e.g., FDA approval for food-grade belts). This clarity helps eliminate unsuitable options early in the process.

Illustrative image related to belting material

Step 2: Research Suitable Materials for Your Application

Different applications require different types of belting materials. Investigate the properties of available materials, focusing on their resistance to chemicals, temperature variations, and wear. For instance, if your operation involves food processing, prioritize FDA-approved options that ensure safety and compliance.

- Common Materials to Consider:

- PVC: Versatile and resistant to oils but not ideal for extreme temperatures.

- Rubber: Durable and flexible, suitable for various general-purpose applications.

Step 3: Evaluate Potential Suppliers

Before committing, thoroughly vet potential suppliers to ensure they meet your quality and service expectations. Request detailed company profiles, product catalogs, and case studies from clients in similar industries or regions. This due diligence helps assess their reliability and capability.

- Key Evaluation Criteria:

- Supplier experience in your industry.

- Availability of customer support and after-sales service.

Step 4: Check for Certifications and Compliance

Verify that suppliers possess the necessary certifications to guarantee product quality and compliance with industry standards. This is particularly crucial in regulated sectors like food and pharmaceuticals. Look for certifications such as ISO standards, FDA approval, or any local regulatory compliance relevant to your market.

Step 5: Request Samples for Testing

Obtaining samples allows you to evaluate the material’s performance in your specific application before making a bulk purchase. Conduct tests to assess durability, flexibility, and compatibility with your existing systems. This step can save you from costly mistakes later on.

Step 6: Analyze Pricing and Payment Terms

Once you have a shortlist of potential suppliers, compare pricing structures and payment terms. Ensure that the costs align with your budget while considering the total cost of ownership, including potential maintenance and replacement expenses. Negotiate payment terms that best suit your financial strategy.

Step 7: Establish a Long-Term Relationship

Building a long-term partnership with your chosen supplier can lead to better pricing, priority service, and enhanced collaboration on future projects. Open lines of communication and regular feedback sessions can foster a mutually beneficial relationship, ensuring that both parties can adapt to changing needs over time.

By following this checklist, B2B buyers can navigate the complexities of sourcing belting material, ensuring they select the right products and suppliers to meet their operational demands.

Comprehensive Cost and Pricing Analysis for belting material Sourcing

What Are the Key Cost Components in Belting Material Sourcing?

Understanding the cost structure of belting materials is essential for B2B buyers aiming to optimize their sourcing strategies. The primary cost components include:

-

Materials: The type of material significantly influences the price. For instance, PVC and rubber are common choices, with costs varying based on quality and market demand. Specialty materials like FDA-approved PVC or thermoplastic polyurethane (TPU) typically command higher prices due to stringent regulatory requirements.

-

Labor: Labor costs are incurred during manufacturing and assembly. Skilled labor may be necessary for high-quality production, particularly for custom belts, which can increase the overall cost.

-

Manufacturing Overhead: This encompasses utilities, equipment maintenance, and factory operational costs. Efficient manufacturing processes can help mitigate overhead costs, making it crucial for buyers to evaluate supplier capabilities.

-

Tooling: The setup costs for molds and dies used in production can be significant, especially for custom or specialized belts. These costs are often amortized over the production run, impacting pricing.

-

Quality Control (QC): Ensuring that products meet required specifications involves QC processes, which can add to the overall expense. Suppliers with robust QC measures may charge higher prices but offer better reliability and performance.

-

Logistics: Shipping, handling, and storage costs must be factored in, especially for international transactions. Different Incoterms can influence these costs, impacting the final price.

-

Margin: Suppliers typically add a profit margin on top of their costs, which can vary based on market competition and demand.

How Do Price Influencers Affect Belting Material Costs?

Several factors can influence pricing beyond the basic cost components:

-

Volume/MOQ: Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) to benefit from bulk pricing.

-

Specifications and Customization: Custom belts tailored to specific applications can increase costs. Buyers should be clear about their requirements to avoid unnecessary expenses.

-

Materials: The choice of materials affects pricing. For instance, specialized materials with certifications (e.g., food-grade certifications) will typically be more expensive.

-

Quality and Certifications: Higher quality materials and certified products may incur additional costs but can provide long-term savings through durability and compliance with industry standards.

-

Supplier Factors: The supplier’s reputation, production capacity, and location can all impact pricing. Established suppliers with a track record of quality may charge premium prices.

-

Incoterms: Understanding the shipping terms is vital for cost management. Different Incoterms can shift responsibilities and costs between buyers and sellers, affecting the total landed cost.

What Are the Best Buyer Tips for Cost-Efficient Belting Material Sourcing?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, here are actionable tips:

-

Negotiate Effectively: Engage suppliers in discussions about pricing, especially for large orders. Leverage competition among suppliers to negotiate better terms.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, replacement, and operational costs over the belt’s life. Higher upfront costs for premium products may lead to lower TCO.

-

Understand Pricing Nuances: Be aware of regional pricing differences and market dynamics. Prices may fluctuate based on local supply and demand, currency exchange rates, and geopolitical factors.

-

Request Detailed Quotes: Ensure that quotes include a breakdown of costs, allowing for better comparison and understanding of what you are paying for.

-

Build Long-Term Relationships: Establishing solid relationships with suppliers can lead to better pricing, priority service, and insights into upcoming market trends.

Disclaimer for Indicative Prices

The prices discussed in this analysis are indicative and can vary based on market conditions, supplier negotiations, and regional factors. Buyers are encouraged to conduct their own research and obtain quotes tailored to their specific needs.

Alternatives Analysis: Comparing belting material With Other Solutions

Understanding the Alternatives to Belting Material

In the quest for optimal material handling solutions, it’s essential to evaluate not only the benefits of traditional belting materials but also viable alternatives that may offer unique advantages. This analysis compares various belting materials with alternative technologies, allowing B2B buyers to make informed decisions based on performance, cost, and application suitability.

Illustrative image related to belting material

Comparison Table

| Comparison Aspect | Belting Material | Modular Plastic Belts | Roller Conveyor Systems |

|---|---|---|---|

| Performance | High tensile strength; suitable for various applications | Flexible design; good for complex layouts | High-speed transportation; ideal for heavy loads |

| Cost | Moderate initial investment; variable based on material type | Higher upfront cost; long-term savings due to durability | Higher installation and maintenance costs |

| Ease of Implementation | Relatively straightforward installation | Requires more planning and design | Complex setup; space-intensive |

| Maintenance | Regular inspections needed; can be replaced easily | Low maintenance; modularity allows for easy repairs | Requires frequent maintenance; parts can be costly |

| Best Use Case | General material handling in various industries | Food processing, packaging, and complex routing | Heavy-duty applications, assembly lines, and warehousing |

Detailed Breakdown of Alternatives

Modular Plastic Belts

Modular plastic belts are an innovative alternative to traditional belting materials. They offer flexibility in design, allowing for intricate layouts and configurations that can adapt to specific operational needs. The modular nature of these belts means that if a section becomes damaged, it can be easily replaced without needing to replace the entire belt. However, the initial investment is higher compared to conventional belting, which might deter some buyers. They are particularly well-suited for food processing and packaging industries, where hygiene and ease of cleaning are paramount.

Roller Conveyor Systems

Roller conveyor systems represent another alternative, particularly effective for high-speed material transportation. These systems excel in moving heavy loads efficiently and can be configured for gravity or powered operation. However, they come with a higher initial installation cost and require more space compared to belting systems. Maintenance can also be more intensive, as components may wear out and require replacement over time. Their best use case lies in heavy-duty applications, such as assembly lines and warehousing, where speed and load capacity are critical.

Conclusion: Choosing the Right Solution for Your Needs

When selecting a material handling solution, B2B buyers must consider their specific operational requirements, budget constraints, and maintenance capabilities. While traditional belting materials offer versatility and reliability, alternatives like modular plastic belts and roller conveyor systems can provide unique advantages in certain scenarios. By analyzing performance, cost, ease of implementation, and maintenance needs, buyers can make informed decisions that align with their business goals and operational efficiency.

Essential Technical Properties and Trade Terminology for belting material

What Are the Key Technical Properties of Belting Material?

When selecting belting materials for industrial applications, understanding their technical specifications is crucial for ensuring optimal performance and longevity. Here are some essential properties that B2B buyers should consider:

Illustrative image related to belting material

1. Material Grade

Material grade refers to the composition and quality of the belting material, which can significantly impact its durability and application suitability. Common materials include PVC, rubber, and thermoplastic polyurethane (TPU). Each grade offers unique advantages; for example, rubber is renowned for its flexibility and wear resistance, making it ideal for heavy-duty applications. Selecting the appropriate material grade ensures that the belt can withstand the operational environment and intended load.

2. Thickness

Thickness is a critical specification that affects the belt’s strength and flexibility. Thicker belts can handle higher loads but may be less flexible, impacting their adaptability in certain setups. Conversely, thinner belts may offer better flexibility but can have lower load capacities. Understanding the required thickness for specific applications helps buyers choose the right product to prevent premature wear or failure.

3. Tensile Strength

Tensile strength measures the maximum load a belt can bear without breaking. This property is vital for determining how much weight the belt can transport under operational conditions. A higher tensile strength typically indicates a more durable belt, capable of handling heavier loads without risk of rupture. This specification is especially important for industries such as mining or manufacturing, where heavy materials are common.

4. Minimum Pulley Diameter

This specification indicates the smallest pulley size that a belt can effectively operate around without compromising its integrity. Choosing a belt with an appropriate minimum pulley diameter ensures smooth operation and reduces the risk of damage to the belt or equipment. For applications involving tight spaces or complex machinery, this property becomes particularly crucial.

5. Operating Temperature Range

The operating temperature range defines the extremes within which the belting material can function without degrading. Certain materials, like TPU, can withstand higher temperatures but may be less effective in cold conditions. Understanding this range helps buyers select a belt that can maintain performance under varying environmental conditions, thus prolonging its lifespan and reliability.

What Are Common Trade Terms in the Belting Material Industry?

Familiarity with industry jargon can facilitate smoother transactions and clearer communication between buyers and suppliers. Here are some common terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of belting materials, buyers often seek OEM products to ensure compatibility with existing machinery and standards. Understanding OEM relationships can help buyers identify trusted suppliers and guarantee product quality.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers, as it can affect budgeting and inventory management. Buyers should assess their needs and ensure that they can meet the MOQ without overcommitting to excess inventory.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent by a buyer to suppliers requesting pricing and other details about specific products. This process is essential for comparing costs and features across different suppliers, allowing buyers to make informed decisions based on budget and requirements.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risks, and responsibilities associated with their purchases, ensuring clarity in logistics and legal obligations.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. Understanding lead times is crucial for project planning and inventory management. Buyers should consider lead times when scheduling production cycles to avoid delays in operations.

By grasping these essential technical properties and trade terminologies, B2B buyers can make informed decisions, ensuring the selection of the most suitable belting materials for their specific applications.

Navigating Market Dynamics and Sourcing Trends in the belting material Sector

What Are the Key Trends Shaping the Belting Material Market?

The belting material sector is experiencing dynamic shifts influenced by globalization, technological advancements, and evolving industrial needs. Key global drivers include the increased demand for automation across various industries, such as manufacturing, logistics, and food processing. Automation requires robust, high-performance conveyor systems, which in turn depend on durable belting materials. Additionally, the rise of e-commerce has amplified the need for efficient material handling solutions, propelling investments in conveyor technology.

Emerging B2B tech trends are reshaping sourcing strategies. The integration of Industry 4.0 technologies, such as IoT and AI, is facilitating real-time monitoring and predictive maintenance of conveyor systems, enhancing operational efficiency. As a result, suppliers are increasingly offering smart belting solutions with embedded sensors that provide data on wear and tear, enabling proactive replacements and minimizing downtime.

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding regional market dynamics is crucial. In Africa and South America, there is a growing emphasis on cost-effective solutions that do not compromise quality. In contrast, buyers in the Middle East and Europe may prioritize advanced materials that comply with stringent regulatory standards, especially in food processing applications.

How Is Sustainability Impacting the Sourcing of Belting Materials?

Sustainability has become a cornerstone of modern procurement strategies in the belting material sector. The environmental impact of manufacturing processes and the lifecycle of materials are increasingly under scrutiny. Companies are now seeking suppliers that prioritize eco-friendly practices, such as utilizing recycled materials and reducing carbon footprints during production.

Illustrative image related to belting material

Ethical sourcing is equally important, as buyers are becoming more aware of the social implications of their supply chains. This includes ensuring fair labor practices and transparent sourcing methods. As a response, many manufacturers are adopting certifications that demonstrate their commitment to sustainability, such as ISO 14001 for environmental management and certifications for recycled materials.

Investing in “green” belting materials, such as those made from thermoplastic polyurethane (TPU) or bio-based rubbers, not only meets regulatory requirements but also enhances a company’s brand image. For B2B buyers, aligning with suppliers who are committed to sustainability can drive long-term savings and foster stronger customer relationships.

What Is the Historical Context of the Belting Material Sector?

The belting material sector has evolved significantly over the decades, paralleling advancements in manufacturing and materials science. Initially dominated by natural rubber, the industry has transitioned to synthetic materials like PVC and polyurethane, which offer enhanced durability and performance. The late 20th century saw the introduction of specialized materials tailored for specific applications, such as food-grade belts that comply with health regulations.

As industrial processes evolved, so too did the technology surrounding belting materials. The advent of conveyor systems revolutionized material handling, leading to the widespread adoption of belts in various sectors. Today, the focus is shifting towards innovative, sustainable solutions that not only enhance operational efficiency but also align with global sustainability goals.

Conclusion

Navigating the complexities of the belting material market requires a keen understanding of current trends and an appreciation for the historical context of the industry. By embracing sustainability and leveraging technological advancements, international B2B buyers can optimize their procurement strategies, ensuring they remain competitive in a rapidly changing landscape.

Illustrative image related to belting material

Frequently Asked Questions (FAQs) for B2B Buyers of belting material

-

How do I choose the right belting material for my application?

Choosing the appropriate belting material depends on several factors including the type of product being conveyed, the operating environment, and specific industry requirements. For example, if you’re in food processing, FDA-approved materials like PVC or TPU are essential. In heavy-duty applications, rubber or polyurethane may be more suitable due to their durability and resistance to abrasion. Consider factors such as temperature extremes, chemical exposure, and load capacity to ensure optimal performance. -

What are the benefits of using custom conveyor belts?

Custom conveyor belts offer tailored solutions that meet specific operational needs. These belts can be designed to fit unique machinery or to handle particular types of materials, enhancing efficiency and productivity. Customization also allows for the incorporation of special features such as cleats, sidewalls, or specific surface textures. This can lead to improved product handling and reduced downtime, ultimately contributing to a better return on investment. -

What are the minimum order quantities (MOQ) for belting materials?

Minimum order quantities can vary significantly between suppliers and depend on factors like material type, customization needs, and production capabilities. Generally, MOQs can range from a few meters for standard products to larger quantities for specialized or custom orders. It’s essential to discuss these details with potential suppliers to understand their policies and to negotiate terms that align with your purchasing needs. -

How do I vet suppliers for belting materials in international trade?

Vetting suppliers is crucial to ensure quality and reliability in international trade. Start by researching potential suppliers’ credentials, including certifications and industry experience. Request samples to evaluate the quality of their products and check for customer reviews or testimonials. Additionally, consider their compliance with international standards and regulations. Engaging in direct communication can also provide insights into their responsiveness and professionalism. -

What payment terms are typically offered for belting material orders?

Payment terms can vary widely among suppliers, but common options include advance payment, net 30, or net 60 days. Some suppliers may offer letters of credit or escrow services for larger orders, providing additional security for both parties. It’s advisable to clarify payment terms upfront and ensure they align with your cash flow needs. Negotiating favorable terms can help establish a mutually beneficial relationship with your supplier. -

How do I ensure quality assurance (QA) for my belting materials?

Implementing a robust quality assurance process is essential when sourcing belting materials. Request documentation such as test certificates and compliance reports from your supplier. Additionally, establish quality benchmarks and conduct inspections upon receipt of materials. Consider third-party inspections if purchasing in bulk or from unfamiliar suppliers. Regular audits and performance reviews can also help maintain high standards throughout the supply chain. -

What logistics considerations should I be aware of when importing belting materials?

When importing belting materials, consider factors such as shipping methods, customs regulations, and lead times. It’s important to understand the logistics involved in transporting materials from the supplier to your facility. Collaborate with reliable freight forwarders who can navigate customs procedures efficiently. Additionally, be aware of potential tariffs and duties that may affect overall costs, and plan accordingly to avoid delays. -

What are the common applications for different types of belting materials?

Different belting materials serve various applications across industries. PVC belts are versatile and commonly used in light to medium-duty applications, while rubber belts are ideal for heavy-duty operations due to their durability. Food-grade belts, such as FDA-approved TPU, are specifically designed for the food industry, ensuring safety and hygiene. Understanding the specific requirements of your application will guide you in selecting the most appropriate belting material for optimal performance.

Top 3 Belting Material Manufacturers & Suppliers List

1. McMaster – Conveyor Belt Materials

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Conveyor Belt Materials, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Belt Power – Conveyor Belting Solutions

Domain: beltpower.com

Registered: 1998 (27 years)

Introduction: Conveyor Belting, Lightweight Conveyor Belting, Food Conveyor Belting (FDA, USDA, AAA Dairy), General Conveyor Belting, Incline Conveyor Belting, Machine Tapes / Power Transmission Conveyor Belting, Airport / Distribution Conveyor Belting, Modular Belting, Modular Plastic Belting, Table Top Conveyor Chains, Wire Belting, Timing / Drive Belts, Timing Belts, Extruded Profiles, Round Belts, Rubber Dr…

3. Dunham Rubber – Conveyor Belts & Accessories

Domain: dunhamrubber.com

Registered: 1999 (26 years)

Introduction: Dunham Rubber & Belting Corporation offers a range of products including: 1. Conveyor Belts & Accessories 2. Hydraulic Hose & Fittings 3. Industrial Hose & Fittings 4. Sanitary Hose & Fittings 5. Material Handling & Ducting 6. Sheet Rubber & Gaskets 7. UHMW, Polycarbonate & Acrylic Sheet. The company also provides services such as Conveyor Belt Fabrication, On-Site Conveyor Belt Installation & Rep…

Strategic Sourcing Conclusion and Outlook for belting material

In today’s competitive landscape, effective strategic sourcing of belting materials is paramount for operational efficiency and cost management. Buyers must prioritize understanding the specific requirements of their applications, whether it involves selecting the right material—be it PVC, rubber, or food-grade options—or ensuring compliance with local and international standards. By leveraging the insights from this guide, businesses can navigate the complexities of the belting market, making informed decisions that enhance productivity and reduce downtime.

Moreover, the importance of cultivating strong supplier relationships cannot be overstated. Collaborating with reliable vendors can lead to better pricing, customized solutions, and access to innovative materials that can give your operations a competitive edge. As markets evolve, particularly in Africa, South America, the Middle East, and Europe, staying abreast of emerging trends and technologies will enable businesses to adapt swiftly and efficiently.

Looking ahead, international buyers should actively seek out partnerships that foster sustainability and resilience. Embracing these principles not only meets consumer demand but also positions your business for long-term success. Invest in strategic sourcing today to secure a robust supply chain that supports your growth ambitions in an increasingly interconnected world.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.