Belt Conveyor Steel: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for belt conveyor steel

In the competitive landscape of industrial manufacturing, sourcing high-quality belt conveyor steel can be a daunting challenge for international B2B buyers. The need for durable, efficient, and versatile conveyor systems is paramount, particularly in regions like Africa, South America, the Middle East, and Europe, where diverse applications—from food processing to heavy manufacturing—demand reliable solutions. This comprehensive guide delves into the various types of belt conveyor steel available, their specific applications, and the critical factors to consider when vetting suppliers.

By exploring the benefits of metal belt conveyor systems, including their high strength-to-weight ratio and resistance to extreme temperatures and chemicals, this guide equips decision-makers with the knowledge needed to make informed purchasing choices. Additionally, it covers essential topics such as cost considerations, maintenance requirements, and the latest industry innovations.

With insights tailored for diverse markets, including Germany and Brazil, this resource empowers buyers to navigate the complexities of the global market confidently. By understanding the unique advantages of different belt conveyor steel options, businesses can optimize their operations, enhance productivity, and ultimately achieve greater success in an ever-evolving industrial landscape.

Understanding belt conveyor steel Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hinged Steel Belt | Versatile design for handling various materials; available in multiple pitch sizes | Chip removal, metal stamping, scrap handling | Pros: Durable, handles heavy loads; Cons: Initial cost can be high. |

| Modular Plastic Belt | Interlocking plastic segments; customizable for various applications | Food processing, packaging, light material handling | Pros: Easy to clean, lightweight; Cons: Less durable than steel belts. |

| Metal Belt | High precision and strength; virtually unstretchable | Automated manufacturing, electronics, pharmaceuticals | Pros: Long lifespan, precise indexing; Cons: Higher initial investment. |

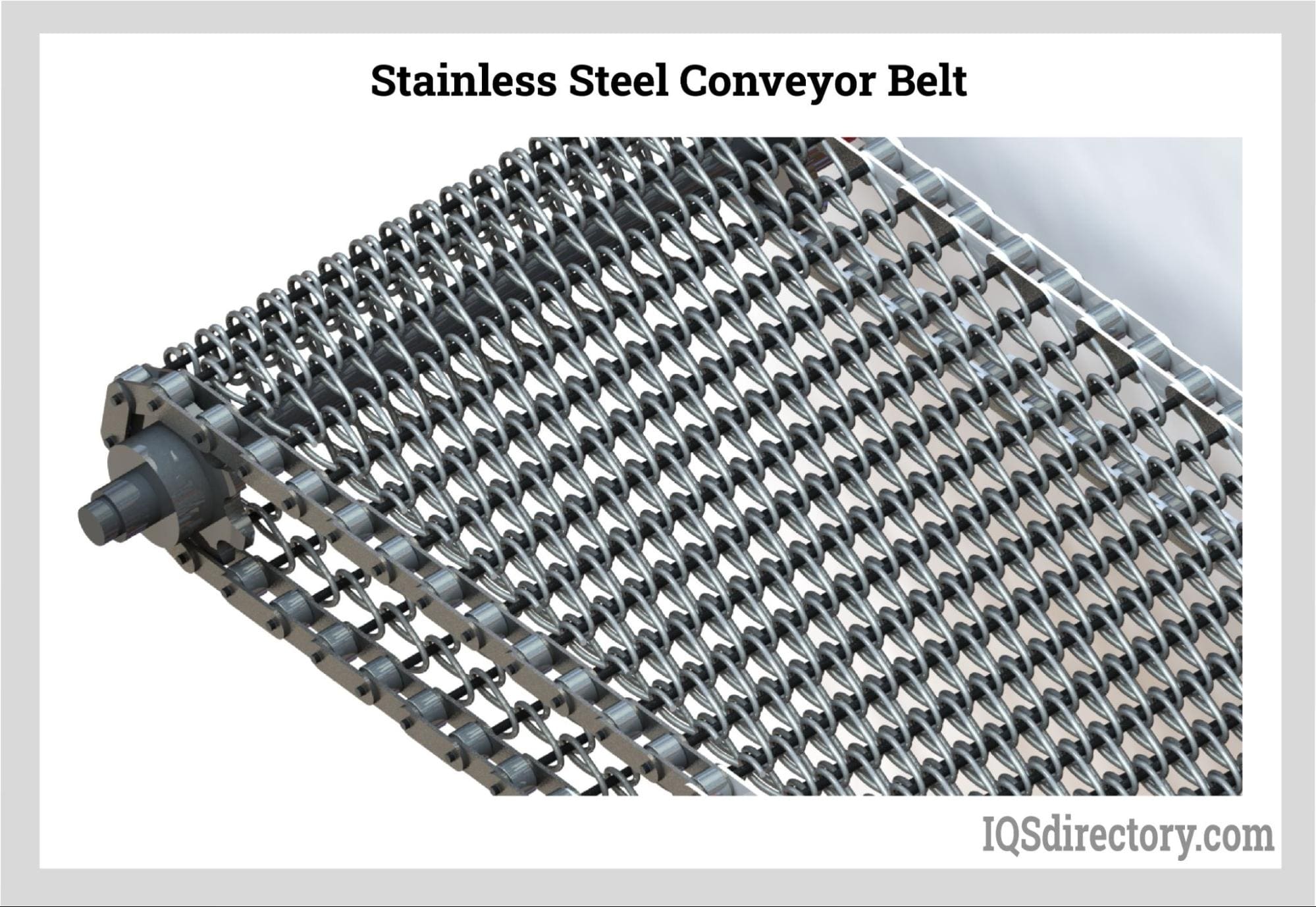

| Wire Mesh Belt | Open structure for air and liquid flow; excellent drainage | Baking, cooling, and drying applications | Pros: Lightweight, good for heat resistance; Cons: Limited load capacity. |

| Chain-Driven Belt | Robust design with chain drive for heavy-duty applications | Heavy industrial settings, bulk material handling | Pros: Strong, reliable for heavy loads; Cons: More maintenance required. |

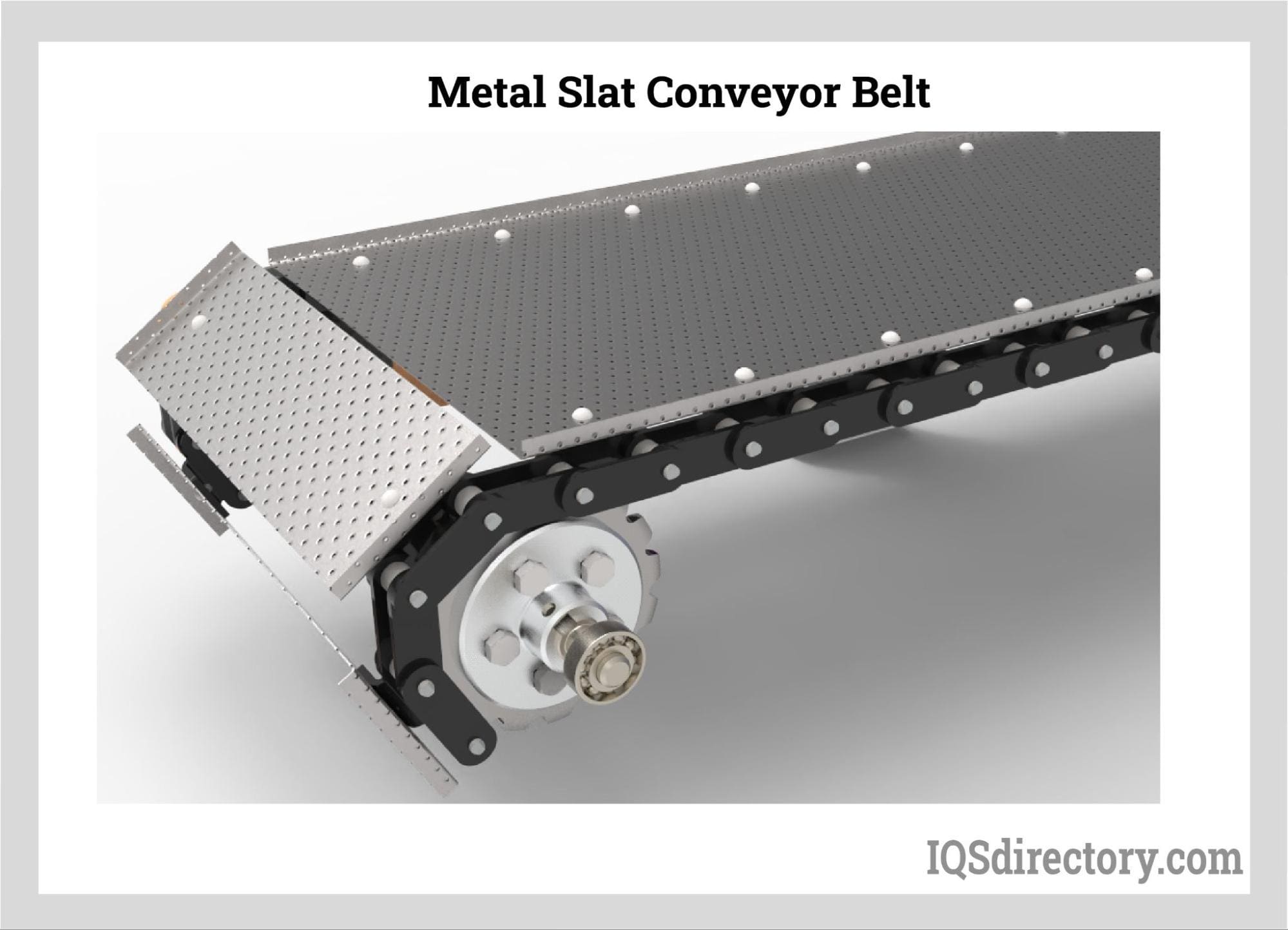

What are the Characteristics of Hinged Steel Belt Conveyors?

Hinged steel belt conveyors are highly adaptable, capable of managing a wide range of materials, including heavy scrap and chips. They feature a durable design with pitches typically ranging from 2.5 inches to 9 inches, making them suitable for both light and heavy-duty applications. When considering a hinged steel belt, buyers should evaluate the specific pitch size needed for their material type and the expected load to ensure optimal performance. While these conveyors are robust, their initial cost might be higher compared to other types.

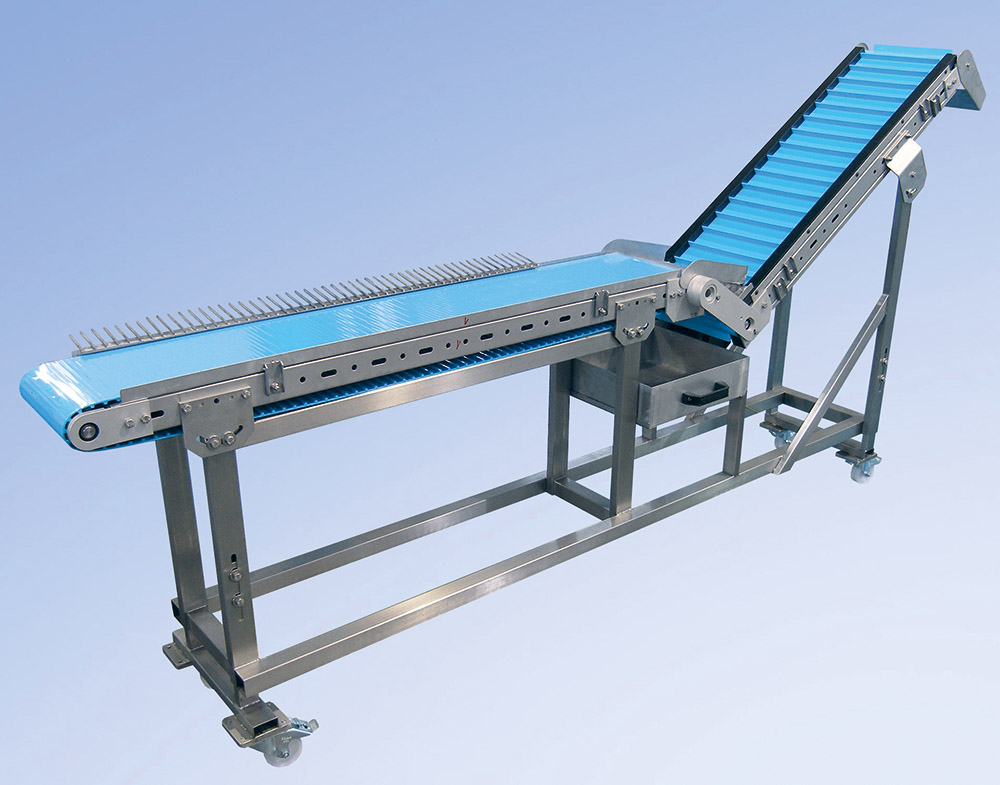

How Does a Modular Plastic Belt Differ from Other Belt Types?

Modular plastic belts consist of interlocking segments that allow for flexibility and customization. They are particularly advantageous in food processing and packaging industries due to their ease of cleaning and lightweight nature. Buyers should consider the specific requirements of their application, such as sanitation needs and material handling, when selecting a modular plastic belt. However, while they are easier to maintain, they may not offer the same durability as metal options, particularly in heavy-load situations.

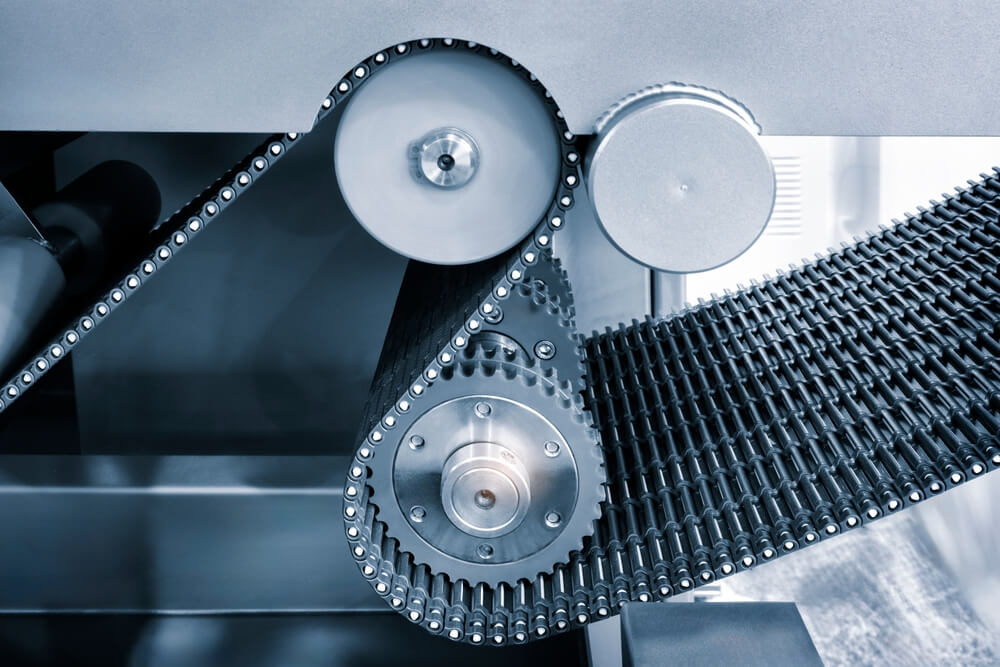

Illustrative image related to belt conveyor steel

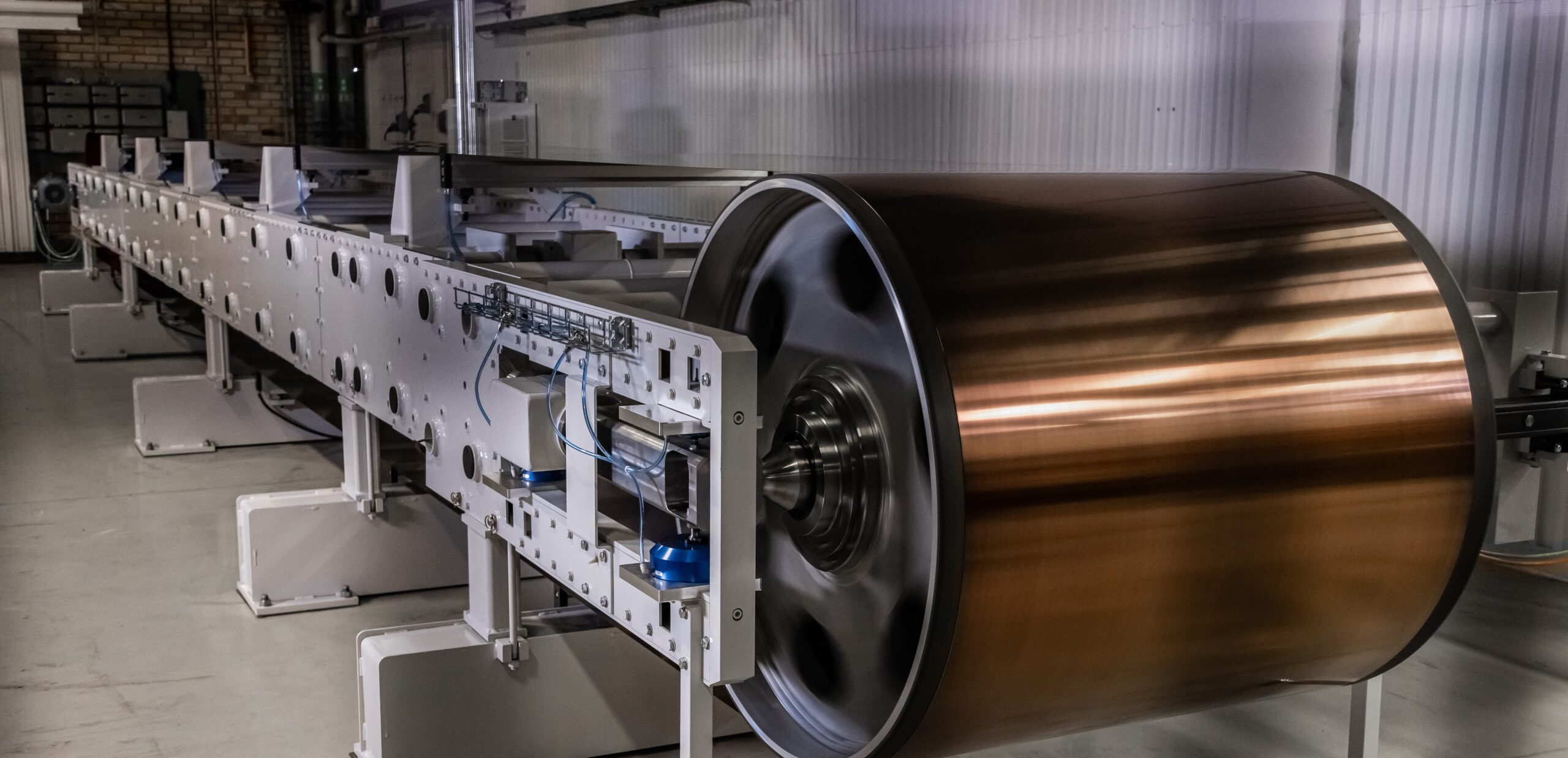

What Makes Metal Belts a Preferred Choice in Automation?

Metal belts are known for their high precision and strength, making them ideal for applications requiring exact indexing and minimal stretch. These belts excel in automated manufacturing, particularly in electronics and pharmaceutical sectors, where cleanliness and durability are paramount. Buyers should assess their operational requirements, including temperature and chemical exposure, when opting for metal belts. Although they come with a higher upfront cost, their longevity and performance can justify the investment.

In What Scenarios Would Wire Mesh Belts Be the Best Option?

Wire mesh belts are characterized by their open structure, allowing for excellent airflow and drainage, making them suitable for applications like baking and cooling. They are lightweight and can withstand high temperatures, which is beneficial in food processing. However, their load capacity is limited compared to other belt types, so businesses should evaluate their specific needs, particularly in terms of the weight and type of materials being handled.

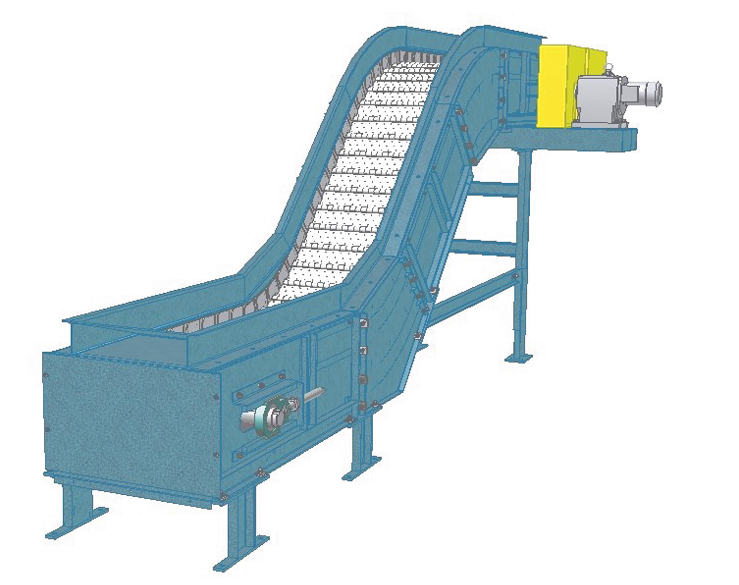

Why Choose Chain-Driven Belts for Heavy-Duty Applications?

Chain-driven belts are designed for robust performance in heavy industrial settings. They utilize a chain drive mechanism that provides strong traction and can handle bulk materials effectively. Buyers should consider the maintenance requirements associated with chain-driven systems, as they may necessitate more frequent upkeep compared to other belt types. Despite this, their reliability and strength make them a go-to choice for industries dealing with heavy loads.

Key Industrial Applications of belt conveyor steel

| Industry/Sector | Specific Application of belt conveyor steel | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Transporting food products through processing lines | Ensures hygiene and prevents contamination, increasing product quality | Need for easy cleaning, compliance with food safety standards |

| Metalworking | Handling metal chips and scrap in machining processes | Reduces downtime and increases efficiency in material handling | Consider durability, load capacity, and compatibility with existing systems |

| Automotive Manufacturing | Assembly line automation for vehicle parts | Enhances precision and speed in production, reducing labor costs | Customization options for specific part sizes and weights |

| Electronics Manufacturing | Transporting delicate electronic components | Minimizes risk of damage and contamination in cleanroom environments | Requirements for high precision and non-particulate generation |

| Mining and Heavy Duty | Moving bulk materials and heavy equipment | Increases throughput and operational efficiency in rugged environments | Need for high strength, corrosion resistance, and temperature tolerance |

How is Belt Conveyor Steel Used in Food Processing, and What Problems Does It Solve?

In the food processing industry, belt conveyor steel is utilized to transport products through various stages, such as washing, cooking, and packaging. The hygienic properties of metal belts prevent contamination, ensuring compliance with food safety regulations. Buyers in this sector must prioritize easy-to-clean designs and materials that withstand high temperatures and corrosive environments. Additionally, sourcing from suppliers who understand local regulations can facilitate smoother operations, especially in regions like Africa and South America, where food safety standards can vary significantly.

What Role Does Belt Conveyor Steel Play in Metalworking Applications?

In metalworking, steel belts are essential for efficiently handling metal chips and scrap generated during machining processes. Their robust design allows for the transport of heavy materials without compromising structural integrity, thus minimizing downtime associated with equipment failure. Buyers should consider the belt’s durability and load capacity, as well as its compatibility with existing conveyor systems. As industries in Europe and the Middle East continue to modernize, investing in high-quality steel belts can significantly enhance productivity and reduce operational costs.

How is Belt Conveyor Steel Essential for Automotive Manufacturing?

Belt conveyor steel plays a critical role in the automotive manufacturing sector, particularly in assembly line automation. These conveyors enable the precise and rapid movement of vehicle parts, thereby enhancing overall production efficiency and reducing labor costs. For international buyers, especially in regions like Germany and Brazil, customization options for various part sizes and weights are crucial. Ensuring that the conveyor system can integrate seamlessly with existing operations is vital for maintaining productivity.

Why is Belt Conveyor Steel Important for Electronics Manufacturing?

In electronics manufacturing, metal belt conveyors are used to transport delicate components through cleanroom environments. Their design minimizes the risk of damage and contamination, which is critical for maintaining product integrity. Buyers should focus on sourcing belts that meet stringent precision requirements and do not generate particulates. Understanding local manufacturing standards, particularly in regions like Europe, can help buyers select the right conveyor systems that align with their operational needs.

How Does Belt Conveyor Steel Benefit the Mining Industry?

In the mining sector, belt conveyor steel is employed to move bulk materials and heavy equipment efficiently. These conveyors are designed to withstand harsh conditions, providing high strength and corrosion resistance. As mining operations in Africa and South America expand, sourcing durable and reliable steel belts becomes increasingly important. Buyers should evaluate the temperature tolerance and load-bearing capacity of the belts to ensure they can handle the demands of rugged mining environments, thereby enhancing operational efficiency.

3 Common User Pain Points for ‘belt conveyor steel’ & Their Solutions

Scenario 1: Inefficient Material Handling Leading to Production Delays

The Problem: In many manufacturing facilities, B2B buyers often face the challenge of inefficient material handling due to outdated or improperly specified belt conveyor systems. This can result in bottlenecks, increased cycle times, and ultimately, production delays. Buyers may find that their current steel conveyor systems struggle with high-volume loads or fail to maintain the necessary speed and reliability, which can jeopardize their ability to meet customer deadlines and maintain competitiveness in the market.

The Solution: To resolve this issue, it is crucial for buyers to conduct a thorough analysis of their operational needs before sourcing belt conveyor steel. Start by assessing the weight and type of materials being transported, as well as the required speed and throughput. Engaging with suppliers who offer custom-designed conveyor systems can provide tailored solutions that meet specific needs. When specifying a new system, focus on high-precision tolerances and a robust construction that can handle the operational demands without stretching or wearing out quickly. Moreover, consider investing in additional features such as motion control and tracking capabilities to optimize efficiency and reduce downtime.

Scenario 2: High Maintenance Costs Due to Unsuitable Conveyor Materials

The Problem: Another common issue faced by B2B buyers is the high maintenance costs associated with using unsuitable materials for their belt conveyors. Many facilities may opt for lower-cost alternatives that compromise on durability, leading to frequent breakdowns and repairs. This not only increases operational costs but also affects the overall productivity of the manufacturing process. Buyers may feel trapped in a cycle of continuous repairs and replacements, which erodes their profit margins.

The Solution: To mitigate maintenance costs, buyers should prioritize sourcing high-quality steel belt conveyor systems specifically designed for their industry needs. Investing in metal belt systems, such as those made from PureSteel, offers significant advantages including a high strength-to-weight ratio and resistance to wear and tear. Additionally, these systems are easier to clean and maintain, especially in industries like food processing where hygiene is critical. Buyers should also work closely with manufacturers to ensure they understand the long-term benefits of using premium materials, which may have a higher upfront cost but can lead to substantial savings over time.

Scenario 3: Compliance Challenges with Industry Standards

The Problem: B2B buyers in industries such as food processing, pharmaceuticals, or electronics often face stringent regulatory compliance challenges. The materials used in conveyor systems must meet specific health, safety, and environmental standards. Failure to comply can result in costly fines, product recalls, and damage to reputation. Buyers may struggle to find steel conveyor systems that meet these rigorous requirements while still delivering the performance needed for efficient operations.

The Solution: To address compliance challenges, it is essential for buyers to collaborate with suppliers who understand the regulatory landscape of their industry. When sourcing belt conveyor steel, prioritize systems that are explicitly designed for compliance with industry standards. For instance, metal belts that are easy to clean and sanitize can be crucial in food processing applications, while those that minimize particulate generation are essential for electronics manufacturing. Buyers should also request certifications and documentation from suppliers to ensure that the conveyor systems they invest in meet all necessary standards. This proactive approach not only safeguards compliance but also enhances operational integrity and consumer trust.

By addressing these pain points with informed strategies, B2B buyers can enhance their operational efficiency, reduce costs, and ensure compliance, ultimately leading to a more productive and profitable business environment.

Strategic Material Selection Guide for belt conveyor steel

What Are the Key Properties of Common Materials Used in Belt Conveyor Steel?

When selecting materials for belt conveyor systems, B2B buyers must consider several factors, including performance properties, application suitability, and compliance with international standards. Here, we analyze four common materials used in belt conveyor steel: carbon steel, stainless steel, aluminum, and composite materials.

How Does Carbon Steel Perform in Belt Conveyor Applications?

Key Properties: Carbon steel is known for its high strength and durability. It can withstand significant loads and is often treated for corrosion resistance. However, its performance can be compromised in extreme temperature environments.

Illustrative image related to belt conveyor steel

Pros & Cons: The primary advantage of carbon steel is its cost-effectiveness and high tensile strength, making it suitable for heavy-duty applications. However, it is prone to rusting if not properly coated, which can lead to increased maintenance costs over time. Manufacturing complexity is moderate, as carbon steel can be easily welded and formed.

Impact on Application: Carbon steel is ideal for applications involving heavy materials, such as metal scrap handling. However, in environments with high humidity or corrosive substances, its longevity may be affected.

Considerations for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should ensure compliance with relevant standards such as ASTM A36 for structural steel. Additionally, understanding local environmental conditions is crucial for selecting the right protective coatings.

What Are the Advantages of Stainless Steel in Conveyor Systems?

Key Properties: Stainless steel offers excellent corrosion resistance and can operate effectively in high-temperature environments. It maintains its strength and structural integrity even under harsh conditions.

Illustrative image related to belt conveyor steel

Pros & Cons: The key advantage of stainless steel is its durability and resistance to corrosion, which minimizes maintenance and replacement costs. However, it is more expensive than carbon steel, and its manufacturing can be more complex due to the need for specialized welding techniques.

Impact on Application: Stainless steel is particularly well-suited for food processing, pharmaceuticals, and any application requiring high hygiene standards. Its resistance to staining and rusting makes it ideal for environments where cleanliness is paramount.

Considerations for International Buyers: Compliance with standards such as ASTM A240 for stainless steel is essential. Buyers should also consider local regulations regarding food safety and hygiene, especially in regions with strict compliance requirements.

How Does Aluminum Compare for Belt Conveyor Use?

Key Properties: Aluminum is lightweight, corrosion-resistant, and has a good strength-to-weight ratio. It performs well in moderate temperature ranges but may not be suitable for heavy loads.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which facilitates easier installation and reduces energy consumption during operation. However, it is not as strong as steel, making it less suitable for heavy-duty applications. The manufacturing process is relatively simple, allowing for quick production times.

Illustrative image related to belt conveyor steel

Impact on Application: Aluminum is ideal for light-duty applications, such as packaging and assembly lines. Its corrosion resistance makes it suitable for environments where moisture is present.

Considerations for International Buyers: Buyers should ensure that aluminum products comply with standards such as ASTM B221. Additionally, understanding the local market for aluminum can help in negotiating better prices and sourcing options.

What Role Do Composite Materials Play in Belt Conveyor Systems?

Key Properties: Composite materials combine various materials to enhance performance characteristics, such as weight reduction and improved durability. They can be engineered for specific applications, providing tailored solutions.

Pros & Cons: The key advantage of composite materials is their versatility and ability to be customized for specific applications. They often offer excellent resistance to chemicals and moisture. However, they can be more expensive than traditional materials, and manufacturing processes can be complex.

Impact on Application: Composites are well-suited for specialized applications that require lightweight solutions without sacrificing strength, such as in aerospace or high-tech manufacturing environments.

Considerations for International Buyers: Buyers should be aware of the specific standards applicable to composite materials in their region, which may vary significantly. Understanding the supplier’s capabilities in producing composites is also vital for ensuring quality.

Summary Table of Material Selection for Belt Conveyor Steel

| Material | Typical Use Case for belt conveyor steel | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Heavy-duty applications | Cost-effective and high tensile strength | Prone to rust without coating | Low |

| Stainless Steel | Food processing and pharmaceuticals | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Aluminum | Light-duty applications | Lightweight and easy to install | Not suitable for heavy loads | Medium |

| Composite Materials | Specialized applications | Customizable for specific needs | Higher cost and complex manufacturing | High |

This strategic material selection guide provides B2B buyers with essential insights to make informed decisions when selecting belt conveyor steel suitable for their specific applications.

In-depth Look: Manufacturing Processes and Quality Assurance for belt conveyor steel

What Are the Key Stages in the Manufacturing Process of Belt Conveyor Steel?

The manufacturing process of belt conveyor steel involves several critical stages, each designed to ensure the highest quality and performance of the final product. Understanding these stages will help B2B buyers make informed decisions when selecting suppliers.

Material Preparation: What Raw Materials Are Used for Belt Conveyor Steel?

The initial phase involves sourcing high-quality raw materials. Typically, stainless steel or carbon steel is selected due to its durability and strength. The material is often subjected to processes such as annealing and pickling to enhance its properties. During this stage, suppliers may also perform chemical analyses to verify the composition and ensure it meets industry standards. Buyers should inquire about the specific grades of steel used and the supplier’s sourcing practices to ensure compliance with international quality standards.

Illustrative image related to belt conveyor steel

How Is Steel Formed into Belt Configurations?

Once the materials are prepared, the next step is forming the steel into the desired belt configuration. This process includes cutting, bending, and welding. Advanced techniques such as laser cutting or CNC machining are often employed for precision. This level of accuracy is crucial for applications requiring tight tolerances, such as in automated manufacturing environments.

The forming process also includes creating various pitch sizes—common sizes range from 2.5 inches to 9 inches—based on the application requirements. Buyers should consider whether the supplier offers custom designs tailored to specific operational needs, as this can significantly impact efficiency and productivity.

What Assembly Techniques Are Used in Belt Conveyor Manufacturing?

The assembly stage involves integrating various components, such as the belt itself, tensioning systems, and drive mechanisms. This phase often utilizes modular designs, allowing for easier maintenance and upgrades. Suppliers may employ automated assembly lines to enhance efficiency and ensure consistent quality.

Illustrative image related to belt conveyor steel

During assembly, it is crucial to ensure that all components are compatible and function seamlessly together. Buyers should ask about the supplier’s assembly protocols and whether they include testing for operational efficacy before shipment.

What Finishing Processes Enhance the Quality of Belt Conveyor Steel?

Finishing processes are essential for enhancing the durability and appearance of the steel belts. Common methods include surface treatments such as galvanization, powder coating, or polishing. These treatments not only improve aesthetics but also provide corrosion resistance, which is particularly important in industries like food processing or pharmaceuticals.

Buyers should inquire about the finishing options available and the expected lifespan of each treatment, as this can influence long-term operational costs.

How Is Quality Assurance Implemented in Belt Conveyor Steel Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that products meet both international and industry-specific standards. This section outlines the QA practices relevant to belt conveyor steel.

What International Standards Should B2B Buyers Look for in Quality Assurance?

B2B buyers should prioritize suppliers who adhere to internationally recognized quality management systems, such as ISO 9001. This certification indicates a commitment to quality and continuous improvement in manufacturing processes. Additionally, industry-specific certifications like CE for European markets or API for oil and gas applications can further assure quality.

Illustrative image related to belt conveyor steel

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are established throughout the manufacturing process to identify and rectify defects. Key checkpoints include:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon receipt to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process, including checks on dimensions, tolerances, and assembly integrity.

-

Final Quality Control (FQC): A thorough inspection of the finished product before shipment, ensuring it meets all specifications and performance criteria.

What Testing Methods Are Commonly Used in Quality Assurance?

Testing methods may include tensile strength tests, fatigue tests, and corrosion resistance tests. Non-destructive testing techniques, such as ultrasonic or magnetic particle inspections, are also employed to detect internal defects without damaging the product.

B2B buyers should ask suppliers about the specific testing methods used and request documentation to verify compliance with relevant standards.

How Can B2B Buyers Verify Supplier Quality Assurance Practices?

To ensure a supplier’s commitment to quality, B2B buyers can take several proactive steps:

-

Conduct Audits: Regular audits of suppliers can help verify adherence to quality standards. Buyers should consider scheduling on-site visits to review manufacturing processes and quality control practices.

-

Request Quality Reports: Suppliers should provide detailed quality assurance reports that outline testing results and compliance with relevant standards.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the supplier’s quality practices and product integrity.

What Are the Quality Control Nuances for International Buyers?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

-

Regulatory Compliance: Different regions may have unique regulations that impact the import and use of steel products. Understanding these regulations is crucial to avoid potential legal issues.

-

Cultural Considerations: Communication styles and business practices can vary significantly across cultures. Establishing a clear understanding of expectations and quality requirements from the outset can mitigate misunderstandings.

-

Supply Chain Transparency: Buyers should prioritize suppliers who are transparent about their sourcing, manufacturing, and QA processes. This transparency fosters trust and ensures a reliable supply chain.

In conclusion, understanding the manufacturing processes and quality assurance practices for belt conveyor steel is essential for B2B buyers. By focusing on key stages of production, implementing rigorous QA measures, and verifying supplier practices, buyers can make informed decisions that enhance operational efficiency and product reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘belt conveyor steel’

Introduction

This sourcing guide is designed to help B2B buyers navigate the procurement process for belt conveyor steel. By following this checklist, you can ensure that you select the right materials and suppliers to meet your operational needs, enhance efficiency, and optimize costs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical for ensuring that the belt conveyor steel meets your operational requirements. Consider factors such as load capacity, environmental conditions (e.g., temperature, moisture), and the specific materials being transported.

- Performance Metrics: Identify the required speed, weight, and durability specifications to ensure that the conveyor operates efficiently within your production line.

Step 2: Research Material Options

Different types of steel belts offer various advantages depending on the application. Research options such as hinged steel belts, modular belts, and metal belts to determine which best suits your needs.

- Material Composition: Assess the strength-to-weight ratio and corrosion resistance of the materials, especially if your application involves harsh chemicals or extreme temperatures.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Look for companies with a strong reputation in the industry and relevant experience in your specific sector.

Illustrative image related to belt conveyor steel

- Request Documentation: Ask for company profiles, case studies, and references from clients in similar industries or regions. This will help you gauge their reliability and the quality of their products.

Step 4: Verify Supplier Certifications

Ensure that your chosen suppliers meet industry standards and hold relevant certifications. This step is vital for guaranteeing the quality and safety of the conveyor systems.

- Certifications to Look For: Check for ISO certifications, compliance with local regulations, and any industry-specific certifications that may apply to your application.

Step 5: Assess Customization Capabilities

Customization can significantly enhance the efficiency of your conveyor system. Engage with suppliers to discuss their ability to design and manufacture tailored solutions that fit your specific needs.

- Collaboration Opportunities: Look for suppliers who offer engineering support and can provide design modifications based on your operational parameters.

Step 6: Review Maintenance and Support Services

Choose suppliers who provide comprehensive after-sales support, including maintenance services and parts availability. This ensures that your conveyor system remains operational with minimal downtime.

- Service Agreements: Investigate the availability of service contracts that cover routine maintenance, emergency repairs, and parts replacement.

Step 7: Compare Pricing and Total Cost of Ownership

Finally, evaluate the pricing structures offered by different suppliers. While upfront costs are important, consider the total cost of ownership, which includes maintenance, energy consumption, and the lifespan of the equipment.

Illustrative image related to belt conveyor steel

- Cost-Benefit Analysis: Create a comparison chart to analyze how each option aligns with your budget and long-term operational goals.

By following this checklist, you can make informed decisions that enhance your operational efficiency and ensure a successful procurement process for belt conveyor steel.

Comprehensive Cost and Pricing Analysis for belt conveyor steel Sourcing

What Are the Key Cost Components in Belt Conveyor Steel Sourcing?

When sourcing belt conveyor steel, understanding the cost structure is vital for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of steel grade and the type of conveyor system (e.g., hinged, modular) significantly influence material costs. For instance, high-quality stainless steel belts may command a premium due to their corrosion resistance and durability, particularly in food processing or pharmaceutical applications.

-

Labor: Labor costs can vary based on geographical location and the complexity of the manufacturing process. Regions with higher labor costs may see increased pricing, while countries with lower labor costs can provide competitive pricing, especially for bulk orders.

-

Manufacturing Overhead: This encompasses indirect costs such as utilities, maintenance, and equipment depreciation. Manufacturers may include these costs in their pricing, affecting the overall cost structure.

-

Tooling: Customized tooling for specific conveyor designs can add to initial costs. However, investing in specialized tools can enhance production efficiency and quality, yielding long-term savings.

-

Quality Control (QC): Rigorous QC processes ensure that the steel conveyor systems meet industry standards. Suppliers may charge more for products that undergo extensive testing and certification, reflecting their commitment to quality.

-

Logistics: Transportation costs can vary widely based on distance, shipping method, and volume. International shipping, especially to regions such as Africa and South America, may incur additional fees due to customs duties and tariffs.

-

Margin: The profit margin that suppliers add to their costs can vary significantly based on market competition, brand reputation, and relationship with buyers.

How Do Price Influencers Affect Belt Conveyor Steel Costs?

Several factors can influence pricing beyond the basic cost structure:

-

Volume/MOQ: Bulk orders often lead to lower unit prices due to economies of scale. Negotiating minimum order quantities (MOQs) can provide significant savings.

-

Specifications and Customization: Custom-designed conveyor systems tailored to specific applications tend to incur higher costs. Buyers should weigh the benefits of customized features against their budget.

-

Quality and Certifications: Products that meet specific industry certifications (e.g., ISO, CE) may be priced higher but can ensure compliance with safety and operational standards.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may offer better quality assurance but might charge a premium for their services.

-

Incoterms: Understanding the Incoterms (International Commercial Terms) involved in the transaction is crucial. They dictate who bears the cost and risk at various points in the shipping process, which can affect the total landed cost.

What Negotiation Strategies Can Enhance Cost Efficiency for Buyers?

For B2B buyers, especially those in international markets like Africa, South America, the Middle East, and Europe, effective negotiation can lead to substantial savings.

-

Highlight Long-Term Relationships: Emphasizing the potential for ongoing partnerships can encourage suppliers to offer better pricing or terms.

-

Be Informed: Understanding market trends and competitor pricing can provide leverage during negotiations.

-

Request Multiple Quotes: Gathering quotes from various suppliers not only provides a clearer picture of the market but also strengthens negotiating power.

-

Evaluate Total Cost of Ownership (TCO): Consider the lifetime costs associated with the conveyor system, including maintenance, operational efficiency, and potential downtime. A higher upfront cost may be justified by lower long-term expenses.

-

Flexibility in Payment Terms: Offering favorable payment terms or upfront deposits can incentivize suppliers to reduce prices.

What Pricing Nuances Should International Buyers Consider?

International buyers should be aware of specific nuances that could affect pricing:

-

Currency Fluctuations: Exchange rate volatility can impact costs, especially for long-term contracts. Locking in prices in a stable currency may mitigate risks.

-

Import Duties and Taxes: Understanding local regulations regarding import duties can help buyers calculate the total cost accurately.

-

Cultural Sensitivity: Recognizing and respecting cultural differences in negotiation styles can facilitate smoother transactions.

Disclaimer on Pricing

Prices mentioned in this analysis are indicative and can fluctuate based on market conditions, supplier negotiations, and specific project requirements. It is advisable for buyers to conduct thorough market research and engage in discussions with multiple suppliers to ensure the best pricing and terms.

Alternatives Analysis: Comparing belt conveyor steel With Other Solutions

Exploring Alternatives to Belt Conveyor Steel

In the ever-evolving landscape of industrial automation and material handling, understanding alternative solutions to belt conveyor steel is essential for optimizing efficiency and productivity. As businesses seek to streamline operations, the choice of conveyor system can significantly impact performance, cost, and maintenance. Below, we compare belt conveyor steel with two viable alternatives: plastic modular belts and roller conveyor systems.

| Comparison Aspect | Belt Conveyor Steel | Plastic Modular Belts | Roller Conveyor Systems |

|---|---|---|---|

| Performance | High durability, excellent for heavy loads and harsh environments | Good for various products, but may not withstand extreme conditions | Efficient for continuous transport of items, especially in bulk |

| Cost | Higher initial investment but long lifespan | Lower initial cost, may require replacement over time | Moderate initial cost, dependent on configuration |

| Ease of Implementation | Generally requires professional installation | Easier to install; modular design allows for customization | Straightforward installation; adaptable to various layouts |

| Maintenance | Requires regular maintenance, but very durable | Lower maintenance needs; easy to clean | Minimal maintenance, but can be affected by load distribution |

| Best Use Case | Heavy-duty applications, high-temperature environments | Food processing, packaging, and light manufacturing | Warehousing, distribution, and assembly lines |

What Are the Advantages and Disadvantages of Plastic Modular Belts?

Plastic modular belts are a popular alternative due to their flexibility and ease of maintenance. They are constructed from interlocking plastic modules, allowing for customization in width and length. The primary advantages include lower upfront costs and simpler installation, making them suitable for food processing and packaging applications. However, they may not perform well under extreme conditions, such as high temperatures or heavy loads, which could lead to a shorter lifespan compared to steel belts.

How Do Roller Conveyor Systems Compare?

Roller conveyor systems utilize a series of rollers to transport goods, making them particularly effective for moving items over long distances. They are known for their efficiency and adaptability, which makes them a preferred choice in warehousing and distribution environments. Roller conveyors can handle a variety of load types, but their performance can be compromised if the load is unevenly distributed. While they require less maintenance than steel belts, they may not be ideal for applications requiring precise indexing or heavy-duty handling.

Making the Right Choice for Your Business Needs

When selecting the right conveyor system for your business, it is crucial to evaluate the specific requirements of your operations. Factors such as load type, environmental conditions, and maintenance capabilities will guide your decision. Belt conveyor steel offers unparalleled durability and performance for heavy-duty applications, while plastic modular belts present a cost-effective solution for lighter tasks. Roller conveyor systems provide versatility for various industrial applications but may not suit all operational needs. By carefully analyzing these alternatives, B2B buyers can make informed choices that align with their operational goals and enhance productivity.

Essential Technical Properties and Trade Terminology for belt conveyor steel

What Are the Key Technical Properties of Belt Conveyor Steel?

When selecting belt conveyor steel, understanding the essential technical properties is crucial for ensuring optimal performance and longevity. Here are some of the critical specifications to consider:

Illustrative image related to belt conveyor steel

1. Material Grade

The material grade of the steel used in conveyor belts is fundamental. Common grades include stainless steel, carbon steel, and alloy steel. Each grade has distinct properties, such as corrosion resistance, strength, and flexibility. For example, stainless steel is ideal for food processing applications due to its resistance to corrosion and ease of cleaning, while carbon steel is often chosen for its strength and cost-effectiveness in heavy-duty applications.

2. Tolerance

Tolerance refers to the allowable deviation from specified dimensions during the manufacturing process. High-precision tolerances are essential for applications requiring accurate indexing and movement, such as robotics and automated assembly lines. Inconsistent tolerances can lead to operational issues and increased wear on components, making it vital to select suppliers who adhere to strict manufacturing standards.

3. Pitch Size

Pitch size is the distance between the centers of two consecutive hinge points on a hinged steel belt. Common pitch sizes range from 2.5 inches to 9 inches. The appropriate pitch size is determined by the type of material being conveyed and the specific application. Smaller pitches are suitable for handling small parts, while larger pitches can accommodate heavier loads and longer runs. Choosing the correct pitch size is critical for maintaining efficient material flow and minimizing operational disruptions.

4. Strength-to-Weight Ratio

The strength-to-weight ratio indicates how much weight the conveyor belt can handle relative to its own weight. A high strength-to-weight ratio allows for lighter and more manageable conveyor systems without compromising durability. This property is particularly important for industries looking to optimize space and reduce energy consumption while ensuring reliable material transport.

Illustrative image related to belt conveyor steel

5. Temperature Tolerance

Belt conveyor steel must withstand varying temperatures based on the application. For example, conveyor systems used in the food processing industry may need to endure high heat during cleaning, while those in manufacturing might face extreme cold in refrigerated environments. Understanding the temperature tolerance of the steel is crucial for preventing material failure and ensuring operational efficiency.

What Are Common Trade Terms in the Belt Conveyor Steel Industry?

Familiarity with industry jargon can significantly enhance communication and negotiation effectiveness. Here are several key terms frequently encountered in the belt conveyor steel sector:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of belt conveyor systems, understanding the OEM relationships can aid in sourcing high-quality components and ensuring compatibility across systems.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. This term is critical for B2B buyers, as it impacts inventory management and pricing strategies. Knowing the MOQ helps businesses plan their purchases and manage cash flow effectively.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. This process is essential for procurement, allowing buyers to compare options and select suppliers based on cost and capability.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers involved in international transactions. Familiarity with these terms is crucial for understanding shipping costs, insurance, and delivery responsibilities, thereby reducing potential disputes and ensuring smoother transactions.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. In the belt conveyor steel industry, understanding lead times is vital for project planning and inventory management, especially in industries where timely delivery is critical to operational success.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing belt conveyor steel, ultimately enhancing operational efficiency and reducing costs.

Navigating Market Dynamics and Sourcing Trends in the belt conveyor steel Sector

What Are the Current Market Dynamics and Key Trends in the Belt Conveyor Steel Sector?

The global belt conveyor steel market is influenced by several key drivers, including the rise of automation across various industries, increasing demand for efficient material handling solutions, and advancements in manufacturing technologies. As industries strive for higher productivity and lower operational costs, metal belt conveyor systems have emerged as a superior choice due to their durability, precision, and versatility. This shift is particularly evident in sectors such as food processing, pharmaceuticals, and electronics, where stringent hygiene and operational standards are paramount.

Emerging technologies are reshaping sourcing trends within the belt conveyor steel sector. Automation and Industry 4.0 initiatives have led to the integration of smart conveyor systems equipped with IoT capabilities, enabling real-time monitoring and predictive maintenance. This trend is driving international B2B buyers to seek suppliers who can provide not only high-quality products but also value-added services like engineering support and customization. For buyers in regions such as Africa, South America, the Middle East, and Europe, understanding these trends is crucial for making informed procurement decisions.

Illustrative image related to belt conveyor steel

Additionally, the growing importance of local sourcing is shaping market dynamics. Buyers are increasingly looking for suppliers who can provide shorter lead times and localized support, which is especially significant in regions with developing manufacturing sectors. This trend encourages international suppliers to establish partnerships with local distributors, enhancing their market reach and responsiveness.

How Can Sustainability and Ethical Sourcing Impact the Belt Conveyor Steel Sector?

Sustainability is becoming a cornerstone of B2B procurement strategies, particularly in the belt conveyor steel sector. The environmental impact of manufacturing processes, including carbon emissions and waste generation, has prompted buyers to prioritize suppliers who adhere to sustainable practices. The demand for “green” certifications, such as ISO 14001, is on the rise, as companies seek to enhance their sustainability credentials and reduce their ecological footprint.

Ethical sourcing also plays a critical role in modern procurement. B2B buyers are increasingly scrutinizing their supply chains to ensure that materials are sourced responsibly. This includes considering the working conditions of employees in manufacturing facilities and the environmental practices of suppliers. By opting for suppliers that demonstrate commitment to ethical sourcing, companies can mitigate risks and enhance their brand reputation.

Moreover, the use of recycled materials in belt conveyor steel production is gaining traction. Buyers who prioritize suppliers utilizing recycled or sustainably sourced steel contribute to a circular economy, reducing the demand for virgin materials and minimizing environmental impact. This trend not only aligns with corporate social responsibility goals but can also lead to cost savings and improved supply chain resilience.

How Has the Belt Conveyor Steel Sector Evolved Over Time?

The evolution of the belt conveyor steel sector reflects broader trends in industrial automation and material handling technology. Initially, conveyor systems were limited to basic mechanical designs that offered limited efficiency and flexibility. Over the decades, advancements in materials science and engineering have led to the development of high-performance steel belts that provide enhanced durability and precision.

Illustrative image related to belt conveyor steel

In the late 20th century, the introduction of automated solutions marked a significant turning point. Manufacturers began integrating sophisticated control systems and automation technologies into conveyor systems, allowing for improved throughput and reduced labor costs. Today, the sector is witnessing a transformation driven by Industry 4.0, with smart, connected systems that offer real-time data analytics and remote monitoring capabilities.

As industries continue to evolve, the belt conveyor steel sector will likely adapt to meet the changing needs of international B2B buyers, emphasizing efficiency, sustainability, and technological innovation. Understanding this historical context can help buyers appreciate the advancements that have shaped the current landscape, enabling them to make strategic sourcing decisions that align with their operational goals.

Frequently Asked Questions (FAQs) for B2B Buyers of belt conveyor steel

-

How do I choose the right belt conveyor steel for my application?

Choosing the right belt conveyor steel depends on your specific application requirements, such as load capacity, environmental conditions, and the type of materials being transported. Consider factors like temperature tolerance, chemical exposure, and the need for hygiene in industries like food processing. Consulting with a supplier’s engineering team can help you identify the best material and design specifications, ensuring the conveyor system meets your operational needs effectively. -

What is the best type of steel belt conveyor for handling heavy materials?

For heavy materials, hinged steel belt conveyors are often the most effective choice. They can withstand significant impact and load without compromising performance, making them ideal for applications involving scrap metal, castings, or heavy-duty parts. Look for options with a larger pitch size (e.g., 4” or 6”) for enhanced strength and durability, ensuring that the conveyor system can handle the demands of your specific operational environment. -

What customization options are available for belt conveyor steel systems?

Customization options for belt conveyor steel systems can include various pitch sizes, belt widths, and materials tailored to your specific needs. Manufacturers often provide options for surface coatings, perforations, and reinforcements to enhance functionality. Additionally, you can collaborate with engineering teams to design systems that integrate seamlessly with existing operations, ensuring optimal performance and efficiency. -

What are the minimum order quantities (MOQ) for belt conveyor steel?

Minimum order quantities (MOQ) for belt conveyor steel can vary significantly by supplier and the complexity of the system. Generally, MOQs can range from a few units for standard models to larger quantities for customized solutions. It’s advisable to discuss your specific requirements with potential suppliers to understand their MOQ policies and explore flexible options that align with your operational needs. -

What are the payment terms typically offered by suppliers for international orders?

Payment terms for international orders of belt conveyor steel typically vary by supplier and the specific deal negotiated. Common terms include upfront deposits, letters of credit, or payment upon delivery. Ensure to clarify these terms during negotiations, as they can impact your cash flow and overall project budgeting. It’s also wise to verify the supplier’s reputation and reliability to mitigate risks associated with international transactions. -

How can I ensure quality assurance for my belt conveyor steel orders?

To ensure quality assurance for your belt conveyor steel orders, request detailed specifications, certifications, and compliance with industry standards from your supplier. Consider establishing a quality control process that includes inspections during production and prior to shipment. Engaging third-party inspection services can also provide an additional layer of assurance, particularly for international shipments, ensuring that the products meet your specified requirements. -

What logistics considerations should I keep in mind when sourcing belt conveyor steel internationally?

When sourcing belt conveyor steel internationally, consider logistics factors such as shipping costs, delivery times, and customs regulations. Work with suppliers who have experience in international shipping and can provide clear timelines and documentation for customs clearance. Additionally, assess the potential impact of tariffs and trade agreements on your overall cost, and consider using a freight forwarder to streamline the logistics process. -

How do I vet suppliers for belt conveyor steel effectively?

To effectively vet suppliers for belt conveyor steel, start by reviewing their industry experience, client testimonials, and case studies to gauge their reliability. Request samples or prototypes to assess product quality and performance. Additionally, inquire about their manufacturing processes, quality control measures, and after-sales support. Establishing clear communication and evaluating their responsiveness can also provide insights into their commitment to customer service and long-term partnership potential.

Top 7 Belt Conveyor Steel Manufacturers & Suppliers List

1. IPCO – Engineered Industrial Processing Solutions

Domain: ipco.com

Registered: 1995 (30 years)

Introduction: IPCO offers engineered industrial processing solutions with a focus on conveyor belts and steel belts. Their solutions cater to various industries including automotive, building materials, chemicals, and energy. Key components include Rotoform systems, scattering systems, and double belt presses.

2. Belt Technologies – Endless Metal Belts

Domain: belttechnologies.com

Registered: 1996 (29 years)

Introduction: Endless Metal Belts and Metal Belt Conveyor Systems, PureSteel® Belts, Endless Belts, Wide Belts, Coated Belts, Perforated Belts, Timing Belts, Drive Tapes, Friction Drive Cylinders, Oil Skimming Belts, Multi-layered Drive Tapes, Wire Mesh Belts, Pulleys (TruTension™, TruPace™, TruTrack™, Friction Drive, Timing), Independently Steerable Pulley Conveyor Systems, Vacuum Conveyors, Vertical Conveyors…

3. Mayfran – Steel Belt Conveyors

Domain: mayfran.com

Registered: 1996 (29 years)

Introduction: Steel Belt Conveyors by Mayfran are designed for low-coolant content and for handling bushy or broken chips. They are available in pitch sizes of 2.5″ (63 mm), 4″ (102 mm), 6″ (152 mm), and 9″ (229 mm). These conveyors are typically used for chip handling based on expected load, and special designs with dimples, perforations, and reinforcements can be provided for more demanding applications.

4. Ashworth – Flat Wire Conveyor Belts

Domain: ashworth.com

Registered: 1996 (29 years)

Introduction: Flat Wire Conveyor Belts manufactured by Ashworth since 1951. Features include:

– Engineered for strict tolerances for longer belt life.

– Efficient performance with maximum open area to minimize spray deflection.

– Versatile for various applications including standard weight and heavy-duty variants.

– Proven reliability with over 75 years of customer satisfaction.

– Suitable for straight run appl…

5. PRAB – Steel Belt Conveyors

Domain: prab.com

Registered: 1997 (28 years)

Introduction: Steel Belt Conveyors by PRAB are heavy-duty systems designed for metal scrap handling. Key features include:

– Robust Construction: Built with heavy-duty components for harsh industrial environments.

– Versatile Handling: Capable of transporting various metal scraps like bushy wads, turnings, die scrap, stamping scrap, and small chips, both wet and dry.

– Customizable Configurations: Available in …

6. VEVOR – Heavy Duty Motorized Belt Conveyor

Domain: vevor.com

Registered: 2009 (16 years)

Introduction: VEVOR Belt Conveyor, 71 x 7.8 inch, Heavy Duty Stainless Steel, Motorized, for Inkjet Coding Applications, Powered PVC Belt, Anti-Static, Adjustable Speed, Double Guardrail; Price: $308.99 (originally $364.99); In Stock.

VEVOR Belt Conveyor, 59 x 7.8 inch, Heavy Duty Stainless Steel, Motorized, for Inkjet Coding Applications, Powered PVC Belt, Anti-Static, Adjustable Speed, Double Guardrail; Pric…

7. Globaltek – Stainless Steel Inline Conveyor

Domain: globaltekconveyors.com

Registered: 2019 (6 years)

Introduction: Product Name: Globaltek Stainless Steel Inline Conveyor with Stainless Steel Belt 4.5 Inches Wide

Main Features:

– Made in USA with 100% UL certified components

– Stainless steel frame

– Speed up to 200 ft/min

– Dual post stainless steel welded base (ideal for lighter and heavier loads)

– Adjustable leveling pads

– Transfer end plates for container transitioning

– Toolless adjustable rail bracket…

Strategic Sourcing Conclusion and Outlook for belt conveyor steel

What Are the Key Takeaways for Strategic Sourcing in Belt Conveyor Steel?

In conclusion, strategic sourcing of belt conveyor steel is pivotal for optimizing manufacturing processes across various industries. The unique properties of metal belt conveyor systems, such as their high strength-to-weight ratio, precision, and low maintenance requirements, position them as superior alternatives to traditional conveyor options. This not only enhances operational efficiency but also ensures compliance with stringent hygiene and environmental standards, especially critical in sectors like food processing and pharmaceuticals.

How Can International B2B Buyers Benefit from Strategic Sourcing?

For international buyers, particularly in Africa, South America, the Middle East, and Europe, a thorough understanding of local market dynamics and supplier capabilities can lead to significant cost savings and improved supply chain resilience. Engaging with experienced suppliers who offer customized solutions can help businesses tailor conveyor systems to specific operational needs, thereby maximizing productivity and reducing downtime.

What’s Next for Your Business in Belt Conveyor Steel Sourcing?

As you evaluate your sourcing strategies, consider the long-term benefits of investing in high-quality, versatile belt conveyor systems. By prioritizing partnerships with reliable manufacturers and leveraging advanced technologies, your business can navigate the evolving landscape of industrial automation with confidence. Take action today—reach out to leading suppliers to explore tailored solutions that align with your operational goals and future-proof your production capabilities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.