Bag Characteristics Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for bag characteristics

Navigating the global market for bag characteristics can be a complex endeavor for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. As demand for quality bags continues to rise, understanding the distinct attributes that define a high-quality handbag is essential. This guide provides a comprehensive analysis of key bag characteristics, including material selection, craftsmanship, design functionality, and supplier vetting processes.

In a market where options abound, discerning the best products can pose challenges, especially when considering factors such as cost, durability, and brand reputation. This guide empowers B2B buyers by equipping them with the knowledge to make informed purchasing decisions, ensuring that their investments reflect quality and reliability. By exploring the nuances of bag characteristics—from the importance of material integrity to the significance of timeless design—buyers will be better positioned to select products that meet their specific needs and stand out in competitive markets.

Furthermore, we delve into strategies for effectively vetting suppliers to ensure alignment with quality standards and ethical practices. By leveraging this guide, businesses can navigate the intricacies of sourcing bags that not only enhance their product offerings but also resonate with their clientele’s aspirations for elegance and functionality.

Understanding bag characteristics Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Leather Handbags | Made from high-quality leather; durable; ages well | Luxury retail, corporate gifts | Pros: Timeless appeal, high durability. Cons: Higher upfront cost. |

| Canvas Bags | Lightweight; versatile; eco-friendly options | Promotional items, trade shows | Pros: Cost-effective, customizable. Cons: Less durable than leather. |

| Backpacks | Ergonomic design; multiple compartments; often made from synthetic materials | Education, corporate travel | Pros: Functional, comfortable for carrying. Cons: Can be bulky. |

| Tote Bags | Open-top design; large capacity; often made from various materials | Retail, grocery, events | Pros: Easy access, reusable. Cons: Limited security for contents. |

| Crossbody Bags | Adjustable straps; compact size; often stylish | Fashion retail, everyday use | Pros: Hands-free convenience, trendy. Cons: Limited storage space. |

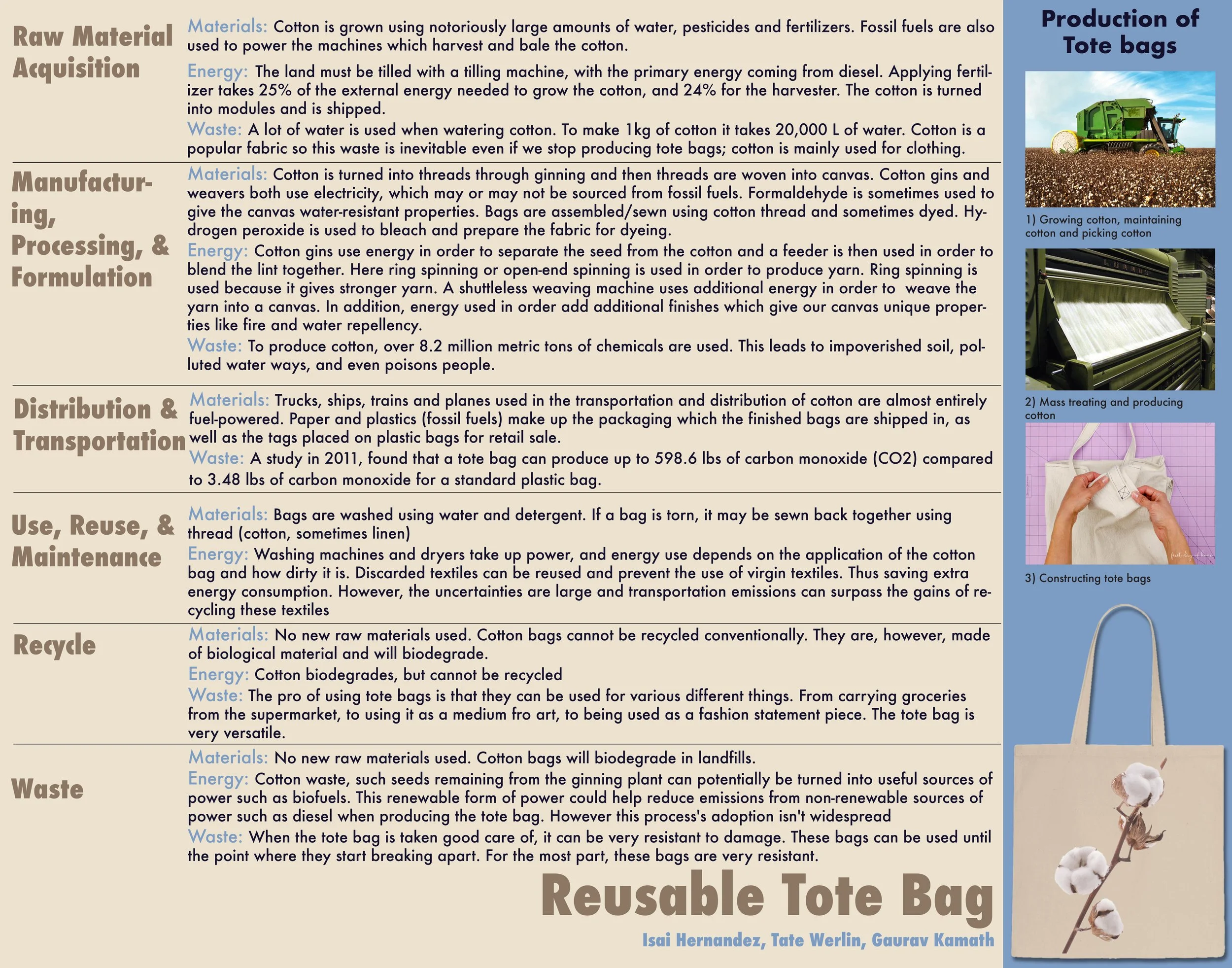

What Are the Key Characteristics of Leather Handbags for B2B Buyers?

Leather handbags are synonymous with luxury and durability, making them ideal for high-end retail markets and corporate gifting. Their key features include premium materials, impeccable craftsmanship, and a timeless aesthetic. B2B buyers should consider the quality of leather (such as full-grain) and the brand’s reputation when purchasing. While the initial investment is higher, the longevity and perceived value can lead to significant returns in customer satisfaction and loyalty.

How Do Canvas Bags Serve B2B Needs?

Canvas bags are a popular choice for promotional items and trade shows due to their lightweight and customizable nature. They are often made from eco-friendly materials, appealing to businesses focused on sustainability. Buyers should look for options that offer durability and design flexibility. While canvas bags are cost-effective, they may not provide the same longevity as leather options, making them suitable for short-term marketing initiatives rather than long-term use.

Why Are Backpacks Essential for Corporate Travel?

Backpacks are designed for ergonomics and practicality, featuring multiple compartments for organization. They are ideal for educational institutions and corporate travel, where functionality is paramount. When purchasing, B2B buyers should evaluate the material quality and comfort features, such as padded straps. Although backpacks can be bulkier than other bag types, their utility makes them a preferred choice for carrying essential items on the go.

What Makes Tote Bags a Versatile Choice in Retail?

Tote bags are characterized by their open-top design and large capacity, making them highly versatile for various applications, including retail and grocery sectors. Their ease of access and reusability are significant advantages for businesses looking to promote sustainability. Buyers should consider the material and design for branding opportunities. However, the lack of closure can pose security risks for contents, which is a consideration for buyers in specific environments.

How Do Crossbody Bags Meet Modern Consumer Demands?

Crossbody bags are increasingly popular for their stylish and hands-free convenience, making them suitable for fashion retail and everyday use. Their adjustable straps and compact size cater to modern consumers seeking practicality without sacrificing style. B2B buyers should focus on design trends and material quality to ensure alignment with consumer preferences. While crossbody bags may offer limited storage space, their appeal can drive significant sales in competitive markets.

Key Industrial Applications of bag characteristics

| Industry/Sector | Specific Application of bag characteristics | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Fashion | High-quality handbags for luxury retail | Enhances brand image and customer satisfaction | Material quality, craftsmanship, and brand reputation |

| Logistics & Packaging | Durable bags for shipping and storage | Reduces breakage and product loss during transit | Strength, weight capacity, and environmental compliance |

| Food & Beverage | Food-grade bags for packaging and distribution | Ensures product safety and compliance with health regulations | Material safety standards, durability, and sealing capabilities |

| Pharmaceuticals | Secure and tamper-proof bags for medication distribution | Protects product integrity and builds consumer trust | Regulatory compliance, material strength, and design functionality |

| Agriculture & Farming | Heavy-duty bags for seed and fertilizer distribution | Increases efficiency in handling and transport | UV resistance, weight capacity, and environmental factors |

How Are Bag Characteristics Applied in the Retail & Fashion Industry?

In the retail and fashion sector, the characteristics of high-quality handbags are critical for establishing brand prestige. Luxury retailers seek bags made from premium materials like full-grain leather, ensuring durability and a sophisticated aesthetic. These bags not only serve functional purposes but also act as status symbols, enhancing customer satisfaction and loyalty. For international buyers, sourcing from reputable manufacturers with proven craftsmanship is essential to maintain brand integrity and meet consumer expectations.

What Role Do Bag Characteristics Play in Logistics & Packaging?

In logistics and packaging, bag characteristics are vital for ensuring safe transport and storage of goods. Durable bags designed to withstand various environmental conditions can significantly reduce breakage and product loss during transit. Buyers in this sector must prioritize sourcing bags that meet specific strength and weight capacities while also complying with environmental regulations. This ensures reliability and sustainability in their supply chain operations, particularly important for international logistics.

How Are Bag Characteristics Utilized in the Food & Beverage Sector?

The food and beverage industry relies heavily on bag characteristics that ensure safety and compliance with health regulations. Food-grade bags must be made from materials that are safe for food contact and capable of maintaining product integrity during distribution. International buyers need to consider sourcing options that guarantee durability and effective sealing capabilities to prevent contamination. This not only protects consumer health but also enhances brand reputation in a competitive market.

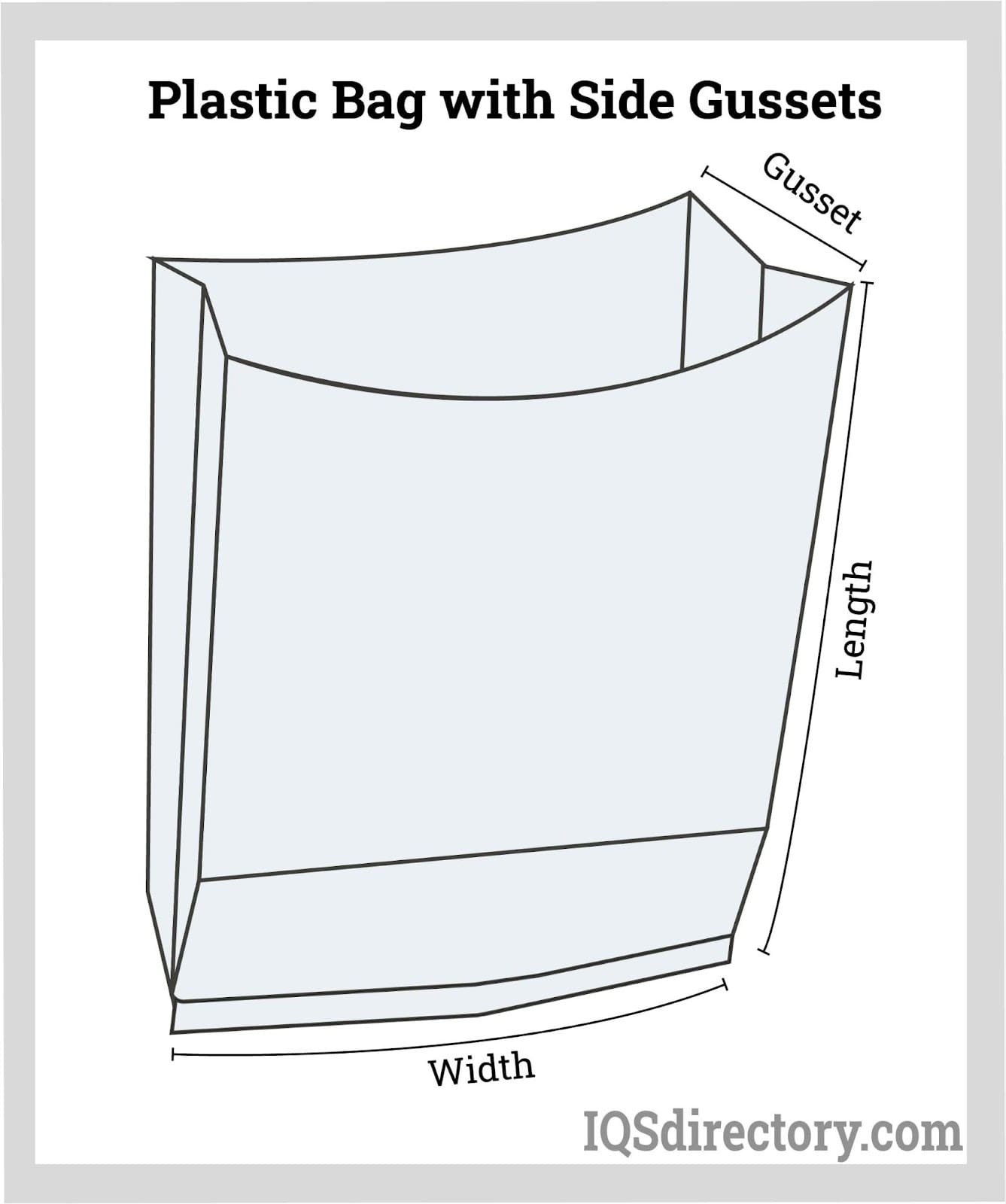

Illustrative image related to bag characteristics

Why Are Bag Characteristics Important for Pharmaceuticals?

In the pharmaceutical sector, secure and tamper-proof bags are essential for medication distribution. The characteristics of these bags, including material strength and design functionality, are critical for protecting product integrity and building consumer trust. Buyers must ensure compliance with regulatory standards, requiring detailed sourcing considerations to guarantee safety and reliability. This is particularly crucial for international buyers who navigate varying regulations across different markets.

How Are Bag Characteristics Applied in Agriculture & Farming?

For the agriculture and farming industry, heavy-duty bags are essential for the efficient distribution of seeds and fertilizers. The characteristics of these bags, such as UV resistance and weight capacity, directly impact their functionality and longevity. Buyers in this sector must consider environmental factors and the specific needs of their products when sourcing bags. This ensures that they can handle the rigors of transportation and storage, ultimately leading to improved operational efficiency.

3 Common User Pain Points for ‘bag characteristics’ & Their Solutions

Scenario 1: Navigating Material Quality Concerns in Handbag Sourcing

The Problem: B2B buyers often struggle with sourcing high-quality handbags, particularly when it comes to material selection. With various materials available, such as genuine leather, synthetic options, and canvas, it can be overwhelming to ensure that the chosen material meets durability and aesthetic standards. Buyers may find themselves receiving products that do not align with their expectations, leading to dissatisfaction from end customers and potential returns.

The Solution: To effectively navigate material quality concerns, B2B buyers should implement a rigorous vendor assessment process that includes material samples and certifications. Start by requesting swatches of the materials used in the handbags. This allows for a tangible assessment of texture, durability, and overall quality. Additionally, inquire about the sourcing practices of the suppliers—understanding where and how materials are sourced can provide insights into their quality and sustainability. Establishing clear specifications in your purchase orders regarding the desired material characteristics, such as full-grain leather or specific synthetic blends, can help mitigate misunderstandings and ensure that the final products meet your quality standards.

Scenario 2: Addressing Craftsmanship Discrepancies

The Problem: Many B2B buyers encounter inconsistencies in craftsmanship when ordering handbags from different manufacturers. Variations in stitching, hardware quality, and overall finish can lead to products that do not meet the expected standards of luxury or functionality. This inconsistency can erode brand reputation and lead to costly returns or customer dissatisfaction.

The Solution: To address craftsmanship discrepancies, buyers should prioritize working with manufacturers that offer transparent production processes. Conduct factory visits, if feasible, to observe the craftsmanship firsthand. Alternatively, request detailed photographs and videos showcasing the production process, particularly the stitching and hardware assembly stages. Establishing a quality control checklist that includes specific craftsmanship criteria can also help. This checklist should outline acceptable standards for stitching tightness, hardware durability, and overall finish. Regular communication with manufacturers about these standards will help ensure that all products maintain consistent quality across orders.

Scenario 3: Ensuring Functional Design Meets User Needs

The Problem: B2B buyers frequently face challenges with the functional design of handbags, as they may not align with the practical needs of their target market. For instance, a handbag might look aesthetically pleasing but lacks essential features like adequate compartments or secure closures, which can frustrate end users and impact sales.

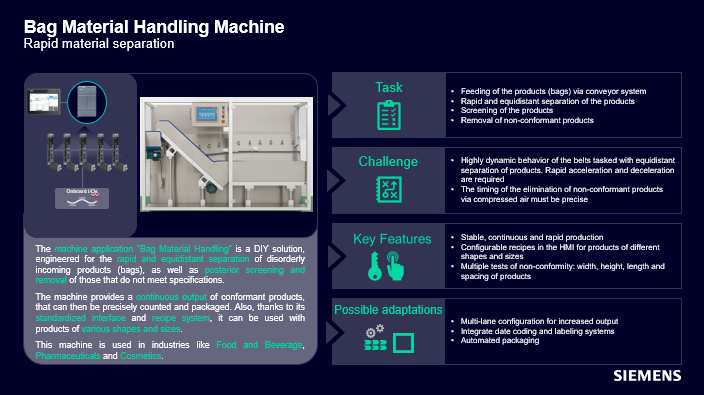

Illustrative image related to bag characteristics

The Solution: To ensure that functional design meets user needs, B2B buyers should conduct thorough market research to understand the preferences and requirements of their target demographic. Engage potential customers through surveys or focus groups to gather insights about desired features, such as pocket configurations, size, and security options. Once this information is collected, collaborate with your manufacturers to create prototypes that incorporate these user-centric design elements. Additionally, establish a feedback loop where end-users can provide input on the prototypes, allowing for iterative improvements before final production. This user-focused approach not only enhances product functionality but also strengthens customer satisfaction and loyalty.

Strategic Material Selection Guide for bag characteristics

What Are the Key Properties of Common Bag Materials?

When selecting materials for bags, understanding their properties and performance characteristics is crucial for B2B buyers. Here, we analyze four common materials: leather, canvas, nylon, and polyester, focusing on their suitability for various bag characteristics.

How Does Leather Perform as a Bag Material?

Leather, particularly full-grain leather, is renowned for its durability and aesthetic appeal. It can withstand various environmental conditions, aging gracefully over time while developing a unique patina. Leather bags typically have a high temperature resistance and can endure pressure without losing shape. However, they require careful maintenance to prevent damage from moisture and scratches.

Pros: Leather offers exceptional durability and a luxurious appearance, making it suitable for high-end products. Its long lifespan can justify the initial investment.

Cons: The manufacturing process is complex and time-consuming, leading to higher costs. Additionally, leather may not be suitable for all climates, particularly humid environments where mold can be a concern.

Impact on Application: Leather bags are ideal for luxury markets and professional settings. They are often preferred in regions with a strong appreciation for craftsmanship, such as Europe.

Considerations for International Buyers: Buyers in Africa and the Middle East should ensure compliance with environmental regulations regarding animal products. In Europe, certifications like the European Union’s REACH regulation may apply.

What Are the Advantages of Canvas for Bag Construction?

Canvas is a versatile material made from cotton or synthetic fibers, known for its strength and resistance to wear. It performs well under various conditions, making it a popular choice for casual and outdoor bags. Canvas can handle moderate temperatures and is generally resistant to tearing.

Pros: Canvas is relatively inexpensive and easy to manufacture, allowing for cost-effective production. It is also lightweight and can be treated for water resistance.

Cons: While durable, canvas is less resistant to moisture than leather and may require additional treatments to enhance its longevity. Its aesthetic appeal is often considered less luxurious compared to leather.

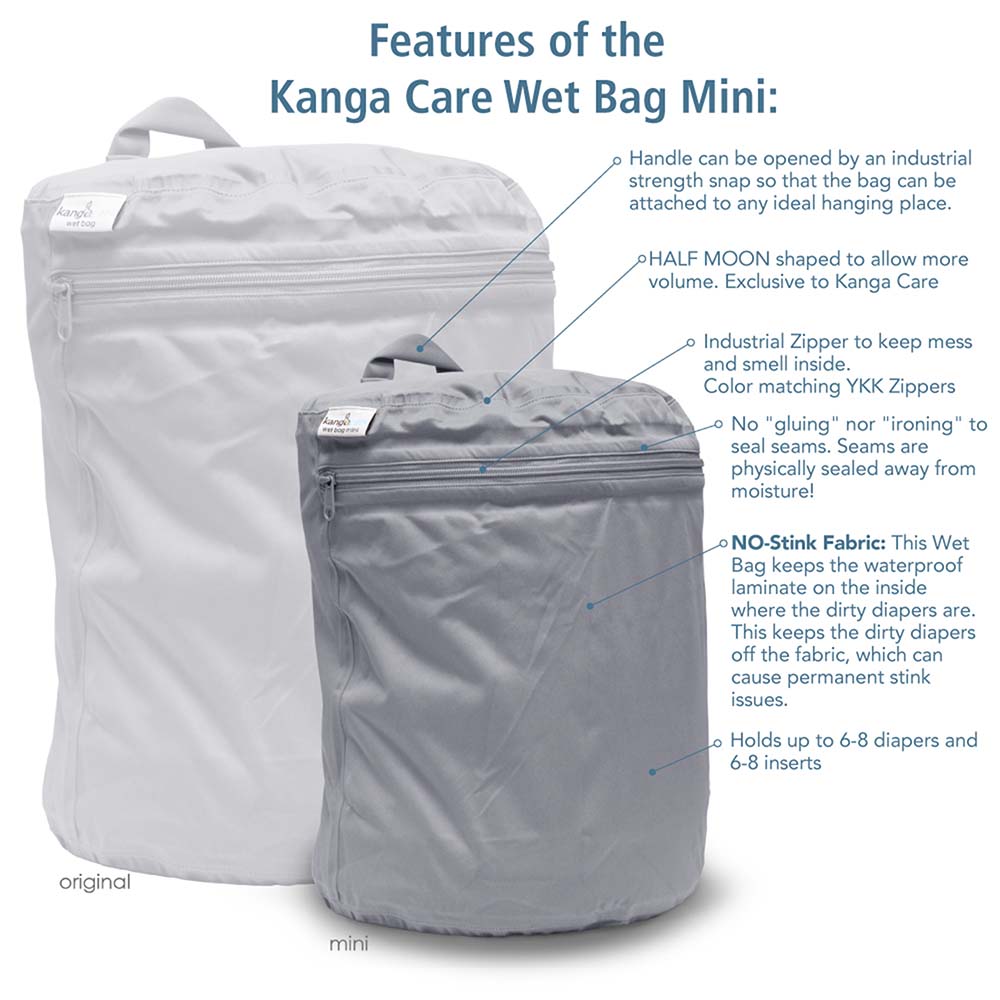

Illustrative image related to bag characteristics

Impact on Application: Canvas bags are frequently used for everyday carry, promotional items, and outdoor activities. They are well-suited for markets in South America where casual styles are prevalent.

Considerations for International Buyers: Compliance with textile regulations and standards, such as ASTM for fabric quality, is essential. Buyers should also consider the environmental impact of cotton sourcing.

How Does Nylon Compare as a Bag Material?

Nylon is a synthetic material known for its lightweight and high tensile strength. It offers excellent resistance to abrasion and is often used in bags designed for travel or outdoor use. Nylon can withstand a range of temperatures and is resistant to mold and mildew.

Pros: Its lightweight nature makes nylon bags easy to carry, and they are often water-resistant, making them suitable for various environments.

Cons: Nylon can be less breathable than natural materials, which may lead to discomfort in hot climates. Additionally, it may not convey the same level of luxury as leather or canvas.

Impact on Application: Nylon is ideal for functional bags, such as backpacks and travel bags, especially in regions like Africa where durability is key.

Considerations for International Buyers: Buyers should be aware of the environmental impact of synthetic materials and ensure compliance with local regulations regarding plastic use.

What Benefits Does Polyester Offer for Bag Manufacturing?

Polyester is another synthetic option that is highly durable and resistant to shrinking and stretching. It performs well under various conditions, making it a practical choice for bags. Polyester is also resistant to UV light, which helps maintain color integrity over time.

Pros: Polyester is cost-effective and easy to clean, making it a popular choice for promotional bags and everyday carry items.

Cons: Similar to nylon, polyester lacks the luxurious feel of natural materials and may not appeal to high-end markets. It can also be less breathable.

Impact on Application: Polyester bags are commonly used for promotional purposes and are well-suited for markets in Europe where functionality is prioritized.

Considerations for International Buyers: Compliance with international standards such as ISO for textile quality is important, particularly in regions with strict regulations like Germany.

Illustrative image related to bag characteristics

Summary Table of Material Characteristics

| Material | Typical Use Case for bag characteristics | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Leather | Luxury handbags, professional bags | Exceptional durability and aesthetics | Higher cost and maintenance required | High |

| Canvas | Casual bags, promotional items | Cost-effective and versatile | Less moisture resistance | Low |

| Nylon | Travel bags, outdoor gear | Lightweight and abrasion-resistant | Less breathable | Medium |

| Polyester | Promotional bags, everyday carry items | Cost-effective and easy to clean | Lacks luxury appeal | Low |

In-depth Look: Manufacturing Processes and Quality Assurance for bag characteristics

Understanding the intricacies of bag manufacturing processes and quality assurance is essential for B2B buyers looking to source high-quality products. This section delves into the various stages of manufacturing and the associated quality control measures, providing actionable insights that buyers from Africa, South America, the Middle East, and Europe can leverage to make informed purchasing decisions.

What Are the Main Stages of the Bag Manufacturing Process?

The manufacturing process for bags typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage is critical to ensuring the final product meets quality standards.

How Is Material Prepared for Bag Production?

Material preparation is the foundational step in bag manufacturing. It involves selecting high-quality materials, which can include leather, synthetic fabrics, and hardware components. For example, genuine leather is often preferred for its durability and aesthetic appeal.

Once selected, materials undergo various treatments such as tanning (for leather) or coating (for synthetic materials) to enhance their performance. This stage may also involve cutting the materials into specific patterns, ensuring that the pieces are optimally sized for the bag’s design. A meticulous approach to material preparation sets the stage for a high-quality end product.

What Techniques Are Used in Forming Bags?

The forming stage is where the bag begins to take shape. Techniques such as die-cutting, sewing, and heat sealing are commonly employed. Die-cutting allows for precise shapes to be created from the prepared materials, while sewing involves stitching the pieces together using strong, durable thread.

Heat sealing is particularly useful for synthetic materials, where edges are fused together for a seamless finish. Advanced machinery is often used in this stage to ensure accuracy and efficiency, reducing the risk of defects.

How Is Assembly Conducted in Bag Manufacturing?

The assembly stage brings together all the components of the bag. This includes attaching straps, zippers, and any additional hardware. Quality craftsmanship is crucial here; artisans often perform intricate work to ensure that all elements fit perfectly and function smoothly.

Attention to detail is essential, as poorly assembled bags can lead to functional issues or aesthetic flaws. High-end manufacturers may use specialized techniques such as double-stitching for added durability and visual appeal.

What Finishing Techniques Are Applied to Bags?

Finishing is the final stage in the manufacturing process and involves adding the last touches to the bag. This can include polishing leather surfaces, applying protective coatings, and adding branding elements such as logos.

Quality control is particularly important at this stage to ensure that the bag meets the desired aesthetic and functional standards. Any defects identified during this phase can lead to rework, which adds time and cost to the production process.

What Are the Key Quality Control Measures in Bag Manufacturing?

Quality assurance in bag manufacturing is vital to ensure that products meet international standards and customer expectations. Various quality control measures are implemented at different stages of the manufacturing process.

What International Standards Should B2B Buyers Be Aware Of?

International standards such as ISO 9001 provide a framework for quality management systems, ensuring that manufacturers maintain consistent quality in their products. Additionally, industry-specific certifications like CE (for products sold within the European Economic Area) and API (for specific materials) offer further assurance of compliance with safety and quality standards.

What Are the Common Quality Control Checkpoints?

Quality control checkpoints are strategically placed throughout the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): Quality checks are conducted during the manufacturing process to identify any defects or deviations from specifications in real-time.

- Final Quality Control (FQC): The completed bags undergo a thorough inspection to ensure they meet all quality standards before being packaged and shipped.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must have confidence in their suppliers’ quality control processes. Here are several strategies to verify and assess supplier quality:

-

Supplier Audits: Conducting regular audits allows buyers to assess the manufacturer’s quality control practices firsthand. This can include reviewing documentation, inspecting facilities, and evaluating production processes.

-

Requesting Quality Reports: Suppliers should provide documentation of their quality control measures, including test results and compliance with international standards.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control processes. These services can perform inspections at various stages of production, ensuring compliance with quality standards.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing bags internationally, particularly from regions such as Africa, South America, the Middle East, and Europe, buyers must navigate various quality control nuances:

- Cultural Differences: Understand that quality expectations may vary by region. Buyers should communicate clearly about their quality standards and requirements.

- Regulatory Compliance: Different countries may have specific regulations regarding materials and manufacturing processes. Buyers should ensure their suppliers comply with local and international regulations.

- Logistical Considerations: Quality control can also be impacted by shipping and handling. It’s essential to discuss packaging and transportation methods with suppliers to minimize the risk of damage during transit.

Conclusion

In conclusion, understanding the manufacturing processes and quality assurance measures for bags is crucial for B2B buyers. By focusing on material selection, manufacturing techniques, and stringent quality control protocols, buyers can ensure they are sourcing high-quality products that meet their needs. Engaging in thorough supplier evaluations and maintaining open lines of communication can further enhance the procurement process, leading to successful partnerships and satisfied customers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘bag characteristics’

In the highly competitive market for bags, understanding the essential characteristics that define quality and functionality is critical for B2B buyers. This guide serves as a practical checklist for evaluating bag characteristics to ensure that your procurement process results in high-quality products that meet your business needs.

Step 1: Identify Your Target Market Needs

Understanding the preferences and requirements of your target market is fundamental. Different regions and demographics may have varying expectations regarding style, material, and functionality. Conduct market research to gather insights on consumer preferences in your target regions, such as Africa or Europe, to inform your sourcing decisions.

Step 2: Define Material Requirements

Material quality directly impacts durability and aesthetics. Opt for materials such as full-grain leather or high-quality synthetic options that offer longevity and appeal. Consider the following:

– Durability: Ensure the material can withstand wear and tear.

– Sustainability: Look for eco-friendly materials, as sustainability is increasingly important in many markets.

Step 3: Evaluate Craftsmanship and Design

Examine the craftsmanship of the bags you are considering. Look for precise stitching, well-finished seams, and quality hardware such as zippers and clasps. High-quality craftsmanship reflects a commitment to excellence and can significantly affect customer satisfaction.

– Attention to Detail: Ensure that all elements, including stitching and hardware, are consistent and of high quality.

– Functionality: Assess the design features, such as compartments and pockets, to ensure they meet user needs.

Step 4: Assess the Supplier’s Reputation

Research potential suppliers thoroughly to gauge their reliability and quality of products. Look for companies with a proven track record in the industry and positive customer reviews.

– Certifications: Verify any industry certifications that may indicate quality standards.

– References: Request references from other businesses in your sector to validate supplier claims.

Step 5: Request Samples for Evaluation

Always request samples before making large orders. This allows you to physically inspect the bags for quality, material, and craftsmanship. When evaluating samples:

– Check for Consistency: Ensure that the samples reflect the same quality and characteristics that were promised.

– Test Durability: Conduct practical tests to assess how the bags hold up under various conditions.

Illustrative image related to bag characteristics

Step 6: Consider Timeliness and Delivery

Evaluate the supplier’s ability to meet your timelines and delivery expectations. A reliable supplier should be able to provide a clear timeline for production and delivery, which is crucial for maintaining your inventory levels.

– Lead Times: Understand the production lead times and factor in shipping durations, especially for international suppliers.

– Flexibility: Assess the supplier’s ability to handle urgent orders or changes in demand.

Step 7: Negotiate Terms and Pricing

Once you have identified a suitable supplier, engage in negotiations to secure favorable terms. Consider not only the price but also payment terms, minimum order quantities, and return policies.

– Long-term Relationships: Establishing a good rapport with suppliers can lead to better pricing and service in the future.

– Bulk Discounts: Inquire about discounts for larger orders or long-term contracts, which can significantly reduce costs.

By following this checklist, B2B buyers can make informed decisions when sourcing bags, ensuring that they procure products that not only meet their specifications but also resonate with their target market.

Comprehensive Cost and Pricing Analysis for bag characteristics Sourcing

Understanding the cost structure and pricing dynamics of bag characteristics sourcing is essential for B2B buyers aiming to make informed purchasing decisions. This analysis will cover the various cost components, price influencers, and provide actionable tips for negotiating and optimizing total cost efficiency.

What Are the Key Cost Components in Bag Sourcing?

-

Materials: The choice of materials significantly impacts the overall cost. High-quality materials such as full-grain leather, durable fabrics, or specialty textiles can elevate both the aesthetic and functional value of the bag. As a B2B buyer, it’s crucial to evaluate the material sourcing, as premium materials will command higher prices but often lead to better longevity and customer satisfaction.

-

Labor: Labor costs vary greatly depending on the region of manufacturing. In countries with lower labor costs, such as some Southeast Asian nations, you may find more competitive pricing. However, this could come at the expense of craftsmanship quality. It’s essential to balance labor costs with the expected quality of the finished product.

-

Manufacturing Overhead: This includes costs related to the facilities, utilities, and equipment used in production. Efficient manufacturers often have streamlined operations that can help reduce these overheads, leading to more competitive pricing for buyers.

-

Tooling: For custom designs, tooling costs can be significant. This covers the creation of molds and tools necessary for production. Understanding these costs upfront can help buyers negotiate better terms, especially when placing bulk orders.

-

Quality Control (QC): Implementing stringent QC processes can add to upfront costs but can ultimately save money by reducing defects and returns. Buyers should inquire about the QC measures in place and their associated costs to ensure product reliability.

-

Logistics: Shipping and handling costs are critical, especially for international transactions. Factors such as distance, shipping method, and Incoterms (International Commercial Terms) can significantly influence logistics costs. Buyers should assess these factors to avoid unexpected expenses.

-

Margin: Supplier margins can vary widely. Understanding the market rates and the typical markup can empower buyers during negotiations, ensuring they pay a fair price without compromising on quality.

How Do Price Influencers Affect Bag Sourcing?

-

Volume/MOQ: Minimum Order Quantities (MOQ) can greatly affect pricing. Suppliers often offer better rates for larger orders. B2B buyers should consider their inventory needs carefully to leverage volume discounts.

-

Specifications and Customization: Unique specifications or customization requests can lead to increased costs. Buyers should clearly define their requirements to avoid unexpected price hikes.

-

Quality Certifications: Bags that meet specific quality standards (like ISO certifications) may have higher costs due to compliance expenses. However, these certifications can enhance marketability and customer trust.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge a premium due to their proven track record, while newer entrants may offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is crucial for international buyers. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) affect who bears the shipping costs and risks, impacting the overall cost structure.

What Tips Can Help B2B Buyers Negotiate Effectively?

-

Negotiate Based on Total Cost of Ownership (TCO): Rather than focusing solely on upfront costs, consider the total cost over the product’s lifecycle. This includes maintenance, potential returns, and longevity, which can justify higher initial costs.

-

Seek Cost-Efficiency: Collaborate with suppliers to find ways to reduce costs without compromising quality. This could involve adjusting designs for easier manufacturing or sourcing materials locally.

-

Understand Pricing Nuances in Different Markets: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional pricing trends and currency fluctuations that could impact costs. This knowledge can enhance negotiation strategies.

-

Request Samples: Before finalizing orders, request samples to assess quality. This can help avoid costly mistakes and ensure the product meets expectations.

-

Build Long-Term Relationships: Establishing a reliable relationship with suppliers can lead to better pricing and priority service in the future. Long-term partnerships often yield benefits that go beyond initial cost savings.

Conclusion

Navigating the complexities of bag characteristics sourcing requires a comprehensive understanding of the cost structure and pricing dynamics. By focusing on key cost components, recognizing price influencers, and employing strategic negotiation techniques, B2B buyers can secure favorable terms that enhance their bottom line while ensuring product quality. Always approach sourcing with a holistic view, considering both immediate costs and long-term value.

Alternatives Analysis: Comparing bag characteristics With Other Solutions

In the competitive landscape of fashion accessories, particularly handbags, understanding the characteristics of bags is essential for B2B buyers. However, it is equally important to evaluate alternative solutions that can serve similar purposes, either in functionality or style. This analysis compares ‘bag characteristics’ against two viable alternatives: tote bags and backpacks, providing insights into their respective advantages and drawbacks.

| Comparison Aspect | Bag Characteristics | Tote Bags | Backpacks |

|---|---|---|---|

| Performance | High durability and style | Versatile but less structured | Excellent for carrying weight |

| Cost | Premium pricing due to quality | Generally more affordable | Mid-range pricing |

| Ease of Implementation | Requires careful selection | Easy to use, no special handling | Requires adjustment for fit |

| Maintenance | Minimal if properly cared for | Low maintenance, easy to clean | Moderate; needs regular cleaning |

| Best Use Case | Formal and casual settings | Shopping, casual outings | Travel, outdoor activities |

How Do Tote Bags Compare to Bag Characteristics?

Tote bags are a popular alternative due to their versatility and practicality. They are typically less expensive than high-quality handbags, making them accessible for a broader audience. Their open design allows for easy access, which is ideal for shopping or casual outings. However, tote bags often lack the structured elegance of a well-crafted handbag, which may affect their appeal in formal environments. Moreover, while they are easy to maintain, their lack of compartments may lead to disorganization, making them less suitable for those who require a more structured approach to carrying essentials.

What Advantages Do Backpacks Offer Over Bag Characteristics?

Backpacks provide a functional alternative, especially for individuals who prioritize comfort and weight distribution. They are particularly advantageous for travel and outdoor activities, as they can carry heavier loads without strain. Backpacks often come with multiple compartments, making organization straightforward and efficient. However, they may not convey the same level of sophistication as high-end handbags, limiting their use in formal settings. Additionally, adjusting the straps for a proper fit can be cumbersome, which might deter some users seeking quick access.

Illustrative image related to bag characteristics

Conclusion: How Should B2B Buyers Choose the Right Bag Solution?

When selecting a bag solution, B2B buyers must consider the specific needs of their target market. If the focus is on luxury and style, investing in high-quality handbags characterized by premium materials and craftsmanship is essential. Conversely, if the target demographic values versatility and affordability, tote bags or backpacks may be more appropriate. Ultimately, understanding the characteristics of each option, alongside the intended use case, will guide buyers in making informed purchasing decisions that align with their business objectives and customer preferences.

Essential Technical Properties and Trade Terminology for bag characteristics

What Are the Key Technical Properties That Define Bag Quality?

When sourcing bags, understanding the technical properties is essential for making informed purchasing decisions. Here are some critical specifications to consider:

1. Material Grade

The material grade refers to the quality of the fabric or leather used in bag production. Common materials include full-grain leather, which is the highest quality leather, and synthetic fabrics like nylon or polyester. For B2B buyers, selecting the right material impacts not only the bag’s durability but also its aesthetic appeal and marketability. A higher grade typically results in a more durable product that can withstand wear and tear, thus reducing the return rate and increasing customer satisfaction.

2. Stitching Quality

Stitching quality is an indicator of craftsmanship. It includes factors like stitch count per inch and the type of thread used. For instance, bags with a higher stitch count are often more durable, as they distribute stress more evenly across seams. B2B buyers should prioritize products that exhibit consistent and tight stitching, as this can significantly affect the lifespan of the bag.

3. Tolerance Levels

Tolerance levels refer to the allowable variation in dimensions during the manufacturing process. This is crucial for ensuring that bags meet specific design specifications. Tighter tolerances generally indicate a higher level of quality control and precision in manufacturing. For international buyers, understanding tolerance levels can aid in assessing whether a supplier can deliver products that meet their exact specifications, thus reducing the risk of defects.

Illustrative image related to bag characteristics

4. Hardware Specifications

The quality of hardware, such as zippers, buckles, and clasps, is critical for both functionality and aesthetics. High-quality hardware is made from durable materials like brass or stainless steel and is designed to operate smoothly. B2B buyers should evaluate hardware specifications to ensure that they align with the intended use of the bag. For instance, a bag meant for heavy-duty use should have more robust hardware compared to a fashion accessory.

5. Lining Material

The lining material contributes to the bag’s overall durability and functionality. High-quality linings, often made from durable fabrics like cotton or polyester, can protect the contents of the bag and enhance the user’s experience. B2B buyers should consider lining materials that offer both strength and aesthetic appeal, as these factors can influence customer perceptions and satisfaction.

What Common Trade Terms Should B2B Buyers Know When Sourcing Bags?

Familiarity with industry jargon is crucial for effective communication and negotiation in the B2B space. Here are some common terms that are particularly relevant:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or products that are then sold under another company’s brand. Understanding OEM relationships is important for buyers who may want to customize bags or create their own branded products. This can also provide insight into the manufacturing capabilities and quality standards of potential suppliers.

2. MOQ (Minimum Order Quantity)

MOQ indicates the minimum number of units a supplier is willing to sell in a single order. Knowing the MOQ is vital for budgeting and inventory planning. Buyers should evaluate whether they can meet the MOQ without overcommitting resources, especially in markets with fluctuating demand.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers. It typically includes detailed specifications and quantities. Submitting an RFQ allows buyers to compare prices and terms from different manufacturers, ensuring they receive the best value for their investment.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. They cover aspects like shipping costs, insurance, and liability. Understanding Incoterms is crucial for B2B buyers engaged in international trade, as they can significantly impact the total landed cost of the product.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. It encompasses manufacturing time, shipping, and customs clearance. For B2B buyers, understanding lead times is essential for inventory management and meeting customer demands.

By familiarizing yourself with these technical properties and trade terms, you can make more informed decisions that enhance your sourcing strategy and ultimately lead to better business outcomes.

Illustrative image related to bag characteristics

Navigating Market Dynamics and Sourcing Trends in the bag characteristics Sector

What Are the Current Market Dynamics and Key Trends in the Bag Characteristics Sector?

The global bag characteristics market is experiencing significant transformation driven by various factors, including changing consumer preferences and technological advancements. As international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, understanding these dynamics is essential for making informed sourcing decisions.

One of the key trends is the increasing demand for high-quality, durable materials such as full-grain leather and sustainable fabrics. Buyers are seeking products that not only meet aesthetic standards but also offer longevity and functionality. This shift is partly fueled by a growing consumer awareness of quality craftsmanship and an appreciation for artisanal products, particularly in markets like Germany and Vietnam, where tradition meets modernity.

Moreover, B2B tech innovations are reshaping sourcing processes. Digital platforms that facilitate direct communication between manufacturers and buyers are becoming commonplace, allowing for better transparency and efficiency. Blockchain technology is also gaining traction, ensuring traceability in the supply chain, which is particularly appealing for buyers focused on ethical sourcing.

Emerging markets are seeing a rise in local brands that prioritize unique characteristics and cultural heritage in their designs, offering international buyers distinctive alternatives. These trends suggest that B2B buyers must remain agile and informed, leveraging technology and focusing on quality and sustainability to stay competitive in a rapidly evolving market.

How Important Is Sustainability and Ethical Sourcing in the Bag Characteristics Sector?

Sustainability and ethical sourcing have become paramount in the bag characteristics sector, reflecting broader environmental concerns and consumer expectations. International B2B buyers are increasingly prioritizing suppliers that demonstrate a commitment to minimizing their environmental impact. This includes using eco-friendly materials, such as recycled fabrics and sustainably sourced leather, which not only reduce waste but also appeal to environmentally conscious consumers.

The importance of ethical supply chains cannot be overstated. Buyers are now more vigilant about labor practices within their supply chains, seeking suppliers that adhere to fair labor standards and promote social responsibility. Certifications such as Fair Trade and Global Organic Textile Standard (GOTS) are becoming essential benchmarks for assessing suppliers’ commitment to ethical practices.

Investing in sustainable and ethically sourced products can yield long-term benefits for B2B buyers, including enhanced brand reputation and customer loyalty. As consumers increasingly favor brands that align with their values, businesses that prioritize sustainability are likely to experience a competitive advantage in the marketplace.

How Has the Bag Characteristics Sector Evolved Over Time?

The evolution of the bag characteristics sector reflects broader societal changes and technological advancements. Historically, bags were primarily functional items designed for utility. However, as consumer preferences shifted towards fashion and personal expression, the industry began emphasizing aesthetics, quality, and craftsmanship.

Illustrative image related to bag characteristics

In recent decades, luxury handbags have emerged as status symbols, often characterized by their exclusivity and meticulous craftsmanship. This trend has driven the market towards high-quality materials and innovative designs, with brands investing heavily in artisanal techniques and sustainable practices.

Moreover, the rise of e-commerce has transformed how bags are marketed and sold, enabling international buyers to access a broader range of products and suppliers. As the sector continues to evolve, it is crucial for B2B buyers to stay abreast of these changes, focusing on quality, sustainability, and ethical sourcing to meet the demands of a discerning consumer base.

Frequently Asked Questions (FAQs) for B2B Buyers of bag characteristics

-

How do I assess the quality of bags when sourcing from international suppliers?

To assess bag quality, focus on key characteristics such as material, craftsmanship, and design. Request samples to evaluate the durability of the materials, particularly leather or canvas. Inspect stitching for consistency and strength, as well as the hardware quality, including zippers and clasps. Additionally, ensure the bag design meets functional requirements, such as compartmentalization and ease of use. Always review supplier certifications and past customer feedback to gauge reliability. -

What is the best material for durable handbags in the B2B market?

The best materials for durable handbags include full-grain leather and high-quality synthetic alternatives like ballistic nylon. Full-grain leather is renowned for its longevity, developing a unique patina over time, while ballistic nylon offers excellent resistance to wear and tear. Additionally, canvas can be a viable option for more casual bags. When selecting materials, consider your target market’s preferences and the intended use of the bags. -

How can I ensure my bag supplier meets quality assurance standards?

To ensure quality assurance, conduct thorough vetting of potential suppliers. Request certifications such as ISO or other relevant quality management systems. Establish clear quality control protocols, including inspections at various production stages. Consider third-party quality audits to provide an unbiased assessment. Regular communication and feedback loops with your supplier can also help maintain standards and address any issues promptly. -

What are the typical minimum order quantities (MOQs) for bags in international trade?

Minimum order quantities for bags can vary widely depending on the supplier and the type of bag. Generally, MOQs can range from 100 to 1,000 units for customized designs, while stock items may have lower MOQs. It’s crucial to discuss MOQs upfront with suppliers to align production capabilities with your needs. Be aware that higher MOQs often lead to better pricing, so consider negotiating if you can commit to larger orders. -

What payment terms should I expect when sourcing bags internationally?

Payment terms can vary based on supplier policies and the buyer’s negotiation power. Common terms include a 30% deposit upon order confirmation, with the balance due before shipment. Some suppliers may offer net 30 or net 60 terms after establishing a relationship. It’s essential to clarify payment methods accepted, such as wire transfers, letters of credit, or escrow services, to ensure security in transactions. -

How do I customize bags to fit my brand’s identity?

Customizing bags involves collaborating closely with your supplier to discuss design specifics, including materials, colors, logos, and functionality. Provide clear guidelines and examples of your brand identity to facilitate the design process. Many suppliers offer design mock-ups to visualize the final product. Additionally, be prepared to pay for custom tooling or molds if necessary, as this can impact the overall cost and lead time. -

What logistics considerations should I keep in mind when importing bags?

When importing bags, consider shipping methods, lead times, and customs regulations. Determine whether air or sea freight is more suitable based on urgency and cost. Familiarize yourself with import duties and tariffs for your destination country to avoid unexpected expenses. Partnering with a reliable freight forwarder can streamline the logistics process, ensuring compliance with international shipping laws and efficient delivery. -

How can I evaluate the market demand for different bag styles?

Evaluating market demand involves conducting thorough market research, including competitor analysis and trend monitoring. Utilize tools like Google Trends or social media insights to gauge consumer interest in various bag styles. Attend trade shows and industry events to gain firsthand insights and network with potential buyers. Additionally, consider surveying your target audience to understand their preferences and willingness to purchase specific styles or features.

Top 3 Bag Characteristics Manufacturers & Suppliers List

1. Esinakan – Free Shipping on Orders Over £200/$250

Domain: esinakan.com

Registered: 2012 (13 years)

Introduction: Free Shipping On All Orders Over £200 | $250

2. Rustic Town – Leather Bags & Accessories

Domain: rustictown.com

Registered: 2007 (18 years)

Introduction: Leather Messenger Bag, Leather Satchel, Leather Travel Bag, Leather Toiletry Bag, Leather Backpack, Leather Watch Case, Leather Wallet, Leather Crossbody Bag, Leather Tote, Leather Backpack, Leather Wallet, Leather Portfolio, Leather Journal, Leather Pencil Case, Leather Desk Mat, Leather Accessories, Leather Knife Roll, Leather Apron.

3. PopFashion – Perfect Tote Bag

Domain: popfashion.co

Registered: 2015 (10 years)

Introduction: The perfect tote bag features include: 1. Material: High-quality fabrics like canvas, nylon, or leather for durability and style. 2. Sturdy Straps: Reinforced stitching and comfortable widths for longevity and comfort, with adjustable options. 3. Roomy Interior: Spacious with a wide opening and interior pockets for organization. 4. Versatile Compartments: Designated laptop sleeves, padded compartm…

Strategic Sourcing Conclusion and Outlook for bag characteristics

In the highly competitive landscape of bag sourcing, understanding the intricate characteristics of quality handbags is paramount for B2B buyers aiming to make informed purchasing decisions. Key factors such as material quality, craftsmanship, and design functionality not only influence customer satisfaction but also enhance brand reputation. Sourcing bags made from durable materials like full-grain leather, with impeccable stitching and reliable hardware, can significantly impact long-term product performance and customer loyalty.

Strategic sourcing is essential for navigating the diverse markets in Africa, South America, the Middle East, and Europe. By prioritizing quality and aligning with reputable manufacturers, buyers can ensure their offerings meet the evolving demands of consumers who value both aesthetics and functionality.

Looking ahead, the demand for timeless, well-crafted handbags will continue to rise as consumers increasingly seek products that represent both style and sustainability. International B2B buyers should seize this opportunity to cultivate partnerships with manufacturers who share a commitment to quality and innovation. By doing so, they will not only enhance their product lines but also position themselves as leaders in the market, ready to meet the future needs of discerning customers.

Illustrative image related to bag characteristics

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.