Automotive Door Latch: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for automotive door latch

Navigating the global market for automotive door latches presents a unique set of challenges for B2B buyers, particularly when it comes to sourcing high-quality components that meet diverse regional standards and specifications. With the automotive industry’s increasing demand for enhanced security, durability, and functionality, understanding the various types of door latches—ranging from universal to custom designs—becomes crucial for manufacturers and suppliers alike. This guide will delve into the intricacies of automotive door latches, covering essential aspects such as their applications across different vehicle types, the importance of supplier vetting to ensure reliability, and a comprehensive overview of costs associated with various latch systems.

International buyers from regions like Africa, South America, the Middle East, and Europe, including markets such as Saudi Arabia and Vietnam, will find this guide particularly valuable. It is designed to empower decision-makers with actionable insights that facilitate informed purchasing decisions, helping to mitigate risks associated with substandard products. By understanding the nuances of automotive door latch technology and procurement processes, B2B buyers can optimize their supply chains, enhance vehicle safety features, and ultimately drive business growth. Whether you are looking for a cost-effective solution or a specialized latch for a unique vehicle model, this guide serves as your essential resource in the global automotive door latch market.

Understanding automotive door latch Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Universal Door Latches | Versatile design, compatible with various vehicle types | Automotive repair shops, customization shops | Pros: Easy to install, cost-effective. Cons: May lack specific fit for certain models. |

| Bear Jaw Latches | Dual claw mechanism for enhanced security and durability | Performance vehicles, custom builds | Pros: High strength, reliable locking. Cons: More complex installation. |

| Gator-Jaw Latches | Compact design, ideal for tight spaces, available in locking variants | Hot rod builds, classic restorations | Pros: Space-saving, stylish. Cons: Limited load capacity. |

| Heavy Duty Door Latches | Rugged construction, designed for high-impact use | Off-road vehicles, heavy-duty applications | Pros: Exceptional durability, secure closure. Cons: Heavier, may require additional installation skills. |

| Electronic Door Latches | Integrated with electronic locking systems, remote access | Modern vehicles, luxury automotive segments | Pros: Enhanced security features, convenience. Cons: Higher cost, potential for electronic failure. |

What Are Universal Door Latches and Their Applications?

Universal door latches are designed for compatibility with a wide range of vehicle models, making them an ideal choice for automotive repair shops and customization centers. Their versatile design ensures smooth door operation, eliminating issues like slamming or misalignment. When purchasing, consider the material quality and installation ease, as these factors can significantly impact long-term performance and customer satisfaction.

How Do Bear Jaw Latches Enhance Security?

Bear jaw latches utilize a dual claw mechanism that provides superior security and durability. They are particularly suited for performance vehicles and custom builds where reliability is paramount. Buyers should evaluate the strength of the materials used, as well as the complexity of installation, which may require specialized skills. These latches often come at a higher price point but offer excellent value for those prioritizing safety.

What Makes Gator-Jaw Latches Ideal for Custom Builds?

Gator-jaw latches are known for their compact design, making them suitable for applications with limited space, such as hot rod builds and classic restorations. They are available in both locking and non-locking variants, providing flexibility based on security needs. While their space-saving advantage is significant, buyers should be aware of their limited load capacity, which may not suit all vehicle types.

Why Choose Heavy Duty Door Latches for Rugged Applications?

Heavy-duty door latches are built to withstand high-impact use, making them perfect for off-road vehicles and heavy-duty applications. Their robust construction ensures a secure closure, critical for vehicles that encounter harsh conditions. Potential buyers should consider the weight and installation requirements, as these latches may necessitate additional installation skills to ensure proper function.

What Are the Benefits of Electronic Door Latches?

Electronic door latches integrate advanced technology, allowing for remote locking and enhanced security features, making them ideal for modern and luxury vehicles. These latches offer convenience but come with a higher price tag and the risk of electronic failure. B2B buyers should assess the reliability of the electronic components and the warranty offered, ensuring they meet the demands of their customer base.

Key Industrial Applications of automotive door latch

| Industry/Sector | Specific Application of automotive door latch | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Standard and custom latches for passenger vehicles | Enhances vehicle safety and user experience | Durability, compliance with safety standards, lead time |

| Commercial Vehicle Fleet | Heavy-duty latches for trucks and vans | Ensures reliability and reduces maintenance costs | Strength, weather resistance, ease of installation |

| Specialty Vehicle Design | Custom latches for hot rods and modified vehicles | Provides unique aesthetics and functionality | Customization options, material quality, cost efficiency |

| Automotive Aftermarket | Replacement latches for repairs and upgrades | Improves vehicle longevity and customer satisfaction | Compatibility with various models, warranty, price point |

| Public Transportation | Latches for buses and coaches | Enhances passenger safety and operational efficiency | Compliance with regulations, durability, ease of use |

How is Automotive Door Latch Utilized in Automotive Manufacturing?

In the automotive manufacturing sector, standard and custom automotive door latches are critical components for passenger vehicles. They ensure that doors open and close securely, thereby enhancing safety and user experience. For international buyers, particularly in regions like Africa and South America, sourcing latches that meet regional safety standards and are durable against local environmental conditions is paramount. Buyers should consider lead times and the ability of manufacturers to provide latches that comply with both local and international automotive safety regulations.

What is the Role of Automotive Door Latch in Commercial Vehicle Fleets?

Heavy-duty automotive door latches are vital for commercial vehicle fleets, including trucks and vans. These latches are designed to endure rigorous usage while ensuring that doors remain secure during transit. For businesses in the Middle East and Europe, reliability translates to reduced maintenance costs and enhanced vehicle uptime. Key sourcing considerations include the strength of materials used, resistance to weather conditions, and ease of installation to minimize downtime during repairs or replacements.

How Do Specialty Vehicle Designers Use Automotive Door Latches?

Specialty vehicle designers often require custom automotive door latches for hot rods and modified vehicles. These latches not only serve a functional purpose but also contribute to the unique aesthetics of the vehicle. For B2B buyers in markets like Saudi Arabia and Vietnam, the ability to customize latches according to specific design requirements is crucial. Buyers should focus on options for customization, the quality of materials, and cost efficiency to ensure the latches meet both functional and aesthetic demands.

Why is Automotive Door Latch Important in the Automotive Aftermarket?

In the automotive aftermarket, door latches are frequently replaced during repairs and upgrades. A reliable latch improves vehicle longevity and enhances customer satisfaction, making it a vital component for service centers and parts suppliers. Buyers from diverse regions must ensure compatibility with various vehicle models and consider warranty options and price points when sourcing replacement latches. This attention to detail helps maintain service quality and fosters customer loyalty.

What is the Significance of Automotive Door Latch in Public Transportation?

In public transportation, such as buses and coaches, automotive door latches play a crucial role in passenger safety and operational efficiency. These latches must withstand frequent use while complying with safety regulations. For buyers in this sector, particularly in Europe and the Middle East, sourcing latches that meet stringent regulatory standards is essential. Durability and ease of use should be prioritized to enhance overall passenger experience and ensure smooth operations.

3 Common User Pain Points for ‘automotive door latch’ & Their Solutions

Scenario 1: Difficulty in Ensuring Door Security

The Problem:

For international B2B buyers in the automotive sector, ensuring the security of vehicle doors is a paramount concern. A faulty or substandard door latch can lead to unauthorized access, theft, and safety hazards. Buyers often struggle with sourcing reliable latches that not only meet safety standards but also provide durability against environmental factors like humidity and rust, particularly in regions prone to such issues, such as parts of Africa and South America.

The Solution:

To address security concerns, buyers should prioritize sourcing door latches that are rigorously tested for strength and reliability. When evaluating suppliers, look for products that meet specific safety certifications, such as Federal Motor Vehicle Safety Standards (FMVSS). Additionally, consider using stainless steel or corrosion-resistant materials to enhance longevity in harsh climates. It is advisable to request samples for testing before making bulk purchases. Collaborating with manufacturers who offer customization options can also ensure that the latches fit perfectly with the vehicles they are intended for, enhancing both security and aesthetics.

Scenario 2: Challenges with Installation and Compatibility

The Problem:

B2B buyers frequently encounter compatibility issues when trying to replace or upgrade door latches in existing vehicle models. Different vehicle designs require specific latching mechanisms, and buyers may find it challenging to source latches that align perfectly with their current systems. This can lead to increased downtime and additional costs associated with modifications or reengineering.

The Solution:

To mitigate installation challenges, buyers should engage with suppliers that provide comprehensive installation kits along with detailed installation guides. Ensure that the latches come with adjustable features or installation templates that cater to various vehicle models. Before finalizing a purchase, it is beneficial to conduct a compatibility check with the manufacturer’s specifications. Many suppliers offer consulting services where technical experts can assist in selecting the right product based on the vehicle’s design. Utilizing universal latches can also offer flexibility, as they can be adapted to fit various applications, reducing the risk of mismatches.

Scenario 3: High Replacement Costs Due to Frequent Failures

The Problem:

Frequent failures of door latches can lead to significant replacement costs and operational inefficiencies for automotive manufacturers and repair shops. Many buyers face the dilemma of balancing cost with quality, as cheaper latches often compromise on durability and performance, resulting in increased maintenance and replacement cycles.

The Solution:

Investing in high-quality door latches that come with warranties can significantly reduce long-term costs associated with replacements. Buyers should conduct a cost-benefit analysis that weighs the initial price against potential savings from decreased failure rates and maintenance. Additionally, implementing a proactive maintenance schedule can help identify wear and tear before it leads to failure. Regular inspections and lubrication of moving parts can extend the lifespan of latches. Partnering with manufacturers who offer robust support and maintenance services can also provide peace of mind, as they can assist in troubleshooting and ensure the longevity of the products used.

Strategic Material Selection Guide for automotive door latch

When selecting materials for automotive door latches, it is crucial to consider performance characteristics, manufacturing complexities, and regional compliance standards. Below is an analysis of four common materials used in the production of automotive door latches.

Illustrative image related to automotive door latch

What are the Key Properties of Steel for Automotive Door Latches?

Steel is one of the most widely used materials for automotive door latches due to its strength and durability. Key properties include high tensile strength, excellent wear resistance, and the ability to withstand high temperatures and pressures. Steel latches typically have good corrosion resistance when treated with protective coatings such as zinc plating or powder coating.

Pros: Steel offers exceptional durability and can handle the mechanical stresses of repeated use. It is also relatively cost-effective and widely available, making it a popular choice for manufacturers.

Cons: The primary drawback of steel is its susceptibility to rust and corrosion if not adequately coated. Additionally, the manufacturing process can be complex, requiring precision machining and finishing.

Impact on Application: Steel latches are well-suited for environments where mechanical strength is paramount, but they require careful consideration regarding exposure to moisture and corrosive elements.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local corrosion resistance standards, while European buyers may refer to ASTM and DIN standards for material specifications.

How Does Aluminum Compare for Automotive Door Latches?

Aluminum is another material option, known for its lightweight properties and good corrosion resistance. Key properties include a lower density than steel, making it easier to handle and install, as well as good thermal conductivity.

Pros: The lightweight nature of aluminum can contribute to overall vehicle weight reduction, which is beneficial for fuel efficiency. It also has excellent resistance to corrosion, particularly in coastal areas.

Cons: While aluminum is strong, it does not match the tensile strength of steel, making it less suitable for high-stress applications. Additionally, aluminum can be more expensive than steel, impacting overall production costs.

Impact on Application: Aluminum latches are ideal for applications where weight savings are critical, but they may not be suitable for heavy-duty applications where high strength is required.

Considerations for International Buyers: Buyers should be aware of the specific aluminum grades and their compliance with international standards such as JIS and ASTM. In regions like the Middle East, where high temperatures can affect material performance, selecting the right aluminum alloy is crucial.

What are the Benefits of Plastic Composites in Automotive Door Latches?

Plastic composites are increasingly being used in automotive applications due to their versatility and lightweight characteristics. Key properties include resistance to corrosion and the ability to mold into complex shapes.

Pros: Plastic composites can be produced at a lower cost and can be manufactured in high volumes with less energy consumption. They also provide excellent resistance to environmental factors.

Cons: The main limitation is their lower mechanical strength compared to metals, which may lead to performance issues in high-stress situations. Additionally, plastics can degrade over time when exposed to UV light unless treated.

Impact on Application: Plastic latches are suitable for applications where weight reduction and corrosion resistance are prioritized, but they may not be appropriate for heavy-duty or high-security environments.

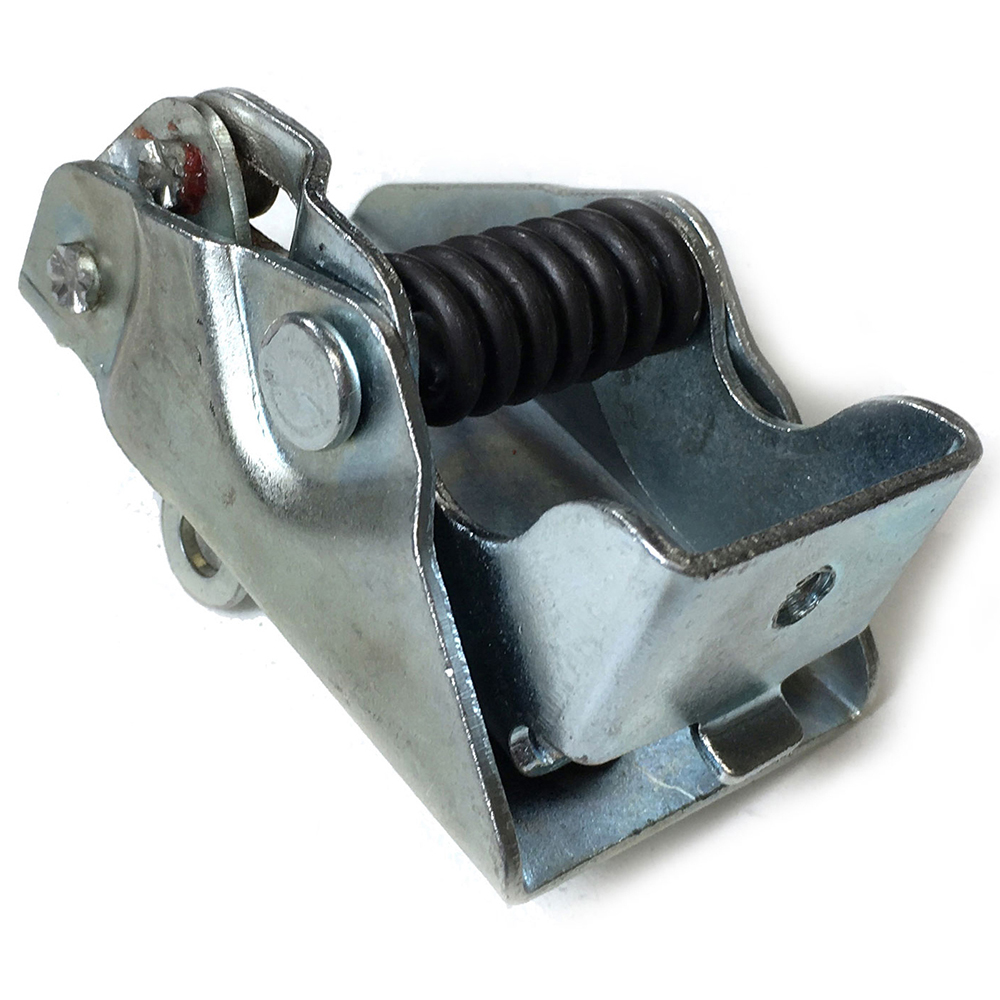

Illustrative image related to automotive door latch

Considerations for International Buyers: Buyers should ensure that the plastic materials meet regional safety and performance standards, especially in Europe, where compliance with REACH regulations is mandatory.

What Role Does Stainless Steel Play in Automotive Door Latch Manufacturing?

Stainless steel is favored for its corrosion resistance and aesthetic appeal. Key properties include high tensile strength, good ductility, and resistance to rust and staining.

Pros: Stainless steel offers a combination of strength and corrosion resistance, making it ideal for automotive applications exposed to harsh environments. It also requires minimal maintenance.

Cons: The primary downside is its higher cost compared to regular steel and aluminum. Additionally, the manufacturing process can be more complex due to its hardness.

Impact on Application: Stainless steel latches are particularly well-suited for luxury vehicles or applications where appearance and longevity are critical.

Considerations for International Buyers: Compliance with international standards is essential, especially in Europe where specific grades of stainless steel are preferred. Buyers in regions like Saudi Arabia should consider the impact of high humidity and saline environments on material selection.

Summary Table

| Material | Typical Use Case for automotive door latch | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Standard automotive applications | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Lightweight vehicles | Lightweight and corrosion-resistant | Lower strength than steel | High |

| Plastic Composites | Lightweight and corrosion-resistant applications | Cost-effective and versatile | Lower mechanical strength | Low |

| Stainless Steel | Luxury vehicles and high-end applications | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

This comprehensive analysis provides valuable insights for B2B buyers, helping them make informed decisions regarding material selection for automotive door latches based on performance, cost, and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for automotive door latch

What Are the Key Stages in the Manufacturing Process of Automotive Door Latches?

Manufacturing automotive door latches involves a series of precise stages to ensure that each component meets the required specifications for safety, functionality, and durability. The main stages typically include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Door Latch Production?

The process begins with selecting high-quality materials, primarily steel or other alloys that can withstand wear and corrosion. The chosen materials are subjected to rigorous testing to confirm their mechanical properties and resistance to environmental factors. After selection, the materials are cut into predetermined sizes and shapes, often utilizing laser cutting or water jet cutting technologies. This ensures accuracy in the dimensions required for further processing.

What Forming Techniques Are Used in Manufacturing Door Latches?

Once the materials are prepared, they undergo forming processes. Common techniques include stamping, forging, and machining. Stamping is particularly popular for producing high volumes of parts with complex geometries, while forging enhances the strength of components through controlled deformation. Machining, such as CNC (Computer Numerical Control) milling, is employed for achieving precise tolerances and finishing surfaces. Each technique plays a crucial role in ensuring the latch components can operate effectively under stress.

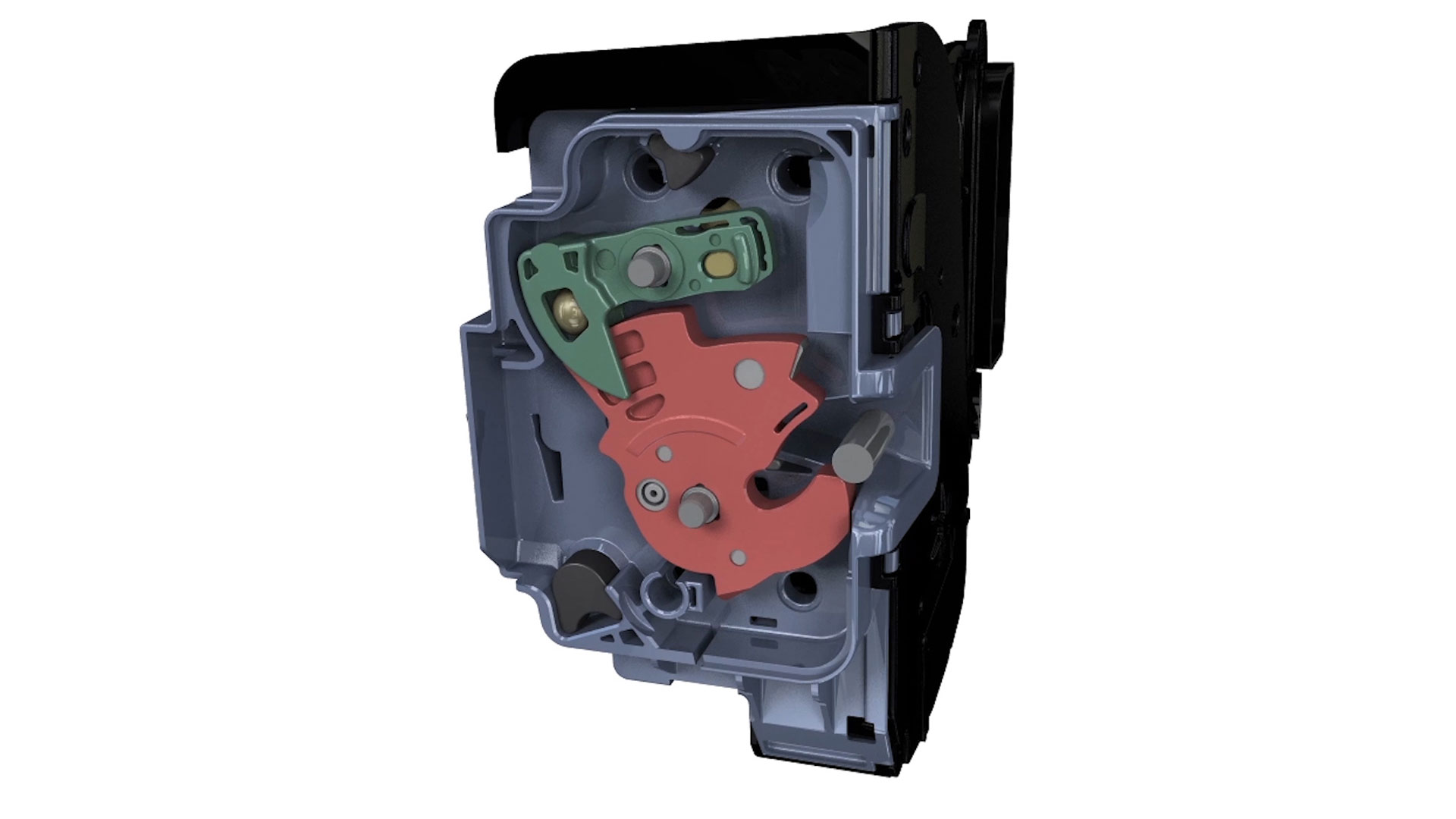

How Are Door Latches Assembled for Optimal Performance?

The assembly stage integrates the various components produced in the forming stage. This may involve manual or automated assembly processes, including the installation of springs, levers, and locking mechanisms. Quality control is vital at this stage, as the proper alignment and fit of parts directly influence the latch’s performance. Employing techniques such as vibration testing can help identify any assembly issues early in the process.

What Finishing Processes Are Essential for Automotive Door Latches?

Finishing processes such as coating, plating, or painting are applied to enhance the durability and aesthetic appeal of the latches. Common finishes include powder coating or zinc plating, which provide corrosion resistance and improve wear properties. These processes also include surface treatments that reduce friction and facilitate smooth operation of the latches. The finishing stage is critical not only for functionality but also for meeting industry aesthetic standards.

How Is Quality Assurance Implemented in Automotive Door Latch Manufacturing?

Quality assurance (QA) is integral to the manufacturing of automotive door latches, ensuring that every product adheres to international and industry-specific standards.

What International Standards Are Relevant for Automotive Door Latch Quality?

ISO 9001 is the most recognized quality management standard globally, providing a framework for consistent quality in manufacturing processes. Additionally, automotive manufacturers may follow specific standards like IATF 16949, which focuses on continuous improvement and defect prevention in the automotive sector. Compliance with these standards is essential for B2B buyers, ensuring that suppliers maintain high-quality production practices.

What Industry-Specific Certifications Should B2B Buyers Look For?

Beyond general quality standards, certain certifications may be relevant based on regional regulations and industry practices. For example, CE marking is critical for products sold within the European Union, indicating compliance with health, safety, and environmental protection standards. In regions like the Middle East and Africa, understanding local compliance requirements can be crucial for market entry.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to ensure product integrity.

Illustrative image related to automotive door latch

How Do Incoming Quality Control (IQC) Measures Work?

Incoming Quality Control (IQC) focuses on inspecting raw materials before production begins. This stage verifies that all materials meet the specified quality standards and are free from defects. B2B buyers should inquire about their supplier’s IQC processes, including the criteria used for material acceptance.

What Is In-Process Quality Control (IPQC) and Its Importance?

In-Process Quality Control (IPQC) occurs during the manufacturing stages. This includes monitoring critical parameters such as dimensions, assembly integrity, and operational functionality. Regular inspections help identify deviations from standards early, reducing the risk of faulty products.

How Does Final Quality Control (FQC) Ensure Product Reliability?

Final Quality Control (FQC) involves comprehensive testing of the completed door latches before shipment. This may include functionality tests, endurance tests, and safety assessments to ensure that products meet all operational requirements. B2B buyers should request details on FQC procedures and the types of tests performed to ensure reliability.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is critical.

What Role Do Audits and Reports Play in Supplier Verification?

Regular audits are essential for assessing a supplier’s compliance with quality standards. Buyers should request access to audit reports, which provide insights into the supplier’s quality management system, operational processes, and any corrective actions taken in response to non-conformities.

How Can Third-Party Inspections Enhance Quality Assurance?

Engaging third-party inspection services can add an extra layer of assurance for B2B buyers. These independent entities can perform quality checks at various stages of the manufacturing process, providing unbiased evaluations of product quality. Buyers should consider incorporating third-party inspections into their procurement strategies to mitigate risks associated with supplier quality.

What Are the Quality Control Nuances for International B2B Buyers?

Understanding the nuances of quality control is crucial for international B2B buyers, particularly in diverse markets. Buyers should be aware of the specific compliance requirements within their target regions, as these can significantly impact product acceptance and liability. Establishing clear communication with suppliers about quality expectations and compliance requirements will foster better partnerships and ensure successful market entry.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices for automotive door latches not only enhances product reliability but also builds trust and confidence in supplier relationships. B2B buyers are encouraged to prioritize these factors when selecting suppliers to ensure that they receive high-quality, compliant products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘automotive door latch’

This guide aims to assist B2B buyers in effectively sourcing automotive door latches, ensuring they make informed decisions that align with their operational needs and safety standards.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications required for the automotive door latches. Consider factors such as size, weight, material (e.g., stainless steel or aluminum), and locking mechanisms. These specifications will help narrow down your options and ensure compatibility with your vehicle models.

Step 2: Research Market Trends and Innovations

Stay updated on the latest market trends and technological advancements in automotive door latches. Understanding innovations, such as electronic latching systems or enhanced safety features, can provide a competitive edge. This knowledge will enable you to identify suppliers offering cutting-edge solutions that meet modern safety and efficiency standards.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers before making any commitments. Request company profiles, product catalogs, and references from similar businesses. Look for suppliers with a proven track record in the automotive industry, as their experience can significantly impact the quality and reliability of the door latches you procure.

- Check for Certifications: Ensure that suppliers hold relevant certifications, such as ISO 9001 or specific automotive industry standards. This verifies their commitment to quality and safety.

Step 4: Request Samples and Conduct Testing

Once you have shortlisted suppliers, request samples of the door latches for testing. Conduct thorough evaluations to assess functionality, durability, and ease of installation. Testing will help you identify any potential issues before placing larger orders, thus minimizing risk.

Step 5: Negotiate Pricing and Terms

Engage in negotiations regarding pricing, payment terms, and delivery schedules. Understand the total cost of ownership, which includes shipping, handling, and any potential tariffs. A clear agreement on terms can help prevent misunderstandings and ensure a smooth procurement process.

Step 6: Assess After-Sales Support and Warranty

Before finalizing your purchase, evaluate the after-sales support provided by the supplier. Reliable after-sales service is crucial for addressing any issues that may arise post-purchase. Additionally, inquire about warranty terms to safeguard your investment against defects or failures.

Step 7: Establish a Long-Term Relationship

Once you have made your purchase, aim to establish a long-term relationship with your supplier. Regular communication can lead to better pricing, priority service, and access to new products. A strong partnership can enhance your supply chain efficiency and overall business performance.

By following these steps, B2B buyers can ensure they make well-informed decisions when sourcing automotive door latches, ultimately contributing to the safety and reliability of their vehicle offerings.

Illustrative image related to automotive door latch

Comprehensive Cost and Pricing Analysis for automotive door latch Sourcing

What Are the Key Cost Components in Automotive Door Latch Sourcing?

When sourcing automotive door latches, understanding the cost structure is essential for B2B buyers. The primary components of cost include:

-

Materials: The choice of materials significantly impacts the cost. High-quality steel or aluminum is often used for durability and corrosion resistance, while additional coatings (e.g., black oxide) enhance longevity. The price of raw materials fluctuates based on market conditions, which can affect overall pricing.

-

Labor: Labor costs vary by region and are influenced by local wage rates. Skilled labor is often required for precision assembly and quality control, especially for specialized or custom latches.

-

Manufacturing Overhead: This includes utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can reduce overhead, which is beneficial for pricing.

-

Tooling: Custom tooling for specialized latches or high-volume production can incur significant upfront costs. These costs are typically amortized over the production run, influencing the unit price.

-

Quality Control (QC): Ensuring that latches meet safety and performance standards is critical. The costs associated with QC processes, including testing and inspections, contribute to the overall cost.

-

Logistics: Shipping costs can vary significantly based on distance, weight, and shipping method. International buyers should consider logistics as a critical component of the total cost.

-

Margin: Suppliers will add a profit margin to cover their risks and ensure business sustainability. Margins can vary widely based on market competition, brand reputation, and customer relationships.

What Factors Influence the Price of Automotive Door Latches?

Several factors can influence pricing for automotive door latches, which are particularly relevant for international B2B buyers:

-

Volume and Minimum Order Quantities (MOQ): Higher purchase volumes typically lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to align with their production needs.

-

Specifications and Customization: Customized latches that meet specific design requirements can lead to higher costs due to additional engineering and production processes. Standardized parts generally offer better pricing.

-

Material Quality and Certifications: Latches that meet specific safety certifications or use premium materials will command higher prices. Buyers should evaluate whether these certifications are necessary for their application.

-

Supplier Factors: The reliability, reputation, and location of the supplier can significantly impact pricing. Suppliers with a proven track record may charge a premium for their products.

-

Incoterms: Understanding shipping terms (e.g., FOB, CIF) is crucial for international buyers. These terms dictate who bears the shipping costs and risks, which can influence overall pricing.

How Can Buyers Negotiate Effectively for Automotive Door Latch Pricing?

Effective negotiation is key to achieving cost-efficiency in automotive door latch sourcing. Here are some tips for buyers:

Illustrative image related to automotive door latch

-

Understand Total Cost of Ownership (TCO): Beyond the unit price, consider the TCO, which includes maintenance, replacement, and logistics costs. This comprehensive view can strengthen your negotiation position.

-

Build Long-term Relationships: Establishing a strong relationship with suppliers can lead to better pricing and terms over time. Loyalty can often yield discounts and preferential treatment.

-

Be Informed About Market Trends: Stay updated on material costs, manufacturing trends, and global supply chain issues. Knowledge empowers better negotiation and can lead to more favorable terms.

-

Leverage Competition: Solicit quotes from multiple suppliers to create a competitive environment. This can help you negotiate better pricing and terms.

-

Tailor Orders to Meet Supplier Needs: Align your order quantities and schedules with the supplier’s production capabilities to negotiate more favorable pricing.

What Pricing Nuances Should International Buyers Consider?

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, several pricing nuances should be considered:

-

Currency Fluctuations: Changes in currency exchange rates can impact the final cost of latches. Buyers should factor this into their budgeting.

-

Import Duties and Taxes: Be aware of any tariffs or taxes that may apply when importing automotive parts. These can significantly affect the total landed cost.

-

Cultural Differences: Understanding cultural nuances in negotiation can enhance communication and lead to more favorable outcomes.

-

Local Regulations: Compliance with local automotive regulations may require additional certifications, influencing both cost and supplier selection.

Disclaimer on Indicative Prices

Prices for automotive door latches can vary widely based on specifications, supplier, and market conditions. The figures discussed are indicative and should be used as a reference point rather than definitive pricing. Always conduct thorough market research and engage directly with suppliers for the most accurate quotes.

Alternatives Analysis: Comparing automotive door latch With Other Solutions

Introduction to Alternative Solutions for Automotive Door Latching

In the automotive industry, the reliability and security of vehicle doors are paramount. While traditional automotive door latches are widely used, various alternative solutions exist that can provide similar or enhanced functionalities. This section will compare the standard automotive door latch against two viable alternatives: electronic locking systems and magnetic door latches. Each solution offers unique advantages and challenges, allowing B2B buyers to make informed decisions based on their specific needs.

Comparison Table

| Comparison Aspect | Automotive Door Latch | Electronic Locking System | Magnetic Door Latch |

|---|---|---|---|

| Performance | Reliable; meets safety standards | High security; remote access | Quick engagement; low wear |

| Cost | $30 – $200 per unit | $100 – $300 per unit | $50 – $150 per unit |

| Ease of Implementation | Moderate; requires mechanical knowledge | Complex; may need professional installation | Simple; easy to install |

| Maintenance | Low; occasional lubrication needed | Moderate; battery replacement required | Low; minimal upkeep |

| Best Use Case | Standard vehicles, classic cars | Luxury vehicles, fleet management | Lightweight vehicles, quick access needs |

Detailed Breakdown of Alternatives

What Are the Pros and Cons of Electronic Locking Systems?

Electronic locking systems enhance the functionality of traditional latches by incorporating remote access and keyless entry features. They provide high security and can be integrated with alarm systems, making them an attractive option for luxury vehicles and fleet management. However, the complexity of installation and reliance on battery power can pose challenges. If the battery fails or the electronic components malfunction, the doors may become inoperable, potentially leading to costly repairs and downtime.

How Do Magnetic Door Latches Compare?

Magnetic door latches utilize magnetic forces to secure doors, allowing for quick engagement and release. This technology is particularly beneficial for lightweight vehicles or applications where rapid access is essential, such as in delivery vans. The simplicity of installation makes magnetic latches appealing for manufacturers looking to streamline production. However, they may not provide the same level of security as traditional mechanical latches, making them less suitable for high-value vehicles.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the appropriate door latch solution, B2B buyers must consider factors such as vehicle type, security requirements, and installation capabilities. Traditional automotive door latches are reliable and cost-effective for standard vehicles, while electronic locking systems offer advanced security features for luxury applications. Magnetic door latches present a practical option for lightweight vehicles requiring quick access. Ultimately, the decision should align with the specific operational needs and budget constraints of the buyer, ensuring optimal performance and reliability in their automotive solutions.

Essential Technical Properties and Trade Terminology for automotive door latch

What Are the Key Technical Properties of Automotive Door Latches?

When evaluating automotive door latches, several critical specifications play a vital role in ensuring functionality, safety, and reliability. Understanding these properties can help B2B buyers make informed purchasing decisions.

1. Material Grade: Why Is It Important?

The material grade of a door latch typically refers to the type of metal used in its construction, such as stainless steel or high-strength carbon steel. This specification is crucial because it determines the latch’s durability, resistance to corrosion, and overall performance under various environmental conditions. For buyers, selecting a latch made from high-quality materials can reduce maintenance costs and enhance the longevity of their products.

2. Tolerance Levels: How Do They Affect Performance?

Tolerance levels indicate the permissible limits of variation in the dimensions of the latch components. Precision in these tolerances is essential for ensuring that the latch fits correctly with other door mechanisms, thereby preventing issues like misalignment or operational failure. In B2B contexts, understanding tolerance specifications helps buyers avoid complications during installation and ensures that the latch operates smoothly.

3. Load Capacity: What Should Buyers Consider?

Load capacity refers to the maximum weight the latch can securely hold when the door is closed. This specification is vital for ensuring that the latch can withstand the forces exerted during normal use, including slamming and vibrations from driving. B2B buyers should assess load capacity to ensure that the latches they select meet the demands of their specific vehicle applications, thus enhancing safety and reliability.

4. Operating Temperature Range: Why Does It Matter?

The operating temperature range indicates the environmental conditions under which the latch can function effectively without degradation. This property is particularly important for vehicles operating in extreme climates, whether hot or cold. Buyers must consider this specification to ensure that the latches will perform optimally in the intended geographical markets, thus minimizing the risk of failure.

5. Compliance Standards: What Are the Key Requirements?

Compliance with industry standards, such as the Federal Motor Vehicle Safety Standards (FMVSS), is essential for automotive door latches. These standards ensure that the latches meet safety requirements for performance and reliability. B2B buyers should prioritize products that comply with relevant regulations to ensure product safety and avoid legal liabilities.

What Are Common Trade Terms in the Automotive Door Latch Industry?

Understanding trade terminology is crucial for effective communication and negotiation in the B2B sector. Here are some commonly used terms in the automotive door latch industry:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are sold directly to vehicle manufacturers. Latches sourced from OEMs are often designed specifically for particular vehicle models, ensuring perfect fit and function. For buyers, choosing OEM parts can enhance reliability and performance.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell in a single order. This term is significant for B2B buyers as it affects inventory management and procurement strategies. Understanding MOQ helps buyers plan their purchases efficiently, especially when dealing with multiple suppliers.

3. RFQ (Request for Quotation)

An RFQ is a formal request from a buyer to suppliers to provide pricing and terms for specific products. In the context of automotive door latches, submitting an RFQ can help buyers compare costs and features across different suppliers, facilitating better purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of standardized international shipping terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is essential for B2B buyers, as they dictate shipping costs, risk management, and delivery obligations.

5. Lead Time: What Is Its Impact?

Lead time refers to the time taken from placing an order to its delivery. Understanding lead times is crucial for buyers who need to manage production schedules and inventory levels. Effective lead time management can prevent production delays and improve operational efficiency.

By grasping these technical properties and trade terms, B2B buyers can navigate the automotive door latch market more effectively, ensuring they make informed decisions that align with their operational needs and business goals.

Navigating Market Dynamics and Sourcing Trends in the automotive door latch Sector

What Are the Current Market Dynamics and Key Trends in the Automotive Door Latch Sector?

The automotive door latch market is witnessing significant growth driven by increasing vehicle production and the rising demand for advanced safety features. Global automotive manufacturers are focusing on enhancing vehicle security, which has led to innovations in door latch technology, such as electronic locking mechanisms and smart latches integrated with vehicle control systems. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial for effective sourcing.

Emerging trends include the shift towards universal and customizable door latch solutions, catering to a diverse range of vehicle types from commercial trucks to luxury cars. Manufacturers are increasingly offering modular systems that allow for easy installation and replacement, a key consideration for buyers looking to streamline their supply chains. Additionally, the integration of IoT technology in latches is on the rise, enabling features like remote locking and diagnostics, which can enhance operational efficiency and security.

The market is also influenced by regional factors. For instance, in the Middle East and Africa, the growing automotive market is prompting local manufacturers to seek partnerships with international suppliers to enhance their product offerings. Meanwhile, European buyers are increasingly prioritizing suppliers who can provide advanced, reliable, and compliant products that meet stringent safety regulations.

How Is Sustainability and Ethical Sourcing Changing the Automotive Door Latch Industry?

Sustainability and ethical sourcing are becoming paramount in the automotive door latch sector, as global awareness of environmental impact rises. B2B buyers are increasingly seeking suppliers who prioritize eco-friendly materials and manufacturing processes. For instance, the use of recycled metals and plastics in door latch production not only reduces waste but also appeals to environmentally conscious consumers and businesses.

Ethical supply chains are crucial for maintaining brand integrity and consumer trust. Buyers are encouraged to vet their suppliers for compliance with environmental regulations and labor practices. Certifications such as ISO 14001 for environmental management and adherence to the UN’s Sustainable Development Goals can serve as benchmarks for evaluating supplier sustainability.

Illustrative image related to automotive door latch

Moreover, as regulations around emissions and waste disposal tighten, manufacturers are incentivized to innovate. This includes the development of “green” latches that use biodegradable materials or energy-efficient production techniques. For buyers, partnering with suppliers who are committed to sustainability can enhance their own market positioning and appeal to a growing demographic that values corporate responsibility.

What Is the Brief Evolution of Automotive Door Latch Technology?

The evolution of automotive door latch technology has been marked by a series of innovations aimed at enhancing safety, security, and user convenience. Initially, simple mechanical latches were employed, primarily relying on manual operation. As vehicle designs became more complex, so too did door latch mechanisms, incorporating features such as dual latching systems for improved security.

The introduction of electronic latches in the late 20th century revolutionized the industry, allowing for remote locking and unlocking, which became a standard feature in modern vehicles. Recent advancements have further integrated these systems with vehicle electronics, enabling smart latches that can communicate with the vehicle’s onboard systems for real-time diagnostics and alerts.

Today, B2B buyers must consider not just the mechanical reliability of door latches but also their integration capabilities with advanced vehicle systems. Understanding the history and evolution of these technologies is vital for making informed sourcing decisions that align with current market demands and future trends.

Frequently Asked Questions (FAQs) for B2B Buyers of automotive door latch

-

1. How do I solve a problem with a faulty automotive door latch?

To address issues with a faulty automotive door latch, begin by diagnosing the symptoms: does the door not latch properly, or does it fail to respond to the lock/unlock mechanism? If the latch is stuck, lubricate it with a suitable automotive lubricant. If problems persist, consider replacing the latch. Evaluate suppliers based on their product offerings and ensure they provide high-quality latches that meet safety standards. Always consult a professional mechanic if you’re unsure about the installation or repair process. -

2. What is the best type of automotive door latch for commercial vehicles?

The best type of automotive door latch for commercial vehicles often depends on the specific application and vehicle type. For heavy-duty use, look for robust latches made from high-strength materials, such as stainless steel, which offer durability and resistance to wear and corrosion. Consider options like universal latches or those with enhanced locking mechanisms for added security. Additionally, ensure the latch complies with safety regulations in your region, as this can vary between markets, especially in Africa and the Middle East. -

3. What factors should I consider when sourcing automotive door latches internationally?

When sourcing automotive door latches internationally, consider the supplier’s reputation, product quality, and compliance with international standards. Research the materials used, as well as the manufacturing process to ensure durability and safety. Investigate the supplier’s ability to provide customization options and their adherence to lead times. Furthermore, assess their logistics capabilities and whether they can deliver to your location efficiently, especially in regions like South America and Europe where shipping regulations may differ. -

4. What are the minimum order quantities (MOQ) for automotive door latches?

Minimum order quantities (MOQ) for automotive door latches can vary significantly among suppliers. Some may offer flexible MOQs for smaller businesses, while others might require larger orders to justify production costs. It’s essential to communicate your needs clearly with potential suppliers and inquire about their MOQ policies. Additionally, consider the potential for bulk discounts, which can reduce the overall cost per unit if you plan to scale your purchases in the future. -

5. How do I vet suppliers for automotive door latches?

Vetting suppliers for automotive door latches involves several steps. Start by checking their certifications and compliance with industry standards, such as ISO certifications. Look for customer reviews and testimonials to gauge their reliability and product quality. Request samples to evaluate the latches’ performance and durability. It’s also advisable to ask about their manufacturing processes and quality assurance protocols to ensure they meet your expectations and safety standards. -

6. What payment terms are commonly used in B2B transactions for automotive parts?

Payment terms for B2B transactions in the automotive parts industry typically include options such as net 30, net 60, or cash in advance. Some suppliers may offer a letter of credit or escrow services for larger orders, providing security for both parties. It’s crucial to negotiate terms that align with your cash flow and budget considerations. Always ensure that you have a clear agreement in place regarding payment schedules and methods to avoid misunderstandings later. -

7. How can I customize automotive door latches to fit my specific needs?

Customization of automotive door latches can be achieved by collaborating closely with your supplier. Discuss your specific requirements, including size, shape, locking mechanisms, and materials. Many manufacturers offer design services to create bespoke latches that meet unique specifications. Ensure to provide detailed drawings or prototypes if possible, and inquire about any additional costs or lead times associated with the customization process. -

8. What logistics considerations should I keep in mind when importing automotive door latches?

When importing automotive door latches, consider logistics factors such as shipping methods, customs regulations, and delivery times. Choose a reliable freight forwarder familiar with international shipping to streamline the process. Be aware of import duties and taxes that may apply to your shipment, as these can affect your overall costs. Additionally, ensure that your supplier can provide the necessary documentation for customs clearance, including invoices, packing lists, and certificates of origin.

Top 7 Automotive Door Latch Manufacturers & Suppliers List

1. Watson’s StreetWorks – Hot Rod Door Latches

Domain: watsons-streetworks.com

Registered: 2000 (25 years)

Introduction: Hot Rod Door Latches – Custom automotive door latches designed for reliability and style. Options include: True Aero Electronic Flush Mount Car Door Handles ($599.00), Manual Safety Lock Pins ($95.00), Power Door Locks (Pair) ($145.00), Gator-Jaw Latches ($33.00 – $64.00), Locking Gator-Jaw Latches ($149.00), Gator-Jaw Medium weld in plates ($34.00), Gator Screws for Latch Installation ($1.15 – $3…

2. Breeze Automotive – Heavy Duty Door Latch Set

Domain: breezeautomotive.com

Registered: 1999 (26 years)

Introduction: {“product_name”: “Heavy Duty Door Latch Set”, “part_number”: “70687”, “price”: “$88.00”, “description”: “The FFR supplied door latches have a nice vintage look but leave a little to be desired in terms of functionality, reliability, and strength. We installed this latch set in our roadster for ease of operation and physical security. They are rugged, reliable, and strong. You can slam your roadste…

3. Bestselling Cars – Car Door Latches

Domain: bestsellingcarsblog.com

Registered: 2011 (14 years)

Introduction: Car door latches are essential components that secure the doors of vehicles, allowing them to open and close seamlessly. They are typically located at the top of the door and are connected to the locking mechanism. Most latches are made from plastic, although high-end vehicles may use metal latches. The latching mechanism consists of two jaws and a lever, which links to the door handle. When the h…

4. NMB Technologies – Latches

Domain: nmbtc.com

Registered: 1999 (26 years)

Introduction: Latches | NMB Technologies offers a comprehensive line-up of mechanical and electronic latches for automotive customers. Key features include:

– Integrated cinch and e-release options

– Mechanical redundancy

– Adaptable functionality based on customer needs

– Embedded logic with integrated ECU and electrical backup

– Software programmable locking functions.

Applications include:

– Trunk an…

5. WITTE Automotive – Tailgate Locking Solutions

Domain: witte-automotive.com

Registered: 2004 (21 years)

Introduction: WITTE Automotive offers a range of latches designed for security and convenience, including tailgate solutions and front hood locks. Key features include: 1. Tailgate Locking: – WITTE Comfort solution enhances user experience by eliminating annoying noises and providing smooth operation. – Soft release mechanism allows for quiet opening of powered tailgates. – Integrated closing aid ensures quiet …

6. Speedway Motors – Bear Jaw Door Latch Kit

Domain: speedwaymotors.com

Registered: 1996 (29 years)

Introduction: This company, Speedway Motors – Bear Jaw Door Latch Kit, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. MinebeaMitsumi – Latches

Domain: minebeamitsumi.com

Registered: 2015 (10 years)

Introduction: Product Name: Latches

Description: Latches keep vehicle doors, hoods, or rear gates closed and release locks when a handle is operated. They are designed with a flexible approach, focusing on downsizing, weight optimization, in-crush stiffness, and noise reduction.

Features:

– Side Door Latch: High holding strength for passenger safety, optional theft prevention mechanisms (Super Lock, Key Direct)…

Strategic Sourcing Conclusion and Outlook for automotive door latch

In the evolving landscape of the automotive industry, strategic sourcing of door latches emerges as a critical component for ensuring safety, reliability, and customer satisfaction. By prioritizing quality and functionality, international B2B buyers can mitigate risks associated with faulty components, which may lead to costly repairs and diminished brand reputation. Collaborating with trusted manufacturers that adhere to stringent quality standards, such as case-hardened materials and innovative designs, will enhance the durability of door latches while also catering to diverse market needs, from classic restorations to modern applications.

Furthermore, the integration of advanced technologies, including electronic and keyless entry systems, is reshaping the door latch sector. Buyers from regions like Africa, South America, the Middle East, and Europe should actively seek suppliers who are at the forefront of these innovations, ensuring their offerings remain competitive.

As the automotive market continues to adapt to emerging trends, now is the time for buyers to engage in proactive sourcing strategies. By investing in high-quality door latches today, businesses can position themselves for success in the future, driving both performance and profitability. Embrace this opportunity to refine your sourcing strategy and secure the best solutions for your automotive needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.