Automatic Screw Machines: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for automatic screw machines

Navigating the global market for automatic screw machines presents a unique challenge for international B2B buyers, particularly when it comes to sourcing reliable and efficient solutions for high-volume production. As industries across Africa, South America, the Middle East, and Europe seek to optimize their manufacturing processes, the demand for advanced automatic screw machines has surged. This guide delves into the complexities of automatic screw machines, offering insights into various types, applications, and the critical factors to consider when vetting suppliers.

Buyers will explore the distinctions between single-spindle and multi-spindle machines, the advantages of hybrid models, and the materials best suited for different applications. Additionally, the guide covers essential aspects such as cost considerations, quality standards, and the importance of after-sales support. By providing a comprehensive overview of the automatic screw machine landscape, this resource empowers international buyers to make informed purchasing decisions that align with their operational needs.

Understanding the intricacies of automatic screw machining not only enhances productivity but also drives competitive advantage in diverse markets. Armed with this knowledge, B2B buyers can confidently navigate supplier options, ensuring they select the right equipment to meet their production goals while adhering to industry standards and regulations.

Understanding automatic screw machines Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Multi-Spindle Screw Machines | High productivity with multiple spindles; ideal for mass production | Aerospace, automotive, electronics | Pros: Fast cycle times, high volume output. Cons: Higher initial investment. |

| Single-Spindle Screw Machines | Simpler design; best for small to medium-sized parts | Medical devices, small fasteners | Pros: Cost-effective, versatile. Cons: Lower production rates compared to multi-spindle. |

| Swiss-style Screw Machines | Capable of high precision and complex geometries | Precision components in aerospace and medical industries | Pros: Exceptional accuracy, flexibility in part design. Cons: More expensive and complex to operate. |

| Chucker Machines | Designed for secondary operations; adaptable for various applications | Manufacturing of fasteners and fittings | Pros: Versatile, can handle various materials. Cons: May require additional setup for different operations. |

| Hybrid Screw Machines | Combines mechanical reliability with CNC technology | Industries needing both high volume and precision machining | Pros: Flexibility, reduced setup times. Cons: Can be complex to maintain. |

What Are the Key Characteristics of Multi-Spindle Screw Machines?

Multi-spindle screw machines are renowned for their high productivity, featuring multiple spindles that allow simultaneous machining operations. These machines excel in producing large quantities of small parts, making them a preferred choice in industries like aerospace and automotive. When considering a purchase, buyers should evaluate the machine’s cycle time, the range of materials it can handle, and its adaptability to various part designs. While the initial investment may be substantial, the long-term productivity gains can justify the cost.

How Do Single-Spindle Screw Machines Compare?

Single-spindle screw machines are simpler and more cost-effective, making them suitable for producing small to medium-sized components, such as medical devices and basic fasteners. Their straightforward design allows for easier operation and maintenance, appealing to businesses with lower production volumes. Buyers should consider their specific production needs, as these machines may not match the output rates of multi-spindle options. However, their versatility and lower upfront costs can be significant advantages for smaller manufacturers.

Why Choose Swiss-style Screw Machines for Precision?

Swiss-style screw machines are distinguished by their ability to produce complex parts with exceptional precision. These machines are ideal for applications in aerospace and medical industries, where tolerances are critical. Their design allows for intricate machining processes, making them suitable for high-value components. Buyers should assess the complexity of the parts they need to produce and the potential return on investment, as these machines typically come at a higher price point but can deliver unmatched precision.

What Makes Chucker Machines Unique?

Chucker machines are versatile tools designed primarily for secondary operations, such as finishing preformed blanks. They are adaptable for various applications, including the manufacturing of fasteners and fittings. When evaluating chucker machines, buyers should consider their production flexibility and the range of materials they can process. While they may require additional setup for different operations, their capability to handle diverse machining tasks can provide significant operational efficiencies.

How Do Hybrid Screw Machines Enhance Production?

Hybrid screw machines combine the mechanical reliability of traditional multi-spindle machines with the precision of CNC technology. This versatility allows manufacturers to achieve high volumes while maintaining tight tolerances, making them ideal for industries that require both speed and accuracy. Buyers should focus on the machine’s adaptability and the potential for reduced setup times, which can enhance overall production efficiency. However, the complexity of these machines may necessitate a more skilled workforce for operation and maintenance.

Key Industrial Applications of automatic screw machines

| Industry/Sector | Specific Application of Automatic Screw Machines | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Manufacturing precision fasteners and components | High accuracy and reliability for critical applications | Compliance with aerospace standards, material traceability |

| Automotive | Production of engine components and fittings | Enhanced production efficiency and reduced lead times | Ability to handle diverse materials and tight tolerances |

| Electronics | Creation of connectors and housings | Fast production cycles for high-demand electronic parts | Customization options and scalability for varying volumes |

| Medical Devices | Fabrication of surgical instruments and implants | Strict adherence to quality and safety standards | ISO certification and biocompatibility of materials |

| Consumer Goods | Manufacturing of household appliance components | Cost-effective solutions for high-volume production | Flexibility in design and the ability to accommodate new product lines |

How Are Automatic Screw Machines Used in Aerospace Manufacturing?

In the aerospace sector, automatic screw machines are essential for producing precision fasteners and components that must meet stringent safety and performance standards. These machines allow manufacturers to create parts with tight tolerances, which is critical in high-stakes applications like aircraft assembly. International buyers from regions such as Europe and the Middle East should prioritize sourcing machines that ensure compliance with aerospace quality standards and provide full material traceability.

What Role Do Automatic Screw Machines Play in the Automotive Industry?

In automotive manufacturing, automatic screw machines are utilized for producing engine components, fittings, and fasteners. Their ability to operate at high speeds while maintaining accuracy significantly boosts production efficiency and reduces lead times. For businesses in South America and Africa, sourcing machines that can handle a variety of materials and accommodate complex part geometries is crucial to meet diverse automotive requirements.

How Are Automatic Screw Machines Used in Electronics Production?

Automatic screw machines are integral in the electronics industry for producing connectors, housings, and other small components. Their rapid production capabilities enable manufacturers to keep pace with the fast-moving consumer electronics market. When sourcing machines, buyers in regions like Germany and Brazil should consider customization options to meet specific design requirements and the scalability of production for varying demand levels.

Illustrative image related to automatic screw machines

What Are the Applications of Automatic Screw Machines in Medical Device Manufacturing?

In the medical device industry, automatic screw machines are employed to fabricate surgical instruments and implants that require high precision and adherence to safety standards. The machines facilitate the production of complex components with minimal human intervention, ensuring consistent quality. Buyers need to ensure that their suppliers are ISO certified and that materials used are biocompatible, especially for applications in healthcare.

How Do Automatic Screw Machines Benefit the Consumer Goods Sector?

Automatic screw machines are widely used in the consumer goods sector for manufacturing components of household appliances, such as screws, bolts, and fittings. Their cost-effective production methods allow businesses to produce high volumes efficiently, which is essential for competitive pricing. For international buyers, flexibility in design and the ability to adapt to new product lines are key considerations when sourcing these machines.

3 Common User Pain Points for ‘automatic screw machines’ & Their Solutions

Scenario 1: High Setup Times Affecting Production Efficiency

The Problem:

Many B2B buyers experience significant delays due to lengthy setup times when using automatic screw machines. This often occurs when switching between different parts or when adjusting machines to meet varying specifications. For instance, a manufacturer producing automotive components may need to frequently change tooling and programming to accommodate different part designs. These delays not only affect production schedules but also increase operational costs, ultimately impacting the bottom line. The frustration of watching potential revenue slip away due to inefficiencies can be overwhelming, especially in competitive markets.

The Solution:

To mitigate high setup times, consider investing in automatic screw machines equipped with advanced features such as quick-change tooling systems and CNC interfaces. These technologies allow for faster adjustments and reconfigurations between jobs. For instance, a machine with a hybrid design can combine the speed of multi-spindle setups with the flexibility of CNC, facilitating quicker transitions. Additionally, implementing standardized processes for setup can streamline operations. Train your team to follow a systematic approach to setup, ensuring that all necessary tools and components are prepared in advance. This can significantly reduce the time spent on machine adjustments, leading to improved overall productivity.

Scenario 2: Inconsistent Quality and Tolerances in Machined Parts

The Problem:

Quality control is paramount in manufacturing, yet inconsistent tolerances in parts produced by automatic screw machines can lead to rejected batches and costly reworks. Buyers often encounter challenges when parts do not meet required specifications, especially in industries like aerospace or medical devices, where precision is critical. This inconsistency may stem from variations in material quality, machine calibration issues, or operator error, leading to a frustrating cycle of quality assurance checks and potential customer dissatisfaction.

Illustrative image related to automatic screw machines

The Solution:

To ensure consistent quality and precision, it is essential to invest in high-quality automatic screw machines that offer robust quality control features, such as in-process monitoring and advanced calibration capabilities. Regularly scheduled maintenance and calibration checks can help mitigate issues related to machine wear and tear. Additionally, implementing a rigorous quality management system, like ISO 9001, can standardize production processes and ensure that every part meets strict quality requirements. Training operators in best practices for machine operation and quality checks can further reduce the risk of errors, leading to a more reliable production output.

Scenario 3: Difficulty in Sourcing the Right Automatic Screw Machine for Specific Applications

The Problem:

B2B buyers often struggle with sourcing the right automatic screw machine that meets their specific production requirements. With a myriad of options available, ranging from single-spindle to multi-spindle and CNC machines, it can be daunting to choose a machine that balances productivity, precision, and cost-effectiveness. This indecision can lead to purchasing a machine that either underperforms for the intended application or exceeds budget constraints, resulting in lost opportunities and potential production bottlenecks.

The Solution:

When sourcing an automatic screw machine, it is crucial to conduct a thorough needs assessment that considers your specific production volumes, materials, and part complexities. Collaborate with suppliers who offer comprehensive consultation services to better understand the capabilities of different machine types. Request demonstrations or trials to see how machines perform in real-world scenarios. Additionally, consider the long-term support and service options provided by the manufacturer, as this can greatly influence the machine’s overall efficiency and reliability. By investing time in selecting the right machine and supplier, you can ensure that your production line is equipped to handle current demands while remaining adaptable for future growth.

Illustrative image related to automatic screw machines

Strategic Material Selection Guide for automatic screw machines

What Are the Key Properties of Common Materials Used in Automatic Screw Machines?

When selecting materials for automatic screw machines, it is essential to consider properties that affect performance, durability, and application suitability. Here, we analyze four common materials: aluminum, stainless steel, brass, and nylon. Each material has unique characteristics that can influence production efficiency and end-product quality.

How Does Aluminum Perform in Automatic Screw Machines?

Aluminum is a lightweight metal known for its excellent machinability and corrosion resistance. It typically has a temperature rating of up to 400°F (204°C) and offers good strength-to-weight ratios. The pros of using aluminum include its low cost, ease of machining, and suitability for high-volume production runs. However, its lower strength compared to other metals can be a disadvantage for applications requiring high durability. In international markets, particularly in Europe and South America, aluminum is widely accepted due to its compliance with standards like ASTM and EN, making it a preferred choice for various industries.

What Are the Advantages and Limitations of Stainless Steel?

Stainless steel is renowned for its exceptional corrosion resistance and high strength, making it suitable for demanding applications in industries such as aerospace and automotive. Its temperature rating can exceed 1500°F (815°C), which is beneficial for high-temperature environments. The advantages of stainless steel include its durability and ability to maintain structural integrity under stress. However, it is more expensive than aluminum and can be more challenging to machine, leading to increased manufacturing complexity. Buyers in the Middle East and Africa may need to consider local availability and compliance with international standards like ASTM A276 or DIN 1.4301 when selecting stainless steel components.

Why Choose Brass for Automatic Screw Machines?

Brass is an alloy of copper and zinc, known for its excellent machinability and good corrosion resistance, particularly in marine environments. It has a temperature rating of around 300°F (149°C) and is often used in applications requiring electrical conductivity. The key advantages of brass include its aesthetic appeal and ease of machining, which can lead to lower production costs. However, brass is generally more expensive than aluminum and may not be suitable for high-stress applications. In regions like Germany and Brazil, brass components must comply with standards such as DIN 17660, which can impact sourcing decisions for international buyers.

How Does Nylon Compare as a Material Choice?

Nylon is a synthetic polymer that offers excellent wear resistance and low friction properties, making it suitable for applications involving moving parts. It can withstand temperatures up to 200°F (93°C) and is often used in applications requiring lightweight and flexible components. The primary advantages of nylon include its low cost and versatility; however, it is less durable than metals and can absorb moisture, which may affect its performance over time. For international buyers, particularly in Africa and South America, compliance with standards like ASTM D4066 is crucial when sourcing nylon components for automatic screw machines.

Summary Table of Material Selection for Automatic Screw Machines

| Material | Typical Use Case for automatic screw machines | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | High-volume production of lightweight parts | Excellent machinability | Lower strength compared to metals | Low |

| Stainless Steel | Aerospace and automotive components | Exceptional corrosion resistance | Higher cost and machining complexity | High |

| Brass | Electrical fittings and decorative components | Good machinability and aesthetics | More expensive than aluminum | Med |

| Nylon | Moving parts and low-friction applications | Low cost and versatile | Less durable and moisture absorption | Low |

This strategic material selection guide provides a comprehensive overview of the materials commonly used in automatic screw machines, offering valuable insights for B2B buyers to make informed decisions tailored to their specific application needs.

In-depth Look: Manufacturing Processes and Quality Assurance for automatic screw machines

What Are the Main Stages in the Manufacturing Process of Automatic Screw Machines?

The manufacturing process for automatic screw machines is a comprehensive operation that includes several key stages: material preparation, forming, assembly, and finishing. Understanding these stages is crucial for B2B buyers seeking to ensure quality and efficiency in their sourcing decisions.

Material Preparation

The first stage involves selecting and preparing the raw materials, which typically include metals such as aluminum, brass, stainless steel, and various alloys, as well as certain plastics. The selected material is cut into bar stock, which is then thoroughly inspected for quality, ensuring that it meets specific industry standards. Material quality is paramount, as it directly impacts the performance and durability of the final products.

Forming

In this stage, the bar stock is loaded into the screw machine, where it is clamped and rotated against cutting tools to form the desired shapes. Automatic screw machines, particularly multi-spindle models, allow for simultaneous operations, significantly increasing production rates. Techniques such as turning, drilling, threading, and tapping are commonly employed. Advanced machines may also utilize CNC technology to enhance precision and versatility, accommodating both simple and complex part geometries.

Assembly

Once the components are formed, they may undergo an assembly process, especially if they are part of a larger assembly, such as fittings or custom fasteners. This stage often involves additional operations like welding or inserting components to create a final product. Efficient assembly processes are critical for maintaining production timelines and ensuring that the components fit together correctly.

Finishing

Finishing processes add the final touches to the manufactured parts, which may include treatments like anodizing, powder coating, or polishing. These processes not only enhance the aesthetic appeal of the parts but also improve their resistance to corrosion and wear. Quality control during this stage is vital, as it ensures that the finishing meets the specifications required by various industries.

How Is Quality Assurance Managed in the Production of Automatic Screw Machines?

Quality assurance (QA) in the manufacturing of automatic screw machines encompasses various international and industry-specific standards, quality checkpoints, and testing methods that ensure products meet customer expectations.

International Standards and Certifications

B2B buyers should prioritize suppliers that adhere to internationally recognized quality standards such as ISO 9001, which focuses on quality management systems. Industry-specific certifications such as CE, API, and others may also be relevant, depending on the application of the screw machine parts. These certifications indicate that the products have been tested and comply with rigorous safety and quality criteria.

Quality Checkpoints

The quality assurance process includes several checkpoints throughout the manufacturing stages:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor the production process. This includes measuring dimensions, checking tolerances, and ensuring that machinery is operating correctly.

-

Final Quality Control (FQC): Once production is complete, a final inspection is performed to verify that all parts meet the required specifications before they are shipped. This may include functional testing, surface finish checks, and dimensional analysis.

What Testing Methods Are Commonly Used in Quality Assurance for Screw Machines?

B2B buyers should be aware of various testing methods employed to ensure quality in automatic screw machining. These include:

-

Dimensional Inspection: Utilizes tools such as calipers and micrometers to measure the physical dimensions of parts against specified tolerances.

-

Functional Testing: Evaluates the performance of parts in real-world applications, ensuring they function as intended.

-

Material Testing: Assesses the properties of materials used, including hardness, tensile strength, and corrosion resistance, often through standardized tests.

-

Visual Inspection: A straightforward method that involves checking for surface defects, dimensional accuracy, and overall appearance.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to mitigate risks associated with sourcing.

Conducting Audits

Buyers should consider conducting on-site audits of potential suppliers to assess their manufacturing and quality assurance practices. This allows buyers to evaluate the facilities, equipment, and overall workflow, ensuring that they align with the expected quality standards.

Requesting Quality Reports

Suppliers should be able to provide comprehensive quality reports that document their QA processes, test results, and compliance with relevant standards. These reports serve as evidence of the supplier’s commitment to quality and can be a deciding factor in procurement decisions.

Illustrative image related to automatic screw machines

Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality assurance processes. These services can conduct thorough inspections and audits, offering buyers peace of mind regarding the quality of the products they are sourcing.

What Are the Nuances of Quality Control for International B2B Buyers?

International B2B buyers must navigate various nuances in quality control that differ by region. Factors such as local regulations, cultural attitudes toward quality, and varying standards can impact the sourcing process.

Understanding Regional Standards

Buyers should familiarize themselves with the specific quality standards that are recognized in their target regions. For instance, European buyers may prioritize compliance with CE marking, while those in the Middle East may focus on local standards that govern specific industries.

Illustrative image related to automatic screw machines

Building Relationships with Suppliers

Establishing strong relationships with suppliers can enhance communication regarding quality expectations. Regular dialogue can help buyers understand the challenges suppliers face and foster collaboration in achieving quality objectives.

Logistics and Supply Chain Considerations

B2B buyers must also consider the logistics involved in international shipping and how they may affect product quality. Delays in transit can lead to issues such as damage or degradation of materials. Implementing thorough inspection protocols upon receipt can help mitigate these risks.

By understanding the manufacturing processes and quality assurance practices associated with automatic screw machines, B2B buyers can make informed decisions that align with their operational needs and quality expectations. Prioritizing suppliers who demonstrate robust QA processes and adherence to international standards will ultimately enhance the reliability of their sourcing strategies.

Illustrative image related to automatic screw machines

Practical Sourcing Guide: A Step-by-Step Checklist for ‘automatic screw machines’

In this guide, we will provide a practical checklist for B2B buyers looking to procure automatic screw machines. This step-by-step approach will help you navigate the complexities of sourcing these essential manufacturing tools, ensuring you make informed decisions that align with your operational needs.

Step 1: Define Your Technical Specifications

Before beginning your search, clearly outline the technical specifications required for your automatic screw machine. Consider factors such as the types of materials you will be machining (e.g., aluminum, brass, stainless steel), part complexity, and production volume. Defining these parameters upfront helps streamline the selection process and ensures you choose a machine that meets your specific needs.

Step 2: Research Available Machine Types

Understanding the different types of automatic screw machines is crucial. Familiarize yourself with single-spindle, multi-spindle, and Swiss-style machines, each designed for varying production capacities and part complexities. Knowing the strengths and weaknesses of each type will enable you to match the machine to your production requirements more effectively.

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, thoroughly vet potential suppliers. Request company profiles, case studies, and references from buyers in similar industries or regions. Look for suppliers with a solid reputation for quality and reliability, as well as those that offer robust after-sales support.

Illustrative image related to automatic screw machines

- Check for industry experience: Suppliers with a long history in the industry are more likely to understand your specific needs and provide tailored solutions.

- Assess global reach: If you’re sourcing from different continents, ensure the supplier can handle international logistics and comply with regional regulations.

Step 4: Verify Supplier Certifications

Ensure that your shortlisted suppliers possess relevant certifications, such as ISO 9001, TS 16949, or other industry-specific standards. These certifications indicate a commitment to quality and adherence to international manufacturing standards. Compliance can significantly impact the reliability and performance of the machines you purchase.

Step 5: Request Detailed Quotes

Once you’ve narrowed down your options, request detailed quotes from each supplier. These quotes should include not only the price of the machines but also additional costs such as shipping, installation, and training. Comparing these details will provide a clearer picture of the total investment required and help you avoid unexpected expenses down the line.

Step 6: Assess After-Sales Support and Maintenance Options

Inquire about the after-sales support offered by suppliers, including warranty terms, service agreements, and availability of spare parts. Reliable support is crucial for minimizing downtime and ensuring your machine operates at peak efficiency over its lifespan.

Illustrative image related to automatic screw machines

- Look for training programs: Suppliers that offer training for your operators can enhance productivity and ensure optimal machine usage.

- Check for local service availability: Having access to local technicians can significantly reduce response times for maintenance and repairs.

Step 7: Consider Long-Term Scalability

Finally, evaluate how well the machine will integrate into your existing operations and whether it can accommodate future growth. Investing in a machine that allows for upgrades or expansions can save you money in the long run and ensure that your production capabilities keep pace with market demands.

By following this checklist, B2B buyers can make informed decisions when sourcing automatic screw machines, ultimately enhancing their manufacturing efficiency and competitiveness in the global market.

Comprehensive Cost and Pricing Analysis for automatic screw machines Sourcing

What Are the Key Cost Components for Automatic Screw Machines?

When sourcing automatic screw machines, understanding the cost structure is vital for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts pricing. Common materials such as aluminum, stainless steel, and various alloys can vary in cost based on market fluctuations. High-quality materials will typically incur higher costs but can lead to better durability and performance.

-

Labor: Labor costs encompass both direct production labor and specialized skilled labor needed for setup, programming, and maintenance of CNC machines. The geographic location of the manufacturing facility can influence labor costs, with regions in Europe or North America generally having higher labor costs compared to parts of Africa or South America.

-

Manufacturing Overhead: This includes costs related to facility maintenance, utilities, equipment depreciation, and administrative expenses. A well-optimized production facility may have lower overhead, allowing for more competitive pricing.

-

Tooling: Tooling costs can vary based on the complexity of the parts being produced. Custom tooling is often required for unique specifications, which can add to the initial investment but may reduce production costs in the long run.

-

Quality Control (QC): Ensuring parts meet stringent quality standards involves costs related to inspection, testing, and certification processes. Buyers should consider suppliers with robust QC systems to minimize defects and returns.

-

Logistics: Shipping costs can vary significantly based on the Incoterms agreed upon. Factors such as distance, mode of transport, and whether the supplier or buyer is responsible for shipping can influence overall costs.

-

Margin: Suppliers will add their profit margin to the total cost of production. This margin can vary widely based on market competition, supplier reputation, and the specific service level provided.

How Do Price Influencers Impact Automatic Screw Machine Costs?

Several factors can influence the pricing of automatic screw machines:

-

Volume/MOQ: Higher order volumes typically lead to lower per-unit costs due to economies of scale. Suppliers may offer better pricing for larger orders, which can be beneficial for buyers planning long-term production runs.

-

Specifications and Customization: Custom machines tailored to specific applications often come at a premium. Buyers should weigh the necessity of customization against the potential cost savings of off-the-shelf solutions.

-

Material Choices: The choice of material not only affects the upfront cost but also the longevity and performance of the final product. For example, opting for a higher-grade alloy can enhance durability but increase initial costs.

-

Quality Certifications: Machines that meet international standards (ISO, TS 16949, etc.) may come at a higher price due to the added costs of compliance and certification processes. Buyers should assess the need for certifications based on their end-use applications.

-

Supplier Factors: Supplier reputation, reliability, and after-sales support can significantly influence pricing. Established suppliers may charge more for their proven track record and additional services.

-

Incoterms: The choice of Incoterms affects logistics costs and responsibilities. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) is crucial for accurate cost estimation.

What Buyer Tips Can Enhance Cost Efficiency in Sourcing?

B2B buyers can leverage several strategies to enhance cost efficiency:

-

Negotiation: Engaging in open discussions with suppliers can lead to better pricing. Buyers should be prepared to negotiate based on volume commitments or long-term contracts.

-

Consider Total Cost of Ownership (TCO): Instead of focusing solely on the purchase price, evaluate the TCO, which includes maintenance, operation, and potential downtime costs. A slightly higher initial investment may yield savings over the machine’s lifespan.

-

Understand Pricing Nuances for International Markets: When sourcing from international suppliers, consider exchange rates, tariffs, and local regulations, which can affect pricing. Buyers from regions like Africa or South America should be aware of these factors to avoid unexpected costs.

-

Request Multiple Quotes: Obtaining quotes from various suppliers allows for better market comparison. It can also provide leverage in negotiations and help identify the best overall value.

Disclaimer on Indicative Prices

Prices for automatic screw machines can vary widely based on the aforementioned factors. Buyers are encouraged to conduct thorough market research and supplier assessments to determine the most accurate pricing for their specific needs.

Alternatives Analysis: Comparing automatic screw machines With Other Solutions

In today’s competitive manufacturing landscape, businesses are increasingly exploring various technologies to enhance productivity, precision, and cost-effectiveness. Automatic screw machines, known for their high-speed and high-volume production capabilities, present one option among several. This section will compare automatic screw machines with other viable alternatives, such as CNC machining and cold heading, to help B2B buyers make informed decisions.

Illustrative image related to automatic screw machines

Comparison Table

| Comparison Aspect | Automatic Screw Machines | CNC Machining | Cold Heading |

|---|---|---|---|

| Performance | High-speed, high-volume production | Versatile with complex geometries | High-speed for specific fasteners |

| Cost | Moderate initial investment, low operational cost | Higher setup and tooling costs | Lower material waste, cost-effective for mass production |

| Ease of Implementation | Requires skilled operators | Steeper learning curve, versatile | Simple setup, specialized training needed |

| Maintenance | Regular maintenance required | High maintenance due to complexity | Low maintenance, fewer moving parts |

| Best Use Case | High-volume, repetitive parts | Custom parts with complex designs | Fasteners and simple components |

Detailed Breakdown of Alternatives

CNC Machining

CNC (Computer Numerical Control) machining is a highly versatile technology that can produce complex geometries with high precision. It allows for the machining of a variety of materials, including metals and plastics, making it ideal for custom parts. However, the initial setup costs can be significant, and the learning curve for operators is steeper than that of automatic screw machines. While CNC machines excel in creating intricate designs, they may not achieve the same high-speed output for repetitive tasks as automatic screw machines.

Cold Heading

Cold heading is a process where metal is shaped into fasteners and other components without the need for machining. It is particularly cost-effective for high-volume production runs, as it results in minimal material waste and faster cycle times. Cold heading is most beneficial for producing simple shapes, such as screws and bolts, but it lacks the flexibility to create more complex geometries. While the setup is relatively straightforward, specialized training may be required to ensure optimal production efficiency.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the appropriate manufacturing solution, B2B buyers must consider several factors, including production volume, complexity of parts, and operational costs. Automatic screw machines are ideal for high-volume production of simple components, while CNC machining offers versatility for complex designs. Cold heading is the best choice for cost-effective fastener production. By carefully evaluating these aspects against specific project requirements, businesses can choose the right technology that aligns with their operational goals and budget constraints.

Illustrative image related to automatic screw machines

Essential Technical Properties and Trade Terminology for automatic screw machines

What are the Key Technical Properties of Automatic Screw Machines?

When considering the purchase of automatic screw machines, understanding their essential technical properties is crucial for making informed decisions. Below are several critical specifications that should be evaluated:

1. Tolerance

Tolerance refers to the allowable deviation from a specified dimension in the manufacturing process. In automatic screw machining, tight tolerances (often within ±0.001 inches) are vital for ensuring that parts fit precisely in their intended applications. For B2B buyers, knowing the required tolerances for your components can directly affect assembly efficiency and product reliability, especially in industries like aerospace and automotive where precision is paramount.

2. Material Grade

The material grade of the components being machined—such as aluminum, stainless steel, or brass—plays a significant role in the performance and durability of the finished parts. Different materials have varying mechanical properties, such as tensile strength and corrosion resistance. Buyers must specify the material grade based on the application to ensure longevity and compliance with industry standards.

Illustrative image related to automatic screw machines

3. Cycle Time

Cycle time is the duration it takes for a machine to complete one production cycle, from raw material input to finished part output. Shorter cycle times enhance productivity and reduce manufacturing costs, making it a key factor for B2B buyers looking for cost-effective solutions. Understanding the cycle time of different machines helps in assessing the overall efficiency and potential return on investment.

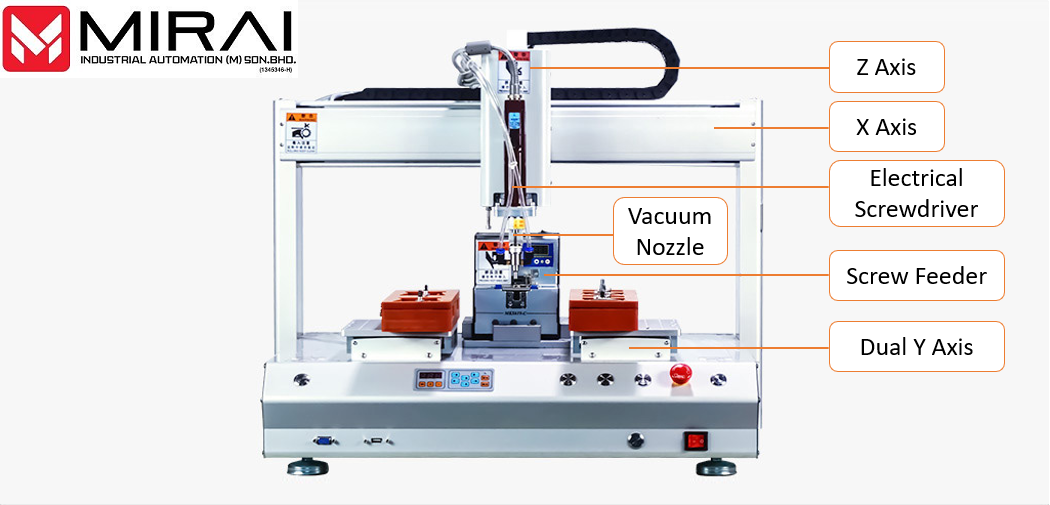

4. Spindle Configuration

Spindle configuration refers to the number of spindles in the machine. Multi-spindle machines, such as those with five spindles, can produce multiple parts simultaneously, vastly improving throughput compared to single-spindle machines. For high-volume production runs, investing in multi-spindle configurations can lead to significant cost savings and faster time-to-market.

5. CNC Capability

CNC (Computer Numerical Control) capability allows for automated precision control of machining operations. Machines equipped with CNC interfaces provide enhanced flexibility and accuracy, enabling the production of complex geometries and tighter tolerances. This technology is particularly beneficial for industries requiring rapid prototyping and custom parts.

6. Secondary Operations

Secondary operations include additional machining processes such as milling, threading, and deburring that may be required after the primary machining is complete. Understanding the available secondary operations can help buyers streamline their production processes and reduce lead times, ultimately leading to more efficient manufacturing workflows.

Illustrative image related to automatic screw machines

What are Common Trade Terms in Automatic Screw Machining?

Familiarity with industry jargon is essential for effective communication and negotiation. Here are several key trade terms relevant to automatic screw machining:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of automatic screw machines, OEMs provide the essential components required for production. Buyers should ensure that their suppliers can meet OEM specifications to guarantee compatibility and quality.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to sell. Understanding MOQ is critical for B2B buyers as it affects inventory levels and cash flow. Buyers should negotiate MOQs that align with their production needs while ensuring they do not overstock or understock essential components.

Illustrative image related to automatic screw machines

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other information for specific products or services. Issuing an RFQ is a standard practice for buyers to compare costs and services, helping them make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms helps B2B buyers clarify their obligations and mitigate risks in international transactions.

5. JIT (Just-In-Time)

JIT is an inventory management strategy that aims to reduce waste by receiving goods only as they are needed in the production process. This method can lower inventory costs and improve cash flow, making it an attractive option for manufacturers looking to optimize their supply chain.

By grasping these technical properties and trade terms, B2B buyers can enhance their understanding of automatic screw machines, leading to more strategic decisions that align with their operational goals.

Navigating Market Dynamics and Sourcing Trends in the automatic screw machines Sector

What Are the Current Market Dynamics in the Automatic Screw Machines Sector?

The automatic screw machines market is experiencing a paradigm shift driven by technological advancements, increasing demand for precision parts, and the need for efficiency across various manufacturing sectors. Key global drivers include the rapid growth of the automotive and aerospace industries, which are pushing for high-volume production capabilities while maintaining stringent quality standards. Additionally, the rise of Industry 4.0 and smart manufacturing technologies is facilitating the integration of automation and data exchange in manufacturing processes, leading to enhanced productivity and reduced operational costs.

Illustrative image related to automatic screw machines

B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, are increasingly seeking suppliers that offer advanced multi-spindle and hybrid machines that combine the mechanical reliability of traditional models with the precision of CNC technologies. The demand for versatile machines capable of producing complex geometries and accommodating various materials is on the rise. Furthermore, emerging trends such as just-in-time (JIT) inventory and Kanban systems are encouraging manufacturers to adopt flexible sourcing strategies that align with real-time production needs.

As international buyers navigate this evolving landscape, they must also consider the implications of geopolitical factors, economic conditions, and trade policies that can influence sourcing decisions. For instance, fluctuating tariffs and trade agreements can impact the cost structure, making it essential for buyers to establish relationships with reliable suppliers who can offer competitive pricing without compromising quality.

How Is Sustainability Influencing Sourcing Decisions in the Automatic Screw Machines Market?

Sustainability is becoming a cornerstone of sourcing strategies in the automatic screw machines sector. The environmental impact of manufacturing processes, including waste generation and resource consumption, is under scrutiny as industries strive to meet global sustainability goals. B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to ethical sourcing and sustainable practices.

Illustrative image related to automatic screw machines

The importance of transparency in supply chains cannot be overstated. Buyers are looking for manufacturers who can provide evidence of sustainable practices, such as the use of recycled materials or adherence to environmental certifications like ISO 14001. Additionally, the demand for ‘green’ certifications is rising, as buyers seek to align their purchasing decisions with their corporate social responsibility (CSR) objectives.

Moreover, the shift towards sustainable practices is prompting innovation in machine design and production processes. Suppliers are investing in technologies that minimize energy consumption and reduce emissions, which not only contributes to environmental conservation but also enhances operational efficiency. As a result, buyers should assess the sustainability credentials of potential suppliers, considering their practices as a critical factor in long-term partnerships.

What Is the Historical Context of Automatic Screw Machines and Their Impact on Today’s Market?

The evolution of automatic screw machines dates back to the early 20th century when manufacturers recognized the need for efficient production methods to meet the growing demand for precision components. The introduction of multi-spindle machines revolutionized the industry by enabling high-volume production with minimal manual intervention. Over the decades, advancements in technology have led to the development of hybrid models that combine the strengths of traditional screw machines with modern CNC capabilities, further enhancing precision and versatility.

Today, the legacy of these innovations continues to shape the market, as manufacturers strive to meet the complexities of modern production requirements. Understanding this historical context allows B2B buyers to appreciate the technological advancements that have led to the current capabilities of automatic screw machines, informing their sourcing strategies and investment decisions in this dynamic sector.

Frequently Asked Questions (FAQs) for B2B Buyers of automatic screw machines

1. How do I choose the right automatic screw machine for my production needs?

Selecting the right automatic screw machine involves evaluating your production volume, part complexity, and material requirements. For high-volume production, multi-spindle machines are ideal due to their efficiency. Conversely, single-spindle machines may be suitable for smaller runs or more complex parts. Additionally, consider the machine’s flexibility, setup times, and compatibility with existing processes. Consulting with manufacturers to understand the capabilities of different models can help you make an informed decision.

2. What are the advantages of using multi-spindle automatic screw machines?

Multi-spindle automatic screw machines are renowned for their high productivity, capable of producing multiple parts simultaneously, which dramatically increases throughput. They offer precision in manufacturing, allowing for tight tolerances and complex geometries. Their versatility enables them to handle various materials, from metals to plastics. Furthermore, these machines often come with reduced cycle times and lower labor costs, making them a cost-effective solution for high-volume production.

Illustrative image related to automatic screw machines

3. How can I ensure the quality of parts produced by automatic screw machines?

To ensure quality, it is essential to work with reputable suppliers who implement rigorous quality control measures, including in-process inspections and final product testing. Look for manufacturers that comply with international standards such as ISO 9001 or TS 16949. Additionally, consider the machine’s capabilities, such as its precision tolerances and ease of setup for different operations. Regular maintenance and calibration of the machines also play a critical role in maintaining consistent quality.

4. What customization options are available for automatic screw machines?

Many manufacturers offer customization options to tailor machines to specific production needs. Customization may include modifications to accommodate unique part sizes, shapes, and materials. Additional features like enhanced CNC interfaces, specialized tooling, or secondary operation capabilities can also be integrated. Discussing your specific requirements with suppliers can help identify the best solutions and configurations to optimize your production process.

5. What are the typical minimum order quantities (MOQ) for automatic screw machines?

Minimum order quantities can vary significantly between manufacturers and depend on the complexity and customization of the machines. Generally, standard models may have lower MOQs, while custom-designed machines may require larger orders to justify production costs. It’s important to communicate your needs clearly with suppliers to negotiate favorable terms that align with your production goals.

6. What payment terms should I expect when purchasing automatic screw machines?

Payment terms for automatic screw machines can range from upfront payments to flexible installment plans, often depending on the supplier’s policies and the machine’s cost. Common arrangements include a percentage deposit upon order confirmation, followed by the balance before delivery. International buyers should also consider currency exchange rates and potential additional costs like tariffs or shipping fees, which can affect the overall investment.

7. How can I vet suppliers of automatic screw machines effectively?

To vet suppliers, start by researching their reputation in the industry through customer reviews, case studies, and testimonials. Request references and conduct site visits if possible to assess their manufacturing capabilities and quality control processes. Ensure the supplier has relevant certifications and compliance with international standards. Engaging in direct communication can also help gauge their responsiveness and willingness to support your specific needs.

8. What logistics considerations should I keep in mind when importing automatic screw machines?

When importing automatic screw machines, consider shipping costs, delivery times, and customs regulations specific to your country. It’s crucial to work with logistics providers experienced in handling industrial equipment to navigate potential challenges. Ensure that all necessary documentation, such as import licenses and compliance certificates, is prepared in advance to avoid delays. Additionally, plan for any installation and setup requirements once the machines arrive at your facility.

Top 3 Automatic Screw Machines Manufacturers & Suppliers List

1. Abbott Interfast – High Precision Automatic Screw Machining Services

Domain: aicfast.com

Registered: 2012 (13 years)

Introduction: High Precision Automatic Screw Machining Services & Products offered by Abbott Interfast include:

– Manufacturing capabilities: Automatic screw machining, CNC machining, CNC milling, CNC turning, cold heading, stamping, plastic injection molding, casting, sub-assembly, and contract manufacturing.

– Materials used: Aluminum, stainless steel, copper, brass, carbon steel, various alloys, nylon, and …

2. Swistek – Swiss Type Automatic Screw Machines

Domain: swistek.com

Registered: 2010 (15 years)

Introduction: New Swiss Type Automatic Screw Machines for sale from brands including STAR, TSUGAMI, GANESH, HANWHA, SWISTEK, and CITIZEN. Located at Swistek Machinery America, 50 Seemans Lane, Milford, CT, 06460. Contact at 203-301-4848 or via email. Offers include new machinery, used machinery, accessories, live tools, inspection services, and cutting oil.

3. Maier – ML32DY CNC Swiss Type Automatic Screw Machine

Domain: igam.com

Registered: 2002 (23 years)

Introduction: This company, Maier – ML32DY CNC Swiss Type Automatic Screw Machine, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for automatic screw machines

In the rapidly evolving landscape of manufacturing, the strategic sourcing of automatic screw machines presents a unique opportunity for businesses across Africa, South America, the Middle East, and Europe. By understanding the capabilities of multi-spindle and hybrid machines, companies can significantly enhance their production efficiency, reduce operational costs, and maintain high precision in their output. The versatility of these machines allows for a wide range of applications, from aerospace components to custom fasteners, catering to diverse industry needs.

Investing in automatic screw machines not only streamlines production processes but also fosters innovation through advanced technologies such as CNC interfaces and automated loading systems. This shift towards automation can lead to improved cycle times and reduced setup, enabling manufacturers to respond swiftly to market demands.

Illustrative image related to automatic screw machines

As we look to the future, international buyers are encouraged to explore partnerships with reputable machine manufacturers. By leveraging the expertise and support offered by established brands, businesses can optimize their supply chains and enhance their competitive edge. Now is the time to act—invest in strategic sourcing to elevate your manufacturing capabilities and position your company for success in the global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.