Automatic Pancake Maker: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for automatic pancake maker

In the fast-paced world of food service, sourcing an automatic pancake maker can be a game-changing decision for businesses aiming to elevate their breakfast offerings. The challenge lies not only in identifying the right equipment but also in understanding the diverse applications and supplier landscape that varies across regions. This comprehensive guide is designed to navigate B2B buyers through the complexities of the global market for automatic pancake makers, providing insights into various types of machines, their applications in different settings—from hotels to buffets—and essential criteria for vetting suppliers.

International buyers, particularly those from Africa, South America, the Middle East, and Europe, will benefit from a thorough examination of factors such as cost, maintenance requirements, and the overall value proposition of these machines. By delving into the latest technologies and trends in automatic pancake production, this guide empowers businesses to make informed purchasing decisions that align with their operational goals and customer expectations.

With a focus on quality, efficiency, and customer satisfaction, investing in an automatic pancake maker not only enhances the dining experience but also streamlines kitchen operations. This resource aims to equip you with the knowledge needed to select the ideal solution tailored to your market needs, ensuring that your establishment stands out in a competitive landscape.

Understanding automatic pancake maker Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fully-Automatic Pancake Maker | Produces pancakes in under a minute with minimal operator input | Hotels, buffets, airport lounges | Pros: Quick service, low maintenance Cons: Higher upfront costs |

| Contactless Pancake Machine | Utilizes hand wave sensors for a hygienic, touchless experience | Cafeterias, hospitals, schools | Pros: Enhanced hygiene, fun for guests Cons: May require more technical support |

| Compact Pancake Dispenser | Smaller footprint, ideal for limited spaces | Small cafes, food trucks | Pros: Space-efficient, cost-effective Cons: Limited production capacity |

| All-in-One Pancake System | Integrated batter dispenser and cooking mechanism | Large-scale catering, event venues | Pros: Streamlined operations, consistent quality Cons: More complex setup |

| Portable Pancake Maker | Lightweight and easy to transport | Mobile catering, outdoor events | Pros: Flexibility, ease of use Cons: Lower output, limited features |

What Are the Key Characteristics of Fully-Automatic Pancake Makers?

Fully-automatic pancake makers are designed to deliver a consistent product with minimal labor. These machines can produce pancakes in under a minute, making them ideal for high-traffic environments like hotels and buffets. Buyers should consider the machine’s capacity, maintenance requirements, and initial investment, as these units often come with a higher price tag but offer significant labor savings and customer satisfaction.

How Do Contactless Pancake Machines Enhance Hygiene?

Contactless pancake machines utilize hand wave sensors to dispense batter, promoting a hygienic, no-touch experience. This feature is particularly beneficial in settings like schools and hospitals, where food safety is paramount. Buyers should evaluate the technical support required for maintenance and the potential for increased customer engagement, as the novelty of a contactless machine can enhance the dining experience.

Why Choose Compact Pancake Dispensers for Smaller Spaces?

Compact pancake dispensers are designed for establishments with limited kitchen space, such as small cafes or food trucks. These machines can still produce quality pancakes while minimizing the footprint. B2B buyers should assess the output capacity to ensure it meets their service demands, as these models typically have a lower production rate compared to larger units.

What Are the Benefits of All-in-One Pancake Systems?

All-in-one pancake systems integrate batter dispensing and cooking in one unit, which streamlines operations for large-scale catering and event venues. These systems ensure consistent pancake quality and reduce the need for multiple pieces of equipment. Buyers should consider the complexity of the setup and the training required for staff, as these systems can be more intricate than standalone models.

How Do Portable Pancake Makers Fit into Mobile Catering?

Portable pancake makers are lightweight and easy to transport, making them an excellent choice for mobile catering and outdoor events. While they offer flexibility and ease of use, their lower output and limited features should be considered when assessing their suitability for larger gatherings. B2B buyers should weigh the benefits of mobility against the potential need for additional equipment to meet customer demand.

Illustrative image related to automatic pancake maker

Key Industrial Applications of automatic pancake maker

| Industry/Sector | Specific Application of automatic pancake maker | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Hospitality | Hotel breakfast services | Enhances guest experience with quick, fresh breakfast options | Equipment reliability, ease of use, maintenance support |

| Food Service | Airport lounges and buffet settings | Reduces waiting time, increases customer satisfaction | Compliance with health standards, space requirements |

| Education | School and university cafeterias | Provides a fun, engaging breakfast option for students | Cost-effectiveness, ease of operation for staff |

| Healthcare | Hospitals and care facilities | Offers nutritious meal options in a fast, hygienic manner | Safety features, low maintenance, and support availability |

| Corporate Dining | Employee cafeterias in large corporations | Encourages healthy eating habits, boosts morale | Bulk purchasing agreements, reliable supply chain |

How is the Automatic Pancake Maker Used in the Hospitality Sector?

In the hospitality industry, automatic pancake makers are increasingly utilized in hotel breakfast services. They allow hotels to offer fresh, hot pancakes in under a minute, enhancing guest satisfaction and streamlining operations. This technology mitigates the chaos of traditional breakfast setups, ensuring guests have quick access to delicious food. For international buyers, considerations such as equipment reliability, maintenance support, and ease of use are crucial to ensure seamless integration into existing breakfast programs.

What Role Does the Automatic Pancake Maker Play in Food Service Environments?

In food service environments like airport lounges and buffet settings, automatic pancake makers serve to reduce waiting times significantly. By providing a self-service option, they allow customers to enjoy freshly made pancakes without lengthy queues, thereby improving overall customer experience. For B2B buyers, it is vital to ensure compliance with local health and safety standards while also considering the machine’s space requirements and ease of cleaning, especially in high-traffic areas.

How Can Educational Institutions Benefit from Automatic Pancake Makers?

Schools and universities are increasingly adopting automatic pancake makers in their cafeterias to provide a fun and engaging breakfast option for students. This technology not only attracts students but also encourages healthier eating habits by offering nutritious meal choices. Buyers in this sector should focus on cost-effectiveness and ease of operation, as staff may have limited time for food preparation, making efficiency a top priority.

Why Are Automatic Pancake Makers Important in Healthcare Facilities?

In healthcare settings, such as hospitals and care facilities, automatic pancake makers offer a quick and hygienic way to serve nutritious meals to patients and staff. The ability to produce pancakes on demand ensures that individuals receive fresh food while adhering to strict health protocols. For healthcare buyers, key considerations include the machine’s safety features, low maintenance requirements, and the availability of support services to address any operational issues swiftly.

Illustrative image related to automatic pancake maker

How Do Corporate Dining Services Utilize Automatic Pancake Makers?

Corporate dining services leverage automatic pancake makers to enhance employee cafeterias, promoting healthy eating habits and boosting morale among staff. By providing fresh pancakes quickly, companies can foster a positive workplace culture and improve employee satisfaction. When sourcing these machines, businesses should consider bulk purchasing agreements and the reliability of the supply chain to ensure consistent availability of pancake mix and equipment functionality.

3 Common User Pain Points for ‘automatic pancake maker’ & Their Solutions

Scenario 1: Ensuring Consistent Quality in High-Volume Settings

The Problem: In food service environments, particularly hotels and airports, maintaining a consistent quality of food offerings is crucial for customer satisfaction. B2B buyers often face challenges with traditional pancake-making methods, where variations in batter preparation, cooking times, and staff skills can lead to inconsistent results. This inconsistency not only affects customer experience but can also lead to increased waste and operational inefficiencies.

The Solution: Investing in a fully automatic pancake maker can significantly alleviate these concerns. These machines are designed to produce uniform pancakes at a consistent speed, ensuring that every pancake meets the same quality standards. To maximize this benefit, buyers should consider models with programmable settings that allow for adjustments in cooking time and temperature based on specific needs. Additionally, sourcing machines that utilize pre-packaged batter mixes can eliminate discrepancies in ingredient ratios, further ensuring consistency. Training staff on the operation of the machine and the importance of using recommended mixes will streamline the process and enhance product quality.

Scenario 2: Managing Maintenance and Operational Downtime

The Problem: B2B buyers in the food service industry frequently worry about the maintenance of equipment. Automatic pancake makers, while designed for efficiency, can experience mechanical issues that lead to downtime. This downtime can result in lost revenue, especially during peak service times like breakfast hours. Buyers often face the dilemma of choosing between machines that are low-maintenance and those that offer advanced features.

The Solution: To address maintenance concerns, buyers should prioritize purchasing automatic pancake makers from reputable manufacturers that offer comprehensive service programs. Look for machines that come with warranties and readily available customer support, including 24/7 helplines for troubleshooting. Additionally, it’s essential to establish a regular maintenance schedule to prevent unexpected breakdowns. Buyers can also consider machines that provide self-diagnostic features, which can alert staff to potential issues before they escalate. This proactive approach not only minimizes downtime but also enhances the longevity of the equipment.

Scenario 3: Catering to Diverse Consumer Preferences

The Problem: In diverse markets, particularly in regions like Africa and South America, consumer preferences for food can vary significantly. Some guests may prefer traditional pancakes, while others may seek gluten-free or vegan options. B2B buyers face the challenge of ensuring that their offerings cater to these varied dietary needs without complicating their operations.

The Solution: Automatic pancake makers that allow for customization can solve this problem effectively. Buyers should seek machines that are compatible with different batter types, enabling the preparation of a variety of pancakes to meet customer preferences. Collaborating with suppliers who offer diverse batter mixes, including gluten-free and vegan options, can enhance menu offerings. Additionally, providing clear signage around the pancake station indicating available options can help guests make informed choices. Training staff to understand these offerings will ensure smooth operations and a better dining experience for customers, ultimately driving repeat business.

Illustrative image related to automatic pancake maker

By addressing these common pain points through strategic equipment choices and operational practices, B2B buyers can enhance their food service offerings, improve customer satisfaction, and drive profitability.

Strategic Material Selection Guide for automatic pancake maker

When selecting materials for automatic pancake makers, it is essential to consider factors such as durability, cost, manufacturing complexity, and compliance with international standards. Here, we analyze four common materials used in the construction of these machines: stainless steel, aluminum, plastic, and silicone.

What Are the Key Properties of Stainless Steel for Automatic Pancake Makers?

Stainless steel is a popular choice for automatic pancake makers due to its excellent corrosion resistance and high-temperature tolerance. Typically, it can withstand temperatures up to 1,500°F (815°C) and is resistant to rust and staining, making it ideal for food service applications.

Pros and Cons: The durability of stainless steel ensures a long lifespan, reducing the need for frequent replacements. However, it can be more expensive than other materials, which may impact initial investment costs. Manufacturing complexity is moderate, as stainless steel requires specialized equipment for cutting and shaping.

Impact on Application: Stainless steel’s compatibility with food-grade standards makes it suitable for direct contact with pancake batter, ensuring food safety. International buyers should ensure compliance with standards such as ASTM A240 or EN 10088, which govern the quality of stainless steel used in food applications.

How Does Aluminum Perform in Automatic Pancake Makers?

Aluminum is another material frequently used in pancake makers, valued for its lightweight and excellent thermal conductivity. It can effectively distribute heat, allowing for even cooking of pancakes.

Pros and Cons: The primary advantage of aluminum is its cost-effectiveness and ease of manufacturing, making it a popular choice among manufacturers. However, it is less durable than stainless steel and may be prone to warping under high temperatures. Additionally, aluminum can react with acidic foods, which may not be ideal for pancake batters containing certain ingredients.

Impact on Application: Buyers should consider the specific media compatibility of aluminum when selecting this material. Compliance with international standards such as ASTM B211 for aluminum alloys is essential for ensuring quality and safety in food applications.

What Role Does Plastic Play in Automatic Pancake Makers?

Plastic components are often used in the construction of automatic pancake makers, particularly for non-structural elements such as dispensers and control panels. Plastics can be designed to withstand moderate temperatures and are generally lightweight.

Pros and Cons: The primary advantage of plastic is its low cost and versatility in design. However, plastics may not have the same durability as metals and can be less resistant to high temperatures. Manufacturing complexity can vary significantly depending on the type of plastic used.

Impact on Application: It is crucial to select food-grade plastics that comply with FDA and EU regulations for food safety. Buyers in regions like Africa and South America should be aware of local regulations that may differ from international standards.

Why Is Silicone Important for Automatic Pancake Makers?

Silicone is increasingly being used in pancake makers, especially for components that require flexibility and heat resistance, such as molds and seals. Silicone can withstand temperatures ranging from -40°F to 450°F (-40°C to 232°C).

Pros and Cons: Silicone’s flexibility allows for easy release of pancakes, reducing waste and improving efficiency. However, it may not provide the structural strength required for more robust components. The cost of silicone can also be higher than traditional plastics.

Impact on Application: Silicone must meet food safety standards such as FDA regulations to ensure it is safe for contact with food. International buyers should verify that the silicone used is compliant with local and international safety standards.

Summary Table of Material Selection for Automatic Pancake Makers

| Material | Typical Use Case for automatic pancake maker | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Cooking surface, structural components | Excellent durability and corrosion resistance | Higher initial cost | High |

| Aluminum | Heating elements, structural parts | Lightweight and cost-effective | Less durable, can warp under high heat | Medium |

| Plastic | Dispensers, control panels | Low cost and versatile design | Less durable, may not handle high heat | Low |

| Silicone | Molds, seals | Flexible and heat-resistant | Higher cost, less structural strength | Medium |

This strategic material selection guide provides insights that can help international B2B buyers make informed decisions when sourcing automatic pancake makers. Understanding the properties, advantages, and limitations of each material will enable buyers to choose the best options that align with their operational needs and compliance requirements.

Illustrative image related to automatic pancake maker

In-depth Look: Manufacturing Processes and Quality Assurance for automatic pancake maker

What Are the Key Stages in the Manufacturing Process of Automatic Pancake Makers?

The manufacturing process for automatic pancake makers involves several critical stages that ensure product quality, efficiency, and functionality. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation

This initial stage involves sourcing high-quality materials, such as stainless steel for the exterior, non-stick coatings for the cooking surface, and electronic components for the automation features. Suppliers often need to meet specific standards to ensure durability and safety. For international buyers, verifying the origin and certification of these materials is crucial, as it impacts the final product’s reliability. -

Forming

In this stage, raw materials are shaped into the various components of the pancake maker. Techniques like stamping, molding, and machining are commonly used. Advanced CNC (Computer Numerical Control) machines are often employed to ensure precision in forming parts such as the batter dispensing mechanism and heating elements. Each component must meet strict dimensional tolerances to guarantee proper assembly and functionality. -

Assembly

During assembly, the formed components are brought together. Automated assembly lines are typical, enhancing efficiency and consistency. Skilled technicians may oversee the process to ensure that each machine is assembled correctly, particularly in aligning mechanical parts and integrating electronic controls. Quality checks at this stage can prevent assembly errors that could lead to malfunctions. -

Finishing

The final stage involves surface treatments, which may include polishing, coating, or painting. These treatments not only enhance the aesthetic appeal but also provide protection against corrosion and wear. This stage is critical for ensuring that the pancake maker can withstand the rigors of daily use in commercial settings.

How Do Quality Assurance Processes Ensure the Reliability of Automatic Pancake Makers?

Quality assurance (QA) is integral to the manufacturing of automatic pancake makers, ensuring that each unit meets stringent performance and safety standards. Effective QA processes encompass various international and industry-specific standards, as well as multiple checkpoints throughout the production cycle.

-

Relevant International Standards

Adherence to international standards such as ISO 9001 is essential for quality management systems. This standard emphasizes a process-oriented approach, ensuring that manufacturers consistently produce products that meet customer and regulatory requirements. Additionally, certifications like CE (Conformité Européenne) are critical for products sold within Europe, indicating compliance with health, safety, and environmental protection standards. -

Quality Checkpoints

Quality control is integrated at multiple checkpoints throughout the manufacturing process, including:

– Incoming Quality Control (IQC): This stage involves inspecting raw materials and components upon arrival to ensure they meet specified standards.

– In-Process Quality Control (IPQC): Continuous monitoring occurs during the manufacturing stages to identify and rectify defects early, reducing waste and ensuring efficiency.

– Final Quality Control (FQC): Before products leave the factory, a thorough inspection is conducted to verify that each pancake maker meets performance and safety criteria. -

Common Testing Methods

Various testing methods are employed to assess functionality and safety, including:

– Performance Testing: Evaluating the cooking efficiency, temperature accuracy, and consistency of pancake output.

– Safety Testing: Ensuring that electrical components comply with safety standards to prevent hazards such as overheating or electrical failure.

– Durability Testing: Simulating long-term use to assess wear and tear, ensuring that the product can withstand daily commercial demands.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is crucial to mitigating risks and ensuring product reliability. Here are key strategies to confirm supplier QC:

-

Conducting Audits

Buyers should consider conducting on-site audits of potential suppliers. This allows them to evaluate the manufacturing processes, quality control systems, and compliance with international standards firsthand. An audit also provides insight into the supplier’s commitment to quality and their ability to meet specific requirements. -

Requesting Quality Reports

Suppliers should be able to provide detailed quality reports, including results from IQC, IPQC, and FQC. These documents should outline any defects identified during production and the corrective actions taken. Reviewing these reports helps buyers assess the supplier’s reliability and attention to quality. -

Third-Party Inspections

Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s quality control practices. These services often conduct random inspections during the manufacturing process and provide comprehensive reports that highlight compliance with relevant standards.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

Navigating quality control and certification can present challenges for international B2B buyers, particularly in regions with varying regulations and standards.

-

Understanding Regional Certifications

Different regions may have specific certifications that manufacturers must obtain. For example, products sold in the European Union must meet CE certification, while those in the U.S. may require UL (Underwriters Laboratories) certification. Buyers should familiarize themselves with these requirements to ensure compliance and avoid potential legal issues. -

Cultural and Regulatory Differences

Buyers should also consider cultural and regulatory differences that may influence quality expectations. For instance, regions like the Middle East may have unique food safety regulations that impact the design and functionality of food service equipment. Understanding these nuances is essential for establishing successful partnerships with suppliers. -

Supplier Relationships

Building strong relationships with suppliers can enhance communication regarding quality expectations and compliance. Regular discussions about quality standards and expectations can help align both parties and improve overall product quality.

By understanding the manufacturing processes and quality assurance practices associated with automatic pancake makers, B2B buyers can make informed decisions that ensure product reliability and customer satisfaction.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘automatic pancake maker’

Introduction

This sourcing guide is designed to assist B2B buyers in the procurement of automatic pancake makers, a valuable addition to food service establishments like hotels, restaurants, and catering businesses. By following this checklist, you can ensure that you select the right equipment that meets your operational needs while maximizing efficiency and guest satisfaction.

1. Identify Your Operational Requirements

Before initiating the procurement process, clearly define your operational needs. Consider factors such as the expected volume of pancakes, the target market (e.g., hotels, buffets), and specific features like contactless operation or cooking speed. Understanding these requirements will help you select a machine that aligns with your business goals.

2. Research Available Models and Features

Explore the different models of automatic pancake makers available in the market. Look for key features that enhance usability and efficiency, such as:

– Cooking Speed: Some machines can produce pancakes in under a minute, which is ideal for high-traffic environments.

– Ease of Use: Features like no-mess dispensers and automatic mixing can significantly reduce preparation time and labor costs.

3. Evaluate Supplier Credentials

Thoroughly vet potential suppliers to ensure they have a solid reputation in the industry. Look for:

– Certifications: Verify that suppliers meet international safety and quality standards, which is crucial for food service equipment.

– Experience: Consider suppliers with a proven track record in providing automatic pancake makers to similar markets or industries.

4. Assess Maintenance and Support Services

Evaluate the maintenance and customer support options provided by the supplier. An effective support service can save you time and costs in the long run. Look for:

– Warranty and Service Plans: Understand the warranty terms and whether the supplier offers ongoing maintenance or replacement services.

– 24/7 Support: A dedicated support line can be invaluable for troubleshooting and ensuring minimal downtime.

Illustrative image related to automatic pancake maker

5. Request Sample Products

Before making a large purchase, request samples or demonstrations of the automatic pancake maker. This step allows you to:

– Test Performance: Assess the quality of pancakes produced and the machine’s ease of operation.

– Evaluate User Experience: Ensure that the machine is user-friendly for both staff and guests, especially in a buffet setting.

6. Compare Pricing Models

Analyze the pricing structures of different suppliers. Some may offer machines on loan with a minimum purchase commitment, while others may require outright purchases. Consider:

– Total Cost of Ownership: Factor in not just the purchase price but also ongoing costs for mix supplies, maintenance, and potential operational disruptions.

– Shipping and Handling: Ensure you understand the shipping terms and any additional costs associated with delivery.

7. Finalize Contract Terms

Once you’ve selected a supplier, carefully review the contract terms before signing. Pay attention to:

– Return Policies: Understand the conditions under which you can return or exchange the machine if it doesn’t meet your expectations.

– Payment Terms: Clarify the payment schedule and any financing options that may be available.

Following this checklist will help you make informed decisions and ensure that your investment in an automatic pancake maker enhances your food service operations effectively.

Comprehensive Cost and Pricing Analysis for automatic pancake maker Sourcing

What Are the Key Cost Components of Automatic Pancake Makers?

When considering the sourcing of automatic pancake makers, understanding the underlying cost components is crucial. The primary elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The quality of components such as heating elements, batter dispensers, and control panels significantly impacts the overall cost. High-grade materials may lead to increased durability and efficiency but will also raise initial expenses.

-

Labor: This encompasses both direct labor involved in the assembly and indirect labor for design and engineering. Efficient manufacturing processes can reduce labor costs, but they may require an upfront investment in training or technology.

-

Manufacturing Overhead: These costs include utilities, rent, and equipment maintenance. Companies should evaluate their production scale; larger operations often benefit from economies of scale, which can lower overhead costs per unit.

-

Tooling: This refers to the costs associated with creating the machinery required to manufacture the pancake makers. Custom tooling for specialized designs can be costly but may be necessary for unique market demands.

-

Quality Control (QC): Ensuring the product meets industry standards involves costs related to testing and inspection. Investing in robust QC processes can prevent costly recalls or repairs down the line.

-

Logistics: Shipping and handling costs can vary based on the destination and volume. International shipping may incur additional tariffs and customs duties, which should be factored into the total cost.

-

Margin: Suppliers typically add a margin to their costs to ensure profitability. Understanding the supplier’s pricing strategy can help in negotiations and finding the best deal.

How Do Price Influencers Impact Sourcing Decisions for Automatic Pancake Makers?

Several factors can influence pricing when sourcing automatic pancake makers, especially for international buyers.

-

Volume/MOQ (Minimum Order Quantity): Bulk purchasing often leads to discounts. Suppliers may offer lower prices for larger orders, making it essential to evaluate your demand carefully.

-

Specifications and Customization: Custom features or specifications can increase costs. Buyers should assess whether standard models meet their needs or if customization is necessary for their target market.

-

Materials and Quality Certifications: The presence of certifications (like CE or ISO) can add credibility but may also increase costs. Buyers should prioritize certifications relevant to their market to ensure compliance and quality assurance.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their brand equity and proven track record, while newer suppliers might offer competitive prices to gain market share.

-

Incoterms: Understanding delivery terms is crucial. Different Incoterms (e.g., FOB, CIF) can affect overall costs, as they dictate who is responsible for shipping, insurance, and tariffs.

What Are the Best Buyer Tips for Cost-Efficiency in Sourcing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, here are essential tips for maximizing cost-efficiency:

-

Negotiate Terms: Always negotiate the price and payment terms. Many suppliers expect negotiations and may have flexibility on pricing, especially for larger orders.

-

Consider Total Cost of Ownership (TCO): Beyond the initial purchase price, evaluate ongoing maintenance, operational costs, and potential downtime. A higher upfront cost may result in lower long-term expenses if the machine is more efficient or durable.

-

Understand Pricing Nuances: Currency fluctuations and international trade tariffs can impact pricing. Stay informed about exchange rates and trade policies that may affect your overall costs.

-

Evaluate Local vs. International Suppliers: While international suppliers may offer competitive prices, local suppliers might provide better support and lower shipping costs. Assess the trade-offs based on your specific needs.

Disclaimer on Indicative Prices

Prices for automatic pancake makers can vary widely based on the aforementioned factors and market conditions. It is recommended that buyers conduct thorough market research and request quotes from multiple suppliers to get a clearer picture of current pricing dynamics.

Alternatives Analysis: Comparing automatic pancake maker With Other Solutions

Exploring Alternatives to the Automatic Pancake Maker

When considering breakfast solutions for food service operations, it’s essential to evaluate alternatives to the automatic pancake maker. This analysis aims to compare the automatic pancake maker with other viable options, including traditional griddle cooking and waffle makers. Each method has unique advantages and drawbacks, which can impact your business’s efficiency, customer satisfaction, and overall operational costs.

Comparison Table

| Comparison Aspect | Automatic Pancake Maker | Traditional Griddle Cooking | Waffle Maker |

|---|---|---|---|

| Performance | Produces pancakes in 1 minute per serving | Varies; typically slower, depends on staff skill | Takes about 3-5 minutes per waffle |

| Cost | Moderate initial investment; low operational costs | Lower initial cost; variable labor costs | Moderate initial investment; higher mix costs |

| Ease of Implementation | Simple setup; minimal training required | Requires skilled staff; more complex operations | Easy setup; requires batter preparation |

| Maintenance | Low maintenance; designed for high volume | Moderate; depends on usage and cleaning routines | Moderate; requires thorough cleaning after each use |

| Best Use Case | High-volume environments like hotels or buffets | Small cafes or diners with skilled cooks | Breakfast-focused venues wanting variety |

Detailed Breakdown of Alternatives

Traditional Griddle Cooking

Traditional griddle cooking involves preparing pancakes manually on a flat cooking surface. This method can be cost-effective, especially for smaller operations, as griddles are typically less expensive than automatic machines. However, this approach requires trained staff to ensure consistency and quality in cooking. While it allows for flexibility in portion sizes and customization, the time taken to cook each pancake can lead to longer wait times during busy hours. Additionally, the need for continuous staff oversight can increase labor costs.

Waffle Maker

Waffle makers serve as another popular breakfast option, providing a unique and customizable product. They typically require a moderate initial investment and can produce waffles in a few minutes. However, the cost of pre-made batter can be higher compared to pancake mix, which may affect overall profitability. Waffle makers also require some level of staff training for optimal use, particularly in batter preparation and cooking times. The appeal of waffles can attract customers seeking variety, but they may not offer the same speed of service as an automatic pancake maker, especially during peak hours.

Conclusion: How to Choose the Right Breakfast Solution for Your Business

Selecting the right breakfast solution involves assessing your specific operational needs, customer preferences, and budget constraints. The automatic pancake maker excels in high-volume environments, delivering consistent quality and quick service with minimal labor involvement. In contrast, traditional griddle cooking may suit smaller operations looking for a cost-effective solution, while waffle makers can diversify your breakfast offerings but may require more complex management. Ultimately, understanding your target audience and operational capabilities will guide you in choosing the most appropriate solution to enhance your breakfast service and drive customer satisfaction.

Essential Technical Properties and Trade Terminology for automatic pancake maker

What Are the Key Technical Properties of an Automatic Pancake Maker?

-

Production Capacity

Automatic pancake makers vary in production capacity, typically measured in pancakes per hour. For example, some machines can produce a pancake every 20 seconds, resulting in up to 180 pancakes per hour. This property is critical for businesses that cater to large volumes of customers, such as hotels and buffets, as it ensures efficiency and meets high demand during peak breakfast hours. -

Power Requirements

Understanding the power specifications, such as voltage and wattage, is essential for proper installation and operation. Most automatic pancake makers operate on 120V and require around 1,700 watts. This information helps businesses ensure that their electrical infrastructure can support the equipment, preventing operational disruptions due to inadequate power supply. -

Material Grade

The construction material of the pancake maker is vital for durability and safety. Stainless steel is commonly used due to its resistance to corrosion and ease of cleaning. This property is particularly important in the foodservice industry, where hygiene and longevity of equipment can significantly impact operational costs and guest satisfaction. -

Maintenance Needs

Automatic pancake makers are designed for low maintenance, often featuring self-cleaning capabilities or easy-to-replace components. For example, some machines utilize a no-mess dispenser bag, which minimizes cleanup time and reduces labor costs. Understanding the maintenance requirements can help businesses plan for operational efficiencies and reduce downtime. -

Portion Control

Many automatic pancake makers are designed to produce “perfect portions” of pancakes, ensuring consistency in size and reducing waste. This is particularly important for cost management in food service, where overproduction can lead to increased expenses. Effective portion control can enhance customer satisfaction by providing a uniform product experience.

What Are the Common Trade Terms Associated with Automatic Pancake Makers?

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are marketed by another company under its brand name. In the context of automatic pancake makers, businesses may source machines from OEMs to offer branded solutions without investing in the manufacturing process. Understanding OEM relationships can streamline procurement and ensure product quality. -

MOQ (Minimum Order Quantity)

MOQ indicates the minimum number of units that a supplier is willing to sell in a single order. This term is crucial for B2B buyers as it affects inventory management and cash flow. Knowing the MOQ helps businesses determine if they can meet supplier requirements while still managing their operational needs effectively. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. In the automatic pancake maker market, issuing an RFQ can help buyers compare options, negotiate better pricing, and make informed purchasing decisions. This process is essential for budgeting and ensuring the best value for investment. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms, such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight), is vital for B2B buyers dealing with suppliers across borders. Understanding these terms can help mitigate risks and clarify shipping costs and responsibilities. -

Lead Time

Lead time refers to the period between placing an order and receiving the product. This term is critical in the foodservice industry, where timing can impact business operations. Knowing the lead time for automatic pancake makers helps businesses plan their inventory and ensure they can meet customer demands without interruption.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing automatic pancake makers, ultimately enhancing their operational efficiency and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the automatic pancake maker Sector

What Are the Current Market Dynamics and Key Trends in the Automatic Pancake Maker Sector?

The automatic pancake maker market is experiencing significant growth, driven by the increasing demand for convenience in the foodservice industry. Key global drivers include the rise of fast-casual dining, the expansion of hotel chains, and an uptick in consumer preference for ready-to-eat meals. International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are seeking equipment that not only enhances service efficiency but also meets safety and hygiene standards.

Emerging technologies are reshaping the landscape, with innovations such as contactless operation and zero-waste systems gaining traction. For instance, machines that use no-touch sensors for batter dispensing are appealing to businesses looking to minimize human contact, particularly in a post-pandemic world. Additionally, the integration of IoT capabilities allows for real-time monitoring of equipment performance, enabling predictive maintenance and reducing downtime.

Another trend is the shift towards customizable options. Buyers are increasingly interested in machines that can accommodate various batter types and dietary preferences, such as gluten-free or vegan options, thereby broadening their customer base. As international markets evolve, B2B buyers must stay attuned to these shifts, ensuring they source equipment that aligns with current consumer expectations and operational efficiencies.

How Is Sustainability and Ethical Sourcing Impacting the Automatic Pancake Maker Market?

Sustainability has become a pivotal consideration in the sourcing of automatic pancake makers. The environmental impact of manufacturing and operating these machines is under scrutiny, and buyers are now prioritizing vendors who demonstrate a commitment to sustainable practices. This includes the use of energy-efficient technologies and materials that minimize waste during production and operation.

Ethical supply chains are also gaining importance, as businesses recognize their role in promoting fair labor practices and responsible sourcing. Buyers should seek manufacturers that provide transparency about their supply chains and that hold certifications for sustainability, such as ISO 14001 or energy star ratings. Incorporating environmentally friendly materials, such as biodegradable or recyclable components, can further enhance a company’s brand reputation and appeal to increasingly eco-conscious consumers.

Moreover, adopting a circular economy approach—where products are designed for longevity, repairability, and recyclability—will be essential for B2B buyers looking to meet sustainability goals. By prioritizing these factors, businesses can not only reduce their environmental footprint but also resonate with consumers who are increasingly supporting brands with strong sustainability credentials.

What Is the Brief Evolution of Automatic Pancake Makers in the B2B Sector?

The evolution of automatic pancake makers can be traced back to the early 2000s when the first fully automated systems emerged, primarily for use in commercial settings such as hotels and restaurants. Initially, these machines focused on efficiency and ease of use, but as consumer preferences shifted, manufacturers began to innovate further.

By integrating features like contactless operation and customizable batter options, modern machines have become essential tools in the foodservice industry. This evolution reflects broader trends in the sector, where convenience, safety, and sustainability have become paramount. As the technology continues to advance, automatic pancake makers are poised to play an even more critical role in enhancing customer experiences and operational efficiencies in the B2B landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of automatic pancake maker

-

How do I choose the right automatic pancake maker for my business needs?

Selecting the right automatic pancake maker involves assessing your establishment’s volume of customers and specific operational requirements. Consider factors such as production speed, ease of use, maintenance needs, and portion control. Additionally, evaluate the machine’s footprint, as space constraints may influence your decision. Comparing models from various suppliers and requesting demonstrations can help you find the best fit for your establishment, whether it’s a hotel, restaurant, or cafeteria. -

What are the benefits of using an automatic pancake maker in a commercial setting?

Automatic pancake makers streamline breakfast service by producing consistent, high-quality pancakes quickly, often in under a minute. This efficiency reduces wait times and labor costs, freeing staff to focus on customer service. Furthermore, these machines minimize waste by dispensing exact portion sizes, ensuring cost-effectiveness. Their ease of use and low maintenance requirements also make them a valuable addition to any food service operation, enhancing guest satisfaction and operational efficiency. -

What is the minimum order quantity (MOQ) for purchasing an automatic pancake maker?

The MOQ for automatic pancake makers can vary significantly between manufacturers. Typically, suppliers may require a minimum purchase of one unit, but bulk purchases often come with discounts or favorable financing options. It’s advisable to consult with your chosen supplier to understand their specific terms. If you’re considering multiple machines, inquire about bulk pricing and potential shipping arrangements to optimize your investment. -

What payment terms should I expect when purchasing an automatic pancake maker?

Payment terms for automatic pancake makers vary by supplier and region. Common arrangements include upfront payments, payment upon delivery, or installment plans. Some suppliers may offer financing options, especially for larger purchases. When negotiating terms, clarify any additional costs such as shipping, taxes, or service fees. It’s also wise to review the supplier’s credit policies, particularly if you’re an international buyer, to ensure seamless transactions. -

How can I ensure quality assurance (QA) for my automatic pancake maker?

To ensure quality assurance, choose suppliers that provide detailed specifications, certifications, and warranties for their machines. Request samples or demonstrations to evaluate performance and reliability. Additionally, inquire about the supplier’s QA processes, including manufacturing standards and testing protocols. Establishing a clear communication channel for ongoing support and maintenance will also help ensure the equipment remains in optimal condition throughout its lifecycle. -

What logistics considerations should I keep in mind when importing an automatic pancake maker?

When importing an automatic pancake maker, consider logistics factors such as shipping costs, delivery times, and customs regulations in your country. Collaborate with a reliable freight forwarder who understands international shipping processes, including tariffs and import duties. Ensure the supplier provides all necessary documentation for customs clearance, and factor in potential delays that may arise during transit. Planning for these logistics will minimize disruptions and ensure timely delivery to your location. -

Can I customize the features of an automatic pancake maker to meet my specific needs?

Many manufacturers offer customization options for automatic pancake makers, allowing you to tailor features such as size, production speed, and design to fit your brand’s requirements. When discussing customization, be clear about your specific needs and how they align with your operational goals. It’s beneficial to work closely with the supplier during the design phase to ensure the final product meets your expectations and complies with local regulations. -

What kind of support can I expect after purchasing an automatic pancake maker?

Post-purchase support varies by supplier but often includes warranty coverage, technical assistance, and maintenance services. Look for suppliers that offer a comprehensive service program, including 24/7 customer support and access to trained technicians for troubleshooting. Regular maintenance schedules can also be arranged to ensure the machine operates efficiently. Establishing a good relationship with your supplier will facilitate prompt support when needed, enhancing the longevity of your equipment.

Top 6 Automatic Pancake Maker Manufacturers & Suppliers List

1. Popcake – Fully-Automatic Pancake Machine

Domain: popcake.com

Registered: 2002 (23 years)

Introduction: Popcake is the world’s first fully-automatic pancake machine designed for the food service industry. It offers hot, fresh, delicious pancakes in just one minute. The machine is safe, cool-to-the-touch, and low maintenance, making it ideal for hotels, airport lounges, buffets, and back-of-house operations. It features a no-touch hand wave sensor for convenience and is an easy-to-use, zero-waste bre…

2. Reddit – Automatic Pancake Dispenser

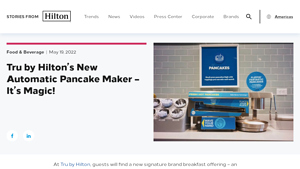

3. Tru by Hilton – Hands-Free Pancake Maker

Domain: stories.hilton.com

Registered: 1994 (31 years)

Introduction: Tru by Hilton offers a new automatic, hands-free pancake maker that creates golden-brown pancakes with the wave of a hand. This breakfast feature complements the existing make-your-own Belgian waffle machine at Hampton by Hilton.

4. Rick and Ann’s – Commercial Pancake Machine

Domain: rickandanns.com

Registered: 2002 (23 years)

Introduction: {“product_name”: “Commercial Pancake Machine”, “features”: {“display”: “Touch Screen”, “adjustable”: “Yes”}, “model_number”: “1012109”}

5. Automatic Pancake Maker – Commercial Gas Electric Pancake Pan

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“title”: “Automatic Pancake Maker Gas Electric Pancake Pan Commercial Pancake Maker”, “condition”: “New”, “price”: “$1,702.38”, “monthly_payment”: “$105.40/mo with Klarna”, “shipping_cost”: “$455.11”, “estimated_delivery”: “Fri, Sep 19 – Wed, Oct 15”, “dimensions”: [{“tabletop_diameter”: “54CM”, “height”: “1.8CM”}, {“tabletop_diameter”: “54CM”, “height”: “2.8CM”}, {“tabletop_diameter”: “54CM”, “h…

6. POPCAKE – Automatic Pancake Maker

Domain: manofmany.com

Registered: 2012 (13 years)

Introduction: Product Name: POPCAKE Automatic Pancake Maker

Sizes: Mini, Medium, Large pancakes

Cooking Features: Adjustable level of doneness, can also make turnovers, canapes, crepes, and more

Warm-up Time: 6 minutes

Production Rate: Can make a certain number of pancakes as programmed

Price: $3,700

Target Audience: Primarily for restaurants or food service, not intended for household use.

Strategic Sourcing Conclusion and Outlook for automatic pancake maker

As the global demand for efficient and high-quality food service solutions continues to rise, investing in automatic pancake makers presents a strategic opportunity for B2B buyers. These machines not only enhance customer satisfaction by delivering fresh, hot pancakes in seconds, but they also significantly reduce waste and streamline operations. With features like contactless operation and easy maintenance, businesses in sectors such as hospitality and catering can improve their service offerings while minimizing labor costs.

The strategic sourcing of automatic pancake makers should focus on reliable suppliers that provide comprehensive support and flexible purchasing options. This ensures that businesses can adapt to changing market conditions while maintaining high standards of service. By leveraging advanced technologies and innovative designs, companies can differentiate themselves in a competitive market, particularly in regions like Africa, South America, the Middle East, and Europe, where consumer preferences for convenience and quality are evolving rapidly.

Looking ahead, the automatic pancake maker is set to become a staple in breakfast offerings worldwide. Now is the time for international buyers to explore partnerships with leading manufacturers, ensuring they stay ahead of the curve in culinary innovation and customer satisfaction. Embrace the future of food service and invest in a solution that not only meets today’s demands but also anticipates tomorrow’s trends.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.