Amana Washer Agitator Parts: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for amana washer agitator parts

In the competitive landscape of appliance repair and maintenance, sourcing Amana washer agitator parts can pose significant challenges for international B2B buyers. Whether you’re operating in Africa, South America, the Middle East, or Europe, the task of finding authentic, high-quality components that meet specific model requirements demands a strategic approach. This comprehensive guide serves as an essential resource for navigating the complexities of sourcing Amana washer agitator parts, offering insights into various types, applications, and the critical factors for supplier vetting.

As you delve into this guide, you will discover a wealth of information on the different types of agitator components, from repair kits to individual parts, tailored to enhance the performance and longevity of Amana washers. We will also explore cost considerations, including how to balance quality with budget constraints, and provide actionable strategies for identifying reliable suppliers that can deliver authentic OEM parts efficiently.

By equipping you with the knowledge and tools necessary to make informed purchasing decisions, this guide empowers you to optimize your supply chain and ensure customer satisfaction. With a focus on actionable insights and practical advice, it addresses the unique challenges faced by B2B buyers across diverse markets, enabling you to confidently source the best Amana washer agitator parts for your business needs.

Understanding amana washer agitator parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Agitator Repair Kit | Includes various internal components like cogs and bearings | Appliance repair shops, wholesalers | Pros: Comprehensive solution for common agitator issues. Cons: Requires technical knowledge for installation. |

| Agitator Cam Kit | Contains a cam holder and individual cams | Retailers, service technicians | Pros: Essential for addressing agitation issues. Cons: Limited to specific models, requiring accurate identification. |

| Agitator Dogs | Small cogs that facilitate the movement of the agitator | Parts distributors, appliance repair shops | Pros: Cost-effective replacement for common failures. Cons: May require multiple units for full repair. |

| Agitator Assembly | Complete assembly including the agitator and necessary components | Large appliance retailers | Pros: Simplifies replacement process. Cons: Higher upfront cost compared to individual parts. |

| Drive Clutch Kit | Includes essential components for the drive mechanism | Appliance service centers, repair shops | Pros: Critical for proper operation of the washer. Cons: Installation can be complex, requiring skilled labor. |

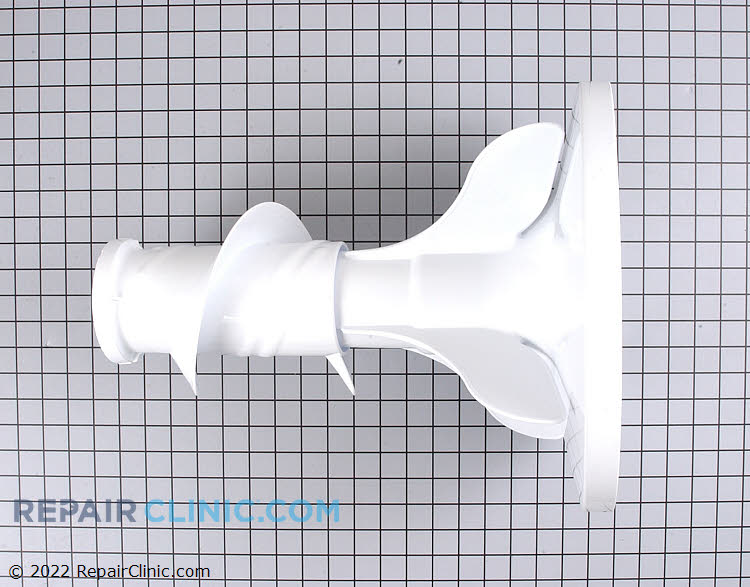

What Are the Key Characteristics of Agitator Repair Kits?

Agitator repair kits are designed to address common issues related to the agitator’s functionality. These kits typically include essential components such as cogs, bearings, and spacers, enabling the upper part of the agitator to move effectively. B2B buyers, especially those in appliance repair and service industries, find these kits valuable due to their comprehensive nature, allowing for efficient repairs without the need for complete unit replacements. It’s essential for buyers to consider the specific model compatibility to ensure optimal performance.

How Does the Agitator Cam Kit Benefit Appliance Service Providers?

The agitator cam kit is crucial for ensuring the agitator operates smoothly. It includes a cam holder and several individual cams that work together to facilitate the agitator’s movement. This kit is particularly beneficial for service technicians who encounter noisy or malfunctioning washers. When purchasing, businesses should ensure they have accurate model information, as compatibility is vital for effective repairs. The ease of installation makes it a preferred choice for quick service.

Why Are Agitator Dogs Important for Maintenance?

Agitator dogs are small yet vital components that ensure the agitator moves correctly during wash cycles. These cogs wear out over time, especially in high-use environments, making them a common replacement part. B2B buyers can benefit from stocking these components in their inventory due to their low cost and high turnover. However, businesses should be aware that multiple units may be necessary for a complete repair, depending on the agitator’s design.

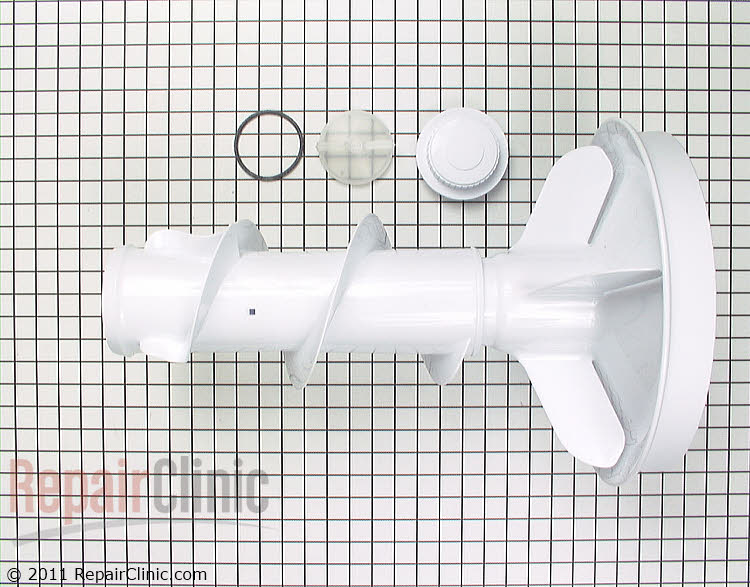

What Should Buyers Know About Complete Agitator Assemblies?

Complete agitator assemblies offer a one-stop solution for replacing worn-out agitators. These assemblies come with all necessary components, simplifying the replacement process for technicians. While the upfront cost may be higher than purchasing individual parts, the time saved during installation can justify the investment. B2B buyers in retail or service sectors should evaluate their inventory turnover rates when deciding whether to stock these complete assemblies.

How Does the Drive Clutch Kit Impact Washer Performance?

The drive clutch kit is critical for the washer’s operation, linking the motor to the agitator. It includes various components that must work together for the washer to function correctly. For service centers and repair shops, having these kits readily available can significantly reduce downtime for repairs. However, the complexity of installation may necessitate skilled labor, making it important for buyers to factor in labor costs when considering these kits.

Key Industrial Applications of amana washer agitator parts

| Industry/Sector | Specific Application of amana washer agitator parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Assembly line washing of textiles and uniforms | Ensures consistent cleaning quality, reducing rework | Need for bulk purchasing, compatibility with existing machinery |

| Hospitality | On-premises laundry operations in hotels and resorts | Enhances guest satisfaction by maintaining clean linens | Reliability and quick turnaround for parts to minimize downtime |

| Healthcare | Laundering of medical scrubs and linens in hospitals | Ensures hygiene compliance and operational efficiency | Certifications for hygiene standards and rapid availability of parts |

| Retail | Cleaning service for clothing and fabric in retail settings | Maintains fabric quality and extends product lifespan | Cost-effective sourcing and compatibility with various washer models |

| Construction | Washing of work uniforms and equipment covers | Improves worker safety and cleanliness | Durability of parts to withstand heavy usage and harsh conditions |

How Are Amana Washer Agitator Parts Used in the Manufacturing Sector?

In the manufacturing industry, especially in textile production, Amana washer agitator parts are crucial for the effective cleaning of uniforms and fabric materials. These parts ensure that washing machines function optimally, providing consistent cleaning results that prevent fabric damage and maintain quality standards. For international buyers, sourcing authentic OEM parts is essential to ensure compatibility with existing machinery and to avoid operational disruptions.

Illustrative image related to amana washer agitator parts

What Role Do Amana Washer Agitator Parts Play in the Hospitality Sector?

In hospitality, on-premises laundry operations rely heavily on Amana washer agitator parts to maintain high standards of cleanliness for linens and uniforms. These components help in the efficient washing of large loads, ensuring that guests receive impeccably clean bedding and towels. Buyers in this sector should prioritize sourcing reliable parts with quick delivery options to minimize downtime and maintain service quality.

Why Are Amana Washer Agitator Parts Essential in Healthcare?

Healthcare facilities utilize Amana washer agitator parts for laundering medical scrubs and linens, which must meet stringent hygiene standards. These parts facilitate effective washing cycles that eliminate contaminants, thus ensuring compliance with health regulations. International buyers in the healthcare sector should consider sourcing parts that come with certifications to guarantee hygiene compliance and ensure rapid availability to avoid operational delays.

How Do Amana Washer Agitator Parts Benefit Retail Cleaning Services?

In retail, cleaning services benefit from using Amana washer agitator parts to maintain the quality of clothing and fabric items. These components help ensure that washing machines operate efficiently, preventing damage to delicate fabrics and extending their lifespan. For B2B buyers in this sector, sourcing cost-effective and compatible parts is crucial to maintaining service quality while keeping operational costs low.

Illustrative image related to amana washer agitator parts

What Advantages Do Amana Washer Agitator Parts Offer in the Construction Industry?

In the construction industry, Amana washer agitator parts are vital for washing work uniforms and equipment covers, promoting cleanliness and safety among workers. These parts ensure that washing machines can handle the demands of heavy-duty cleaning, providing reliable performance. Buyers in this sector should focus on the durability of parts to withstand rigorous usage and harsh cleaning conditions, ensuring long-term operational efficiency.

3 Common User Pain Points for ‘amana washer agitator parts’ & Their Solutions

Scenario 1: Inconsistent Agitation Leading to Poor Cleaning Results

The Problem: B2B buyers, particularly in the laundry service industry, often face the issue of inconsistent agitation in Amana washers. This can lead to clothes not being cleaned properly, resulting in customer dissatisfaction and potential loss of business. The problem usually arises from worn-out agitator components, such as the agitator dogs or cam kit, which fail to engage the agitator effectively during the wash cycle. For businesses relying on efficient laundry operations, this is a critical pain point that directly affects their service quality.

The Solution: To address this issue, it is crucial for buyers to conduct regular maintenance checks and replace agitator components as needed. Sourcing authentic OEM parts, such as the Agitator Repair Kit (part #285811), can ensure that the agitator functions as intended. When replacing these parts, make sure to follow the manufacturer’s guidelines, including any specific installation instructions. For enhanced performance, consider using agitator grease during installation, as it helps reduce friction and prolongs the lifespan of the components. By proactively managing these repairs, businesses can maintain optimal washing conditions and improve customer satisfaction.

Scenario 2: Frequent Breakdowns Due to Low-Quality Replacement Parts

The Problem: Many B2B buyers in regions with limited access to genuine parts often resort to purchasing low-cost, generic replacement parts for Amana washers. These parts may seem like a budget-friendly option initially, but they often lead to frequent breakdowns and increased operational costs due to their inferior quality. This cycle not only disrupts service but can also damage the washer itself, leading to even higher repair expenses.

The Solution: To mitigate this risk, B2B buyers should prioritize sourcing genuine OEM parts from reputable suppliers. Investing in high-quality components ensures compatibility and durability, minimizing the likelihood of future breakdowns. Establishing a relationship with trusted suppliers who offer fast shipping and a wide range of Amana washer parts can streamline procurement processes. Additionally, creating a maintenance schedule that includes regular inspections of agitator parts can help identify issues before they escalate, thus ensuring uninterrupted service and long-term savings.

Scenario 3: Difficulty in Identifying the Correct Parts for Different Models

The Problem: Buyers often encounter challenges when trying to identify the right agitator parts for various Amana washer models, especially when dealing with multiple units. Misidentification can lead to ordering incorrect components, resulting in delays and additional costs associated with returns and reorders. This situation is particularly frustrating for businesses that need to maintain their equipment for smooth operations.

The Solution: To overcome this challenge, B2B buyers should leverage resources that provide detailed model information and part specifications. Utilizing online part lookup tools that allow users to search by model number can significantly reduce errors in ordering. Additionally, it is advisable to maintain a comprehensive inventory list of all washer models in use and their corresponding parts. Training staff to understand these specifications will also facilitate quicker decision-making when repairs are needed. By taking these proactive steps, businesses can streamline their parts procurement process, ensuring they have the correct agitator components on hand when required.

Strategic Material Selection Guide for amana washer agitator parts

What Are the Key Materials Used in Amana Washer Agitator Parts?

When selecting materials for Amana washer agitator parts, several factors must be considered, including performance, durability, and compliance with international standards. Below, we analyze four common materials used in these components, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Plastic Perform in Amana Washer Agitator Parts?

Plastic is widely used in various components of washer agitators, particularly for parts like the agitator dogs and cam kits.

Key Properties: Plastics, such as polypropylene and polycarbonate, offer excellent resistance to moisture and chemical corrosion, making them suitable for the wet environment of washing machines. They typically have a temperature rating of up to 100°C (212°F).

Pros & Cons: The primary advantage of plastic is its lightweight nature and low cost, which makes it economical for mass production. However, plastics may not withstand high mechanical stress as well as metals, leading to potential wear and tear over time.

Illustrative image related to amana washer agitator parts

Impact on Application: Plastic components are compatible with a wide range of detergents and fabric softeners, but they may degrade when exposed to certain solvents.

Considerations for International Buyers: Compliance with standards such as ASTM D638 for tensile strength and ISO 527 for plastic materials is crucial. Buyers should also consider local regulations regarding plastic use, particularly in regions with strict environmental laws.

What Role Does Steel Play in Amana Washer Agitator Parts?

Steel, particularly stainless steel, is often utilized for parts requiring higher strength and durability, such as the agitator shaft and drive components.

Key Properties: Stainless steel exhibits excellent corrosion resistance and can withstand high temperatures and pressures, making it ideal for the demanding conditions of washing machines.

Illustrative image related to amana washer agitator parts

Pros & Cons: The key advantage of steel is its durability and strength, which ensures a longer lifespan for components. However, the higher cost of steel compared to plastic and its susceptibility to rust if not properly treated can be significant drawbacks.

Impact on Application: Steel parts are compatible with a variety of washing media, including harsh chemicals, but they require proper maintenance to prevent corrosion.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM A240 for stainless steel. Additionally, understanding local market preferences for materials can influence sourcing decisions.

How Does Rubber Contribute to Amana Washer Agitator Parts?

Rubber is commonly used in seals, gaskets, and suspension components within agitator assemblies.

Key Properties: Rubber provides excellent elasticity and resilience, allowing it to absorb vibrations and prevent leaks. It typically has a temperature tolerance of around -30°C to 100°C (-22°F to 212°F).

Illustrative image related to amana washer agitator parts

Pros & Cons: The primary advantage of rubber is its ability to create airtight seals, which enhances the overall efficiency of the washing machine. However, rubber can degrade over time due to exposure to heat and certain chemicals, leading to potential failures.

Impact on Application: Rubber components are crucial for maintaining water integrity in the washer, but they must be selected based on compatibility with specific detergents and fabric softeners.

Considerations for International Buyers: Compliance with standards such as ASTM D2000 for rubber materials is essential. Buyers should also consider the availability of specific rubber grades in their local markets.

What Advantages Does Aluminum Offer for Amana Washer Agitator Parts?

Aluminum is sometimes used for lightweight components such as the agitator body and certain brackets.

Key Properties: Aluminum is lightweight yet strong, with good corrosion resistance, particularly when anodized. It can withstand moderate temperatures and pressures.

Illustrative image related to amana washer agitator parts

Pros & Cons: The main advantage of aluminum is its low weight, which reduces the overall weight of the washing machine, improving shipping and handling. However, aluminum may not provide the same level of strength as steel, which can be a limitation for high-stress applications.

Impact on Application: Aluminum parts are compatible with most washing media but can be susceptible to corrosion if not properly coated.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM B221 for aluminum extrusions. Additionally, understanding local preferences for lightweight materials can influence purchasing decisions.

Summary of Material Selection for Amana Washer Agitator Parts

| Material | Typical Use Case for amana washer agitator parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Agitator dogs, cam kits | Lightweight and low cost | Less durable under mechanical stress | Low |

| Steel | Agitator shafts, drive components | High strength and durability | Higher cost and rust susceptibility | High |

| Rubber | Seals and gaskets | Excellent sealing properties | Degrades over time with heat/chemicals | Medium |

| Aluminum | Agitator body, brackets | Lightweight and good corrosion resistance | Lower strength compared to steel | Medium |

This guide aims to provide actionable insights for international B2B buyers, helping them make informed decisions when selecting materials for Amana washer agitator parts.

In-depth Look: Manufacturing Processes and Quality Assurance for amana washer agitator parts

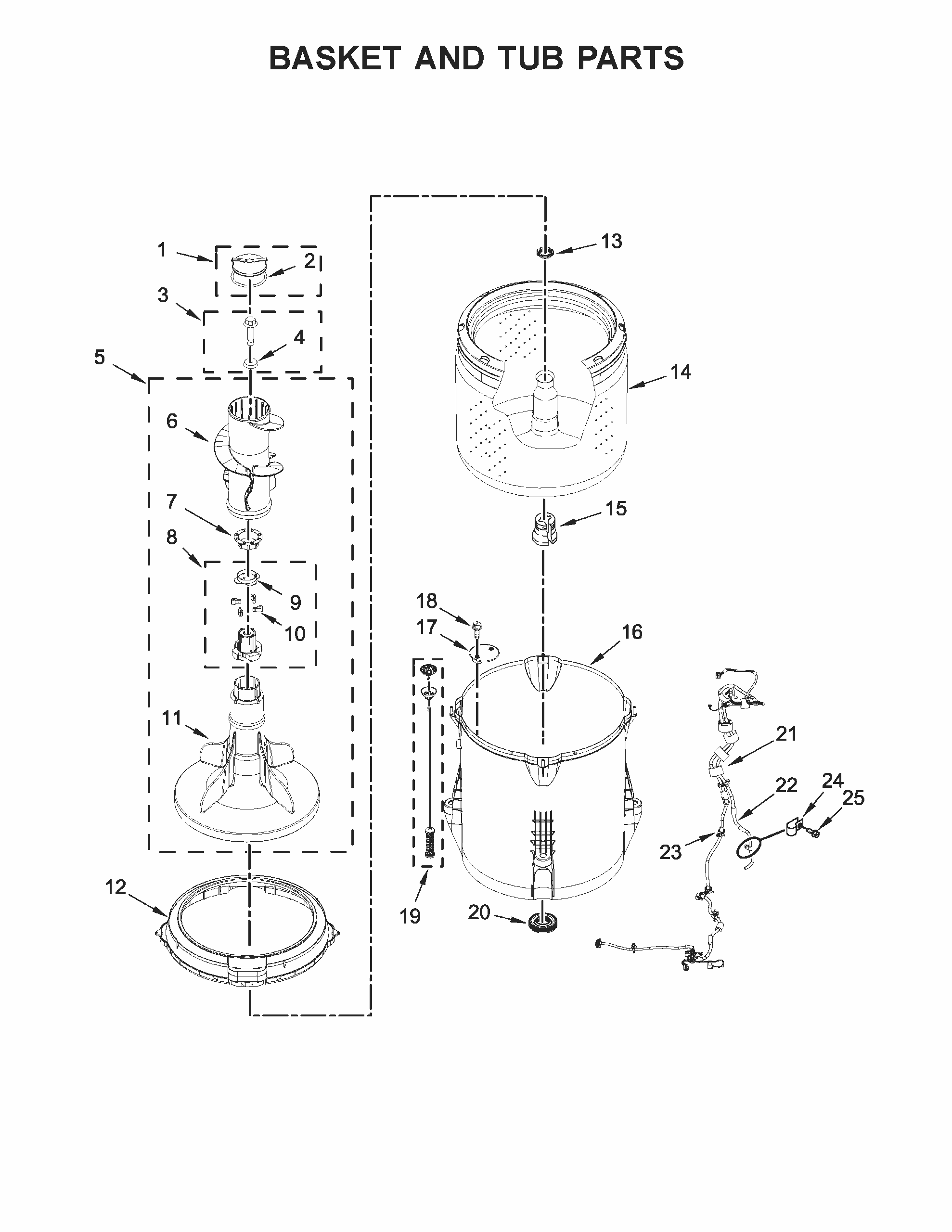

What Are the Main Stages of Manufacturing Amana Washer Agitator Parts?

The manufacturing process for Amana washer agitator parts involves several critical stages that ensure each component meets the required specifications for performance and durability. These stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Amana Washer Agitator Parts?

The first step in manufacturing involves sourcing high-quality raw materials. Typically, steel and plastic are the primary materials used for agitator components due to their strength and resilience. The materials undergo a thorough inspection to ensure they meet industry standards. This often includes checking for any defects or inconsistencies that could affect the final product’s performance.

Once the materials are approved, they are cut and shaped into the necessary dimensions. This can involve techniques such as machining, where parts are shaped using tools, or molding, particularly for plastic components. The preparation stage is crucial, as any errors here can lead to inefficiencies in the subsequent manufacturing processes.

Illustrative image related to amana washer agitator parts

What Techniques Are Used in the Forming Process?

The forming process is where raw materials are transformed into specific agitator parts. For metal components, techniques like stamping, forging, or extrusion are commonly used. These methods allow for the mass production of precise parts that fit together seamlessly.

For plastic parts, injection molding is often employed. This technique involves injecting molten plastic into a mold, where it cools and solidifies into the desired shape. The choice of technique is critical and is influenced by the part’s complexity, volume, and required tolerances.

How Are Amana Washer Agitator Parts Assembled?

After individual components are manufactured, they move to the assembly stage. This process involves combining various parts, such as gears, cogs, and seals, to create the final agitator assembly. Skilled workers or automated systems carefully fit these components together, ensuring that they function correctly when the washer operates.

Quality control is integral during assembly; each unit is tested for fit and function to prevent downstream issues. Any discrepancies or defects identified during assembly can be addressed immediately, reducing waste and ensuring high standards are maintained.

What Finishing Techniques Are Applied to Amana Washer Agitator Parts?

Finishing processes enhance the durability and aesthetic appeal of the agitator parts. These techniques can include surface treatments such as painting, coating, or galvanizing, which protect against corrosion and wear. The final inspection checks for surface imperfections and ensures that all specifications are met.

Moreover, parts may undergo additional testing to evaluate their performance under simulated conditions. This is crucial for ensuring that the agitators will function optimally within the washer, providing reliable and efficient service to end-users.

Illustrative image related to amana washer agitator parts

What Quality Assurance Measures Are in Place for Amana Washer Agitator Parts?

Quality assurance (QA) is paramount in the manufacturing of Amana washer agitator parts. This process involves several checkpoints and standards that help maintain product integrity.

Which International Standards Are Relevant for Quality Assurance?

Manufacturers of Amana washer agitator parts typically adhere to international quality standards such as ISO 9001. This certification indicates that a company maintains a robust quality management system that emphasizes continuous improvement and customer satisfaction. Additionally, compliance with CE marking requirements ensures that products meet European health, safety, and environmental protection standards.

For certain components, adherence to industry-specific standards such as those set by the American Petroleum Institute (API) may be necessary, especially when parts are designed for heavy-duty applications.

What Are the Key Quality Control Checkpoints?

Quality control involves multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial inspection verifies the quality of raw materials before they enter the production line.

- In-Process Quality Control (IPQC): During manufacturing, random samples are tested to ensure that processes are functioning correctly and that parts meet specifications.

- Final Quality Control (FQC): After assembly, each agitator part undergoes a comprehensive inspection to confirm it meets all quality standards before shipping.

These checkpoints help to minimize defects and ensure that only high-quality products reach the market.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control processes of their suppliers. Conducting audits is one effective method. These audits can assess whether the supplier adheres to international standards and practices.

Additionally, requesting quality reports and certifications can provide insights into the supplier’s commitment to quality. Third-party inspections can also serve as a valuable resource, ensuring that independent evaluators verify the quality of products before they are shipped.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is essential. Different regions may have varying regulatory requirements and expectations regarding product quality.

Buyers should familiarize themselves with local standards and certifications that may apply to imported goods. Establishing a clear communication channel with suppliers regarding these requirements can help mitigate misunderstandings and ensure compliance.

Additionally, understanding the supply chain dynamics in these regions can provide insights into potential challenges related to quality assurance. For instance, logistical issues may affect the timely delivery of quality parts, making it crucial for buyers to establish reliable partnerships with suppliers who have proven track records in quality management.

Conclusion

The manufacturing processes and quality assurance for Amana washer agitator parts are intricate and rigorous, designed to ensure that each component meets high performance and durability standards. By understanding these processes, B2B buyers can make informed decisions when sourcing parts, ensuring they partner with suppliers committed to quality and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘amana washer agitator parts’

This guide aims to provide B2B buyers with a comprehensive checklist for sourcing Amana washer agitator parts. By following these steps, you can ensure that your procurement process is efficient, cost-effective, and aligned with your technical requirements.

Step 1: Define Your Technical Specifications

Before you start sourcing, it’s essential to clarify the specific parts you need for the Amana washers. Determine the model numbers and any unique requirements that may affect compatibility, such as the agitator type or repair kits necessary for your operations. This clarity will streamline your search and help avoid costly errors in ordering.

Step 2: Research Reliable Suppliers

Invest time in identifying reputable suppliers that specialize in Amana washer parts. Look for distributors that have a strong track record and positive reviews from other B2B buyers. Assess their reputation in the market by checking their online presence, including their website and social media profiles.

- Key Considerations:

- Supplier longevity in the industry

- Customer testimonials and case studies

- Availability of OEM parts versus generic alternatives

Step 3: Evaluate Potential Suppliers

Before committing to any supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This due diligence will help you gauge their reliability and service quality.

- What to Look For:

- Certifications and compliance with international standards

- Responsiveness and customer service approach

- Return policy and warranty terms

Step 4: Assess Inventory and Lead Times

Once you have shortlisted suppliers, inquire about their inventory levels and lead times for Amana washer agitator parts. Understanding their ability to fulfill orders promptly is crucial for maintaining your supply chain efficiency.

- Important Factors:

- Availability of key components (e.g., agitator repair kits)

- Shipping options and timelines

- Minimum order quantities and bulk pricing discounts

Step 5: Compare Pricing and Terms

Gather quotes from multiple suppliers to compare pricing structures. Look beyond the base price; consider additional costs such as shipping, handling, and potential customs duties, especially for international transactions.

- Pricing Factors to Consider:

- Payment terms (e.g., upfront payment versus net terms)

- Discounts for bulk purchases

- Hidden fees or additional costs

Step 6: Conduct a Quality Check

Before finalizing your order, ensure that the parts meet the required quality standards. Request samples if possible, or check if the supplier provides quality assurance documentation for the agitator parts.

- Quality Assurance:

- OEM certifications for authenticity

- Testing reports or guarantees of durability

- Compatibility confirmations for specific washer models

Step 7: Establish a Communication Plan

After placing your order, maintain open communication with your supplier. Regular updates regarding your order status can prevent misunderstandings and ensure timely deliveries.

- Best Practices:

- Schedule periodic check-ins or updates

- Document all communications for future reference

- Set clear expectations regarding response times and issue resolution processes

By following this structured checklist, B2B buyers can navigate the complexities of sourcing Amana washer agitator parts with confidence and efficiency.

Comprehensive Cost and Pricing Analysis for amana washer agitator parts Sourcing

When sourcing Amana washer agitator parts, understanding the cost structure is crucial for international B2B buyers. The overall cost is influenced by various components, including materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s margin.

What Are the Key Cost Components for Amana Washer Agitator Parts?

-

Materials: The primary materials used in agitator parts include high-grade plastics and metals designed for durability and resistance to wear. The quality of these materials directly impacts the performance and longevity of the parts.

-

Labor: Labor costs vary significantly based on the region of production. Countries with lower labor costs can offer competitive pricing, while regions with higher wages may reflect those costs in the final product price.

-

Manufacturing Overhead: This includes costs associated with production facilities, utilities, and administrative expenses. Efficient manufacturing processes can reduce these overhead costs, benefiting both suppliers and buyers.

-

Tooling: Custom tooling can add significant costs, especially if specific designs or adaptations are required. Buyers should consider whether standard parts meet their needs or if customization is necessary.

-

Quality Control (QC): Rigorous QC processes ensure that parts meet specifications and standards. The associated costs can vary depending on the supplier’s commitment to quality, impacting the final pricing.

-

Logistics: Shipping costs, including freight and handling fees, play a significant role, especially for international shipments. Factors like distance, transportation mode, and local regulations can influence these costs.

-

Margin: Suppliers typically add a margin to cover their costs and generate profit. Understanding the competitive landscape can help buyers gauge whether the pricing is reasonable.

How Do Price Influencers Affect Amana Washer Agitator Parts Sourcing?

Several factors influence the pricing of Amana washer agitator parts:

-

Volume/MOQ: Larger orders often qualify for bulk pricing discounts. Buyers should assess their needs to determine if they can meet minimum order quantities (MOQs) for better pricing.

-

Specifications/Customization: Custom specifications can lead to higher costs due to additional tooling and production complexities. Buyers should weigh the necessity of customization against budget constraints.

-

Materials and Quality Certifications: Parts made from superior materials or those that come with quality certifications (ISO, CE) may carry a premium price. Buyers should evaluate the trade-off between cost and quality.

-

Supplier Factors: Established suppliers with a reputation for quality may charge more than lesser-known suppliers. However, the risk of poor-quality parts may outweigh the initial savings.

-

Incoterms: Understanding shipping terms is critical. Different Incoterms (e.g., FOB, CIF) can affect the total cost of acquisition, as they dictate who is responsible for shipping and insurance costs.

What Are the Best Buyer Tips for Cost-Efficiency in International Sourcing?

-

Negotiate: Always negotiate prices and terms. Suppliers may have room for adjustment, especially on larger orders or long-term contracts.

-

Assess Total Cost of Ownership (TCO): Consider all costs involved, including purchase price, shipping, potential tariffs, and costs related to quality issues. A lower upfront price may lead to higher TCO if quality is compromised.

-

Understand Pricing Nuances for International Markets: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of local market conditions, currency fluctuations, and regulatory requirements that can impact pricing.

-

Research Local Suppliers: Local suppliers may reduce logistics costs and provide better support for warranty and service issues. Building relationships with local distributors can be advantageous.

-

Evaluate Supplier Reliability: Before finalizing a purchase, assess supplier reliability through references, reviews, and past performance. This can help mitigate risks associated with sourcing.

Conclusion

Sourcing Amana washer agitator parts involves navigating a complex cost structure influenced by various components and price influencers. By understanding these dynamics and employing strategic sourcing practices, international B2B buyers can optimize their procurement processes and ensure they receive the best value for their investments. Note that the prices mentioned in various sources are indicative and may vary based on specific sourcing conditions.

Alternatives Analysis: Comparing amana washer agitator parts With Other Solutions

Introduction to Alternative Solutions for Amana Washer Agitator Parts

In the competitive landscape of appliance repair and maintenance, B2B buyers must evaluate various solutions to ensure optimal performance and cost-effectiveness. When it comes to Amana washer agitator parts, it is essential to consider alternatives that can deliver similar or enhanced functionality. This analysis will compare Amana washer agitator parts with alternative solutions, focusing on performance, cost, ease of implementation, maintenance, and best use cases.

Comparison Table

| Comparison Aspect | Amana Washer Agitator Parts | Alternative 1: Universal Washer Agitator Parts | Alternative 2: High-Efficiency Washing Machines |

|---|---|---|---|

| Performance | Designed for specific models, ensuring optimal fit and function. | Variable performance; may not fit all models perfectly. | Superior cleaning efficiency and energy savings. |

| Cost | Generally affordable; OEM parts range from $3.20 to $145.23. | Typically lower cost but can vary widely. | Higher initial investment, but long-term savings on energy and water. |

| Ease of Implementation | Straightforward installation with model-specific instructions. | May require additional adjustments during installation. | Requires more complex setup; professional installation recommended. |

| Maintenance | Regular maintenance needed; OEM quality ensures durability. | Maintenance frequency varies based on quality; some parts may wear quickly. | Minimal maintenance; self-cleaning features reduce upkeep. |

| Best Use Case | Ideal for Amana washer repairs, ensuring original performance. | Suitable for budget-conscious buyers with non-specific needs. | Best for users seeking long-term efficiency and modern features. |

Detailed Breakdown of Alternatives

Alternative 1: Universal Washer Agitator Parts

Universal agitator parts offer a cost-effective solution for various washer brands, including Amana. These parts can be a viable option for repair shops servicing multiple brands, as they provide flexibility in inventory management. However, the performance may be inconsistent, as these parts might not fit all models perfectly, leading to potential issues during installation or operation. While they are generally more affordable, buyers must consider the trade-off between cost and compatibility.

Alternative 2: High-Efficiency Washing Machines

Investing in high-efficiency washing machines represents a significant shift from traditional agitator-based systems. These machines utilize advanced technologies that provide superior cleaning power while using less water and energy. Although the initial investment is higher, the long-term savings on utility bills and reduced environmental impact make them an attractive option. However, the complexity of installation and potential need for professional services can be a downside for some businesses. Moreover, transitioning to these machines means moving away from the traditional agitator parts, which may require retraining staff on new systems.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the right solution for washing machine repairs, B2B buyers should consider their specific needs, budget constraints, and operational goals. Amana washer agitator parts offer reliable performance and a perfect fit for Amana machines, making them the best choice for direct replacements. However, for businesses aiming to reduce costs or service multiple brands, universal parts may be a suitable alternative, albeit with potential compatibility risks. On the other hand, investing in high-efficiency washing machines could lead to significant long-term savings and improved performance, albeit at a higher upfront cost and complexity. Ultimately, understanding the unique requirements of your business will guide you in making an informed decision that balances cost, performance, and efficiency.

Essential Technical Properties and Trade Terminology for amana washer agitator parts

What Are the Key Technical Properties of Amana Washer Agitator Parts?

Understanding the essential technical properties of Amana washer agitator parts is crucial for international B2B buyers. These specifications not only affect the performance and durability of the parts but also influence purchasing decisions and inventory management.

-

Material Grade: Most Amana agitator parts are constructed from high-grade materials such as reinforced plastics or stainless steel. The material choice impacts the part’s resistance to corrosion, wear, and heat, which is particularly important in regions with high humidity or temperature fluctuations. Buyers should prioritize parts made from durable materials to ensure longevity and reliability.

-

Tolerance: This refers to the allowable variation in dimensions for parts, which is critical for ensuring proper fit and function. For example, a tolerance of ±0.01 mm may be specified for certain components. Inaccurate tolerances can lead to improper assembly or malfunction, making it essential for buyers to confirm that suppliers adhere to these specifications to maintain operational efficiency.

-

Load Capacity: This specification indicates the maximum weight or force that a part can withstand during operation. For instance, an agitator assembly must effectively handle the weight of wet laundry without failure. Understanding load capacities helps buyers select parts that will not only perform as expected but also minimize the risk of breakdowns and service calls.

-

Compatibility: Many parts are designed to fit specific Amana washer models, and compatibility is a critical factor for buyers. Knowing the exact model number and the associated parts ensures that the right components are sourced, reducing the likelihood of returns and increasing customer satisfaction.

-

Lifecycle: This property refers to the expected operational lifespan of the part. A longer lifecycle reduces the frequency of replacements, which is particularly advantageous for businesses managing large volumes of laundry equipment. Buyers should inquire about the lifecycle of parts to assess total cost of ownership effectively.

-

Performance Ratings: Performance ratings, such as energy efficiency or noise levels, provide insights into how well the part functions under various conditions. High-performance ratings can lead to lower operational costs and improved customer satisfaction, making them an important consideration for B2B buyers.

What Are Common Trade Terms Used in Amana Washer Agitator Parts?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B marketplace. Here are several key terms that buyers should understand:

-

OEM (Original Equipment Manufacturer): This term refers to parts made by the original manufacturer of the appliance, ensuring compatibility and quality. OEM parts often come with warranties, making them a preferred choice for businesses focused on reliability.

-

MOQ (Minimum Order Quantity): MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for inventory planning, especially for businesses that may not require large quantities of parts at once.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to request pricing and availability for specific parts. Submitting an RFQ allows buyers to compare offers and negotiate better terms, which can lead to cost savings.

-

Incoterms (International Commercial Terms): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping responsibilities, insurance, and customs clearance, ensuring smoother logistics.

-

Lead Time: This term indicates the time it takes for a supplier to fulfill an order from the moment it is placed until it is delivered. Knowing lead times aids in planning and helps businesses manage inventory levels effectively.

-

Warranty: A warranty is a guarantee provided by the manufacturer regarding the quality and performance of a part. Understanding warranty terms is essential for managing risk, as it can provide assurance regarding the product’s reliability and longevity.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing Amana washer agitator parts, ultimately leading to improved operational efficiency and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the amana washer agitator parts Sector

What Are the Key Trends Shaping the Amana Washer Agitator Parts Market?

The global market for Amana washer agitator parts is witnessing significant changes driven by various factors. One of the primary drivers is the increasing demand for durable and reliable appliance components, particularly in regions like Africa, South America, the Middle East, and Europe. These regions are experiencing a surge in appliance ownership, which directly correlates with the need for quality replacement parts. Furthermore, the rise of e-commerce platforms has made sourcing these components easier for international buyers, allowing them to access a broader range of products at competitive prices.

Emerging technologies are also reshaping the sourcing landscape. Innovations such as artificial intelligence and machine learning are being utilized to enhance inventory management and streamline supply chain processes. Additionally, the adoption of digital platforms for B2B transactions is growing, enabling buyers to quickly compare suppliers and products, thus improving decision-making efficiency.

Market dynamics are also shifting as manufacturers increasingly focus on producing OEM (Original Equipment Manufacturer) parts. This trend is fueled by a growing awareness of the importance of quality and compatibility in replacement parts, as businesses seek to minimize downtime and enhance customer satisfaction. As such, sourcing strategies are evolving, with buyers prioritizing suppliers who can provide authentic OEM parts and demonstrate a commitment to quality and service.

How Does Sustainability Influence Sourcing Decisions in the Amana Washer Agitator Parts Sector?

Sustainability is becoming an essential consideration for B2B buyers in the Amana washer agitator parts sector. The environmental impact of manufacturing and distributing appliance parts has prompted businesses to seek suppliers who adhere to sustainable practices. This includes using recyclable materials, reducing waste in production processes, and minimizing carbon footprints throughout the supply chain.

The importance of ethical sourcing cannot be overstated, as consumers and businesses alike are increasingly prioritizing suppliers who demonstrate social responsibility. Certifications such as ISO 14001 for environmental management and Fair Trade certification are gaining traction among buyers looking to ensure that their sourcing practices align with global sustainability standards. For example, suppliers who utilize green materials in the manufacturing of agitator parts not only meet regulatory requirements but also appeal to environmentally conscious buyers.

Moreover, businesses are beginning to recognize that sustainable practices can lead to cost savings in the long term. By investing in energy-efficient production methods and sustainable materials, suppliers can reduce operational costs, which can be passed on to buyers in the form of competitive pricing. As the focus on sustainability continues to grow, B2B buyers will need to incorporate these considerations into their sourcing strategies to remain competitive in the market.

What Is the Historical Context of the Amana Washer Agitator Parts Industry?

The Amana washer agitator parts industry has evolved significantly since the inception of washing machines in the mid-20th century. Initially, appliance parts were primarily manufactured locally, with limited options available for international sourcing. As technology advanced and global trade became more prevalent, the market for replacement parts began to expand.

By the late 20th century, the introduction of OEM parts marked a turning point in the industry. Manufacturers recognized the need for high-quality, compatible parts that could meet the evolving demands of consumers. This shift not only improved the reliability of washing machines but also fostered the development of a robust aftermarket for replacement parts.

Today, the market is characterized by a diverse range of suppliers, including both OEM and aftermarket manufacturers, catering to a global customer base. The rise of digital platforms has further transformed the industry, enabling international buyers to easily access a wide array of Amana washer agitator parts, thus enhancing competition and driving innovation. As the market continues to grow and evolve, understanding its historical context will be crucial for B2B buyers looking to navigate current trends and make informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of amana washer agitator parts

-

How do I solve issues with my Amana washer not agitating?

To troubleshoot agitation problems in your Amana washer, start by checking the agitator assembly for any signs of wear or damage, particularly the agitator dogs and cam. If the top part isn’t moving, it may indicate a need for an agitator repair kit. Ensure that the washer is not overloaded, as excessive weight can hinder performance. Additionally, inspect the drive belt and motor coupler for any faults. If these components are intact, consider contacting a qualified technician for further diagnosis. -

What is the best agitator repair kit for my Amana washer?

The best agitator repair kit for your Amana washer will depend on your model and the specific issues you are encountering. For models where the top part of the agitator isn’t moving, the OEM Agitator Repair Kit (part number 285811) is highly recommended. It includes essential components like directional cogs and a thrust spacer. Always verify compatibility with your washer’s model number before purchasing to ensure optimal performance. -

What are the minimum order quantities (MOQ) for Amana washer agitator parts?

Minimum order quantities for Amana washer agitator parts can vary by supplier. Typically, B2B suppliers may set an MOQ ranging from 10 to 100 units, depending on the part and demand. When sourcing internationally, consider negotiating MOQs, especially if you are looking for specific parts or if your order volume is lower. Establishing a good relationship with your supplier can often lead to more favorable terms. -

How can I vet suppliers for Amana washer agitator parts?

Vetting suppliers involves several steps: check their certifications to ensure they are authorized distributors of OEM parts, review customer testimonials, and analyze their track record for quality and delivery times. It’s also beneficial to request samples of the parts to assess quality before placing a larger order. Additionally, consider suppliers with established logistics networks, especially for international shipping, to minimize delays and costs. -

What payment terms should I expect when sourcing Amana washer parts internationally?

Payment terms can vary significantly based on the supplier and the nature of the transaction. Common practices include advance payments, letters of credit, or payment upon delivery. It’s important to clarify these terms before finalizing any agreement. Additionally, ensure that the payment methods are secure and that the supplier has a clear return and refund policy in place for defective parts. -

How do I ensure quality assurance (QA) for parts I purchase?

To ensure quality assurance for the Amana washer agitator parts you purchase, request detailed quality control processes from your supplier. Look for suppliers who provide warranties or guarantees on their parts. It’s also advisable to conduct periodic inspections of shipments to ensure they meet your specifications. Collaborating with suppliers who have ISO certifications or adhere to recognized quality standards can further enhance your confidence in the products. -

What are the best practices for shipping Amana washer parts internationally?

When shipping Amana washer parts internationally, it’s crucial to select a reliable logistics partner with experience in handling appliance parts. Ensure that the supplier uses appropriate packaging to protect parts during transit. Be aware of customs regulations and tariffs in the destination country to avoid unexpected delays or costs. It’s also wise to track shipments and maintain communication with your logistics provider for timely updates. -

Can I customize Amana washer agitator parts for specific needs?

Customization options for Amana washer agitator parts depend on the manufacturer and supplier capabilities. Some suppliers may offer bespoke solutions or modifications for specific requirements, such as size or material changes. Discuss your needs with potential suppliers to explore available customization services. Keep in mind that custom orders may have higher costs and longer lead times, so plan accordingly.

Top 5 Amana Washer Agitator Parts Manufacturers & Suppliers List

1. Whirlpool – Washer Lower Agitator

Domain: reliableparts.com

Registered: 1996 (29 years)

Introduction: 1. Product Name: Washer Lower Agitator

– Part #: WP3951632

– Price: $86.01 (Regular Price: $95.57)

– Description: High-quality lower agitator for select Whirlpool models and compatible brands. Ensures optimal agitation for thorough cleaning.

– Installation: Straightforward, suitable for DIYers.

2. Product Name: Washer Agitator

– Part #: W10908289

– Price: $72.85 (R…

2. Amana – Washing Machine Parts

Domain: appliancerepair.homedepot.com

Registered: 1992 (33 years)

Introduction: Amana Washing Machine Parts | Ships Today! 365-Day Returns. Common Problems: Washer beeping/alarm sounding, clothes still wet at end of cycle, controls not working, damaging clothes, dispenser not working, door/lid won’t lock/unlock, filling when not in use, filling and draining at same time, burning smell, loud noise, unbalanced, leaking water, lights flashing, not filling properly, not washing/c…

3. OEM – Agitator Repair Kit

Domain: fix.com

Registered: 1995 (30 years)

Introduction: [{‘name’: ‘Agitator Repair Kit’, ‘price’: ‘$20.89’, ‘in_stock’: ‘In Stock’, ‘fix_number’: ‘FIX334650’, ‘manufacturer_part_number’: ‘285811’, ‘description’: ‘This is an OEM agitator repair kit that includes an agitator cam, four directional cogs, a bearing, thrust spacer, inner cap seal, and washer. Used when the top portion of the agitator is not moving correctly but the bottom part is.’, ‘symptom…

4. Amana – NTW4516FW Washer Agitator Repair

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Amana washer, model ntw4516fw, agitator not spinning. Issue identified: motor and transmission are functioning, but agitator may have a stripped block. Suggested repair kit part number: 285811, available for $10 on Amazon. User resolved issue by tightening the bolt, which may have been affected by a degrading rubber washer.

5. Amana – Washer Agitator Repair Kit

Domain: partselect.com

Registered: 1999 (26 years)

Introduction: Amana Washer Agitators | OEM Replacement Parts – PartSelect.com

1. Amana Washer Agitator Repair Kit

– Price: $20.89

– PartSelect Number: PS334650

– Manufacturer Part Number: 285811

– Description: Used to repair the agitator, includes an agitator cam, 4 directional cogs, a bearing, thrust spacer, inner cap seal, and a washer. Constructed of plastic and rubber, available in black/white….

Strategic Sourcing Conclusion and Outlook for amana washer agitator parts

In navigating the strategic sourcing landscape for Amana washer agitator parts, international buyers can unlock significant advantages. Understanding the diverse range of OEM parts available, such as agitator repair kits and essential components, is crucial for ensuring optimal performance and longevity of appliances. By prioritizing genuine parts, businesses not only enhance operational efficiency but also foster customer satisfaction through reliable service.

Strategic sourcing empowers buyers to establish robust relationships with reputable suppliers, ensuring access to high-quality components while optimizing costs. This approach mitigates risks associated with counterfeit products and enhances supply chain resilience, particularly in emerging markets across Africa, South America, the Middle East, and Europe.

Looking ahead, the demand for reliable appliance parts will continue to grow, driven by an increase in consumer expectations and technological advancements in washing machines. We encourage international B2B buyers to proactively engage with suppliers and invest in inventory that meets these evolving needs. By doing so, businesses will position themselves to capitalize on emerging opportunities and drive sustainable growth in their markets.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.