Aluminum Trimming Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for aluminum trimming

In the ever-evolving landscape of global trade, sourcing aluminum trimming presents unique challenges for international B2B buyers. With the diverse applications ranging from construction to automotive industries, understanding the nuances of this market is essential for making informed purchasing decisions. This guide aims to illuminate the complexities involved in sourcing aluminum trim products, including various types, their applications, supplier vetting processes, and pricing strategies.

As buyers from regions like Africa, South America, the Middle East, and Europe—including key markets such as Brazil and Nigeria—navigate this intricate marketplace, having access to reliable information becomes paramount. This comprehensive resource empowers businesses to streamline their procurement processes, ensuring they partner with reputable suppliers who can meet their specific needs. Moreover, it highlights best practices in evaluating product quality and cost-effectiveness, enabling buyers to negotiate favorable terms and avoid common pitfalls.

By addressing critical aspects of the aluminum trimming market, this guide serves as a valuable tool for B2B buyers seeking to enhance their competitive edge. Whether you are looking for extruded shapes for architectural projects or specialized trims for manufacturing, understanding the landscape will position your business for success in the global market.

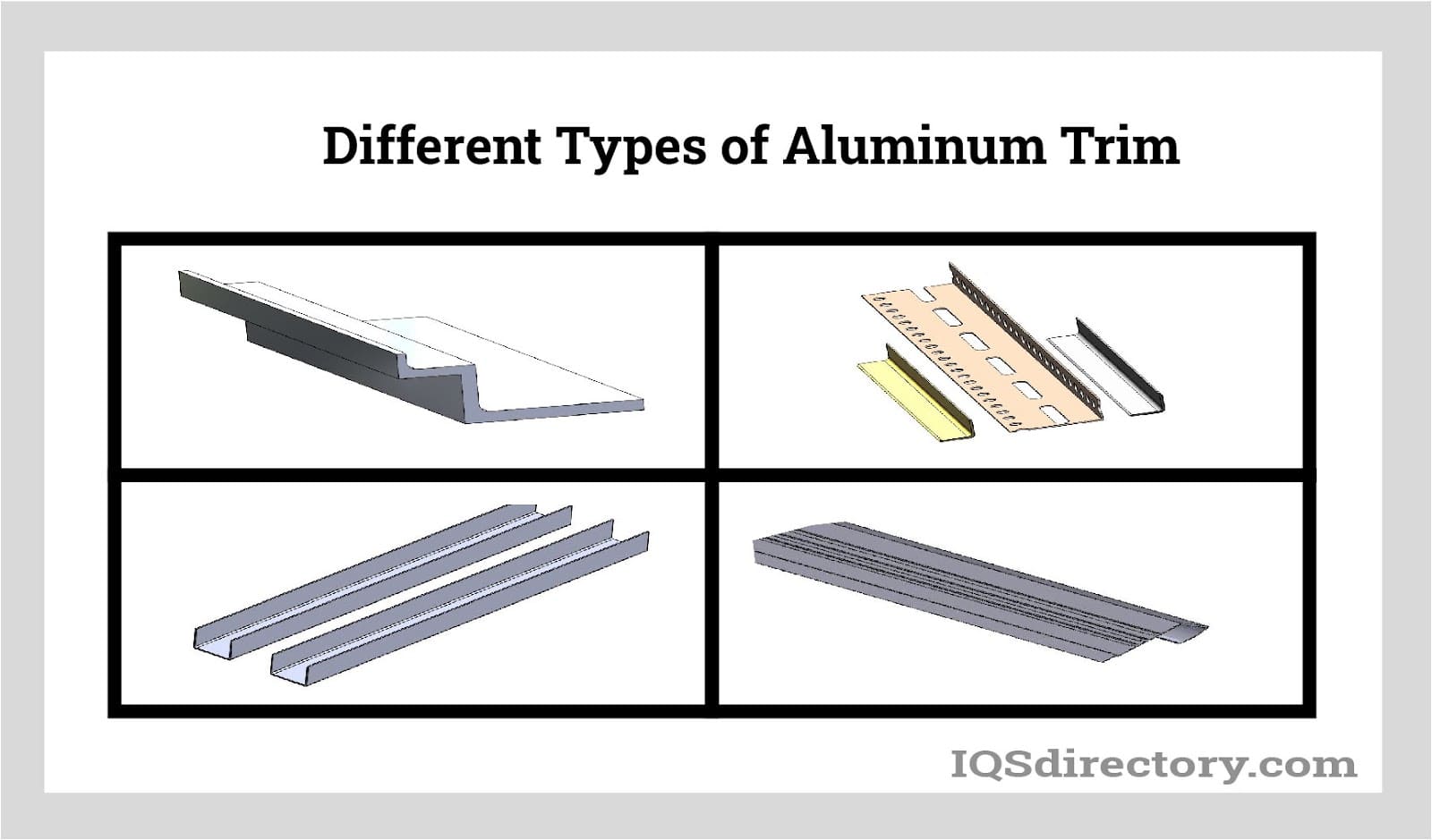

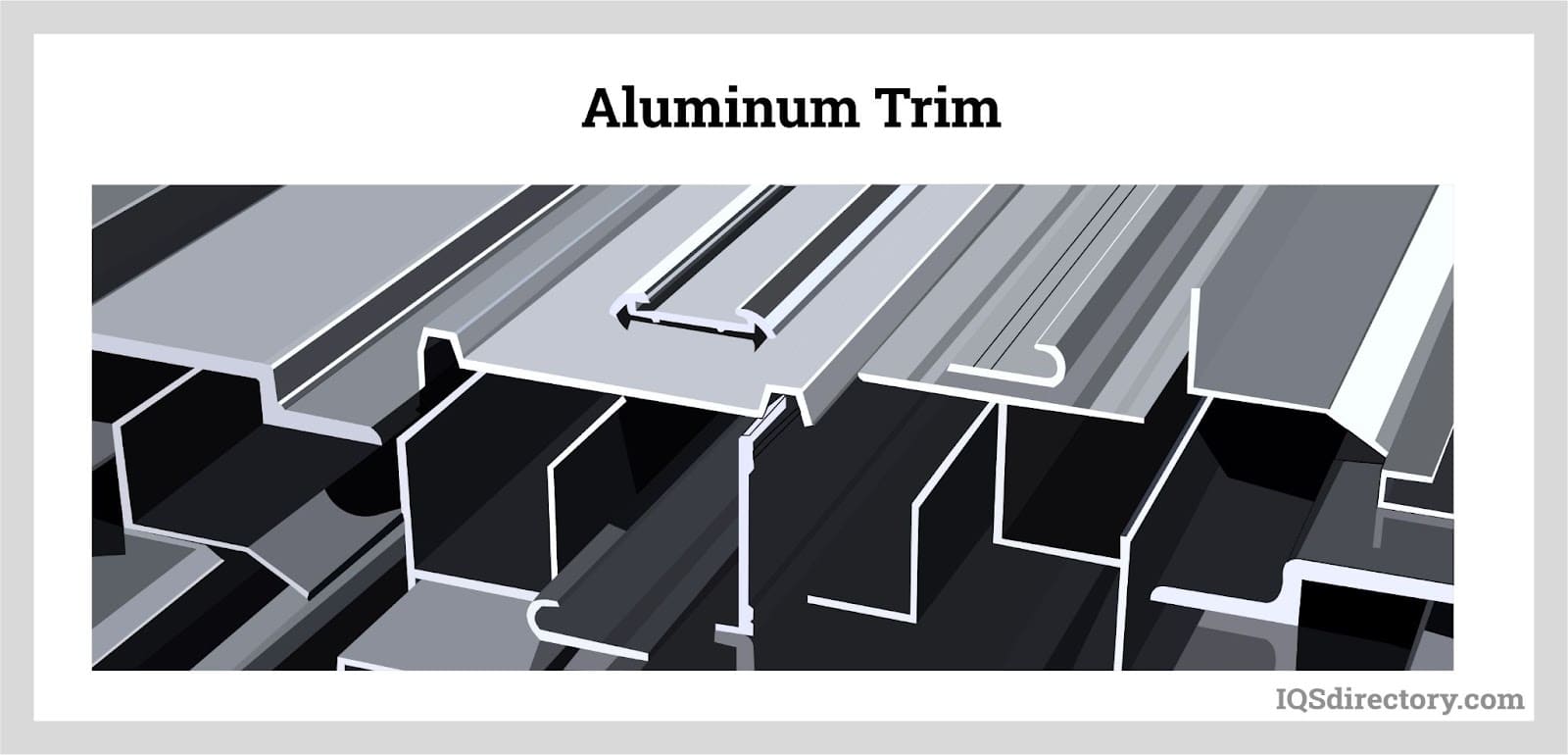

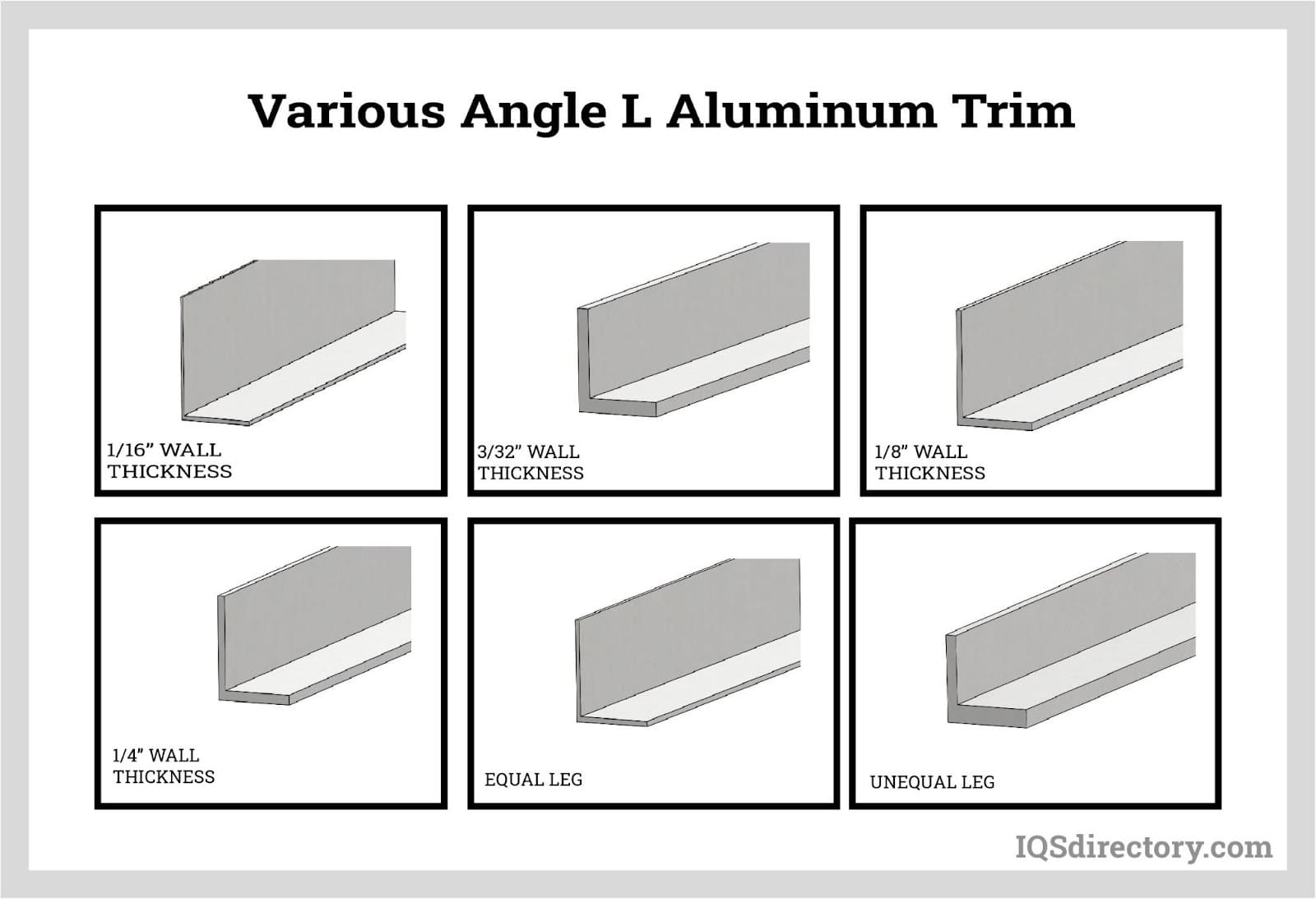

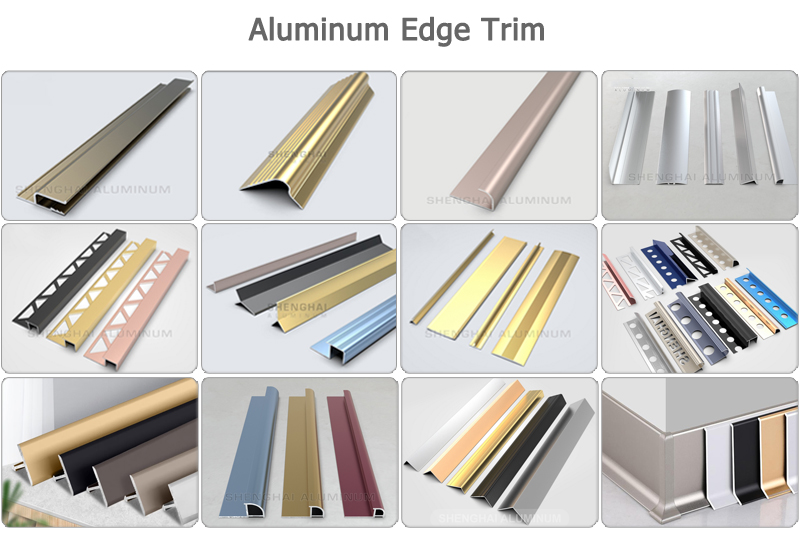

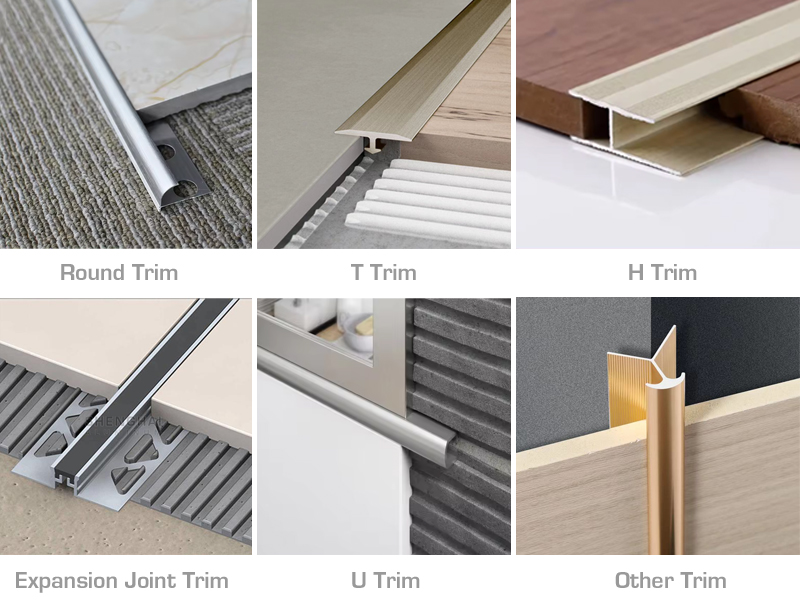

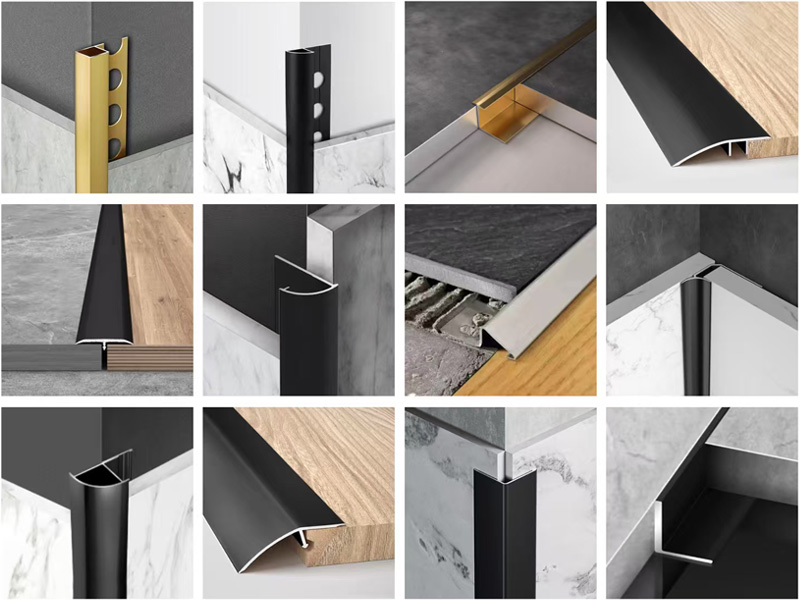

Understanding aluminum trimming Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Extruded Aluminum Trim | Continuous profiles with varied shapes | Construction, Automotive | Pros: Versatile, strong; Cons: Higher cost for custom shapes. |

| Aluminum Siding Trim | Specifically designed for exterior cladding | Residential & Commercial Siding | Pros: Weather-resistant, aesthetic; Cons: Limited color options. |

| Decorative Trim | Ornamental designs with aesthetic appeal | Interior Design, Retail Displays | Pros: Enhances visual appeal; Cons: May require more maintenance. |

| Trimming Stands | Adjustable stands for livestock grooming | Agriculture, Livestock Handling | Pros: Portable, stable; Cons: Price may vary based on features. |

| J-Channel Trim | J-shaped profile for securing siding edges | Siding Installation | Pros: Effective water drainage; Cons: Installation complexity. |

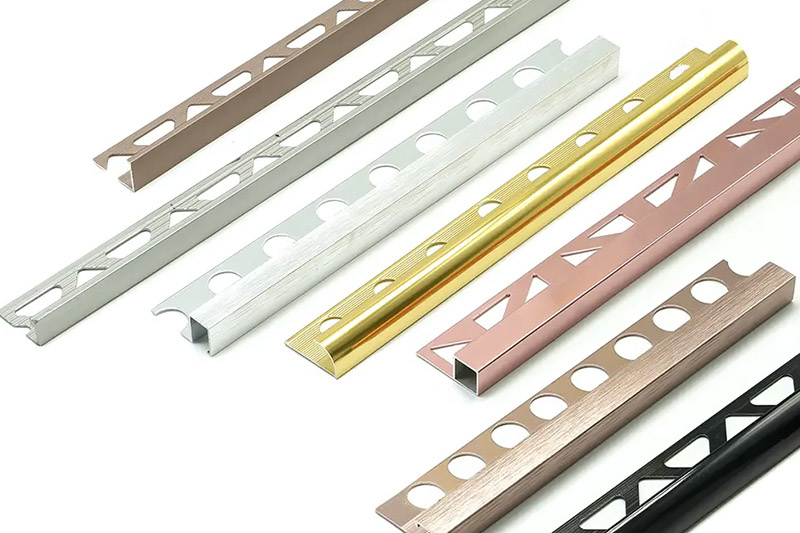

What are the characteristics of Extruded Aluminum Trim, and where is it used?

Extruded aluminum trim is characterized by its continuous profiles that can be manufactured in various shapes and sizes. This type of trim is particularly strong and durable, making it suitable for demanding applications in construction and automotive industries. When purchasing, buyers should consider factors such as the specific shape required, the strength needed for the application, and the potential for custom orders, which may increase lead times and costs.

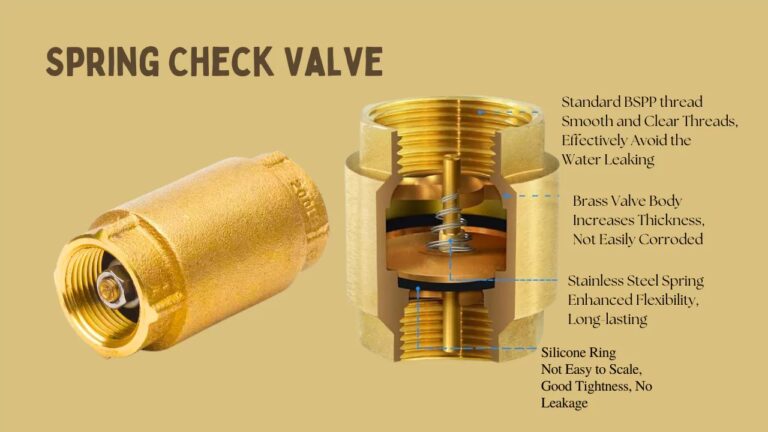

Illustrative image related to aluminum trimming

Why is Aluminum Siding Trim popular for construction projects?

Aluminum siding trim is specifically designed for exterior cladding and is highly valued in both residential and commercial siding projects. Its weather-resistant properties ensure longevity and performance in diverse climates. Buyers should evaluate the trim’s compatibility with existing siding materials, as well as color options and finishes to ensure aesthetic alignment with their projects. While it provides excellent durability, the limited color choices may necessitate additional finishes.

How does Decorative Trim enhance interior spaces?

Decorative aluminum trim features ornamental designs that add aesthetic value to interior spaces. Commonly used in interior design and retail displays, this type of trim can significantly enhance visual appeal. When considering decorative trim, buyers should assess the design’s compatibility with existing decor and the maintenance required to keep it looking pristine. While it adds beauty, it may also involve higher upkeep compared to simpler trims.

What are the advantages of using Trimming Stands in agriculture?

Trimming stands made of aluminum are adjustable and designed for livestock grooming, providing stability and portability. They are essential tools in agriculture, especially for livestock handling. Buyers should consider the stand’s weight capacity, adjustability, and ease of transport. While these stands can be pricier than non-adjustable models, their durability and functionality often justify the investment.

Illustrative image related to aluminum trimming

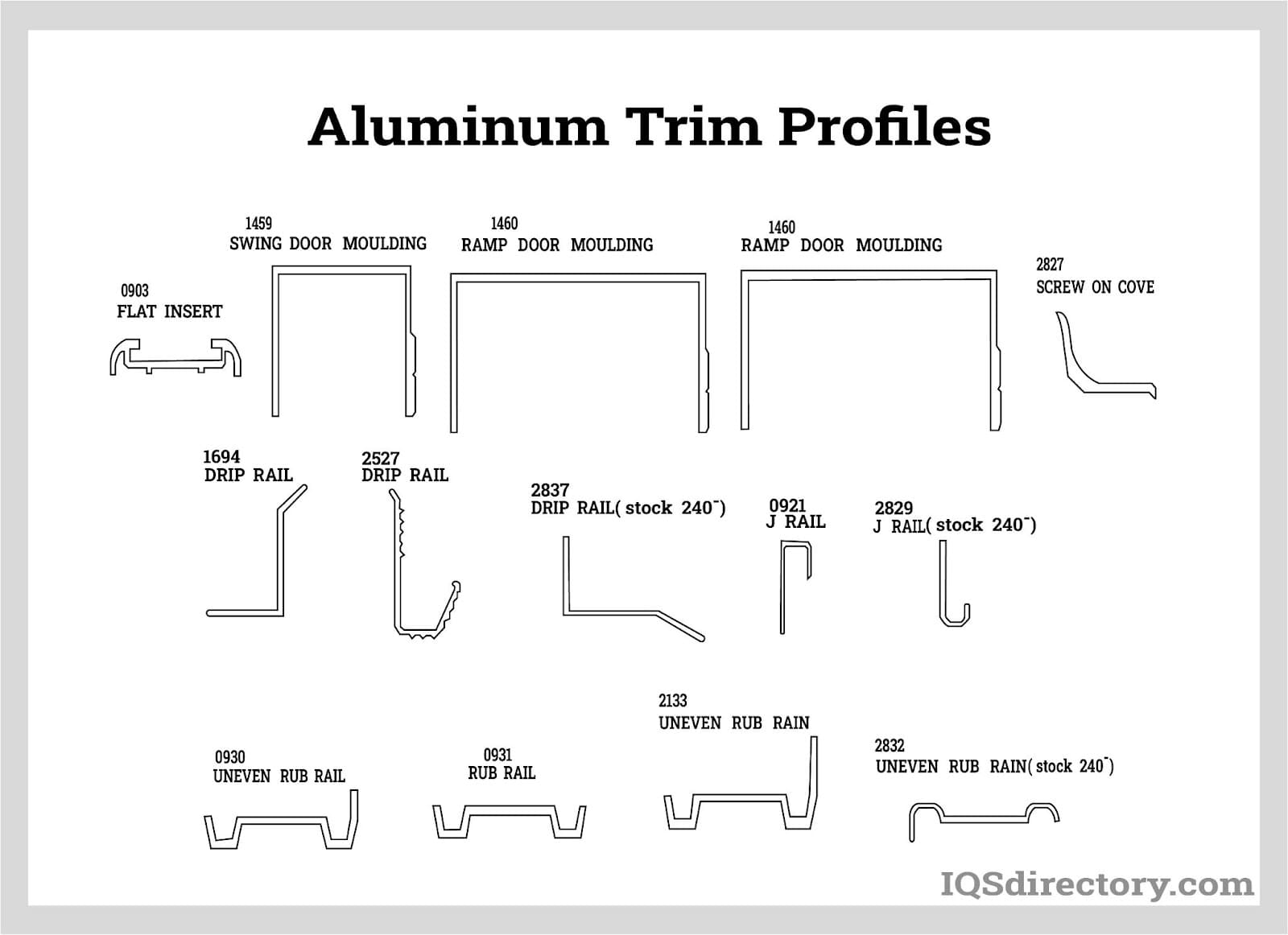

What role does J-Channel Trim play in siding installation?

J-channel trim is a specialized trim with a J-shaped profile that secures the edges of siding, providing effective water drainage and a clean finish. It is commonly used in siding installations to ensure a professional appearance and to protect against moisture infiltration. Buyers should evaluate the installation complexity and compatibility with various siding types. While it is effective for drainage, its installation may require more skill, potentially increasing labor costs.

Key Industrial Applications of aluminum trimming

| Industry/Sector | Specific Application of Aluminum Trimming | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Exterior Siding and Trim for Buildings | Enhances aesthetics and protects against weather | Durability, corrosion resistance, and color options |

| Agriculture | Livestock Trimming Stands | Improves animal handling and grooming efficiency | Weight, portability, and stability of the structure |

| Automotive | Trim for Vehicle Interiors and Exteriors | Provides a lightweight yet strong solution | Customization options and compatibility with designs |

| Furniture Manufacturing | Decorative Edging and Trim for Furniture | Adds value and visual appeal to products | Finish options, precision in cutting, and design flexibility |

| HVAC | Trim for Ductwork and Ventilation Systems | Ensures energy efficiency and effective airflow | Thermal resistance, ease of installation, and size specifications |

How is Aluminum Trimming Used in Construction Projects?

In the construction sector, aluminum trimming is widely used for exterior siding and trim applications. It serves both functional and aesthetic purposes, enhancing the visual appeal of buildings while providing protection against the elements. This is particularly important in regions with harsh weather conditions, such as those found in parts of Africa and the Middle East. Buyers should prioritize sourcing durable and corrosion-resistant materials that can withstand local environmental challenges, ensuring long-term performance and lower maintenance costs.

What Role Does Aluminum Trimming Play in Agriculture?

In agriculture, aluminum trimming is crucial for livestock trimming stands, which facilitate efficient grooming and handling of animals. These stands are designed to be lightweight yet sturdy, allowing for easy transport and setup during shows or grooming sessions. International buyers, especially from South America and Africa, should consider sourcing options that prioritize stability and ease of use, as these features significantly enhance the efficiency of livestock management practices.

How is Aluminum Trimming Beneficial in the Automotive Sector?

The automotive industry utilizes aluminum trimming for both interior and exterior applications, providing a lightweight solution that does not compromise on strength. This is particularly beneficial for vehicle manufacturers looking to improve fuel efficiency without sacrificing design. B2B buyers should focus on sourcing aluminum trims that offer customization options and compatibility with various vehicle designs to meet specific brand requirements and consumer expectations.

Why is Aluminum Trimming Important for Furniture Manufacturing?

In furniture manufacturing, aluminum trimming is used as decorative edging and trim to enhance the visual appeal and perceived value of products. This application allows manufacturers to offer a modern and sleek finish, making their products more attractive to consumers. When sourcing aluminum trim for furniture, businesses should consider finish options and precision in cutting to ensure high-quality results that align with their design specifications.

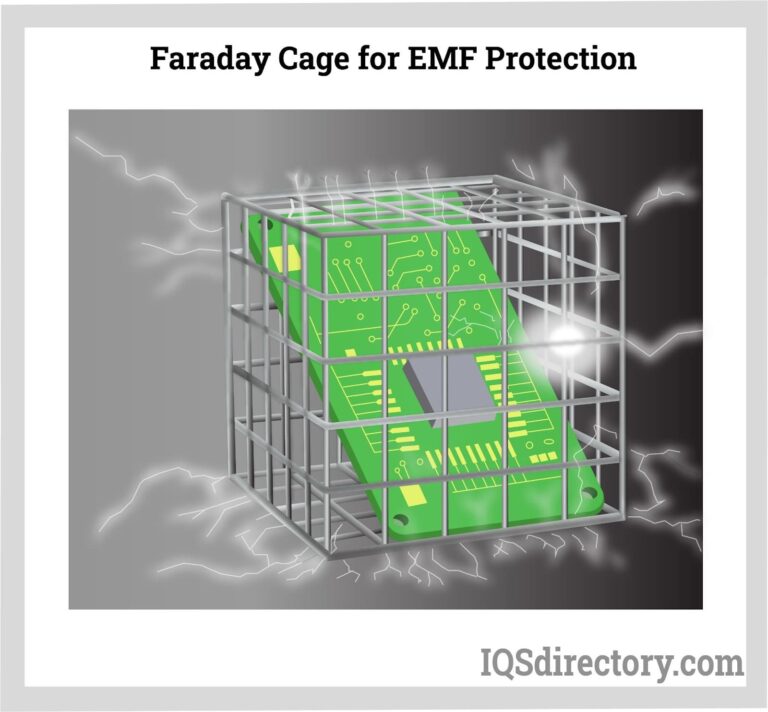

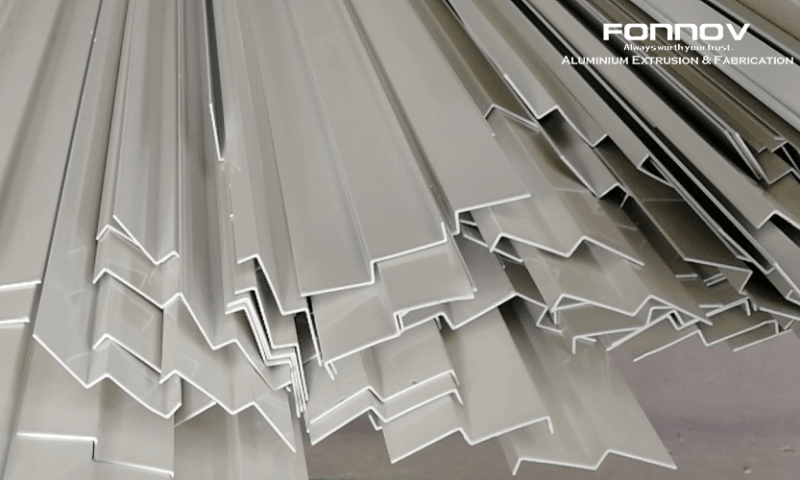

Illustrative image related to aluminum trimming

How Does Aluminum Trimming Enhance HVAC Systems?

In the HVAC sector, aluminum trimming is essential for ductwork and ventilation systems, ensuring energy efficiency and effective airflow management. Properly designed aluminum trims can help reduce air leakage and improve system performance. International buyers should focus on sourcing materials that offer thermal resistance and are easy to install, as these factors can significantly influence the overall effectiveness and durability of HVAC installations.

3 Common User Pain Points for ‘aluminum trimming’ & Their Solutions

Scenario 1: Sourcing Quality Aluminum Trimming Materials

The Problem: B2B buyers often struggle to find high-quality aluminum trimming materials that meet their specific project requirements. This challenge is exacerbated by the vast array of options available, which can lead to confusion about material quality, specifications, and compliance with local regulations. Buyers in regions like Africa and South America may also face difficulties in finding reliable suppliers due to inconsistent product availability and fluctuating market prices, which can lead to project delays and increased costs.

The Solution: To effectively source quality aluminum trimming materials, B2B buyers should first conduct thorough market research to identify reputable suppliers with a track record of reliability and product quality. Engaging in industry networks or forums can provide valuable insights and recommendations. When evaluating suppliers, prioritize those who offer detailed product specifications, including alloy composition, finish options, and compliance with international standards. Request samples before placing bulk orders to assess quality firsthand. Establishing long-term relationships with reliable suppliers can also provide better pricing and priority access to new products, ensuring that projects are not delayed by material shortages.

Scenario 2: Managing Installation Challenges with Aluminum Trimming

The Problem: Installation of aluminum trimming can present various challenges, particularly for businesses that may lack experience in handling this specific material. Issues such as improper alignment, inadequate fastening techniques, or choosing the wrong profile can lead to compromised aesthetics and functionality. For companies in regions with diverse climates, such as the Middle East, consideration of thermal expansion and contraction is crucial. Misalignment or improper installation can result in costly rework and client dissatisfaction.

The Solution: To overcome installation challenges, B2B buyers should invest in training their teams on best practices for installing aluminum trimming. This could involve workshops or training sessions led by experienced professionals in the field. Additionally, creating detailed installation guides tailored to specific products and applications can serve as valuable resources for installers. Incorporating tools such as laser alignment systems can help ensure accuracy during the installation process. Buyers should also consider selecting aluminum trims with built-in features that facilitate easier installation, such as pre-drilled holes or interlocking designs, which can reduce labor costs and installation time.

Scenario 3: Addressing Aesthetic Consistency in Aluminum Trimming Products

The Problem: A common pain point for B2B buyers is ensuring aesthetic consistency across aluminum trimming products, especially when sourcing from multiple suppliers. Variations in color, finish, and profile can lead to an unprofessional appearance in finished projects, impacting client satisfaction and brand reputation. This is particularly critical for projects in competitive markets in Europe and Africa, where visual appeal is paramount.

Illustrative image related to aluminum trimming

The Solution: To ensure aesthetic consistency, B2B buyers should develop a standardized specification document that outlines the exact requirements for aluminum trimming, including color codes, finish types, and profiles. When sourcing from multiple suppliers, insist on obtaining matching products that adhere to these specifications. Utilizing a single supplier for all trimming needs can help maintain consistency, as they are likely to provide materials from the same production batch. Furthermore, conducting regular quality checks on materials upon delivery can help identify discrepancies early, allowing for timely resolutions before installation begins. Leveraging technology, such as color-matching software, can also assist in ensuring that the materials selected meet the desired aesthetic standards across various project applications.

Strategic Material Selection Guide for aluminum trimming

What Are the Key Properties of Common Materials Used in Aluminum Trimming?

When selecting materials for aluminum trimming, several options are prevalent in the industry, each with unique properties that affect performance and suitability for specific applications. The most common materials include anodized aluminum, extruded aluminum, painted aluminum, and aluminum alloys. Understanding their characteristics is essential for B2B buyers to make informed decisions.

How Does Anodized Aluminum Perform in Trimming Applications?

Anodized aluminum undergoes an electrochemical process that enhances its natural oxide layer, providing increased corrosion resistance and durability. This material typically withstands temperatures up to 150°C (302°F) and exhibits excellent wear resistance. Anodized aluminum is particularly suitable for applications exposed to harsh environments, such as coastal regions.

Pros: The primary advantage of anodized aluminum is its enhanced corrosion resistance, making it ideal for outdoor applications. Additionally, it offers a variety of aesthetic finishes, which can be a selling point for design-oriented projects.

Cons: The anodizing process can increase manufacturing complexity and costs. Moreover, while it is durable, it may not be as strong as some aluminum alloys, limiting its use in high-stress applications.

Illustrative image related to aluminum trimming

Considerations for International Buyers: Compliance with standards such as ASTM B580 for anodized coatings is crucial. Buyers from regions like Africa and South America should also consider local climatic conditions that may affect material performance.

What Are the Benefits of Using Extruded Aluminum for Trimming?

Extruded aluminum is produced by forcing aluminum through a shaped die, resulting in a variety of profiles suitable for trimming applications. This material is lightweight yet strong, with a typical temperature resistance of around 200°C (392°F).

Pros: Extruded aluminum is versatile and can be customized to meet specific design requirements. Its lightweight nature reduces shipping costs, making it an economical choice for large-scale projects.

Cons: While extruded aluminum is generally durable, it can be susceptible to scratching and denting, which may affect its aesthetic appeal over time. Additionally, the initial tooling costs for custom shapes can be high.

Illustrative image related to aluminum trimming

Considerations for International Buyers: Buyers should ensure that the extruded aluminum complies with relevant standards, such as DIN 1725, to guarantee quality and performance. Understanding local market preferences for specific profiles can also enhance product acceptance.

Why Choose Painted Aluminum for Trimming Solutions?

Painted aluminum is coated with a protective layer of paint, enhancing its aesthetic appeal while providing some level of corrosion resistance. It typically performs well in temperatures up to 120°C (248°F).

Pros: The main advantage of painted aluminum is its wide range of color options, allowing for customization to match branding or design requirements. It is also less expensive than anodized options, making it a cost-effective solution for many projects.

Cons: The paint can chip or fade over time, particularly in harsh environments, which may necessitate repainting. Its corrosion resistance is generally lower than that of anodized aluminum.

Considerations for International Buyers: Buyers should look for compliance with standards like ASTM D3359 for paint adhesion. In regions with high UV exposure, such as the Middle East, selecting high-quality paint is essential to ensure longevity.

What Are the Advantages of Using Aluminum Alloys in Trimming Applications?

Aluminum alloys, such as 6061 and 5052, offer a combination of strength, corrosion resistance, and formability. These alloys can withstand higher temperatures, typically up to 300°C (572°F).

Pros: The primary advantage of aluminum alloys is their superior strength-to-weight ratio, making them suitable for structural applications. They also exhibit excellent weldability and machinability, enhancing their versatility.

Cons: The cost of aluminum alloys is generally higher than that of standard aluminum, which can impact budget considerations. Additionally, specific alloys may require specialized processing techniques, increasing manufacturing complexity.

Considerations for International Buyers: Buyers should be aware of the specific alloy grades and their corresponding standards, such as ASTM B221 for extruded products. Understanding local regulations regarding alloy usage can also facilitate compliance.

Summary Table of Material Selection for Aluminum Trimming

| Material | Typical Use Case for aluminum trimming | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Anodized Aluminum | Outdoor architectural applications | Enhanced corrosion resistance | Increased manufacturing complexity and cost | Medium |

| Extruded Aluminum | Custom profiles for various applications | Versatile and lightweight | Susceptible to scratching and denting | Medium |

| Painted Aluminum | Interior and exterior decorative trims | Wide range of color options | Paint can chip or fade over time | Low |

| Aluminum Alloys | Structural and high-stress applications | Superior strength-to-weight ratio | Higher cost and specialized processing required | High |

This strategic material selection guide provides essential insights for international B2B buyers looking to optimize their aluminum trimming applications, ensuring they choose the right material for their specific needs.

In-depth Look: Manufacturing Processes and Quality Assurance for aluminum trimming

What Are the Key Stages in the Manufacturing Process of Aluminum Trimming?

The manufacturing process of aluminum trimming involves several crucial stages that ensure the final product meets both aesthetic and functional requirements. Understanding these stages is essential for B2B buyers seeking reliable suppliers.

Material Preparation: What Comes First?

The initial step in the manufacturing of aluminum trimming is material preparation. High-quality aluminum alloy sheets are sourced, often based on specific project requirements. These sheets are then cleaned and cut to the desired dimensions. The preparation stage may also include the application of protective coatings to prevent oxidation and enhance durability.

Illustrative image related to aluminum trimming

How Is Aluminum Trimming Formed?

Once the materials are prepared, the forming process begins. This can include techniques such as extrusion, bending, and stamping.

-

Extrusion: This process involves forcing aluminum through a die to create specific shapes. It is particularly beneficial for creating complex profiles and uniform cross-sections.

-

Bending: For aluminum trims that require angles or curves, bending machines are used. This process must be executed carefully to maintain the integrity of the metal.

-

Stamping: This technique is employed for creating detailed designs or features in the aluminum. Stamping can be used in conjunction with other methods to create multi-faceted products.

What Is Involved in the Assembly Stage?

After forming, the assembly stage focuses on integrating various components, if applicable. This may involve welding, riveting, or using adhesives to join different aluminum parts or to attach aluminum trims to other materials. Proper assembly techniques are critical to ensure the durability and longevity of the final product.

Finishing: How Is Quality Enhanced?

The finishing stage is where aluminum trims receive their final touches. This can include anodizing, painting, or powder coating, which not only enhance appearance but also improve corrosion resistance.

- Anodizing: This electrochemical process thickens the natural oxide layer on aluminum, providing increased durability and a variety of color options.

- Powder Coating: This method involves applying a dry powder that is cured under heat to create a hard finish, known for its toughness and resistance to scratching.

What Quality Assurance Standards Should B2B Buyers Be Aware Of?

Quality assurance is critical in the manufacturing of aluminum trimming, ensuring that products meet international and industry-specific standards. Buyers should be familiar with the following standards:

What Are the Relevant International Standards?

-

ISO 9001: This is the most recognized international standard for quality management systems. It focuses on meeting customer expectations and delivering customer satisfaction.

-

CE Marking: In Europe, the CE mark indicates conformity with health, safety, and environmental protection standards.

-

API Standards: For trims used in industrial applications, the American Petroleum Institute (API) standards may also apply, ensuring products meet specific industry requirements.

What Are the Key Quality Control Checkpoints in Aluminum Trimming Manufacturing?

Quality control (QC) checkpoints are vital throughout the manufacturing process to ensure consistent product quality. These checkpoints include:

Incoming Quality Control (IQC)

This is the first line of defense against defects. IQC involves inspecting raw materials upon arrival at the manufacturing facility. Suppliers should provide certificates of conformity, and samples should be tested to ensure they meet specified standards.

In-Process Quality Control (IPQC)

During manufacturing, IPQC involves continuous monitoring of the production process. This includes regular inspections and testing at various stages to catch defects early. Techniques such as statistical process control (SPC) can be employed to monitor production quality.

Final Quality Control (FQC)

Once the aluminum trims are completed, FQC involves thorough inspection and testing of the final products. This may include dimensional checks, visual inspections, and functional tests to ensure all specifications are met.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain high-quality standards, B2B buyers should consider several verification methods:

Illustrative image related to aluminum trimming

What Documentation Should Buyers Request?

Buyers should request and review the supplier’s quality management documentation, including:

- Quality Assurance Manuals: These documents outline the supplier’s quality control processes.

- Test Reports: Independent test results can provide assurance that products meet required standards.

- Audit Reports: Regular audits by third parties can confirm adherence to quality standards.

What Role Do Audits and Inspections Play?

Conducting supplier audits is a proactive way for B2B buyers to assess a supplier’s quality management system. On-site inspections allow buyers to observe the manufacturing process firsthand, ensuring compliance with both international standards and specific project requirements.

What Are the Nuances of Quality Control for International Buyers?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, there are unique considerations:

-

Regulatory Compliance: Different countries have varying regulations regarding aluminum products. Buyers should ensure that suppliers comply with the relevant local standards.

-

Logistics and Supply Chain: Quality control can be impacted by logistics. Buyers should confirm that suppliers have robust systems in place for inventory management and shipping to prevent damage during transit.

-

Cultural and Communication Factors: Understanding cultural differences in business practices can affect quality assurance processes. Clear communication regarding quality expectations is essential for successful international partnerships.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices in aluminum trimming is essential for B2B buyers. By focusing on these areas, buyers can make informed decisions, ensuring they partner with reliable suppliers who meet their quality standards.

Illustrative image related to aluminum trimming

Practical Sourcing Guide: A Step-by-Step Checklist for ‘aluminum trimming’

In the competitive landscape of B2B procurement, sourcing aluminum trimming requires a structured approach to ensure quality, compliance, and value. This guide provides a step-by-step checklist to assist international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, in making informed purchasing decisions.

Step 1: Define Your Technical Specifications

Begin by outlining the specific requirements for your aluminum trimming needs. This includes dimensions, alloy types, finishes, and tolerances. Clearly defining these specifications ensures that you receive products that meet your project requirements and reduces the risk of costly mistakes later.

- Considerations:

- What are the environmental conditions the aluminum will face?

- Are there industry standards or regulations you need to comply with?

Step 2: Identify Potential Suppliers

Research and compile a list of potential suppliers who specialize in aluminum trimming. Utilize online directories, trade shows, and industry networks to find reputable manufacturers.

- Sources:

- Industry-specific platforms like Alibaba or ThomasNet.

- Local suppliers in your target regions, which may offer better shipping rates and cultural familiarity.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. This step helps ensure that the suppliers have a proven track record of delivering quality products.

- What to look for:

- Certifications and compliance with international standards.

- Feedback from previous clients regarding reliability and service quality.

Step 4: Request Samples

Always request product samples before finalizing your order. Samples allow you to assess the quality, gauge the supplier’s adherence to your specifications, and ensure the product matches your requirements.

Illustrative image related to aluminum trimming

- Key Actions:

- Evaluate the finish, dimensions, and overall quality of the sample.

- Test the sample in real-world applications if possible.

Step 5: Verify Supplier Certifications

Confirm that your chosen suppliers have the necessary certifications, such as ISO or ASTM, which indicate their commitment to quality and industry standards. This verification is particularly important for international transactions where standards may vary.

- Important Certifications:

- ISO 9001 for quality management systems.

- Compliance with environmental standards, especially for buyers in Europe.

Step 6: Negotiate Terms and Pricing

Once you’ve narrowed down your options, engage in discussions regarding pricing, payment terms, and delivery schedules. Effective negotiation can lead to significant savings and more favorable terms.

- Negotiation Tips:

- Be clear about your budget and expectations.

- Consider long-term relationships for better pricing on future orders.

Step 7: Finalize the Purchase Agreement

Before placing your order, ensure that all terms are clearly documented in a purchase agreement. This should include product specifications, pricing, delivery timelines, and any warranties or return policies.

- What to include:

- Clear definitions of quality expectations and penalties for non-compliance.

- A timeline for delivery and consequences for delays.

By following this structured checklist, B2B buyers can effectively navigate the complexities of sourcing aluminum trimming, ensuring they select the right suppliers and products for their specific needs.

Comprehensive Cost and Pricing Analysis for aluminum trimming Sourcing

What Are the Key Cost Components in Aluminum Trimming Sourcing?

Understanding the cost structure of aluminum trimming is essential for B2B buyers to make informed purchasing decisions. The primary cost components include:

-

Materials: The price of aluminum fluctuates based on market conditions, which can significantly impact overall costs. High-quality aluminum alloys may be more expensive but can offer better performance and durability, influencing the long-term value.

-

Labor: The cost of labor varies by region and can include skilled and unskilled workforce expenses. Regions with higher labor costs may influence the overall pricing, especially if specialized skills are required for intricate designs.

-

Manufacturing Overhead: This encompasses expenses related to production facilities, utilities, and indirect labor. Manufacturers often calculate these costs into their pricing models, which can vary significantly based on operational efficiencies.

-

Tooling: Custom tooling for specific aluminum trim shapes or designs can add to initial costs. Buyers should consider whether the tooling costs can be amortized over large production runs to reduce per-unit costs.

-

Quality Control (QC): Ensuring that products meet required standards incurs additional costs. Buyers should inquire about the QC processes of suppliers and how they impact pricing.

-

Logistics: Transportation costs can vary widely depending on the location of the supplier, shipping methods, and Incoterms chosen. For international buyers, understanding logistics is crucial to avoid unexpected expenses.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market competition and the perceived value of the product.

How Do Volume and Customization Affect Pricing in Aluminum Trimming?

The pricing of aluminum trimming is highly influenced by the volume of the order and the level of customization required.

-

Volume/MOQ (Minimum Order Quantity): Larger orders often qualify for bulk discounts, which can significantly reduce the unit price. Buyers should evaluate their needs carefully and consider the benefits of ordering in larger quantities to achieve better pricing.

-

Specifications and Customization: Custom designs or specific requirements can lead to higher costs due to the need for specialized tooling and production processes. Buyers should weigh the necessity of customization against potential cost increases.

What Are the Key Price Influencers for International B2B Buyers?

Several factors can influence pricing for international buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe:

-

Quality and Certifications: Products that meet international quality standards or certifications may command higher prices. Buyers should assess the importance of these certifications in relation to their market requirements.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may offer better quality and service but at a premium. Conducting due diligence on potential suppliers can help buyers make informed decisions.

-

Incoterms: The chosen Incoterms can significantly affect the total landed cost of the product. Buyers should understand the implications of terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) to accurately assess costs.

What Are the Best Negotiation Strategies for Cost-Efficiency in Aluminum Trimming?

Effective negotiation strategies can lead to substantial savings:

-

Research and Benchmarking: Before negotiations, buyers should gather data on market prices and competitor offerings. This knowledge can empower them during discussions and help them set realistic expectations.

-

Total Cost of Ownership (TCO): Buyers should consider the TCO, which includes not just the purchase price but also maintenance, logistics, and operational costs over the product’s lifecycle. This holistic view can influence negotiations favorably.

-

Flexibility in Specifications: Being open to alternative materials or designs that might reduce costs can provide leverage during negotiations. Suppliers may be more willing to offer discounts if they can use existing tools or stock materials.

Conclusion and Disclaimer

While this analysis provides a comprehensive overview of cost and pricing factors in aluminum trimming sourcing, prices can fluctuate based on market conditions and specific supplier circumstances. Buyers should conduct thorough market research and engage in negotiations to secure the best pricing tailored to their unique needs.

Alternatives Analysis: Comparing aluminum trimming With Other Solutions

When considering aluminum trimming for various applications, it’s essential to evaluate alternative solutions that may offer different advantages or suit specific needs better. Understanding these alternatives can help B2B buyers make informed decisions based on their unique requirements.

| Comparison Aspect | Aluminum Trimming | PVC Trimming | Wood Trimming |

|---|---|---|---|

| Performance | High durability, resistant to rust and corrosion | Good for moisture resistance but can warp | Aesthetic appeal but prone to decay and damage |

| Cost | Moderate to high | Generally lower | Varies widely, often higher for quality wood |

| Ease of Implementation | Moderate; requires specific tools for cutting and installation | Easy to handle and install; lightweight | Requires skilled labor for installation |

| Maintenance | Low; minimal upkeep needed | Moderate; cleaning required to maintain appearance | High; needs regular maintenance and treatment |

| Best Use Case | Commercial and industrial applications | Residential applications, particularly in moist environments | High-end residential and decorative applications |

What Are the Pros and Cons of PVC Trimming as an Alternative to Aluminum Trimming?

PVC trimming offers a cost-effective and lightweight alternative to aluminum. Its moisture-resistant properties make it ideal for environments prone to high humidity, such as bathrooms or coastal areas. However, while PVC is easier to install and handle, it lacks the durability of aluminum, especially in high-traffic or industrial settings. Over time, PVC can become discolored and may require replacement sooner than aluminum options.

How Does Wood Trimming Compare with Aluminum Trimming?

Wood trimming is often chosen for its aesthetic qualities, providing a warm and natural look that many buyers prefer for residential applications. High-quality wood can enhance the overall value of a property and offers flexibility in design. However, wood requires significant maintenance to prevent decay, warping, and pest infestations. Its cost can also be higher, particularly for premium species, making it less appealing for larger projects where budget constraints are a concern.

Conclusion: How Can B2B Buyers Choose the Right Trimming Solution?

Choosing the right trimming solution involves evaluating the specific needs of the project, including budget, durability, and aesthetic preferences. For buyers focused on long-term performance and minimal maintenance, aluminum trimming stands out as a superior choice. Conversely, for those prioritizing cost or specific environmental conditions, PVC or wood may be more suitable alternatives. Ultimately, a thorough understanding of each option’s pros and cons will empower buyers to select the most effective solution tailored to their operational requirements.

Essential Technical Properties and Trade Terminology for aluminum trimming

Aluminum trimming is a critical aspect of various construction and manufacturing processes, particularly for B2B buyers looking to enhance their product offerings. Understanding the essential technical properties and trade terminology is crucial for making informed purchasing decisions.

What Are the Key Technical Properties of Aluminum Trimming?

-

Material Grade

Aluminum trims are categorized by their material grade, which indicates the alloy composition and its specific properties. Common grades include 6061 and 6063, each offering different mechanical strengths, corrosion resistance, and weldability. For B2B buyers, selecting the appropriate grade ensures that the aluminum trim meets the specific demands of their applications, such as structural integrity and aesthetic quality. -

Tolerance

Tolerance refers to the allowable deviation in dimensions during manufacturing. For aluminum trimming, tight tolerances (e.g., ±0.005 inches) are critical to ensure proper fit and functionality in assembly processes. Understanding tolerance requirements helps buyers avoid costly rework and ensures compatibility with other components. -

Finish

The finish of aluminum trims can vary from anodized to mill finish. Anodized finishes provide enhanced corrosion resistance and surface hardness, which are essential for outdoor applications. Buyers must consider the finish type based on the environment in which the aluminum will be used, as it directly affects durability and maintenance needs. -

Thickness

The thickness of aluminum trims typically ranges from 0.020 to 0.125 inches, impacting strength and weight. Thicker materials may be necessary for structural applications, while thinner trims may suffice for decorative purposes. B2B buyers should assess the required thickness based on their project specifications and budget constraints. -

Length and Width

Aluminum trims come in various lengths and widths, often determined by standard sizes or custom orders. Standardization can lead to cost savings and simplified logistics, whereas custom dimensions might be necessary for specific applications. Buyers should clearly define their size requirements to ensure efficient procurement. -

Corrosion Resistance

Aluminum is naturally resistant to corrosion, but the level of resistance can vary based on alloy composition and surface treatment. For industries operating in harsh environments, such as marine or chemical, specifying high corrosion resistance in aluminum trims is essential to prolong product life and reduce maintenance costs.

What Are Common Trade Terms Related to Aluminum Trimming?

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable suppliers and ensure compatibility with existing systems. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, knowing the MOQ helps in budgeting and inventory management, as larger orders may lead to cost efficiencies. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing for specific products. It is essential for buyers to clearly outline their requirements to receive accurate quotes, facilitating better negotiations and decision-making. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping costs, insurance, and liability during transit, which is crucial for effective supply chain management. -

Lead Time

Lead time refers to the time taken from placing an order to delivery. Understanding lead times is vital for project planning and ensuring that materials are available when needed, preventing delays in production. -

Surface Treatment

This term encompasses various processes applied to aluminum trims to enhance their properties, such as anodizing or painting. Knowing the available surface treatments allows buyers to select products that best fit their aesthetic and functional requirements.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions regarding aluminum trimming, ensuring that their projects meet quality standards and operational needs.

Navigating Market Dynamics and Sourcing Trends in the aluminum trimming Sector

What Are the Current Market Dynamics and Key Trends in the Aluminum Trimming Sector?

The aluminum trimming sector is witnessing significant evolution driven by both technological advancements and changing market demands. Globally, the demand for lightweight, durable, and aesthetically pleasing materials is propelling the growth of aluminum trimming in various industries, including construction, automotive, and consumer goods. Emerging technologies such as automation in manufacturing processes are enhancing production efficiency and reducing costs, making aluminum trims more accessible to international buyers.

Notably, the market is experiencing a shift towards customization, with buyers increasingly seeking tailored solutions that meet specific project requirements. This trend is particularly pronounced among B2B buyers in regions like Africa, South America, the Middle East, and Europe, where diverse applications necessitate a variety of aluminum trim shapes and finishes. Additionally, the rise of e-commerce platforms is transforming sourcing strategies, enabling buyers to access a wider range of suppliers and products with greater convenience.

Another critical market driver is the increasing focus on energy efficiency and sustainability. As regulations tighten and consumers become more environmentally conscious, there is a notable push towards sourcing aluminum trims that adhere to sustainable practices. This trend is underscored by the growing importance of certifications that validate the environmental impact of products, thereby influencing purchasing decisions among international buyers.

How Is Sustainability Shaping the Aluminum Trimming Supply Chain?

Sustainability is at the forefront of discussions in the aluminum trimming sector, with significant implications for B2B sourcing strategies. The production of aluminum, while resource-intensive, can be optimized through recycling and the use of energy-efficient manufacturing processes. Buyers are increasingly prioritizing suppliers who implement sustainable practices, including the use of recycled aluminum and eco-friendly production methods.

Ethical sourcing has also gained traction, as companies strive to ensure that their supply chains align with their corporate social responsibility goals. This includes vetting suppliers for compliance with environmental regulations and labor standards. Green certifications, such as LEED (Leadership in Energy and Environmental Design) or ISO 14001, are becoming essential for suppliers looking to appeal to environmentally conscious buyers.

Furthermore, the importance of transparency in the supply chain cannot be overstated. Buyers are now demanding visibility into the sourcing processes, which has prompted many suppliers to adopt traceability systems. By doing so, they can demonstrate their commitment to ethical and sustainable practices, thus enhancing their competitiveness in the global market.

How Has the Aluminum Trimming Sector Evolved Over Time?

The aluminum trimming sector has evolved significantly over the past few decades, transitioning from traditional manufacturing methods to advanced, automated processes. Initially dominated by manual techniques, the industry has embraced technological innovations that enhance production efficiency and product quality. The introduction of extrusion and fabrication techniques has allowed for a wider variety of aluminum trim shapes and sizes, catering to diverse applications.

Moreover, the global aluminum market has experienced fluctuations due to economic shifts, trade policies, and environmental regulations. These factors have influenced sourcing strategies for international B2B buyers, prompting a greater emphasis on local suppliers to mitigate risks associated with global supply chains. As sustainability continues to shape the industry’s future, the evolution of aluminum trimming will likely focus on innovation, efficiency, and ethical practices, ensuring that it meets the demands of modern consumers and businesses alike.

Illustrative image related to aluminum trimming

Frequently Asked Questions (FAQs) for B2B Buyers of aluminum trimming

-

How do I ensure the quality of aluminum trimming products when sourcing?

To ensure the quality of aluminum trimming products, it’s essential to vet suppliers thoroughly. Request samples to evaluate material quality, finish, and durability. Additionally, inquire about their manufacturing processes, quality control measures, and certifications (e.g., ISO standards). It’s also beneficial to check for customer reviews and case studies that demonstrate successful deliveries and product performance. Establishing clear quality assurance protocols in your purchase agreements can help mitigate risks associated with product quality. -

What is the best type of aluminum trimming for exterior applications?

For exterior applications, anodized aluminum trimming is often the best choice due to its superior corrosion resistance and durability. This type of trimming withstands harsh weather conditions, making it ideal for climates with significant temperature fluctuations or moisture. Additionally, consider aluminum trims with a powder-coated finish for enhanced aesthetic appeal and added protection against UV rays. Always consult with your supplier about the specific environmental conditions of your project to ensure optimal material selection. -

How can I customize aluminum trimming to meet my specific project needs?

Customization of aluminum trimming can be achieved by collaborating closely with your supplier. Discuss your specific requirements such as dimensions, finishes, and shapes. Many manufacturers offer bespoke solutions and can create trims tailored to your project’s unique specifications. Ensure that you provide detailed drawings or prototypes, and clarify any design constraints. This proactive approach not only guarantees that the trims fit your needs but also enhances the overall project outcome. -

What are the typical minimum order quantities (MOQs) for aluminum trimming?

Minimum order quantities for aluminum trimming can vary significantly based on the supplier and the type of product. Generally, MOQs range from 100 to 1,000 units, particularly for standard profiles. However, for custom designs, suppliers may require higher MOQs due to the setup costs involved. It’s advisable to communicate your project needs early on and negotiate MOQs that align with your budget and requirements, especially when sourcing from international suppliers. -

What payment terms should I expect when sourcing aluminum trimming internationally?

Payment terms for international sourcing of aluminum trimming typically include options like advance payment, letters of credit, or payment upon delivery. Many suppliers may request a deposit upfront, especially for custom orders. It’s crucial to clarify these terms before finalizing agreements and ensure they align with your cash flow capabilities. Using secure payment methods that provide buyer protection can also mitigate risks associated with international transactions. -

How do I navigate logistics and shipping for aluminum trimming orders?

Navigating logistics for aluminum trimming requires understanding both shipping options and regulations. Discuss with your supplier the best shipping methods—air freight for speed or sea freight for cost-effectiveness. Ensure compliance with customs regulations in your country, including duties and taxes. It’s beneficial to work with a logistics provider experienced in international shipping to streamline the process and avoid delays. Clear communication with your supplier about shipping timelines and tracking can also enhance efficiency. -

What should I look for in a supplier to ensure reliability?

When evaluating suppliers for aluminum trimming, assess their industry experience, production capabilities, and customer service track record. Look for suppliers with a history of timely deliveries and adherence to quality standards. Request references from previous clients and verify their credentials. Additionally, consider suppliers who offer transparency in their operations and are willing to provide detailed information about their processes, material sourcing, and quality control measures. -

How do I handle potential issues with international suppliers?

Handling issues with international suppliers requires clear communication and a proactive approach. If problems arise, such as delays or quality concerns, address them directly with the supplier as soon as possible. Document all communications and agreements to maintain a record of expectations. It may also be beneficial to establish a dispute resolution process in your contracts. If issues persist, consider involving a third-party mediator or legal counsel experienced in international trade disputes.

Top 7 Aluminum Trimming Manufacturers & Suppliers List

1. Metals Depot – Aluminum Trim Shapes & Edging

Domain: metalsdepot.com

Registered: 1999 (26 years)

Introduction: Aluminum Trim Shapes & Edging: 1. Aluminum J Trim 1/8″ – Stock Number: JCAP18, Sizes Available: 48″, 96″, 144″. 2. Aluminum T Divider Trim – Stock Number: MDT-E110, Sizes Available: 48″, 96″. 3. Aluminum Outside Corner Trim – Stock Number: MDT-E93, Sizes Available: 48″, 96″. 4. Aluminum Inside Corner Trim – Stock Number: MDT-E85, Sizes Available: 48″, 96″. All products are available for any quanti…

2. Weaver – Complete Aluminum Trimming Stand

Domain: weaverlivestock.com

Registered: 2010 (15 years)

Introduction: Complete Aluminum Trimming Stand

SKU: 69500-20-05

Price: $422.29 (Narrow) / $437.79 (Original)

Variants: Adj Nose Loop / Narrow, Adj Nose Loop / Original, Adj Solid Cheek / Narrow, Adj Solid Cheek / Original, Adj Wire Cheek / Narrow, Adj Wire Cheek / Original

Dimensions: Original stand measures 24.5″ wide; Narrow size measures 20″ wide

Features: Designed for smaller animals; Narrow width for easie…

3. Brand X Metals – Extruded Aluminum Trims

Domain: brandxmetals.com

Registered: 2007 (18 years)

Introduction: Brand X Metals manufactures a wide variety of extruded aluminum trims designed for the lath, plaster, stucco, and drywall construction industry. Key features include:

– Made from 6063 aluminum alloy.

– Products designed for ease of installation and performance.

– Includes options like Eliminator Trim, Streamline Channel Screed, and various J-Molds.

– Offers a selection of money-saving products.

– …

4. Facebook – Aluminum Trimming Stand Solutions

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: Aluminum trimming/fitting stand suggestions

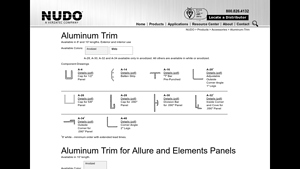

5. Nudo – Aluminum Trim

Domain: nudo.com

Registered: 1996 (29 years)

Introduction: Aluminum Trim available in 8′ and 10′ lengths. Suitable for exterior and interior use. Available colors: A-28, A-30, A-32, and A-34 (only in anodized); all others available in white or anodized. Specific components include caps for various panel sizes (1/2″, 5/8″, .090″, and .150″), batten strips, adjustable outside corner angles, inside corners, and division bars. Minimum order with extended lead…

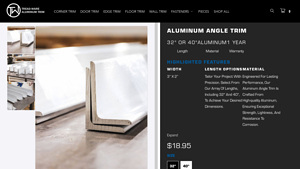

6. Tread-Ware – Aluminum Angle Trim

Domain: tread-ware.com

Registered: 2008 (17 years)

Introduction: This company, Tread-Ware – Aluminum Angle Trim, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

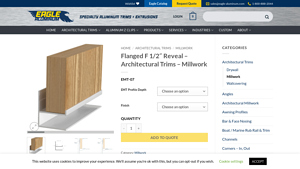

7. Eagle Aluminum – Millwork Flanged F Reveal Trim

Domain: eagle-aluminum.com

Registered: 2010 (15 years)

Introduction: Product Name: Millwork Flanged F Reveal Architectural Trim

SKU: EMT-07

Price Range: $23.28 – $32.31

Profile Depths Available: 1.00″ (EMT-07100), .75″ (EMT-07075)

Material: 6063-T5 Aluminum

Finish Options: Clear Satin Anodized, Mill Finish (specialty finishes available upon request)

Length: Stocked in 10′ (120″) lengths

Key Features: .50″ reveal, .19″ return key, suitable for ceiling to wall transi…

Strategic Sourcing Conclusion and Outlook for aluminum trimming

What Are the Key Takeaways for Strategic Sourcing in Aluminum Trimming?

In the evolving landscape of aluminum trimming, strategic sourcing emerges as a vital approach for international B2B buyers. By understanding regional market trends and leveraging local suppliers, businesses can optimize procurement processes, reduce costs, and enhance product quality. The diverse applications of aluminum trims—from construction to livestock management—underscore the material’s versatility, making it essential to align sourcing strategies with specific industry needs.

How Can Businesses Leverage Strategic Sourcing to Gain Competitive Advantage?

Investing in relationships with reliable suppliers can lead to better pricing and access to innovative products, which is crucial in competitive markets across Africa, South America, the Middle East, and Europe. Buyers should prioritize suppliers who demonstrate commitment to sustainability and quality assurance, reflecting the growing demand for eco-friendly materials and compliance with international standards.

What Does the Future Hold for International Buyers in Aluminum Trimming?

As the market continues to expand, staying informed about technological advancements and emerging trends will be key. Engaging with suppliers who embrace innovation can provide a competitive edge. Therefore, we encourage B2B buyers to act proactively—evaluate your sourcing strategies today to not only meet current demands but also prepare for future opportunities in the global aluminum trimming market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.