Alu Metallic Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for alu metallic

Navigating the global market for aluminum metallic products presents a unique challenge for international B2B buyers, particularly when sourcing high-quality materials that meet specific industry standards. With the increasing demand for aluminum metallic in various applications—from automotive and construction to consumer goods—it’s essential for businesses in regions like Africa, South America, the Middle East, and Europe to understand the nuances of this market. This guide provides a comprehensive overview of aluminum metallic, detailing its types, applications, and the critical factors to consider when vetting suppliers.

By exploring the intricacies of sourcing aluminum metallic, including cost considerations and quality assessments, this guide empowers B2B buyers to make informed purchasing decisions. We delve into the characteristics that differentiate aluminum metallic products, such as their strength-to-weight ratio and corrosion resistance, while also highlighting emerging trends that could impact supply chains.

Additionally, we provide actionable insights for selecting reputable suppliers, ensuring that buyers can navigate the complexities of international trade with confidence. Whether you’re based in Germany, Nigeria, or any other global market, this guide is designed to equip you with the knowledge needed to optimize your procurement strategies and enhance your competitive edge.

Understanding alu metallic Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Aluminium Metallic Paint | High luster, thick consistency, water-dilutable | Automotive, furniture, and decorative finishes | Pros: Easy application, versatile, no priming. Cons: May require multiple coats for full opacity. |

| Ultra Gloss Vinyl Wrap | Flexible, high-gloss finish, various sizes available | Vehicle customization, signage, interior design | Pros: Durable, easy to install, customizable. Cons: Requires specific installation techniques, can be expensive. |

| Aluminum Coated Products | Enhanced corrosion resistance, lightweight | Aerospace, automotive, and construction | Pros: Superior strength-to-weight ratio, cost-effective. Cons: Susceptible to surface oxidation if not treated. |

| Aluminum Composite Panels | Two-layer structure, excellent insulation properties | Building facades, interior walls, signage | Pros: Aesthetic appeal, good thermal insulation. Cons: Installation can be complex, limited to certain applications. |

| Metallic Aluminum Alloys | Varied compositions for specific properties | Electrical components, automotive parts | Pros: High conductivity, tailored properties. Cons: Price volatility depending on alloy composition. |

What are the Characteristics and Suitability of Aluminium Metallic Paint?

Aluminium metallic paint is a versatile option that provides a radiant finish, ideal for a variety of applications including automotive refinishing and decorative projects. Its thick consistency allows for dimensional effects, making it suitable for both professional and DIY applications. When considering a purchase, buyers should note that while the paint adheres well to most surfaces without the need for sanding or priming, achieving full opacity may require multiple coats, which can increase labor costs.

How Does Ultra Gloss Vinyl Wrap Stand Out in the Market?

Ultra gloss vinyl wraps are designed for durability and aesthetic appeal, making them a popular choice for vehicle customization and advertising. The flexibility of the material allows it to conform to various surfaces, providing a seamless finish. However, installation requires specific techniques and tools, which may necessitate hiring professional installers. Buyers should weigh the long-term benefits of durability against the upfront investment and potential installation challenges.

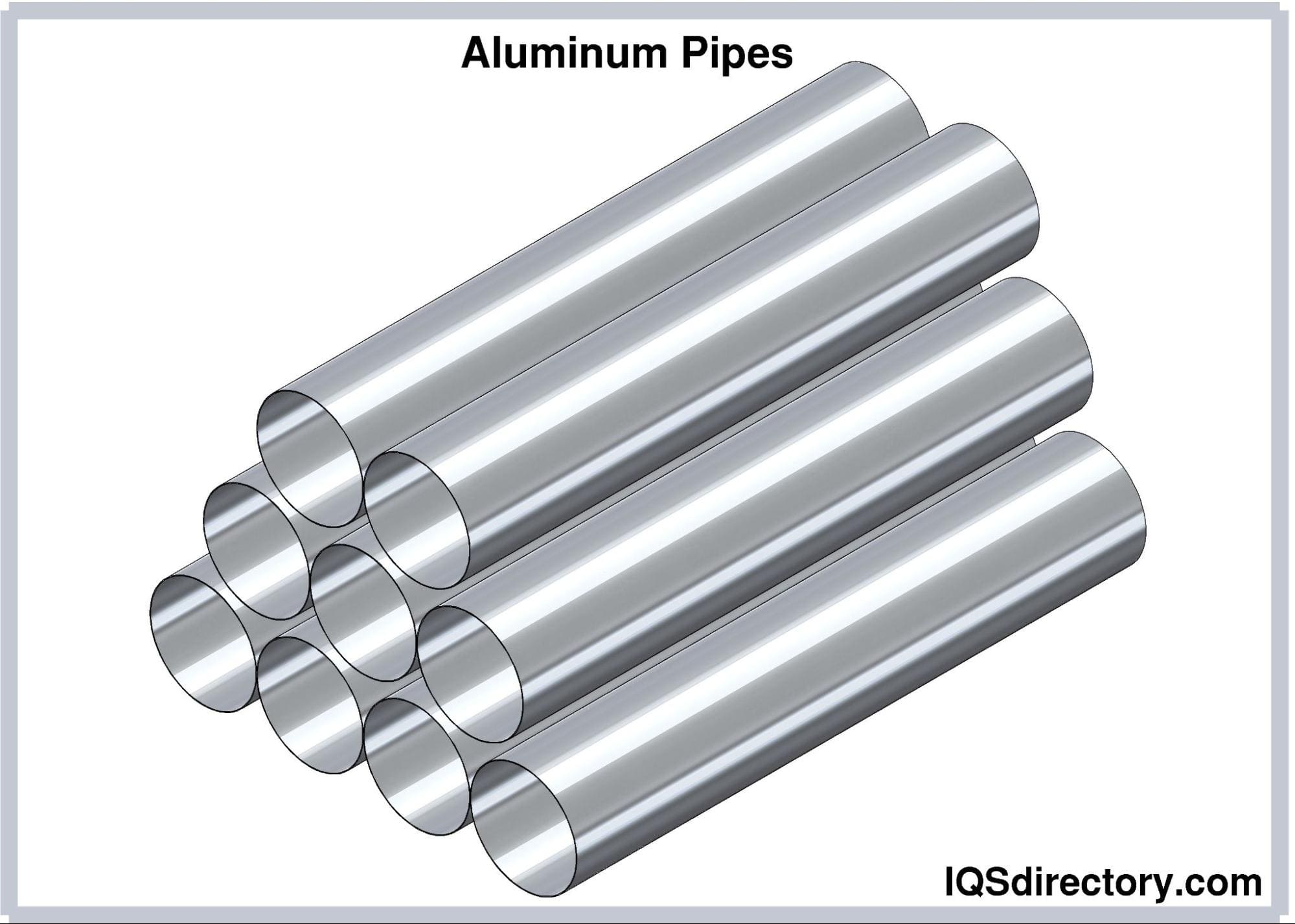

What Advantages Do Aluminum Coated Products Offer to B2B Buyers?

Aluminum coated products enhance the natural properties of aluminum, offering improved corrosion resistance and a lighter weight compared to alternatives like stainless steel. These features make them particularly valuable in industries such as aerospace and automotive, where weight savings can lead to significant performance improvements. Buyers should consider the necessity of additional protective treatments to prevent surface oxidation, which can affect longevity and performance.

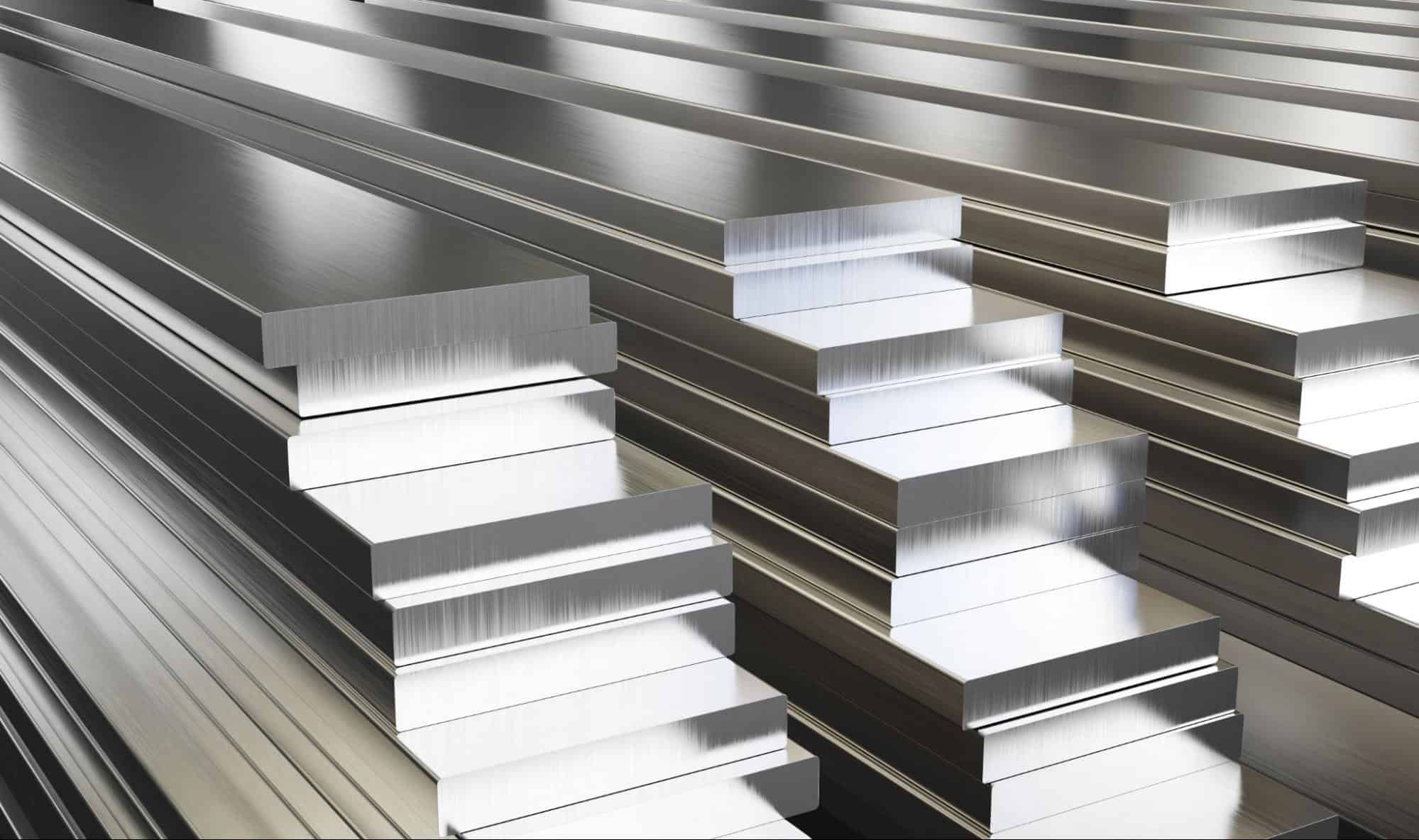

Illustrative image related to alu metallic

Why Are Aluminum Composite Panels Preferred in Construction?

Aluminum composite panels consist of two thin layers of aluminum enclosing a non-aluminum core, providing excellent thermal insulation and aesthetic versatility. They are commonly used in building facades and interior applications due to their lightweight nature and modern appearance. However, the complexity of installation can deter some buyers, making it essential to partner with experienced contractors who understand the nuances of working with these materials.

How Do Metallic Aluminum Alloys Cater to Specific Industry Needs?

Metallic aluminum alloys are engineered to meet specific performance criteria, making them suitable for applications in electrical components and automotive parts. Their high electrical and thermal conductivity, combined with a lower weight compared to traditional metals, offers significant advantages. Buyers should be mindful of the price volatility associated with different alloy compositions, which can impact overall project budgets.

Key Industrial Applications of alu metallic

| Industry/Sector | Specific Application of alu metallic | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Vehicle wraps and coatings | Enhances aesthetic appeal and brand visibility while protecting surfaces. | Ensure compatibility with vehicle surfaces and climate conditions. |

| Construction | Structural components and facades | Provides lightweight strength and durability, reducing overall project costs. | Assess corrosion resistance and compliance with local regulations. |

| Aerospace | Aircraft components | Reduces weight, improving fuel efficiency and performance. | Verify material certifications and performance under extreme conditions. |

| Electronics | Heat sinks and enclosures | Improves thermal management, enhancing device reliability and lifespan. | Source materials with high thermal conductivity and low weight. |

| Renewable Energy | Solar panel frames and components | Increases energy efficiency and lowers maintenance costs. | Consider environmental impact and recyclability of materials. |

How is alu metallic used in the automotive industry, and what are the benefits for B2B buyers?

In the automotive sector, alu metallic is commonly used for vehicle wraps and protective coatings. These applications enhance aesthetic appeal and brand visibility while providing a protective layer against environmental factors. For international buyers, especially in regions like Africa and South America, sourcing high-quality alu metallic that adheres well to various surfaces and withstands local climate conditions is crucial. Ensuring compatibility with vehicle surfaces and understanding local regulations regarding vehicle modifications can significantly impact purchasing decisions.

What role does alu metallic play in construction, and why is it a preferred choice?

In construction, alu metallic is utilized for structural components and facade applications due to its lightweight yet durable properties. This material helps reduce overall project costs while maintaining structural integrity and aesthetic appeal. For buyers in Europe and the Middle East, it is essential to assess the corrosion resistance of alu metallic, especially in coastal areas, and ensure compliance with local building codes. Understanding the lifecycle cost and maintenance requirements can further enhance decision-making for construction projects.

Illustrative image related to alu metallic

How does alu metallic contribute to aerospace applications, and what should buyers consider?

Alu metallic is critical in aerospace applications, particularly for aircraft components, as it significantly reduces weight, thus improving fuel efficiency and overall performance. International buyers, particularly from Germany and other European nations, must verify material certifications and ensure that the alu metallic used meets stringent aerospace standards. Buyers should also consider the performance of these materials under extreme conditions, including temperature fluctuations and stress, to ensure safety and reliability in aviation.

In what ways is alu metallic beneficial for electronics, and what are the sourcing challenges?

In the electronics industry, alu metallic is often used for heat sinks and enclosures, playing a vital role in thermal management. By improving heat dissipation, alu metallic enhances device reliability and prolongs lifespan, which is essential for manufacturers. Buyers should prioritize sourcing materials with high thermal conductivity and low weight to optimize device performance. Additionally, understanding the specific requirements for electronics applications, such as electromagnetic compatibility, can be a critical factor in the sourcing process.

Why is alu metallic significant in renewable energy applications, and what should buyers keep in mind?

Alu metallic is increasingly used in renewable energy sectors, particularly for solar panel frames and components. Its lightweight nature increases energy efficiency and reduces maintenance costs. For buyers in regions like Africa and South America, considering the environmental impact and recyclability of alu metallic is crucial for aligning with sustainability goals. Additionally, buyers should evaluate the durability of materials in various environmental conditions to ensure long-term performance and reliability in renewable energy systems.

3 Common User Pain Points for ‘alu metallic’ & Their Solutions

Scenario 1: Challenges with Surface Preparation for Alu Metallic Coatings

The Problem: One common issue faced by B2B buyers dealing with alu metallic coatings is ensuring proper surface preparation before application. Many buyers may underestimate the importance of this step, leading to poor adhesion and a compromised finish. For instance, a manufacturer in South America might apply metallic aluminum paint directly onto a substrate without adequately cleaning or sanding the surface, resulting in peeling or bubbling. This not only affects the aesthetics of the product but can also lead to additional costs and time delays due to the need for reapplication.

The Solution: To overcome this challenge, it is essential to follow a meticulous surface preparation protocol. First, ensure the surface is free from dust, grease, and contaminants by cleaning it with appropriate solvents. For metallic surfaces, light sanding is recommended to create a profile that enhances adhesion. Additionally, utilizing a primer specifically designed for metallic coatings can significantly improve the bond. B2B buyers should source high-quality primers and cleaning agents, and consider conducting a small test patch to verify adhesion before full-scale application. This proactive approach not only ensures a durable finish but also enhances overall customer satisfaction.

Scenario 2: Navigating Corrosion Resistance in Different Environments

The Problem: B2B buyers often encounter difficulties in selecting the right alu metallic products that can withstand varying environmental conditions. For example, a construction firm operating in the Middle East may require metallic aluminum components that can endure high temperatures and humidity without corroding. However, many suppliers do not provide sufficient information about the corrosion resistance of their products, leaving buyers unsure about their long-term performance.

The Solution: To address this pain point, buyers should prioritize suppliers that offer detailed product specifications, including corrosion resistance ratings and environmental suitability. It’s beneficial to look for alu metallic products that come with protective coatings or treatments, such as anodizing, which enhance durability against corrosion. Additionally, engaging with manufacturers who provide case studies or testimonials from similar environments can offer valuable insights. Buyers should also consider implementing a robust maintenance plan that includes regular inspections and touch-ups to ensure the longevity of their alu metallic products in harsh conditions.

Scenario 3: High Costs Associated with Sourcing Quality Alu Metallic Products

The Problem: Many international B2B buyers face the challenge of high costs when sourcing alu metallic products, particularly when importing from regions with strong manufacturing capabilities, like Europe. A buyer in Nigeria may find themselves paying significantly more for metallic aluminum paints or coatings due to shipping fees and tariffs, impacting their overall project budgets and profitability.

The Solution: To mitigate these costs, buyers should explore local suppliers who can offer competitive pricing without the added shipping expenses. Developing relationships with regional manufacturers can lead to better pricing and more favorable payment terms. Additionally, bulk purchasing agreements or long-term contracts can yield discounts and reduce overall costs. Buyers should also leverage technology by using online platforms to compare prices and quality from different suppliers. Regularly attending industry trade shows can help establish contacts with new vendors and keep abreast of market trends that could lead to cost-saving opportunities. By strategically sourcing and negotiating, B2B buyers can significantly enhance their bottom line while still obtaining quality alu metallic products.

Illustrative image related to alu metallic

Strategic Material Selection Guide for alu metallic

What Are the Key Properties of Common Alu Metallic Materials?

When selecting materials for alu metallic applications, several options stand out based on their properties and suitability for various industries. Here, we analyze four common materials: pure aluminum, aluminum alloys, aluminum composite materials, and metallic aluminum paint. Each material presents unique characteristics that influence their performance, durability, and cost-effectiveness.

What Are the Key Properties of Pure Aluminum?

Pure aluminum is known for its excellent corrosion resistance, high thermal and electrical conductivity, and lightweight nature. It typically performs well under moderate temperatures, making it suitable for various applications, including electrical components and architectural elements. However, its lower strength compared to alloys can limit its use in high-stress environments.

Pros: Pure aluminum is cost-effective, easy to fabricate, and has a high resistance to oxidation.

Cons: Its lower mechanical strength and susceptibility to deformation under heavy loads can be a drawback in certain applications.

Impact on Application: Pure aluminum is compatible with a range of media but may not withstand extreme conditions without reinforcement.

Considerations for International Buyers: Compliance with standards such as ASTM and DIN is crucial, especially in regulated markets like Europe and the Middle East.

How Do Aluminum Alloys Compare?

Aluminum alloys, such as 6061 and 7075, are engineered to enhance strength and durability. They exhibit good corrosion resistance and can be heat-treated to improve mechanical properties. These alloys are often used in aerospace, automotive, and construction industries due to their strength-to-weight ratio.

Pros: Aluminum alloys offer enhanced strength, durability, and versatility in manufacturing processes.

Cons: They can be more expensive than pure aluminum and may require specialized fabrication techniques.

Impact on Application: Alloys are suitable for high-stress applications but may require coatings to enhance corrosion resistance in aggressive environments.

Considerations for International Buyers: Buyers should ensure compliance with specific alloy standards and certifications, especially for aerospace applications in Europe and North America.

Illustrative image related to alu metallic

What Advantages Do Aluminum Composite Materials Offer?

Aluminum composite materials (ACM) consist of two thin layers of aluminum enclosing a non-aluminum core. They are lightweight, durable, and provide excellent insulation and soundproofing properties. ACM is widely used in building facades and signage.

Pros: ACM offers excellent aesthetic appeal, thermal insulation, and sound attenuation.

Cons: They can be more expensive and require careful handling during installation due to their composite nature.

Impact on Application: ACM is ideal for exterior applications but may not be suitable for high-temperature environments.

Considerations for International Buyers: Understanding local building codes and fire safety regulations is essential when sourcing ACM for construction projects.

How Does Metallic Aluminum Paint Perform?

Metallic aluminum paint provides a decorative and protective finish for various surfaces. It is easy to apply and can be used on metal, wood, and plastic. This paint offers good weather resistance and can enhance the aesthetic appeal of products.

Pros: Easy application, cost-effective, and enhances surface durability and appearance.

Cons: Limited to surface applications and may require reapplication over time due to wear.

Impact on Application: Suitable for decorative finishes but may not provide the same level of protection as coatings on structural materials.

Considerations for International Buyers: Buyers should look for compliance with environmental regulations regarding VOC emissions, particularly in Europe.

Summary Table of Material Selection for Alu Metallic

| Material | Typical Use Case for alu metallic | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Pure Aluminum | Electrical components, architectural elements | Excellent corrosion resistance | Lower mechanical strength | Low |

| Aluminum Alloys | Aerospace, automotive, construction | High strength-to-weight ratio | Higher cost, specialized fabrication | Med |

| Aluminum Composite Materials | Building facades, signage | Aesthetic appeal, thermal insulation | Higher cost, careful handling required | High |

| Metallic Aluminum Paint | Decorative finishes on various surfaces | Easy application, cost-effective | Limited protective capabilities | Low |

This strategic material selection guide provides essential insights for B2B buyers in Africa, South America, the Middle East, and Europe, enabling informed decisions based on specific application needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for alu metallic

What Are the Key Stages in the Manufacturing Process of Alu Metallic?

The manufacturing process of alu metallic involves several critical stages that ensure the final product meets the required specifications for various applications.

Material Preparation

The first stage is material preparation, where high-quality aluminum is sourced, typically from bauxite ore. This involves refining the bauxite through the Bayer Process to extract alumina, which is then subjected to the Hall-Héroult electrolytic process to produce pure aluminum. For products requiring specific properties, alloying elements may be added during this stage to enhance strength, corrosion resistance, or conductivity.

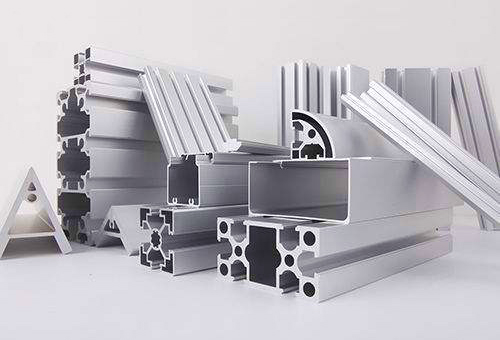

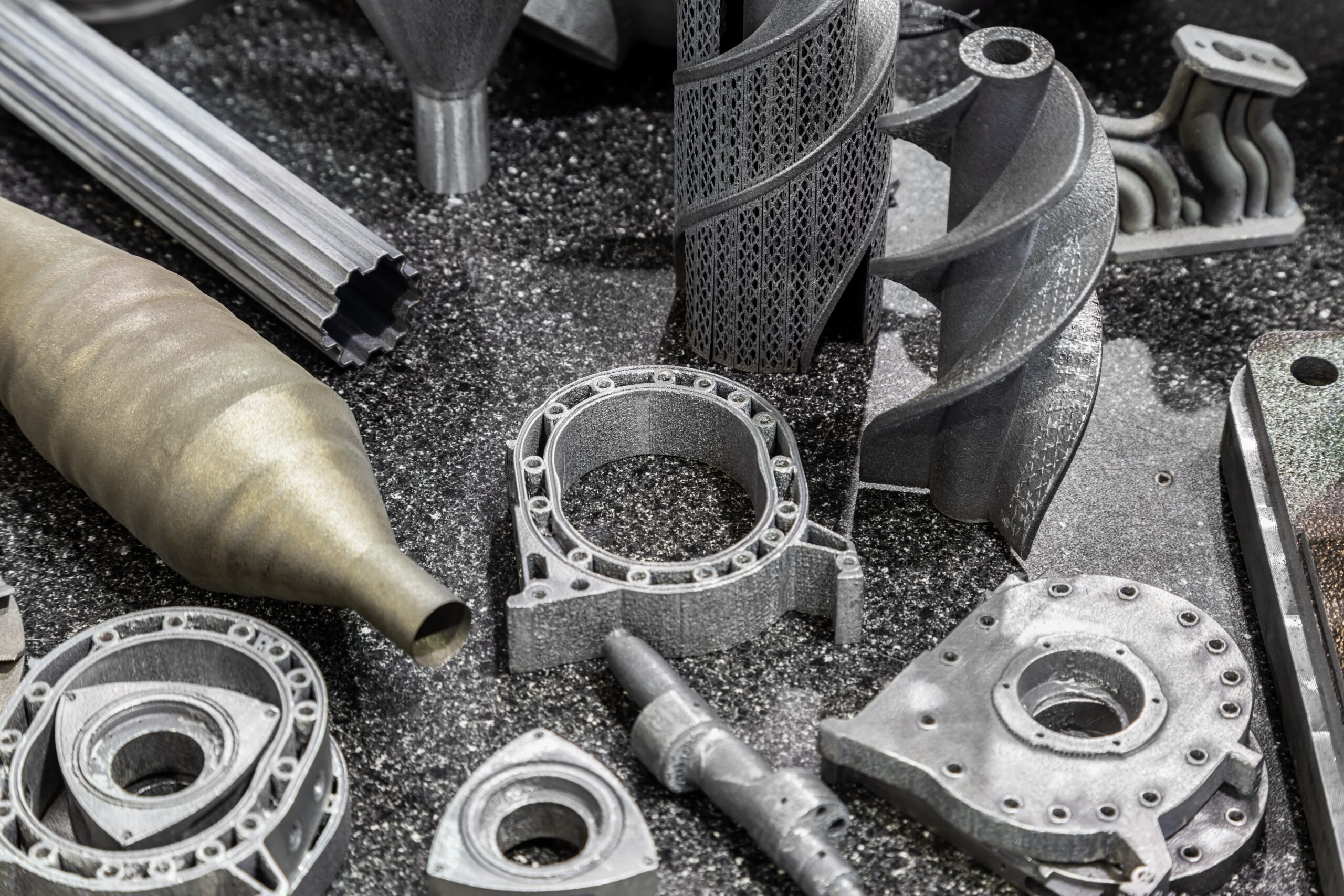

Forming Techniques

Once the aluminum is prepared, various forming techniques are employed. Common methods include:

- Casting: Molten aluminum is poured into molds to create specific shapes. This is beneficial for producing complex geometries.

- Extrusion: Aluminum billets are heated and forced through a die to create long sections with a constant cross-section. This technique is widely used for profiles and tubes.

- Rolling: Aluminum sheets are produced by passing the metal through rollers, which reduces thickness while increasing length. This is crucial for applications requiring thin sheets or foils.

Each method presents unique advantages, and the choice often depends on the end product’s requirements.

Illustrative image related to alu metallic

Assembly and Finishing Processes

After forming, components may undergo assembly, particularly in applications involving multiple parts. Following assembly, finishing processes such as anodizing, painting, or coating are applied to enhance surface properties. Anodizing not only improves corrosion resistance but also provides aesthetic appeal. Additionally, metallic paints can be applied to achieve specific visual effects, which are increasingly popular in automotive and consumer goods.

How Is Quality Assurance Implemented in Alu Metallic Production?

Quality assurance (QA) is paramount in the manufacturing of alu metallic products to ensure they meet international standards and customer specifications.

What Are the Relevant International Standards for Quality Assurance?

Many manufacturers adhere to international quality standards, such as ISO 9001, which outlines the requirements for a quality management system. This certification is essential for global trade, as it assures buyers of consistent quality. Additionally, industry-specific certifications such as CE marking for compliance with European safety standards or API specifications for oil and gas applications are critical for establishing credibility and market acceptance.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is integrated into various stages of the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet predetermined specifications before processing begins.

- In-Process Quality Control (IPQC): During manufacturing, continuous monitoring is performed to identify defects early. This can include dimensional checks, visual inspections, and functional testing.

- Final Quality Control (FQC): After the manufacturing process, finished products undergo rigorous testing to confirm they meet quality standards. This may include mechanical testing, corrosion resistance evaluations, and surface finish inspections.

What Common Testing Methods Are Used in Alu Metallic Quality Assurance?

Several testing methods are commonly employed to validate the quality of alu metallic products:

- Tensile Testing: Measures the material’s strength and ductility, ensuring it can withstand operational stresses.

- Hardness Testing: Assesses the material’s resistance to deformation, which is critical for applications requiring durability.

- Corrosion Testing: Evaluates the material’s resistance to various environmental conditions, crucial for products exposed to harsh elements.

- Non-Destructive Testing (NDT): Techniques like ultrasonic testing or dye penetrant testing are used to detect internal flaws without damaging the product.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially in diverse markets like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for ensuring product reliability.

What Steps Can Be Taken to Verify Supplier QC?

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide insights into their manufacturing processes, quality management systems, and adherence to standards.

-

Reviewing Quality Reports: Requesting detailed quality reports, including results from IQC, IPQC, and FQC, can help assess a supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of a supplier’s quality control measures. These organizations can conduct random inspections and provide certification that the products meet specified standards.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various nuances related to quality control, particularly when sourcing products across borders.

Illustrative image related to alu metallic

How Do Regional Standards Affect Quality Control?

Different regions may have varying standards and certifications, which can affect product acceptance in local markets. For instance, products manufactured in Europe may need to comply with CE marking, while those in the Middle East might require adherence to local regulatory standards. Understanding these requirements is crucial for successful market entry.

How Do Language and Cultural Differences Impact Quality Assurance?

Language barriers and cultural differences can complicate communication regarding quality expectations. B2B buyers should ensure clear documentation and agreements regarding quality standards, testing methods, and certifications. Utilizing local representatives or consultants can facilitate smoother interactions and ensure that both parties are aligned in their expectations.

Conclusion

The manufacturing processes and quality assurance practices for alu metallic products are critical for ensuring that these materials meet the high standards required by various industries. By understanding the key stages of manufacturing, relevant quality standards, and effective verification methods, B2B buyers can make informed decisions and foster successful partnerships with suppliers globally.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘alu metallic’

Introduction

This practical sourcing guide is designed for B2B buyers seeking to procure aluminum metallic products. It outlines essential steps to ensure that you select the right suppliers and materials, maximizing quality while minimizing risks. This checklist will help you navigate the complexities of sourcing aluminum metallic efficiently, ensuring you make informed purchasing decisions.

1. Define Your Technical Specifications

Establishing precise technical specifications is critical in sourcing aluminum metallic. This includes understanding the required alloy grade, dimensions, and surface treatments needed for your applications. Clearly defined specifications will help you communicate your needs to suppliers, ensuring that the products meet your operational requirements.

Illustrative image related to alu metallic

2. Research the Market Landscape

Before engaging with suppliers, conduct thorough market research to identify potential vendors. Look into the competitive landscape, pricing trends, and product availability in your target regions, such as Africa, South America, the Middle East, and Europe. This knowledge will enable you to benchmark offerings and negotiate effectively.

3. Verify Supplier Certifications

✅ Ensure Compliance with Industry Standards

Certification is a hallmark of quality and reliability in the manufacturing of aluminum metallic products. Verify that potential suppliers hold relevant certifications, such as ISO 9001 for quality management or specific industry-related standards. This step is crucial for ensuring that the supplier adheres to recognized quality practices, which can significantly impact product performance.

4. Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; consider visiting their facilities if possible to assess their production capabilities and quality control processes firsthand.

5. Request Samples and Test Quality

Before finalizing any orders, request samples of the aluminum metallic products to assess their quality. Conduct tests to evaluate their properties, such as corrosion resistance, conductivity, and weight. This step helps ensure that the products not only meet your specifications but also perform adequately in real-world applications.

6. Negotiate Terms and Conditions

Once you’ve identified a suitable supplier, engage in negotiations regarding pricing, delivery timelines, and payment terms. Clear communication about expectations can prevent misunderstandings and ensure a smoother procurement process. Additionally, discuss after-sales support and warranty terms to safeguard your investment.

7. Establish a Long-term Relationship

Building a long-term relationship with your supplier can lead to better pricing, priority service, and collaborative opportunities in product development. Maintain regular communication and feedback to foster a partnership that benefits both parties. This approach can help streamline future procurement processes and enhance your supply chain resilience.

By following this step-by-step checklist, B2B buyers can effectively navigate the complexities of sourcing aluminum metallic products, ensuring that they choose the best suppliers and materials for their needs.

Comprehensive Cost and Pricing Analysis for alu metallic Sourcing

What Are the Key Cost Components in Alu Metallic Sourcing?

When sourcing alu metallic products, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The price of aluminum is influenced by global market fluctuations, extraction costs, and the quality of the raw material. Suppliers often provide variations in grades, impacting the overall cost.

-

Labor: Labor costs can vary significantly based on the region and the skill level required for production. In countries with higher labor costs, such as Germany, the impact on pricing may be more pronounced compared to regions like Nigeria or South America.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce these costs, impacting the final pricing.

-

Tooling: Initial investment in tooling can be substantial, especially for custom orders. However, this is a one-time cost that can be amortized over large production runs.

-

Quality Control (QC): Implementing stringent quality control measures ensures that the products meet required specifications, which can add to the overall cost but is essential for maintaining standards.

-

Logistics: Shipping and handling costs, including transportation and warehousing, are critical, particularly for international buyers. These costs can vary based on distance, shipping method, and local tariffs.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks, which can vary depending on market conditions and competition.

How Do Price Influencers Impact Alu Metallic Sourcing?

Several factors can influence the pricing of alu metallic products, including:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often qualify for discounts, making it essential to assess your needs carefully. Buyers should consider potential stockpiling to benefit from lower per-unit costs.

-

Specifications and Customization: Customized products often incur higher costs due to the additional processes involved in meeting specific requirements. It’s vital to clearly define your specifications upfront to avoid unexpected charges.

-

Materials: The choice of aluminum grade can significantly affect pricing. Higher-grade materials, which offer better performance, will naturally cost more.

-

Quality and Certifications: Products certified to international standards (e.g., ISO, ASTM) may carry a premium price. However, these certifications can enhance product reliability and marketability.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to their proven track record, while emerging suppliers might offer competitive pricing to gain market share.

-

Incoterms: Understanding the agreed-upon Incoterms (International Commercial Terms) is crucial, as they define the responsibilities of buyers and sellers in shipping. This can significantly impact total costs.

What Buyer Tips Can Enhance Cost-Efficiency in Alu Metallic Sourcing?

-

Negotiation: Engage in open discussions with suppliers to negotiate prices, especially for larger orders. Building a long-term relationship can also yield better pricing over time.

-

Total Cost of Ownership (TCO): Consider the TCO, which includes purchase price, maintenance, and potential disposal costs. An initially higher price may be justified by lower operational costs over the product’s life.

-

Pricing Nuances for International Buyers: International buyers should be aware of currency fluctuations, trade tariffs, and shipping costs, which can all impact the final price. Establishing clear contracts that outline responsibilities and pricing structures can mitigate risks.

-

Market Research: Conduct thorough research on market trends and pricing benchmarks in your region. This knowledge can empower you during negotiations and help you identify fair pricing.

-

Supplier Diversification: Don’t rely solely on one supplier. Engaging multiple suppliers can enhance competition and provide leverage in negotiations.

Disclaimer on Indicative Prices

Prices for alu metallic products can fluctuate based on a multitude of factors, including raw material costs, labor markets, and global economic conditions. Therefore, the prices referenced in this analysis are indicative and should be verified with suppliers for current rates.

Alternatives Analysis: Comparing alu metallic With Other Solutions

Understanding Alternatives in the Context of Alu Metallic Solutions

In the competitive landscape of industrial materials, businesses often seek alternatives to optimize performance, reduce costs, and enhance operational efficiency. When considering ‘alu metallic,’ a versatile material known for its lightweight and corrosion-resistant properties, it is essential to analyze comparable solutions that can meet similar needs. This analysis will help B2B buyers make informed decisions based on their specific requirements, such as performance, cost, and ease of implementation.

Comparison Table

| Comparison Aspect | Alu Metallic | Ultra Gloss Paint Metallic Aluminum | Vinyl Wrap Solutions |

|---|---|---|---|

| Performance | High strength-to-weight ratio; excellent corrosion resistance | Good aesthetic finish; less durable than metal | Flexible, easy to apply; varies in durability |

| Cost | Moderate to high initial investment | High per roll, suitable for larger applications | Generally lower upfront cost |

| Ease of Implementation | Requires skilled labor for installation | Can be applied by professionals or DIYers | DIY-friendly; relatively simple application |

| Maintenance | Low maintenance; resistant to wear | Moderate; may require periodic touch-ups | High; can be damaged easily and requires replacement |

| Best Use Case | Ideal for structural applications and high-performance settings | Aesthetic enhancements in automotive and design sectors | Cost-effective branding and temporary applications |

Detailed Breakdown of Alternatives

Ultra Gloss Paint Metallic Aluminum

This alternative is a high-quality paint designed to provide a glossy finish with metallic effects. While it offers a visually appealing aesthetic, its durability may not match that of alu metallic. Ultra Gloss Paint is best suited for applications where appearance is prioritized, such as automotive customization and interior design. However, it may require more frequent maintenance and touch-ups due to environmental wear, making it less ideal for high-performance structural applications.

Vinyl Wrap Solutions

Vinyl wraps present a flexible alternative that is particularly popular in branding and temporary applications. They are cost-effective and easy to apply, allowing for quick customization without the need for extensive labor. However, vinyl wraps may not offer the same level of durability or resistance to the elements as alu metallic. They are best used for vehicles or surfaces that require frequent changes in appearance but may necessitate replacement more often due to potential damage.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the appropriate solution, B2B buyers should assess their specific needs, including the intended application, budget constraints, and required durability. Alu metallic stands out for applications demanding high strength and longevity, particularly in structural and industrial contexts. In contrast, alternatives like Ultra Gloss Paint and vinyl wraps offer aesthetic benefits and flexibility for projects where visual appeal is the primary concern. By carefully considering these factors, buyers can make informed decisions that align with their operational goals and budget, ensuring the chosen solution effectively meets their unique requirements.

Essential Technical Properties and Trade Terminology for alu metallic

What Are the Key Technical Properties of Alu Metallic?

When sourcing alu metallic materials, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications to consider:

-

Material Grade

Material grade indicates the specific composition and properties of aluminum alloys. Common grades such as 6061 and 7075 are utilized in various applications due to their unique strength, corrosion resistance, and workability. For B2B buyers, selecting the right grade ensures that the material meets performance requirements, especially in demanding environments like automotive or aerospace industries. -

Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension. It is critical in manufacturing processes where precision is necessary. For example, tighter tolerances can lead to higher production costs but are essential for components that require a perfect fit. Understanding tolerance levels helps buyers assess whether the material will suit their specific manufacturing processes and end-use applications. -

Corrosion Resistance

This property denotes the material’s ability to withstand degradation caused by environmental factors. Alu metallic typically exhibits good corrosion resistance, which is vital for applications exposed to moisture or chemicals. For international buyers, especially in humid or coastal regions, selecting aluminum with adequate corrosion resistance can prolong the life of products and reduce maintenance costs. -

Electrical Conductivity

Electrical conductivity measures how easily electricity can pass through a material. Aluminum is known for its excellent conductivity, making it ideal for electrical applications, such as wiring and connectors. For B2B buyers in sectors like energy or electronics, this property is crucial for ensuring efficiency and performance in their products. -

Thermal Conductivity

Similar to electrical conductivity, thermal conductivity indicates how well a material can conduct heat. Alu metallic is often used in heat exchangers and cooling systems due to its superior thermal properties. Buyers in industries such as HVAC or automotive should prioritize materials with high thermal conductivity to enhance product performance. -

Weight-to-Strength Ratio

This ratio describes the strength of the material relative to its weight. Alu metallic typically offers a high weight-to-strength ratio, which makes it an attractive option for industries seeking lightweight components that do not compromise on strength. Understanding this property helps buyers in sectors like aerospace and automotive optimize their designs for fuel efficiency and performance.

What Are Common Trade Terms Used in Alu Metallic Procurement?

Navigating the procurement landscape involves familiarity with specific jargon. Here are some common terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers who need components that fit seamlessly into existing systems or products. -

MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a supplier is willing to sell. This term is vital for buyers to understand, as it can impact inventory management and cash flow. Negotiating MOQs can lead to cost savings for larger orders. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific quantities of products. This process helps buyers compare options and make informed purchasing decisions. Crafting a clear RFQ can lead to better pricing and terms. -

Incoterms (International Commercial Terms)

These are standardized international shipping terms that define the responsibilities of buyers and sellers. Understanding Incoterms is essential for international transactions, as they dictate who is responsible for shipping, insurance, and tariffs. Familiarity with these terms can help prevent misunderstandings and additional costs. -

Lead Time

Lead time is the duration from placing an order to receiving the goods. In B2B transactions, understanding lead times is critical for project planning and inventory management. Buyers should communicate their needs clearly to align with suppliers’ timelines. -

Certification

Certification indicates that a product meets specific industry standards or regulations. For buyers, ensuring that aluminum products are certified can guarantee quality and compliance, particularly in regulated industries such as aerospace and automotive.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and strategic goals.

Navigating Market Dynamics and Sourcing Trends in the alu metallic Sector

What Are the Current Market Dynamics and Key Trends in the alu metallic Sector?

The alu metallic sector is experiencing significant growth driven by various global factors, particularly in emerging markets such as Africa, South America, and the Middle East. The increasing demand for lightweight materials in industries like automotive, aerospace, and construction is a key driver. For instance, the shift towards electric vehicles (EVs) necessitates lightweight components to enhance battery efficiency and vehicle performance. Additionally, the ongoing urbanization in regions like Africa and South America is spurring infrastructure development, which further fuels the demand for aluminum products.

Current and emerging sourcing trends include a greater reliance on digital procurement tools, enabling buyers to streamline their sourcing processes and enhance supply chain visibility. Technologies such as blockchain are being utilized for improved traceability in supply chains, ensuring that materials meet regulatory and quality standards. Furthermore, buyers are increasingly seeking suppliers who can provide comprehensive data analytics, which can inform purchasing decisions and optimize inventory management.

International B2B buyers, particularly from regions like Europe and Nigeria, should also be aware of fluctuating aluminum prices influenced by geopolitical tensions and environmental regulations. The ongoing transition towards renewable energy sources is prompting a shift in the supply dynamics, as companies prioritize suppliers with sustainable practices. Thus, understanding these market dynamics is crucial for making informed sourcing decisions.

How Can Sustainability and Ethical Sourcing Be Integrated in the alu metallic Sector?

Sustainability is becoming a cornerstone of procurement strategies in the alu metallic sector. The environmental impact of aluminum production, notably its carbon footprint, has prompted buyers to prioritize suppliers who engage in sustainable practices. This includes the use of recycled aluminum, which not only reduces energy consumption but also lessens the ecological footprint associated with primary aluminum production.

Ethical sourcing is equally important, as buyers are increasingly aware of the social implications of their supply chains. Companies are expected to demonstrate transparency and responsibility in their sourcing practices, which includes ensuring fair labor practices and minimizing environmental degradation. Certifications such as ISO 14001 for environmental management and the Aluminium Stewardship Initiative (ASI) certification are becoming pivotal in evaluating suppliers.

Moreover, integrating ‘green’ materials into product offerings is a growing trend. B2B buyers should seek suppliers who can provide eco-friendly aluminum coatings and finishes that comply with stringent environmental regulations. By aligning with sustainable and ethical sourcing practices, companies can not only enhance their brand reputation but also meet the demands of environmentally conscious consumers.

How Has the alu metallic Sector Evolved Over Time?

The evolution of the alu metallic sector is marked by significant technological advancements and changing market demands. Initially dominated by traditional manufacturing methods, the sector has seen a shift towards more innovative processes, such as the development of high-performance alloys and surface treatments that enhance durability and aesthetics.

The rise of digital technologies has further transformed the landscape, enabling more efficient production and supply chain management. With the increasing emphasis on sustainability, the sector has also adapted by incorporating recycling and waste reduction strategies into manufacturing processes. This evolution reflects a broader trend towards a circular economy, where the focus is on resource efficiency and minimizing environmental impact.

Illustrative image related to alu metallic

As international B2B buyers navigate this dynamic landscape, understanding the historical context of the alu metallic sector can provide valuable insights into future trends and opportunities. Adapting to these changes will be essential for maintaining competitiveness in an increasingly globalized market.

Frequently Asked Questions (FAQs) for B2B Buyers of alu metallic

1. How do I solve quality issues with aluminum metallic products?

To address quality issues with aluminum metallic products, start by implementing a robust quality assurance process. This includes sourcing from reputable suppliers who provide certifications for their materials. Conduct pre-shipment inspections to verify product specifications and consistency. Additionally, establish clear communication channels with suppliers to discuss quality concerns and potential solutions. Utilizing third-party testing labs can also enhance confidence in product quality and performance.

2. What is the best aluminum metallic option for automotive applications?

The best aluminum metallic option for automotive applications typically includes high-strength alloys with excellent corrosion resistance and lightweight properties. Look for aluminum grades like 6061 or 7075, which offer a favorable strength-to-weight ratio and are widely used in vehicle manufacturing. Ensure that the aluminum meets industry-specific standards and regulations to guarantee durability and performance under various conditions.

3. What factors should I consider when vetting aluminum metallic suppliers?

When vetting aluminum metallic suppliers, evaluate their industry experience, production capacity, and quality certifications (such as ISO 9001). Request samples to assess product quality and adherence to specifications. Investigate their supply chain reliability, customer service responsiveness, and ability to meet delivery timelines. Additionally, consider their financial stability to ensure long-term partnership viability.

4. What is the typical minimum order quantity (MOQ) for aluminum metallic products?

The minimum order quantity (MOQ) for aluminum metallic products can vary significantly by supplier and product type. Generally, MOQs range from 500 kg to several tons, depending on the manufacturing process and material specifications. It’s advisable to discuss your specific needs with suppliers to negotiate a suitable MOQ that aligns with your project requirements and budget.

5. How can I customize aluminum metallic products to meet specific needs?

Customization of aluminum metallic products can be achieved through various methods, including alloy selection, surface treatments, and specific dimensions. Discuss your requirements with suppliers who offer tailored solutions, such as anodizing, painting, or machining services. Providing detailed specifications and prototypes can help ensure the final product meets your exact needs while maintaining performance standards.

6. What payment terms are commonly used in international aluminum metallic transactions?

Common payment terms for international aluminum metallic transactions include advance payment, letters of credit, and payment upon delivery. Many suppliers may request a deposit (e.g., 30%) upfront, with the remaining balance due before shipping. Ensure to clarify terms in the purchase agreement and consider using escrow services to protect both parties during the transaction.

7. How do I ensure timely logistics for importing aluminum metallic products?

To ensure timely logistics for importing aluminum metallic products, collaborate closely with suppliers and freight forwarders. Plan shipments well in advance, considering production lead times and potential customs delays. Utilize tracking systems to monitor shipments and stay informed about their status. Additionally, familiarize yourself with local regulations and duties to avoid unexpected holdups at customs.

8. What quality assurance measures should I implement for aluminum metallic imports?

Implementing quality assurance measures for aluminum metallic imports includes conducting thorough inspections upon arrival, utilizing standardized testing methods, and maintaining proper documentation. Establish a set of quality benchmarks based on industry standards and supplier specifications. Regular audits and feedback loops with suppliers can help address any recurring issues and maintain product integrity throughout the supply chain.

Top 3 Alu Metallic Manufacturers & Suppliers List

1. Krylon – ColorMaxx Spray Paint 12oz Metallic Aluminum

Domain: artsupplywarehouse.com

Registered: 1997 (28 years)

Introduction: {“product_name”: “Krylon ColorMaxx Spray Paint”, “size”: “12oz”, “color”: “Metallic Aluminum”, “sku”: “KRY5587”}

2. 40Visuals – Metallic Alu-Panel

Domain: 40visuals.com

Registered: 2013 (12 years)

Introduction: Metallic Alu-Panel is a sturdy 1/8″ thick signage solution made of two .3mm aluminum composite sheets with a polyethylene core. It is designed for long-term indoor and outdoor use, offering durability, smoothness, lightweight, and rigidity. The graphics printed on this substrate have vibrant colors and an authentic metal look. All signage is UV protected to maintain its appearance. Available optio…

3. ALU – Sterling Silver Powder Paint

Domain: allpowderpaints.com

Registered: 2011 (14 years)

Introduction: {“Product Name”: “ALU Sterling Silver”, “Price”: “$17.57 (lb.)”, “Product ID”: “PMMS79230”, “Price Breaks”: [{“Weight Range”: “1 lbs. – 4 lbs.”, “Price Per Pound”: “$17.57”}, {“Weight Range”: “5 lbs. – 10 lbs.”, “Price Per Pound”: “$17.13”}, {“Weight Range”: “11 lbs. – 19 lbs.”, “Price Per Pound”: “$16.62”}, {“Weight Range”: “20 lbs. – 29 lbs.”, “Price Per Pound”: “$16.08”}, {“Weight Range”: “30 l…

Strategic Sourcing Conclusion and Outlook for alu metallic

As the global market for aluminum metallic continues to expand, strategic sourcing has become essential for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. The versatility of aluminum metallic—coupled with its superior strength-to-weight ratio, corrosion resistance, and thermal conductivity—positions it as an invaluable material across various sectors, including automotive, construction, and electronics.

Understanding the nuances of sourcing aluminum metallic, from evaluating suppliers to assessing product quality, can lead to significant cost savings and enhanced operational efficiency. By leveraging advanced sourcing strategies, businesses can not only secure high-quality materials but also foster long-term partnerships that drive innovation and sustainability.

Looking ahead, the demand for aluminum metallic is poised to grow, driven by advancements in technology and increasing environmental regulations. B2B buyers should proactively engage with suppliers who demonstrate a commitment to quality and sustainability. Embrace this opportunity to refine your sourcing strategies and position your business at the forefront of the aluminum metallic market. Engage with trusted suppliers, explore innovative applications, and ensure your procurement practices align with future market trends for sustained competitive advantage.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.