Allen Roth Replacement Parts: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for allen roth replacement parts

In today’s competitive landscape, sourcing reliable allen roth replacement parts can pose significant challenges for international B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe. With the growing demand for high-quality cabinetry and lighting solutions, ensuring access to authentic replacement parts is crucial for maintaining product integrity and customer satisfaction. This comprehensive guide aims to equip businesses with the knowledge needed to navigate the complexities of the global market for allen roth replacement parts, addressing key considerations such as types of parts available, their applications, and effective strategies for supplier vetting.

Throughout this guide, we delve into the essential aspects of sourcing, including cost analysis and procurement best practices. By understanding the nuances of the market, buyers can make informed purchasing decisions that align with their operational needs and budget constraints. Additionally, we provide insights into the logistics of international shipping and the importance of establishing reliable partnerships with suppliers.

Empowering businesses to confidently procure allen roth replacement parts, this guide will help you streamline your operations and enhance your service offerings. As you explore the sections ahead, you’ll gain valuable insights that can lead to significant cost savings and improved customer experiences, ultimately supporting your business’s growth in diverse global markets.

Understanding allen roth replacement parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cabinetry Replacement Parts | Includes doors, drawer fronts, and hardware like hinges and handles. | Furniture manufacturers, contractors, and retailers. | Pros: Customizable options; easy installation. Cons: May require precise measurements for fitting. |

| Lighting Replacement Parts | Comprises light bulbs, shades, and electrical components like sockets. | Retailers, electricians, and interior designers. | Pros: Wide variety available; enhances existing fixtures. Cons: Compatibility issues with older models. |

| Bathroom Fixtures | Includes faucets, showerheads, and cabinet hardware. | Plumbing suppliers, contractors, and home improvement stores. | Pros: Upgrades aesthetic and functionality; often water-efficient. Cons: Can be costly if replacing entire sets. |

| Outdoor Lighting Components | Features posts, mounts, and fixtures designed for exterior use. | Landscape architects, outdoor event planners, and construction firms. | Pros: Durable materials; enhances outdoor spaces. Cons: May require professional installation for optimal results. |

| Miscellaneous Accessories | Additional parts such as connectors, brackets, and mounting hardware. | General contractors and DIY suppliers. | Pros: Versatile applications; often inexpensive. Cons: Quality may vary; requires careful selection for specific needs. |

What Are the Key Characteristics of Cabinetry Replacement Parts?

Cabinetry replacement parts are essential for maintaining and upgrading kitchen and bathroom environments. They include a range of components such as doors, drawer fronts, and hardware like hinges and handles. For B2B buyers, particularly furniture manufacturers and contractors, these parts offer customization options that can significantly enhance the appeal and functionality of cabinetry. When purchasing, it’s crucial to consider the specific measurements and design compatibility to ensure seamless integration into existing setups.

How Do Lighting Replacement Parts Enhance Fixtures?

Lighting replacement parts encompass a variety of components, including bulbs, shades, and sockets. These parts are vital for retailers, electricians, and interior designers looking to refresh or upgrade existing lighting solutions. They provide an opportunity to improve energy efficiency and aesthetic appeal. Buyers should focus on compatibility with existing fixtures and the availability of energy-efficient options to maximize value and sustainability in their projects.

Why Are Bathroom Fixtures Important for Upgrades?

Bathroom fixtures, such as faucets and showerheads, play a significant role in both the functionality and visual appeal of bathroom spaces. They are essential for plumbing suppliers, contractors, and home improvement stores focused on providing quality upgrades. When considering purchases, B2B buyers should prioritize water efficiency and design trends to meet consumer demands while ensuring compliance with local regulations.

What Are the Benefits of Outdoor Lighting Components?

Outdoor lighting components, including posts, mounts, and fixtures, are designed specifically for exterior applications. They are crucial for landscape architects and construction firms aiming to enhance outdoor spaces for residential or commercial use. The durability of materials used in these components is a significant consideration, as they must withstand various weather conditions. Buyers should also evaluate installation requirements to ensure optimal performance and safety.

How Do Miscellaneous Accessories Fit into Replacement Parts?

Miscellaneous accessories, such as connectors, brackets, and mounting hardware, serve versatile roles in various applications. They are particularly useful for general contractors and DIY suppliers looking to complete projects efficiently. While these parts are often inexpensive and readily available, buyers must carefully assess quality and suitability for their specific needs to avoid potential issues in installation or performance.

Key Industrial Applications of allen roth replacement parts

| Industry/Sector | Specific Application of allen roth replacement parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Renovation | Replacement of cabinetry hardware and fixtures | Enhances durability and aesthetics of installations | Quality assurance, compatibility with existing designs, and local availability |

| Hospitality & Retail | Upgrading lighting fixtures in hotels and stores | Improves ambiance and customer experience | Energy efficiency, design aesthetics, and compliance with local regulations |

| Interior Design | Customization of cabinetry and furniture | Allows for tailored solutions to client specifications | Availability of styles and finishes, lead times, and bulk purchasing options |

| Landscaping & Outdoor | Replacement parts for outdoor lighting systems | Enhances safety and visual appeal of outdoor spaces | Weather resistance, energy efficiency, and ease of installation |

| Home Improvement | DIY projects involving lighting and cabinetry | Cost-effective solutions for personal or rental properties | Product availability, ease of installation, and warranty options |

How Are allen roth Replacement Parts Utilized in Construction and Renovation Projects?

In the construction and renovation sector, allen roth replacement parts are crucial for enhancing the functionality and appearance of cabinetry and fixtures. These parts, including handles, hinges, and shelving, provide durable replacements that can withstand heavy use. For international buyers, especially from regions like Africa and the Middle East, sourcing high-quality parts that are compatible with existing installations is essential. Additionally, considering local building codes and aesthetic preferences can guide purchasing decisions, ensuring that the products meet both safety and design standards.

What Role Do allen roth Replacement Parts Play in Hospitality and Retail Settings?

In hospitality and retail industries, upgrading lighting fixtures with allen roth replacement parts can significantly improve the ambiance of spaces like hotels and stores. High-quality lighting enhances customer experience and can lead to increased sales. Buyers from South America and Europe should prioritize energy-efficient lighting solutions that align with sustainability goals. Understanding local energy regulations and availability of parts in the region will facilitate better sourcing decisions, ultimately leading to enhanced customer satisfaction and loyalty.

How Can Interior Designers Leverage allen roth Replacement Parts for Custom Projects?

Interior designers often require tailored solutions to meet specific client needs, making allen roth replacement parts invaluable. These components allow designers to customize cabinetry and furniture, ensuring that each project aligns with the client’s vision. When sourcing these parts, designers must consider the variety of styles and finishes available, along with lead times for delivery. For international projects, understanding local trends and preferences will help in selecting the most appealing options, enhancing the overall design quality.

What Benefits Do Landscaping and Outdoor Projects Gain from allen roth Replacement Parts?

In landscaping and outdoor applications, allen roth replacement parts are essential for maintaining and upgrading outdoor lighting systems. These parts not only improve the safety of outdoor spaces but also enhance their visual appeal, making them attractive for events or gatherings. Buyers in regions like Europe and the Middle East should focus on sourcing weather-resistant components that can withstand local climate conditions. Additionally, ease of installation and compatibility with existing systems are key considerations to ensure efficient upgrades.

Why Are allen roth Replacement Parts Important for Home Improvement Initiatives?

For DIY enthusiasts and homeowners, allen roth replacement parts offer cost-effective solutions for various home improvement projects, particularly in cabinetry and lighting. These parts allow for easy upgrades and repairs, enhancing the functionality and aesthetics of living spaces. International buyers should consider product availability and warranty options when sourcing these components. Understanding the installation requirements will also help ensure that projects are completed successfully, ultimately adding value to the property.

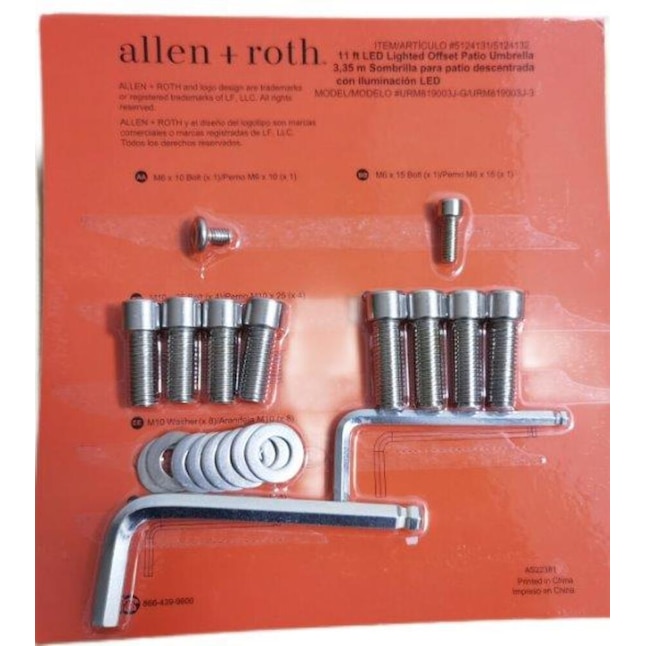

Illustrative image related to allen roth replacement parts

3 Common User Pain Points for ‘allen roth replacement parts’ & Their Solutions

Scenario 1: Navigating Limited Availability of Replacement Parts

The Problem: B2B buyers often encounter challenges in sourcing specific allen roth replacement parts due to limited availability in their regions. This can be particularly frustrating for businesses in Africa and South America, where access to certain products may be restricted. The lack of local suppliers can lead to extended downtime, increased project costs, and dissatisfaction from clients expecting timely service.

The Solution: To effectively navigate this issue, B2B buyers should establish relationships with reliable distributors who specialize in home improvement and cabinetry products. Consider reaching out to international suppliers who can ship products directly to your location, ensuring that you have a consistent supply of allen roth replacement parts. Additionally, leveraging online marketplaces such as Walmart or Wayfair can provide alternative sourcing options. It’s essential to maintain an updated inventory of commonly used parts to minimize delays. Implementing a proactive inventory management system can also help predict future needs based on project timelines, enabling timely orders and reducing the risk of stockouts.

Scenario 2: Ensuring Compatibility with Existing Products

The Problem: Another common pain point is the challenge of ensuring that replacement parts are compatible with existing allen roth products. B2B buyers often face difficulties when they need to replace components in older models, as specifications may have changed over time. This can lead to costly errors, including purchasing incompatible parts that cannot be used, thereby wasting both time and resources.

The Solution: To address compatibility concerns, B2B buyers should invest time in understanding the specifications of their existing allen roth products. This involves consulting product manuals or contacting customer support for guidance on compatible parts. Creating a detailed database of current inventory, including model numbers and specifications, can streamline the replacement process. Additionally, when sourcing parts, utilize online tools provided by retailers to cross-reference items and ensure that they meet the necessary compatibility criteria. Always confirm compatibility before finalizing orders to avoid unnecessary returns and delays.

Scenario 3: Managing Logistics and Delivery Times

The Problem: Logistics and delivery times can be a significant hurdle for B2B buyers sourcing allen roth replacement parts, particularly in regions with less developed infrastructure. Delays in shipping can disrupt project timelines and affect overall customer satisfaction. Buyers may find themselves waiting weeks for essential components, jeopardizing their business relationships and project commitments.

The Solution: To mitigate logistics challenges, B2B buyers should implement strategic planning around their sourcing practices. Consider establishing agreements with suppliers that offer expedited shipping options or local warehousing solutions to reduce delivery times. It’s also beneficial to explore partnerships with logistics providers who have experience navigating the complexities of international shipping. Buyers can negotiate favorable terms for bulk orders, which not only improves lead times but can also result in cost savings. Additionally, planning for seasonal fluctuations in demand can help ensure that replacement parts are in stock ahead of time, allowing for smoother project execution without unexpected delays.

Strategic Material Selection Guide for allen roth replacement parts

What Are the Key Properties of Common Materials Used in allen roth Replacement Parts?

When selecting replacement parts for allen roth products, understanding the materials used is crucial for ensuring optimal performance and longevity. Here, we will analyze four common materials: plastic, metal, glass, and composite materials. Each material has unique properties that influence its suitability for various applications, particularly in international markets.

How Does Plastic Perform in Replacement Parts?

Plastic is widely used in allen roth replacement parts due to its versatility and cost-effectiveness. Key properties of plastic include lightweight nature, resistance to corrosion, and ease of manufacturing. Common types of plastic, such as polycarbonate and polypropylene, offer good temperature resistance, typically ranging from -40°F to 200°F (-40°C to 93°C).

Pros: Plastics are durable, resistant to moisture, and relatively inexpensive. They can be molded into complex shapes, making them suitable for intricate designs.

Cons: While plastics are resistant to corrosion, they may not perform well under high temperatures or heavy loads. Over time, exposure to UV light can lead to degradation, making them less suitable for outdoor applications.

Impact on Application: Plastic components are ideal for indoor use or environments with minimal exposure to harsh conditions. However, international buyers should consider the compatibility of specific plastics with local environmental regulations and standards.

What Advantages Do Metals Offer for Replacement Parts?

Metals, such as aluminum and stainless steel, are often preferred for their strength and durability. Key properties include high tensile strength, excellent temperature resistance, and corrosion resistance, particularly in stainless steel variants.

Pros: Metals provide exceptional durability and can withstand high temperatures and pressures. They are also recyclable, which appeals to environmentally conscious buyers.

Cons: The cost of metal parts is generally higher than plastic, and the manufacturing process can be more complex, requiring specialized tools and techniques.

Impact on Application: Metals are suitable for high-stress applications, such as structural components. For international B2B buyers, compliance with standards such as ASTM or DIN is crucial, especially in regions with stringent quality requirements.

Why Is Glass a Consideration for Replacement Parts?

Glass is commonly used in lighting fixtures and decorative elements of allen roth products. Its key properties include high transparency, aesthetic appeal, and resistance to heat.

Pros: Glass provides excellent light transmission and is resistant to high temperatures. It can enhance the aesthetic value of products, making them more appealing to end consumers.

Illustrative image related to allen roth replacement parts

Cons: Glass is fragile and can break easily, which may lead to higher shipping costs and potential safety concerns. Additionally, it is heavier than plastic, which can affect shipping logistics.

Impact on Application: Glass parts are typically used in controlled environments where they are less likely to be damaged. International buyers should be aware of shipping regulations regarding fragile items and consider local preferences for glass versus plastic alternatives.

What Role Do Composite Materials Play in Replacement Parts?

Composite materials, which combine two or more different materials, are increasingly used in replacement parts for their enhanced properties. For instance, fiberglass composites offer high strength-to-weight ratios and excellent corrosion resistance.

Pros: Composites can be tailored for specific applications, providing a balance of strength, weight, and durability. They are often resistant to environmental degradation.

Cons: The manufacturing process for composites can be complex and costly. Additionally, they may not be as widely accepted or understood in certain international markets.

Impact on Application: Composites are suitable for specialized applications where traditional materials may fall short. B2B buyers should evaluate local market acceptance and compliance with relevant standards when considering composite materials.

Summary Table of Material Selection for allen roth Replacement Parts

| Material | Typical Use Case for allen roth replacement parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Cabinet components, light fixtures | Lightweight and cost-effective | UV degradation over time | Low |

| Metal | Structural supports, hardware | High strength and durability | Higher cost and complex manufacturing | High |

| Glass | Lighting fixtures, decorative elements | Excellent light transmission | Fragile and heavy | Medium |

| Composite | Specialty applications, high-stress components | Tailored properties for performance | Complex manufacturing process | Medium |

This analysis provides a comprehensive overview of the materials used in allen roth replacement parts, helping international B2B buyers make informed decisions based on performance, cost, and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for allen roth replacement parts

What Are the Typical Manufacturing Processes for allen roth Replacement Parts?

The manufacturing of allen roth replacement parts encompasses several critical stages, ensuring that each component meets the high standards expected by B2B buyers. The primary stages of the manufacturing process include material preparation, forming, assembly, and finishing.

How is Material Prepared for Manufacturing?

Material preparation is the foundation of the manufacturing process. It involves sourcing high-quality raw materials that adhere to industry standards. For allen roth replacement parts, common materials include engineered wood, metals, and plastics, each selected based on the specific application of the part. Suppliers often conduct rigorous testing of incoming materials to verify compliance with specifications.

What Forming Techniques Are Used in Manufacturing?

Once materials are prepared, the next step is forming, which shapes the materials into the required components. Techniques such as machining, molding, and extrusion are prevalent. For example, molded parts may be produced using injection molding for plastic components, while metal parts might be fabricated through stamping or CNC machining. These techniques ensure precision and consistency in the dimensions and performance of the replacement parts.

How Are Components Assembled?

Assembly involves bringing together the various formed components into a complete unit. This process can be manual or automated, depending on the complexity of the part. Automated assembly lines are often used for high-volume production, ensuring speed and efficiency. Each assembly station typically has specific quality checks to ensure that components fit together correctly and function as intended.

What Finishing Processes Are Important?

Finishing processes are essential for enhancing the aesthetic and functional qualities of the replacement parts. This can include painting, varnishing, or applying protective coatings. Finishing not only improves the visual appeal but also extends the durability and resistance of the parts to environmental factors. For instance, outdoor lighting components may undergo corrosion resistance treatments to withstand harsh weather conditions.

How Is Quality Assurance Implemented in Manufacturing?

Quality assurance (QA) is a fundamental aspect of the manufacturing process for allen roth replacement parts. Adherence to international standards, such as ISO 9001, is crucial for ensuring that products meet customer expectations and regulatory requirements.

What Are the Relevant International and Industry-Specific Standards?

ISO 9001 sets the framework for quality management systems, emphasizing continuous improvement and customer satisfaction. In addition to ISO standards, industry-specific certifications such as CE for European markets and API for oil and gas applications may also be relevant. These certifications demonstrate a commitment to quality and safety, which is particularly important for international B2B buyers.

Illustrative image related to allen roth replacement parts

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to catch defects early. Common checkpoints include:

- Incoming Quality Control (IQC): Verifying the quality of raw materials upon receipt.

- In-Process Quality Control (IPQC): Monitoring production processes to ensure compliance with specifications during manufacturing.

- Final Quality Control (FQC): Conducting thorough inspections of finished products before they are shipped.

These checkpoints help ensure that any issues are identified and addressed promptly, reducing the risk of defective products reaching customers.

What Common Testing Methods Are Used?

Common testing methods for allen roth replacement parts include functional testing, durability testing, and compliance testing. Functional testing verifies that parts perform as intended under real-world conditions, while durability testing assesses their longevity and resistance to wear and tear. Compliance testing ensures that parts meet specific regulatory requirements, which is crucial for international markets.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those operating internationally, verifying a supplier’s quality control practices is essential. There are several ways to ensure that suppliers maintain high standards:

- Conducting Audits: Regular audits of the manufacturing facility can provide insights into the supplier’s quality management practices and adherence to international standards.

- Requesting Quality Reports: Suppliers should provide documentation on their quality control processes, including test results and compliance certifications.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of product quality before shipment. These services are especially beneficial for buyers in regions like Africa and South America, where local regulations may vary.

What Are the QC and Certification Nuances for International Buyers?

International B2B buyers need to be aware of the nuances in quality control and certification requirements across different regions. For instance, products sold in Europe must often carry the CE mark, indicating compliance with EU safety, health, and environmental protection standards. In contrast, buyers in the Middle East might need to consider local certifications specific to their markets.

Additionally, understanding the logistical aspects of quality assurance, such as shipping regulations and customs requirements, is vital for ensuring a smooth import process. Buyers should communicate clearly with suppliers about their quality expectations and ensure that all necessary documentation is provided.

Illustrative image related to allen roth replacement parts

Conclusion

The manufacturing processes and quality assurance practices for allen roth replacement parts are crucial for ensuring high-quality products that meet the demands of international B2B buyers. By understanding the intricacies of material preparation, forming, assembly, finishing, and quality control, buyers can make informed decisions when sourcing replacement parts. Furthermore, verifying supplier quality through audits, reports, and third-party inspections will help mitigate risks and ensure satisfaction with their purchases.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘allen roth replacement parts’

To effectively source allen roth replacement parts, a strategic approach is essential. This guide provides a detailed checklist to streamline your procurement process, ensuring that you secure the right parts efficiently and reliably.

Step 1: Define Your Technical Specifications

Clearly outline the specifications of the allen roth replacement parts you need. This includes the type of parts (e.g., cabinetry, lighting, or hardware), dimensions, materials, and compatibility with existing products. Having precise specifications helps in communicating effectively with suppliers and reduces the risk of errors in your order.

Step 2: Conduct Market Research

Investigate the current market landscape for allen roth replacement parts. Identify the leading suppliers and manufacturers who specialize in these products. Utilize online marketplaces, trade shows, and industry reports to gather insights. This knowledge will empower you to make informed decisions and potentially negotiate better terms.

Step 3: Evaluate Potential Suppliers

Before finalizing a supplier, conduct thorough evaluations. Review their company profiles, product catalogs, and customer feedback. Request case studies or references from other businesses, particularly those in similar regions or industries. This diligence ensures that you partner with a reliable supplier who meets your quality standards.

Step 4: Verify Supplier Certifications and Compliance

Ensure that your chosen suppliers have the necessary certifications and comply with international quality standards. Look for certifications such as ISO 9001 or product-specific compliance that aligns with regional regulations, especially if you’re sourcing from different continents. Verification of these credentials protects your business from subpar products and potential legal issues.

Step 5: Request Samples and Prototypes

Before committing to a large order, request samples or prototypes of the replacement parts. Testing these samples allows you to assess their quality, fit, and performance in real-world applications. This step is crucial, especially for intricate parts where compatibility and durability are paramount.

Step 6: Negotiate Terms and Pricing

Once you’ve identified suitable suppliers and evaluated their offerings, enter negotiations regarding pricing, payment terms, and delivery schedules. Aim for transparency and clarity in your agreements to avoid misunderstandings later. Consider bulk purchasing discounts, which can significantly reduce costs.

Step 7: Establish a Communication Plan

Develop a robust communication strategy with your suppliers. Clearly outline who will be the point of contact for order updates, issues, or questions. Regular check-ins can help maintain a strong relationship and ensure that any potential problems are addressed promptly, facilitating smoother transactions.

By following this checklist, international B2B buyers can navigate the complexities of sourcing allen roth replacement parts effectively. Each step builds upon the last, ensuring a comprehensive approach to procurement that prioritizes quality, reliability, and efficiency.

Comprehensive Cost and Pricing Analysis for allen roth replacement parts Sourcing

What Are the Key Cost Components in Sourcing allen roth Replacement Parts?

When analyzing the cost structure for sourcing allen roth replacement parts, several critical components come into play. The primary cost elements include:

-

Materials: The quality of materials used in replacement parts significantly influences overall costs. Higher-grade materials may increase unit prices but can enhance durability and performance, ultimately benefiting long-term usage.

-

Labor: Labor costs can vary depending on the manufacturing location. In regions with lower labor costs, such as parts of Africa and South America, buyers may find more competitive pricing. Conversely, labor in Europe and the Middle East may be higher, impacting the final cost.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and administrative expenses. Efficient factories with lower overhead can offer more competitive pricing.

-

Tooling: Custom tooling for specific replacement parts can be a significant upfront cost. Buyers should consider the impact of tooling on pricing, especially for bespoke or low-volume orders.

-

Quality Control (QC): Investing in robust QC processes can lead to higher initial costs but may reduce returns and replacements in the long run, enhancing overall cost-effectiveness.

-

Logistics: Shipping costs, including freight and customs duties, play a vital role in pricing. International buyers must factor in logistics when determining the total cost of ownership.

-

Margin: Suppliers typically build a margin into their pricing to ensure profitability. Understanding typical margins in the industry can help buyers negotiate more effectively.

How Do Price Influencers Impact the Sourcing of Replacement Parts?

Several factors can influence the pricing of allen roth replacement parts, particularly for international B2B buyers:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often attract discounts. Buyers should assess their needs and consider bulk purchases to reduce per-unit costs.

-

Specifications and Customization: Customized parts may incur additional costs. Buyers must clarify their requirements upfront to avoid unexpected charges.

-

Materials and Quality Certifications: The presence of certifications (e.g., ISO, CE) can affect pricing. Parts that meet higher standards may be more expensive but offer better reliability.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more due to their proven track record, while newer suppliers might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is crucial for international transactions, as they define the responsibilities of buyers and sellers regarding shipping costs, insurance, and liability. This knowledge can help buyers avoid unforeseen expenses.

What Are Essential Buyer Tips for Cost-Efficiency in Sourcing?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, there are several strategies to ensure cost-efficient sourcing of allen roth replacement parts:

-

Negotiation: Always be prepared to negotiate terms and prices. Understanding market rates and having alternatives can strengthen your position.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price but also maintenance, logistics, and potential replacement costs over the product’s lifecycle. This holistic view can lead to more informed purchasing decisions.

-

Pricing Nuances: Be aware that prices can fluctuate based on currency exchange rates, geopolitical factors, and trade tariffs. Monitoring these elements can provide strategic advantages in timing purchases.

-

Supplier Relationships: Building strong relationships with suppliers can lead to better pricing and favorable terms. Consider long-term partnerships to foster loyalty and reliability.

Conclusion

Sourcing allen roth replacement parts requires a comprehensive understanding of the cost structure and pricing influencers. By considering the outlined components and employing strategic negotiation tactics, international B2B buyers can achieve cost-efficient procurement while ensuring quality and reliability in their purchases. Always remember to factor in the total cost of ownership to make informed decisions that align with your business goals.

Alternatives Analysis: Comparing allen roth replacement parts With Other Solutions

When considering replacement parts for cabinetry and lighting solutions, it is essential for B2B buyers to explore various alternatives to determine the best fit for their specific requirements. Allen Roth replacement parts are a popular choice, but understanding how they compare to other solutions can help buyers make informed decisions that meet their operational needs and budget constraints.

| Comparison Aspect | Allen Roth Replacement Parts | Alternative 1: Generic Replacement Parts | Alternative 2: Custom Fabricated Parts |

|---|---|---|---|

| Performance | High compatibility with Allen Roth products; durable and reliable | Varies widely; may not match original quality | Tailored to specific needs; can outperform standard parts |

| Cost | Moderate price range; often higher due to brand reputation | Generally lower cost; potential for lower quality | Typically higher upfront cost but can save money in the long run |

| Ease of Implementation | Designed for straightforward installation with existing products | Installation difficulty varies; may require adjustments | Often requires professional installation and longer lead time |

| Maintenance | Low maintenance; designed for longevity | May require more frequent replacements | Potentially lower maintenance if designed correctly |

| Best Use Case | Ideal for existing Allen Roth products needing replacements | Suitable for budget-conscious projects or less critical applications | Best for unique or high-performance needs where standard parts are insufficient |

What Are the Advantages and Disadvantages of Generic Replacement Parts?

Generic replacement parts are often favored for their cost-effectiveness. These parts can be sourced at a lower price point, making them attractive for budget-sensitive projects. However, the performance can be inconsistent, and compatibility issues may arise, leading to potential disruptions in operations. Buyers should carefully assess the quality and suitability of generic parts against their specific requirements to avoid future complications.

How Do Custom Fabricated Parts Compare to Allen Roth Replacement Parts?

Custom fabricated parts offer a unique advantage by being tailored to specific applications and requirements. This can result in superior performance and compatibility, especially in specialized projects where standard options fall short. However, the trade-off includes a higher initial investment and potential delays in sourcing. Custom solutions may also necessitate professional installation, adding to the overall project timeline and cost. Businesses with unique needs should weigh these factors when considering custom solutions.

Conclusion: How Can B2B Buyers Choose the Right Replacement Parts for Their Needs?

When selecting replacement parts, B2B buyers should evaluate their specific needs, budget, and the context of their projects. Allen Roth replacement parts provide high compatibility and reliability for existing products, making them a solid choice for those already invested in the brand. However, buyers should also consider generic and custom alternatives, particularly if cost savings or specialized solutions are paramount. By thoroughly assessing the performance, cost, and ease of implementation of each option, businesses can make well-informed decisions that enhance their operational efficiency and product longevity.

Essential Technical Properties and Trade Terminology for allen roth replacement parts

What Are the Key Technical Properties of allen roth Replacement Parts?

When sourcing allen roth replacement parts, understanding specific technical properties is crucial for ensuring compatibility, durability, and performance. Here are some essential specifications:

1. Material Grade

Material grade refers to the quality and type of materials used in the production of replacement parts. Common materials include high-grade plastics, metals like aluminum and steel, and glass for lighting fixtures. B2B buyers should prioritize parts made from durable materials that can withstand environmental factors, especially for outdoor applications. This ensures longevity and reduces the frequency of replacements.

2. Tolerance

Tolerance indicates the allowable variation in dimensions during manufacturing. For instance, a part may have a tolerance of ±0.5 mm, which means it can vary slightly from its specified size. In a B2B context, precise tolerances are vital for ensuring that parts fit together correctly, particularly in cabinetry and lighting installations. This minimizes installation issues and enhances the overall quality of the finished product.

3. Load Capacity

Load capacity specifies the maximum weight or force a part can safely handle. This is particularly relevant for lighting fixtures and cabinetry components, where structural integrity is crucial. Understanding the load capacity helps buyers select appropriate parts for their specific applications, ensuring safety and functionality.

Illustrative image related to allen roth replacement parts

4. Finish and Coating

The finish or coating on replacement parts, such as powder coating or anodizing, can significantly affect durability and aesthetic appeal. A high-quality finish protects against corrosion, UV damage, and wear, making it essential for outdoor and high-usage applications. B2B buyers should consider the finish in relation to the environment in which the parts will be used.

5. Compatibility Standards

Compatibility standards ensure that replacement parts can be integrated seamlessly with existing systems or products. These standards may include specific measurements, connection types, or electrical specifications. For international buyers, ensuring compatibility with local regulations and standards is crucial to avoid costly errors and delays.

Which Common Trade Terms Should B2B Buyers Know?

Understanding industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are several key terms relevant to allen roth replacement parts:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are used in another company’s end product. In the context of allen roth replacement parts, sourcing OEM parts ensures that buyers receive components designed specifically for compatibility and quality with original products.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Knowing the MOQ helps B2B buyers plan their inventory and budget, ensuring that they can meet demand without over-purchasing or incurring excess storage costs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. For buyers looking to procure allen roth replacement parts, issuing an RFQ can streamline the sourcing process and provide competitive pricing options.

4. Incoterms (International Commercial Terms)

Incoterms are standardized terms that define the responsibilities of buyers and sellers in international shipping. Understanding these terms helps B2B buyers clarify shipping costs, risks, and logistics, ensuring smoother transactions across borders.

5. SKU (Stock Keeping Unit)

SKU is a unique identifier for each product, allowing for efficient tracking and inventory management. For businesses dealing with multiple replacement parts, having a clear SKU system is essential for maintaining accurate stock levels and facilitating reorders.

By familiarizing themselves with these technical properties and trade terms, international B2B buyers can make informed decisions when purchasing allen roth replacement parts, ensuring they meet both their operational needs and market standards.

Illustrative image related to allen roth replacement parts

Navigating Market Dynamics and Sourcing Trends in the allen roth replacement parts Sector

What Are the Key Market Dynamics and Trends in the Allen Roth Replacement Parts Sector?

The global market for allen roth replacement parts is experiencing dynamic shifts driven by several key factors. Rapid urbanization and the increasing trend towards home improvement projects are propelling the demand for replacement parts across various regions, particularly in Africa, South America, the Middle East, and Europe. B2B buyers are increasingly seeking versatile and durable products that can enhance the functionality and aesthetics of residential and commercial spaces.

Emerging technologies are reshaping sourcing strategies, with e-commerce platforms becoming pivotal for international buyers. The proliferation of digital marketplaces like Walmart and Wayfair offers a wide array of options for sourcing allen roth replacement parts, enabling buyers to compare prices and specifications easily. Additionally, the rise of data analytics is helping companies anticipate market trends and consumer preferences, allowing for more strategic inventory management.

In regions like Saudi Arabia and Brazil, local regulations and standards are influencing procurement processes. International buyers must navigate these complexities while seeking partnerships that can provide reliable logistics and support. Furthermore, the focus on customization and personalization in home décor is driving demand for specific replacement parts, necessitating manufacturers to offer tailored solutions to meet diverse consumer needs.

How Is Sustainability and Ethical Sourcing Shaping the Allen Roth Replacement Parts Market?

Sustainability has become a central theme in the global procurement landscape, significantly affecting the sourcing of allen roth replacement parts. International buyers are increasingly aware of the environmental impact associated with manufacturing and distribution processes. This awareness is prompting businesses to prioritize ethical sourcing practices that minimize waste and reduce carbon footprints.

The importance of transparency in supply chains cannot be overstated. Buyers are now looking for manufacturers who can demonstrate compliance with environmental standards and provide certifications for sustainable materials. Green certifications, such as FSC (Forest Stewardship Council) for wood products and Energy Star ratings for lighting components, are becoming essential criteria for procurement decisions.

Moreover, the emphasis on circular economy principles is encouraging manufacturers to explore recycling and upcycling options for old parts, reducing the need for new raw materials. This shift not only benefits the environment but also appeals to consumers who are increasingly making purchasing decisions based on sustainability considerations. By aligning with suppliers who prioritize ethical practices, B2B buyers can enhance their corporate social responsibility profiles while meeting market demand for eco-friendly products.

How Has the Allen Roth Replacement Parts Sector Evolved Over Time?

The evolution of the allen roth replacement parts sector reflects broader trends in home improvement and consumer preferences. Initially focused on basic functionality, the market has expanded to offer an extensive range of options that cater to aesthetic and performance needs. Innovations in materials and manufacturing processes have enabled the production of higher-quality, more durable replacement parts, which are essential for maintaining the integrity of cabinetry and lighting fixtures.

Over the years, the introduction of online platforms has revolutionized how buyers source replacement parts. The ease of access to product information and customer reviews has empowered buyers to make informed decisions. As the market continues to evolve, the emphasis on customization and sustainability is likely to shape future product offerings, ensuring that the allen roth brand remains relevant in a competitive landscape.

In summary, understanding the market dynamics, embracing sustainability, and recognizing the historical context are crucial for B2B buyers in navigating the allen roth replacement parts sector effectively.

Illustrative image related to allen roth replacement parts

Frequently Asked Questions (FAQs) for B2B Buyers of allen roth replacement parts

-

How do I troubleshoot common issues with allen roth replacement parts?

To troubleshoot issues with allen roth replacement parts, start by identifying the specific problem, such as compatibility or functionality. Check the part numbers and specifications against your existing products to ensure they match. If you’re encountering installation difficulties, consult the manufacturer’s installation guidelines, which often include detailed diagrams and instructions. For persistent issues, contacting customer support can provide additional insights. It’s crucial to document the problem and the steps taken for resolution, especially if you need to escalate the matter or seek replacements. -

What is the best method for sourcing allen roth replacement parts internationally?

The best method for sourcing allen roth replacement parts internationally involves researching reliable suppliers with a proven track record. Use B2B marketplaces to compare prices, lead times, and reviews. Establish communication with potential suppliers to inquire about their product range and availability. Additionally, verify their compliance with international trade regulations and quality standards. Don’t hesitate to request samples to assess quality before placing larger orders. Building strong relationships with suppliers can also lead to better negotiation terms and ongoing support. -

What are the minimum order quantities (MOQs) for allen roth replacement parts?

Minimum order quantities (MOQs) for allen roth replacement parts can vary significantly based on the supplier and the specific parts required. Generally, MOQs may range from as few as 10 units to several hundred, depending on the item’s popularity and manufacturing capabilities. It’s important to discuss MOQs upfront with your supplier, as some may offer flexibility for new customers or bulk purchases. Understanding the MOQ is crucial for budgeting and inventory management, especially if you are catering to a specific market segment. -

What payment terms should I expect when ordering replacement parts?

Payment terms for ordering allen roth replacement parts typically include options such as upfront payment, partial payment upon order confirmation, or net payment terms (e.g., 30, 60, or 90 days after delivery). Suppliers may require a deposit for larger orders. It’s essential to clarify payment methods accepted, such as bank transfers, credit cards, or letters of credit, especially for international transactions. Always ensure that the terms are documented in your purchase agreement to avoid any misunderstandings. -

How can I ensure the quality of allen roth replacement parts?

To ensure the quality of allen roth replacement parts, partner with reputable suppliers who adhere to strict quality assurance standards. Request certifications that demonstrate compliance with international quality standards, such as ISO. Conducting regular audits and inspections can also help assess the quality of incoming shipments. Additionally, consider establishing a returns policy that allows for the return of defective parts, which can serve as a quality control measure. Building a feedback loop with your suppliers can further enhance product quality. -

What logistics considerations should I keep in mind for international orders?

When ordering allen roth replacement parts internationally, consider logistics factors such as shipping methods, costs, and delivery times. Choose a reliable freight forwarder experienced in handling your specific product types and regions. Be mindful of customs regulations in both the exporting and importing countries, including duties and taxes that may apply. Additionally, track your shipments to monitor their progress and address any potential delays proactively. Planning your logistics strategy can significantly impact your overall supply chain efficiency. -

Can I customize allen roth replacement parts to fit specific needs?

Customization of allen roth replacement parts is often possible, depending on the supplier’s capabilities and the specific parts in question. Discuss your requirements with potential suppliers, as many manufacturers offer bespoke solutions to meet unique specifications. Be clear about the dimensions, materials, and functionality you require. While customization can lead to higher costs and longer lead times, it can also result in a better fit for your applications, enhancing customer satisfaction and operational efficiency. -

What should I do if I receive defective or incorrect replacement parts?

If you receive defective or incorrect allen roth replacement parts, promptly contact your supplier’s customer service team. Document the issue with photos and detailed descriptions to facilitate the return process. Most suppliers will have a returns policy in place, allowing you to return defective items for a replacement or refund. Be aware of the time frame for reporting such issues, as it may vary by supplier. Establishing a good relationship with your supplier can ease the resolution process and ensure better service in the future.

Top 3 Allen Roth Replacement Parts Manufacturers & Suppliers List

1. Allen + Roth – 10×10 Gazebo

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Allen + Roth 10×10 gazebo in brown; originally priced at $800, purchased for $300; missing 2 metal cross braces; replacement parts ordered from manufacturer; issues with customer service and availability of parts.

2. Allen + Roth – Track Lighting Flexible Connectors

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Allen + Roth Lighting Parts include various items such as: 1. Track Lighting Flexible Connector to join 2 tracks – Dark Bronze Finish, Brand New, priced at $42.99 with free shipping. 2. Another Track Lighting Flexible Connector – Dark Bronze Finish, Brand New, priced at $19.99 with $3.99 shipping. 3. Quad Toggle Switch in Dark Oil Rubbed Bronze and Satin Nickel Finish, Brand New, priced at $10.99 …

3. Target – Allen Roth Gazebo Replacement Parts

Domain: target.com

Registered: 1997 (28 years)

Introduction: This company, Target – Allen Roth Gazebo Replacement Parts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for allen roth replacement parts

In the competitive landscape of cabinetry and lighting solutions, strategic sourcing of allen roth replacement parts presents a robust opportunity for international B2B buyers. By prioritizing quality, reliability, and supplier partnerships, businesses can ensure that they not only meet customer needs but also enhance their own operational efficiency. Sourcing from reputable distributors and manufacturers, such as those linked with allen roth, allows for streamlined procurement processes, reducing lead times and minimizing errors.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should leverage local market insights to navigate logistics and regulatory challenges effectively. Building strong relationships with suppliers can facilitate better pricing, faster delivery, and access to a broader range of products.

As the demand for high-quality replacement parts continues to rise, businesses that engage in proactive sourcing strategies will position themselves as leaders in their respective markets. Now is the time to invest in reliable sourcing solutions that can drive growth and customer satisfaction. Embrace the future of your business by prioritizing strategic sourcing for allen roth replacement parts today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.