Air Solenoid Valve Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for air solenoid valve

In the rapidly evolving landscape of industrial automation, sourcing the right air solenoid valve can be a daunting challenge for international B2B buyers. With various types available, including direct-acting and pilot-operated models, navigating this market requires a keen understanding of applications and specifications. This guide is designed to demystify the complexities associated with air solenoid valves, empowering buyers from diverse regions—Africa, South America, the Middle East, and Europe, including key markets like Saudi Arabia and Germany—to make informed purchasing decisions.

Throughout this comprehensive resource, we will explore the various types of air solenoid valves and their applications across industries, from manufacturing to agriculture. We will also delve into critical aspects such as supplier vetting processes, ensuring that you partner with reliable manufacturers who uphold quality and compliance standards. Additionally, we will provide insights on pricing, helping you align your budget with the best options available in the market.

By equipping you with the knowledge needed to evaluate performance, reliability, and cost-effectiveness, this guide aims to streamline your sourcing process. Whether you are looking to optimize your existing systems or invest in new technology, understanding the nuances of air solenoid valves will enhance your operational efficiency and drive your business forward.

Understanding air solenoid valve Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Direct-Acting Solenoid Valves | Compact, fast-switching, operates under low pressure | Automation, packaging, pneumatic systems | Pros: Reliable under varying pressures; Cons: Limited flow capacity. |

| Pilot-Operated Solenoid Valves | Uses pilot pressure to operate, larger flow rates | Industrial machinery, HVAC systems | Pros: High flow efficiency; Cons: More complex and costly. |

| 2-Way Solenoid Valves | Simple on/off control, two ports | Fluid control, irrigation systems | Pros: Easy to install and operate; Cons: Limited functionality. |

| 3-Way Solenoid Valves | Three ports for diverting flow | Automotive applications, process control | Pros: Versatile flow control; Cons: More potential points of failure. |

| Miniature Solenoid Valves | Small size, low power consumption | Robotics, medical devices | Pros: Space-saving design; Cons: Limited operating pressure. |

What Are the Characteristics of Direct-Acting Solenoid Valves?

Direct-acting solenoid valves are known for their compact design and fast switching capabilities. They operate effectively across a full pressure range, including low pressures and vacuum conditions. This type is particularly suitable for applications requiring rapid on/off control, such as in automation and packaging systems. When purchasing, consider the valve’s compatibility with your existing systems and the specific media being controlled, as these factors can significantly impact performance.

How Do Pilot-Operated Solenoid Valves Differ from Direct-Acting Types?

Pilot-operated solenoid valves utilize a pilot pressure to control a larger flow of fluid, making them ideal for industrial applications where high flow rates are necessary. These valves tend to be more complex due to their reliance on additional pressure sources, which can lead to higher costs. B2B buyers should evaluate their operational requirements, including flow demands and available pressure sources, to determine if this type suits their needs.

Why Choose 2-Way Solenoid Valves for Fluid Control?

2-way solenoid valves provide straightforward on/off control, making them a popular choice for fluid control applications such as irrigation systems. Their simplicity facilitates easy installation and operation, which is advantageous for businesses looking to minimize downtime. However, buyers should be aware that their functionality is limited to basic flow control, which may not meet the needs of more complex systems.

What Advantages Do 3-Way Solenoid Valves Offer?

3-way solenoid valves are designed with three ports, allowing for more versatile flow control, including the ability to divert flow between two different outlets. This makes them suitable for automotive applications and process control systems. While they provide enhanced functionality, the added complexity can introduce more potential points of failure. Buyers should assess their application requirements to ensure that the benefits outweigh the risks.

How Do Miniature Solenoid Valves Fit into B2B Applications?

Miniature solenoid valves are characterized by their small size and low power consumption, making them ideal for space-constrained applications such as robotics and medical devices. Their compact design allows for integration into smaller systems, but they often come with limitations in terms of operating pressure. B2B buyers should consider the specific requirements of their applications, particularly regarding pressure and flow, to ensure optimal performance and reliability.

Key Industrial Applications of air solenoid valve

| Industry/Sector | Specific Application of air solenoid valve | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Automation of assembly lines | Increased efficiency and reduced labor costs | Compatibility with existing systems and pressure ratings |

| Agriculture | Irrigation control systems | Optimized water usage and improved crop yields | Durability against environmental factors and flow rates |

| Automotive | Fuel delivery systems in vehicles | Enhanced performance and fuel efficiency | Compliance with industry standards and safety certifications |

| Food and Beverage | Beverage dispensing systems | Consistent quality and reduced waste | Hygiene standards and material compatibility |

| HVAC Systems | Control of pneumatic actuators in climate control systems | Improved energy efficiency and comfort | Voltage requirements and response times |

How Are Air Solenoid Valves Used in Manufacturing Automation?

In the manufacturing sector, air solenoid valves are integral to the automation of assembly lines. They control the flow of compressed air to actuators and cylinders, facilitating precise movements and operations. This automation leads to increased efficiency and reduced labor costs, which are critical for competitive advantage. International buyers, especially from regions like Europe and the Middle East, should consider compatibility with existing systems and the pressure ratings of solenoid valves to ensure seamless integration into their operations.

What Role Do Air Solenoid Valves Play in Agricultural Irrigation?

In agriculture, air solenoid valves are employed in automated irrigation control systems. They regulate water flow based on real-time data, optimizing water usage and enhancing crop yields. This application is particularly beneficial in regions prone to water scarcity, making it essential for farmers to invest in reliable solenoid valves. Buyers from Africa and South America should prioritize durability against environmental factors and the specific flow rates required for their irrigation systems to maximize productivity.

How Do Air Solenoid Valves Enhance Automotive Fuel Delivery?

In the automotive industry, air solenoid valves are crucial for fuel delivery systems, ensuring the precise control of fuel flow to engines. This enhances vehicle performance and fuel efficiency, which are key selling points in today’s market. As international buyers, especially in regions like Germany, seek to meet stringent environmental regulations, they must ensure that the solenoid valves comply with industry standards and safety certifications to avoid costly compliance issues.

Why Are Air Solenoid Valves Important in Food and Beverage Applications?

In the food and beverage industry, air solenoid valves are utilized in beverage dispensing systems. They ensure a consistent flow of drinks, maintaining quality while minimizing waste. This is vital for businesses aiming to enhance customer satisfaction and reduce operational costs. Buyers in this sector should focus on hygiene standards and material compatibility to ensure that the solenoid valves do not contaminate the products, thus safeguarding public health and brand reputation.

How Do Air Solenoid Valves Contribute to HVAC System Efficiency?

Air solenoid valves are also significant in HVAC systems, controlling pneumatic actuators that regulate airflow and temperature. Their use leads to improved energy efficiency and comfort within buildings, making them essential components in modern climate control systems. For buyers in Europe and the Middle East, it is crucial to consider the voltage requirements and response times of these valves, as they directly impact the effectiveness and reliability of HVAC operations.

3 Common User Pain Points for ‘air solenoid valve’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Valve Size and Type

The Problem:

One of the most common challenges faced by B2B buyers when sourcing air solenoid valves is selecting the appropriate size and type for their specific application. Inadequate sizing can lead to inefficient performance, increased energy consumption, or even system failures. Buyers often grapple with technical specifications, such as flow rates, pressure ratings, and compatibility with existing systems. This complexity can result in costly mistakes, including returning products or experiencing operational downtime due to improper installations.

Illustrative image related to air solenoid valve

The Solution:

To overcome this challenge, buyers should conduct a thorough needs assessment before purchasing. Start by understanding the application requirements, such as the medium (air, gas, etc.), pressure levels, and the necessary flow rate. Utilize manufacturer catalogs and technical datasheets to compare valve specifications against the operational demands. Collaborating with a knowledgeable supplier or manufacturer can also provide valuable insights. They can assist in determining the right valve size, type (e.g., direct-acting vs. pilot-operated), and any necessary accessories, such as fittings or regulators. Additionally, consider investing in simulation software or tools that can predict valve performance in real-world conditions to ensure optimal selection.

Scenario 2: Facing Compatibility Issues with Existing Systems

The Problem:

Buyers often encounter compatibility issues when integrating new air solenoid valves into existing systems. This may arise from variations in thread types, connection sizes, or control voltages. Such mismatches can lead to leaks, system inefficiencies, and ultimately, increased maintenance costs. Moreover, the lack of standardized sizing and connections across manufacturers can make it challenging to find a suitable replacement or upgrade.

The Solution:

To mitigate compatibility issues, thorough documentation of existing systems is crucial. Buyers should maintain a comprehensive inventory of all components, including specifications like port sizes, thread types, and voltage requirements. When sourcing new valves, ensure that these specifications align with the existing infrastructure. Engage suppliers who offer a range of customization options, allowing for tailored solutions that fit seamlessly into current setups. Additionally, consider using adaptors or conversion kits where feasible, but only as a last resort, as they can introduce additional points of failure. Regular consultations with technical support teams from manufacturers can help identify potential compatibility issues before they arise.

Scenario 3: Managing Maintenance and Longevity Concerns

The Problem:

Another significant pain point for B2B buyers is the maintenance and longevity of air solenoid valves. Many buyers are uncertain about the best practices for installation and upkeep, leading to premature valve failure. Issues such as dirt buildup, corrosion, or wear and tear can drastically reduce the lifespan of these valves, resulting in costly repairs and unplanned downtimes.

The Solution:

To ensure the longevity of air solenoid valves, establish a proactive maintenance routine. Start with proper installation practices, including ensuring that all connections are tight and leak-free. Incorporate filters in the system to minimize contamination from dirt and particulates. Regularly inspect valves for signs of wear or damage, and maintain a clean environment around them. Additionally, consider investing in high-quality valves that offer robust materials resistant to corrosion and wear, which can significantly reduce the need for frequent replacements. Documenting maintenance activities and scheduling regular check-ups can also help in identifying potential issues early, thus enhancing the reliability of the system. For businesses operating in harsh environments, selecting valves specifically designed for those conditions can further extend service life and reduce maintenance needs.

Strategic Material Selection Guide for air solenoid valve

What Are the Key Materials Used in Air Solenoid Valves?

When selecting air solenoid valves, the choice of materials is crucial for ensuring optimal performance, durability, and compatibility with specific applications. Here, we analyze four common materials used in the construction of air solenoid valves: brass, stainless steel, plastic, and aluminum. Each material has unique properties, advantages, and limitations that can significantly impact the valve’s performance and suitability for various applications.

How Does Brass Perform in Air Solenoid Valves?

Brass is a widely used material in air solenoid valves due to its excellent corrosion resistance and good mechanical properties. It typically has a temperature rating of up to 180°C (356°F) and can handle moderate pressure levels, making it suitable for various applications, including pneumatic systems.

Pros: Brass is durable and offers good thermal conductivity, which can be beneficial in applications where heat dissipation is necessary. It is also relatively easy to machine and manufacture, resulting in lower production costs.

Cons: While brass is resistant to corrosion, it can be susceptible to dezincification in certain environments, particularly in the presence of chlorides. This can lead to premature failure in aggressive media.

Impact on Application: Brass solenoid valves are compatible with air, water, and some oils. However, they may not be suitable for highly corrosive environments.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is essential. Buyers in regions like Europe and the Middle East may prefer brass valves that meet stringent quality standards.

What Are the Advantages of Stainless Steel in Air Solenoid Valves?

Stainless steel is renowned for its exceptional corrosion resistance and strength, making it an ideal choice for air solenoid valves used in harsh environments. It can operate effectively at temperatures up to 300°C (572°F) and is capable of withstanding high pressures.

Pros: The durability of stainless steel ensures a long service life, reducing maintenance costs. Its resistance to corrosion makes it suitable for applications involving aggressive media, including chemicals and saline environments.

Cons: Stainless steel is generally more expensive than brass and can be more challenging to manufacture due to its hardness. This can lead to higher initial costs for the end product.

Impact on Application: Stainless steel valves are compatible with a wide range of media, including air, water, and various chemicals, making them versatile for many applications.

Considerations for International Buyers: Compliance with international standards is critical, particularly in Europe and the Middle East, where regulations may dictate the use of specific materials.

How Does Plastic Compare in Air Solenoid Valve Applications?

Plastic solenoid valves are becoming increasingly popular due to their lightweight nature and resistance to corrosion. Commonly used plastics include PVC and nylon, which can handle temperatures ranging from -10°C to 70°C (14°F to 158°F).

Pros: Plastic valves are cost-effective and lightweight, making them easy to install and handle. They are also resistant to many chemicals, which can extend their lifespan in specific applications.

Cons: Plastic valves may not withstand high pressures as effectively as metal options and can be prone to deformation under extreme temperatures. Their overall durability is lower than that of metal valves.

Impact on Application: Plastic solenoid valves are ideal for applications involving water, air, and some non-aggressive chemicals. However, they are unsuitable for high-pressure systems.

Considerations for International Buyers: Buyers should ensure that the selected plastic meets relevant safety and quality standards, especially in regions with strict regulations.

Why Choose Aluminum for Air Solenoid Valves?

Aluminum is a lightweight and corrosion-resistant material that is increasingly used in air solenoid valves. It typically operates effectively at temperatures up to 150°C (302°F) and can handle moderate pressures.

Pros: The lightweight nature of aluminum makes it easy to install and transport. It also offers good thermal conductivity and is generally more affordable than stainless steel.

Cons: While aluminum is resistant to corrosion, it may not perform well in highly corrosive environments compared to stainless steel. Additionally, it can be less durable than brass or stainless steel.

Illustrative image related to air solenoid valve

Impact on Application: Aluminum valves are suitable for air and non-corrosive fluids but may not be ideal for applications involving aggressive chemicals.

Considerations for International Buyers: Compliance with material standards is essential, particularly for buyers in Europe and the Middle East, where specific regulations may apply.

Summary Table of Material Selection for Air Solenoid Valves

| Material | Typical Use Case for air solenoid valve | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | General pneumatic applications | Good corrosion resistance | Susceptible to dezincification | Medium |

| Stainless Steel | Harsh environments and chemicals | Exceptional durability and strength | Higher cost and manufacturing complexity | High |

| Plastic | Water and air applications | Lightweight and cost-effective | Lower pressure tolerance | Low |

| Aluminum | Air and non-corrosive fluid applications | Lightweight and affordable | Less durable in aggressive environments | Medium |

This guide provides B2B buyers with valuable insights into material selection for air solenoid valves, enabling informed decisions that align with their specific application requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for air solenoid valve

What Are the Main Stages of Manufacturing Air Solenoid Valves?

The manufacturing process of air solenoid valves is intricate, involving multiple stages to ensure high performance and reliability. Here’s a breakdown of the main stages:

Material Preparation

The first stage involves the selection and preparation of materials. Common materials for air solenoid valves include brass, stainless steel, and various plastics, each chosen based on the application requirements. Manufacturers often conduct a thorough analysis of material properties, ensuring they meet industry standards for corrosion resistance, pressure tolerance, and temperature stability.

Once materials are selected, they undergo treatments such as machining, where they are cut to precise dimensions. This stage also includes cleaning processes to remove impurities that could affect the final product’s performance.

Forming Techniques

Forming is the next critical stage, where the prepared materials are shaped into the components of the solenoid valve. Common techniques include:

- Casting: Used for producing complex shapes, particularly in brass and stainless steel valves.

- Machining: Involves processes like turning, milling, and drilling to achieve exact specifications and tolerances.

- Injection Molding: Often used for plastic components, allowing for high-volume production with consistent quality.

Each forming technique is selected based on the required precision and the specific characteristics of the materials used.

Assembly Process

The assembly stage is where all individual components come together. This process typically involves:

Illustrative image related to air solenoid valve

- Alignment and Fitting: Ensuring that all parts, such as the solenoid coil, valve body, and seals, fit together perfectly.

- Welding or Fastening: Depending on the design, components may be welded or mechanically fastened to ensure a secure assembly.

- Integration of Electrical Components: For electrically operated solenoid valves, this includes connecting wiring and solenoids.

During assembly, manufacturers often use jigs and fixtures to maintain consistency and accuracy, which is crucial for the valve’s performance.

Finishing Processes

Finishing processes enhance the valve’s appearance and functionality. Typical finishing techniques include:

- Surface Treatment: Methods such as anodizing, plating, or painting to improve corrosion resistance and aesthetic appeal.

- Quality Inspection: Before final packaging, valves undergo rigorous testing to ensure they meet operational specifications.

How Is Quality Assurance Implemented in Air Solenoid Valve Manufacturing?

Quality assurance (QA) is a cornerstone of air solenoid valve manufacturing, ensuring that products meet both international standards and customer specifications. Here are the key components of a robust QA system:

What Are the Relevant International Standards for Quality Assurance?

Manufacturers typically adhere to several international and industry-specific standards to maintain quality. Key standards include:

- ISO 9001: This standard focuses on quality management systems and is essential for ensuring consistent quality in manufacturing processes.

- CE Marking: Required for products sold in the European Economic Area, it indicates conformity with health, safety, and environmental protection standards.

- API Standards: The American Petroleum Institute sets standards for products used in the oil and gas industry, ensuring reliability and safety.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) involves multiple checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This initial step involves inspecting raw materials and components upon arrival. Suppliers must provide certification that materials meet specified standards.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, operators monitor critical parameters to ensure compliance with specifications. This may include dimensional checks and functional tests at various assembly stages.

- Final Quality Control (FQC): Once assembled, the valves undergo comprehensive testing, including pressure testing, leak testing, and operational testing to ensure performance under expected conditions.

Which Testing Methods Are Commonly Used for Air Solenoid Valves?

Manufacturers employ various testing methods to validate the performance and reliability of air solenoid valves:

Illustrative image related to air solenoid valve

- Pressure Testing: Verifies the valve’s ability to withstand specified pressure levels without leaking.

- Functional Testing: Assesses the operational performance of the valve, ensuring it opens and closes correctly under different conditions.

- Life Cycle Testing: Simulates long-term usage to identify potential failure points or wear over time.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are some actionable steps:

- Supplier Audits: Conduct on-site audits to assess the manufacturing processes, quality control measures, and adherence to international standards. This can provide insights into the supplier’s operational practices.

- Request Quality Reports: Suppliers should provide documentation of their quality control processes, including results from IQC, IPQC, and FQC.

- Third-Party Inspections: Engage independent organizations to conduct inspections and testing. Certifications from recognized entities can provide an additional layer of assurance regarding quality and compliance.

What Are the QC and Certification Nuances for International Buyers?

International buyers must navigate various nuances related to quality control and certification:

- Understanding Regional Standards: Familiarize yourself with the specific standards and regulations applicable in your region. For example, CE marking is vital for products sold in Europe, while other regions may have different requirements.

- Language Barriers: Ensure that quality documentation and reports are available in a language you understand to facilitate accurate assessments.

- Cultural Differences in Business Practices: Be aware of the cultural context in which suppliers operate, as this can influence communication and expectations regarding quality assurance.

In conclusion, a comprehensive understanding of the manufacturing processes and quality assurance protocols for air solenoid valves is essential for B2B buyers. By focusing on these aspects, buyers can make informed decisions, ensuring they partner with reliable suppliers capable of delivering high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘air solenoid valve’

This guide aims to provide a practical checklist for B2B buyers seeking to procure air solenoid valves. By following these steps, you can ensure a smooth sourcing process, minimize risks, and select the right valves that meet your operational needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly define the technical requirements of the air solenoid valves needed for your application. Consider factors such as valve type (2-way, 3-way, or 4-way), operating pressure, voltage (AC or DC), and media compatibility. This step is crucial as it helps narrow down options and ensures that you select valves that will function correctly within your systems.

Step 2: Research Market Trends and Pricing

Conduct thorough market research to understand current trends and pricing for air solenoid valves. Prices can vary significantly based on materials, features, and suppliers. Being informed about the price range for your specified valves allows you to identify competitive offers and negotiate better deals.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s essential to vet them thoroughly. Request company profiles, product catalogs, and references from existing clients, especially those in similar industries or regions. Look for suppliers with a proven track record, as this can indicate reliability and quality in product delivery.

Step 4: Verify Supplier Certifications

Ensure that potential suppliers hold relevant certifications and adhere to industry standards. Certifications such as ISO 9001 for quality management and CE marking for compliance with European standards are indicators of a supplier’s commitment to quality. This verification protects your investment and ensures that the products meet safety and performance requirements.

Step 5: Request Samples or Prototypes

Before making a bulk purchase, request samples or prototypes of the air solenoid valves. Testing these samples in your applications allows you to evaluate their performance and compatibility. This step helps mitigate risks associated with functionality and ensures that you are satisfied with the product quality before committing to a larger order.

Illustrative image related to air solenoid valve

Step 6: Assess After-Sales Support and Warranty Terms

Investigate the after-sales support and warranty options provided by the supplier. A reputable supplier should offer robust customer support, including technical assistance and a clear warranty policy. Understanding these terms is vital as it affects the long-term reliability of your investment and can save costs on repairs or replacements.

Step 7: Finalize the Contract and Payment Terms

Once you’ve evaluated the suppliers and selected the best option, finalize the contract. Ensure that the terms of payment, delivery schedules, and conditions for returns or exchanges are clearly stated. A well-defined contract protects both parties and facilitates a smoother transaction process.

By following this checklist, B2B buyers can navigate the complexities of sourcing air solenoid valves effectively, ensuring that they make informed decisions that align with their operational needs.

Comprehensive Cost and Pricing Analysis for air solenoid valve Sourcing

When sourcing air solenoid valves, understanding the comprehensive cost structure and pricing elements is essential for making informed purchasing decisions. This analysis breaks down the key cost components, price influencers, and offers practical tips for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe.

Illustrative image related to air solenoid valve

What Are the Key Cost Components of Air Solenoid Valves?

The cost structure of air solenoid valves can be categorized into several components:

-

Materials: The choice of materials directly impacts the cost. Common materials include brass, stainless steel, and plastic, with brass typically being more affordable but less durable than stainless steel. High-grade materials may be necessary for specific applications, affecting overall pricing.

-

Labor: Labor costs can vary significantly based on the manufacturing location. In regions with higher wage standards, such as Europe, the labor component may contribute more to the overall cost than in countries with lower wage expectations.

-

Manufacturing Overhead: This includes costs associated with the factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs, which is beneficial for both suppliers and buyers.

-

Tooling: Custom tooling for specialized valves can add significant costs. For standard products, tooling costs are generally amortized over larger production runs, making them less impactful per unit.

-

Quality Control (QC): Ensuring that the valves meet specific performance and safety standards is vital. Robust QC processes may increase costs but are essential for maintaining product integrity and compliance with international standards.

-

Logistics: Transporting valves involves shipping costs, customs duties, and insurance. The complexity of logistics can vary based on the supplier’s location and the buyer’s destination, affecting final pricing.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure sustainability. This margin can fluctuate based on market demand, competition, and perceived value.

What Factors Influence Pricing for Air Solenoid Valves?

Several key influencers can affect the pricing of air solenoid valves:

-

Volume/MOQ (Minimum Order Quantity): Purchasing in bulk can often lead to significant discounts. Suppliers are typically more willing to negotiate prices with buyers who commit to larger volumes.

-

Specifications/Customization: Custom specifications tailored to specific applications may lead to higher costs. Standardized products usually offer better pricing due to economies of scale.

-

Materials and Quality/Certifications: High-quality valves with certifications (such as ISO or CE) may command higher prices. Buyers should assess whether the certifications are necessary for their intended application.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established manufacturers may charge a premium for their products based on trust and proven performance.

-

Incoterms: The terms of shipping can significantly impact costs. Understanding the responsibilities of both the buyer and seller under various Incoterms (like FOB or CIF) is crucial for accurate cost assessments.

What Buyer Tips Can Help in Negotiating Prices?

For international B2B buyers, particularly those from diverse regions, employing effective negotiation strategies can enhance cost-efficiency:

-

Understand Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the long-term costs associated with maintenance, potential downtime, and the expected lifespan of the valves. A lower upfront cost may not always translate to savings over time.

-

Research Market Prices: Gather data on competitive pricing to inform negotiations. Understanding the market landscape enables buyers to advocate for reasonable pricing based on current trends.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Trust and communication are vital in negotiating favorable contracts.

-

Evaluate Alternative Suppliers: Don’t hesitate to explore multiple suppliers to compare prices and quality. This can create competitive tension, potentially leading to better offers.

-

Be Aware of Pricing Nuances: International buyers should remain conscious of currency fluctuations and regional economic conditions, which can impact pricing and overall budgeting.

Disclaimer

Prices for air solenoid valves can vary widely based on the factors discussed above. The figures presented in this analysis are indicative and may fluctuate based on market conditions, supplier pricing strategies, and buyer-specific requirements. Always confirm current pricing with suppliers before making purchasing decisions.

Alternatives Analysis: Comparing air solenoid valve With Other Solutions

When evaluating the best solutions for fluid control in industrial applications, it’s crucial to consider various alternatives to air solenoid valves. These alternatives can offer different advantages depending on specific needs, application environments, and operational requirements. Below, we compare air solenoid valves with two viable alternatives: pneumatic valves and electric actuated valves.

| Comparison Aspect | Air Solenoid Valve | Pneumatic Valve | Electric Actuated Valve |

|---|---|---|---|

| Performance | Fast switching, reliable control for air | High flow rates, excellent for compressed air systems | Precise control, suitable for various media |

| Cost | Moderate initial investment, low operational cost | Generally lower cost, but may require air compressor | Higher initial investment, but lower maintenance costs |

| Ease of Implementation | Simple installation and integration | Requires air supply setup | More complex wiring but flexible in operation |

| Maintenance | Low, but depends on environment | Moderate, requires regular checks | Low, typically requires minimal upkeep |

| Best Use Case | Ideal for quick actuations in automation | Best for high-volume air control | Suitable for precise applications needing variable control |

What Are the Advantages and Disadvantages of Pneumatic Valves as an Alternative?

Pneumatic valves are specifically designed for controlling air in compressed systems. They excel in applications where high flow rates are necessary. The primary advantages include their lower cost compared to electric options and their ability to operate effectively under various pressure conditions. However, they require a consistent air supply, which can lead to increased operational costs if an air compressor is needed. Additionally, pneumatic systems can be less precise than solenoid-operated systems, which may be a drawback in certain applications.

How Do Electric Actuated Valves Compare to Air Solenoid Valves?

Electric actuated valves offer precise control over fluid flow and can handle a variety of media, making them highly versatile. They are typically more reliable in terms of consistent performance across different operational conditions. However, the initial investment for electric actuated valves can be higher, and they may require more complex installation due to wiring and power supply considerations. Maintenance is generally low, but troubleshooting can be more involved than with simpler solenoid valves. These valves are best suited for applications where precision is paramount, such as in chemical processing or food and beverage industries.

How Can B2B Buyers Select the Right Solution for Their Needs?

Choosing the right fluid control solution involves evaluating the specific requirements of your application. Consider the performance needs—do you require quick actuation or high flow rates? Analyze the cost implications, including installation and operational expenses. Maintenance needs should also factor into your decision; a low-maintenance option can reduce long-term costs. Lastly, assess the complexity of implementation based on your existing infrastructure. By carefully weighing these factors, B2B buyers can select the solution that best aligns with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for air solenoid valve

What Are the Key Technical Properties of Air Solenoid Valves?

When evaluating air solenoid valves, understanding their technical properties is crucial for making informed purchasing decisions. Here are some essential specifications:

Illustrative image related to air solenoid valve

-

Material Grade: The material used in the construction of the valve, such as brass, stainless steel, or plastic, significantly influences durability and resistance to corrosion. For instance, stainless steel valves are preferred in harsh environments due to their robustness and resistance to oxidation. In contrast, brass valves may offer better conductivity and are typically less expensive. Selecting the appropriate material can help reduce maintenance costs and extend the lifespan of the equipment.

-

Pressure Rating: This specification indicates the maximum pressure the valve can handle. It’s vital for ensuring the valve can operate effectively within the parameters of the intended application. A higher pressure rating is essential for applications involving high-pressure air systems, preventing failures that could lead to costly downtimes or safety hazards.

-

Electrical Rating: The electrical requirements, including voltage and current specifications, dictate the power supply needed for operation. Common ratings include 12V DC, 24V DC, and 110V AC. Understanding these ratings is important for compatibility with existing electrical systems, thereby avoiding operational issues.

-

Flow Rate: Measured in liters per minute (LPM) or cubic feet per minute (CFM), the flow rate indicates how much air the valve can control. A higher flow rate means faster operation, which is crucial in applications requiring quick response times, such as automation in manufacturing processes. Buyers should match the flow rate to their system’s requirements to ensure efficiency.

-

Actuation Type: Air solenoid valves can be either normally open (NO) or normally closed (NC). An NO valve allows air to flow when energized, while an NC valve prevents flow until energized. Understanding this distinction is essential for system design and functionality, influencing how the valve integrates into the overall system.

-

Thread Type and Size: The valve’s connection size and thread type (e.g., NPT, G-thread) determine compatibility with existing piping systems. Choosing the correct size and type is critical to prevent leaks and ensure proper installation, thereby reducing the risk of system failures.

What Are Common Trade Terms Related to Air Solenoid Valves?

Navigating the purchasing process for air solenoid valves involves familiarizing yourself with industry-specific terminology. Here are some key terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding whether a valve is an OEM product can help buyers assess quality and compatibility with existing systems.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory planning, especially for businesses looking to maintain stock levels without overcommitting financially.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to obtain price quotes for specific products. It is a critical step in the procurement process, allowing buyers to compare pricing and terms from multiple vendors to secure the best deal.

-

Incoterms: Short for International Commercial Terms, Incoterms are a set of rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms is crucial for managing shipping costs, insurance, and liability, ensuring smooth logistics in cross-border trades.

-

Lead Time: This refers to the time taken from placing an order to the delivery of the product. Understanding lead times helps businesses plan their operations and avoid delays in production or project timelines.

-

Warranty: A warranty is a guarantee provided by the manufacturer regarding the product’s performance and reliability. Knowing the warranty terms can help buyers assess the risk associated with their investment and ensure they have recourse in case of defects or malfunctions.

By grasping these technical specifications and industry terms, B2B buyers can make more informed decisions regarding air solenoid valves, leading to better procurement outcomes and enhanced operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the air solenoid valve Sector

What Are the Key Trends Shaping the Global Air Solenoid Valve Market?

The air solenoid valve sector is currently experiencing significant growth, driven by increasing automation across various industries, including manufacturing, automotive, and healthcare. As global markets expand, particularly in regions such as Africa, South America, the Middle East, and Europe, international B2B buyers are seeking reliable and efficient solutions to enhance operational productivity. Current trends indicate a shift towards more compact and energy-efficient solenoid valves, which can easily integrate into existing systems while reducing overall energy consumption.

Illustrative image related to air solenoid valve

Moreover, the rise of Industry 4.0 and the Internet of Things (IoT) is prompting manufacturers to develop smart solenoid valves equipped with sensors and connectivity features. This technological advancement allows for real-time monitoring and predictive maintenance, enabling companies to minimize downtime and improve process efficiency. Buyers from regions like Germany and Saudi Arabia are particularly keen on sourcing these innovative products, as they align with their goals for enhanced automation and operational excellence.

Emerging sourcing trends also highlight the importance of local suppliers. With global supply chains facing disruptions, many buyers are increasingly prioritizing domestic and regional suppliers to ensure timely deliveries and mitigate risks associated with long-distance logistics. This trend is especially relevant for B2B buyers in Africa and South America, where local sourcing can lead to reduced lead times and lower shipping costs.

How Can Sustainability and Ethical Sourcing Impact B2B Relationships in the Air Solenoid Valve Sector?

Sustainability is becoming a pivotal factor in procurement strategies for air solenoid valves. As environmental regulations tighten and consumers demand greener products, companies are compelled to evaluate the environmental impact of their supply chains. B2B buyers are now prioritizing suppliers who can demonstrate commitment to sustainable practices, such as using recyclable materials and minimizing waste during production.

Ethical sourcing is equally important, as buyers seek to partner with manufacturers who uphold fair labor practices and transparency throughout their operations. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming prerequisites for suppliers aiming to engage with international buyers. This trend is particularly relevant in regions like Europe, where regulations are stringent, and buyers are increasingly scrutinizing supply chain practices.

Furthermore, the integration of ‘green’ materials in the production of air solenoid valves can significantly enhance a company’s marketability. As buyers look for solutions that align with their corporate social responsibility (CSR) goals, manufacturers who adopt sustainable materials and practices will likely gain a competitive edge.

What Is the Historical Context of Air Solenoid Valves in B2B Applications?

The evolution of air solenoid valves dates back to the early 20th century when advancements in electrical engineering led to the development of these essential components for fluid control systems. Initially used in simple pneumatic applications, the technology has evolved significantly, with modern solenoid valves now featuring advanced designs that offer improved efficiency and reliability.

Over the decades, the integration of automation technologies has transformed the use of air solenoid valves across various industries. From traditional manufacturing processes to sophisticated robotics in today’s smart factories, the role of solenoid valves has expanded dramatically. This historical context underscores the ongoing innovation within the sector and the increasing importance of these devices in modern industrial applications, making them a critical area of focus for B2B buyers seeking to enhance operational capabilities.

In summary, understanding the market dynamics, sustainability imperatives, and historical evolution of air solenoid valves equips international B2B buyers with the insights needed to make informed sourcing decisions. By prioritizing innovative technologies and ethical practices, companies can position themselves as leaders in a rapidly evolving marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of air solenoid valve

-

How do I select the right air solenoid valve for my application?

Choosing the right air solenoid valve involves understanding your specific application requirements, including the type of media (air, gas, or liquid), pressure range, and flow rate. Additionally, consider whether you need a normally open or normally closed valve based on your operational needs. It’s essential to assess the valve’s size, material (such as brass or stainless steel), and electrical specifications (like voltage and current) to ensure compatibility with your system. Consulting with suppliers and reviewing technical documentation can also provide valuable insights for making an informed choice. -

What are the key differences between direct-acting and pilot-operated solenoid valves?

Direct-acting solenoid valves are compact and can operate at low pressures, making them suitable for applications requiring fast switching and reliability. They contain fewer parts, which simplifies maintenance and reduces costs. In contrast, pilot-operated valves use a small pilot signal to control a larger flow, making them ideal for high-pressure applications. Understanding these differences will help you select the most appropriate valve type based on your operational needs, efficiency requirements, and budget constraints. -

What customization options are available for air solenoid valves?

Many manufacturers offer customization options for air solenoid valves, including modifications to size, port configuration, and materials. You can also request specific electrical connections, pressure ratings, and special coatings for corrosion resistance. Custom designs can enhance compatibility with your existing systems and optimize performance. When considering customization, it’s crucial to communicate your exact specifications to the supplier to ensure that your needs are met effectively. -

What is the typical minimum order quantity (MOQ) for air solenoid valves?

Minimum order quantities (MOQs) for air solenoid valves can vary significantly among suppliers, typically ranging from 10 to 100 units. Factors influencing the MOQ include the valve type, material, and customization requirements. For international buyers, it’s essential to discuss MOQs upfront to understand potential pricing advantages and inventory management strategies. Additionally, some suppliers may offer flexibility on MOQs for repeat customers or larger contracts. -

What payment terms should I expect when sourcing air solenoid valves internationally?

Payment terms for international purchases of air solenoid valves can vary based on supplier policies, order size, and the buyer’s relationship with the supplier. Common payment methods include wire transfers, letters of credit, and PayPal. It’s advisable to negotiate terms that protect your interests, such as partial payment upon order confirmation and the remainder upon shipment. Always clarify currency exchange rates and any potential additional fees that may apply to international transactions. -

How can I ensure quality assurance for my purchased air solenoid valves?

To ensure quality assurance, consider sourcing from reputable suppliers who offer certifications such as ISO 9001 or specific industry standards relevant to your application. Request detailed product specifications, test reports, and material certifications before finalizing your order. Additionally, inquire about the supplier’s quality control processes, including testing procedures for leak rates and operational performance. Establishing a clear communication channel with your supplier can also facilitate ongoing quality assurance. -

What logistics considerations should I keep in mind when importing air solenoid valves?

When importing air solenoid valves, consider shipping methods, lead times, and customs regulations specific to your country. Evaluate options such as air freight for faster delivery or sea freight for cost-effectiveness. Be aware of import duties and taxes that may apply, and ensure compliance with local regulations. It’s also wise to work with experienced logistics partners who can help navigate the complexities of international shipping and ensure timely delivery. -

How do I vet potential suppliers for air solenoid valves?

Vetting potential suppliers involves researching their industry reputation, customer reviews, and certifications. Consider requesting samples to evaluate product quality firsthand. Additionally, check for references from other international buyers and assess their responsiveness and communication practices. Attending industry trade shows or utilizing online platforms can provide further insights into a supplier’s capabilities. Establishing a good relationship with suppliers can lead to better service and support in the long run.

Top 4 Air Solenoid Valve Manufacturers & Suppliers List

1. US Solid – Pneumatic Valves

Domain: ussolid.com

Registered: 2010 (15 years)

Introduction: This company, US Solid – Pneumatic Valves, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Pneumatic Plus – Solenoid Valves

Domain: pneumaticplus.com

Registered: 2011 (14 years)

Introduction: Solenoid Valves: G1/8 – 1/8″ NPT (18mm Body) – MSRP: $46.50; M5/10-32 UNF (15mm Body) – MSRP: $46.13; G1/8 – 1/8″ NPT (23mm Body) – MSRP: $46.88; G1/4 – 1/4″ NPT (26mm Body) – MSRP: $46.88; G3/8 – 3/8″ NPT (32mm Body) – MSRP: $67.13.

3. SMC – Pneumatic Actuators & Valves

Domain: smcusa.com

Registered: 1995 (30 years)

Introduction: Air Cylinders, Solenoid Valves, Pneumatics, Actuators, Linear Actuators, Guided Actuators, Grippers, Rotary Actuators, Rodless Actuators, Clamps, Specialty Actuators, Hydraulic Equipment, Actuator Accessories, Directional Control Valves, Air Operated Valves, Mechanical & Hand Operated Valves, Safety Pressure Relief Valves, Clean Room Products, Airline Equipment, Combination Units, Filters, Pressur…

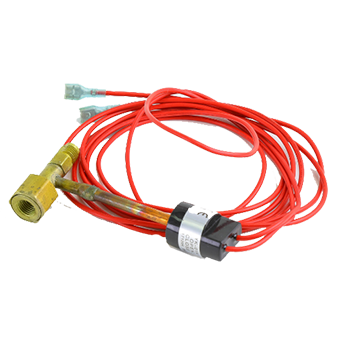

4. AutomationDirect – Directional Control Solenoid Valves

Domain: automationdirect.com

Registered: 1999 (26 years)

Introduction: Directional control solenoid valves are essential components in pneumatic systems, allowing for the control of airflow and direction. These valves come in various configurations, including 2-way, 3-way, and 4-way options, suitable for different applications. Key features include voltage ratings, port sizes, and actuation methods. The valves are designed for reliability and efficiency, with options…

Strategic Sourcing Conclusion and Outlook for air solenoid valve

In the dynamic landscape of air solenoid valves, strategic sourcing emerges as a crucial factor for international B2B buyers. By understanding the diverse range of products—from miniature to large solenoid valves—buyers can ensure they select the right components for their specific applications. Cost-effective options are available without compromising quality, allowing businesses to optimize their operations while maintaining budgetary constraints.

Furthermore, the importance of precise specifications cannot be overstated. Selecting the appropriate thread size and port type can prevent costly leaks and returns, ultimately enhancing operational efficiency. As industries across Africa, South America, the Middle East, and Europe continue to evolve, the demand for reliable and efficient solenoid valves will only grow.

Looking ahead, international buyers should leverage strategic sourcing to build partnerships with reputable suppliers who prioritize quality and innovation. By doing so, they can secure a competitive edge in their respective markets. Engage with suppliers today to explore tailored solutions that align with your business needs and set the stage for future growth.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.