Air Hydraulic Pump: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for air hydraulic pump

Navigating the complexities of sourcing an air hydraulic pump can be daunting for international B2B buyers, especially when facing diverse market dynamics across regions like Africa, South America, the Middle East, and Europe. The challenge lies not only in identifying the right type of pump—whether single-acting or double-acting, high or low pressure—but also in understanding the specific applications that suit their operational needs. This comprehensive guide delves deep into the various types of air hydraulic pumps available, their applications across industries, and critical factors for supplier vetting.

Buyers will gain insights into essential considerations such as pressure ratings, reservoir capacities, and compatibility with different hydraulic systems. By evaluating suppliers based on reliability, quality, and service, businesses can ensure they partner with manufacturers that align with their operational demands. Additionally, we will explore cost implications, helping stakeholders make informed purchasing decisions that balance quality with budget constraints.

Empowering buyers with actionable knowledge, this guide serves as an essential resource for navigating the global air hydraulic pump market. Whether you’re looking to enhance productivity, improve safety, or streamline operations, understanding these facets will enable you to make strategic choices that drive success in your projects and operations.

Understanding air hydraulic pump Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single Acting Hydraulic Pumps | Operate using air pressure to push hydraulic fluid in one direction; typically have a lower flow rate. | Small-scale applications like automotive repair and light industrial tasks. | Pros: Cost-effective, easy to operate. Cons: Limited to one-directional force. |

| Double Acting Hydraulic Pumps | Capable of moving hydraulic fluid in both directions, allowing for greater versatility and control. | Heavy machinery operations, construction, and manufacturing processes. | Pros: Higher efficiency, suitable for complex tasks. Cons: Typically more expensive. |

| Air Over Hydraulic Pumps | Combines pneumatic and hydraulic systems, achieving high pressure (up to 10,000 PSI) with air compression. | Industrial applications requiring high force, such as metal forming and assembly. | Pros: High power output, suitable for diverse applications. Cons: Requires a reliable air supply. |

| Two-Speed Hydraulic Pumps | Feature two operational speeds for increased efficiency, allowing for rapid movement and controlled pressure. | Production lines, assembly operations, and environments requiring both speed and precision. | Pros: Enhanced productivity, versatile. Cons: More complex, potential for higher maintenance. |

| Portable Hydraulic Pumps | Compact and lightweight, designed for mobility and ease of use in various locations. | Fieldwork, maintenance tasks, and remote operations. | Pros: Easy to transport, user-friendly. Cons: Limited capacity and power compared to stationary models. |

What Are the Characteristics of Single Acting Hydraulic Pumps?

Single acting hydraulic pumps are designed to exert force in one direction, making them ideal for straightforward tasks such as lifting or pressing. They typically feature a lower flow rate, which can be advantageous in applications that don’t require rapid movement. B2B buyers should consider the specific needs of their operations, as these pumps are often more cost-effective and simpler to operate, but they may not be suitable for applications requiring bidirectional force.

How Do Double Acting Hydraulic Pumps Enhance Operational Efficiency?

Double acting hydraulic pumps are engineered to move hydraulic fluid in both directions, providing enhanced versatility and control. This feature allows them to perform more complex tasks, making them indispensable in heavy machinery operations, construction, and manufacturing. B2B buyers should assess the complexity of their applications, as these pumps offer higher efficiency but come at a higher cost compared to single acting models.

Why Choose Air Over Hydraulic Pumps for High-Pressure Applications?

Air over hydraulic pumps leverage both pneumatic and hydraulic systems to achieve high pressures—up to 10,000 PSI—making them suitable for demanding industrial applications such as metal forming and assembly. Their ability to deliver significant power output while being relatively compact makes them a preferred choice for many B2B buyers. However, it is crucial to ensure a reliable air supply to maximize their effectiveness.

What Advantages Do Two-Speed Hydraulic Pumps Offer in Industrial Settings?

Two-speed hydraulic pumps provide the flexibility of operating at two different speeds, allowing for rapid movement when needed and controlled pressure for precision tasks. This functionality is particularly beneficial in production lines and assembly operations where both speed and accuracy are critical. Buyers should weigh the advantages of increased productivity against potential complexities and maintenance requirements.

How Do Portable Hydraulic Pumps Meet the Needs of Fieldwork?

Portable hydraulic pumps are designed for mobility, making them ideal for fieldwork and maintenance tasks. Their lightweight and compact nature allows for easy transport to various job sites. However, B2B buyers should consider that while these pumps are user-friendly and convenient, they may have limited capacity and power compared to their stationary counterparts.

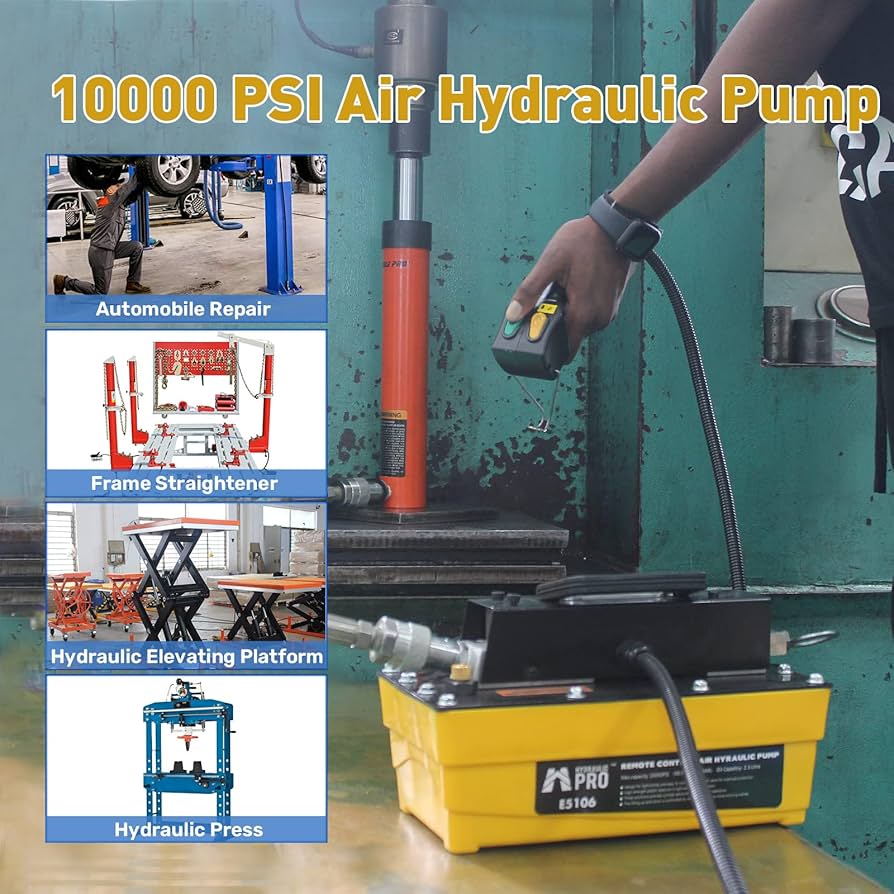

Key Industrial Applications of air hydraulic pump

| Industry/Sector | Specific Application of air hydraulic pump | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Pressing and forming metal components | Increases production efficiency and reduces labor costs | Ensure compatibility with various cylinder sizes and pressure ratings. |

| Automotive | Lifting and positioning vehicle frames during assembly | Enhances safety and precision in assembly processes | Look for pumps with high pressure ratings and compact designs. |

| Construction | Powering pneumatic tools for heavy lifting | Improves operational efficiency and reduces downtime | Consider the air supply requirements and pump durability in harsh environments. |

| Oil & Gas | Bolt tensioning and maintenance of equipment | Ensures safety and reliability in high-stakes operations | Source pumps with intrinsic safety features for hazardous environments. |

| Metal Fabrication | Hydraulic shearing and bending of metal sheets | Streamlines production processes and enhances product quality | Evaluate reservoir capacity and flow rates to meet production demands. |

How Are Air Hydraulic Pumps Used in Manufacturing?

In the manufacturing sector, air hydraulic pumps are crucial for pressing and forming metal components. They provide the necessary force to shape materials into desired forms, significantly increasing production efficiency while reducing labor costs. For international buyers, it’s essential to consider the compatibility of pumps with various cylinder sizes and ensure the pressure ratings meet specific application requirements. The durability of the pump in different operational environments also plays a critical role in sourcing decisions.

What Role Do Air Hydraulic Pumps Play in the Automotive Industry?

In automotive assembly, air hydraulic pumps are utilized for lifting and positioning vehicle frames. This application enhances safety and precision during assembly processes, minimizing the risk of accidents and ensuring that components are accurately aligned. Buyers in regions like Europe and South America should prioritize pumps with high pressure ratings and compact designs that can easily fit into tight spaces on assembly lines. Additionally, the ability to operate multiple tools simultaneously can further streamline production.

How Are Air Hydraulic Pumps Beneficial in Construction?

Air hydraulic pumps are essential for powering pneumatic tools used in heavy lifting within the construction industry. By improving operational efficiency and reducing downtime, these pumps contribute to faster project completion times. International buyers should consider the air supply requirements, as well as the pump’s durability to withstand harsh construction environments. Ensuring that the pump can operate effectively under varying conditions is vital for maintaining productivity on job sites.

Why Are Air Hydraulic Pumps Important in the Oil & Gas Sector?

In the oil and gas industry, air hydraulic pumps are employed for bolt tensioning and maintenance of critical equipment. This application ensures safety and reliability in high-stakes operations where equipment failure can lead to catastrophic consequences. For buyers in this sector, sourcing pumps with intrinsic safety features is paramount, particularly in hazardous environments. Understanding the pump’s operational limits and maintenance requirements will also help in selecting the right equipment for demanding applications.

How Do Air Hydraulic Pumps Enhance Metal Fabrication Processes?

In metal fabrication, air hydraulic pumps facilitate hydraulic shearing and bending of metal sheets, streamlining production processes. This capability enhances product quality by ensuring precise cuts and bends. Buyers should evaluate the reservoir capacity and flow rates of pumps to ensure they meet the demands of their production lines. Additionally, considering the pump’s compatibility with different hydraulic oils can optimize performance in various temperature conditions, which is crucial for international operations.

3 Common User Pain Points for ‘air hydraulic pump’ & Their Solutions

Scenario 1: Struggling with Inconsistent Pressure Delivery

The Problem: Many B2B buyers encounter issues with inconsistent pressure delivery from air hydraulic pumps, which can lead to inefficient operations and compromised safety. For example, in a manufacturing setting, if the pump fails to maintain the expected 10,000 PSI, it can result in incomplete tasks, such as forming or pressing materials. This inconsistency not only delays production but may also require additional labor to troubleshoot, ultimately increasing operational costs.

The Solution: To address this challenge, buyers should prioritize sourcing air hydraulic pumps with adjustable pressure settings and built-in pressure regulators. When selecting a pump, it is crucial to verify the specifications, such as maximum pressure and flow rate, to ensure they align with operational requirements. Additionally, regular maintenance of the pump, including checking for air leaks and ensuring proper lubrication, can significantly enhance performance stability. Implementing a systematic maintenance schedule and training staff on the importance of maintaining optimal air pressure can further mitigate issues related to inconsistent pressure delivery.

Scenario 2: Complications with Pump Compatibility and Sizing

The Problem: Another common pain point for B2B buyers is the compatibility of air hydraulic pumps with existing systems and equipment. Often, businesses may invest in a pump only to discover it does not fit their hydraulic cylinder’s specifications, leading to operational disruptions. For instance, a company may have a single-acting cylinder but purchase a double-acting pump, which can cause performance issues and necessitate additional purchases.

The Solution: To avoid compatibility issues, it is essential to conduct a thorough assessment of existing hydraulic equipment before making a purchase. Buyers should examine the specifications of their hydraulic cylinders, including size, type (single or double acting), and required pressure ratings. When sourcing an air hydraulic pump, opt for suppliers that offer a range of models with detailed compatibility information. Engaging with technical sales representatives can provide insights into the best pump options that align with current systems. Additionally, considering modular pump designs can allow for future scalability, ensuring that the investment remains relevant as operational needs evolve.

Scenario 3: High Operating Costs Due to Inefficient Energy Use

The Problem: Many companies face high operating costs associated with energy inefficiencies in air hydraulic pumps. For instance, if a pump consumes excessive compressed air to achieve the desired hydraulic pressure, it can lead to inflated energy bills and reduced profitability. Businesses in regions with high energy costs, such as parts of Europe and the Middle East, can find this particularly burdensome.

The Solution: To combat high operating costs, buyers should evaluate energy-efficient air hydraulic pumps that are designed to maximize performance while minimizing air consumption. Look for pumps that operate effectively within a lower range of air pressure (e.g., 60-80 PSI), as this can lead to significant energy savings. Additionally, consider investing in pumps equipped with variable speed drives, which allow for adjustments in performance based on real-time demand, reducing unnecessary energy expenditure. Regularly auditing energy usage and maintaining the pump system to ensure optimal performance can further help in identifying inefficiencies and areas for cost reduction. Collaborating with energy consultants to explore alternatives, such as integrating renewable energy sources, can also contribute to lowering long-term operational costs.

Illustrative image related to air hydraulic pump

Strategic Material Selection Guide for air hydraulic pump

What Are the Key Materials Used in Air Hydraulic Pumps?

When selecting air hydraulic pumps, the choice of materials plays a critical role in determining performance, durability, and suitability for specific applications. Here, we analyze four common materials used in the construction of air hydraulic pumps: aluminum alloy, cast iron, stainless steel, and composite materials.

How Does Aluminum Alloy Benefit Air Hydraulic Pumps?

Aluminum alloy is a popular choice for air hydraulic pumps due to its lightweight and corrosion-resistant properties. With a pressure rating that can reach up to 10,000 PSI, aluminum alloys are suitable for high-performance applications. They also offer excellent thermal conductivity, which aids in heat dissipation during operation.

Pros: Aluminum alloy pumps are lightweight, making them easier to handle and transport. They are also resistant to corrosion, which is particularly beneficial in humid or chemically aggressive environments.

Cons: While aluminum alloys are durable, they may not withstand extreme temperatures as well as other materials, such as stainless steel. Additionally, they can be more expensive than traditional steel options.

Illustrative image related to air hydraulic pump

Impact on Application: Aluminum alloy pumps are ideal for applications requiring portability and resistance to corrosion, such as in automotive repair or outdoor construction.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial. Buyers from regions like Europe may prefer aluminum pumps that meet these standards for quality assurance.

What Advantages Does Cast Iron Offer for Air Hydraulic Pumps?

Cast iron is known for its strength and durability, making it a reliable choice for heavy-duty air hydraulic pumps. It can withstand high pressure and offers excellent wear resistance, which is essential for long-term use.

Illustrative image related to air hydraulic pump

Pros: Cast iron pumps are robust and can handle harsh working conditions, making them suitable for industrial applications.

Cons: The weight of cast iron can be a disadvantage for mobility. Additionally, it is more prone to corrosion if not properly coated or maintained.

Impact on Application: Cast iron is suitable for applications that involve heavy loads and require high durability, such as in manufacturing plants.

Considerations for International Buyers: Buyers should be aware of the need for protective coatings to prevent rust, especially in humid climates found in parts of Africa and South America.

Why Choose Stainless Steel for Air Hydraulic Pumps?

Stainless steel is often chosen for its excellent corrosion resistance and high strength-to-weight ratio. It can operate effectively in a wide range of temperatures and pressures, making it versatile for various applications.

Pros: Stainless steel pumps are highly durable and resistant to corrosion, making them suitable for both indoor and outdoor applications. They also have a sleek appearance, which may be preferred in consumer-facing settings.

Cons: The primary downside is the higher cost compared to other materials. Additionally, stainless steel can be more challenging to machine, potentially increasing manufacturing complexity.

Impact on Application: Stainless steel is ideal for applications in food processing or pharmaceuticals, where hygiene and corrosion resistance are critical.

Illustrative image related to air hydraulic pump

Considerations for International Buyers: Compliance with hygiene standards (e.g., FDA regulations) is essential for buyers in sectors that require sanitary conditions, particularly in Europe.

How Do Composite Materials Enhance Air Hydraulic Pumps?

Composite materials, such as reinforced plastics, are increasingly being used in air hydraulic pumps due to their lightweight and corrosion-resistant properties. They can be engineered to meet specific performance criteria.

Pros: Composites are lightweight and can be designed to offer specific mechanical properties, such as flexibility or rigidity, depending on the application.

Illustrative image related to air hydraulic pump

Cons: They may not be as durable as metals and can be susceptible to damage from UV exposure or extreme temperatures.

Impact on Application: Composite materials are suitable for applications where weight savings are critical, such as in portable hydraulic tools.

Considerations for International Buyers: Buyers should ensure that composite materials meet local regulations regarding material safety and performance standards.

Illustrative image related to air hydraulic pump

Summary Table of Material Selection for Air Hydraulic Pumps

| Material | Typical Use Case for air hydraulic pump | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloy | Automotive repair, outdoor construction | Lightweight and corrosion-resistant | Limited temperature range | Medium |

| Cast Iron | Industrial manufacturing | High durability and wear resistance | Heavy and prone to corrosion | Low |

| Stainless Steel | Food processing, pharmaceuticals | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Composite Materials | Portable hydraulic tools | Lightweight and customizable | Less durable and UV susceptible | Medium |

This strategic material selection guide provides valuable insights into the materials used in air hydraulic pumps, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for air hydraulic pump

What Are the Key Stages in the Manufacturing Process of Air Hydraulic Pumps?

The manufacturing of air hydraulic pumps involves several critical stages that ensure the final product meets industry standards and customer expectations. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation

The process begins with the selection of high-quality materials, typically aluminum alloys for the reservoir and steel or stainless steel for the internal components. These materials are chosen for their strength, corrosion resistance, and lightweight properties. Once selected, materials undergo cutting and machining to create specific dimensions required for each component.

Forming Techniques

After preparation, the forming stage utilizes techniques such as casting, forging, and machining. For instance, the reservoir may be cast into shape, while internal components like pistons are often machined to ensure precise tolerances. Advanced forming technologies, including CNC machining and hydraulic forming, enhance the accuracy and consistency of parts, which is crucial for high-pressure applications.

Assembly Process

Following forming, components are meticulously assembled. This stage involves fitting together various parts, including the pump housing, cylinder, and valves. Skilled technicians often perform assembly to ensure each component is correctly aligned and securely fastened. For air hydraulic pumps, maintaining tight seals is critical to prevent leaks and ensure optimal performance.

Finishing Operations

The final stage involves surface treatment and finishing processes. Components may undergo anodizing or powder coating to enhance durability and resistance to environmental factors. Rigorous cleaning is also performed to remove any contaminants that could affect performance. This stage is vital for ensuring that the pumps can operate efficiently in diverse conditions, especially in industrial settings.

How Is Quality Assurance Implemented in the Production of Air Hydraulic Pumps?

Quality assurance (QA) is integral to the manufacturing of air hydraulic pumps, ensuring that every unit meets both domestic and international standards. The QA process encompasses various international standards, checkpoints, and testing methods.

Adherence to International Standards

Manufacturers typically comply with ISO 9001, which outlines requirements for a quality management system. This certification ensures that products are consistently produced to meet customer and regulatory requirements. Additionally, industry-specific certifications such as CE marking for compliance with European safety standards and API (American Petroleum Institute) standards for hydraulic products are crucial for international buyers.

Illustrative image related to air hydraulic pump

Key Quality Control Checkpoints

Quality control in the manufacturing process includes several checkpoints:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards. Any subpar materials are rejected before they enter the production line.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, periodic inspections are conducted. This may include monitoring dimensional accuracy during machining and checking assembly integrity to prevent defects from progressing down the line.

-

Final Quality Control (FQC): Once the air hydraulic pumps are assembled, they undergo rigorous testing. This includes pressure testing to verify that the pumps can withstand their rated pressure without leaks, as well as operational tests to ensure performance meets specifications.

What Testing Methods Are Commonly Used for Quality Assurance in Air Hydraulic Pumps?

Testing methods are critical to validating the performance and reliability of air hydraulic pumps. Common methods include:

-

Hydrostatic Testing: This method involves filling the pump with a liquid and applying pressure to check for leaks and structural integrity. It is essential for ensuring that the pump can handle its maximum rated pressure.

-

Functional Testing: Each pump is operated under its intended conditions to verify that it performs as expected. This includes checking for flow rates, pressure output, and operational noise levels.

-

Fatigue Testing: To assess the durability of components, manufacturers may conduct fatigue tests that simulate long-term use, ensuring that parts can withstand repeated cycles without failure.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those in diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential for risk management. Here are actionable steps buyers can take:

-

Supplier Audits: Conducting regular audits of suppliers helps verify compliance with quality standards. This can include reviewing their quality management systems and inspecting their facilities.

-

Requesting Quality Reports: Buyers can ask suppliers for quality control reports, which should detail the methodologies employed, results of testing, and any corrective actions taken for past issues.

-

Engaging Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased assessment of the manufacturing processes and quality assurance measures in place. These inspections can be scheduled at various stages of production.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate specific challenges related to quality control that can vary by region. Understanding these nuances can help mitigate risks:

-

Regulatory Compliance: Different regions have varying regulatory requirements. For example, pumps sold in the European market must comply with CE regulations, while those in the U.S. may need to meet OSHA standards. Buyers should ensure their suppliers are compliant with the relevant regulations for their target market.

-

Cultural Differences in Quality Standards: Quality expectations may differ between regions. For instance, European buyers may have stricter standards compared to some manufacturers in developing countries. It’s essential for buyers to communicate their quality expectations clearly and ensure that suppliers understand these standards.

-

Logistical Considerations: Shipping and handling can affect product quality. Buyers should inquire about how suppliers handle logistics, including packaging and transportation, to ensure that products arrive in optimal condition.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing air hydraulic pumps, ensuring they select reliable suppliers that meet their quality standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘air hydraulic pump’

When sourcing an air hydraulic pump, it is essential to follow a structured approach to ensure you select the right product for your operational needs. This checklist serves as a practical guide for B2B buyers, particularly in international markets such as Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for your air hydraulic pump based on your application. Consider factors such as:

– Pressure Rating: Determine the required PSI for your operations, with common ratings ranging from 3,200 to 10,000 PSI.

– Flow Rate: Assess the flow rate needed for your tasks, as this affects the pump’s efficiency and operational speed.

Illustrative image related to air hydraulic pump

Step 2: Assess Cylinder Compatibility

Identify the types of hydraulic cylinders that will be used with the pump. Understanding whether you need single-acting or double-acting cylinders is crucial, as it influences the pump selection. Ensure the pump’s specifications align with the cylinder’s requirements to avoid operational inefficiencies.

Step 3: Evaluate Supplier Certifications

Ensure that potential suppliers hold relevant certifications and adhere to international quality standards. Look for:

– ISO Certifications: This indicates that the supplier maintains quality management systems.

– Safety Certifications: Verify that products meet safety regulations applicable in your region, especially if working in hazardous environments.

Step 4: Review Product Durability and Construction Material

The construction material of the pump can significantly affect its performance and lifespan. Focus on:

– Material Quality: Aluminum alloy is often preferred for its strength-to-weight ratio and corrosion resistance.

– Environmental Suitability: Ensure the pump is designed for the operating conditions, whether that involves extreme temperatures or exposure to harsh environments.

Step 5: Compare Warranty and Support Options

A robust warranty and support system can save you time and money in the long run. Look for:

– Warranty Terms: A longer warranty period typically indicates greater manufacturer confidence in product durability.

– Customer Support: Assess the availability of technical support and spare parts, which can minimize downtime during operations.

Step 6: Request Samples or Demonstrations

Before making a bulk purchase, request product samples or demonstrations. This allows you to evaluate the pump’s performance in real-world conditions. Pay attention to:

– Ease of Use: Consider how user-friendly the pump is, including the controls and operational setup.

– Noise Levels: A quieter pump can enhance workplace safety and comfort.

Step 7: Negotiate Pricing and Payment Terms

Once you’ve narrowed down your options, engage in discussions regarding pricing and payment terms. Consider:

– Bulk Discounts: Many suppliers offer reduced prices for larger orders, which can be beneficial for businesses planning for growth.

– Payment Flexibility: Ensure payment terms align with your budget and cash flow requirements to facilitate smoother transactions.

Following this checklist will help you make informed decisions when sourcing air hydraulic pumps, ensuring you select the best product for your needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for air hydraulic pump Sourcing

What Are the Key Cost Components in Sourcing Air Hydraulic Pumps?

When sourcing air hydraulic pumps, understanding the cost structure is vital for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The choice of materials significantly impacts the cost. High-quality aluminum alloys are often used for durability but come at a higher price. The specifics of the hydraulic oil required (such as ISO 32 or ISO 46) also add to the material costs.

-

Labor: Labor costs vary depending on the region of production. Countries with lower labor costs may provide competitive pricing, but this can affect quality control and production speed.

-

Manufacturing Overhead: This encompasses expenses related to the factory’s operations, such as utilities, equipment maintenance, and administrative costs. Efficient manufacturing processes can help reduce overhead costs, making the final product more competitive.

-

Tooling: The initial investment in tooling for specialized pumps can be significant. Custom designs or unique specifications may require additional tooling, which can increase the upfront costs.

-

Quality Control (QC): Ensuring that the pumps meet industry standards involves rigorous testing and certification processes. The costs associated with QC are crucial for maintaining product reliability and safety, particularly for pumps used in hazardous environments.

-

Logistics: Shipping costs, including freight and insurance, must be accounted for, especially when sourcing from international suppliers. Incoterms can influence logistics costs, as they define the responsibilities of buyers and sellers in the shipping process.

-

Margin: Suppliers will typically add a margin to cover their costs and ensure profitability. Understanding the expected margin can aid buyers in negotiating better pricing.

How Do Price Influencers Affect the Cost of Air Hydraulic Pumps?

Several factors influence the pricing of air hydraulic pumps, particularly for international buyers from regions like Africa, South America, the Middle East, and Europe.

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often result in lower unit prices. Buyers should assess their needs and negotiate for favorable terms based on potential order volumes.

-

Specifications and Customization: Custom pumps or those with specific features (like dual-action capabilities or specialized pressure ratings) will generally command higher prices. Buyers must balance the need for customization with budget constraints.

-

Material Quality and Certifications: Pumps that meet international safety and performance certifications may be priced higher. Buyers should evaluate whether the added cost aligns with their operational requirements.

-

Supplier Factors: The supplier’s reputation, reliability, and geographic location can significantly impact pricing. Established suppliers may charge more for their proven quality and service, while newer entrants may offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is essential for international shipping. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the overall cost structure and risk exposure.

What Are the Best Buyer Tips for Cost-Efficient Sourcing of Air Hydraulic Pumps?

For B2B buyers, particularly those operating in diverse international markets, several strategies can enhance cost efficiency:

-

Negotiate Effectively: Always enter negotiations with a clear understanding of the market prices and cost structures. Leverage volume commitments or long-term contracts to secure better pricing.

-

Consider Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, operational costs, and potential downtime. A lower-priced pump may incur higher operational costs if it lacks reliability.

-

Understand Pricing Nuances: Be aware that international shipping, tariffs, and local regulations can affect the final price. Engage with local agents or distributors who understand the local market dynamics.

-

Request Multiple Quotes: Solicit quotes from multiple suppliers to compare pricing, terms, and quality. This practice can reveal significant savings and help identify the best overall value.

In conclusion, a comprehensive understanding of cost components, price influencers, and strategic negotiation techniques will empower B2B buyers to make informed decisions when sourcing air hydraulic pumps, ensuring both quality and cost-effectiveness in their procurement processes.

Illustrative image related to air hydraulic pump

Alternatives Analysis: Comparing air hydraulic pump With Other Solutions

Exploring Alternative Solutions to Air Hydraulic Pumps for Industrial Applications

In the quest for effective hydraulic solutions, B2B buyers often consider various options to meet their operational needs. While air hydraulic pumps are renowned for their efficiency and high pressure output, alternative technologies can also provide viable solutions depending on specific application requirements. This analysis compares air hydraulic pumps with electric hydraulic pumps and manual hydraulic hand pumps.

| Comparison Aspect | Air Hydraulic Pump | Electric Hydraulic Pump | Manual Hydraulic Hand Pump |

|---|---|---|---|

| Performance | High pressure (up to 10,000 PSI) | Moderate to high pressure (up to 5,000 PSI) | Moderate pressure (up to 2,000 PSI) |

| Cost | Mid to high ($800 – $1,800) | High ($1,500 – $3,000) | Low ($100 – $500) |

| Ease of Implementation | Requires compressed air source | Requires electrical power supply | Simple setup, no power required |

| Maintenance | Moderate; regular air filter checks | Low; minimal maintenance needed | Low; infrequent maintenance |

| Best Use Case | Heavy-duty industrial applications | Medium-duty applications in workshops | Light-duty tasks and portable use |

In-Depth Look at Alternatives

What Are the Benefits and Drawbacks of Electric Hydraulic Pumps?

Electric hydraulic pumps are designed to provide a consistent and reliable power source, often used in environments where compressed air is not readily available. They typically offer lower noise levels and can be more energy-efficient than air pumps. However, their initial cost is generally higher, and they may require more extensive electrical infrastructure, which can complicate implementation. For applications that do not require extreme pressures, electric pumps can be an excellent choice for workshops and assembly lines.

How Do Manual Hydraulic Hand Pumps Compare?

Manual hydraulic hand pumps are the most cost-effective option, making them ideal for small businesses or occasional use. They are straightforward to operate and require no external power source, making them portable and easy to use in remote locations. However, their limitations in pressure output and efficiency make them unsuitable for heavy-duty applications. For light tasks such as lifting and pressing smaller components, manual pumps can be an effective solution without the need for complex setups.

Conclusion: Choosing the Right Solution for Your Needs

When deciding between an air hydraulic pump, electric hydraulic pump, or manual hydraulic hand pump, B2B buyers should evaluate their specific operational requirements. Considerations such as the nature of the tasks, available infrastructure (e.g., compressed air or electrical supply), budget constraints, and required pressure levels will guide the decision-making process. By aligning the choice of hydraulic solution with operational needs, businesses can enhance productivity while ensuring cost-effectiveness and reliability in their hydraulic systems.

Essential Technical Properties and Trade Terminology for air hydraulic pump

What Are the Key Technical Properties of Air Hydraulic Pumps?

Understanding the technical specifications of air hydraulic pumps is crucial for B2B buyers to make informed purchasing decisions. Here are some essential properties:

Illustrative image related to air hydraulic pump

-

Pressure Rating (PSI)

The pressure rating indicates the maximum pressure the pump can generate, typically expressed in pounds per square inch (PSI). Common ratings for air hydraulic pumps range from 3,200 PSI to 10,000 PSI. A higher PSI rating allows the pump to handle heavier loads, making it suitable for demanding industrial applications. For buyers, selecting a pump with an appropriate PSI ensures that it meets the operational requirements of their specific tasks. -

Flow Rate (in³/min)

This specification measures the volume of hydraulic fluid the pump can move in a minute, usually in cubic inches. A higher flow rate indicates faster operation, which is essential for high-efficiency tasks in environments like manufacturing or construction. Understanding the flow rate helps buyers assess whether a pump can meet their production timelines without bottlenecks. -

Reservoir Capacity (in³)

The reservoir capacity specifies how much hydraulic fluid the pump can hold. This is significant for continuous operation, as a larger reservoir minimizes the need for frequent refills, enhancing productivity. For B2B buyers, evaluating reservoir size is vital for ensuring that the pump can sustain longer operational cycles, especially in high-demand situations. -

Cylinder Compatibility

Air hydraulic pumps can be designed for either single-acting or double-acting cylinders. Single-acting pumps use hydraulic pressure in one direction, while double-acting pumps can apply pressure in both directions. Understanding compatibility is crucial for buyers to ensure that the pump they select will work seamlessly with the hydraulic cylinders they intend to use. -

Material Construction

The materials used in the construction of the pump, such as aluminum alloy or steel, influence durability, weight, and resistance to corrosion. High-quality materials can withstand harsh conditions, making them suitable for various applications, including those in challenging environments. Buyers should consider the material properties to ensure longevity and reliability in their investment.

What Are Common Trade Terms in the Air Hydraulic Pump Industry?

Familiarity with industry jargon can greatly enhance communication between buyers and suppliers. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of air hydraulic pumps, buyers may seek OEM parts for replacements, ensuring compatibility and quality that meets original specifications. -

MOQ (Minimum Order Quantity)

MOQ is the smallest amount of product that a supplier is willing to sell. Understanding MOQ is critical for buyers, especially those in emerging markets, as it can affect inventory management and cash flow. Buyers should negotiate MOQs that align with their operational needs. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. For B2B buyers, issuing an RFQ allows them to compare prices and terms from different suppliers, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risks, and delivery responsibilities, ensuring smoother transactions across borders. -

CFM (Cubic Feet per Minute)

CFM measures the volume of air flow produced by the pump, which is essential for pneumatic applications. Buyers need to know the CFM rating to ensure that the pump operates efficiently with their air supply systems. -

Two-Stage Pump

A two-stage pump uses two cylinders to create different pressure levels, enhancing efficiency and speed. Understanding this feature helps buyers choose pumps that optimize performance for specific applications, particularly in high-demand scenarios.

By grasping these technical properties and trade terms, B2B buyers can navigate the complexities of purchasing air hydraulic pumps with greater confidence and effectiveness.

Navigating Market Dynamics and Sourcing Trends in the air hydraulic pump Sector

What Are the Current Market Dynamics and Key Trends in the Air Hydraulic Pump Sector?

The air hydraulic pump market is experiencing significant transformation driven by various global factors. The demand for efficient, reliable, and high-pressure hydraulic solutions has surged across industries such as manufacturing, automotive, and construction. As international markets evolve, particularly in regions like Africa, South America, the Middle East, and Europe, buyers are increasingly seeking pumps that offer enhanced performance and versatility. Key trends include a shift towards dual-action and multi-speed pumps, which provide flexibility for various applications, allowing businesses to optimize their operations.

Illustrative image related to air hydraulic pump

Technological advancements are also pivotal. The integration of smart technology in hydraulic systems enables real-time monitoring and predictive maintenance, which enhances productivity and reduces downtime. Furthermore, the availability of pneumatic hydraulic pumps with higher pressure ratings, such as those reaching up to 10,000 PSI, caters to the needs of buyers requiring robust solutions for heavy-duty applications. As the global supply chain adapts, sourcing strategies are increasingly focused on suppliers that offer customizable solutions and rapid delivery options to meet urgent project timelines.

How Is Sustainability and Ethical Sourcing Shaping the Air Hydraulic Pump Market?

Sustainability has become a critical consideration for B2B buyers in the air hydraulic pump sector. The environmental impact of manufacturing processes and product lifecycle is under scrutiny, prompting companies to seek suppliers who prioritize eco-friendly practices. Ethical sourcing of materials, including the use of recyclable and biodegradable components, is increasingly important for maintaining a competitive edge in the market. Buyers are encouraged to look for certifications that indicate compliance with environmental standards, such as ISO 14001, which ensures that suppliers adhere to effective environmental management practices.

Additionally, the industry is witnessing a trend towards the adoption of ‘green’ hydraulic fluids and lubricants that minimize environmental harm while maintaining performance standards. As regulations regarding emissions and waste management become more stringent, companies that proactively engage in sustainable practices can not only enhance their corporate responsibility profile but also reduce operational costs in the long run.

What Is the Brief Evolution of Air Hydraulic Pumps in the B2B Landscape?

The evolution of air hydraulic pumps can be traced back to the early 20th century when hydraulic technology began to gain traction in industrial applications. Initially designed for simple lifting tasks, these pumps have evolved into sophisticated systems capable of delivering high pressure and efficiency. The introduction of pneumatic power has revolutionized the industry, allowing for more versatile applications in diverse sectors.

In recent decades, the focus has shifted towards enhancing safety, reliability, and performance. Innovations such as two-stage release mechanisms and built-in safety features have become standard, making air hydraulic pumps safer and easier to operate. As global industries demand more from hydraulic systems, the future of air hydraulic pumps will likely be characterized by continued technological advancements, sustainability initiatives, and an emphasis on meeting the specific needs of international B2B buyers.

Illustrative image related to air hydraulic pump

Frequently Asked Questions (FAQs) for B2B Buyers of air hydraulic pump

-

How do I choose the right air hydraulic pump for my application?

Selecting the right air hydraulic pump involves assessing your specific application requirements, such as the required pressure rating, flow rate, and cylinder compatibility. Consider the type of operation—single or double-acting—and the size of the reservoir that best fits your needs. Additionally, evaluate the environmental conditions where the pump will be used, as some pumps are designed for harsh environments. It’s also beneficial to consult with suppliers about their product range to identify options that align with your operational demands. -

What is the best pressure rating for air hydraulic pumps used in industrial applications?

For industrial applications, a pressure rating of 10,000 PSI is often recommended, as it provides sufficient force for heavy-duty tasks. However, the ideal rating depends on the specific tasks you’ll be performing. If your operations involve lighter tasks, pumps rated at 3,200 PSI may suffice. Always consider the safety factors and the compatibility of the pump with your hydraulic systems to ensure optimal performance and longevity. -

What customization options are available for air hydraulic pumps?

Many manufacturers offer customization options, including reservoir size, pressure settings, and valve configurations. Customization can enhance the pump’s efficiency and compatibility with your existing equipment. It’s advisable to discuss your unique requirements with the supplier to ensure that the modifications meet your operational needs. Additionally, inquire about lead times for custom orders, as they may vary based on the complexity of the modifications. -

What are the typical minimum order quantities (MOQ) for air hydraulic pumps?

Minimum order quantities can vary significantly between suppliers, ranging from a single unit to several dozen, depending on the manufacturer and the model. For international buyers, it’s crucial to communicate your requirements clearly during the negotiation process. Some suppliers may offer flexible MOQ terms, especially for new customers or bulk purchases. Always clarify these details upfront to avoid any misunderstandings later in the procurement process. -

What payment terms should I expect when sourcing air hydraulic pumps internationally?

Payment terms can vary widely among suppliers, but common practices include upfront payments, partial payments upon order confirmation, or payment upon delivery. For international transactions, it’s important to consider methods like letters of credit or escrow services to mitigate risks. Always negotiate terms that provide both security and flexibility for your business, and ensure that you understand the implications of currency exchange rates and transaction fees. -

How do I vet suppliers for air hydraulic pumps effectively?

Vetting suppliers involves researching their reputation, checking references, and reviewing customer feedback. Verify their certifications and compliance with international standards to ensure product quality and safety. Attending trade shows or industry conferences can also provide insights into potential suppliers. Additionally, consider requesting samples or trial products to evaluate quality before committing to a larger order. -

What logistics considerations should I keep in mind when importing air hydraulic pumps?

When importing air hydraulic pumps, consider shipping methods, customs regulations, and potential tariffs. Evaluate the lead times for shipping and factor in the costs associated with freight, insurance, and handling. It’s advisable to work with a logistics partner who understands international shipping processes to ensure smooth delivery. Additionally, ensure that all necessary documentation, such as import permits and certificates of origin, is prepared in advance to avoid delays. -

What quality assurance measures should I look for in air hydraulic pumps?

Quality assurance is critical when sourcing air hydraulic pumps. Look for suppliers that adhere to internationally recognized standards, such as ISO certifications, which indicate commitment to quality and safety. Inquire about their testing processes, warranty policies, and after-sales support. Additionally, consider conducting independent inspections or audits of the manufacturing facility to assess their quality control measures and ensure that they align with your business expectations.

Top 4 Air Hydraulic Pump Manufacturers & Suppliers List

1. PowerX International – Air/Over Single Acting Hydraulic Pump

Domain: powerxinternational.com

Registered: 2016 (9 years)

Introduction: Air/Over Single Acting Hydraulic Pump with Foot Treadle Actuator. Designed for high flow needs with usable oil capacities of 98, 122, and 231 in³. Constructed from aluminum alloy, these pumps are durable for tough environments. Operates various cylinders/rams/jacks with minimal noise. Features include: 10,000 PSI factory setting (adjustable), 15% faster operation than industry standard. Product op…

2. Pro Tools – 10,000-psi Air/Hydraulic Pump

Domain: pro-tools.com

Registered: 1998 (27 years)

Introduction: 10,000-psi Air/Hydraulic Pump

– Effortlessly handles even the heaviest materials

– Easily operated by hand or foot

– Operating air pressure: 60-150 psi

– 13 cubic inches of oil/minute output at full pressure (compared to standard 6 cubic inches of oil/minute on competing models)

– Requires ISO 32 weight hydraulic oil (better in colder temperatures) or ISO 46 weight hydraulic oil (better in hotter …

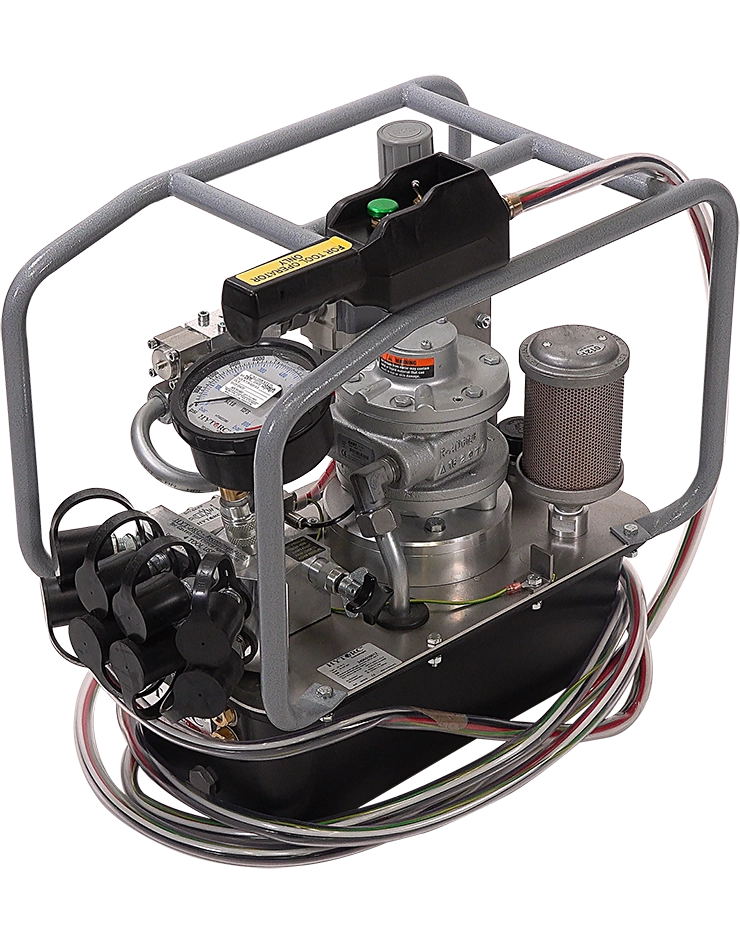

3. OTC – Air/Hydraulic Pump

Domain: otctools.com

Registered: 1995 (30 years)

Introduction: {“title”:”Air/Hydraulic Pump”,”ideal_power_source”:”Develops 10,000 PSI at 100 PSI air”,”oil_port”:”3/8\” NPTF oil port”,”usable_oil”:”98 cu. inches of usable oil”,”release_mechanism”:”Two-stage release mechanism; internal relief valve”,”product_dimensions”:”10.4 × 5.4 × 8.9 in”,”shipping_weight”:”15.1 lb”,”sku”:”4020″,”categories”:[“Specialty Tools”,”Heavy Duty Tools”,”Shop Equipment”,”Hydraulic …

4. HYTORC – HY-AIR Pneumatic Hydraulic Pump

Domain: hytorc.com

Registered: 1996 (29 years)

Introduction: HY-AIR Pneumatic Hydraulic Pump is designed for safe and efficient bolting in hazardous environments with an intrinsically safe design that prevents sparks. It features a built-in FRL (Filter, Regulator, Lubricator) for optimal air quality and pressure, enhancing the pump’s life and performance. The pump allows for easy pressure adjustments with user-friendly controls, suitable for operators of al…

Strategic Sourcing Conclusion and Outlook for air hydraulic pump

As the demand for efficient and reliable air hydraulic pumps continues to rise across industries, strategic sourcing emerges as a critical component for international B2B buyers. Organizations in Africa, South America, the Middle East, and Europe should prioritize understanding the diverse product offerings, such as single-acting and double-acting pumps, to align with specific operational needs. By evaluating factors like pressure ratings, reservoir capacities, and compatibility with various hydraulic cylinders, businesses can optimize their supply chain and enhance productivity.

Investing in high-quality air hydraulic pumps not only boosts operational efficiency but also contributes to safety and reliability in demanding environments. With the ability to handle high pressures and varying oil capacities, these pumps are essential for a multitude of applications, from manufacturing to automotive industries.

Looking ahead, international buyers are encouraged to engage with manufacturers who demonstrate innovation and quality assurance. By fostering strong partnerships and utilizing strategic sourcing practices, organizations can secure the best solutions for their hydraulic needs, ultimately driving growth and competitiveness in their respective markets. Embrace the opportunity to enhance your operations with the right air hydraulic pump solutions today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.