Air Hydraulic Piston Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for air hydraulic piston

Navigating the complexities of sourcing air hydraulic pistons can be a daunting challenge for international B2B buyers, particularly in dynamic markets across Africa, South America, the Middle East, and Europe, such as Nigeria and Germany. With a diverse array of products available, understanding the unique advantages of air hydraulic pistons—combining the rapid responsiveness of pneumatic systems with the robust force of hydraulic systems—is crucial for optimizing operational efficiency.

This guide serves as a comprehensive resource, delving into the various types of air hydraulic pistons, their applications across different industries, and essential criteria for supplier vetting. It provides insights into cost considerations, maintenance requirements, and innovative applications that enhance productivity while reducing energy consumption.

By equipping B2B buyers with the knowledge to make informed purchasing decisions, this guide aims to streamline the sourcing process, ensuring that you can select the right air hydraulic piston solutions tailored to your operational needs. Whether you’re looking to enhance manufacturing processes, improve assembly line efficiency, or meet specific industry standards, understanding these key factors will empower you to navigate the global market with confidence.

Understanding air hydraulic piston Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hydro-Pneumatic | Combines pneumatic speed with hydraulic force. | Bending, pressing, assembly. | Pros: Fast operation, reduced energy use. Cons: More complex installation. |

| Pneumatic Cylinder | Operates solely on compressed air. | Material handling, packaging. | Pros: Lightweight, low maintenance. Cons: Limited force compared to hydraulic. |

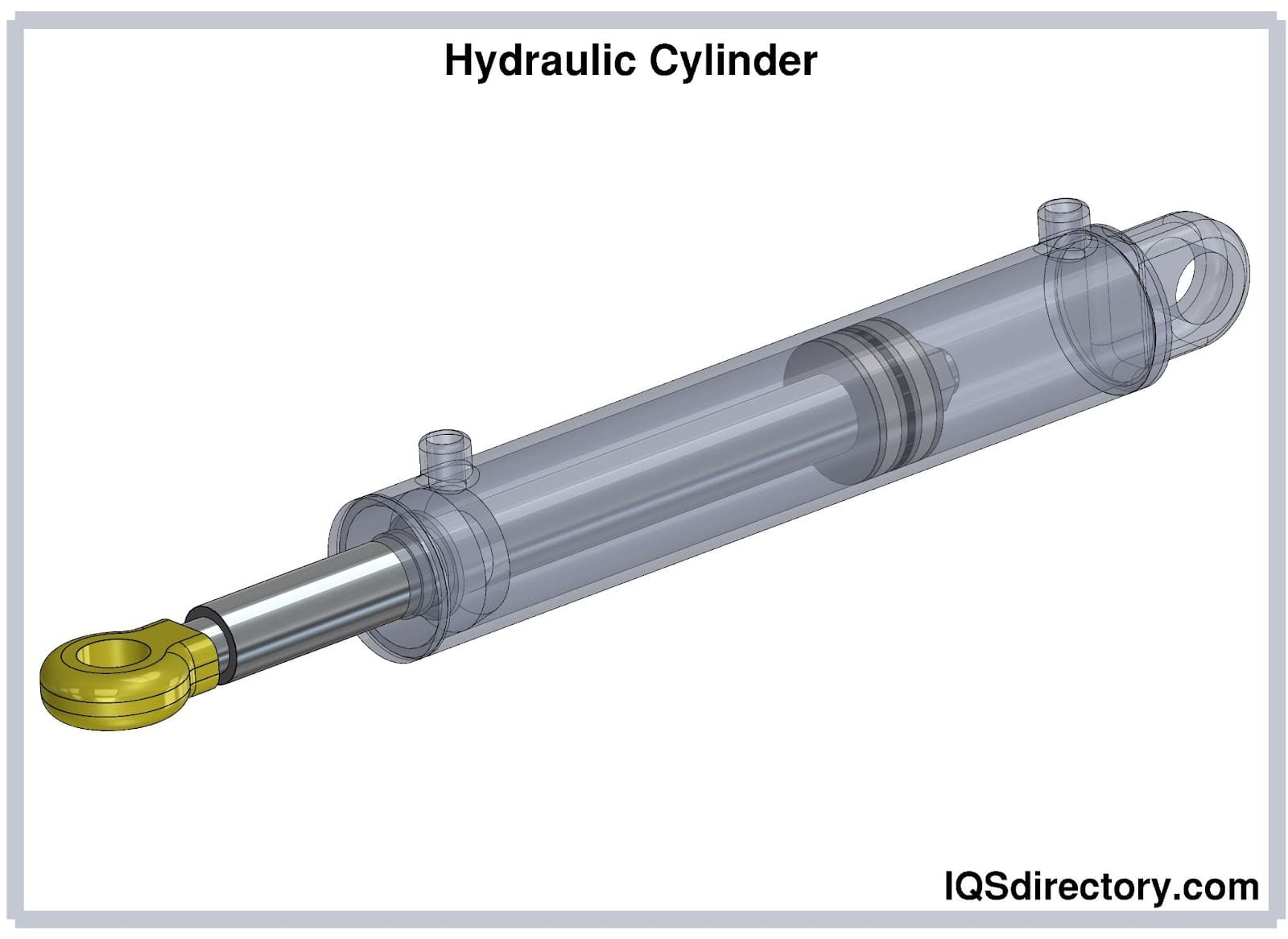

| Hydraulic Cylinder | Uses hydraulic fluid for high force applications. | Heavy machinery, industrial presses. | Pros: High power and efficiency. Cons: Requires hydraulic system setup. |

| Compact Cylinder | Smaller footprint with integrated systems. | Space-constrained environments. | Pros: Space-saving design, versatile. Cons: May sacrifice power for size. |

| Multi-Stage Cylinder | Multiple stages for adjustable force and stroke. | Precision tasks, automotive. | Pros: Adjustable performance, high versatility. Cons: Higher cost and complexity. |

What are Hydro-Pneumatic Cylinders and Their B2B Applications?

Hydro-pneumatic cylinders are innovative devices that integrate pneumatic and hydraulic technologies. They allow for rapid movement using compressed air while providing significant force during the pressing phase through hydraulic action. This dual-functionality makes them ideal for applications like bending, pressing, and assembly in industries such as manufacturing and automotive. B2B buyers should consider the initial complexity of installation and maintenance, but the energy efficiency and reduced cycle times often justify the investment.

How do Pneumatic Cylinders Serve Different Industries?

Pneumatic cylinders operate exclusively on compressed air, making them lightweight and easy to maintain. They are commonly used in material handling and packaging applications where speed and simplicity are vital. While their force output is lower than hydraulic options, their simplicity and cost-effectiveness make them attractive for businesses looking for reliable solutions without the overhead of hydraulic systems. Buyers should assess the specific force requirements of their applications to determine if pneumatic cylinders meet their operational needs.

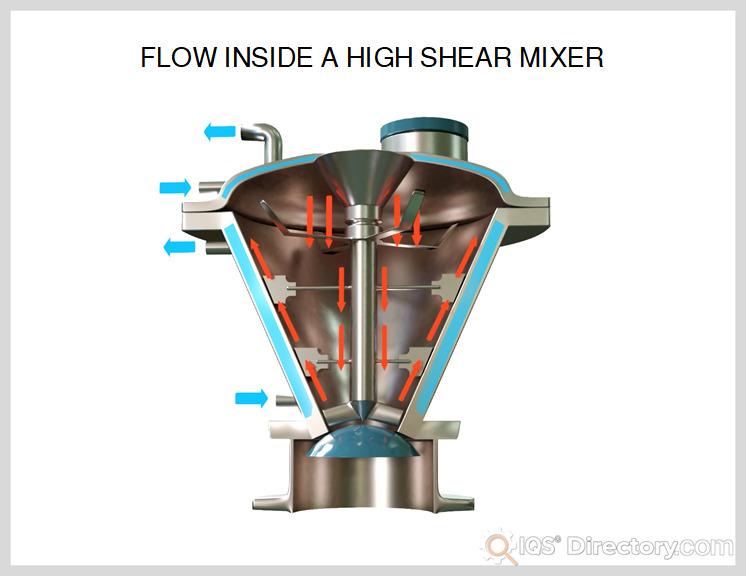

Illustrative image related to air hydraulic piston

What Benefits Do Hydraulic Cylinders Offer for Heavy Machinery?

Hydraulic cylinders are renowned for their ability to generate high force through hydraulic fluid. They are indispensable in heavy machinery and industrial presses, where substantial power is necessary for operations like lifting and compressing. While they offer remarkable efficiency and strength, the requirement for a dedicated hydraulic system can be a drawback for some businesses. Buyers should evaluate the total cost of ownership, including installation and maintenance, when considering hydraulic cylinders for their operations.

Why Choose Compact Cylinders for Space-Constrained Environments?

Compact cylinders are designed for applications where space is at a premium. They integrate both pneumatic and hydraulic components in a smaller footprint, making them suitable for environments like automated production lines. Their versatility allows them to perform effectively in various tasks while conserving valuable space. However, potential buyers should be aware that compact designs may compromise some power output, necessitating careful evaluation of performance requirements.

What are the Advantages of Multi-Stage Cylinders in Precision Tasks?

Multi-stage cylinders feature several stages that allow for adjustable force and stroke lengths, making them ideal for precision applications in industries such as automotive and aerospace. Their design enables precise control over the motion and force exerted, which is crucial for tasks requiring high accuracy. However, the complexity and higher costs associated with these cylinders may deter some buyers. Understanding specific application needs and budget constraints will help businesses decide if multi-stage cylinders are the right fit for their operations.

Key Industrial Applications of air hydraulic piston

| Industry/Sector | Specific Application of air hydraulic piston | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Pressing and forming metal components | Enhanced precision and speed in production processes | Quality certifications, compatibility with existing systems |

| Automotive | Assembly line automation for vehicle components | Increased efficiency and reduced labor costs | Customization options, availability of spare parts |

| Construction | Lifting and positioning heavy materials | Improved safety and reduced manual handling risks | Load capacity, durability in harsh environments |

| Oil and Gas | Pipe handling and installation | Streamlined operations and reduced downtime | Resistance to corrosive environments, energy efficiency |

| Aerospace | Component testing and assembly | High reliability and precision in critical applications | Compliance with industry standards, technical support |

How is the air hydraulic piston used in manufacturing?

In the manufacturing sector, air hydraulic pistons are instrumental in pressing and forming metal components. These systems combine the rapid action of pneumatic cylinders with the powerful force of hydraulic systems, allowing for quick and precise operations. By adopting air hydraulic pistons, manufacturers can significantly enhance production speed while maintaining high accuracy, which is crucial for meeting stringent quality standards. International buyers, particularly in regions like Germany and Nigeria, should consider sourcing pistons that comply with ISO standards to ensure reliability and performance.

What role does the air hydraulic piston play in automotive applications?

In the automotive industry, air hydraulic pistons are widely used for automating assembly line processes. They facilitate the accurate positioning and assembly of vehicle components, such as doors and frames, which helps in achieving higher production rates. The use of these pistons leads to reduced labor costs and minimized human error, thus ensuring consistent quality in vehicle production. Buyers from South America and the Middle East should focus on suppliers that offer customizable solutions tailored to their specific assembly line configurations.

How can air hydraulic pistons improve construction operations?

In construction, air hydraulic pistons are vital for lifting and positioning heavy materials, such as steel beams and concrete slabs. Their ability to provide high force with controlled precision enhances safety by minimizing the risks associated with manual handling. This efficiency translates to faster project completion times and reduced labor costs. When sourcing for construction applications, buyers should prioritize products with high load capacities and those designed to withstand the rigors of outdoor environments.

Why are air hydraulic pistons essential in the oil and gas industry?

In the oil and gas sector, air hydraulic pistons are employed for tasks like pipe handling and installation. Their robust design allows for the lifting and maneuvering of heavy pipes, which is essential for maintaining operational efficiency and safety in potentially hazardous environments. These systems help reduce downtime and streamline operations. Buyers in this sector should look for pistons that demonstrate resistance to corrosion and meet energy efficiency standards to optimize their operations.

How do air hydraulic pistons contribute to aerospace applications?

In aerospace, air hydraulic pistons are crucial for component testing and assembly. Their reliability and precision are vital in applications where safety and performance are non-negotiable. These pistons support rigorous testing procedures, ensuring that components meet strict regulatory standards before being integrated into aircraft. Buyers in the aerospace sector, especially those in Europe, should ensure that their suppliers provide products compliant with aerospace industry standards and offer robust technical support for maintenance and troubleshooting.

3 Common User Pain Points for ‘air hydraulic piston’ & Their Solutions

Scenario 1: Reliability Issues During High-Pressure Operations

The Problem: B2B buyers often face challenges with air hydraulic pistons failing during high-pressure operations, leading to costly downtime and production delays. These failures can stem from inadequate sealing solutions or low-quality materials that cannot withstand extreme conditions. When these critical components malfunction, the entire operation can come to a halt, resulting in lost revenue and damaged relationships with clients who rely on timely deliveries.

The Solution: To mitigate reliability issues, it is essential to source air hydraulic pistons from reputable manufacturers that adhere to stringent quality standards, such as ISO 9001 certifications. Buyers should prioritize products that utilize high-quality hydraulic and pneumatic seals specifically designed for high-pressure applications. Additionally, conducting regular maintenance checks and using advanced monitoring systems can help identify potential issues before they escalate into catastrophic failures. Investing in training for staff on proper installation and maintenance techniques can also enhance operational reliability and extend the lifespan of the pistons.

Scenario 2: Compatibility Challenges with Existing Machinery

The Problem: Many buyers encounter compatibility issues when integrating air hydraulic pistons into their existing machinery. Variations in specifications, such as dimensions, pressure ratings, and force outputs, can lead to inefficiencies or even require costly modifications to existing systems. This lack of standardization can complicate the purchasing process, leaving buyers frustrated and uncertain about which products will meet their operational needs.

The Solution: To address compatibility challenges, it is crucial for buyers to thoroughly assess their current machinery’s specifications before selecting air hydraulic pistons. Engaging with suppliers who offer customization options can also be beneficial. This allows buyers to specify the exact dimensions and force requirements needed for their applications. Moreover, leveraging the expertise of engineering consultants during the selection process can help ensure that the chosen pistons will work seamlessly with existing systems, thereby reducing the risk of costly retrofits or operational disruptions.

Scenario 3: High Energy Consumption and Operating Costs

The Problem: Many businesses are increasingly concerned about the high energy consumption associated with air hydraulic systems, which can lead to inflated operational costs. The inefficiencies often arise from the continuous operation of hydraulic power units, which consume energy even when not actively performing work. This can be particularly burdensome for companies looking to optimize their budgets and improve their sustainability practices.

The Solution: To lower energy consumption, businesses should consider integrating more efficient air hydraulic piston systems that utilize a pneumatic approach for the initial stroke, reserving hydraulic power only for the pressing phase. This hybrid approach not only reduces energy usage during non-pressing phases but also accelerates cycle times. Buyers should seek out manufacturers who provide systems designed for energy efficiency and can demonstrate significant reductions in operational costs. Additionally, implementing energy monitoring tools can help track usage patterns and identify areas for further optimization, allowing companies to make data-driven decisions to enhance their overall energy efficiency.

Strategic Material Selection Guide for air hydraulic piston

When selecting materials for air hydraulic pistons, it is crucial to consider properties that directly affect performance, durability, and suitability for specific applications. Below is an analysis of several common materials used in the manufacturing of air hydraulic pistons, focusing on their key properties, advantages, disadvantages, and implications for international buyers.

What Are the Key Properties of Aluminum for Air Hydraulic Pistons?

Aluminum is a popular choice for air hydraulic pistons due to its lightweight and excellent corrosion resistance. It typically has a temperature rating up to 150°C and can withstand moderate pressures, making it suitable for various applications.

Pros: Aluminum’s low density contributes to reduced overall system weight, enhancing portability and ease of installation. Additionally, it offers good thermal conductivity, which can be advantageous in applications requiring heat dissipation.

Cons: While aluminum is durable, it is not as strong as other metals like steel, which may limit its use in high-pressure environments. It can also be more expensive than some alternatives, impacting overall project costs.

Impact on Application: Aluminum is compatible with many hydraulic fluids, but users should confirm compatibility with specific media to avoid degradation.

Considerations for International Buyers: Buyers from regions like Europe (e.g., Germany) may prioritize compliance with standards such as DIN for material quality, while buyers in Africa and South America may focus on cost-effectiveness and availability.

How Does Ductile Cast Iron Perform in Air Hydraulic Pistons?

Ductile cast iron is known for its high strength and excellent wear resistance, making it ideal for high-pressure applications. It can withstand temperatures up to 300°C, providing robust performance in demanding environments.

Pros: The material’s durability and strength make it suitable for applications requiring high load-bearing capabilities. Additionally, ductile cast iron has good vibration-damping properties, which can enhance system longevity.

Cons: The primary drawback is its weight; ductile cast iron is significantly heavier than aluminum, which may not be ideal for all applications. Furthermore, the manufacturing process can be more complex, leading to higher costs.

Illustrative image related to air hydraulic piston

Impact on Application: Ductile cast iron can handle a wide range of hydraulic fluids, but it is essential to ensure compatibility with corrosive media.

Considerations for International Buyers: Buyers should be aware of ASTM and JIS standards that govern ductile cast iron specifications, particularly in regions with stringent quality controls.

What Are the Benefits of Stainless Steel for Air Hydraulic Pistons?

Stainless steel is renowned for its corrosion resistance and strength, making it a preferred choice for harsh environments. It can typically handle temperatures up to 400°C and high pressures, providing versatility across various applications.

Pros: Its resistance to corrosion and staining makes stainless steel ideal for applications involving aggressive fluids. The material’s strength allows for thinner designs without compromising durability.

Cons: The primary disadvantage is the cost; stainless steel is generally more expensive than aluminum and ductile cast iron. Additionally, it can be more challenging to machine, which may increase manufacturing time.

Impact on Application: Stainless steel is compatible with a wide range of hydraulic fluids, including those with corrosive properties.

Considerations for International Buyers: Buyers in the Middle East and Europe often seek stainless steel components due to their reliability in extreme conditions, necessitating compliance with international standards.

How Does Composite Material Compare for Air Hydraulic Pistons?

Composite materials, such as reinforced plastics, offer a lightweight alternative with unique properties. They can be engineered to withstand specific temperature and pressure ratings, typically up to 200°C.

Pros: Composites are highly resistant to corrosion and can be tailored for specific applications, making them versatile. Their lightweight nature can significantly reduce overall system weight.

Cons: However, composites may not provide the same load-bearing capacity as metals, limiting their use in high-pressure applications. Additionally, they can be more expensive to produce due to specialized manufacturing processes.

Impact on Application: Compatibility with hydraulic fluids varies significantly, requiring careful selection based on the specific composite used.

Considerations for International Buyers: Buyers should consider the availability of composite materials in their regions and ensure compliance with relevant standards, especially in industries with stringent regulations.

Summary Table of Material Selection for Air Hydraulic Pistons

| Material | Typical Use Case for air hydraulic piston | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight applications | Excellent corrosion resistance | Lower strength compared to metals | Medium |

| Ductile Cast Iron | High-pressure environments | High strength and wear resistance | Heavier and more complex to manufacture | High |

| Stainless Steel | Harsh environments | Superior corrosion resistance | Higher cost and machining difficulty | High |

| Composite Materials | Specialized applications | Lightweight and customizable | Limited load-bearing capacity | Medium to High |

This guide serves as a strategic resource for B2B buyers, enabling informed decisions in material selection for air hydraulic pistons, tailored to their specific operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for air hydraulic piston

What Are the Key Stages in the Manufacturing Process of Air Hydraulic Pistons?

The manufacturing of air hydraulic pistons is a multifaceted process that encompasses several stages, each critical for ensuring the final product meets quality and performance standards. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Air Hydraulic Pistons?

Material selection is fundamental in the production of air hydraulic pistons. Typically, materials such as aluminum, ductile cast iron, or high-strength alloys are chosen for their durability and resistance to wear. The process begins with the careful sourcing of raw materials, which are then subjected to rigorous quality checks to ensure they meet specified standards.

After sourcing, the materials undergo processes such as cutting and machining to prepare them for forming. This stage may involve creating precise dimensions and surface finishes that are essential for the functionality of the pistons. Advanced technologies such as CNC machining are often employed to achieve high accuracy and repeatability.

What Forming Techniques Are Used in the Production of Air Hydraulic Pistons?

Forming is a critical stage where the prepared materials are shaped into the desired configurations. Common techniques include forging, casting, and extrusion, each selected based on the specific requirements of the piston design.

- Forging: This method involves shaping the material through compressive forces, resulting in a dense and strong component. Forged pistons tend to exhibit superior mechanical properties, making them ideal for high-stress applications.

- Casting: In this technique, molten metal is poured into molds to create intricate shapes. This method is particularly useful for producing complex designs that would be challenging to achieve through forging.

- Extrusion: This process involves forcing material through a die to create long sections of uniform cross-section. It is often used for producing cylindrical components with consistent dimensions.

Each of these techniques has its advantages and is chosen based on factors such as cost, production volume, and the specific mechanical properties required for the pistons.

What Does the Assembly Process for Air Hydraulic Pistons Involve?

Once formed, the components are assembled into the final air hydraulic piston units. This stage is crucial for ensuring that all parts fit together correctly and function as intended. Assembly typically includes the installation of seals, valves, and other critical components.

Illustrative image related to air hydraulic piston

Quality assurance during assembly is paramount. Each assembly line may have designated checkpoints where workers verify the alignment and integrity of components before proceeding to the next stage. Automated assembly techniques can also be employed to enhance precision and reduce human error.

How Is Finishing Applied to Air Hydraulic Pistons?

Finishing processes are applied to enhance the performance and durability of air hydraulic pistons. These may include surface treatments such as anodizing, plating, or painting, which protect against corrosion and wear.

In addition to surface treatments, finishing may involve polishing and grinding to achieve a smooth surface finish, which is essential for reducing friction and ensuring efficient operation. Finishing processes are carefully monitored to ensure compliance with international standards.

What Quality Assurance Measures Are Essential for Air Hydraulic Pistons?

Quality assurance (QA) is an integral part of the manufacturing process for air hydraulic pistons, ensuring that the products meet industry standards and customer expectations.

Which International Standards Should Be Considered?

For air hydraulic pistons, compliance with international standards such as ISO 9001:2015 is crucial. This standard focuses on quality management systems and emphasizes continuous improvement and customer satisfaction. In addition, industry-specific certifications such as CE (European Conformity) and API (American Petroleum Institute) may also be relevant depending on the application.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are established throughout the manufacturing process to maintain high standards. Key checkpoints include:

- Incoming Quality Control (IQC): This step involves the inspection of raw materials upon arrival to ensure they meet specified requirements.

- In-Process Quality Control (IPQC): During manufacturing, various parameters are monitored to detect any deviations from quality standards. This may include checking dimensions, surface finishes, and assembly tolerances.

- Final Quality Control (FQC): Before shipment, the finished pistons undergo a comprehensive inspection to verify that they meet all specifications and performance criteria.

What Testing Methods Are Commonly Used for Air Hydraulic Pistons?

Testing methods for air hydraulic pistons are essential for verifying performance and durability. Common testing methods include:

- Hydraulic Testing: This involves subjecting the piston to high-pressure conditions to ensure it can withstand operational demands without failure.

- Leak Testing: Ensuring that seals and joints are airtight is crucial, as leaks can compromise the performance of hydraulic systems.

- Performance Testing: This assesses the piston’s response under operational conditions, including speed, force output, and cycle times.

How Can B2B Buyers Verify Supplier Quality Assurance?

For international B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality assurance is vital to mitigate risks associated with purchasing air hydraulic pistons.

What Steps Can Be Taken to Verify Supplier QC?

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide insights into their manufacturing processes, quality control measures, and compliance with international standards.

-

Requesting Quality Reports: Buyers should ask for quality assurance reports that outline the testing methods used, results, and certifications achieved. This documentation can serve as evidence of the supplier’s commitment to quality.

-

Engaging Third-Party Inspection Services: Utilizing third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control processes and product performance.

What Are the Unique Quality Control Considerations for International Buyers?

International buyers must also consider the nuances of quality control that may vary by region. Understanding local regulations, certification requirements, and cultural attitudes toward quality can play a significant role in the procurement process. For instance, European buyers may prioritize CE certification, while buyers in the Middle East might emphasize compliance with API standards.

By understanding the manufacturing processes and quality assurance measures associated with air hydraulic pistons, B2B buyers can make informed purchasing decisions that align with their operational requirements and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘air hydraulic piston’

Introduction

Sourcing an air hydraulic piston can be a complex process, especially for B2B buyers looking for reliable, efficient, and cost-effective solutions. This step-by-step checklist is designed to guide you through the critical phases of procurement, ensuring that you select the right product and supplier for your business needs.

1. Define Your Technical Specifications

Understanding the technical requirements for your air hydraulic piston is the foundation of effective sourcing. Clearly outline the necessary specifications, such as:

– Pressure Ratings: Determine the maximum pressure your application will require.

– Dimensions: Specify the bore size and stroke length based on your operational needs.

– Material Requirements: Choose materials that suit your environment and application, such as aluminum or ductile cast iron.

2. Research the Market

Conduct thorough market research to identify potential suppliers. Look for companies that specialize in air hydraulic systems and have a solid reputation. Pay attention to:

– Product Range: Ensure they offer a variety of models and sizes to meet your needs.

– Technological Innovations: Seek suppliers that incorporate modern technology for improved efficiency and reliability.

3. Evaluate Potential Suppliers

Before making a commitment, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. Consider:

– Certifications: Verify that suppliers have relevant industry certifications (e.g., ISO 9001) to ensure quality standards.

– Customer Reviews: Look for testimonials or reviews that provide insights into their reliability and service.

Illustrative image related to air hydraulic piston

4. Assess After-Sales Support

After-sales support can significantly impact your operational efficiency. Inquire about the level of support offered, including:

– Warranty Terms: Understand the warranty coverage for the pistons and the terms of service.

– Maintenance Services: Check if they provide maintenance or repair services and the availability of spare parts.

5. Request Samples or Prototypes

Whenever possible, request samples or prototypes of the air hydraulic pistons you are considering. This allows you to:

– Test Performance: Evaluate the pistons under actual working conditions to ensure they meet your requirements.

– Quality Check: Assess the build quality and materials used, giving you confidence in your purchase.

6. Negotiate Terms and Pricing

Once you have identified a suitable supplier, engage in negotiations to secure favorable terms. Consider:

– Volume Discounts: Discuss pricing structures for bulk purchases to reduce costs.

– Payment Terms: Clarify payment terms to ensure they align with your financial processes.

7. Finalize Your Order

After completing the previous steps, finalize your order with the selected supplier. Ensure that you:

– Review Contracts: Carefully read through all contracts and agreements to avoid any hidden fees or obligations.

– Confirm Delivery Timelines: Establish clear delivery timelines to align with your project schedules.

By following this checklist, B2B buyers can streamline their sourcing process, ensuring they procure air hydraulic pistons that meet their technical needs and provide reliable performance in their applications.

Illustrative image related to air hydraulic piston

Comprehensive Cost and Pricing Analysis for air hydraulic piston Sourcing

What Are the Key Cost Components for Sourcing Air Hydraulic Pistons?

When sourcing air hydraulic pistons, understanding the cost structure is critical for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly influences the price. Common materials such as aluminum and ductile cast iron offer a balance between strength and weight, impacting both performance and cost. High-quality seals and hydraulic components also add to the material costs.

-

Labor: Labor costs vary based on the region and the complexity of the manufacturing process. Skilled labor is essential for precision machining and assembly, which can increase costs but ensures higher quality and reliability.

-

Manufacturing Overhead: This encompasses indirect costs associated with production, including utilities, rent, and equipment maintenance. Efficient manufacturing processes can help minimize overhead costs.

-

Tooling: Specialized tooling for the production of air hydraulic pistons can represent a significant upfront investment. Custom tooling is often required for specific piston designs or applications, which can increase costs but is necessary for achieving precision.

-

Quality Control (QC): Implementing robust QC measures ensures product reliability and compliance with international standards. The costs associated with testing and certification can vary widely, but they are essential for maintaining quality, especially for international markets.

-

Logistics: Shipping costs can be a substantial part of the total price, particularly for international buyers. Factors such as distance, shipping method, and import tariffs must be considered.

-

Margin: Suppliers will typically add a margin to cover their costs and profit. Understanding typical margins in the industry can help buyers gauge fair pricing.

What Influences the Pricing of Air Hydraulic Pistons?

Several factors can influence the pricing of air hydraulic pistons:

-

Volume/MOQ: Larger orders often lead to reduced unit costs due to economies of scale. Understanding the minimum order quantities (MOQ) can help negotiate better pricing.

-

Specifications and Customization: Customized pistons with specific dimensions or features can increase costs. Buyers should clearly define their specifications to avoid unexpected expenses.

-

Materials and Quality Certifications: Higher-quality materials and certifications (like ISO 9001) often come at a premium. Buyers should weigh the benefits of quality against cost to determine their needs.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more for their experience and quality assurance.

-

Incoterms: The choice of Incoterms affects shipping costs and risks. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can help buyers manage overall expenses.

What Tips Can Help Buyers Negotiate Better Prices?

-

Effective Negotiation: Engage suppliers in open discussions about pricing. Understanding the supplier’s cost structure can help in negotiating better terms and conditions.

-

Focus on Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes purchase price, maintenance, and operational costs. A cheaper piston may not always be the most cost-effective in the long run.

-

Explore Multiple Suppliers: Don’t limit yourself to a single supplier. Obtaining quotes from multiple sources can provide leverage in negotiations and reveal market pricing trends.

-

Understand Pricing Nuances for International Markets: Different regions may have varying pricing strategies influenced by local market conditions, tariffs, and logistics costs. Buyers from Africa, South America, the Middle East, and Europe should consider these factors when sourcing.

-

Stay Informed on Market Trends: Keeping abreast of industry trends, material costs, and technological advancements can provide insights that enhance negotiation strategies.

Disclaimer on Pricing

Prices for air hydraulic pistons can vary significantly based on numerous factors, including market conditions and specific supplier circumstances. This analysis aims to provide indicative pricing insights, and buyers are encouraged to conduct thorough research and obtain direct quotes to ensure accurate budgeting for their specific requirements.

Alternatives Analysis: Comparing air hydraulic piston With Other Solutions

Understanding Alternatives to Air Hydraulic Pistons

In the realm of industrial applications, selecting the right actuation technology is crucial for operational efficiency and cost-effectiveness. Air hydraulic pistons are widely recognized for their ability to combine the rapid approach of pneumatic systems with the high force output of hydraulic systems. However, several alternatives may also suit specific applications, each with its own advantages and disadvantages. This section delves into a comparison of air hydraulic pistons against two viable alternatives: traditional pneumatic cylinders and hydro-pneumatic cylinders.

Comparison Table

| Comparison Aspect | Air Hydraulic Piston | Traditional Pneumatic Cylinder | Hydro-Pneumatic Cylinder |

|---|---|---|---|

| Performance | High force output, moderate speed | Fast actuation, lower force | Fast and powerful, combines both |

| Cost | Moderate to high initial investment | Generally lower cost | Moderate, potentially higher ROI |

| Ease of Implementation | Requires hydraulic systems | Easier to install and operate | Slightly complex due to dual systems |

| Maintenance | Moderate maintenance needs | Low maintenance, few moving parts | Moderate, requires attention to both systems |

| Best Use Case | Heavy-duty applications needing high force | Light to medium-duty tasks | Versatile applications requiring speed and force |

Detailed Breakdown of Alternatives

Traditional Pneumatic Cylinders: What Are Their Strengths and Weaknesses?

Traditional pneumatic cylinders utilize compressed air for actuation, making them ideal for applications that require rapid movement. Their primary advantages include lower costs and simpler installation processes, which can significantly reduce upfront expenses. However, they deliver lower force output compared to air hydraulic pistons, making them less suitable for heavy-duty tasks. Additionally, the energy consumption can be higher during continuous operations, which may impact overall efficiency.

Illustrative image related to air hydraulic piston

Hydro-Pneumatic Cylinders: How Do They Compare?

Hydro-pneumatic cylinders combine pneumatic and hydraulic systems in a single unit, offering the speed of pneumatic actuation along with the force capabilities of hydraulic systems. This dual functionality allows for efficient operation in applications that demand both rapid movement and significant force. They are particularly advantageous in assembly or pressing operations. However, their complexity can lead to higher initial costs and maintenance requirements, as both pneumatic and hydraulic components must be managed effectively.

Conclusion: Choosing the Right Solution for Your Needs

For B2B buyers evaluating actuation solutions, the choice between air hydraulic pistons and their alternatives hinges on specific operational requirements. If your application demands high force and can accommodate the complexity of hydraulic systems, air hydraulic pistons may be the best fit. Conversely, for applications prioritizing speed and simplicity, traditional pneumatic cylinders could be more suitable. Hydro-pneumatic cylinders serve as an excellent middle ground for tasks requiring both speed and strength. Ultimately, a thorough assessment of operational needs, budget constraints, and maintenance capabilities will guide buyers in selecting the most appropriate solution for their unique circumstances.

Essential Technical Properties and Trade Terminology for air hydraulic piston

What Are the Key Technical Properties of Air Hydraulic Pistons?

Air hydraulic pistons are essential components in various industrial applications, combining the advantages of pneumatic and hydraulic systems. Understanding their technical specifications can help businesses make informed purchasing decisions.

1. Material Grade

Air hydraulic pistons are typically manufactured from materials like aluminum, ductile cast iron, or high-strength steel. The choice of material impacts the piston’s durability, weight, and resistance to corrosion. For example, aluminum is lightweight and resistant to rust, making it ideal for applications requiring mobility, while ductile cast iron offers strength and longevity under heavy loads. Selecting the right material grade is crucial for ensuring the piston meets the operational demands of specific applications.

2. Bore Size

The bore size refers to the internal diameter of the piston cylinder, directly influencing the force output and efficiency. A larger bore allows for greater force generation, which is essential in applications like pressing and lifting. However, it also requires more air and hydraulic fluid to operate, which can lead to increased operational costs. B2B buyers should consider the balance between required force and cost-efficiency when selecting bore sizes for their operations.

3. Stroke Length

Stroke length is the maximum distance the piston can travel within the cylinder. It is a critical specification that determines the range of motion and the types of applications the piston can handle. For example, a longer stroke length is beneficial in applications like assembly lines where significant movement is needed. Businesses should assess the operational requirements to choose an appropriate stroke length that maximizes productivity without unnecessary complexity.

4. Pressure Rating

The pressure rating indicates the maximum pressure the piston can safely operate under, typically measured in bar or psi. This specification is vital for ensuring that the piston can handle the operational conditions of a given application without risk of failure. A piston with a higher pressure rating may be necessary for heavy-duty applications, while lower ratings might suffice for lighter tasks. Understanding the pressure requirements will help B2B buyers avoid equipment failures and ensure operational safety.

5. Tolerance

Tolerance refers to the permissible limit of variation in the piston dimensions and is crucial for ensuring proper fit and function within the hydraulic system. Tight tolerances can improve performance and reduce wear but may increase manufacturing costs. Businesses should evaluate the importance of precision in their applications to determine the appropriate tolerance levels required for their pistons.

What Are Common Trade Terms Related to Air Hydraulic Pistons?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B environment. Here are some common terms related to air hydraulic pistons:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are marketed by another company under its brand. In the context of air hydraulic pistons, working with OEMs can ensure that components are designed for specific applications, enhancing reliability and compatibility. Businesses often seek OEM partnerships to ensure high-quality standards and reduce the risk of integration issues.

Illustrative image related to air hydraulic piston

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is critical for B2B buyers as it can affect inventory management and operational costs. Buyers must assess their demand to negotiate favorable MOQs that align with their production needs without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers requesting a price quote for specific products. It typically includes details about quantities, specifications, and delivery timelines. Utilizing RFQs can streamline the procurement process, allowing businesses to compare offers and choose the best supplier based on cost and capability.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international trade to clarify the responsibilities of buyers and sellers. They define aspects like shipping responsibilities, risk transfer, and cost allocation. Understanding Incoterms is essential for B2B buyers engaged in international procurement, as they help avoid misunderstandings and ensure smooth transactions.

5. Lead Time

Lead time is the amount of time it takes from placing an order to receiving the product. It is crucial for production planning and inventory management. B2B buyers should be aware of lead times to ensure that they maintain adequate stock levels and meet production schedules without delays.

By understanding these technical properties and trade terms, businesses can enhance their decision-making processes, ensuring they select the right air hydraulic pistons for their needs while navigating the complexities of international procurement.

Navigating Market Dynamics and Sourcing Trends in the air hydraulic piston Sector

Market Overview & Key Trends: What Drives the Air Hydraulic Piston Market?

The air hydraulic piston market is experiencing significant growth, driven by the increasing demand for efficient and versatile power solutions across various industries, including manufacturing, automotive, and construction. The integration of pneumatic and hydraulic technologies allows for faster operation cycles and reduced energy consumption, making these systems particularly appealing for businesses looking to enhance productivity and minimize operational costs.

Key trends influencing the market include the rise of automation and smart manufacturing technologies, which necessitate advanced actuation systems like air hydraulic pistons. International buyers, especially from Africa, South America, the Middle East, and Europe, are increasingly prioritizing suppliers that offer innovative solutions, such as hydro-pneumatic cylinders that provide high force and speed while reducing the need for extensive hydraulic setups. Furthermore, the emphasis on Industry 4.0 is prompting businesses to seek out components that can easily integrate with IoT systems, enhancing monitoring and maintenance capabilities.

Emerging sourcing trends reveal a growing preference for suppliers who can offer custom solutions tailored to specific operational needs, as well as those who maintain robust supply chains that can withstand global disruptions. As geopolitical shifts and economic fluctuations impact trade, international buyers are advised to establish relationships with multiple suppliers to mitigate risks and ensure consistent quality and availability of air hydraulic pistons.

Illustrative image related to air hydraulic piston

How Does Sustainability and Ethical Sourcing Impact the Air Hydraulic Piston Sector?

Sustainability has become a crucial consideration for B2B buyers in the air hydraulic piston market. The environmental impact of manufacturing processes, including energy consumption and waste generation, is under increasing scrutiny. Buyers are now more inclined to partner with manufacturers who demonstrate a commitment to sustainable practices, such as using recycled materials and employing energy-efficient production techniques.

Ethical sourcing is equally important, as businesses aim to ensure that their supply chains are not only environmentally responsible but also socially conscious. This includes adhering to fair labor practices and ensuring transparency throughout the supply chain. Certifications like ISO 14001 for environmental management and the use of green materials are becoming essential factors in supplier selection.

Moreover, as regulatory frameworks around environmental protection tighten globally, suppliers who can provide products with verified sustainability credentials are likely to gain a competitive edge. This shift not only aligns with corporate social responsibility goals but also appeals to environmentally conscious consumers, further driving demand for sustainably sourced air hydraulic pistons.

What is the Evolution of Air Hydraulic Pistons and Their Role in Modern Industry?

The evolution of air hydraulic pistons reflects broader advancements in pneumatic and hydraulic technologies. Initially, pneumatic cylinders were favored for their speed, while hydraulic cylinders were preferred for their force capabilities. The introduction of air hydraulic pistons, which combine the benefits of both systems, marked a significant turning point in industrial applications.

These hybrid systems emerged to meet the growing demand for efficiency and performance in various sectors. By utilizing compressed air for rapid movement and hydraulic fluid for high-force applications, air hydraulic pistons offer a versatile solution that can adapt to a range of operational needs. This innovation has led to their widespread adoption across industries, including automotive manufacturing, metal forming, and packaging, where speed and precision are critical.

Today, the ongoing development of smart technologies continues to shape the future of air hydraulic pistons, enabling features such as real-time monitoring and predictive maintenance. As industries strive for greater efficiency and sustainability, the role of these advanced actuators is set to expand, making them an integral part of modern manufacturing processes.

Frequently Asked Questions (FAQs) for B2B Buyers of air hydraulic piston

-

1. How do I choose the right air hydraulic piston for my application?

Selecting the appropriate air hydraulic piston involves understanding your specific application requirements, including load capacity, speed, and stroke length. Assess the force requirements and the type of operation—whether it’s continuous or intermittent. Consider the environmental conditions, such as temperature and humidity, that may affect performance. Additionally, review the manufacturer’s specifications, including materials used and compatibility with existing systems, to ensure optimal functionality and longevity. -

2. What are the advantages of using air hydraulic pistons over traditional hydraulic cylinders?

Air hydraulic pistons combine the speed of pneumatic systems with the force of hydraulic systems, providing efficient operation for various applications. They eliminate the need for separate hydraulic power units, reducing costs and space requirements. Their design allows for rapid approach speeds and high pressing forces, making them versatile for tasks like assembly, pressing, and bending. Moreover, their energy consumption is limited to the pressing phase, leading to lower operational costs. -

3. What is the typical lead time for sourcing air hydraulic pistons internationally?

Lead times for sourcing air hydraulic pistons can vary based on the supplier’s location, production capacity, and shipping methods. Typically, expect a lead time of 4 to 12 weeks for international orders. Factors such as customization requests, order quantities, and potential delays in customs clearance can also impact delivery times. It’s advisable to communicate directly with suppliers to get accurate timelines and plan accordingly for your project needs. -

4. How can I vet suppliers for air hydraulic pistons to ensure quality?

To vet suppliers effectively, start by checking their certifications, such as ISO 9001, which indicates adherence to quality management standards. Review their product quality through customer testimonials and case studies. Request samples to evaluate the pistons’ performance and durability. Additionally, inquire about their production processes, quality assurance measures, and after-sales support to ensure they meet your operational standards. -

5. Are customization options available for air hydraulic pistons?

Yes, many manufacturers offer customization options for air hydraulic pistons, including variations in size, stroke length, and mounting configurations to fit specific applications. Customization can also extend to materials used, seal types, and performance specifications. It’s crucial to discuss your requirements with potential suppliers early in the sourcing process to ensure they can accommodate your needs and to understand any associated costs and lead times. -

6. What is the minimum order quantity (MOQ) for air hydraulic pistons?

Minimum order quantities for air hydraulic pistons can vary significantly between suppliers and depend on factors such as the complexity of the product and the level of customization. Generally, MOQs can range from a few units for standard products to several hundred for customized solutions. It’s advisable to clarify these details upfront to avoid any misunderstandings and to assess if the supplier aligns with your purchasing strategy. -

7. What payment terms should I expect when sourcing air hydraulic pistons?

Payment terms for air hydraulic pistons typically vary based on supplier policies and your relationship with them. Common terms include upfront payments, partial payments during production, or payment upon delivery. Some suppliers may also offer credit terms for established customers. Ensure to negotiate favorable terms that align with your cash flow and project timelines, and consider using secure payment methods to mitigate risks. -

8. How do I handle logistics and shipping for air hydraulic pistons?

When managing logistics for air hydraulic pistons, coordinate with your supplier to determine the best shipping method based on urgency and cost. Consider using freight forwarders experienced in handling industrial equipment, as they can assist with customs clearance and documentation. Be mindful of import regulations in your country, and factor in shipping insurance to protect against potential damages during transit. Tracking shipments can help you stay informed about delivery timelines.

Top 7 Air Hydraulic Piston Manufacturers & Suppliers List

1. Hydraulic Supply – Pneumatic Cylinders & Actuators

Domain: hydraulic-supply.com

Registered: 1997 (28 years)

Introduction: Explore our extensive range of pneumatic cylinders and actuators, designed for reliability and efficiency across various applications.

2. CRC – Hydraulic & Pneumatic Pistons

Domain: crconline.com

Registered: 2000 (25 years)

Introduction: Hydraulic Pistons & Pneumatic Pistons; Materials: Aluminum, Ductile Cast Iron; Categories: Accessories, Braided Packing, Cylinder Components, Cylinder Repair, Bench Products, Kraken Marine Bearings, Round Bar Seals, Seal Kits, Tube.

3. McMaster – Air Cylinders

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Air Cylinders, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Festo – Compressed Air Hydraulic Cylinder

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Compressed Air Hydraulic & Pneumatic Cylinders available on eBay include various types such as Single-Rod Cylinder, Compact Cylinder, Tie-Rod Cylinder, Double-Rod Cylinder, Welded Cylinder, and Rotary Cylinder. Popular brands featured are Enerpac, Parker, and Festo. Notable listings include: Festo DSBC-40-250-PPVA-N3 ISO cylinder for $54.15, Parker 1.50DPSR05.00 Round Air Cylinder for $24.99, and …

5. Festo – Pneumatic Cylinders

Domain: festo.com

Registered: 1997 (28 years)

Introduction: Pneumatic cylinders are components that perform movement using compressed air, also known as compressed air cylinders. They are cost-effective solutions for various applications, characterized by simple commissioning and speeds between 10 mm/s and 3 m/s. Pneumatic cylinders are classified into single-acting and double-acting types. Single-acting cylinders generate movement in one direction using c…

6. Industrial Tool Supply – EPC Series Air/Hydraulic Pumps

Domain: industrialtoolsupply.com

Registered: 2001 (24 years)

Introduction: EPC Series – AIR/HYDRAULIC PUMPS – Single Acting Product Number: EPC-001, Regular price: $683.57; EPC Series – AIR/HYDRAULIC PUMPS – Double Acting – PLAST RES 140 IN3 – Product Number: EPC-001S, Regular price: $1,348.91. Types of hydraulic cylinders and jacks include: Pancake style, Single Acting Hydraulic Cylinder, Double Acting Hydraulic Cylinder, Air Hydraulic Pumps, Electric & Gas Powered Hydr…

7. PHD – Key Cylinders

Domain: phdinc.com

Registered: 1995 (30 years)

Introduction: PHD offers a range of cylinders including Pneumatic, Hydraulic, and Electric types for various applications such as automated manufacturing, packaging, and assembly. Key product series include: 1. Series CRS: Compact pneumatic cylinder with self-lubricating nitrile piston seal. 2. Series ECFA: Electric ball screw cylinder designed for precision and reliability. 3. Series CTS: Guided pneumatic comp…

Strategic Sourcing Conclusion and Outlook for air hydraulic piston

What Are the Key Takeaways for Strategic Sourcing of Air Hydraulic Pistons?

In the evolving landscape of industrial automation, air hydraulic pistons present a compelling solution that marries the speed of pneumatic systems with the strength of hydraulic technology. For international B2B buyers, particularly those operating in Africa, South America, the Middle East, and Europe, understanding the nuances of these systems is essential for optimizing operational efficiency. The strategic sourcing of air hydraulic pistons not only enhances productivity but also contributes to significant cost savings through reduced energy consumption and improved cycle times.

How Can You Benefit from Effective Sourcing Strategies?

Investing in high-quality air hydraulic pistons can lead to increased reliability and longevity of your equipment, reducing maintenance costs in the long run. By partnering with reputable suppliers who offer tailored solutions, businesses can ensure they are equipped to handle diverse applications—from assembly and pressing to cutting and compressing.

What Should Be Your Next Steps?

As you consider your options for air hydraulic pistons, prioritize suppliers who demonstrate a commitment to quality and innovation. Engage in discussions with manufacturers that understand your specific needs and can provide customized solutions. By adopting a forward-thinking approach to sourcing, your business can leverage the advantages of air hydraulic technology to stay competitive in a rapidly changing market. Explore your sourcing options today and position your organization for future growth.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.