Air Dreyer Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for air dreyer

In today’s competitive global market, sourcing reliable air dryers can pose significant challenges for B2B buyers, especially those operating in diverse regions like Africa, South America, the Middle East, and Europe. The need for efficient air drying solutions is paramount, as improper moisture management can lead to costly operational inefficiencies and equipment damage. This guide aims to provide an in-depth exploration of the air dryer market, addressing various types, their applications across different industries, and best practices for supplier vetting.

As you navigate this comprehensive resource, you’ll discover detailed insights into the various air dryer technologies, including refrigerated, desiccant, and membrane systems, tailored to meet specific business needs. The guide also covers critical factors such as cost considerations, energy efficiency, and maintenance requirements, ensuring that you make informed purchasing decisions.

By leveraging this guide, international buyers from regions like Nigeria and Saudi Arabia will gain the confidence needed to evaluate options effectively and select the right air dryer for their operations. With a focus on actionable insights and strategic sourcing, this resource empowers you to streamline your procurement process and enhance operational efficiency, positioning your business for success in a rapidly evolving marketplace.

Understanding air dreyer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Refrigerated Air Dryer | Uses refrigeration to cool air and condense moisture | Manufacturing, automotive, food processing | Pros: Efficient moisture removal; compact size. Cons: Can be energy-intensive; limited to moderate temperatures. |

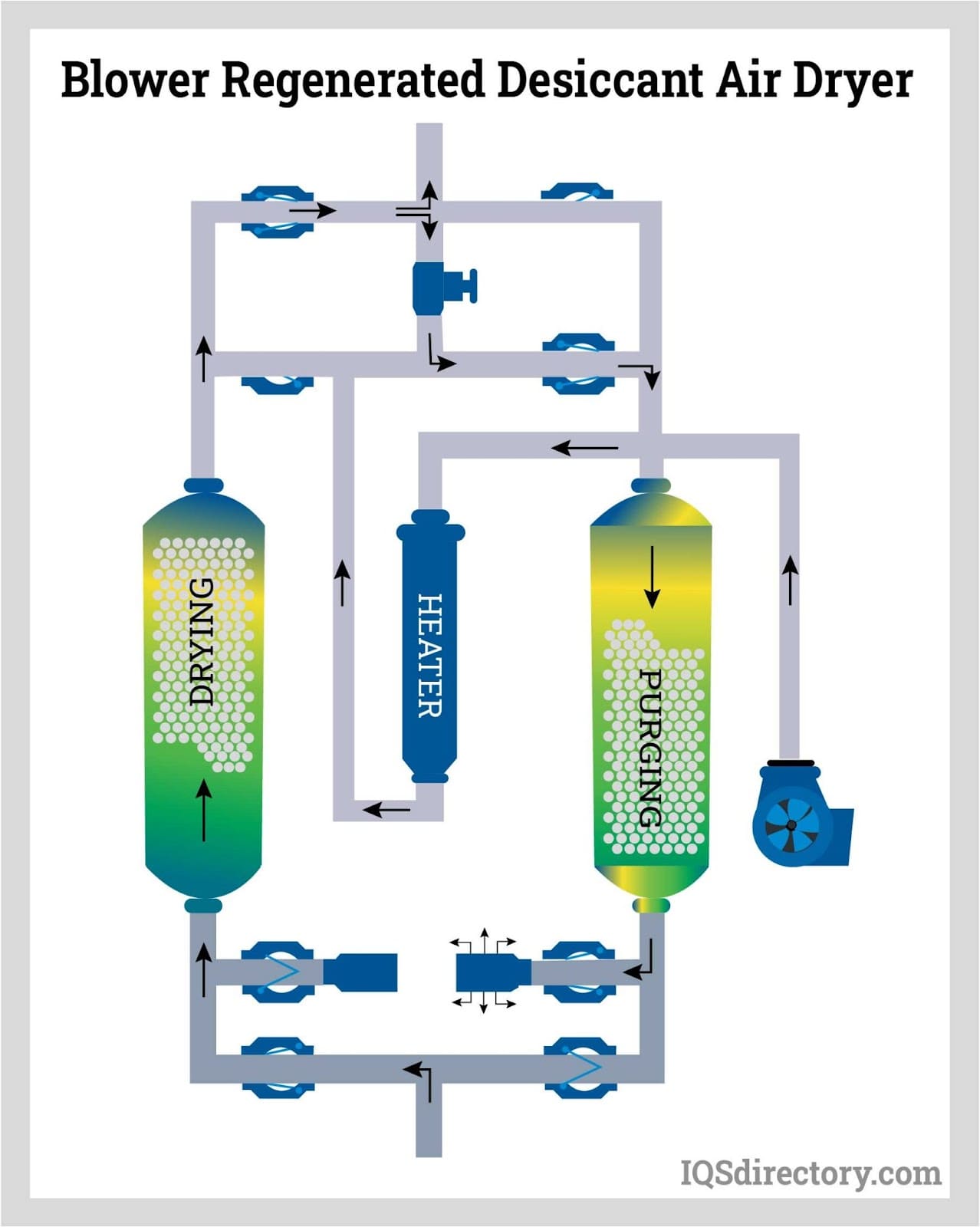

| Desiccant Air Dryer | Utilizes desiccant materials to absorb moisture | Pharmaceuticals, electronics, aerospace | Pros: Excellent for low dew points; reusable desiccants. Cons: Higher initial costs; requires regular maintenance. |

| Membrane Air Dryer | Employs membrane technology to separate moisture | Oil and gas, pneumatic tools, packaging | Pros: Compact and low maintenance; energy-efficient. Cons: Limited moisture removal capacity; sensitive to pressure variations. |

| High-Temperature Air Dryer | Designed to handle high-temperature applications | Metalworking, chemical processing | Pros: Operates effectively in extreme conditions; durable materials. Cons: Higher costs; may require specialized installation. |

| Cycling Refrigerated Air Dryer | Cycles on and off to save energy during low demand | Automotive, textile, and food industries | Pros: Energy-efficient; adaptable to varying loads. Cons: More complex design; potential for higher maintenance needs. |

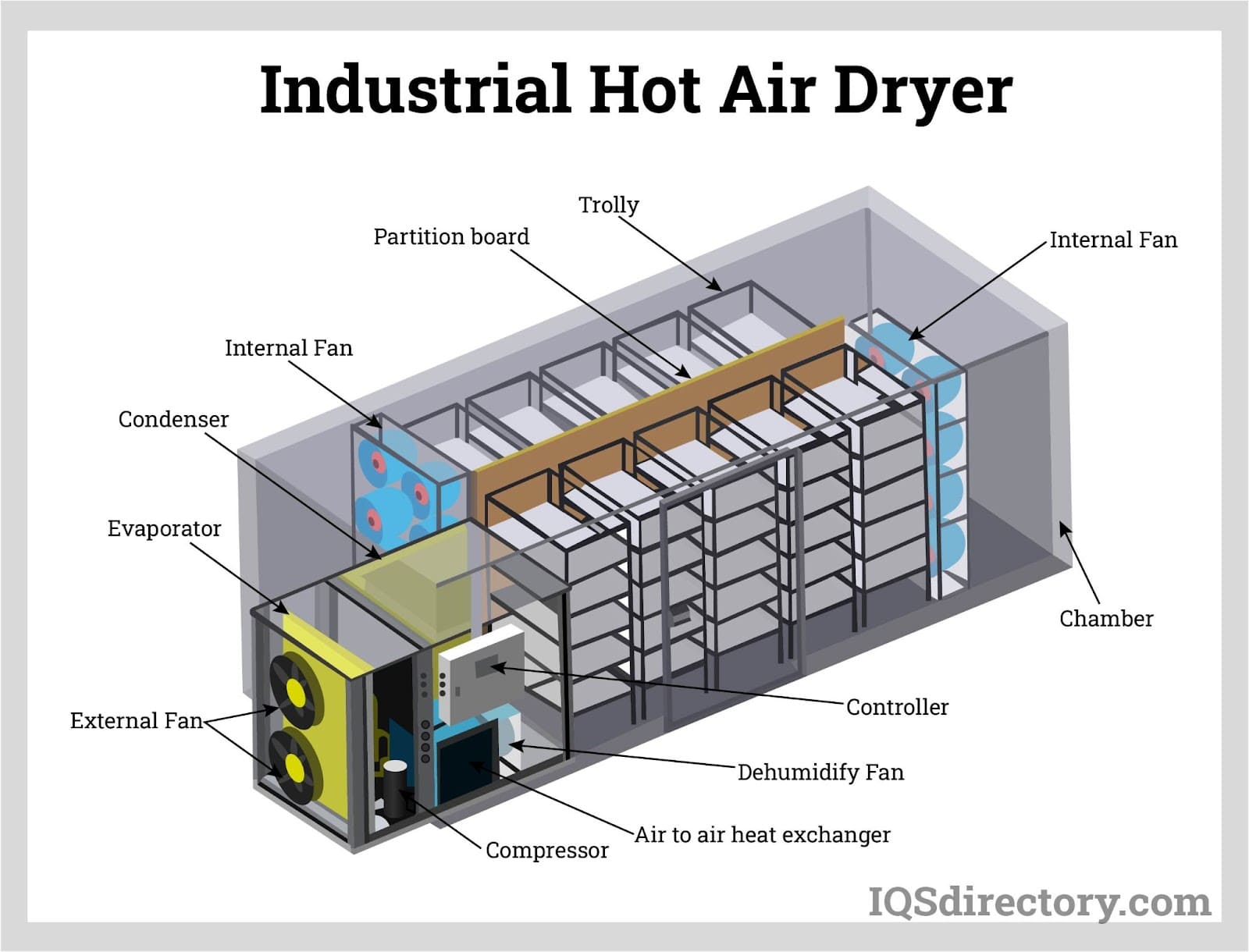

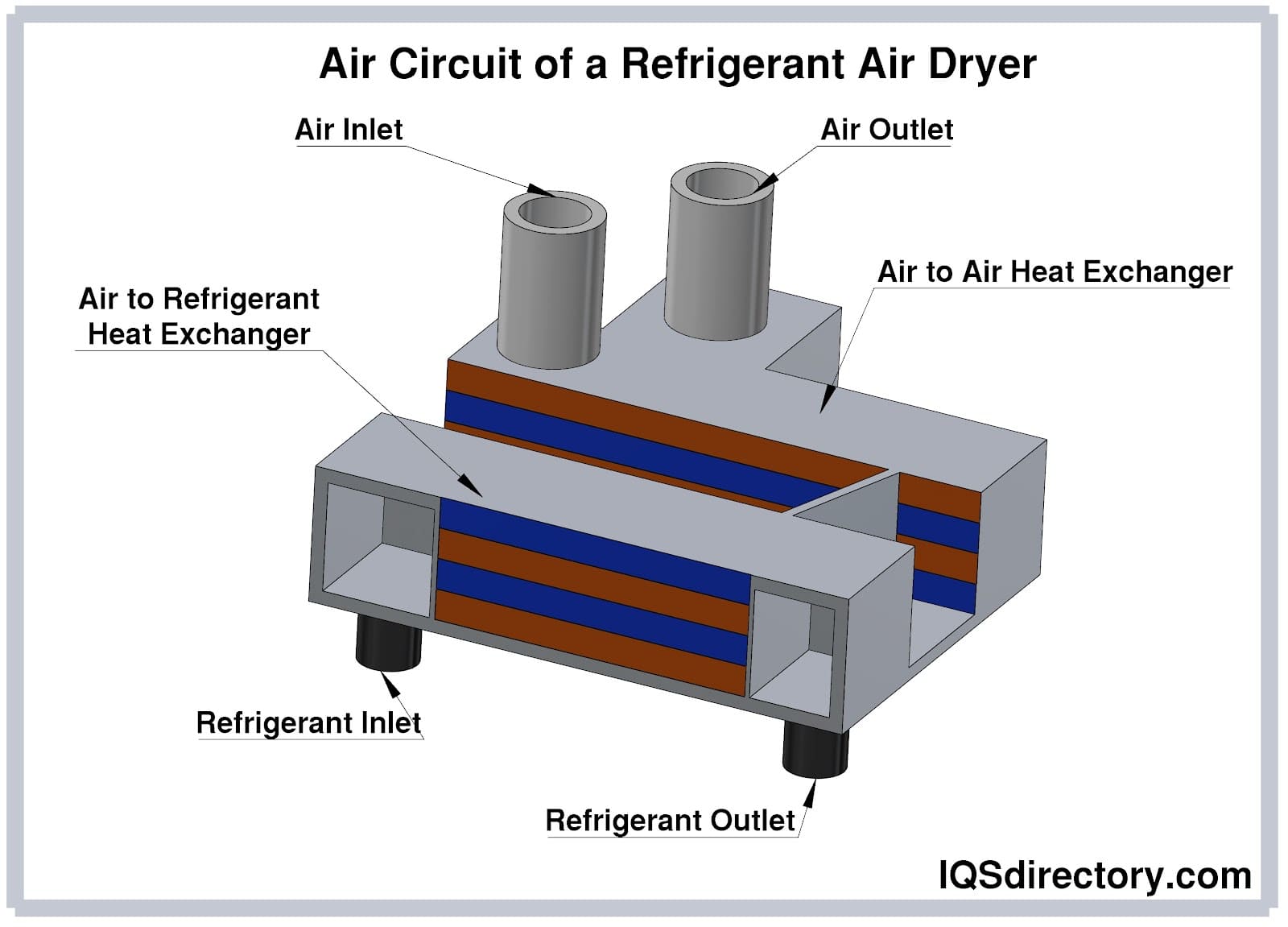

What Are the Key Characteristics of Refrigerated Air Dryers?

Refrigerated air dryers are widely used in various industries due to their ability to effectively remove moisture from compressed air. They work by cooling the air, which condenses moisture that is then removed from the system. These dryers are suitable for applications that require moderate dew points and are commonly found in manufacturing and automotive sectors. When considering a refrigerated air dryer, buyers should evaluate energy efficiency and operational costs, as some models can be energy-intensive.

Illustrative image related to air dreyer

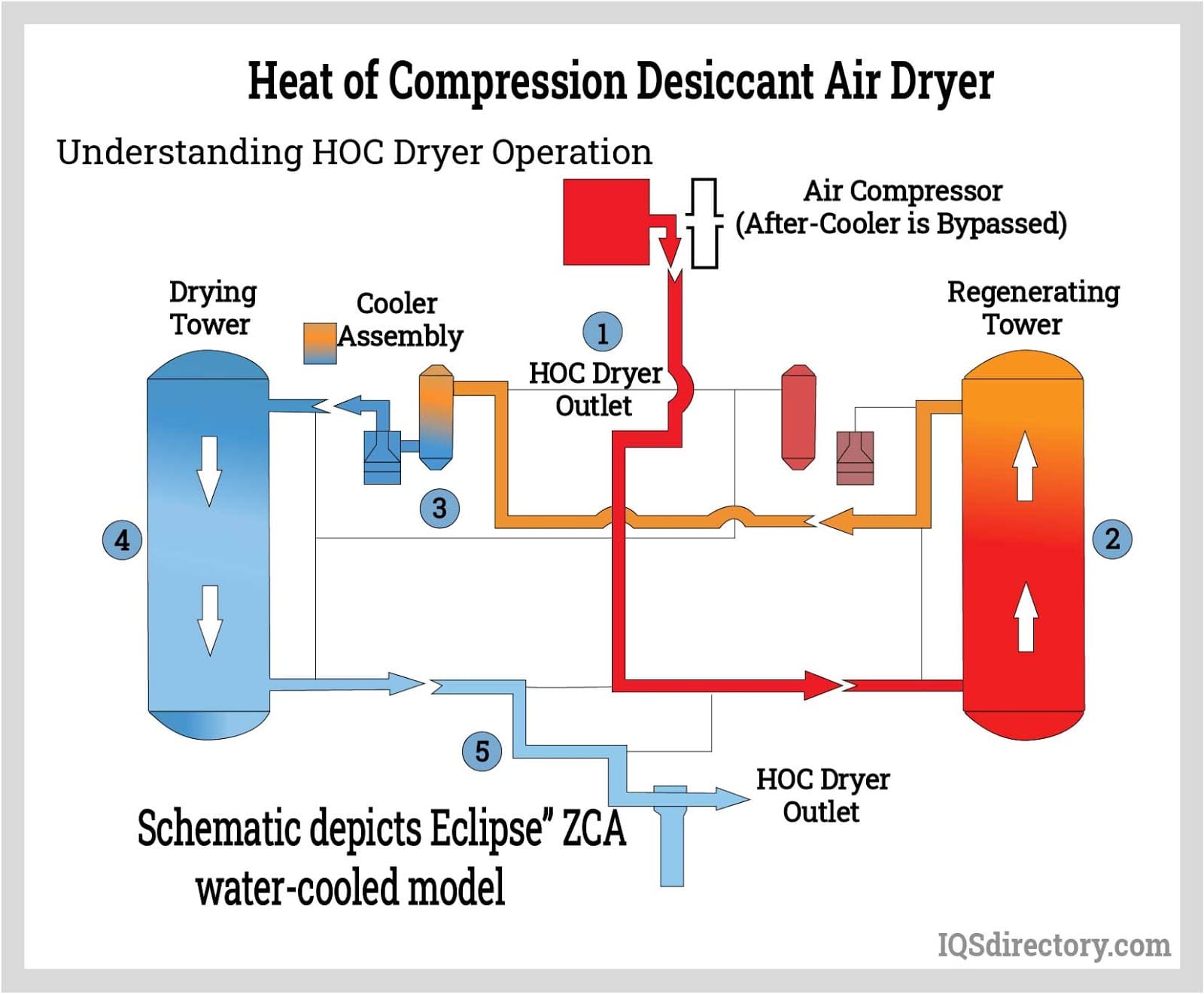

Why Choose Desiccant Air Dryers for Your Business?

Desiccant air dryers are characterized by their use of hygroscopic materials to absorb moisture from compressed air. This type is ideal for applications requiring very low dew points, such as in pharmaceuticals and electronics manufacturing. While the initial investment may be higher, the long-term benefits include reduced maintenance and the ability to regenerate desiccants. B2B buyers should consider the specific moisture removal needs of their processes when selecting this type of dryer.

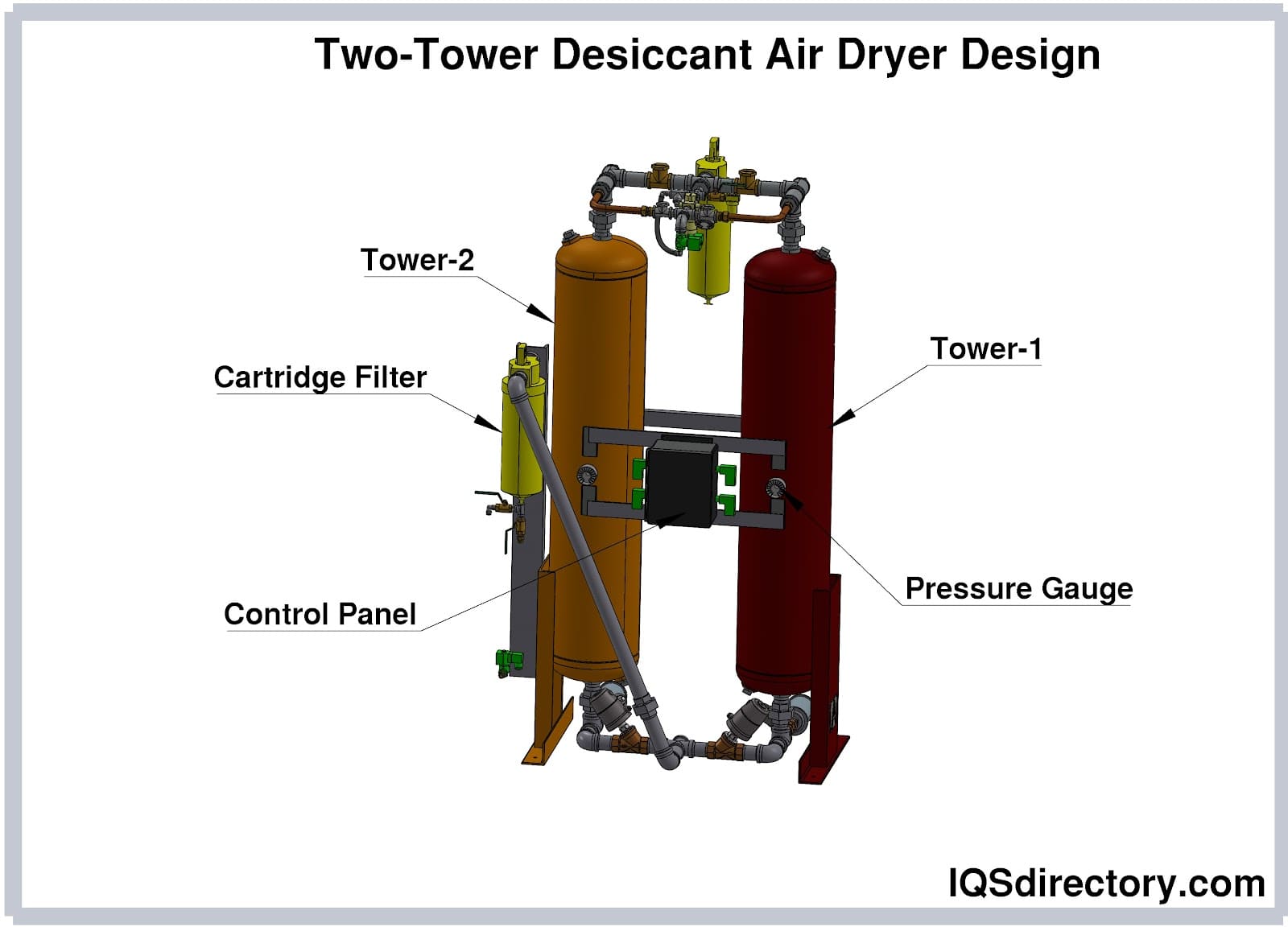

How Do Membrane Air Dryers Work?

Membrane air dryers operate using semi-permeable membranes that allow moisture to pass through while retaining dry air. These dryers are compact and require minimal maintenance, making them suitable for industries like oil and gas and packaging. However, their moisture removal capacity is limited compared to other types. Buyers should assess the pressure conditions of their applications, as membrane dryers can be sensitive to fluctuations.

What Are the Benefits of High-Temperature Air Dryers?

High-temperature air dryers are engineered to handle extreme conditions, making them suitable for metalworking and chemical processing environments. They maintain efficiency even at elevated temperatures, which can be critical for certain industrial processes. While they offer durability and reliability, the initial investment may be higher. B2B buyers should consider the specific temperature ranges of their operations when evaluating these dryers.

What Makes Cycling Refrigerated Air Dryers Energy Efficient?

Cycling refrigerated air dryers feature a design that allows them to operate in cycles, conserving energy during periods of low demand. This adaptability makes them well-suited for industries such as automotive and textiles, where air demand can fluctuate. While they offer significant energy savings, the complexity of their design may lead to higher maintenance requirements. Businesses should weigh these factors against their operational needs when selecting this dryer type.

Key Industrial Applications of air dreyer

| Industry/Sector | Specific Application of Air Dryer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Compressed Air Systems for Tool Operation | Enhances equipment longevity and reduces downtime | Ensure compatibility with existing systems and pressure requirements. |

| Food and Beverage | Packaging and Processing Equipment | Maintains product quality and safety | Consider regulations for food safety and moisture control. |

| Pharmaceuticals | Cleanroom Environments | Ensures compliance with stringent cleanliness standards | Look for dryers with specific certifications for pharmaceutical use. |

| Automotive | Paint Booth Applications | Improves paint adhesion and finish quality | Evaluate drying capacity and efficiency under varying temperatures. |

| Textile | Air Drying of Fabrics | Reduces drying time and energy consumption | Assess energy efficiency ratings and maintenance needs. |

How Is Air Dryer Used in Manufacturing Applications?

In the manufacturing sector, air dryers are crucial for maintaining compressed air systems that power pneumatic tools and machinery. By removing moisture from the compressed air, these dryers prevent corrosion and wear, which can lead to costly downtime and repairs. International buyers, especially from regions like Africa and South America, should consider the compatibility of air dryers with their existing systems and the pressure requirements to ensure optimal performance and reliability.

What Role Does Air Dryer Play in Food and Beverage Processing?

Air dryers are essential in the food and beverage industry, where they are used to maintain the integrity of packaging and processing equipment. Moisture can lead to spoilage and contamination, so effective moisture control is vital. Buyers in this sector, particularly in the Middle East and Europe, must ensure that the air dryers comply with food safety regulations and can operate efficiently under varying humidity levels, thereby safeguarding product quality.

How Are Air Dryers Critical in Pharmaceutical Cleanrooms?

In pharmaceutical manufacturing, air dryers are integral to maintaining the sterile environments of cleanrooms. They help in controlling humidity levels and ensuring that the air used in production processes meets stringent cleanliness standards. B2B buyers in this industry must look for air dryers that have specific certifications for pharmaceutical applications, as well as features that facilitate easy maintenance and monitoring to ensure compliance with health regulations.

What Benefits Do Air Dryers Provide in Automotive Paint Booths?

In the automotive industry, air dryers are utilized in paint booths to ensure that the air used during the painting process is free from moisture. Moisture can adversely affect paint adhesion and finish quality, leading to defects and rework. Buyers should evaluate the drying capacity and efficiency of air dryers under varying temperatures, especially in regions like Saudi Arabia, where high ambient temperatures can influence performance.

Illustrative image related to air dreyer

How Do Air Dryers Enhance Textile Drying Processes?

In the textile sector, air dryers are employed to expedite the drying of fabrics post-washing. By reducing drying time and energy consumption, these dryers enhance productivity and cost-effectiveness. B2B buyers should assess the energy efficiency ratings of air dryers, as well as their maintenance needs, to ensure long-term operational efficiency and to minimize downtime in production processes.

3 Common User Pain Points for ‘air dreyer’ & Their Solutions

Scenario 1: The Cost of Downtime Due to Inefficient Air Dryers

The Problem: Many B2B buyers in manufacturing or industrial sectors face significant challenges when their air dryers fail or operate inefficiently. This inefficiency can lead to excessive moisture in compressed air systems, which can cause equipment malfunctions, product defects, and ultimately, costly downtime. In regions like Africa and South America, where machinery reliability is critical, the financial impact of such disruptions can be substantial. Buyers often struggle to find a reliable air dryer that meets their specific operational needs without overspending.

The Solution: To mitigate downtime, it is crucial for buyers to invest in high-quality, energy-efficient air dryers that are tailored to their specific application. Conduct thorough research on manufacturers and suppliers, focusing on those who provide comprehensive technical support and warranties. Request case studies or references to verify performance in similar operating conditions. Additionally, consider investing in predictive maintenance solutions that monitor air dryer performance in real-time. This proactive approach allows for timely repairs or replacements before a complete failure occurs, significantly reducing the risk of costly downtime.

Scenario 2: The Challenge of Sizing Air Dryers for Diverse Applications

The Problem: Sizing an air dryer correctly is a common pain point for B2B buyers. An undersized air dryer may lead to inadequate moisture removal, while an oversized unit can waste energy and increase operational costs. In diverse environments—such as those found in the Middle East and Europe—where humidity levels fluctuate, it can be challenging to determine the right capacity. Buyers often find themselves confused by the technical specifications and may end up making a poor choice that impacts their operational efficiency.

Illustrative image related to air dreyer

The Solution: To accurately size an air dryer, buyers should first conduct a thorough analysis of their compressed air system requirements, including peak flow rates and moisture load. Engage with manufacturers or suppliers who offer free consultation services to help assess your specific needs. Utilize tools such as sizing calculators available on many manufacturer websites, which can provide insights based on your input parameters. Moreover, consider the inclusion of a margin for future growth or changes in production demands. This strategic approach not only ensures optimal performance but also enhances energy efficiency, ultimately leading to cost savings.

Scenario 3: Navigating the Complexities of Installation and Maintenance

The Problem: B2B buyers often encounter difficulties during the installation and ongoing maintenance of air dryers. In regions with limited technical expertise or resources, improper installation can lead to suboptimal performance or even damage to the equipment. Additionally, buyers may struggle with understanding the maintenance requirements, leading to neglect and, consequently, reduced lifespan and efficiency of the air dryers.

The Solution: To simplify installation and maintenance, buyers should prioritize working with suppliers who provide comprehensive installation guides and ongoing support. Choosing a supplier that offers training for in-house technicians can significantly enhance the understanding of the equipment and its requirements. Additionally, implementing a scheduled maintenance program can ensure that the air dryer operates efficiently over its lifespan. Regularly changing filters, checking for leaks, and monitoring performance metrics can prevent minor issues from escalating into major problems. Investing in such practices not only prolongs the life of the air dryer but also ensures that it operates at peak efficiency, thus safeguarding the overall productivity of the operations.

Strategic Material Selection Guide for air dreyer

What Are the Key Materials Used in Air Dryers?

Air dryers are critical components in various industrial applications, ensuring that compressed air is free from moisture and contaminants. The choice of materials used in air dryers significantly affects their performance, durability, and overall operational efficiency. Below, we analyze four common materials utilized in the construction of air dryers, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

Illustrative image related to air dreyer

How Does Aluminum Perform in Air Dryer Applications?

Key Properties: Aluminum is lightweight yet strong, with excellent corrosion resistance and good thermal conductivity. It can withstand moderate pressure and temperature variations, making it suitable for many air dryer applications.

Pros & Cons: The primary advantage of aluminum is its resistance to corrosion, which extends the life of the air dryer. Its lightweight nature also facilitates easier installation and maintenance. However, aluminum can be more expensive than other materials and may not withstand very high pressures, limiting its use in heavy-duty applications.

Impact on Application: Aluminum is compatible with a wide range of media, including water and oil. However, it may not be suitable for applications involving aggressive chemicals, which could lead to degradation.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure that the aluminum used complies with local standards, such as ASTM or DIN, especially in industries like oil and gas where stringent regulations exist.

Why Choose Stainless Steel for Air Dryers?

Key Properties: Stainless steel offers high strength, excellent corrosion resistance, and the ability to withstand high pressures and temperatures. It is often used in environments where durability is paramount.

Illustrative image related to air dreyer

Pros & Cons: The strength and longevity of stainless steel make it ideal for high-performance air dryers. However, it tends to be more expensive than aluminum and may require more complex manufacturing processes, increasing overall production costs.

Impact on Application: Stainless steel is highly compatible with various media, including corrosive substances. Its durability makes it suitable for applications in harsh environments, such as chemical processing.

Considerations for International Buyers: Buyers in Europe and South America should consider the specific grades of stainless steel (e.g., 304 or 316) that meet their industry standards. Compliance with international standards is crucial for ensuring safety and reliability.

What Role Does Plastic Play in Air Dryer Manufacturing?

Key Properties: Plastics, particularly high-density polyethylene (HDPE) and polyvinyl chloride (PVC), are lightweight and resistant to corrosion and chemical exposure. They can handle moderate pressures but are generally not suitable for high-temperature applications.

Pros & Cons: The primary advantage of plastic is its low cost and ease of manufacturing, which can lead to lower overall production costs. However, plastics may not offer the same durability as metals, particularly in high-pressure environments.

Illustrative image related to air dreyer

Impact on Application: Plastics are compatible with non-corrosive media and are often used in applications where weight is a concern. However, their limitations in pressure and temperature make them unsuitable for heavy-duty air dryers.

Considerations for International Buyers: Buyers from regions with stringent environmental regulations should ensure that the plastics used are compliant with local standards. Additionally, they should consider the long-term durability of plastic components in their specific applications.

How Effective is Copper in Air Dryer Systems?

Key Properties: Copper is known for its excellent thermal conductivity and corrosion resistance. It can handle high temperatures and pressures, making it suitable for various applications.

Illustrative image related to air dreyer

Pros & Cons: The thermal efficiency of copper can enhance the performance of air dryers, particularly in cooling applications. However, copper is relatively expensive and can be subject to corrosion over time, especially in humid environments.

Impact on Application: Copper is compatible with most media but may not be suitable in environments with aggressive chemicals that can cause corrosion.

Considerations for International Buyers: Buyers from regions like Saudi Arabia should ensure that copper components meet industry standards to prevent corrosion-related failures, especially in high-humidity environments.

Summary of Material Selection for Air Dryers

| Material | Typical Use Case for air dryer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight air dryers | Corrosion resistance | Limited pressure tolerance | Medium |

| Stainless Steel | Heavy-duty applications | High strength and durability | Higher cost and manufacturing complexity | High |

| Plastic | Low-pressure applications | Cost-effective and lightweight | Limited durability under pressure | Low |

| Copper | High-performance systems | Excellent thermal conductivity | Expensive and potential corrosion | High |

This material selection guide provides valuable insights for B2B buyers, helping them make informed decisions based on the specific needs of their applications and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for air dreyer

What Are the Main Stages in the Manufacturing Process of Air Dryers?

The manufacturing process of air dryers involves several critical stages designed to ensure quality and performance. These stages typically include material preparation, forming, assembly, and finishing.

Material Preparation: Ensuring Quality from the Start

The first step in manufacturing air dryers is material preparation. Manufacturers commonly use high-grade metals such as aluminum and stainless steel for their durability and corrosion resistance. This stage involves sourcing raw materials that meet specific standards, such as ASTM or ISO specifications. Advanced testing may be conducted to assess the material’s integrity before proceeding. For B2B buyers, understanding the material standards used can provide insights into the product’s longevity and performance in various environments.

How Is Forming Executed in Air Dryer Manufacturing?

Once the materials are prepared, the forming stage begins. This typically includes processes like cutting, bending, and machining to create the various components of the air dryer. Techniques such as CNC (Computer Numerical Control) machining are often employed to ensure precision and consistency. For manufacturers targeting international markets, adhering to international quality standards during this phase is crucial to meet diverse regulatory requirements.

Illustrative image related to air dreyer

What Assembly Techniques Are Commonly Used for Air Dryers?

The assembly stage is where individual components are brought together to form the complete air dryer. This may involve welding, bolting, or using adhesives, depending on the design and material. Manufacturers often utilize automated assembly lines to increase efficiency and reduce human error. This stage also includes the installation of essential components, such as filters, condensate drains, and control systems.

How Is Finishing Completed to Ensure Durability and Aesthetics?

The finishing stage encompasses processes like painting, coating, or polishing to enhance both the aesthetic appeal and the functional properties of the air dryer. Protective coatings are particularly important, as they shield the unit from environmental factors that could lead to corrosion or wear. Manufacturers may also apply quality checks during this stage to ensure that the finishing meets both aesthetic and functional standards.

What Are the Key Quality Assurance Measures for Air Dryers?

Quality assurance (QA) is critical in the manufacturing of air dryers, ensuring that each unit meets the required performance and safety standards. International standards like ISO 9001 are commonly adopted, focusing on quality management systems to enhance customer satisfaction. Additionally, industry-specific certifications such as CE marking and API standards play a crucial role in affirming product reliability and safety.

What QC Checkpoints Are Essential in Air Dryer Production?

Quality control (QC) checkpoints are integrated throughout the manufacturing process. These checkpoints typically include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet predefined specifications. Non-conforming materials are rejected or returned, minimizing the risk of defects in the final product.

-

In-Process Quality Control (IPQC): During the manufacturing process, various checkpoints are established to monitor production stages. This may include dimensional inspections and functional tests to ensure that components meet design specifications.

-

Final Quality Control (FQC): Once assembly is complete, FQC checks are performed on the finished product. This includes operational testing, safety assessments, and visual inspections. Detailed reports documenting the FQC process can provide B2B buyers with confidence in the product’s quality.

Which Testing Methods Are Commonly Used in Air Dryer Quality Assurance?

Various testing methods are employed to evaluate the performance and safety of air dryers. Common tests include:

- Pressure Testing: To ensure the unit can withstand operational pressures without leaks.

- Performance Testing: Assessing the dryer’s efficiency in removing moisture and contaminants from the compressed air.

- Electrical Safety Testing: Verifying that all electrical components meet safety standards to prevent hazards.

These tests are crucial for ensuring that the air dryers can perform effectively in real-world applications, particularly in diverse climates and conditions.

How Can B2B Buyers Verify Supplier Quality Assurance?

For B2B buyers, verifying the quality assurance processes of suppliers is essential in making informed purchasing decisions. Here are several strategies:

-

Conduct Supplier Audits: Regular audits can provide insights into a manufacturer’s quality control processes and adherence to international standards. This can be done through on-site visits or by requesting audit reports.

-

Request Quality Reports: Suppliers should be willing to provide detailed reports on their quality control procedures, including IQC, IPQC, and FQC data.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can offer an unbiased assessment of the manufacturing processes and quality control measures in place.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of the specific certifications and quality standards relevant to their markets. For instance, CE marking is vital for European markets, indicating compliance with EU legislation. In contrast, buyers in the Middle East might focus on local standards such as the Gulf Cooperation Council (GCC) certifications.

Illustrative image related to air dreyer

Understanding these nuances can aid B2B buyers in evaluating suppliers more effectively, ensuring that the air dryers they procure will meet both local regulations and international quality expectations. This diligence can ultimately safeguard against procurement risks and enhance operational efficiencies.

Conclusion

In conclusion, the manufacturing processes and quality assurance measures for air dryers are intricate and vital for ensuring product reliability and performance. For B2B buyers, especially those operating in diverse international markets, a thorough understanding of these processes can enhance procurement strategies and result in better long-term partnerships with suppliers. Prioritizing quality assurance not only mitigates risks but also fosters trust and satisfaction in the products acquired.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘air dreyer’

In today’s competitive industrial landscape, sourcing the right air dryer is crucial for maintaining the efficiency and reliability of compressed air systems. This guide provides a practical checklist for B2B buyers to ensure they make informed purchasing decisions when procuring air dryers, especially for businesses operating in diverse regions such as Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Identify the required airflow capacity, type of air dryer (e.g., refrigerated, desiccant), and operating pressure. Understanding these parameters will help you narrow down options that meet your operational needs and avoid costly mistakes.

Step 2: Research Reliable Suppliers

Engaging with reputable suppliers can significantly impact the quality and reliability of the equipment you procure. Investigate potential suppliers by checking their industry reputation, customer reviews, and years of experience. Look for suppliers who specialize in air dryers and have a proven track record in your specific industry.

Illustrative image related to air dreyer

Step 3: Evaluate Supplier Certifications and Compliance

Verification of supplier certifications is essential to ensure that the air dryers meet international quality and safety standards. Check for relevant certifications such as ISO 9001 or CE marking, which indicate adherence to quality management systems and compliance with European safety standards. This step safeguards your business against subpar products and potential legal issues.

Step 4: Assess Product Features and Technology

Examine the features and technologies of the air dryers being offered. Look for advanced functionalities such as energy efficiency ratings, automatic drain systems, and ease of maintenance. These features not only enhance operational efficiency but can also lead to significant cost savings in the long run.

Step 5: Request Quotes and Compare Pricing

Once you have identified potential suppliers, request detailed quotations that outline the costs involved, including shipping and any additional fees. Comparing pricing across multiple suppliers can help you identify the best value for your investment. Be cautious of prices that seem too low, as they may indicate compromised quality.

Illustrative image related to air dreyer

Step 6: Verify Warranty and After-Sales Support

A robust warranty and reliable after-sales support are critical considerations when purchasing air dryers. Ensure the supplier offers a comprehensive warranty that covers parts and labor for a reasonable duration. Additionally, inquire about their support services, such as maintenance contracts and availability of spare parts, to ensure your operations remain uninterrupted.

Step 7: Conduct a Site Assessment

Before finalizing your purchase, consider conducting a site assessment if feasible. This allows you to evaluate the space requirements, installation processes, and integration with existing systems. A site assessment can reveal potential challenges and help you prepare accordingly, leading to a smoother installation process.

By following these steps, B2B buyers can confidently navigate the procurement process for air dryers, ensuring they select the most suitable products that meet their operational requirements and contribute to long-term success.

Comprehensive Cost and Pricing Analysis for air dreyer Sourcing

What are the Key Cost Components in Air Dryer Manufacturing?

When sourcing air dryers, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The cost of raw materials, such as metals and plastics, significantly influences the overall price. High-quality materials often lead to longer-lasting products but may come at a premium.

-

Labor: Labor costs vary by region and can impact the final pricing. Countries with higher wages may see increased manufacturing costs, while regions with lower labor costs can offer more competitive pricing.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and equipment maintenance. Efficient production processes can help minimize these overheads, leading to more favorable pricing.

-

Tooling: The initial investment in machinery and tools needed for production can be substantial. Custom tooling for specialized air dryer designs may increase upfront costs but can be amortized over larger production runs.

-

Quality Control (QC): Ensuring product reliability and compliance with international standards incurs additional costs. Buyers should consider manufacturers with robust QC processes to avoid future costs related to defects or compliance failures.

-

Logistics: Shipping and handling costs are critical, especially for international buyers. Factors like shipping methods, distance, and insurance can significantly affect overall expenses.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure sustainability. This margin can vary widely based on market competition and the uniqueness of the product.

How Do Price Influencers Affect Air Dryer Costs?

Several factors can influence the pricing of air dryers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for discounts, making it crucial for buyers to assess their needs against supplier MOQs. Bulk purchasing can lead to significant cost savings.

-

Specifications and Customization: Custom features or specifications can increase costs. Buyers should evaluate whether customization is necessary or if standard models meet their requirements.

-

Materials: The choice of materials not only affects durability but also the cost. Premium materials can enhance performance and lifespan but come with higher price tags.

-

Quality and Certifications: Compliance with international standards (ISO, CE, etc.) may add to the price but ensures that the product meets safety and performance benchmarks, which is particularly important for industrial applications.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more due to their experience and quality assurance, while emerging suppliers may offer lower prices to gain market entry.

-

Incoterms: Understanding delivery terms is essential. Incoterms dictate who bears shipping costs and responsibilities, impacting the total landed cost of the air dryer.

What Buyer Tips Can Help Negotiate Better Prices?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, should consider the following strategies:

-

Negotiate Wisely: Leverage your purchasing power. Suppliers may be open to negotiating prices for bulk orders or long-term contracts, especially if they perceive a strong partnership potential.

-

Focus on Cost-Efficiency: Evaluate the Total Cost of Ownership (TCO), which includes purchase price, maintenance, energy consumption, and potential downtime costs. A lower upfront price may not always translate to savings if the product requires frequent repairs or has high operating costs.

-

Understand Pricing Nuances: Be aware of regional pricing variances due to tariffs, taxes, and shipping costs. Understanding these nuances can help in selecting the right supplier and negotiating effectively.

-

Consider Long-Term Relationships: Building strong relationships with suppliers can lead to better pricing over time. Loyalty can often result in preferential pricing, improved service, and access to exclusive products.

Disclaimer on Indicative Prices

Pricing for air dryers can fluctuate based on market conditions, supplier changes, and geopolitical factors. Therefore, it is advisable for buyers to request updated quotations and consider all cost components when making sourcing decisions.

Alternatives Analysis: Comparing air dreyer With Other Solutions

When considering air dryers for industrial applications, it’s essential to evaluate various options that can meet your business’s specific needs. While air dryers are a popular choice for removing moisture from compressed air, several alternatives can also achieve similar results. This analysis will compare air dryers with two viable alternatives: desiccant dryers and membrane dryers.

| Comparison Aspect | Air Dryer | Desiccant Dryer | Membrane Dryer |

|---|---|---|---|

| Performance | Efficient at high flow rates; removes moisture to low dew points | High moisture removal efficiency; ideal for critical applications | Good for low-volume applications; removes moisture without cooling |

| Cost | Moderate initial cost; ongoing energy consumption | Higher upfront cost; energy-efficient options available | Generally lower cost; minimal maintenance expenses |

| Ease of Implementation | Typically straightforward installation; may require specific space | More complex installation; requires more space and planning | Easy to install; compact and portable |

| Maintenance | Regular maintenance required to ensure optimal performance | Requires periodic media replacement; low maintenance otherwise | Minimal maintenance; typically requires periodic checks |

| Best Use Case | General industrial applications; suitable for varied environments | Critical applications requiring ultra-dry air; pharmaceuticals, food processing | Small-scale operations or mobile applications needing quick moisture removal |

What Are the Advantages and Disadvantages of Desiccant Dryers?

Desiccant dryers are designed to achieve very low dew points, making them ideal for applications where air quality is critical, such as in the pharmaceutical and food processing industries. They use hygroscopic materials to absorb moisture from the air. The primary advantage of desiccant dryers is their ability to provide ultra-dry air consistently. However, they typically come with a higher initial cost and require periodic replacement of the desiccant media, which can increase ongoing operational costs.

What Are the Benefits and Limitations of Membrane Dryers?

Membrane dryers utilize semi-permeable membranes to separate moisture from the compressed air. They are particularly effective for low-volume applications and are often more affordable than traditional air dryers. The advantages of membrane dryers include their low maintenance requirements and ease of installation, making them suitable for mobile or temporary setups. However, they may not achieve the same level of moisture removal as air or desiccant dryers, making them less suitable for critical applications where air quality is paramount.

How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting an air drying solution, B2B buyers should consider their specific operational requirements, including the volume of air processed, the criticality of air quality, and budget constraints. For general industrial applications with moderate air quality needs, an air dryer may be sufficient. In contrast, businesses in industries requiring stringent moisture control may benefit from the enhanced performance of desiccant dryers. Meanwhile, companies looking for a cost-effective, low-maintenance solution for smaller operations might find membrane dryers to be the best fit. By carefully assessing these factors, buyers can make informed decisions that align with their operational goals and financial constraints.

Essential Technical Properties and Trade Terminology for air dreyer

What Are the Key Technical Properties of Air Dryers?

Understanding the essential technical specifications of air dryers is crucial for B2B buyers, particularly when evaluating performance and compatibility with existing systems. Below are some critical specifications that should be considered:

1. Flow Rate (CFM)

The flow rate, measured in cubic feet per minute (CFM), indicates the volume of air the dryer can process. This is vital for ensuring that the air dryer meets the demands of the application. Insufficient flow rates can lead to inefficiencies and equipment failures, impacting productivity. Buyers should match the CFM to their air compressor’s output to maintain optimal performance.

2. Pressure Drop

Pressure drop refers to the reduction in air pressure as it passes through the dryer. A lower pressure drop means that the system can maintain more consistent pressure, which is essential for applications requiring precise air pressure levels. High pressure drops can lead to increased energy costs and reduced efficiency, making this a critical factor for B2B decision-makers.

3. Temperature Control

Temperature control is an important feature that ensures the air dryer operates within specific thermal parameters. Effective temperature regulation prevents condensation, which can lead to moisture accumulation in the air supply. Buyers should consider dryers with advanced temperature management systems to enhance reliability and extend equipment lifespan.

4. Condensate Management

Condensate management systems are designed to efficiently handle the moisture extracted from compressed air. Buyers should evaluate the type of condensate drain (manual or automatic) and its capacity to ensure it aligns with their operational needs. Effective condensate management minimizes downtime and maintenance costs.

5. Energy Efficiency Rating

Energy efficiency is a key consideration in the selection of air dryers, especially in regions where operational costs are high. Look for dryers with energy-efficient designs and features, such as variable speed drives or heat recovery systems. Higher efficiency ratings can lead to significant cost savings over time, making them a smart investment for businesses.

What Common Trade Terms Should B2B Buyers Know When Purchasing Air Dryers?

Familiarizing yourself with industry jargon can enhance communication and decision-making in the purchasing process. Here are some essential terms to know:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces components or products that are sold under another company’s brand. In the context of air dryers, knowing whether a product is OEM can inform buyers about quality, warranty, and support options.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to ensure they meet supplier requirements without overcommitting resources.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products or services. This term is essential for buyers looking to compare costs and negotiate terms effectively.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in the shipping process. Familiarity with these terms can help buyers understand their obligations regarding shipping, insurance, and tariffs, which is particularly important when importing air dryers.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is vital for B2B buyers to manage inventory levels and production schedules effectively.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing air dryers, ensuring they select products that meet their operational needs and budget constraints.

Navigating Market Dynamics and Sourcing Trends in the air dreyer Sector

What Are the Current Market Dynamics and Key Trends in the Air Dryer Sector?

The air dryer market is experiencing significant growth, driven by increased industrial activity and the need for efficient compressed air systems. Key global drivers include the rising demand for energy-efficient solutions and stringent regulations regarding air quality. Emerging technologies, such as advanced filtration systems and smart monitoring, are gaining traction. These innovations not only enhance the performance of air dryers but also contribute to energy savings, making them attractive options for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe.

As companies strive for operational excellence, there is a growing emphasis on integrating digital solutions into air dryer systems. Predictive maintenance technologies and IoT-enabled devices allow for real-time monitoring of performance, leading to reduced downtime and maintenance costs. Furthermore, the trend toward modular systems enables businesses to customize their air dryer solutions according to specific operational requirements, which is particularly beneficial for diverse markets in Nigeria and Saudi Arabia.

In addition, sustainability is becoming a focal point in sourcing strategies. Buyers are increasingly seeking products that not only meet performance standards but also align with their corporate social responsibility goals. This shift is encouraging manufacturers to prioritize sustainable practices in their production processes, thereby influencing the supply chain dynamics within the air dryer sector.

How Is Sustainability and Ethical Sourcing Shaping the Air Dryer Market?

The environmental impact of manufacturing processes and product lifecycle management is under scrutiny, making sustainability a key concern for B2B buyers in the air dryer sector. Companies are now evaluating suppliers based on their commitment to sustainable practices, such as reducing carbon footprints and waste. This shift towards eco-friendly solutions is not just a trend; it is becoming a necessity as governments enforce stricter environmental regulations.

Ethical sourcing is also gaining importance, with buyers looking for suppliers who uphold fair labor practices and responsible sourcing of materials. Certifications such as ISO 14001 for environmental management and other ‘green’ certifications can significantly influence purchasing decisions. Buyers are more likely to partner with manufacturers who demonstrate transparency and a commitment to sustainable practices throughout their supply chains.

In the air dryer market, the integration of recyclable materials and energy-efficient designs is becoming standard. This not only helps in reducing the overall environmental impact but also enhances the appeal of products to a growing segment of eco-conscious consumers. As a result, companies that prioritize sustainability will likely gain a competitive edge in attracting international buyers who value ethical and environmentally responsible products.

What Is the Historical Context of Air Dryer Technology in B2B Applications?

The evolution of air dryer technology has significantly shaped its application in various industrial sectors. Initially developed to remove moisture from compressed air systems, air dryers have undergone substantial advancements since their inception in the early 20th century. The introduction of refrigeration technology in the 1950s allowed for more efficient moisture removal, leading to the development of refrigerated air dryers.

As industries expanded and the need for high-quality compressed air grew, innovations such as desiccant dryers emerged, offering even greater moisture control. These advancements have made air dryers integral to processes in sectors like manufacturing, pharmaceuticals, and food processing, where air quality is critical. Today, the focus is on enhancing efficiency and sustainability, with ongoing research into smart technologies and environmentally friendly designs, ensuring that air dryers remain vital in modern industrial applications.

This historical context provides valuable insights for B2B buyers, highlighting the importance of selecting air dryers that not only meet current performance standards but also anticipate future needs in an increasingly competitive and environmentally conscious marketplace.

Frequently Asked Questions (FAQs) for B2B Buyers of air dreyer

-

How do I choose the right air dryer for my industrial application?

Selecting the right air dryer involves understanding your specific needs, including airflow capacity (CFM), operating temperature, and humidity levels in your environment. Assess the type of air dryer that best fits your application, such as refrigerated, desiccant, or membrane dryers. Consider the energy efficiency ratings and maintenance requirements, as these factors can significantly impact long-term operational costs. Engaging with a knowledgeable supplier can help you determine the most suitable model tailored to your industry requirements. -

What are the key specifications to consider when sourcing air dryers?

When sourcing air dryers, key specifications include airflow capacity (CFM), power requirements (voltage and phase), maximum inlet temperature, and pressure ratings. Additionally, consider the dryer type (refrigerated, desiccant, etc.), moisture removal capabilities, and energy efficiency ratings. You should also evaluate the dimensions and weight for installation feasibility. Understanding these specifications ensures that the air dryer meets your operational needs and integrates seamlessly with existing equipment. -

What are common payment terms for international purchases of air dryers?

Payment terms for international purchases typically range from advance payment, letters of credit, to payment upon delivery, depending on the supplier’s policies and the buyer’s relationship with them. It’s crucial to clarify these terms upfront and ensure that they align with your financial capabilities. Additionally, consider transaction fees, currency exchange rates, and potential financing options. Establishing clear payment agreements can help mitigate risks and foster trust between parties. -

How can I ensure the quality of the air dryers I am sourcing?

To ensure quality, vet potential suppliers by checking certifications, customer reviews, and their track record in the industry. Request product samples or conduct factory visits to evaluate manufacturing processes. Additionally, inquire about warranty terms and after-sales support. It’s advisable to establish quality assurance protocols, such as third-party inspections, to verify that the products meet your specifications before shipment. -

What is the Minimum Order Quantity (MOQ) for air dryers?

MOQs for air dryers can vary widely among suppliers, ranging from one unit for small manufacturers to larger quantities for major distributors. Factors influencing MOQ include production capacity, material availability, and shipping logistics. If you’re a smaller buyer, consider negotiating with suppliers or looking for distributors that cater to lower order volumes. Understanding the MOQ will help you plan your purchasing strategy and manage inventory effectively. -

What logistical considerations should I keep in mind when importing air dryers?

When importing air dryers, consider shipping methods, lead times, and customs regulations in your country. Evaluate whether the supplier provides shipping options, including freight forwarding services. Additionally, be aware of import duties, taxes, and compliance with local standards. Proper documentation is essential for smooth customs clearance. Collaborating with experienced logistics partners can help streamline the shipping process and reduce the risk of delays. -

Can I customize air dryers to meet specific operational needs?

Yes, many manufacturers offer customization options for air dryers, allowing you to tailor features such as size, airflow capacity, and additional components like filters or condensate drains. Customization can enhance performance in specific environments or applications. When discussing your needs with suppliers, provide detailed specifications to ensure that the final product aligns with your operational requirements. Be mindful that customization may impact lead times and costs. -

How can I assess the reliability of an air dryer supplier?

To assess supplier reliability, review their industry experience, customer testimonials, and product warranties. Look for suppliers with established reputations and those that adhere to international quality standards. Engaging in direct communication with suppliers can provide insights into their responsiveness and customer service approach. Additionally, consider visiting their facility if feasible or requesting references from other customers to gauge their reliability and service levels.

Top 4 Air Dreyer Manufacturers & Suppliers List

1. RevAir – Reverse-Air Hair Dryer

Domain: myrevair.com

Registered: 2017 (8 years)

Introduction: RevAir Reverse-Air Hair Dryer with friction-free technology, 3 heat settings, 7 tension settings. 70% faster dry time compared to traditional blow dryers. Suitable for all hair types, including extensions, twist outs, braids, locs, and wigs. Variable tension settings and internal temperature sensors to reduce damage and breakage. Preserves curl pattern, keeping hair healthier, shinier, and stronge…

2. Compressed Air Advisors – Super-Dry D1 Desiccant Air Dryer

Domain: compressedairadvisors.com

Registered: 2015 (10 years)

Introduction: Super-Dry D1 – Desiccant Air Dryer – up to 70 CFM, Original price $795.00, Sale price $759.00

3. Atlas Copco – Compressed Air Dryers

Domain: atlascopco.com

Registered: 1995 (30 years)

Introduction: Atlas Copco offers a complete range of compressed air dryers designed to efficiently remove moisture from compressed air systems, preventing corrosion, equipment damage, and product spoilage while optimizing energy use. Key features include:

1. **Dew Point Range**: Wide range from +3 to -70 °C (37.4 to -94°F) for precise air quality control.

2. **Types of Air Dryers**:

– **Desiccant Air Dryers…

4. Pneumatech – Compressed Air Dryers

Domain: pneumatech.com

Registered: 1996 (29 years)

Introduction: Compressed Air Dryers: 1. Refrigeration Dryers: Most commonly used for removing moisture, maintaining a Pressure Dew Point (PDP) of +3 °C/37.4 °F. Available in air-cooled, water-cooled, non-cycling, cycling, and VSD options. 2. Adsorption Dryers: Use hygroscopic materials like silica gel to achieve PDP from -10 °C/14 °F to -70 °C/-94 °F. Feature two drying vessels for consistent operations and uti…

Strategic Sourcing Conclusion and Outlook for air dreyer

What Are the Key Takeaways for B2B Buyers in the Air Dryer Market?

In the evolving landscape of industrial air dryers, strategic sourcing emerges as a critical factor for B2B buyers. Understanding the diverse range of products, such as refrigerated and regenerative air dryers, enables companies to make informed decisions that align with their operational needs and budgets. Key considerations include evaluating the efficiency of various models, the total cost of ownership, and the availability of local support and service options.

Illustrative image related to air dreyer

Moreover, international buyers from regions like Africa, South America, the Middle East, and Europe should prioritize suppliers that offer reliable shipping solutions and local pickup options. This flexibility not only optimizes logistics but also enhances inventory management.

How Can B2B Buyers Prepare for Future Air Dryer Investments?

Looking ahead, the demand for high-efficiency air dryers is set to rise, driven by advancements in technology and sustainability goals. B2B buyers are encouraged to stay abreast of innovations in air dryer technology and consider suppliers that demonstrate a commitment to quality and customer service.

As you embark on your sourcing journey, leverage strategic partnerships and engage with manufacturers who understand the unique challenges of your industry. By doing so, you will not only secure the best products but also position your organization for sustained growth and operational excellence.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.