Air Conditioner Dc: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for air conditioner dc

In today’s increasingly competitive global market, sourcing efficient air conditioner DC units poses a significant challenge for B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. With rising temperatures and the demand for energy-efficient solutions, businesses must navigate a complex landscape of suppliers and technologies. This comprehensive guide addresses the critical factors involved in selecting the right DC air conditioning systems, including various types, applications, supplier vetting strategies, and cost considerations.

International buyers will benefit from insights into the latest innovations in DC air conditioning technology, such as high-efficiency models designed for both marine and off-grid applications. The guide delves into the specifics of product features, including energy consumption, durability against harsh environments, and maintenance requirements. Furthermore, it provides actionable advice on establishing reliable supplier partnerships that can enhance operational efficiency and reduce long-term costs.

Armed with this knowledge, B2B buyers can make informed purchasing decisions that not only meet their cooling needs but also align with sustainability goals and budget constraints. Whether you’re in Brazil seeking solutions for industrial applications or in Saudi Arabia looking for residential systems, this guide empowers you to navigate the global market confidently and effectively.

Understanding air conditioner dc Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Marine DC Air Conditioners | Designed for marine environments, high efficiency, mold resistance | Marine vessels, yachts, offshore installations | Pros: High durability, effective in humid conditions. Cons: Higher initial investment. |

| Solar DC Air Conditioners | Operates directly from solar power, no inverters required | Off-grid homes, remote sites, telecom applications | Pros: Energy-efficient, reduces operational costs. Cons: Dependent on sunlight availability. |

| Battery-Powered DC Units | Operates on 12V/24V/48V battery systems, compact design | RVs, heavy equipment, mobile applications | Pros: Flexible installation, low noise. Cons: Limited run time without recharging. |

| Direct DC Air Conditioners | All-DC systems, variable speed, designed for native DC power | Industrial facilities, telecom stations | Pros: High efficiency, reduced power costs. Cons: Requires specialized maintenance. |

| Hybrid AC-DC Systems | Combines AC and DC power sources, versatile operation | Commercial buildings, residential applications | Pros: Flexible power options, adaptable to various settings. Cons: Complexity in installation. |

What Are Marine DC Air Conditioners and Their Applications?

Marine DC air conditioners are specifically engineered to withstand the rigors of marine environments, featuring high efficiency and resistance to mold and bacteria. They are ideal for use in yachts, fishing boats, and offshore platforms where humidity is prevalent. When purchasing, B2B buyers should consider durability, energy efficiency, and warranty options, as these factors significantly impact long-term operational costs and reliability.

How Do Solar DC Air Conditioners Work for Off-Grid Applications?

Solar DC air conditioners operate directly from solar power, eliminating the need for inverters, which enhances efficiency. These units are particularly suitable for off-grid homes, remote installations, and telecom applications where traditional power sources are unavailable. Buyers should evaluate the solar energy potential of their location and consider battery backup options to ensure consistent operation during low sunlight periods.

What Are the Benefits of Battery-Powered DC Units?

Battery-powered DC air conditioning units are designed to run on 12V, 24V, or 48V battery systems, making them highly versatile for applications in RVs, heavy equipment, and mobile units. Their compact design allows for flexible installation in constrained spaces. B2B buyers should assess their power needs and the frequency of use, as these units may require regular recharging, impacting operational efficiency.

Why Choose Direct DC Air Conditioners for Industrial Applications?

Direct DC air conditioners are built to operate on native DC power, offering variable speed and capacity options that enhance energy efficiency. These systems are ideal for industrial facilities and telecom stations where consistent cooling is essential. Buyers should focus on the unit’s efficiency ratings and maintenance requirements, as specialized knowledge may be necessary for optimal performance.

What Makes Hybrid AC-DC Systems Versatile for Commercial Use?

Hybrid AC-DC systems provide the flexibility of using both AC and DC power sources, making them suitable for a wide range of commercial applications. Their adaptability allows them to meet varying energy demands efficiently. When considering a purchase, B2B buyers should weigh the complexity of installation against the potential for energy savings and operational flexibility, as these factors can influence the overall cost-effectiveness of the investment.

Key Industrial Applications of air conditioner dc

| Industry/Sector | Specific Application of air conditioner dc | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Marine & Offshore | Cooling systems for ships and offshore platforms | Enhanced reliability in harsh environments; energy efficiency | Ensure units are corrosion-resistant and compliant with marine standards |

| Telecommunications | Cooling for telecom shelters and data centers | Protects sensitive equipment from overheating; reduces downtime | Look for energy-efficient models with low maintenance requirements |

| Agriculture & Food Storage | Temperature control in storage facilities and refrigerated trucks | Maintains product quality; extends shelf life of perishables | Evaluate capacity needs and energy consumption for sustainable operations |

| Automotive & Heavy Equipment | Climate control in trucks, buses, and construction machinery | Improves operator comfort; increases productivity | Consider compatibility with existing systems and power requirements |

| Renewable Energy | Integration with solar-powered systems for off-grid cooling | Reduces operational costs; promotes sustainability | Assess compatibility with solar setups and battery systems |

How is Air Conditioner DC Used in Marine and Offshore Industries?

In the marine and offshore sectors, DC air conditioners are crucial for maintaining comfortable and safe environments on ships and platforms. These units are designed to withstand harsh marine conditions, resisting saltwater corrosion and mold growth. For international buyers, especially from regions like the Middle East and South America, sourcing durable, energy-efficient models that meet regulatory standards is essential. Such systems enhance the reliability of cooling solutions, ensuring that equipment and personnel remain protected from extreme temperatures.

What Role Does Air Conditioner DC Play in Telecommunications?

Telecommunications companies rely heavily on DC air conditioning systems to cool their equipment housed in remote shelters and data centers. These systems prevent overheating, which can lead to equipment failure and costly downtime. For B2B buyers in Africa and Europe, selecting energy-efficient models with low maintenance needs can significantly reduce operational costs. Additionally, understanding the power requirements and compatibility with existing setups is vital for seamless integration.

How Does Air Conditioner DC Benefit Agriculture and Food Storage?

In agriculture and food storage, DC air conditioners play a pivotal role in preserving the quality of perishable goods. By maintaining optimal temperatures in storage facilities and refrigerated transport, these systems extend the shelf life of products, reducing waste and ensuring safety. Buyers from South America and Africa should consider the cooling capacity and energy consumption of these units to align with sustainable practices and operational efficiency.

How is Air Conditioner DC Utilized in Automotive and Heavy Equipment?

In the automotive and heavy equipment sectors, DC air conditioners provide essential climate control for trucks, buses, and construction machinery. These systems enhance operator comfort, which can lead to improved productivity on job sites. For international buyers, particularly in regions with extreme climates, it is crucial to evaluate compatibility with existing systems and the specific power requirements to ensure efficient operation.

What Are the Advantages of Using Air Conditioner DC in Renewable Energy Applications?

DC air conditioners are increasingly being integrated into renewable energy setups, particularly solar-powered systems. They provide a sustainable cooling solution that minimizes operational costs while promoting eco-friendly practices. Buyers looking for these systems should assess compatibility with solar power configurations and battery systems to maximize efficiency and reliability. This is particularly relevant for businesses in regions like Africa and the Middle East, where solar energy is abundant.

3 Common User Pain Points for ‘air conditioner dc’ & Their Solutions

Scenario 1: Ensuring Efficient Cooling in Harsh Environments

The Problem: B2B buyers in regions with extreme temperatures, such as the Middle East or parts of Africa, often struggle with the reliability and efficiency of air conditioning units. Traditional systems may fail to provide adequate cooling under intense heat, leading to equipment failure or discomfort for personnel in facilities like warehouses or manufacturing plants. Additionally, the corrosive nature of these environments can rapidly degrade standard air conditioning systems, leading to increased maintenance costs and downtime.

The Solution: When sourcing air conditioner DC units, prioritize models specifically designed for high-temperature and corrosive conditions. For instance, look for units featuring advanced materials such as stainless steel and anti-corrosion technology, which are essential for longevity in harsh environments. Additionally, consider systems with variable speed compressors that adjust their power consumption based on cooling demand. This not only enhances energy efficiency but also prolongs the lifespan of the unit. Before finalizing your purchase, request detailed specifications and warranties from manufacturers to ensure they meet the required standards for your operational conditions.

Scenario 2: Navigating Power Supply Limitations

The Problem: In many developing regions, stable power supply can be a significant concern. B2B buyers often face challenges in sourcing air conditioning systems that can operate effectively on limited or fluctuating power sources. This is particularly critical for businesses relying on solar power or battery systems, where traditional AC units may not function optimally or could lead to frequent breakdowns.

The Solution: Opt for air conditioner DC systems that are specifically designed to operate on low-voltage power sources, such as 12V, 24V, or 48V DC. These units typically include features such as soft-start technology, which minimizes current load during startup, and eco-mode settings that reduce energy consumption when full cooling capacity is not required. When engaging suppliers, inquire about the unit’s compatibility with your existing power infrastructure and request information on energy consumption metrics. Additionally, consider systems that can be easily integrated with solar panels or batteries for off-grid applications, ensuring a reliable and efficient cooling solution.

Scenario 3: Overcoming Installation and Maintenance Challenges

The Problem: B2B buyers often encounter difficulties with the installation and ongoing maintenance of air conditioning units, especially in unique applications such as marine or mobile settings. Complex installation requirements can lead to increased labor costs, while poor access to replacement parts can create prolonged downtimes when maintenance is needed.

The Solution: When selecting a DC air conditioning unit, focus on models that offer straightforward installation processes and comprehensive support from the manufacturer. For instance, units that come with clear installation guides and training materials can significantly reduce labor costs and installation time. Additionally, choose suppliers who provide local support and a robust parts supply chain to facilitate quick repairs and maintenance. Consider also leveraging remote monitoring technologies that allow for real-time performance tracking, enabling proactive maintenance and reducing the risk of unexpected failures. Before making a purchase, evaluate the manufacturer’s reputation for customer service and parts availability to ensure your investment remains operational over the long term.

Strategic Material Selection Guide for air conditioner dc

When selecting materials for DC air conditioners, several factors must be considered to ensure optimal performance, durability, and compliance with international standards. This analysis focuses on four common materials used in the construction of DC air conditioning units: copper, stainless steel, aluminum, and plastic composites. Each material has unique properties that affect the overall performance and suitability for specific applications, particularly in diverse environments such as those found in Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Copper in DC Air Conditioners?

Copper is widely used in DC air conditioners, particularly for evaporators and heat exchangers. Its excellent thermal conductivity allows for efficient heat transfer, crucial for maintaining optimal cooling performance. Additionally, copper has inherent antimicrobial properties, which help reduce mold and bacteria growth within the system.

Pros and Cons:

Copper is highly durable and resistant to corrosion, especially when treated with protective coatings. However, it is more expensive than other materials, which can increase the overall cost of the air conditioning unit. The manufacturing complexity is moderate, as copper components require precise fabrication techniques.

Impact on Application:

Copper is compatible with various refrigerants and is suitable for high-pressure applications. However, it may not be ideal for environments with high salinity, such as coastal areas, unless adequately protected.

Considerations for International Buyers:

International buyers should ensure that copper components meet relevant standards, such as ASTM B280 for seamless copper tubing. Compliance with local regulations regarding materials and environmental impact is also essential.

Why Choose Stainless Steel for DC Air Conditioners?

Stainless steel is another popular choice, especially for structural components and casings. It offers excellent corrosion resistance, making it suitable for harsh environments, including marine applications.

Pros and Cons:

The durability of stainless steel is a significant advantage, as it can withstand extreme temperatures and pressures. However, it is heavier than aluminum and can be more expensive, impacting shipping costs. The manufacturing process can be complex, requiring specialized welding techniques.

Impact on Application:

Stainless steel is ideal for applications exposed to moisture and corrosive elements. Its strength allows for the design of robust units that can endure rigorous usage.

Considerations for International Buyers:

Buyers should verify that stainless steel used in air conditioners complies with international standards like ASTM A240 for stainless steel sheets. Understanding local preferences for material grades can also influence purchasing decisions.

How Does Aluminum Benefit DC Air Conditioner Design?

Aluminum is often utilized for components like heat exchangers and casings due to its lightweight nature and good thermal conductivity. It is an excellent alternative for applications where weight savings are critical.

Pros and Cons:

Aluminum is cost-effective and easy to fabricate, which simplifies manufacturing processes. However, it has lower corrosion resistance compared to stainless steel and copper, necessitating protective coatings in certain environments.

Impact on Application:

Aluminum is suitable for low to moderate pressure applications and is often used in residential air conditioning units. Its compatibility with various refrigerants makes it versatile.

Considerations for International Buyers:

Buyers should ensure that aluminum components comply with standards such as ASTM B221 for extruded aluminum products. Understanding local market preferences for aluminum grades can also affect sourcing decisions.

What Role Do Plastic Composites Play in DC Air Conditioners?

Plastic composites are increasingly used in DC air conditioners for components such as fan blades and insulation. They offer lightweight solutions and can be engineered for specific thermal and mechanical properties.

Pros and Cons:

The primary advantage of plastic composites is their resistance to corrosion and lightweight nature, which can enhance energy efficiency. However, they may not be as durable as metals and can be sensitive to UV exposure unless treated.

Impact on Application:

Plastic composites are suitable for non-structural components and insulation in air conditioning systems. Their flexibility allows for innovative designs that can improve overall system efficiency.

Considerations for International Buyers:

International buyers should ensure that plastic materials comply with standards like ASTM D638 for tensile properties. Understanding local regulations regarding the use of plastics in HVAC systems is crucial.

Summary Table

| Material | Typical Use Case for air conditioner dc | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Copper | Evaporators, heat exchangers | Excellent thermal conductivity | Higher cost, moderate manufacturing complexity | High |

| Stainless Steel | Structural components, casings | Exceptional corrosion resistance | Heavier, more expensive | High |

| Aluminum | Heat exchangers, casings | Lightweight, cost-effective | Lower corrosion resistance | Medium |

| Plastic Composites | Fan blades, insulation | Corrosion resistance, lightweight | Less durable, UV sensitivity | Low |

This strategic material selection guide provides a comprehensive overview of the materials commonly used in DC air conditioners, helping international B2B buyers make informed decisions based on performance, cost, and compliance with local standards.

In-depth Look: Manufacturing Processes and Quality Assurance for air conditioner dc

What Are the Key Stages in the Manufacturing Process for DC Air Conditioners?

The manufacturing process of DC air conditioners involves several critical stages that ensure the units are efficient, durable, and meet international quality standards.

1. Material Preparation

The first step involves sourcing high-quality materials. Manufacturers typically use corrosion-resistant materials, such as stainless steel and copper, to enhance durability and efficiency. For instance, copper is favored for its excellent thermal conductivity, making it ideal for evaporators. Manufacturers often establish relationships with reliable suppliers to ensure a consistent supply of quality materials. Additionally, incoming materials undergo inspections to verify they meet required specifications before proceeding to the next stage.

2. Forming

In this stage, raw materials are shaped into specific components of the air conditioning units. Techniques such as stamping, bending, and welding are commonly used to create parts like the chassis, evaporators, and condensers. Advanced machinery, including CNC (Computer Numerical Control) machines, is employed to achieve precision and repeatability in component manufacturing. This precision is vital, as even minor deviations can affect the overall performance and efficiency of the air conditioning units.

3. Assembly

Once the components are formed, they are assembled into complete units. This process may involve manual labor and automated assembly lines, depending on the manufacturer’s capabilities. Key assembly techniques include the installation of compressors, fans, and electrical systems. During this stage, manufacturers often implement modular assembly practices, which allow for easier repairs and upgrades. Quality checks are integrated into the assembly line, ensuring that each unit meets design specifications before moving on to the finishing stage.

4. Finishing

The finishing stage focuses on finalizing the product for market readiness. This includes painting, coating, or applying anti-corrosive treatments to protect the units from environmental factors. For example, units designed for marine applications often undergo additional treatments to withstand saltwater corrosion. The finishing process also includes thorough cleaning of the units to remove any manufacturing residues that could affect performance.

How Is Quality Assurance Implemented in DC Air Conditioner Manufacturing?

Quality assurance (QA) in the manufacturing of DC air conditioners is crucial for ensuring reliability and performance. Manufacturers adhere to several international and industry-specific standards.

1. International Standards and Certifications

Most manufacturers pursue ISO 9001 certification, which outlines quality management principles. This certification helps companies ensure consistent quality in their products and processes. Additionally, compliance with CE marking is essential for products sold within the European market, indicating conformity with health, safety, and environmental protection standards. For manufacturers targeting specific sectors, adherence to API standards may also be relevant, particularly in oil and gas applications.

2. QC Checkpoints Throughout the Manufacturing Process

Quality control (QC) is integrated at multiple checkpoints throughout the manufacturing process.

- Incoming Quality Control (IQC): This initial stage involves inspecting raw materials to ensure they meet predetermined specifications.

- In-Process Quality Control (IPQC): During assembly, various checks are performed to monitor the quality of components and assemblies. This includes functional testing of compressors and electrical systems.

- Final Quality Control (FQC): The completed units undergo rigorous testing to validate performance, efficiency, and safety. This can include cooling capacity tests, noise level assessments, and energy consumption evaluations.

These checkpoints are vital for identifying defects early in the production process, minimizing waste, and ensuring that only high-quality products reach the market.

3. Common Testing Methods and Their Importance

Manufacturers employ several testing methods to verify the performance of DC air conditioners. Common tests include:

- Thermal Performance Tests: Assessing the cooling capacity and efficiency under various conditions.

- Electrical Testing: Ensuring the electrical components function correctly and safely.

- Durability Testing: Simulating real-world conditions to evaluate the longevity and reliability of the units.

These tests are essential for building trust with B2B buyers, as they confirm that products meet performance expectations and comply with relevant standards.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe, should take proactive steps to verify the quality control processes of potential suppliers.

1. Conducting Supplier Audits

One effective way to assess a supplier’s quality control is through on-site audits. This allows buyers to evaluate the manufacturing processes, inspect facilities, and review QC documentation. An audit can reveal insights into the supplier’s commitment to quality and adherence to international standards.

2. Requesting Quality Control Reports

Buyers should request detailed QC reports, including test results and compliance certifications. These documents provide transparency regarding the supplier’s quality assurance practices and can help identify any historical issues with product performance or safety.

3. Engaging Third-Party Inspection Services

Utilizing third-party inspection services can add an extra layer of assurance. These independent organizations can conduct random inspections and testing of products before shipment, ensuring they meet specified standards and requirements.

What Are the QC and Certification Nuances for International B2B Buyers?

International B2B buyers must navigate various nuances in quality control and certification when sourcing DC air conditioners.

1. Understanding Regional Regulations

Different regions have specific regulations and standards that products must comply with. For instance, products sold in the European Union must meet CE marking requirements, while those in the United States may need to adhere to UL standards. Buyers should familiarize themselves with these regulations to avoid potential compliance issues.

2. Recognizing the Importance of Local Certifications

In addition to international standards, local certifications may be essential for market entry. For example, products intended for the Middle East may require specific certifications that align with regional energy efficiency standards. Understanding these nuances can help buyers make informed decisions and avoid costly delays in product acceptance.

3. Building Long-Term Relationships with Suppliers

Establishing strong relationships with suppliers can facilitate better communication regarding quality control processes. Engaging with suppliers who prioritize transparency and collaboration can lead to more reliable partnerships and enhanced product quality over time.

In summary, understanding the manufacturing processes and quality assurance practices of DC air conditioners is essential for B2B buyers. By focusing on the stages of manufacturing, quality control measures, and the importance of verification, buyers can make informed decisions that ensure the reliability and efficiency of their cooling solutions.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘air conditioner dc’

In today’s competitive market, sourcing the right DC air conditioner is essential for businesses looking to optimize cooling efficiency while minimizing energy costs. This practical checklist will guide B2B buyers through the necessary steps to make informed decisions when procuring DC air conditioning units.

Step 1: Define Your Technical Specifications

Understanding your specific cooling requirements is the first step in the sourcing process. Consider factors such as the size of the area to be cooled, the expected ambient temperature, and the type of installation (e.g., marine, off-grid). This clarity will help you identify the appropriate BTU capacity and voltage options, ensuring the selected unit meets operational needs.

Step 2: Research Energy Efficiency Ratings

Energy efficiency is a crucial factor for long-term cost savings and sustainability. Look for units with high Energy Efficiency Ratio (EER) and Seasonal Energy Efficiency Ratio (SEER) ratings. Units with advanced features like variable speed compressors can significantly reduce energy consumption, making them a more economical choice over time.

Step 3: Evaluate Supplier Certifications

Before committing to a supplier, verify their industry certifications and compliance with international standards. Certifications such as ISO 9001 for quality management or specific energy efficiency certifications can indicate a supplier’s commitment to quality. Additionally, check if the products comply with local regulations in your target market, especially in regions with stringent energy efficiency laws.

Step 4: Assess Product Features and Durability

Investigate the features that enhance product longevity and performance. Look for units constructed with materials resistant to corrosion, especially for marine or harsh environments. Features like antimicrobial evaporators and high static pressure blowers can improve air quality and system efficiency, making them advantageous for both comfort and health.

Step 5: Request Detailed Product Documentation

Always ask for comprehensive product specifications, installation manuals, and warranty information. Detailed documentation helps ensure that the unit can be properly integrated into your existing systems and provides clarity on maintenance requirements. Understanding the warranty terms, such as lifetime coverage on compressors, can also influence your decision.

Step 6: Seek References and Case Studies

Request references from previous clients who have purchased similar units. Case studies can provide insights into the performance and reliability of the air conditioners in real-world applications. This information is invaluable in assessing how well the product will meet your specific operational needs and challenges.

Step 7: Compare Pricing and Payment Terms

Finally, conduct a thorough comparison of pricing and payment options from different suppliers. While the initial cost is important, consider the total cost of ownership, including maintenance and energy consumption. Look for flexible payment terms or bulk purchase discounts that can enhance your procurement strategy and improve cash flow.

By following these steps, B2B buyers can confidently navigate the sourcing process for DC air conditioners, ensuring they select the right units that meet both operational requirements and budget constraints.

Comprehensive Cost and Pricing Analysis for air conditioner dc Sourcing

What Are the Key Cost Components in Air Conditioner DC Sourcing?

When evaluating the cost structure of DC air conditioners, several components come into play. The primary costs include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials significantly impacts the overall cost. High-quality components, such as copper evaporators and stainless steel chassis, enhance durability and efficiency but also increase upfront costs.

-

Labor: Labor costs can vary based on the region where the units are manufactured. Countries with higher wage standards may see increased production costs, while those with lower labor costs can offer competitive pricing.

-

Manufacturing Overhead: This includes expenses related to the factory environment, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce these costs.

-

Tooling: The initial investment in tooling for production lines can be substantial. Custom designs or specialized units may require additional tooling costs, impacting the final pricing.

-

Quality Control (QC): Rigorous QC processes are essential to ensure product reliability. These costs are often factored into the price, particularly for high-end units that require certification for international markets.

-

Logistics: Shipping costs, including freight, customs duties, and insurance, can significantly affect total costs. International buyers must consider these factors in their sourcing strategies.

-

Margin: Manufacturers typically apply a profit margin to cover their operational risks. This margin can vary based on market conditions and competition.

How Do Price Influencers Affect DC Air Conditioner Costs?

Several factors influence the pricing of DC air conditioners, particularly in international markets:

-

Volume/MOQ: Minimum order quantities (MOQ) can affect pricing. Bulk purchases usually lead to discounts, making it beneficial for larger buyers to negotiate for lower unit prices.

-

Specifications and Customization: Customized units with specific features or specifications often come at a premium. Buyers must balance their needs for customization against their budget constraints.

-

Materials: The selection of materials directly affects pricing. For example, using eco-friendly or high-efficiency components may incur higher costs but can lead to long-term savings in energy consumption.

-

Quality and Certifications: Products with recognized quality certifications (such as ISO or CE) may be priced higher due to the assurance of quality and compliance with international standards.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may command higher prices due to their proven track record.

-

Incoterms: The agreed-upon Incoterms can significantly impact total costs. Buyers should understand terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) to anticipate shipping and risk management costs.

What Are Essential Buyer Tips for Cost-Efficiency in DC Air Conditioner Sourcing?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, several strategies can enhance cost efficiency:

-

Negotiate Wisely: Always negotiate pricing, particularly if purchasing in bulk. Leverage market research to understand typical pricing structures and establish a strong negotiation position.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the initial purchase price but also operational costs, maintenance, and energy efficiency. A higher upfront investment in quality units can lead to lower long-term costs.

-

Understand Pricing Nuances: Be aware of regional pricing differences and the impact of local tariffs and taxes. This knowledge can aid in making informed purchasing decisions.

-

Seek Reliable Suppliers: Partnering with reputable suppliers can mitigate risks associated with product quality and delivery timelines. Always check references and certifications before finalizing agreements.

-

Plan Logistics Efficiently: Understand logistics costs and timing to avoid unexpected expenses. Work with suppliers who have established shipping routes and can provide competitive freight options.

Disclaimer on Indicative Prices

The prices mentioned in sourcing discussions may vary based on market fluctuations, supplier conditions, and specific buyer requirements. Always obtain updated quotes and consider all cost components when making purchasing decisions.

Alternatives Analysis: Comparing air conditioner dc With Other Solutions

Introduction to Alternative Air Conditioning Solutions

In the quest for effective cooling solutions, businesses often evaluate various technologies to meet their specific requirements. Air conditioner DC systems are popular for their efficiency and adaptability, particularly in off-grid or marine applications. However, alternatives such as conventional air conditioners, battery-powered units, and solar-powered systems may also be considered. This analysis aims to provide B2B buyers with a clear comparison of these options to facilitate informed decision-making.

| Comparison Aspect | Air Conditioner DC | Battery-Powered Air Conditioner | Solar-Powered Air Conditioner |

|---|---|---|---|

| Performance | High efficiency, variable speed | Good cooling, dependent on battery life | Extremely efficient, ideal for off-grid |

| Cost | Moderate initial investment | Higher upfront costs due to batteries | Varies; initial investment can be high but long-term savings are possible |

| Ease of Implementation | Requires professional installation | Relatively easy installation; portable | More complex setup involving solar panels |

| Maintenance | Low maintenance, long lifespan | Moderate; battery replacement needed | Low, but requires upkeep of solar components |

| Best Use Case | Marine and off-grid applications | RVs, remote sites, heavy equipment | Off-grid homes, remote telecom stations |

What Are the Pros and Cons of Battery-Powered Air Conditioners?

Battery-powered air conditioners, such as those from Cruise N Comfort, provide an efficient cooling solution by drawing power directly from batteries. The primary advantage is their portability and ease of installation, making them suitable for RVs and remote work sites. However, the dependence on battery capacity can limit cooling duration, especially in extreme heat conditions. This solution may incur higher initial costs due to the need for robust batteries, which may affect cost-effectiveness in the long run.

How Do Solar-Powered Air Conditioners Compare?

Solar-powered air conditioners, like those offered by HotSpot Energy, are designed to operate using solar energy, making them an excellent choice for off-grid applications. They boast exceptional energy efficiency and minimal operational costs after installation. However, the initial investment can be significant, as it involves purchasing solar panels and related equipment. Furthermore, the effectiveness of these units is highly dependent on sunlight availability, which may not be consistent in certain regions.

Conclusion: Which Air Conditioning Solution Is Right for Your Business?

When choosing between air conditioner DC systems and alternatives such as battery-powered or solar-powered units, businesses should consider specific operational requirements, environmental conditions, and long-term cost implications. For marine or off-grid applications, air conditioner DC systems may provide unmatched efficiency and reliability. In contrast, battery-powered units can offer flexibility for mobile operations, while solar-powered systems can deliver sustainable cooling solutions for those looking to minimize their environmental impact. By carefully evaluating these factors, B2B buyers can select the most suitable air conditioning solution that aligns with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for air conditioner dc

What Are the Key Technical Properties of DC Air Conditioners?

When evaluating DC air conditioners, several critical specifications are essential for B2B buyers to understand. These properties not only influence performance but also impact the longevity and efficiency of the units.

-

Cooling Capacity (BTU): This specification indicates the unit’s ability to cool a space, measured in British Thermal Units (BTU). A higher BTU rating means a greater cooling capacity, which is vital for large spaces or regions with extreme temperatures. Understanding the required BTU for specific applications helps buyers select the right unit to optimize energy usage and comfort.

-

Operating Voltage: DC air conditioners typically operate at specific voltages, such as 12V, 24V, or 48V. This characteristic is crucial for compatibility with existing electrical systems, particularly in off-grid or renewable energy applications. Ensuring the correct voltage can prevent electrical failures and enhance energy efficiency.

-

Compressor Type: The compressor is the heart of any air conditioning system. DC air conditioners often use variable speed compressors, which adjust their operation based on cooling demand. This technology leads to reduced energy consumption and quieter operation, making it an attractive feature for many buyers focused on sustainability and noise reduction.

-

Material Durability: The materials used in construction, such as stainless steel and copper, significantly affect the unit’s resistance to corrosion and wear. High-grade materials ensure longevity and reliability, especially in harsh environments like marine or industrial settings. Buyers should prioritize units with robust construction to minimize maintenance costs.

-

Energy Efficiency Ratio (EER): This ratio measures the cooling output divided by the energy input, indicating how efficiently a unit operates. A higher EER signifies lower operational costs, making energy-efficient units more appealing to budget-conscious businesses. Buyers should compare EER ratings when making purchasing decisions to ensure long-term savings.

-

Warranty and Support: The warranty offered by manufacturers can vary significantly. Understanding the terms of warranty, including duration and coverage details, is essential for risk management. A comprehensive warranty can provide peace of mind and indicate the manufacturer’s confidence in their product.

What Are Common Trade Terms in the DC Air Conditioning Industry?

Familiarizing oneself with industry jargon can streamline the procurement process and facilitate better communication with suppliers.

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce components or products that are sold under another company’s brand name. In the context of DC air conditioners, OEM relationships can ensure that components meet specific quality standards and performance metrics.

-

MOQ (Minimum Order Quantity): MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, as it affects inventory management and initial investment costs. Negotiating lower MOQs can be beneficial for smaller businesses or those testing new products.

-

RFQ (Request for Quotation): An RFQ is a formal document sent to suppliers requesting pricing and availability for specific products. This process is essential for comparing multiple suppliers and obtaining the best value. Crafting a precise RFQ helps ensure accurate responses that align with project requirements.

-

Incoterms (International Commercial Terms): These are standardized terms used in international trade to clarify the responsibilities of buyers and sellers. Understanding Incoterms is vital for B2B transactions, as they dictate who is responsible for shipping, insurance, and tariffs, ultimately affecting total cost calculations.

-

Lead Time: This term refers to the time it takes from placing an order to the delivery of the product. Knowing lead times is essential for planning and inventory management, especially for projects with tight deadlines. Buyers should communicate clearly with suppliers to establish realistic expectations.

-

After-Sales Support: This encompasses the services provided by manufacturers or suppliers after the purchase, including installation, maintenance, and troubleshooting. Strong after-sales support can enhance customer satisfaction and ensure the longevity of the air conditioning units, making it a key consideration for B2B buyers.

By understanding these technical properties and trade terms, international B2B buyers can make informed decisions, optimize procurement processes, and enhance operational efficiencies when purchasing DC air conditioners.

Navigating Market Dynamics and Sourcing Trends in the air conditioner dc Sector

What Are the Key Market Drivers and Trends Impacting the Air Conditioner DC Sector?

The air conditioner DC sector is witnessing a transformative phase driven by several global factors. Increasing urbanization and rising temperatures across regions, particularly in Africa, South America, the Middle East, and Europe, are compelling businesses to seek efficient cooling solutions. The surge in demand for energy-efficient appliances is also a significant driver, as both consumers and businesses prioritize lower energy consumption and reduced operational costs. Furthermore, advancements in technology, such as variable speed compressors and eco-friendly refrigerants, are enhancing the performance and sustainability of DC air conditioners.

Emerging trends in sourcing are leaning towards integrated solutions that combine air conditioning with renewable energy sources, such as solar power. This is particularly relevant for markets with unreliable electricity supply, making battery and solar-powered DC air conditioners an attractive option. In addition, the shift towards modular and customizable systems allows businesses to tailor solutions to specific operational needs, making procurement more strategic. International buyers are increasingly looking for suppliers that can provide not just products, but comprehensive systems that include installation and maintenance support.

How Can Sustainability and Ethical Sourcing Shape B2B Purchasing Decisions in the Air Conditioner DC Market?

Sustainability is becoming a cornerstone of purchasing decisions in the air conditioner DC market. The environmental impact of traditional cooling systems has prompted buyers to seek alternatives that minimize their carbon footprint. DC air conditioners are often more energy-efficient than their AC counterparts, leading to lower greenhouse gas emissions and energy costs over time.

Ethical sourcing is equally critical, as businesses become more aware of the social and environmental ramifications of their supply chains. Buyers are increasingly favoring manufacturers that adhere to sustainable practices and offer certifications such as ENERGY STAR, which signify compliance with energy efficiency standards. Furthermore, the use of recyclable materials and sustainable production methods is gaining traction, appealing to eco-conscious businesses. By prioritizing sustainability and ethical sourcing, B2B buyers not only enhance their brand reputation but also contribute positively to environmental conservation.

How Has the Air Conditioner DC Sector Evolved Over Time?

The evolution of the air conditioner DC sector is marked by significant technological advancements and changing consumer preferences. Initially, DC air conditioners were primarily used in niche markets, such as marine applications and off-grid living. However, as energy costs rose and climate change became a pressing concern, the demand for energy-efficient solutions expanded across various sectors, including residential, commercial, and industrial applications.

Modern DC air conditioners are now designed with advanced features such as variable speed compressors, smart controls, and compatibility with renewable energy systems. These innovations have made them more accessible and appealing to a broader audience, fostering growth in international markets. As energy efficiency and sustainability continue to shape the future of the HVAC industry, the DC air conditioner segment is poised for further expansion, offering significant opportunities for B2B buyers to invest in innovative, eco-friendly solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of air conditioner dc

-

How do I choose the right DC air conditioner for my business needs?

Selecting the right DC air conditioner involves assessing your specific cooling requirements, such as the size of the space, climate conditions, and energy sources. Consider the BTU capacity needed for efficient cooling; larger spaces may require units with higher BTU ratings. Additionally, evaluate the energy efficiency ratings to minimize operational costs. Consulting with manufacturers or distributors can provide valuable insights into models best suited for your application, whether it’s for marine, off-grid, or commercial settings. -

What are the advantages of using DC air conditioners over traditional AC units?

DC air conditioners offer several advantages, including higher energy efficiency, quieter operation, and the ability to run directly off batteries or solar power. This makes them ideal for off-grid applications and environments where noise reduction is crucial. Additionally, many DC units feature variable speed compressors, allowing them to adjust cooling output based on demand, which further enhances energy savings and reduces wear on components. -

What customization options are available for DC air conditioners?

Many manufacturers provide customization options to cater to specific business needs. Customization can include varying voltage levels (12V, 24V, 48V), different BTU capacities, and specialized features like remote controls or corrosion-resistant coatings. It’s advisable to discuss your requirements with suppliers during the purchasing process to ensure that the unit meets your operational needs and complies with local regulations. -

What is the typical minimum order quantity (MOQ) for DC air conditioners?

The minimum order quantity for DC air conditioners can vary significantly among manufacturers and suppliers. Typically, MOQs range from a few units to several dozen, depending on the product line and the supplier’s production capabilities. Larger orders may also qualify for volume discounts. It is essential to communicate with potential suppliers early in the negotiation process to understand their specific MOQ policies and any associated pricing incentives. -

How do I ensure the quality and reliability of the DC air conditioners I purchase?

To ensure quality and reliability, research potential suppliers thoroughly. Look for manufacturers with a proven track record and positive customer reviews. Request certifications such as ISO or CE to verify compliance with international standards. Additionally, inquire about warranty terms; reputable suppliers often offer warranties that cover the unit and key components, providing peace of mind regarding the longevity and performance of your purchase. -

What payment terms should I expect when sourcing DC air conditioners internationally?

Payment terms can vary widely based on the supplier and the size of your order. Common terms include advance payment, letters of credit, or payment upon delivery. It is crucial to negotiate terms that suit your cash flow and risk tolerance while ensuring they are aligned with industry standards. Always confirm the payment methods accepted by the supplier, as some may prefer wire transfers or credit terms based on established relationships. -

How should I handle logistics and shipping for my DC air conditioner order?

When sourcing DC air conditioners, it’s important to discuss logistics with your supplier. Confirm who will handle shipping, the expected delivery timelines, and the associated costs. Ensure that the units are packaged appropriately to withstand transit conditions, especially for international shipping. Consider working with a freight forwarder experienced in handling air conditioning equipment to streamline the process and navigate customs regulations effectively. -

What are the common challenges faced in international trade for DC air conditioners?

Common challenges in international trade include navigating varying regulations and standards across different countries, customs clearance delays, and potential tariffs. Additionally, language barriers and cultural differences can complicate negotiations. To mitigate these issues, work with suppliers who have experience in international markets and consider hiring local experts or consultants who can provide insights into the regulatory landscape and help facilitate smoother transactions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Air Conditioner Dc Manufacturers & Suppliers List

1. Mabru Power Systems – Marine Air Conditioning Units

Domain: mabrustore.com

Introduction: This company, Mabru Power Systems – Marine Air Conditioning Units, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Hotspot Energy – DC Air Conditioners

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: DC air conditioners from Hotspot Energy are designed for high efficiency and operate on solar power during the day, with the capability to charge batteries for extended use into the evening. The system is self-contained, requires no inverter, and does not consume grid power. The cost of the system is approximately $5,000, with additional costs for batteries not included in the package. Users have …

3. Hotspot Energy – DC4812VRF Air Conditioner

Domain: hotspotenergy.com

Registered: 2010 (15 years)

Introduction: DC4812VRF Air Conditioner

– Type: 12,000 BTU DC Air Conditioner for Off-Grid Solar & Telecom Applications

– Power Source: Native 48VDC (or -48VDC)

– Efficiency: All-DC system for high efficiency without inverters

– Features:

– Variable capacity, variable speed, variable refrigerant flow

– SeaSpray Anti-Corrosion technology for protection against salt air corrosion

– Designed for reliable op…

4. B-COOL – DC Powered Air Conditioners

Domain: dcpowersales.com

Registered: 2004 (21 years)

Introduction: B-COOL AIR CONDITIONERS: 12V, 24V, 48V DC Powered Air Conditioners. Models include: B-COOL6RM ($1,925.00), B-COOL9RM ($1,995.00), B-COOL 12RMDUALFAN ($2,175.00), B-COOLX7RM ($2,095.00), B-COOL12RV ($1,995.00), B-COOLFLEX ($1,775.00), B-COOLWMB ($1,775.00), B-COOLRF ($1,925.00). Applications in agriculture, construction, trucking, warehousing, waste management, forestry, military, marine, and recre…

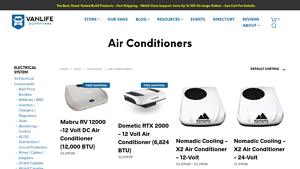

5. Mabru – RV 12000 Air Conditioner

Domain: vanlifeoutfitters.com

Registered: 2017 (8 years)

Introduction: {“products”: [{“name”: “Mabru RV 12000 -12 Volt DC Air Conditioner”,”price”: “$2,399.00″,”BTU”: “12,000”,”shipping”: “Free”},{“name”: “Dometic RTX 2000 – 12 Volt Air Conditioner”,”price”: “$2,399.99″,”BTU”: “6,824”,”shipping”: “Free”},{“name”: “Nomadic Cooling – X2 Air Conditioner – 12-Volt”,”price_range”: “$3,075.00 – $3,175.00″,”shipping”: “Free”},{“name”: “Nomadic Cooling – X2 Air Conditioner –…

6. B-COOL – DC Powered Air Conditioning Systems

Domain: bcoolaircon.com

Registered: 2020 (5 years)

Introduction: B-COOL AIR CONDITIONERS offers a range of 12V, 24V, and 48V DC powered air conditioning systems suitable for various applications. Key products include:

– B-COOL6RM: US$1,925.00 / CA$2,000.00

– B-COOL9RM: US$1,995.00 / CA$2,100.00

– B-COOL 12RMDUALFAN: US$2,175.00 / CA$2,450.00

– B-COOLX7RM: US$2,095.00 / CA$2,100.00

– B-COOL12RV: US$1,995.00 / CA$2,250.00

– B-COOL6RV: US$1,925.00 / CA$2,000…

Strategic Sourcing Conclusion and Outlook for air conditioner dc

In navigating the evolving landscape of DC air conditioning solutions, international B2B buyers must prioritize strategic sourcing to maximize efficiency, cost-effectiveness, and reliability. The demand for high-efficiency, environmentally friendly systems is on the rise, particularly in regions like Africa, South America, the Middle East, and Europe, where energy sustainability is paramount. By partnering with reputable manufacturers that offer advanced technologies—such as variable speed compressors and anti-corrosive designs—buyers can ensure they are investing in products that not only meet their cooling needs but also withstand challenging climates.

Furthermore, the integration of solar and battery-powered systems presents a lucrative opportunity for businesses looking to reduce operational costs while enhancing their environmental stewardship. As the market continues to innovate, leveraging comprehensive supplier networks and understanding regional specifications will be crucial for making informed purchasing decisions.

Looking ahead, we encourage international buyers to engage proactively with suppliers, explore diverse product offerings, and consider the long-term benefits of investing in advanced DC air conditioning technologies. By doing so, you can position your organization as a leader in energy-efficient solutions and contribute to a more sustainable future.