Adjustable Connector Clamp Square 1 3/8 Explained: From A to Z for B2B Buyers

Introduction: Navigating the Global Market for adjustable connector clamp square 1 3/8

In the fast-paced world of international manufacturing and construction, sourcing high-quality adjustable connector clamps, particularly the square 1 3/8 variant, presents a significant challenge for B2B buyers. With diverse material options, varying specifications, and a multitude of suppliers, making an informed purchasing decision can be daunting. This guide aims to streamline that process, offering insights into the different types of adjustable connector clamps available, their various applications across industries, and key considerations for supplier vetting.

We delve into the intricacies of material choices, such as aluminum, stainless steel, and plastic, alongside the advantages of each for specific applications. Additionally, we address cost considerations, helping buyers navigate pricing structures that align with their budgetary constraints. By focusing on the unique needs of international buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Germany and Nigeria—this guide empowers procurement professionals to make strategic decisions that enhance operational efficiency.

Armed with this comprehensive resource, B2B buyers can confidently approach the global market for adjustable connector clamps, ensuring that their selections not only meet technical requirements but also support their business goals in a competitive landscape.

Understanding adjustable connector clamp square 1 3/8 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Two-Way Connector Clamp | Connects two pipes at a right angle; available in various materials | Structural frames, support systems | Pros: Versatile, easy to install. Cons: Limited to two connections. |

| Flanged Connector Clamp | Features flanges for mounting; offers robust connection options | Machinery, industrial equipment | Pros: High stability, secure mounting. Cons: Requires precise alignment. |

| Base Plate Connector Clamp | Includes a base plate for added support; ideal for heavy loads | Heavy machinery, scaffolding | Pros: Enhanced load-bearing capacity. Cons: Bulkier design may limit flexibility. |

| Swivel Connector Clamp | Allows for angular adjustments; great for dynamic applications | Automotive, robotics | Pros: Flexibility in positioning. Cons: More complex installation. |

| Split Assembly Connector Clamp | Facilitates easy assembly/disassembly; ideal for maintenance | Temporary structures, modular setups | Pros: Time-saving for maintenance. Cons: Potentially less rigid. |

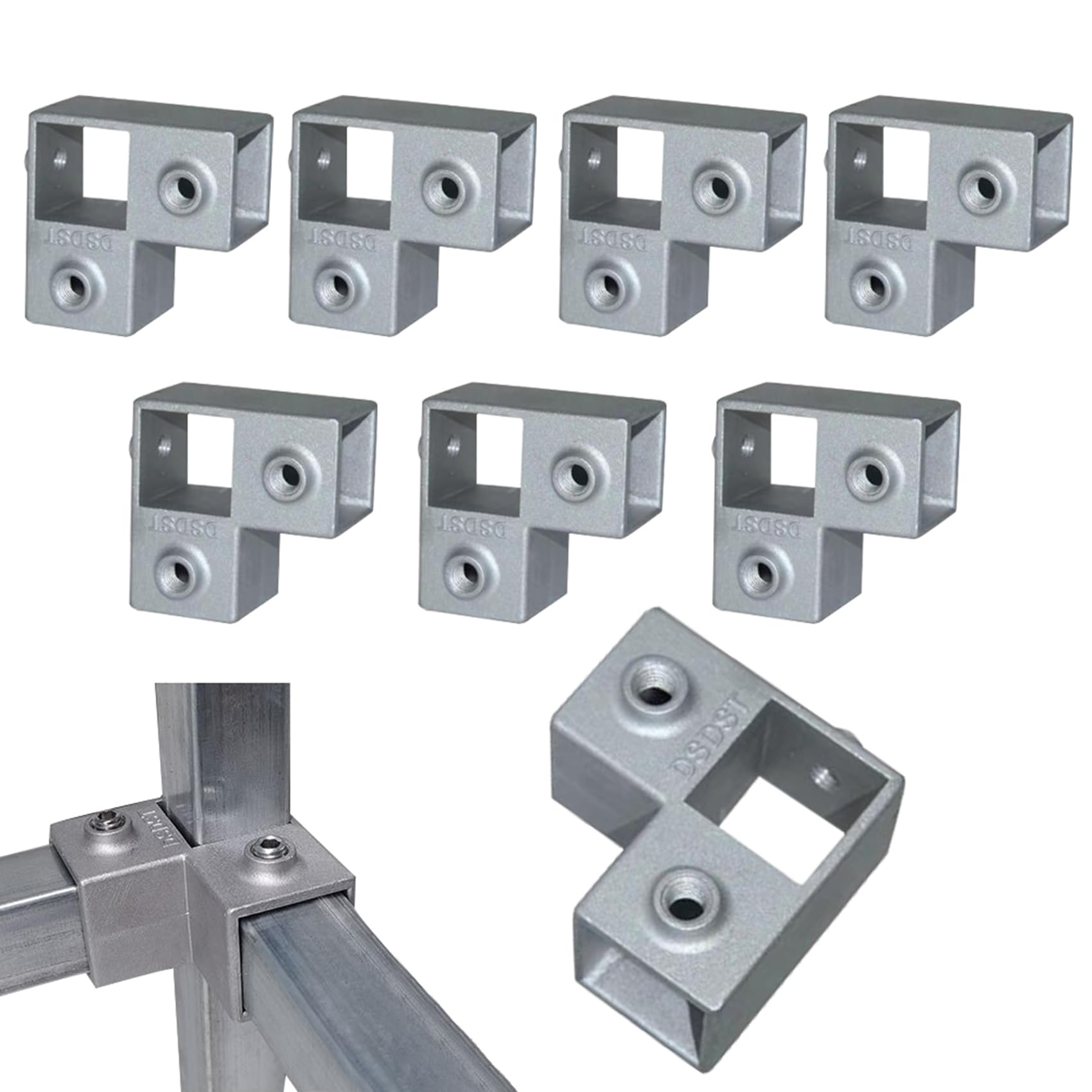

What Are the Characteristics of Two-Way Connector Clamps?

Two-way connector clamps are designed to connect two square pipes at a right angle, making them essential for creating robust structural frameworks. Typically available in materials such as aluminum and stainless steel, these clamps can support various applications, including the assembly of frames and support systems. When purchasing, buyers should consider the material’s strength and corrosion resistance, especially if used in outdoor or industrial settings. Their ease of installation is a significant advantage for projects requiring quick assembly.

How Do Flanged Connector Clamps Enhance Stability?

Flanged connector clamps incorporate flanges that facilitate secure mounting to surfaces, providing a stable and rigid connection. This type of clamp is particularly useful in applications involving machinery and industrial equipment where stability is paramount. Buyers should assess the flange size and mounting hole configuration to ensure compatibility with their existing setups. While offering excellent stability, flanged clamps require precise alignment during installation, which may demand additional labor.

Why Choose Base Plate Connector Clamps for Heavy Loads?

Base plate connector clamps are engineered to provide additional support through a sturdy base plate, making them ideal for applications involving heavy loads, such as scaffolding and heavy machinery. This type of clamp allows for secure attachment to floors or other surfaces, enhancing overall load-bearing capacity. Buyers should focus on the material specifications and load ratings when selecting base plate clamps to ensure safety and compliance with industry standards. However, their bulkier design might limit the flexibility of configurations.

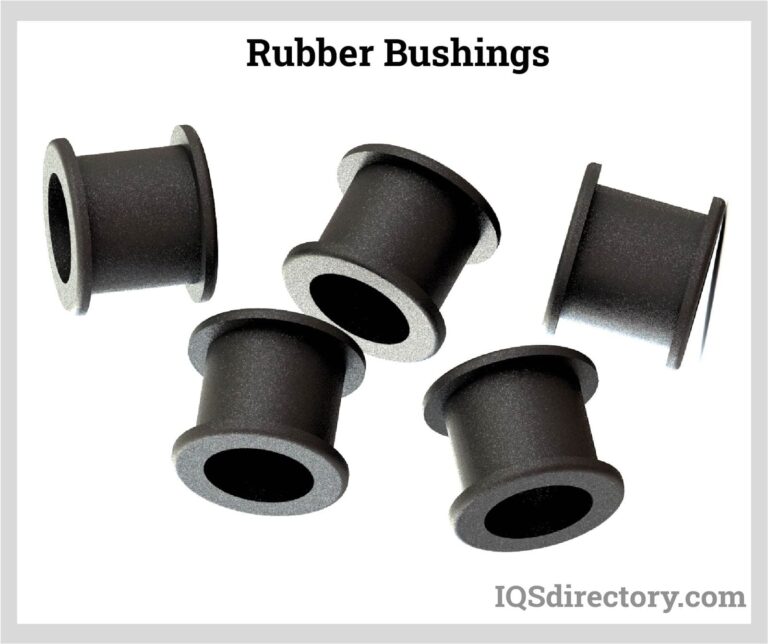

Illustrative image related to adjustable connector clamp square 1 3/8

What Advantages Do Swivel Connector Clamps Offer?

Swivel connector clamps are uniquely designed to allow for angular adjustments, making them suitable for dynamic applications in automotive and robotics sectors. These clamps facilitate flexibility in positioning, enabling users to achieve optimal angles for their installations. When purchasing swivel clamps, buyers should consider the range of motion and locking mechanisms to ensure reliability during operation. While providing significant flexibility, the complexity of installation may deter some users.

How Do Split Assembly Connector Clamps Benefit Maintenance?

Split assembly connector clamps are designed for easy assembly and disassembly, making them particularly beneficial for temporary structures or modular setups. This feature allows for quick maintenance and reconfiguration, which is advantageous in environments where flexibility is essential. Buyers should evaluate the ease of disassembly and the clamp’s ability to maintain rigidity when reassembled. Although they save time during maintenance, split assembly clamps may be less rigid compared to traditional designs, which could impact long-term stability.

Key Industrial Applications of adjustable connector clamp square 1 3/8

| Industry/Sector | Specific Application of adjustable connector clamp square 1 3/8 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Assembly of modular structures and frameworks for machinery | Enhances structural integrity and flexibility in design | Material durability, load capacity, and corrosion resistance |

| Construction | Support and mounting systems for scaffolding and temporary structures | Provides secure and adjustable support for safety | Compliance with local regulations and safety standards |

| Renewable Energy | Installation of solar panel support systems | Facilitates quick adjustments for optimal panel positioning | Weather resistance and adaptability to various terrains |

| Automotive | Framework for custom vehicle builds and modifications | Allows for rapid prototyping and adjustments | Compatibility with various tubing materials and sizes |

| Telecommunications | Mounting systems for antennas and communication towers | Ensures stability and ease of maintenance | Sourcing from certified manufacturers for reliability |

How is the Adjustable Connector Clamp Square 1 3/8 Used in Manufacturing?

In manufacturing, the adjustable connector clamp square 1 3/8 is essential for assembling modular structures, such as machinery frames and conveyor systems. These clamps allow manufacturers to create flexible and robust configurations that can be easily adjusted or reconfigured as production needs change. For international buyers, particularly in regions like Africa and South America, sourcing high-quality clamps that meet specific load capacities and material requirements is crucial to ensure operational efficiency and safety.

What Role Does the Adjustable Connector Clamp Play in Construction?

In the construction sector, these clamps are widely used for scaffolding and temporary structures, providing secure connections that are critical for worker safety. Their adjustable nature allows for quick setup and takedown, which is vital in fast-paced construction environments. Buyers from Europe, such as Germany, should consider compliance with local safety standards and the environmental conditions of the project site when sourcing these clamps to ensure they meet all necessary regulations.

How Does the Adjustable Connector Clamp Benefit Renewable Energy Projects?

For renewable energy applications, particularly in solar energy, the adjustable connector clamp square 1 3/8 is used in the installation of solar panel support systems. These clamps allow for precise adjustments to optimize the angle of solar panels, enhancing energy capture. Buyers in the Middle East and Africa should focus on sourcing clamps that offer durability against harsh weather conditions and corrosion, ensuring long-term reliability in outdoor installations.

Why is the Adjustable Connector Clamp Important for Automotive Applications?

In the automotive industry, these clamps facilitate the construction of custom vehicle frameworks. They enable manufacturers and custom builders to create adaptable designs that can be easily modified. This flexibility is particularly beneficial for international buyers looking to innovate or prototype new vehicle designs. It’s essential to ensure compatibility with various tubing materials and sizes to meet diverse automotive requirements.

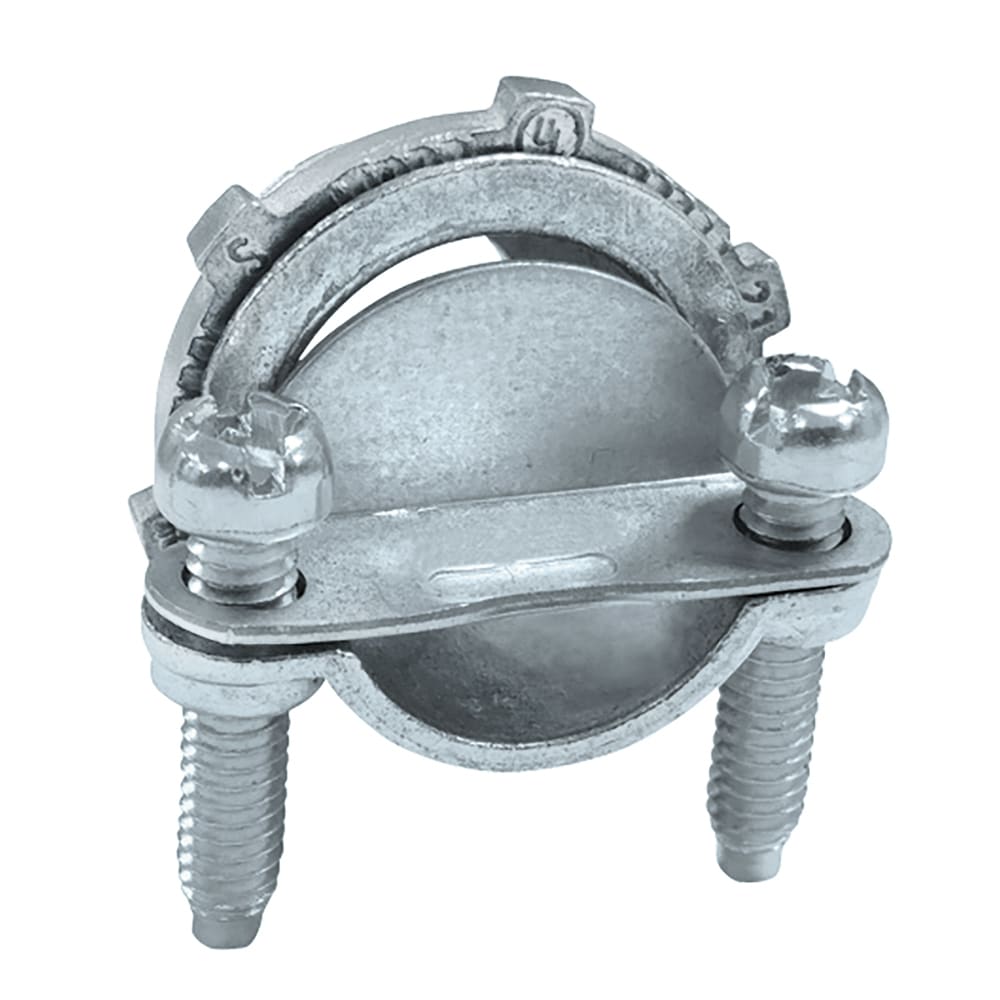

Illustrative image related to adjustable connector clamp square 1 3/8

What is the Importance of Adjustable Connector Clamps in Telecommunications?

In telecommunications, adjustable connector clamps are vital for mounting antennas and communication towers. They provide stability and ease of maintenance, allowing technicians to make necessary adjustments without extensive downtime. Buyers should prioritize sourcing clamps from certified manufacturers to guarantee reliability and performance, especially in regions where infrastructure development is rapidly advancing, such as in parts of Africa and South America.

3 Common User Pain Points for ‘adjustable connector clamp square 1 3/8’ & Their Solutions

Scenario 1: Difficulty in Ensuring Proper Fit and Compatibility

The Problem: B2B buyers often encounter challenges when selecting adjustable connector clamps for specific applications, particularly in ensuring a proper fit with existing structures. For instance, if a buyer is sourcing clamps for a project involving 1 3/8″ square tubing, they may find that not all clamps are created equal. Variations in manufacturing tolerances, finishes, and materials can lead to compatibility issues. This can result in delays, increased costs, and frustration as teams work to resolve discrepancies in fittings that should ideally work seamlessly together.

The Solution: To avoid such pitfalls, it is crucial to conduct thorough research when sourcing adjustable connector clamps. Buyers should focus on suppliers who provide detailed specifications, including dimensions, tolerances, and material compositions. Utilizing a standardized measurement approach, such as ensuring that the clamp’s inner diameter matches the outer diameter of the tubing, can help in selecting the right product. Additionally, requesting samples or detailed product drawings can mitigate risks. Collaborating with manufacturers who offer custom solutions can also ensure that the clamps meet specific project requirements, reducing the likelihood of compatibility issues.

Scenario 2: Challenges with Installation and Assembly

The Problem: Another common pain point is the complexity involved in the installation and assembly of adjustable connector clamps. For many international buyers, particularly in regions with varying levels of technical expertise, the process can be daunting. Misalignment during installation can lead to structural weaknesses or even failure of the assembly, causing safety concerns and project delays.

The Solution: To streamline installation, it is beneficial for buyers to invest in training or instructional materials provided by manufacturers. Many suppliers offer installation guides, videos, or on-site training sessions to educate the installation teams on best practices. Additionally, choosing clamps that feature user-friendly designs, such as those with quick-release mechanisms or intuitive assembly processes, can significantly reduce installation time and errors. Engaging local experts or contractors who are familiar with the product can also help ensure that installations are carried out correctly, thus enhancing safety and efficiency.

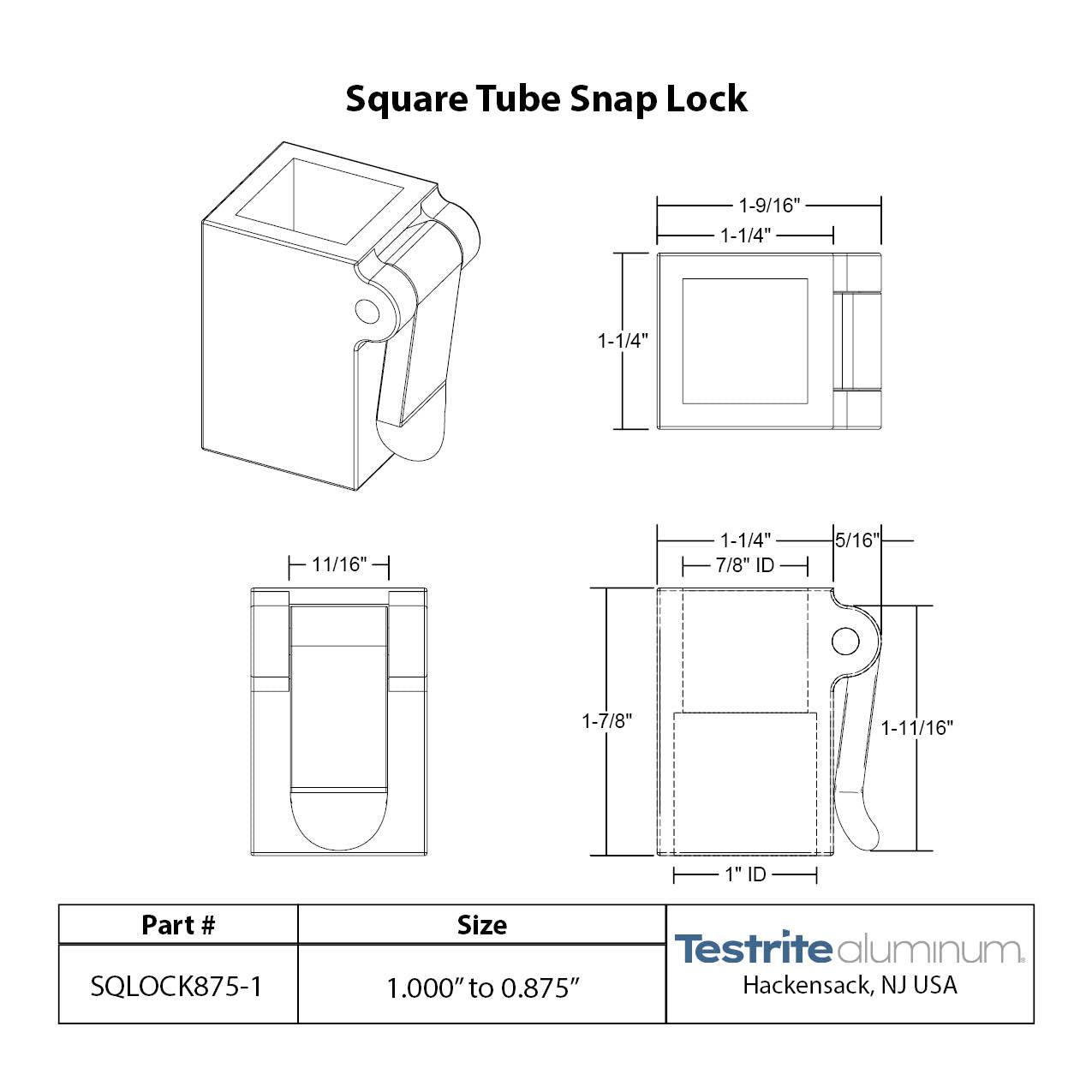

Illustrative image related to adjustable connector clamp square 1 3/8

Scenario 3: Cost Management and Bulk Sourcing Issues

The Problem: B2B buyers often face budget constraints, particularly when dealing with large-scale projects that require numerous adjustable connector clamps. Fluctuations in pricing, combined with the need for reliable suppliers who can deliver on time, can complicate procurement strategies. Buyers may find themselves struggling to balance quality with cost-effectiveness, leading to potential compromises that could affect overall project integrity.

The Solution: To effectively manage costs, buyers should consider developing long-term relationships with trusted suppliers who can offer bulk pricing discounts. This not only ensures better pricing but also fosters reliability in supply chains. Buyers should also explore options such as consignment inventory or blanket purchase agreements, which can help stabilize costs over time. Additionally, implementing an inventory management system can aid in tracking usage and forecasting future needs, allowing for more strategic purchasing decisions. Regularly reviewing supplier contracts for opportunities to renegotiate terms based on usage can further enhance cost efficiency.

Strategic Material Selection Guide for adjustable connector clamp square 1 3/8

What Are the Key Materials for Adjustable Connector Clamps Square 1 3/8″?

When selecting materials for adjustable connector clamps, particularly the square 1 3/8″ variety, it’s essential to consider the properties and performance of various materials. The choice of material can significantly impact durability, cost, and compatibility with specific applications. Below is an analysis of four common materials used in the manufacturing of these clamps.

1. Aluminum

Key Properties: Aluminum is lightweight yet strong, with excellent corrosion resistance. It typically withstands temperatures up to 150°C (302°F) and has good thermal conductivity.

Pros & Cons: The primary advantage of aluminum is its low weight, making it easy to handle and install. It is also cost-effective compared to stainless steel. However, aluminum may not be suitable for high-stress applications or environments with extreme temperatures, as it can deform under excessive load.

Illustrative image related to adjustable connector clamp square 1 3/8

Impact on Application: Aluminum clamps are ideal for applications in dry environments, such as indoor frameworks or lightweight structures. They are not recommended for use in marine or highly corrosive environments.

Considerations for International Buyers: Compliance with international standards like ASTM and DIN is crucial. Buyers in regions such as Germany and Nigeria should ensure that the aluminum used meets local regulations regarding material quality and environmental impact.

2. Stainless Steel

Key Properties: Stainless steel offers superior strength and excellent corrosion resistance, making it suitable for harsh environments. It can withstand temperatures up to 800°C (1472°F) and is often used in food and pharmaceutical applications due to its non-reactive nature.

Pros & Cons: The key advantage of stainless steel is its durability and resistance to corrosion, making it suitable for outdoor and industrial applications. However, it is heavier and more expensive than aluminum, which may increase shipping costs and installation complexity.

Impact on Application: Stainless steel clamps are ideal for applications exposed to moisture, chemicals, or extreme temperatures, such as in oil and gas industries or coastal regions.

Considerations for International Buyers: Buyers should look for compliance with ASTM A276 or similar standards. In regions like South America and the Middle East, where humidity can be high, stainless steel is often preferred due to its longevity.

3. Plastic (Polyamide)

Key Properties: Plastic clamps, particularly those made from polyamide, are lightweight and resistant to a wide range of chemicals. They typically operate well in temperatures up to 100°C (212°F).

Pros & Cons: The main advantage of plastic clamps is their resistance to corrosion and chemicals, making them suitable for various environments. However, they may not provide the same level of strength as metal options and can be less durable under high-stress conditions.

Impact on Application: Plastic clamps are ideal for applications involving corrosive substances or where weight is a critical factor, such as in electrical installations.

Considerations for International Buyers: Compliance with international standards like ISO 9001 is important for ensuring quality. Buyers in Africa may prefer plastic clamps for their cost-effectiveness in low-stress applications.

4. Carbon Steel

Key Properties: Carbon steel is known for its high strength and durability. It can withstand high pressures and is often treated with coatings for corrosion resistance.

Pros & Cons: The primary advantage of carbon steel is its strength and affordability. However, it is prone to rusting if not properly coated, making it less suitable for outdoor applications without protective finishes.

Impact on Application: Carbon steel clamps are commonly used in structural applications where strength is paramount, such as in construction and heavy machinery.

Considerations for International Buyers: Buyers should ensure that carbon steel products comply with ASTM A36 or similar standards. In regions like Europe, where environmental regulations are stringent, proper coatings and treatments are essential to prevent corrosion.

Summary Table of Material Selection

| Material | Typical Use Case for adjustable connector clamp square 1 3/8 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Indoor frameworks, lightweight structures | Lightweight and cost-effective | Not suitable for high-stress loads | Medium |

| Stainless Steel | Outdoor and industrial applications | Superior corrosion resistance | Heavier and more expensive | High |

| Plastic | Chemical environments, electrical installations | Corrosion and chemical resistance | Lower strength compared to metals | Low |

| Carbon Steel | Structural applications in construction | High strength and affordability | Prone to rust without coatings | Medium |

This material selection guide provides valuable insights for B2B buyers in various international markets, helping them make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for adjustable connector clamp square 1 3/8

What Are the Main Stages of Manufacturing an Adjustable Connector Clamp Square 1 3/8?

The manufacturing process for an adjustable connector clamp square 1 3/8 involves several critical stages that ensure the final product meets quality and performance standards. These stages typically include material preparation, forming, assembly, and finishing.

-

Material Preparation:

The process begins with selecting the appropriate materials, commonly aluminum, stainless steel, or high-grade plastic like polyamide. Each material is chosen based on the intended application, environmental conditions, and required strength. Raw materials are then cut into standardized sizes, and surface treatments may be applied to enhance corrosion resistance, especially for clamps intended for outdoor or humid environments. -

Forming:

This stage involves shaping the raw materials into the desired form. Techniques like extrusion or stamping are often employed to create the clamp’s body. For example, aluminum may be extruded to achieve the specific profile required for the 1 3/8 dimensions. Precision is crucial during this stage to ensure that the clamps fit together seamlessly and can support the intended loads. -

Assembly:

After forming, the components of the clamp are assembled. This may involve welding, screwing, or using adhesive bonding methods depending on the design specifications. Each connection point is carefully aligned to ensure structural integrity. In some cases, adjustable features are integrated during this stage, allowing for flexibility in application. -

Finishing:

The final manufacturing stage involves surface finishing processes such as anodizing, powder coating, or galvanization. These treatments not only enhance aesthetics but also provide additional protection against wear and corrosion. The finishing process is critical, especially for products used in diverse climates across regions like Africa, South America, and Europe.

What International Standards Are Relevant for Quality Assurance in Manufacturing?

Quality assurance (QA) is vital in ensuring that adjustable connector clamps meet international and industry-specific standards. Key standards that manufacturers typically adhere to include:

Illustrative image related to adjustable connector clamp square 1 3/8

-

ISO 9001: This globally recognized standard specifies requirements for a quality management system (QMS). Companies in the manufacturing sector use ISO 9001 to demonstrate their ability to consistently provide products that meet customer and regulatory requirements.

-

CE Marking: In Europe, products must often bear the CE mark to indicate compliance with safety, health, and environmental protection standards. This is especially relevant for adjustable clamps used in construction and industrial applications.

-

API Standards: For clamps utilized in oil and gas applications, adherence to American Petroleum Institute (API) standards is crucial. These standards ensure that products can withstand the demanding environments often encountered in these industries.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are integral to the manufacturing process, ensuring that each clamp meets specified standards before reaching the market. The main QC checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon delivery. Suppliers must provide documentation confirming that materials meet specified standards, including chemical composition and mechanical properties.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted at various stages to detect any deviations from the quality standards. This may involve dimensional checks, visual inspections, and functional testing of the clamps.

-

Final Quality Control (FQC): Once the clamps are fully assembled, they undergo final inspections and testing. This may include load testing to ensure they can handle specified weights and environmental testing for durability in various conditions.

What Common Testing Methods Are Used to Ensure Quality?

Manufacturers implement several testing methods to verify the quality of adjustable connector clamps:

-

Tensile Testing: This method evaluates the strength of the materials used, ensuring that they can withstand expected loads without failure.

-

Dimensional Inspection: Utilizing calipers and gauges, manufacturers verify that the dimensions of the clamps conform to design specifications.

-

Corrosion Resistance Testing: For clamps intended for outdoor use, manufacturers may conduct salt spray tests to ensure the materials can resist corrosion over time.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must be diligent in verifying the quality control processes of their suppliers. Here are actionable steps to ensure compliance and quality:

-

Supplier Audits: Conducting regular audits of the supplier’s manufacturing facility can provide insights into their quality management practices. This includes reviewing their adherence to ISO 9001 and other relevant standards.

-

Requesting Quality Reports: Buyers should request documentation of quality control processes and results. This may include IQC, IPQC, and FQC reports, which detail the inspections and tests performed during manufacturing.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased evaluation of the supplier’s quality control processes. This is particularly important for international transactions, where local standards may differ.

What Are the Quality Control and Certification Nuances for International Buyers?

International B2B buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, must navigate various quality control and certification nuances:

Illustrative image related to adjustable connector clamp square 1 3/8

-

Understanding Local Standards: Each region may have specific quality standards and certifications. Buyers should familiarize themselves with these to ensure compliance and product acceptance.

-

Language and Documentation: Ensure that all quality documents are available in a language that is understandable to the buyer. This is crucial for clarity and transparency in international transactions.

-

Cultural Considerations: Recognize that quality expectations may vary based on cultural contexts. Building strong relationships with suppliers can facilitate better communication and understanding of quality standards.

Conclusion

The manufacturing and quality assurance processes for adjustable connector clamps square 1 3/8 are complex and multifaceted. B2B buyers must be proactive in understanding these processes, verifying supplier capabilities, and ensuring compliance with international standards. By doing so, they can mitigate risks and secure high-quality products that meet their specific needs and applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘adjustable connector clamp square 1 3/8’

In the competitive landscape of B2B procurement, selecting the right adjustable connector clamp square 1 3/8″ is crucial for ensuring project success and operational efficiency. This guide provides a structured approach to sourcing these components, enabling buyers to make informed decisions that align with their technical needs and business goals.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the adjustable connector clamp. Consider the materials, dimensions, load capacities, and compatibility with existing systems. This will help you filter suppliers who can meet your specific needs and ensure the clamps can withstand the intended application.

- Material Considerations: Look for options in aluminum, stainless steel, or plastic based on the environment where the clamps will be used.

- Load Capacity: Ensure that the clamps can handle the maximum load expected in your application.

Step 2: Research Potential Suppliers

Conduct comprehensive research to identify potential suppliers who specialize in adjustable connector clamps. Evaluate their reputation in the market by checking customer reviews and industry ratings.

- Supplier Directories: Utilize online platforms such as ThomasNet or Alibaba to find verified suppliers.

- Industry References: Seek recommendations from industry peers to ensure reliability.

Step 3: Evaluate Supplier Certifications

Before making a commitment, it’s essential to verify that your chosen suppliers hold relevant certifications. This could include ISO certifications, material quality certifications, and compliance with international standards.

- Quality Assurance: Certifications demonstrate a commitment to quality and can minimize risks associated with substandard products.

- Regulatory Compliance: Ensure that the products meet local regulations in your target markets, particularly in regions like Europe or the Middle East.

Step 4: Request Samples for Testing

Before finalizing your order, request samples of the adjustable connector clamps. Testing these samples can help ensure they meet your specifications and quality standards.

- Performance Testing: Evaluate how the clamps perform under stress and in real-world conditions.

- Compatibility Check: Confirm that the clamps integrate seamlessly with your existing systems.

Step 5: Negotiate Pricing and Terms

Once you have identified a suitable supplier, engage in negotiations to secure the best pricing and terms. This includes discussing bulk discounts, payment terms, and delivery schedules.

- Bulk Pricing: Inquire about pricing structures for large orders to maximize cost-efficiency.

- Flexible Terms: Look for suppliers who offer favorable payment terms that align with your cash flow.

Step 6: Confirm Logistics and Delivery Times

Understanding the logistics involved in your order is crucial for planning. Confirm the delivery timelines and shipping methods to avoid any disruptions in your supply chain.

- Shipping Options: Evaluate different shipping methods and their costs, ensuring they fit your timeline.

- Tracking Capabilities: Ensure the supplier provides tracking information for better transparency.

Step 7: Establish a Communication Plan

Finally, set up a communication plan with your chosen supplier. Clear communication channels are vital for addressing any issues that arise during production and delivery.

- Regular Updates: Schedule regular check-ins to discuss order status and any potential challenges.

- Feedback Mechanism: Establish a process for providing feedback on product quality and service, fostering a long-term partnership.

By following this structured checklist, B2B buyers can streamline their procurement process for adjustable connector clamps, ensuring they source high-quality products that meet their specific needs efficiently.

Comprehensive Cost and Pricing Analysis for adjustable connector clamp square 1 3/8 Sourcing

What Are the Key Cost Components for Adjustable Connector Clamp Square 1 3/8 Sourcing?

When sourcing adjustable connector clamps, particularly those sized at 1 3/8 inches, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The choice of materials (e.g., aluminum, stainless steel, or plastic) significantly impacts the overall cost. For instance, stainless steel clamps are generally more expensive due to their corrosion resistance and durability compared to aluminum or plastic options.

-

Labor: Labor costs vary based on the manufacturing location. Regions with lower labor costs can offer competitive pricing, but this may come at the expense of quality or delivery timelines.

-

Manufacturing Overhead: This encompasses the indirect costs associated with production, such as utilities, equipment depreciation, and facility maintenance. Buyers should assess whether the supplier maintains efficient manufacturing practices to minimize overhead costs.

-

Tooling: Custom tooling for specific clamp designs can add to initial costs. Buyers should inquire about any tooling fees if they require custom specifications.

-

Quality Control (QC): Effective QC processes ensure product reliability but can also raise costs. Suppliers that prioritize stringent QC measures may charge a premium, reflecting their commitment to quality.

-

Logistics: Shipping costs can fluctuate based on the supplier’s location, shipping method, and destination. For international buyers, understanding Incoterms is crucial to determine who bears the cost and risk during transit.

-

Margin: Suppliers will typically add a margin to cover their costs and profit. This can vary significantly based on the supplier’s reputation, market demand, and exclusivity of the product.

How Do Price Influencers Impact the Cost of Adjustable Connector Clamps?

Several factors can influence the pricing of adjustable connector clamps:

-

Volume/MOQ: Suppliers often provide tiered pricing based on order volume. Larger orders generally lead to lower per-unit costs, making it advantageous for buyers to consolidate their purchases.

-

Specifications and Customization: Custom features or unique specifications can increase costs. Buyers should weigh the benefits of customization against the additional expenses.

-

Materials and Quality Certifications: Higher quality materials and certifications (like ISO or ASTM) can justify higher prices. Buyers in industries with stringent regulations may prioritize certified products despite the added cost.

-

Supplier Factors: The supplier’s reputation, reliability, and service level can impact pricing. Established suppliers may charge more due to their proven track record.

-

Incoterms: Understanding the agreed Incoterms can help buyers anticipate additional costs related to shipping, insurance, and tariffs, especially for international transactions.

What Are Effective Buyer Tips for Cost-Efficient Sourcing?

B2B buyers can adopt several strategies to maximize cost-efficiency when sourcing adjustable connector clamps:

-

Negotiation: Engage suppliers in discussions about pricing, especially if ordering in bulk. Many suppliers are open to negotiations, particularly for long-term partnerships.

-

Total Cost of Ownership (TCO): Consider not just the upfront cost but also the long-term implications, such as maintenance, durability, and potential replacements. A higher initial cost may lead to lower TCO if the product outlasts cheaper alternatives.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, and the Middle East should be aware of local market conditions, tariffs, and currency fluctuations that can affect pricing. Always obtain quotes in your local currency and clarify all associated costs, including shipping and customs duties.

-

Supplier Diversification: Do not rely on a single supplier. Exploring multiple suppliers can provide leverage in negotiations and help identify the best pricing.

Disclaimer on Pricing

Prices for adjustable connector clamps can vary widely based on the factors discussed above. The figures mentioned in this analysis are indicative and may not reflect current market conditions. Always obtain the latest quotes and consider all variables to ensure an accurate assessment of costs.

Alternatives Analysis: Comparing adjustable connector clamp square 1 3/8 With Other Solutions

Exploring Viable Alternatives to the Adjustable Connector Clamp Square 1 3/8

In the realm of B2B solutions for connecting structural elements, the adjustable connector clamp square 1 3/8 is a popular choice due to its flexibility and ease of use. However, it’s essential to evaluate alternative options that may provide similar functionality while catering to specific project requirements. Below, we compare the adjustable connector clamp square 1 3/8 with two viable alternatives: the Electro-Galvanized Strut Clamp and the Plastic Tube Connector.

| Comparison Aspect | Adjustable Connector Clamp Square 1 3/8 | Electro-Galvanized Strut Clamp | Plastic Tube Connector |

|---|---|---|---|

| Performance | High load capacity and adjustable fit | Good load capacity, fixed size | Moderate load capacity, flexible assembly |

| Cost | Moderate price point | Generally lower cost | Lowest cost |

| Ease of Implementation | Easy to install with adjustable features | Requires specific fittings | Simple installation with standard tools |

| Maintenance | Low maintenance required | Moderate maintenance; corrosion can be an issue | Very low maintenance |

| Best Use Case | Customizable frameworks and supports | Standard channel systems | Lightweight applications and temporary setups |

Detailed Breakdown of Alternatives

1. Electro-Galvanized Strut Clamp

The Electro-Galvanized Strut Clamp offers a robust solution for securing tubing in various applications. With a good load capacity, this clamp is particularly effective when used in standard channel systems. Its primary advantage is cost-effectiveness; however, it may require more maintenance due to potential corrosion issues, particularly in humid environments. This clamp is best suited for applications where budget constraints are critical, but it may not provide the same level of flexibility and adjustability as the adjustable connector clamp square 1 3/8.

2. Plastic Tube Connector

Plastic tube connectors present a lightweight and cost-efficient alternative. They are easy to install and require minimal tools, making them ideal for temporary setups or lightweight applications. While they boast very low maintenance, their moderate load capacity limits their use in heavy-duty applications. These connectors are best for projects where flexibility and budget are paramount, but they may not withstand the same stresses as metal counterparts.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting a connector solution, B2B buyers should carefully consider their specific requirements, such as load capacity, environmental conditions, and project duration. The adjustable connector clamp square 1 3/8 excels in customization and durability, making it a strong choice for complex frameworks. Conversely, the Electro-Galvanized Strut Clamp may appeal to those with budget limitations, while the Plastic Tube Connector is ideal for lightweight, temporary applications. Ultimately, aligning the product’s characteristics with your operational needs will ensure optimal performance and value for your investment.

Essential Technical Properties and Trade Terminology for adjustable connector clamp square 1 3/8

What Are the Key Technical Properties of Adjustable Connector Clamps for Square 1 3/8″?

When considering adjustable connector clamps, particularly those designed for square 1 3/8″ tubing, several technical properties are vital to ensure optimal performance and compatibility in various applications. Understanding these properties not only aids in making informed purchasing decisions but also enhances the efficiency and safety of installations.

1. Material Composition

The most common materials for adjustable connector clamps include aluminum, stainless steel, and polyamide. Aluminum clamps are lightweight and resistant to corrosion, making them ideal for various indoor and outdoor applications. Stainless steel offers greater strength and durability, suitable for harsh environments. Polyamide, a type of plastic, is often used for lighter-duty applications where flexibility and resistance to chemicals are required.

2. Load Capacity

Load capacity refers to the maximum weight the clamp can securely hold without failing. This specification is crucial for ensuring that the clamp can support the intended application, whether it’s in construction, machinery, or structural frameworks. A clamp’s load capacity is typically influenced by its material, design, and dimensions.

3. Finish and Corrosion Resistance

The finish of a clamp, such as electro-galvanized or powder-coated, affects its corrosion resistance. Electro-galvanized clamps are treated to resist rust and are suitable for dry environments, while powder-coated options provide additional protection against moisture and abrasion. Selecting the right finish helps extend the lifespan of the clamp in various environmental conditions.

4. Adjustability and Tolerance

Adjustability refers to the clamp’s ability to accommodate slight variations in tubing dimensions. Tolerance levels indicate how much deviation from the standard size the clamp can handle without compromising its performance. This feature is especially important in applications where precision is critical, allowing for easy installation and adjustments.

5. Mounting Configuration

Mounting configurations, such as flanged or split assembly designs, affect how the clamp attaches to the tubing or frame. The choice of configuration can impact installation ease and the stability of the assembly. Understanding the available mounting options helps in selecting the right clamp for specific structural requirements.

Illustrative image related to adjustable connector clamp square 1 3/8

What Are Common Trade Terms Associated with Adjustable Connector Clamps?

In the B2B marketplace, understanding trade terminology is crucial for effective communication and negotiation. Here are some common terms associated with adjustable connector clamps:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of adjustable clamps, working with OEMs ensures that buyers receive high-quality, compatible components that meet specific industry standards.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for budgeting and inventory management, especially for B2B buyers who may require large quantities of clamps for projects.

3. RFQ (Request for Quotation)

An RFQ is a document that buyers use to request pricing and terms from suppliers. This process is vital for comparing offers and ensuring that the best deal is secured, particularly when sourcing adjustable connector clamps from different manufacturers.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping costs, risk management, and delivery responsibilities when procuring clamps from overseas suppliers.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Knowing the lead time is essential for project planning and ensuring that materials arrive when needed to avoid delays.

6. Certification

Certification pertains to the formal approval of products meeting specific industry standards. For adjustable connector clamps, relevant certifications can include ISO or ASTM standards, indicating reliability and safety in applications.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when procuring adjustable connector clamps for their projects, ensuring compatibility, safety, and cost-effectiveness.

Navigating Market Dynamics and Sourcing Trends in the adjustable connector clamp square 1 3/8 Sector

What Are the Current Market Dynamics and Key Trends in the Adjustable Connector Clamp Square 1 3/8 Sector?

The adjustable connector clamp sector, particularly for the 1 3/8″ size, is experiencing notable growth driven by several global factors. As industries worldwide strive for flexibility and efficiency, the demand for modular construction solutions is increasing. This trend is especially pronounced in emerging markets across Africa and South America, where rapid urbanization is pushing for innovative building techniques. Meanwhile, in Europe and the Middle East, the focus is shifting towards advanced manufacturing processes, which require adaptable and durable connector solutions.

Emerging technologies such as 3D printing and digital manufacturing are reshaping sourcing strategies for B2B buyers. Companies are increasingly leveraging these technologies to create custom clamps tailored to specific applications, enhancing the efficiency of their supply chains. Additionally, the rise of e-commerce platforms has enabled international buyers to source products more easily, allowing for better price comparisons and access to a wider range of manufacturers.

Sustainability is becoming a pivotal factor in the purchasing decisions of B2B buyers. The push for environmentally friendly materials and manufacturing processes is influencing product development, with many suppliers focusing on aluminum and recyclable plastics for their adjustable clamps. As a result, manufacturers are innovating to meet the dual demands of performance and environmental responsibility.

How Is Sustainability Shaping the Sourcing of Adjustable Connector Clamps?

The environmental impact of adjustable connector clamps is increasingly under scrutiny, making sustainability a critical consideration for international B2B buyers. The production processes for these clamps can involve significant energy consumption and emissions, prompting businesses to seek suppliers who prioritize sustainable practices.

Ethical sourcing has gained traction, particularly in regions with stringent regulations regarding labor practices and environmental impact. Buyers are looking for suppliers who can demonstrate transparency in their supply chains, ensuring that materials are sourced responsibly and that manufacturing processes minimize waste and pollution. Certifications such as ISO 14001 (Environmental Management) and sustainable materials certifications are becoming essential criteria for procurement.

Moreover, the use of green materials, such as recycled aluminum and low-impact plastics, is becoming a selling point for suppliers. These materials not only reduce the carbon footprint of the products but also appeal to environmentally conscious buyers who are eager to align their purchasing decisions with corporate sustainability goals.

What Is the Historical Evolution of Adjustable Connector Clamps?

The adjustable connector clamp has evolved significantly over the past few decades, transitioning from basic fasteners to sophisticated components integral to modular construction. Initially, these clamps were primarily made of steel and designed for heavy-duty applications in industrial settings. However, as construction methodologies evolved, the need for lighter, more versatile materials led to the incorporation of aluminum and plastic composites.

The introduction of advanced manufacturing techniques in the late 20th century allowed for the production of more complex designs, enhancing the functionality of adjustable clamps. Today, manufacturers offer a wide range of options, including swivel and flanged designs that accommodate various assembly requirements. This evolution reflects a broader trend towards modular construction, where flexibility and adaptability are paramount.

As the industry continues to innovate, the future of adjustable connector clamps will likely see further advancements in materials and technology, catering to the ever-changing demands of global markets.

Illustrative image related to adjustable connector clamp square 1 3/8

Frequently Asked Questions (FAQs) for B2B Buyers of adjustable connector clamp square 1 3/8

-

How do I choose the right adjustable connector clamp square 1 3/8 for my application?

When selecting an adjustable connector clamp, consider the material (aluminum, stainless steel, or plastic) based on your environmental conditions and load requirements. Evaluate the clamp’s design—whether it’s a two-way or flanged connector—depending on the structural assembly you intend to create. Additionally, check for compatibility with existing tubing or frames to ensure a secure fit. Lastly, assess the ease of installation and adjustability features that can save time during assembly. -

What are the key benefits of using adjustable connector clamps in my projects?

Adjustable connector clamps offer versatility, allowing quick adjustments and reconfigurations in your assembly setups. They facilitate easy assembly and disassembly, making them ideal for temporary structures or projects requiring frequent modifications. These clamps also provide robust support, ensuring stability in various applications, from construction to manufacturing. Their availability in multiple materials ensures you can select the best option for durability and environmental resistance. -

What should I consider when vetting suppliers for adjustable connector clamps?

When evaluating suppliers, prioritize their reputation and experience in the industry. Check for certifications that ensure product quality and compliance with international standards. Request references or case studies from previous clients to gauge their reliability and service level. Additionally, inquire about their manufacturing capabilities, lead times, and customer support services, as these factors significantly impact your supply chain efficiency. -

Are there minimum order quantities (MOQs) for adjustable connector clamps?

Yes, many suppliers impose minimum order quantities, which can vary based on the product type and material. It’s essential to discuss MOQs upfront with potential suppliers to understand how they align with your project needs. Some suppliers may offer flexibility for first-time orders or smaller projects, while others might require bulk orders for competitive pricing. Always clarify this aspect to avoid unexpected costs. -

What are the typical payment terms for international purchases of adjustable connector clamps?

Payment terms can differ widely among suppliers. Common arrangements include upfront payments, net 30 or 60 days after invoice, or letters of credit for larger orders. For international transactions, consider factors like currency exchange rates and transaction fees. It’s advisable to negotiate terms that protect both parties, ensuring timely delivery and payment while minimizing financial risk. -

How can I ensure the quality of adjustable connector clamps from international suppliers?

To guarantee product quality, request detailed specifications and certifications from suppliers. Conduct factory audits or quality inspections before shipment, if feasible. Utilizing third-party quality assurance services can also provide an additional layer of verification. Furthermore, consider starting with a smaller order to evaluate the product’s performance before committing to larger quantities. -

What are the logistics considerations for importing adjustable connector clamps?

When importing, factor in shipping costs, customs duties, and delivery times. Choose reliable logistics partners experienced in handling industrial components to ensure smooth transit. Familiarize yourself with local import regulations and ensure that all necessary documentation is in order to avoid delays. Additionally, consider the potential for tariffs or trade agreements that may affect overall costs. -

Can I customize adjustable connector clamps to fit my specific project needs?

Many manufacturers offer customization options for adjustable connector clamps, including specific dimensions, materials, and finishes. Discuss your project requirements with potential suppliers to explore available customization services. Customization can enhance compatibility with your existing systems and improve functionality, though it may involve longer lead times and higher costs. Always request samples or prototypes to validate the design before full-scale production.

Top 8 Adjustable Connector Clamp Square 1 3/8 Manufacturers & Suppliers List

1. JW Winco – Tube Clamp Connectors

Domain: jwwinco.com

Registered: 1997 (28 years)

Introduction: Tube clamp connectors, also called tube connectors, are made of aluminum, cast stainless steel, or plastic (Polyamide). They can be divided into subgroups: two-way connector clamps, flanged connector clamps, base plate connector clamps, swivel connector clamps, and swivel clamp connector joints. They allow for flexible, easy, and quick assembly of round and square pipes as well as pipe assemblies …

2. McMaster – Square Tube Clamps

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Square Tube Clamps, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Rose Brand – Pipe and Tube Connectors

Domain: rosebrand.com

Registered: 1995 (30 years)

Introduction: Pipe and Tube Connectors & Clamps from Rose Brand. Call for Sales Support 1-800-223-1624. Part of a larger inventory including theatrical fabrics, custom curtains, and production supplies. Related categories include Pipe & Base, Pipe & Base 2.0, Pipe & Base Accessories, and various rigging accessories.

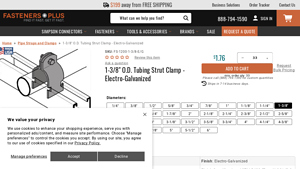

4. Fasteners Plus – Electro-Galvanized Carbon Steel Fastener

Domain: fastenersplus.com

Registered: 2003 (22 years)

Introduction: {“SKU”: “FS-1200-1-3/8-E/G”, “Diameter”: “1-3/8 inch”, “Finish”: “Electro-Galvanized”, “Material”: “Carbon Steel”, “Price”: “$1.76”, “Minimum Order Quantity”: 33, “Shipping Time”: “7-14 business days”}

5. Square Tubing Connector – 8 Pcs 3 Way Fitting

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“title”:”8 Pcs 1″ 3 Way T Shape Square Tube Connector Fitting Rail Clamp”,”condition”:”New”,”quantity_available”:2,”price”:”$32.73″,”shipping”:”Free 2-4 day delivery”,”item_number”:”197643973432″,”included_components”:”8 Pcs Square Tubing Connector”,”model_name”:”8 Pcs Square Tubing Connector”,”fit_with_tube_size”:”1″ x 1″ x 1″ (25.4 x 25.4 x 25.4mm)”,”applicable_project”:”square tube”,”weight_pe…

6. CompleteEQ – Square Tube Clamp Connectors

Domain: completeeq.com

Registered: 2006 (19 years)

Introduction: Square Tube Clamp Connectors, 3-Way, designed for connecting square tubes, suitable for various applications, durable construction, easy installation.

7. Econoco – Spring Clamp for 1 Square Tubing

Domain: econoco.com

Registered: 1998 (27 years)

Introduction: Spring Clamp for 1″ Square Tubing with 3/8″ Fitting

8. Bulkley Capital – U-Bolt Pipe Clamps

Domain: bulkleycapital.com

Registered: 1999 (26 years)

Introduction: U-Bolt Pipe Clamps, Adjustable Greenhouse Connectors, Fits various pipe sizes, Durable construction, Easy installation, Ideal for greenhouse structures, Provides secure connections.

Strategic Sourcing Conclusion and Outlook for adjustable connector clamp square 1 3/8

In conclusion, the strategic sourcing of adjustable connector clamps, particularly the square 1 3/8″ variant, presents a significant opportunity for international B2B buyers. The versatility of these clamps, available in materials such as aluminum, stainless steel, and plastic, allows for flexible applications across various industries, from construction to manufacturing. By prioritizing quality and reliability in sourcing, companies can enhance their operational efficiency and ensure the durability of their projects.

Moreover, engaging with reputable suppliers who offer customizable solutions can lead to cost savings and improved supply chain resilience. As markets in Africa, South America, the Middle East, and Europe continue to evolve, leveraging strategic sourcing will be essential for maintaining a competitive edge.

Looking forward, international buyers are encouraged to explore partnerships with manufacturers that not only provide high-quality products but also demonstrate a commitment to innovation and customer support. By doing so, businesses can position themselves for growth and success in an increasingly interconnected global marketplace. Take the next step in optimizing your sourcing strategy—connect with trusted suppliers today to meet your adjustable connector clamp needs effectively.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.