Ac In Cord: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for ac in cord

In today’s interconnected world, sourcing reliable AC power cords presents a significant challenge for international B2B buyers, particularly those operating in diverse markets like Africa, South America, the Middle East, and Europe. With a myriad of applications—from powering office equipment to supporting critical medical devices—the need for high-quality, compliant, and durable AC power cords cannot be overstated. This guide aims to demystify the complexities of the global AC power cord market, offering insights into various types, applications, and essential supplier vetting processes.

Understanding the nuances of AC power cords is crucial for making informed purchasing decisions. This comprehensive resource covers everything from the different plug types and cable lengths to safety standards and certifications that ensure product reliability. Buyers will also find valuable information on cost considerations and how to identify reputable suppliers, helping to navigate potential pitfalls in sourcing.

By leveraging the insights provided in this guide, B2B buyers can enhance their procurement strategies, ensuring they select the best AC power cords for their specific needs. Whether you’re in Saudi Arabia or Brazil, this guide empowers you to confidently engage with suppliers and make choices that align with both operational efficiency and safety standards. Embrace the opportunity to optimize your supply chain and elevate your business with quality AC power solutions.

Understanding ac in cord Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Power Cords | Commonly used, various lengths, NEMA and IEC connectors | Computers, monitors, printers, general office equipment | Pros: Widely available, cost-effective. Cons: May lack durability for heavy-duty use. |

| Hospital Grade Power Cords | Enhanced safety features, higher durability, green jacket | Medical equipment, healthcare facilities | Pros: Complies with strict safety standards. Cons: Higher cost compared to standard cords. |

| Power Cord Splitters | Allows multiple devices to connect from a single outlet | Data centers, office environments | Pros: Space-saving, convenient. Cons: Risk of overloading if not properly managed. |

| Extension Cords | Longer length options, various gauges for different currents | Events, temporary setups, hard-to-reach areas | Pros: Versatile, useful for temporary installations. Cons: Can be bulky and less durable. |

| Surge Protector Power Cords | Built-in surge protection, often with multiple outlets | Electronics, sensitive equipment | Pros: Protects devices from power surges. Cons: Generally more expensive, may reduce power efficiency. |

What Are the Characteristics and Suitability of Standard Power Cords?

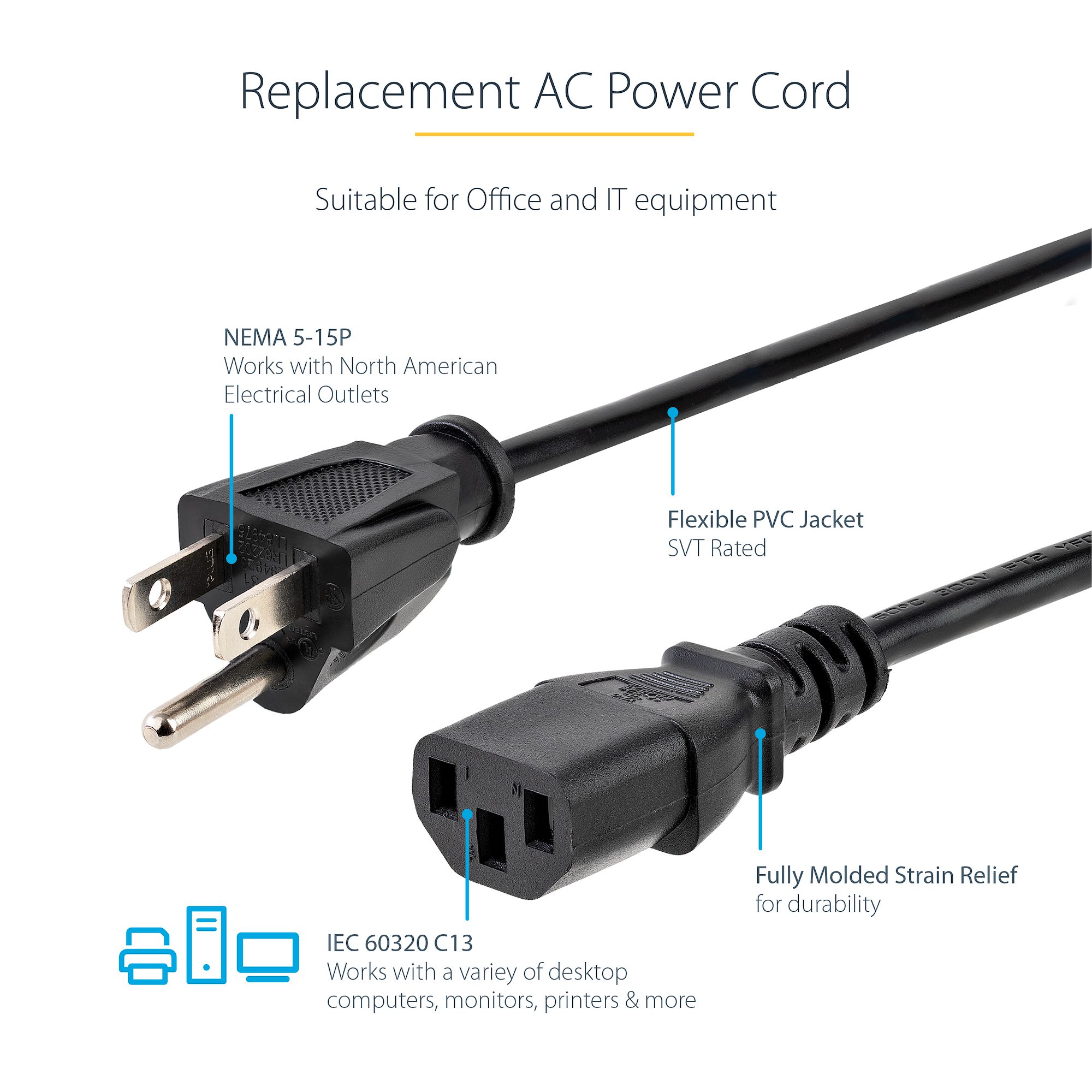

Standard power cords are the backbone of electrical connectivity in many B2B environments. They typically feature NEMA or IEC connectors, making them compatible with a wide range of devices, including computers, printers, and monitors. These cords come in various lengths and wire gauges, allowing businesses to select options that best suit their specific setups. When purchasing, buyers should consider the required length, gauge, and connector type to ensure compatibility with their equipment.

How Do Hospital Grade Power Cords Differ from Standard Options?

Hospital grade power cords are specifically designed for healthcare environments, where safety and reliability are paramount. These cords have enhanced insulation, are made from durable materials, and often feature a green jacket to signify compliance with safety standards. They are essential for powering medical devices, ensuring they operate safely in critical environments. Buyers should prioritize these cords for any healthcare facility to mitigate risks associated with electrical faults.

What Are the Advantages of Using Power Cord Splitters?

Power cord splitters are invaluable in settings where multiple devices need to be powered from a single outlet. They help maximize limited electrical resources, making them ideal for data centers and office environments. However, businesses must be cautious about potential overloads, as using too many devices on a single splitter can lead to safety hazards. When purchasing, consider the current rating and the number of outlets offered by the splitter.

Why Choose Extension Cords for Temporary Setups?

Extension cords are a practical solution for temporary setups or situations where devices are far from power sources. Available in various lengths and wire gauges, they are versatile for events or hard-to-reach areas. However, buyers should be mindful of the potential for wear and tear, especially with frequent use. Selecting the right gauge is crucial to ensure safety and efficiency in power delivery.

What Benefits Do Surge Protector Power Cords Offer?

Surge protector power cords come equipped with built-in surge protection, safeguarding sensitive electronic equipment from voltage spikes. They are particularly beneficial in environments where electronic devices are at risk, such as offices with expensive technology. While they tend to be pricier than standard options, the investment is often justified by the protection they offer. Buyers should assess the surge protection rating and the number of outlets to ensure they meet their operational needs.

Key Industrial Applications of ac in cord

| Industry/Sector | Specific Application of ac in cord | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Information Technology | Powering Servers and Data Centers | Ensures reliable operation of critical IT infrastructure | Compliance with safety standards and voltage ratings |

| Healthcare | Medical Equipment Power Supply | Maintains operational readiness of life-saving devices | Hospital-grade cords for safety and reliability |

| Manufacturing | Machinery and Equipment Power Connections | Enhances productivity and reduces downtime | Durability and compatibility with various machinery |

| Telecommunications | Powering Network Equipment | Supports continuous connectivity and data transmission | Length and gauge specifications for optimal performance |

| Retail | Powering Point-of-Sale Systems | Ensures seamless transaction processing and customer service | Versatility in plug types and lengths for different setups |

How is ‘ac in cord’ used in Information Technology?

In the Information Technology sector, AC power cords are essential for powering servers and data centers. These cords provide the necessary electrical supply for critical IT infrastructure, ensuring uninterrupted operation. International buyers must prioritize compliance with safety standards and voltage ratings, particularly in regions like Africa and the Middle East, where power stability can vary. Reliable AC cords help mitigate risks associated with power surges and outages, safeguarding valuable data and equipment.

What role does ‘ac in cord’ play in Healthcare?

In healthcare settings, AC power cords are crucial for powering medical equipment such as imaging devices, monitors, and life-support systems. These cords must meet stringent safety requirements to ensure patient safety and equipment reliability. Hospital-grade cords are often required to minimize the risk of electrical hazards. For B2B buyers in regions like Europe and South America, sourcing high-quality AC power cords that comply with local regulations is vital for maintaining operational readiness in medical facilities.

How is ‘ac in cord’ utilized in Manufacturing?

In manufacturing, AC power cords are used to connect various machinery and equipment, facilitating seamless operations. Reliable power supply is critical to enhancing productivity and minimizing downtime. When sourcing AC cords, manufacturers should consider durability and compatibility with different machinery types, especially in regions with diverse industrial applications. The ability to withstand harsh environments and frequent use can significantly impact operational efficiency and cost-effectiveness.

How does ‘ac in cord’ support Telecommunications?

Telecommunications companies rely on AC power cords to power network equipment, including routers, switches, and servers. These cords ensure continuous connectivity and support data transmission, which is essential for maintaining service quality. Buyers should focus on sourcing cords with appropriate length and gauge specifications to optimize performance, especially in expansive network setups. In regions like Brazil and Saudi Arabia, where rapid technological advancements are occurring, reliable AC cords are key to sustaining high service standards.

What is the significance of ‘ac in cord’ in Retail?

In retail environments, AC power cords are critical for powering point-of-sale (POS) systems, ensuring that transactions are processed efficiently. A reliable power supply is essential for maintaining customer service and operational flow. Retailers should consider the versatility of AC cords, including different plug types and lengths, to accommodate various setups. For businesses in emerging markets, sourcing adaptable and durable AC power cords can enhance the overall customer experience and streamline operations.

3 Common User Pain Points for ‘ac in cord’ & Their Solutions

Scenario 1: Ensuring Compatibility Across International Standards

The Problem: B2B buyers often face challenges in sourcing AC power cords that meet varying international standards. With different countries having specific requirements for voltage, amperage, and plug types, a buyer may inadvertently purchase cords that are incompatible with their equipment or electrical systems. This can lead to delays in project timelines, increased costs due to returns and replacements, and potential safety hazards if improper cords are used.

The Solution: To mitigate compatibility issues, it is crucial for buyers to conduct thorough research on the specific electrical standards in the regions they operate. Before placing orders, verify the required specifications for each piece of equipment, including voltage ratings, plug types (like NEMA or IEC standards), and amperage requirements. Partnering with a reputable supplier that provides detailed product information and compliance certifications can streamline this process. Additionally, consider investing in universal power cords or adapters that offer flexibility across different standards, which can be particularly useful for businesses operating in multiple countries.

Scenario 2: Managing Power Cord Lengths for Diverse Setups

The Problem: In many B2B environments, such as offices or industrial settings, the physical layout can pose significant challenges regarding power cord lengths. Buyers frequently find themselves with cords that are either too short, leading to unsafe daisy-chaining of power strips, or excessively long, resulting in clutter and potential tripping hazards. This can complicate setups and impact operational efficiency.

The Solution: To effectively manage power cord lengths, buyers should perform a detailed assessment of their workspace layout before procurement. Measure the distance from power outlets to equipment to determine the optimal cord length. When sourcing AC power cords, opt for a variety of lengths or consider purchasing extension cords that can provide additional flexibility without compromising safety. Furthermore, using cord management solutions—like cable trays or ties—can help maintain organization and reduce hazards associated with loose cables.

Scenario 3: Protecting Equipment with Quality Surge Protection

The Problem: AC power cords are often at risk of damage from power surges, which can lead to significant equipment failures and data loss. B2B buyers may not prioritize surge protection when selecting power cords, potentially overlooking this critical aspect until it’s too late. This negligence can result in expensive downtime and repair costs, affecting overall business productivity.

The Solution: To ensure equipment longevity and reliability, buyers should prioritize sourcing AC power cords that include built-in surge protection or pair them with surge protectors and power strips designed for their specific needs. It is essential to choose products that comply with safety standards and have undergone rigorous testing for surge protection capabilities. Buyers should also consider the environment in which the cords will be used; for instance, industrial settings may require heavy-duty surge protectors. Regularly reviewing and maintaining surge protection equipment will help safeguard against unforeseen electrical issues, ensuring uninterrupted operations and protecting valuable investments.

Strategic Material Selection Guide for ac in cord

When selecting materials for AC power cords, several factors must be considered to ensure optimal performance, safety, and compliance with international standards. Below is an analysis of four common materials used in the manufacturing of AC power cords, highlighting their properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of PVC in AC Power Cords?

Polyvinyl Chloride (PVC) is one of the most widely used materials for insulation and jacketing in AC power cords. It is known for its excellent electrical insulation properties and resistance to moisture and chemicals. PVC can operate effectively in temperatures ranging from -10°C to 70°C, making it suitable for a variety of environments.

Pros & Cons:

The durability of PVC is a significant advantage; however, it can become brittle over time when exposed to UV light or extreme temperatures. Additionally, while PVC is generally cost-effective, its manufacturing process can be complex due to the need for additives to enhance its properties.

Impact on Application:

PVC is compatible with a wide range of media, including water and oils, making it versatile for various applications. However, its performance may degrade in high-temperature environments.

Considerations for International Buyers:

Buyers from regions such as Africa and the Middle East should ensure that PVC products meet local compliance standards, such as those set by ASTM or DIN. Additionally, the presence of phthalates in PVC may raise regulatory concerns in certain markets.

How Does Rubber Compare as a Material for AC Power Cords?

Rubber, particularly thermoplastic elastomers (TPE), is another common material used in AC power cords. It offers excellent flexibility, resilience, and a high degree of temperature resistance, typically ranging from -40°C to 90°C.

Pros & Cons:

The primary advantage of rubber is its durability and resistance to abrasion, making it ideal for rugged environments. However, rubber can be more expensive than PVC and may require more complex manufacturing processes.

Impact on Application:

Rubber’s flexibility makes it suitable for applications requiring frequent movement or bending of cords. It is also resistant to various chemicals, which enhances its usability in industrial settings.

Considerations for International Buyers:

International buyers should consider the specific rubber formulations used, as they can vary significantly in terms of performance and compliance with standards. Countries like Brazil may have specific regulations regarding the use of certain rubber compounds.

What Are the Benefits of Using Silicone in AC Power Cords?

Silicone is increasingly popular in the production of AC power cords due to its high-temperature resistance (up to 200°C) and excellent electrical insulation properties. It is also highly resistant to UV radiation and ozone.

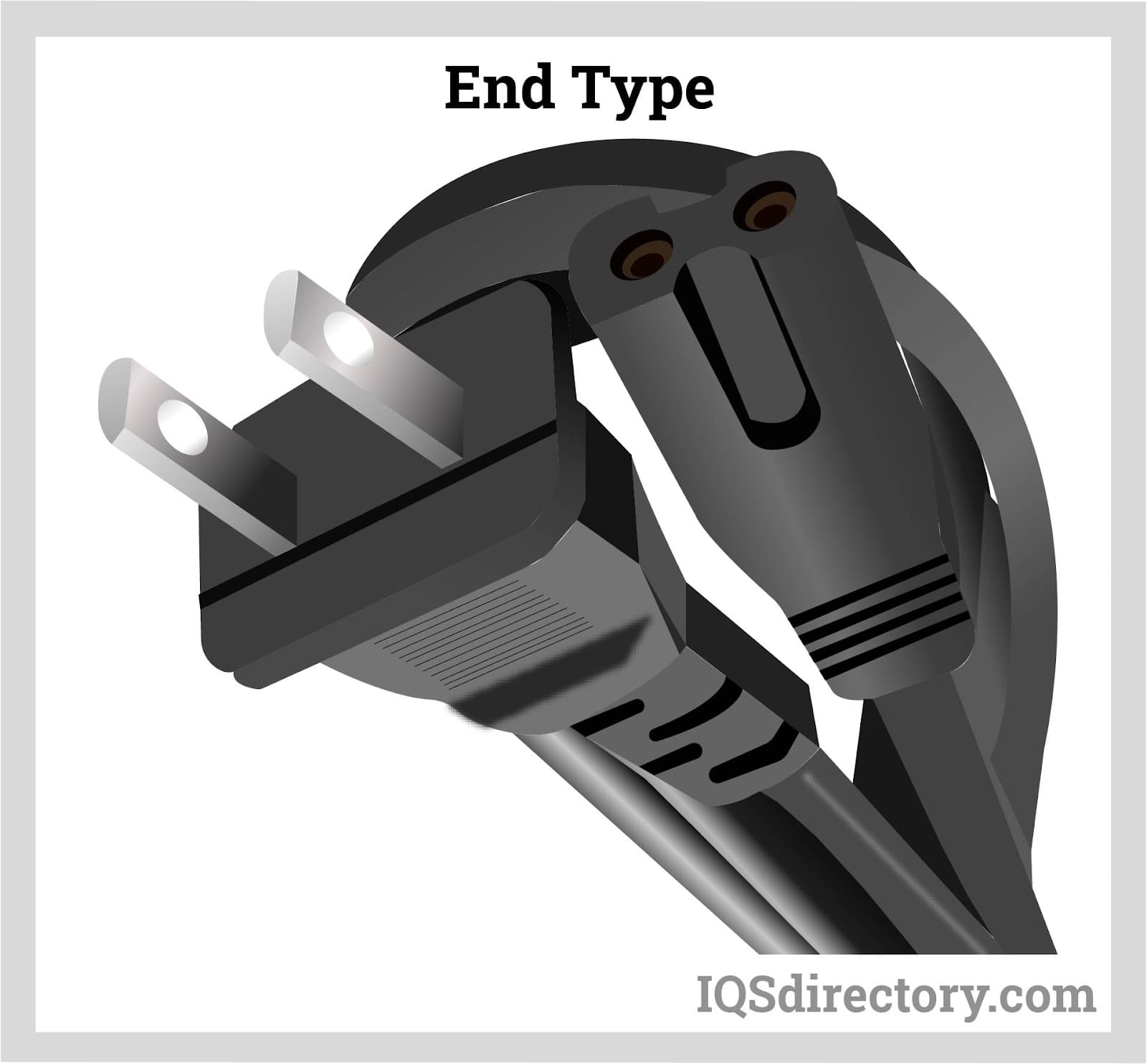

Illustrative image related to ac in cord

Pros & Cons:

The main advantage of silicone is its ability to maintain flexibility and performance in extreme temperatures. However, silicone is generally more expensive than both PVC and rubber, which can impact overall production costs.

Impact on Application:

Silicone is particularly suited for applications in high-heat environments, such as industrial machinery or outdoor settings. Its chemical resistance also makes it ideal for use in harsh conditions.

Considerations for International Buyers:

Buyers in Europe and the Middle East should ensure that silicone products comply with local safety and environmental regulations, particularly regarding the use of additives and fillers.

Why Is Polyethylene a Viable Option for AC Power Cords?

Polyethylene (PE) is often used for insulation in AC power cords due to its lightweight nature and good electrical properties. It operates effectively in a temperature range of -40°C to 80°C.

Pros & Cons:

PE is cost-effective and provides good moisture resistance. However, it may not be as durable as PVC or rubber in terms of abrasion resistance, which can limit its application in demanding environments.

Impact on Application:

PE is suitable for applications where weight is a concern, such as in portable devices. However, its lower temperature tolerance may restrict its use in high-heat applications.

Considerations for International Buyers:

Buyers should verify that PE materials meet the relevant international standards for electrical safety and environmental impact, particularly in regions with stringent regulations like Europe.

Summary Table of Material Selection for AC Power Cords

| Material | Typical Use Case for ac in cord | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | General-purpose power cords | Cost-effective and durable | Can become brittle over time | Low |

| Rubber | Industrial and outdoor applications | High flexibility and durability | Higher cost and complex mfg | Med |

| Silicone | High-temperature applications | Excellent heat and UV resistance | Higher production costs | High |

| Polyethylene | Lightweight and portable devices | Cost-effective and moisture resistant | Limited abrasion resistance | Low |

This strategic material selection guide provides essential insights for international B2B buyers, enabling them to make informed decisions based on material properties, application suitability, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for ac in cord

What Are the Main Stages of Manufacturing AC Power Cords?

The manufacturing process for AC power cords involves several key stages, each critical to ensuring the final product meets safety and performance standards. The primary stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for AC Power Cords?

Material preparation begins with sourcing high-quality raw materials, including copper wire, insulation, and outer jackets. Copper wire is typically chosen for its excellent conductivity, while insulation materials like PVC or thermoplastic elastomers (TPE) provide flexibility and resistance to heat and abrasion. The selection of materials must comply with international safety standards such as IEC 60227 for PVC cables or UL 62 for flexible cords.

After sourcing, the materials undergo a series of tests to verify their properties, such as electrical conductivity and thermal resistance. This ensures that only materials meeting specified performance criteria are used in the manufacturing process.

Illustrative image related to ac in cord

What Techniques Are Used in Forming AC Power Cords?

The forming stage involves several techniques, including wire drawing, stranding, and insulation extrusion. Wire drawing reduces the diameter of the copper wire to the desired gauge, while stranding involves twisting multiple strands together to enhance flexibility and strength. Insulation is then extruded around the wire to provide protection against electrical hazards.

These processes can vary based on the type of cord being manufactured. For instance, hospital-grade power cords may require additional shielding to prevent interference and ensure safety in sensitive environments.

How Is the Assembly of AC Power Cords Conducted?

Once the individual components are prepared, the assembly stage begins. This involves cutting the insulated wires to the required lengths, attaching connectors, and performing initial quality checks. Connectors may vary by application, with options including NEMA, IEC, or custom connectors based on client specifications.

Automated machinery often assists in this process to enhance accuracy and efficiency. Each connection is meticulously crimped or soldered to ensure a secure fit, minimizing the risk of disconnections or electrical failures during use.

What Are the Finishing Processes for AC Power Cords?

The finishing stage encompasses several steps, including testing, labeling, and packaging. Each cord undergoes electrical testing to ensure it meets performance specifications, such as voltage and amperage ratings. Additionally, visual inspections are conducted to check for any defects in the insulation or connectors.

Cords are then labeled according to regulatory requirements, and appropriate packaging is applied to protect the products during transport. Manufacturers must ensure that packaging is compliant with international shipping regulations to prevent damage and ensure safe delivery.

What Quality Assurance Standards Are Relevant for AC Power Cords?

Quality assurance is paramount in the manufacturing of AC power cords to ensure safety, reliability, and compliance with international standards. Key standards include ISO 9001, which outlines a framework for quality management systems, and specific certifications such as CE marking for products sold in the European market.

How Do International Standards Impact Quality Control?

International standards dictate the minimum requirements for materials, manufacturing processes, and testing methods. Compliance with standards such as UL, CSA, and IEC ensures that AC power cords are safe for use in various applications, from consumer electronics to industrial machinery.

Illustrative image related to ac in cord

For B2B buyers, understanding these standards is crucial when evaluating suppliers. Buyers should verify that manufacturers possess the necessary certifications and regularly conduct audits to maintain compliance with these standards.

What Are the Key Quality Control Checkpoints in AC Power Cord Manufacturing?

Quality control (QC) checkpoints are established throughout the manufacturing process to identify and rectify issues early. Common checkpoints include:

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Throughout the manufacturing process, random samples are tested to verify that production adheres to quality benchmarks.

- Final Quality Control (FQC): Before packaging, each finished product undergoes rigorous testing to confirm it meets all performance and safety criteria.

These checkpoints help to reduce the likelihood of defects reaching the market, ultimately protecting both the manufacturer’s reputation and the end user’s safety.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify the quality control processes of their suppliers. This can be achieved through:

- Supplier Audits: Conducting on-site audits allows buyers to assess manufacturing processes and QC measures firsthand. It provides insight into the supplier’s commitment to quality and compliance.

- Quality Reports: Requesting detailed quality reports from suppliers can offer transparency regarding their QC methods and performance metrics.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s compliance with international standards and internal QC processes.

What Nuances Should International B2B Buyers Consider Regarding Quality Control?

For international buyers, especially those from regions such as Africa, South America, the Middle East, and Europe, understanding regional regulations and standards is essential. Different markets may have varying requirements for safety certifications and product testing.

Illustrative image related to ac in cord

Buyers should also consider the logistical aspects of quality assurance, such as shipping regulations and potential delays in obtaining certifications. Establishing clear communication with suppliers regarding quality expectations and compliance can help mitigate risks and ensure that products meet local regulations.

In conclusion, the manufacturing processes and quality assurance measures for AC power cords are critical factors for B2B buyers to consider. By understanding these processes and the relevant standards, buyers can make informed decisions that ensure the reliability and safety of the products they procure.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ac in cord’

Introduction

This guide provides a structured approach for B2B buyers seeking to procure AC power cords, ensuring informed decision-making and compliance with international standards. With the diverse applications of AC cords across industries—from electronics to healthcare—understanding key procurement steps will enhance your sourcing strategy and minimize operational risks.

Step 1: Define Your Technical Specifications

Clearly outline the technical requirements for the AC power cords you need. Consider factors such as voltage ratings, wire gauge, connector types, and length. This step is crucial as it ensures compatibility with your equipment and meets local electrical standards.

Illustrative image related to ac in cord

- Voltage Ratings: Ensure the cords can handle the required voltage for your devices.

- Wire Gauge: Select an appropriate wire gauge to prevent overheating and ensure safety.

Step 2: Research Regulatory Compliance and Safety Standards

Verify that the AC power cords comply with relevant safety standards and certifications applicable in your region. This is vital not only for legal compliance but also for ensuring the safety and reliability of your electrical installations.

- Certifications to Look For: UL (Underwriters Laboratories), CE (Conformité Européenne), and RoHS (Restriction of Hazardous Substances).

- Local Standards: Familiarize yourself with any specific regulations in your country or region.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website; conduct due diligence to gauge their reliability.

- Supplier Reputation: Look for reviews and testimonials from other businesses.

- Experience in Your Sector: Suppliers with experience in your specific industry can better understand your needs.

Step 4: Request Samples for Quality Assessment

Before making a bulk purchase, request samples of the AC power cords. This allows you to assess their quality, durability, and suitability for your applications. Testing samples can prevent costly mistakes and ensure you receive the best products.

- Testing for Performance: Check for flexibility, insulation quality, and connector strength.

- Compatibility Tests: Ensure the cords work seamlessly with your devices.

Step 5: Compare Pricing and Terms

Gather quotes from multiple suppliers to compare pricing and terms. Look beyond the initial cost; consider factors like warranty, return policies, and shipping costs. A lower price may not always mean better value if the quality or service is compromised.

Illustrative image related to ac in cord

- Total Cost of Ownership: Factor in the lifespan of the cords and potential maintenance costs.

- Negotiation Opportunities: Be prepared to negotiate terms that align with your budget and needs.

Step 6: Confirm After-Sales Support and Warranty

Evaluate the after-sales support offered by suppliers. Reliable customer service can be invaluable in addressing any issues that arise post-purchase. Also, ensure the products come with a warranty to protect your investment.

- Support Availability: Confirm the supplier’s responsiveness and support channels.

- Warranty Length and Coverage: Understand what is covered under the warranty and for how long.

Step 7: Finalize Your Purchase and Monitor Performance

Once you’ve selected a supplier and confirmed the details, finalize your purchase. After receiving the cords, monitor their performance closely during initial use. This ongoing evaluation can help identify any issues early and ensure you maintain operational efficiency.

- Feedback Loop: Establish a method to provide feedback to suppliers on product performance.

- Continuous Improvement: Use insights gained from this procurement process to refine future sourcing strategies.

Comprehensive Cost and Pricing Analysis for ac in cord Sourcing

What Are the Key Cost Components in AC Power Cord Sourcing?

Understanding the cost structure is essential for B2B buyers sourcing AC power cords. The main components influencing the pricing include:

-

Materials: The choice of materials significantly affects the cost. High-quality copper wires, durable insulation materials, and certified connectors contribute to higher prices but ensure safety and longevity. Buyers should evaluate the trade-off between material quality and cost.

-

Labor: Labor costs can vary widely depending on the manufacturing location. Regions with lower labor costs may offer cheaper products, but this can sometimes compromise quality. Consider the skill level of the workforce, as more experienced labor might lead to better manufacturing outcomes.

-

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, and operational expenses. Efficient manufacturing processes can reduce overhead, which in turn can lower the product price.

-

Tooling: Custom tooling for specific designs or specifications can add significant upfront costs. However, for large volume orders, the amortization of tooling costs can be spread out, making it more economical per unit.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability and compliance with safety standards. While this may increase initial costs, it is crucial for maintaining brand reputation and reducing returns.

-

Logistics: Shipping and handling costs can vary based on distance, mode of transport, and packaging requirements. International buyers should factor in these costs, especially if sourcing from overseas.

-

Margin: Supplier margin is the profit added on top of the manufacturing cost. This can vary based on supplier reputation, relationship with the buyer, and market demand.

What Influences Pricing for AC Power Cords?

Several factors can impact the pricing of AC power cords, especially for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically lead to lower unit prices. Buyers should negotiate MOQs that align with their needs while ensuring they maximize cost efficiency.

-

Specifications and Customization: Custom designs or specific certifications can increase costs. Buyers should assess whether the additional features justify the price difference.

-

Material Quality and Certifications: Products that meet specific safety and quality certifications tend to be priced higher. Buyers must balance the need for compliance with budget constraints.

-

Supplier Factors: The reliability and reputation of the supplier can influence pricing. Established suppliers may charge more but offer better warranties and customer service.

-

Incoterms: Understanding shipping terms is crucial for international purchases. Different Incoterms (like FOB, CIF) can significantly affect the total landed cost of goods.

How Can Buyers Negotiate for Better Pricing on AC Power Cords?

Effective negotiation strategies can help buyers secure more favorable pricing:

-

Leverage Volume Discounts: Buyers should aim for bulk purchasing agreements, which can lead to substantial savings.

-

Be Transparent About Budget Constraints: Open discussions about budget limitations can foster goodwill and lead suppliers to offer better terms.

-

Compare Supplier Quotes: Obtaining multiple quotes allows buyers to benchmark pricing and negotiate from a position of strength.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the purchase price but the long-term costs associated with quality, maintenance, and potential failures.

-

Utilize Local Contacts: Buyers in regions like Africa or South America may benefit from local suppliers who understand regional needs and can provide competitive pricing.

What Are the Pricing Nuances for International B2B Buyers?

International buyers must be aware of specific pricing nuances:

-

Currency Fluctuations: Changes in exchange rates can impact the final cost, so it’s wise to negotiate prices in a stable currency.

-

Import Duties and Taxes: Understanding applicable tariffs is crucial, as these can add to the total cost.

-

Shipping Times and Costs: Longer shipping times can impact inventory management and should be factored into the pricing analysis.

-

Cultural Considerations: Different regions may have varying expectations regarding pricing and negotiation styles. Understanding these cultural nuances can enhance the negotiation process.

In conclusion, a comprehensive understanding of the cost structure and pricing influences, combined with strategic negotiation tactics, can empower B2B buyers to make informed decisions when sourcing AC power cords. Always remember that indicative prices may vary based on market conditions, so continuous market research is essential.

Alternatives Analysis: Comparing ac in cord With Other Solutions

When evaluating solutions for powering electronic devices, businesses often explore various alternatives to traditional AC power cords. Understanding the strengths and weaknesses of these options is crucial for making informed purchasing decisions. This analysis will compare ‘ac in cord’ with two viable alternatives: Power Over Ethernet (PoE) and Wireless Power Transfer (WPT).

| Comparison Aspect | Ac In Cord | Power Over Ethernet (PoE) | Wireless Power Transfer (WPT) |

|---|---|---|---|

| Performance | Reliable and consistent power supply, suitable for high wattage devices. | Limited by power requirements of devices; effective for low to moderate power needs. | Varies based on distance; generally less efficient for high power applications. |

| Cost | Generally low initial cost; prices vary by type and length. | Higher upfront costs due to specialized equipment and installation. | High cost due to technology and infrastructure requirements. |

| Ease of Implementation | Simple plug-and-play setup; minimal installation required. | Requires network infrastructure and PoE switches; more complex setup. | Installation can be complicated; requires specific alignment and technology. |

| Maintenance | Low maintenance; occasional replacement of damaged cords. | Moderate maintenance; network equipment may require updates or replacements. | Higher maintenance due to potential misalignment and wear over time. |

| Best Use Case | Ideal for powering high-demand devices like computers and printers. | Best for powering network devices like IP cameras and VoIP phones. | Suitable for portable devices and applications where cabling is impractical. |

What Are the Advantages and Disadvantages of Power Over Ethernet (PoE)?

Power Over Ethernet (PoE) technology allows electrical power and data to be transmitted over standard Ethernet cables. This solution is particularly advantageous for network devices that require both connectivity and power, such as IP cameras and VoIP phones. The primary benefit of PoE is its ability to simplify installation by reducing the need for additional electrical outlets, which can be especially valuable in environments where infrastructure modifications are challenging.

However, PoE has limitations, particularly in terms of power delivery. It is effective for devices that require low to moderate power, but it may not suffice for high-wattage equipment. Additionally, the initial setup can be complex, requiring specialized switches and cabling, which may increase costs and implementation time.

How Does Wireless Power Transfer (WPT) Compare?

Wireless Power Transfer (WPT) is an innovative technology that allows for the transfer of electrical energy without physical connectors. This method is particularly beneficial for mobile devices and applications in environments where traditional wiring is impractical. The main advantage of WPT is its convenience; users can charge devices simply by placing them on a charging pad, which eliminates the hassle of cords and connectors.

Despite its advantages, WPT has significant drawbacks. The efficiency of power transfer diminishes with distance, making it less suitable for high-power applications. Moreover, the technology can be expensive, and misalignment of devices can lead to charging failures, necessitating careful positioning.

Illustrative image related to ac in cord

How Should B2B Buyers Choose the Right Solution?

When selecting a power solution, B2B buyers must consider their specific operational needs, the power requirements of their devices, and the existing infrastructure. For businesses that rely on high-wattage equipment, traditional AC power cords remain a reliable and cost-effective choice. In contrast, organizations focused on network devices may find PoE to be a more efficient solution, while those dealing with portable electronics might benefit from the flexibility of wireless power transfer.

Ultimately, the right choice will depend on the unique requirements of each business, including budget constraints, installation capabilities, and the types of devices being powered. By carefully weighing these factors, buyers can ensure they select the most appropriate power solution for their operations.

Essential Technical Properties and Trade Terminology for ac in cord

What Are the Essential Technical Properties of AC Power Cords?

When selecting AC power cords for various applications, several key technical properties are critical for ensuring reliability, safety, and compatibility with devices. Here are some essential specifications to consider:

Illustrative image related to ac in cord

1. Material Grade

The material grade refers to the quality of the conductors and insulation used in the cord. High-quality copper is typically used for conductors due to its excellent conductivity, while PVC or rubber is common for insulation. Selecting cords with superior materials ensures better performance, durability, and resistance to wear, which is essential for B2B buyers looking to reduce replacement costs over time.

2. Wire Gauge

Wire gauge indicates the diameter of the wire used in the cord. It is measured according to the American Wire Gauge (AWG) system, where a lower gauge number signifies a thicker wire capable of carrying more current. For example, a 14 AWG wire can handle higher amperage than an 18 AWG wire. Understanding wire gauge is vital for ensuring that the power cord can safely handle the electrical load without overheating, which is critical for operational safety.

3. Voltage Rating

The voltage rating specifies the maximum voltage the cord can safely handle. Common ratings include 250V or 125V, depending on the geographical region and application. Choosing cords with appropriate voltage ratings is crucial for preventing electrical failures and ensuring compatibility with devices used in different countries, especially when dealing with international suppliers.

4. Amperage Capacity

Amperage capacity indicates the maximum current the cord can carry without overheating. This specification is vital for ensuring that the cord can support the electrical demands of connected devices. B2B buyers should assess the amperage needs of their equipment to select cords that provide adequate power without risking safety.

5. Jacket Rating

The jacket rating describes the protective outer layer of the power cord, which can vary based on environmental conditions (e.g., abrasion resistance, temperature tolerance). Common ratings include SJT, SJTW, and SVT. Selecting the correct jacket rating is important for ensuring that cords can withstand specific operational environments, particularly in industrial or outdoor settings.

What Are Common Trade Terms Related to AC Power Cords?

Understanding industry terminology is crucial for effective communication and negotiation in B2B transactions. Here are some common terms you should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of AC power cords, OEMs often supply cords that meet specific standards for devices, ensuring compatibility and quality. Understanding OEM relationships can help buyers source high-quality products tailored to their needs.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for B2B buyers to manage inventory costs and ensure they meet supplier requirements. It can affect purchasing decisions, especially for smaller businesses or those testing new products.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. B2B buyers often use RFQs to compare offers and negotiate better deals. Including detailed specifications in an RFQ helps ensure that responses are relevant and tailored to the buyer’s needs.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers involved in cross-border trade, as they help mitigate risks and ensure smooth logistics.

5. TAA Compliance (Trade Agreements Act Compliance)

TAA compliance indicates that products meet the standards set by the Trade Agreements Act, which governs the procurement of goods in the U.S. Federal government. For international buyers, understanding TAA compliance is crucial when dealing with U.S. suppliers to ensure that products are eligible for government contracts.

Illustrative image related to ac in cord

By familiarizing yourself with these essential technical properties and trade terminology, you can make informed purchasing decisions that align with your business needs.

Navigating Market Dynamics and Sourcing Trends in the ac in cord Sector

What Are the Current Market Dynamics and Key Trends in the AC Power Cord Sector?

The global AC power cord market is experiencing significant growth, driven by the increasing demand for electronic devices across various sectors, including IT, healthcare, and consumer electronics. With technological advancements, buyers are increasingly favoring power cords that offer enhanced safety features, such as surge protection and hospital-grade specifications. The rise of smart devices and IoT (Internet of Things) also fuels the need for versatile and high-quality power solutions, particularly in emerging markets like Africa and South America, where infrastructure development is accelerating.

International B2B buyers are now more focused on sourcing products that comply with regional safety and quality standards. For instance, buyers from the Middle East and Europe often prioritize products with certifications such as CE, UL, and RoHS, ensuring that the products meet stringent safety requirements. Furthermore, emerging trends in e-commerce and digital procurement platforms are reshaping how B2B transactions are conducted, allowing buyers to easily compare options, negotiate prices, and ensure timely delivery.

Additionally, the global supply chain landscape has become increasingly complex due to geopolitical tensions and disruptions caused by events like the COVID-19 pandemic. This has led to a greater emphasis on diversified sourcing strategies, where buyers seek reliable suppliers from multiple regions to mitigate risks and ensure continuity of supply.

How Is Sustainability Impacting the Sourcing of AC Power Cords?

Sustainability is becoming a critical consideration in the procurement of AC power cords, reflecting a broader trend toward environmental responsibility in B2B transactions. The production of power cords can have significant environmental impacts, including energy consumption during manufacturing and the disposal of non-biodegradable materials. Consequently, businesses are increasingly prioritizing suppliers that adhere to sustainable practices, such as using recyclable materials and minimizing waste.

Ethical sourcing has gained traction among B2B buyers who are concerned about the social implications of their supply chains. This includes ensuring that suppliers uphold labor rights and engage in fair trade practices. Certifications such as ISO 14001 for environmental management and ISO 26000 for social responsibility are becoming essential benchmarks for buyers looking to align their sourcing practices with their corporate social responsibility (CSR) goals.

Moreover, the demand for ‘green’ certifications is rising, with buyers seeking products made from eco-friendly materials, such as PVC-free cables or those using recycled components. This shift not only helps in reducing the carbon footprint but also appeals to consumers who increasingly prefer brands that demonstrate a commitment to sustainability.

Illustrative image related to ac in cord

What Is the Historical Context of the AC Power Cord Market?

The AC power cord industry has evolved significantly over the past few decades. Initially, power cords were basic in design and function, primarily serving the purpose of delivering electricity to devices. However, as technology advanced, so did the complexity and requirements of power cords. The introduction of safety regulations and standards in the late 20th century marked a pivotal moment, ensuring that power cords could handle various voltages and currents safely.

The 1990s and early 2000s saw the proliferation of electronic devices, leading to a surge in demand for specialized power cords, including those for computers and peripherals. As globalization took hold, manufacturers began sourcing materials from different regions, resulting in a more competitive market landscape. Today, the focus is not only on functionality but also on safety, sustainability, and ethical sourcing, reflecting the changing values of consumers and businesses alike.

As the market continues to evolve, B2B buyers must stay informed about technological advancements and regulatory changes to make informed sourcing decisions that align with their business objectives and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of ac in cord

-

How do I solve compatibility issues with AC power cords?

To address compatibility issues with AC power cords, first, identify the specifications required for your devices, such as plug type, voltage, and amperage. Ensure the power cords you source match these specifications. Additionally, consider purchasing universal power cords that can adapt to various devices. It’s also advisable to consult with suppliers about the compatibility of their products with your equipment, especially if you are importing from different regions. -

What is the best type of AC power cord for my electronic equipment?

The best type of AC power cord depends on the specific requirements of your electronic equipment. For general use, a standard NEMA 5-15P to IEC320C13 power cord is widely compatible with many devices like computers and printers. If you’re dealing with high-performance equipment, consider heavy-duty cords rated for higher amperage or specialized hospital-grade cords for medical devices. Always verify the specifications of your equipment to ensure optimal performance and safety. -

What should I consider when sourcing AC power cords internationally?

When sourcing AC power cords internationally, consider factors such as voltage compatibility, plug types, and local regulations regarding electrical safety standards. It’s crucial to vet suppliers for compliance with international certifications, such as UL, CE, or RoHS. Additionally, consider the logistics of shipping and customs regulations, which may affect the delivery timeline and cost. Establishing a reliable communication channel with suppliers can also facilitate smoother transactions and clarify any concerns. -

What are the minimum order quantities (MOQ) for AC power cords?

Minimum order quantities (MOQ) for AC power cords can vary significantly between suppliers. Some manufacturers may offer flexible MOQs for trial orders, while others may require larger quantities for bulk pricing. It’s advisable to discuss your needs with potential suppliers to negotiate favorable terms. Keep in mind that placing larger orders can reduce per-unit costs, but ensure that you can manage inventory effectively to avoid excess stock. -

How can I ensure the quality of AC power cords from suppliers?

To ensure the quality of AC power cords, request product samples and review them for compliance with industry standards. Look for certifications from recognized organizations that validate the safety and performance of the cords. Additionally, inquire about the supplier’s quality assurance processes, such as testing procedures and warranty policies. Establishing a long-term relationship with reputable suppliers can also enhance trust in the quality of products you receive. -

What payment terms should I expect when purchasing AC power cords internationally?

Payment terms for international purchases of AC power cords can vary widely among suppliers. Common terms include advance payment, letter of credit, or open account terms for established relationships. It’s essential to clarify payment methods, currency, and any potential fees with your supplier. Additionally, consider using payment protection services to mitigate risks, especially when dealing with new suppliers or larger transactions. -

How do I handle logistics and shipping for AC power cords?

Handling logistics and shipping for AC power cords involves coordinating with freight forwarders to select the most efficient shipping method, whether by air or sea. Ensure that you understand the customs regulations of both the exporting and importing countries to avoid delays. Request shipping insurance to protect your investment during transit, and track your shipment to stay informed about its status. Clear communication with your supplier about shipping timelines is crucial for planning. -

What customization options are available for AC power cords?

Customization options for AC power cords can include variations in length, gauge, plug type, and color coding for easier identification. Many suppliers offer the ability to create bespoke solutions tailored to your specific requirements. When discussing customization, provide detailed specifications and any relevant certifications needed for your target market. Customization can enhance brand visibility and ensure compatibility with your unique devices or systems.

Top 4 Ac In Cord Manufacturers & Suppliers List

1. Cables To Go – Power Solutions

Domain: cablestogo.com

Registered: 1995 (30 years)

Introduction: AC Power Cords, Splitters, Surge Protectors, Hospital Grade Power Cords, Surge Suppressors & Power Strips, Internal PC Power Cables, Mobile Charging & Power Adapters.

2. Target – AC Power Cords & Adapters

Domain: target.com

Registered: 1997 (28 years)

Introduction: This company, Target – AC Power Cords & Adapters, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Best Buy Brands – Power Cords & Strips

Domain: bestbuy.com

Registered: 1994 (31 years)

Introduction: {“category”:”Power Cords & Strips”,”total_items”:142,”brands”:[“Best Buy Brands”,”Apple”,”Maximm”,”5 CORE”,”Insignia™”,”Tripp Lite”,”Belkin”,”Nintendo”],”price_ranges”:[“Less than $25″,”$25 – $49.99″,”$50 – $74.99″,”$75 – $99.99″,”$100 – $149.99″,”$150 – $199.99″,”$200 – $249.99″,”$250 – $499.99″],”current_deals”:[“On Sale”,”Free Shipping Eligible”,”Package Deals”,”Clearance”],”colors”:[“Black”,”W…

4. IQS Directory – AC Power Cords

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: AC Power Cord: A detachable device delivering alternating current (AC) from mains supply to electrical devices and appliances. Used in sectors like retail, industrial, electronics, entertainment, and residential for applications such as lighting, power tools, home appliances, shop equipment, and musical instruments. Construction includes conductive wires (often copper) shielded in insulation and e…

Strategic Sourcing Conclusion and Outlook for ac in cord

How Can Strategic Sourcing Transform Your AC Power Cord Procurement?

In today’s competitive landscape, the importance of strategic sourcing for AC power cords cannot be overstated. Key takeaways highlight the necessity for international buyers to focus on quality, compliance with safety standards, and adaptability to diverse application needs. By leveraging strategic sourcing, businesses can optimize their supply chains, reduce costs, and ensure consistent availability of high-quality products, which is vital for maintaining operational efficiency.

Furthermore, understanding regional market trends and specific requirements—especially in areas like Africa, South America, the Middle East, and Europe—enables companies to make informed purchasing decisions. For instance, opting for cords that meet local electrical standards and certifications can mitigate risks associated with product failures and enhance overall safety.

Looking ahead, the demand for reliable AC power solutions will only increase as technology continues to advance. International buyers are encouraged to proactively engage with suppliers who demonstrate a commitment to innovation and sustainability in their product offerings. By prioritizing strategic sourcing, you position your business for growth in an evolving market landscape. Embrace the opportunity to enhance your procurement strategy and secure a competitive edge today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.