Ac Capacitor Home Depot: The Ultimate 2025 B2B Sourcing Guide

Introduction: Navigating the Global Market for ac capacitor home depot

Navigating the global market for AC capacitors, particularly those available at Home Depot, poses unique challenges for international B2B buyers. With the increasing reliance on efficient air conditioning systems across regions such as Africa, South America, the Middle East, and Europe, sourcing high-quality capacitors that meet specific operational requirements has never been more critical. This guide serves as a comprehensive resource for understanding the various types of AC capacitors, their applications, and the nuances of supplier vetting to ensure optimal performance and reliability.

Within these pages, you will find detailed insights into the specifications that matter most—capacitance ratings, voltage standards, and terminal types—empowering you to make informed purchasing decisions. Additionally, we explore cost considerations and strategies for negotiating with suppliers, ensuring that you not only secure the right products but also achieve the best value for your investment. This guide is tailored for B2B professionals in countries like Nigeria and Saudi Arabia, where understanding the local market dynamics and supplier capabilities is essential for success.

By equipping yourself with the knowledge contained in this guide, you will be better positioned to navigate the complexities of sourcing AC capacitors effectively. Whether you are upgrading existing systems or launching new projects, the insights provided will enhance your procurement strategy and drive operational excellence.

Understanding ac capacitor home depot Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Dual Run Capacitors | Combines functions for both compressor and fan; usually cylindrical. | HVAC systems needing dual functionality. | Pros: Space-saving design; simplifies installation. Cons: More complex replacement process. |

| Start Capacitors | Provides initial boost of energy to start the motor; typically smaller. | Used in air conditioning units and some refrigeration systems. | Pros: Cost-effective; essential for starting motors. Cons: Limited lifespan; may require frequent replacements. |

| Run Capacitors | Maintains energy flow to the motor during operation; larger and cylindrical. | Continuous operation HVAC systems. | Pros: Enhances motor efficiency; longer lifespan. Cons: Higher initial cost; requires precise specifications. |

| Motor Start Capacitors | Specifically designed for high starting torque; often have a larger capacitance. | Heavy-duty air conditioning units. | Pros: Essential for high-demand systems; reliable performance. Cons: Can be bulky; requires careful handling. |

| Capacitor Banks | Multiple capacitors grouped together for enhanced performance; often modular. | Industrial HVAC systems and large-scale applications. | Pros: Improves power factor; scalable solution. Cons: Higher installation complexity; requires professional setup. |

What Are Dual Run Capacitors and Their B2B Relevance?

Dual run capacitors serve a critical role in HVAC systems by combining the functions of both the compressor and the fan into a single unit. Their cylindrical shape allows for easier installation in tight spaces, making them ideal for commercial air conditioning systems. When purchasing, B2B buyers should consider the specific voltage and capacitance ratings required for their systems, as mismatched specifications can lead to inefficiencies or equipment failure.

How Do Start Capacitors Function in Air Conditioning Units?

Start capacitors are essential for providing the initial energy surge needed to kickstart the motor in air conditioning and refrigeration units. Their compact design makes them suitable for various applications, particularly in smaller systems. B2B purchasers should pay attention to the capacitor’s rated voltage and capacitance, as these factors directly impact the reliability and longevity of the motor. Additionally, understanding the expected lifespan can help in planning maintenance schedules.

What Are the Benefits of Run Capacitors for Continuous Operation?

Run capacitors are designed to maintain a steady flow of electrical energy to the motor during its operation, enhancing efficiency and extending the lifespan of HVAC systems. These capacitors are typically larger and cylindrical, making them suitable for continuous operation applications. B2B buyers should ensure that the replacement run capacitor matches the original specifications, as improper ratings can lead to reduced performance and increased energy costs.

Why Choose Motor Start Capacitors for High-Demand Systems?

Motor start capacitors are tailored for applications requiring high starting torque, making them ideal for heavy-duty air conditioning units. Their larger capacitance allows for a reliable start under demanding conditions. When selecting motor start capacitors, B2B buyers must consider the physical size and electrical specifications to ensure compatibility with existing systems, as well as the environmental conditions they will be subjected to.

What Are Capacitor Banks and Their Industrial Applications?

Capacitor banks consist of multiple capacitors connected together to enhance performance, particularly in industrial HVAC systems. They are designed to improve the power factor and efficiency of large-scale applications, making them a scalable solution for businesses looking to optimize energy usage. B2B buyers should evaluate the installation requirements and seek professional assistance, as the complexity of setting up capacitor banks can be significant compared to standard capacitor replacements.

Key Industrial Applications of ac capacitor home depot

| Industry/Sector | Specific Application of ac capacitor home depot | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| HVAC Systems | Replacement capacitors for air conditioning units | Ensures efficient cooling and energy savings | Voltage ratings, capacitance, and terminal compatibility |

| Manufacturing | Power factor correction in industrial motors | Reduces energy costs and improves equipment lifespan | Compliance with local electrical standards and certifications |

| Renewable Energy | Capacitors in solar inverter systems | Enhances energy conversion efficiency | Environmental regulations and compatibility with specific inverter models |

| Automotive | Capacitors in electric vehicle charging stations | Supports rapid charging and system reliability | Voltage ratings and compatibility with various EV models |

| Telecommunications | Capacitors in power supply units for telecom towers | Ensures stable power supply for uninterrupted service | Durability under extreme weather conditions and voltage specifications |

How Are AC Capacitors Used in HVAC Systems and What Benefits Do They Provide?

In HVAC systems, AC capacitors are crucial for the operation of air conditioning units. They provide the initial electrical charge needed to start the motor and maintain its function. For businesses, this translates to consistent cooling performance, which is vital for customer satisfaction and energy efficiency. International buyers, particularly in regions with extreme climates like Nigeria and Saudi Arabia, must consider the voltage ratings and capacitance specifications to ensure compatibility with local AC units.

What Role Do AC Capacitors Play in Manufacturing and How Can They Optimize Operations?

In manufacturing, AC capacitors are employed for power factor correction in industrial motors. By improving the power factor, these capacitors reduce energy costs and enhance the lifespan of the equipment. This is particularly beneficial for businesses in South America and Africa, where energy costs can significantly impact operational budgets. Buyers should be aware of local electrical standards and ensure that capacitors meet compliance requirements for safe and efficient operation.

How Are AC Capacitors Essential for Renewable Energy Applications?

AC capacitors are integral to solar inverter systems, where they enhance energy conversion efficiency. For businesses in the renewable energy sector, particularly in Europe, this efficiency translates to higher returns on investment and reduced energy waste. When sourcing capacitors for this application, buyers must consider environmental regulations and compatibility with specific inverter models to ensure optimal performance.

What Are the Applications of AC Capacitors in the Automotive Sector?

In the automotive industry, AC capacitors are utilized in electric vehicle (EV) charging stations to support rapid charging capabilities. This is essential for businesses involved in EV infrastructure development, as it ensures reliable and efficient charging solutions. Buyers should focus on voltage ratings and compatibility with various EV models to meet the diverse needs of consumers in different markets.

Why Are AC Capacitors Critical for Telecommunications Infrastructure?

Telecommunications rely on AC capacitors in power supply units for telecom towers, ensuring stable power supply and uninterrupted service. For businesses in this sector, particularly in the Middle East, the reliability of power systems is paramount. When sourcing these capacitors, durability under extreme weather conditions and adherence to voltage specifications are key considerations to ensure long-term operational success.

3 Common User Pain Points for ‘ac capacitor home depot’ & Their Solutions

Scenario 1: Difficulty in Identifying the Right AC Capacitor Type

The Problem: B2B buyers often face challenges when trying to identify the correct type of AC capacitor for their specific air conditioning units. This confusion arises from the vast range of capacitors available, with varying specifications such as capacitance, voltage ratings, and terminal configurations. In many cases, buyers may not have access to comprehensive technical data or may lack familiarity with the nuances of AC capacitor specifications, leading to potential mismatches and costly errors in their projects.

The Solution: To effectively source the right capacitor, buyers should begin by thoroughly examining the existing capacitor for its specifications, which are typically printed on a label attached to the component. Key specifications to note include capacitance (measured in microfarads), voltage rating, and frequency (50 or 60 Hz). Once these details are established, buyers can utilize the Home Depot website or visit their local store, where they can filter capacitor options based on these parameters. Additionally, leveraging Home Depot’s customer service can provide further assistance in identifying the right product. For buyers operating in regions with limited access to technical support, having a reliable partner or technician who understands these specifications can save time and ensure the correct component is selected.

Scenario 2: Safety Concerns When Replacing AC Capacitors

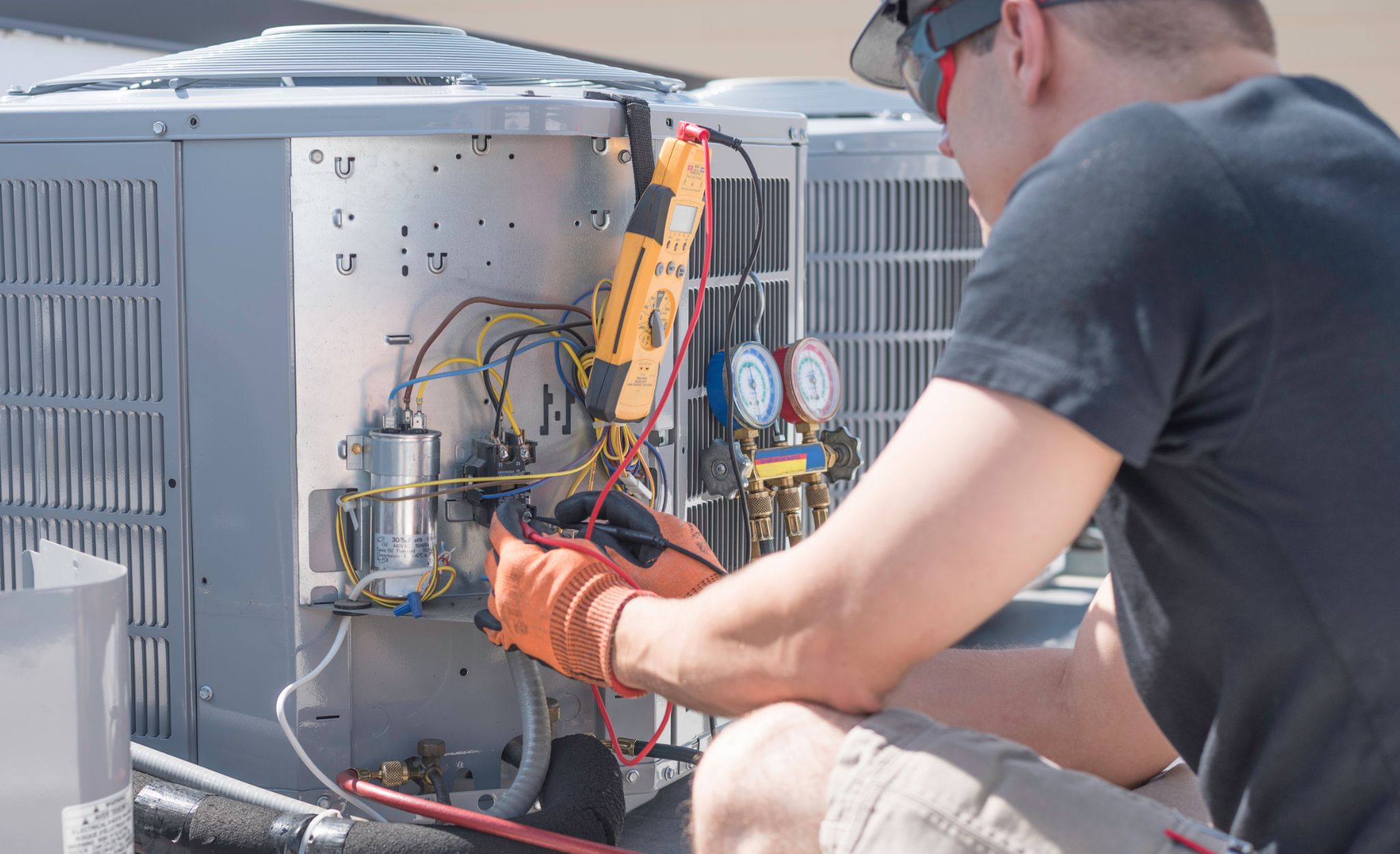

The Problem: Safety is a paramount concern for B2B buyers, especially HVAC technicians, when replacing AC capacitors. Improper handling of capacitors can lead to electrical shocks, equipment damage, or even personal injury. Many technicians may not be familiar with the necessary safety precautions, which can deter them from performing this essential maintenance task effectively.

The Solution: To mitigate safety risks, buyers should invest in comprehensive training for their technicians that covers the safe handling and replacement of AC capacitors. This training should emphasize the importance of wearing appropriate safety gear, such as insulated gloves and safety glasses, and ensuring that the power supply is completely shut off before beginning any work. Additionally, Home Depot provides resources and guides on capacitor replacement, including safety protocols that can be reviewed beforehand. Technicians should also familiarize themselves with the discharging process of capacitors, which can prevent accidental shocks. By prioritizing safety training and following established guidelines, buyers can enhance their operational safety and confidence when handling AC capacitors.

Illustrative image related to ac capacitor home depot

Scenario 3: Challenges in Managing Capacitor Inventory and Supply Chain

The Problem: For B2B buyers in HVAC maintenance, managing inventory levels of AC capacitors can be a logistical challenge. Fluctuations in demand, coupled with inconsistent supply chains, can lead to shortages that hinder service delivery. Additionally, buyers may struggle with overstocking or understocking specific capacitor types, which affects cash flow and operational efficiency.

The Solution: To address these inventory management challenges, buyers should implement a robust inventory tracking system that monitors usage rates of different capacitor types. By analyzing historical data on capacitor replacements, businesses can predict future needs more accurately. Collaborating with Home Depot’s Pro Services can also provide insights into current market trends and availability, allowing buyers to adjust their purchasing strategies accordingly. Establishing a close relationship with suppliers and utilizing Home Depot’s bulk purchasing options can help secure necessary stock while optimizing costs. Finally, adopting a just-in-time inventory approach can minimize overstocking, ensuring that the right capacitors are on hand when needed without tying up excessive capital in inventory.

Strategic Material Selection Guide for ac capacitor home depot

What Are the Common Materials Used in AC Capacitors?

When selecting AC capacitors for applications from Home Depot or similar suppliers, understanding the materials used in their construction is crucial for ensuring optimal performance and longevity. Here, we analyze four common materials: aluminum, polypropylene, polyester, and ceramic, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Aluminum Impact Capacitor Performance?

Aluminum is a prevalent material in AC capacitors, particularly for its conductivity and lightweight properties. Key properties include a high temperature rating, typically around 85°C to 105°C, and good corrosion resistance when anodized.

Pros: Aluminum capacitors are generally cost-effective and have a high capacitance-to-volume ratio, allowing for compact designs. They are also widely available and compatible with many applications.

Cons: However, aluminum capacitors can be sensitive to high humidity and temperature fluctuations, which may lead to reduced lifespan. Additionally, they may require more complex manufacturing processes to ensure reliability.

Impact on Application: Aluminum capacitors are suitable for various media, including air conditioning systems, but may not perform well in extreme conditions.

Considerations for International Buyers: Buyers from regions like Africa and the Middle East should ensure compliance with local standards, such as ASTM and IEC, and consider the environmental conditions that may affect aluminum performance.

What Role Does Polypropylene Play in Capacitors?

Polypropylene is another common material used in AC capacitors, especially in film capacitors. It boasts excellent electrical properties, including a high dielectric strength and low dissipation factor.

Pros: Polypropylene capacitors are highly durable, withstanding high temperatures (up to 105°C) and offering good resistance to moisture and chemicals. They also have a long lifespan, making them suitable for demanding applications.

Cons: The primary drawback is the higher cost compared to aluminum capacitors. Additionally, manufacturing polypropylene capacitors can be more complex due to the need for precise winding and encapsulation.

Impact on Application: Polypropylene capacitors are ideal for applications requiring stability and reliability, such as in HVAC systems.

Considerations for International Buyers: Buyers should verify compliance with international standards and consider the availability of polypropylene capacitors in their region, especially in South America and Europe.

How Does Polyester Compare in Capacitor Applications?

Polyester, often used in film capacitors, is known for its versatility and reliability. It has a moderate temperature rating (typically around 85°C) and decent moisture resistance.

Pros: Polyester capacitors are generally less expensive than polypropylene and provide good performance for many applications. They are also lightweight and compact, making them easy to integrate into various systems.

Cons: However, polyester capacitors may have lower voltage ratings and can be less durable in high-temperature environments compared to polypropylene.

Impact on Application: They are suitable for general-purpose applications, including air conditioning systems, where extreme performance is not critical.

Considerations for International Buyers: Buyers should be aware of the varying standards for polyester capacitors across regions, particularly in Europe where regulations may differ.

What Advantages Do Ceramic Capacitors Offer?

Ceramic capacitors are known for their stability and reliability, especially in high-frequency applications. They have a wide temperature rating (up to 125°C) and excellent voltage ratings.

Pros: Ceramic capacitors are highly durable, resistant to moisture, and offer low losses. They are also compact and lightweight, making them suitable for various applications.

Cons: The main limitation is their cost, which can be higher than other materials. Additionally, they may have lower capacitance values compared to aluminum or film capacitors.

Illustrative image related to ac capacitor home depot

Impact on Application: Ceramic capacitors are ideal for applications requiring high stability and precision, such as in advanced HVAC systems.

Considerations for International Buyers: Compliance with international standards is crucial, and buyers should consider the specific needs of their applications, especially in diverse climates found in Africa and the Middle East.

Summary Table of Material Selection for AC Capacitors

| Material | Typical Use Case for ac capacitor home depot | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | General AC applications | Cost-effective and compact | Sensitive to humidity and temperature | Low |

| Polypropylene | HVAC systems requiring stability | High durability and long lifespan | Higher cost and complex manufacturing | High |

| Polyester | General-purpose AC applications | Lightweight and affordable | Lower voltage ratings and durability | Medium |

| Ceramic | High-frequency and precision applications | High stability and moisture resistance | Higher cost and lower capacitance values | High |

This guide provides a comprehensive overview of the materials used in AC capacitors, assisting B2B buyers in making informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for ac capacitor home depot

What Are the Main Stages of Manufacturing AC Capacitors for Home Depot?

The manufacturing process of AC capacitors involves several critical stages that ensure the final product meets the necessary performance and safety standards. Understanding these stages can aid B2B buyers in making informed purchasing decisions.

Material Preparation: What Raw Materials Are Used in AC Capacitor Production?

The first step in manufacturing AC capacitors is material preparation. Key raw materials typically include:

- Aluminum Foil: Used for the electrodes, aluminum is favored for its excellent conductivity and lightweight properties.

- Dielectric Material: Commonly polypropylene, polyester, or paper impregnated with oil. This material is essential for storing electrical energy.

- Metal Terminals: These are often made from brass or nickel-plated steel to ensure corrosion resistance and electrical conductivity.

These materials must meet stringent quality standards to ensure longevity and reliability in electrical applications.

How Are AC Capacitors Formed and Assembled?

The next stage is forming and assembling the capacitors. Key techniques include:

- Electrode Stacking: The aluminum foil and dielectric material are layered together in a specific arrangement to create the capacitor’s core. The layering process must be precise to ensure optimal performance.

- Winding: For cylindrical capacitors, the stacked layers are wound into a coil. This technique maximizes capacitance and minimizes space.

- Sealing: After winding, the capacitor is sealed in a protective casing, often made of plastic or metal. This step is critical to protect the internal components from environmental factors.

During this phase, manufacturers may employ automated machinery to enhance precision and efficiency.

What Finishing Techniques Are Used in AC Capacitor Manufacturing?

The finishing stage involves several processes to ensure that the capacitors are ready for market:

- Testing and Quality Control: Each capacitor undergoes rigorous testing to verify its performance metrics, such as capacitance and voltage ratings.

- Labeling: Proper labeling is crucial for compliance with international standards, and it typically includes capacitance values, voltage ratings, and safety warnings.

- Packaging: The final step involves packaging the capacitors in a manner that protects them during shipping and handling. This often includes bubble wrap and sturdy boxes to prevent damage.

What Quality Assurance Standards Are Relevant for AC Capacitors?

Quality assurance (QA) is a vital aspect of AC capacitor manufacturing, ensuring products meet both safety and performance standards. International and industry-specific standards play a crucial role in this process.

Which International Standards Should B2B Buyers Be Aware Of?

AC capacitors should comply with several international standards, including:

- ISO 9001: This standard focuses on quality management systems. Compliance indicates that the manufacturer has a robust QA process in place.

- CE Marking: Essential for products sold in the European market, CE marking signifies that the product meets EU safety, health, and environmental protection standards.

- UL Certification: For North American markets, Underwriters Laboratories (UL) certification ensures that products have been tested for safety.

These certifications not only enhance product reliability but also facilitate easier market access across different regions.

What Are the Key Quality Control Checkpoints in AC Capacitor Manufacturing?

Throughout the manufacturing process, several quality control checkpoints are implemented to maintain high standards:

- Incoming Quality Control (IQC): Raw materials are tested upon arrival to ensure they meet required specifications before production begins.

- In-Process Quality Control (IPQC): Ongoing monitoring during the manufacturing process helps catch any defects early. This includes testing capacitance and voltage at various stages.

- Final Quality Control (FQC): Before packaging, finished capacitors undergo comprehensive testing to verify their performance and compliance with specifications.

These checkpoints are crucial for minimizing defects and ensuring that only high-quality products reach the market.

How Can B2B Buyers Verify the Quality Control Processes of AC Capacitor Suppliers?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential.

What Are the Best Practices for Supplier Audits?

Conducting supplier audits is a practical approach to ensure quality assurance. Here are key steps:

- Request Documentation: Ask for quality management system documents, including certifications like ISO 9001 or CE marking.

- On-Site Audits: Whenever possible, conduct on-site audits to observe manufacturing processes and quality control measures firsthand. This provides valuable insights into the supplier’s capabilities.

- Third-Party Inspections: Engage third-party inspection services to conduct independent assessments. These services can offer objective evaluations of the supplier’s quality management practices.

What Testing Methods Can B2B Buyers Expect for AC Capacitors?

Common testing methods that B2B buyers should inquire about include:

- Capacitance Testing: Verifying that the capacitance value falls within the specified range.

- Voltage Testing: Ensuring that the capacitor can handle its rated voltage without failure.

- Life Cycle Testing: Assessing how the capacitor performs under various environmental conditions and over time.

Understanding these testing methods can help buyers gauge the reliability of the capacitors they intend to purchase.

What Are the QC and Certification Nuances for International B2B Buyers?

International B2B buyers must navigate various quality control and certification nuances when sourcing AC capacitors. Here are some considerations:

- Regional Standards: Different regions may have specific standards that must be adhered to. For instance, products sold in the EU must comply with CE marking, while products in the U.S. may require UL certification.

- Documentation Requirements: Ensure that all necessary documentation accompanies the products, including test reports and certificates of conformity.

- Cultural Differences: Be aware of cultural differences in business practices that may affect communication and negotiations with suppliers. Building strong relationships can facilitate better quality assurance.

By understanding the manufacturing processes and quality assurance protocols for AC capacitors, B2B buyers can make informed decisions that enhance their procurement strategies and ensure they receive high-quality products.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ac capacitor home depot’

Introduction

Sourcing AC capacitors for air conditioning systems requires careful consideration to ensure compatibility, reliability, and value. This checklist provides B2B buyers with a structured approach to procuring AC capacitors, particularly from retailers like Home Depot. By following these steps, you can make informed purchasing decisions that align with your technical requirements and business needs.

Illustrative image related to ac capacitor home depot

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s essential to outline the technical specifications of the AC capacitors you require. This includes understanding the capacitance (in microfarads), voltage rating (typically 370V or 440V), and frequency (50Hz or 60Hz). Having these specifications clearly defined helps narrow down options and ensures compatibility with existing equipment.

- Capacitance: Determine the required microfarads based on the specifications of your current capacitor.

- Voltage Rating: Ensure the voltage rating of the new capacitor is equal to or greater than the existing one.

Step 2: Research Reliable Suppliers

Identifying reliable suppliers is crucial for obtaining quality products. Investigate suppliers like Home Depot and others in your region, focusing on their track record in the HVAC market. Look for reviews, ratings, and any certifications that indicate quality assurance.

- Supplier Reputation: Check online reviews and industry ratings.

- Certifications: Verify if suppliers hold relevant quality certifications, such as ISO or similar.

Step 3: Assess Product Availability and Lead Times

Once you have a list of potential suppliers, assess their product availability and lead times. This is particularly important for businesses operating in regions where demand may outstrip supply. Understanding lead times allows for better planning and avoids disruptions in your operations.

- Stock Levels: Confirm whether the supplier has the required capacitors in stock.

- Delivery Times: Inquire about estimated delivery times to ensure they meet your project timelines.

Step 4: Evaluate Pricing Structures

Pricing can vary significantly among suppliers. Compare the costs of AC capacitors while considering the total cost of ownership, which includes shipping, taxes, and any additional fees. This evaluation helps you identify the most cost-effective option without compromising quality.

- Unit Prices: Obtain quotes for bulk purchases to leverage potential discounts.

- Hidden Costs: Clarify shipping and handling fees that might impact total costs.

Step 5: Verify Warranty and Return Policies

A strong warranty and return policy can safeguard your investment in case of defects or compatibility issues. Before finalizing your purchase, review the warranty terms and return policy of the supplier to ensure they align with your risk management strategies.

- Warranty Duration: Look for warranties that cover a reasonable time frame.

- Return Conditions: Understand the conditions under which returns are accepted.

Step 6: Request Samples or Technical Support

If possible, request samples of the capacitors or technical support to verify compatibility before bulk purchasing. This step can prevent costly mistakes and ensure that the products meet your operational needs.

Illustrative image related to ac capacitor home depot

- Sample Requests: Inquire if suppliers can provide samples for testing.

- Technical Assistance: Ensure that the supplier offers technical support for installation and troubleshooting.

Step 7: Finalize the Purchase Agreement

After completing the previous steps, finalize your purchase agreement with the chosen supplier. Ensure all terms, including pricing, delivery, and warranty, are clearly outlined in the contract to avoid misunderstandings.

- Contract Clarity: Review the contract for clarity on all terms.

- Payment Terms: Confirm payment methods and terms to facilitate a smooth transaction.

By following this practical sourcing guide, B2B buyers can navigate the complexities of procuring AC capacitors effectively, ensuring they meet their technical requirements and achieve optimal value for their investments.

Comprehensive Cost and Pricing Analysis for ac capacitor home depot Sourcing

What Are the Key Cost Components for AC Capacitors Sourced from Home Depot?

When analyzing the cost structure for AC capacitors sourced from Home Depot, several key components must be taken into account:

-

Materials: The primary cost driver is the raw materials used in capacitor manufacturing. High-quality dielectric materials and metal elements contribute significantly to the total cost. The quality of these materials directly affects performance and longevity, making it crucial to choose suppliers who provide certified components.

-

Labor: Labor costs encompass both direct and indirect labor involved in the manufacturing and assembly processes. Skilled technicians are required for production, especially for quality control and testing phases, which are essential to ensure the capacitors meet industry standards.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, maintenance, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs, thus providing a competitive edge.

-

Tooling: Investment in tooling and equipment is necessary for the production of capacitors. This cost can vary based on the complexity of the designs and the technology used in manufacturing.

-

Quality Control (QC): Implementing a robust QC process ensures that the capacitors produced meet safety and performance standards. This involves testing each batch of products, which can add to the overall cost but is vital for maintaining reliability.

-

Logistics: Shipping and handling costs must also be factored in, especially for international buyers. The distance from manufacturing sites, shipping methods, and import duties can significantly influence the final pricing.

-

Margin: Finally, suppliers will include a margin on top of their costs to ensure profitability. This margin can vary based on competition and market demand.

What Influences the Pricing of AC Capacitors for International Buyers?

Several factors affect the pricing of AC capacitors, particularly for international B2B buyers from regions such as Africa, South America, the Middle East, and Europe:

-

Volume/MOQ: Bulk purchases often lead to lower unit costs. Understanding the minimum order quantities (MOQ) can provide opportunities for negotiating better pricing.

-

Specifications and Customization: Custom specifications can lead to increased costs due to the need for specialized materials or tooling. However, tailored solutions may be necessary for specific applications.

-

Materials: The choice of materials impacts both the performance and the cost. Higher quality materials may be more expensive but can lead to lower failure rates and longer lifespans, thus affecting the Total Cost of Ownership (TCO).

-

Quality Certifications: Products that come with industry certifications or meet international standards may command higher prices. Buyers should evaluate whether the premium is justified based on their operational requirements.

-

Supplier Factors: The reputation, reliability, and financial stability of the supplier can influence pricing. Established suppliers may charge more due to perceived value and reliability.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can significantly affect the final price. Understanding who bears the cost of shipping, insurance, and customs duties is essential for accurate pricing.

What Tips Should International B2B Buyers Consider When Sourcing AC Capacitors?

-

Negotiation: Always negotiate terms and pricing. Suppliers may have flexibility in pricing, especially for larger orders or long-term contracts.

-

Cost-Efficiency: Focus on the Total Cost of Ownership rather than just the purchase price. Consider factors like warranty, expected lifespan, and energy efficiency when evaluating costs.

-

Pricing Nuances: Be aware of potential hidden costs such as tariffs, taxes, and shipping fees when importing capacitors. These can significantly impact the overall expenditure.

-

Supplier Relationships: Building a good relationship with suppliers can lead to better pricing, priority service, and access to exclusive products.

-

Market Research: Conduct thorough market research to understand the price range and quality of capacitors available. This knowledge can empower you during negotiations and help you identify reputable suppliers.

Disclaimer

The prices mentioned are indicative and can vary based on market conditions, supplier negotiations, and specific requirements. Always conduct thorough research and consultations before making purchasing decisions.

Illustrative image related to ac capacitor home depot

Alternatives Analysis: Comparing ac capacitor home depot With Other Solutions

Introduction: Exploring Alternatives to AC Capacitors from Home Depot

When sourcing components for air conditioning systems, businesses often seek reliable and cost-effective solutions. While AC capacitors from Home Depot are a popular choice for many, exploring alternative options can lead to improved performance, cost savings, and enhanced serviceability. In this analysis, we will compare the AC capacitors available at Home Depot with two viable alternatives: high-efficiency capacitors and universal replacement capacitors.

Comparison Table

| Comparison Aspect | Ac Capacitor Home Depot | High-Efficiency Capacitors | Universal Replacement Capacitors |

|---|---|---|---|

| Performance | Standard reliability; suitable for most applications | Higher efficiency; can improve energy savings by up to 20% | Versatile but may not match original performance specifications |

| Cost | Moderate pricing; competitive with local retailers | Typically higher initial investment | Generally lower cost; may require additional adjustments |

| Ease of Implementation | Simple installation; clear guidelines available | Installation may require specialized knowledge | User-friendly; designed for easy replacement |

| Maintenance | Minimal maintenance; standard durability | Longer lifespan; less frequent replacements needed | Varies by model; some may require more frequent checks |

| Best Use Case | General residential and light commercial use | High-demand environments where energy efficiency is critical | Older systems or where specific capacitor types are unavailable |

Detailed Breakdown of Alternatives

High-Efficiency Capacitors

High-efficiency capacitors are designed to enhance the performance of air conditioning units by reducing energy consumption. They can provide significant energy savings, making them an ideal choice for businesses looking to lower operational costs. While their initial cost is higher than standard capacitors from Home Depot, the long-term savings can offset this expense. The installation process may require specialized knowledge, which could add to the overall investment if professional assistance is needed. However, their durability and longer lifespan make them a worthwhile investment for high-demand applications.

Universal Replacement Capacitors

Universal replacement capacitors offer flexibility for various air conditioning systems, making them a viable alternative for businesses with mixed equipment types. They are generally more affordable than specific capacitors sold at Home Depot, which can be appealing for budget-conscious buyers. However, while universal capacitors can fit many systems, they may not always meet the original performance specifications, leading to potential inefficiencies. They are designed for user-friendly installation, which can be advantageous for those who prefer DIY maintenance. Still, it’s essential to verify compatibility with specific AC units to avoid performance issues.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate capacitor solution for air conditioning systems requires careful consideration of performance, cost, and application. While AC capacitors from Home Depot offer a reliable and straightforward option, exploring high-efficiency and universal replacement capacitors can lead to improved energy savings and flexibility. B2B buyers should assess their specific needs, including system compatibility and operational demands, to make an informed decision that aligns with their long-term maintenance and cost-efficiency goals. By weighing these alternatives, businesses can optimize their HVAC systems for better performance and reduced energy consumption.

Essential Technical Properties and Trade Terminology for ac capacitor home depot

What Are the Key Technical Properties of AC Capacitors for B2B Buyers?

When sourcing AC capacitors, understanding the essential specifications is crucial for ensuring compatibility and performance in air conditioning systems. Here are some key properties to consider:

-

Capacitance (µF or MFD)

Capacitance indicates the capacitor’s ability to store electrical charge, measured in microfarads (µF) or MFD. This specification directly influences the efficiency of the air conditioning unit. For B2B buyers, matching the capacitance of replacement capacitors with the original is critical to avoid operational inefficiencies or failures. -

Voltage Rating

Capacitors are typically rated for either 370 volts or 440 volts. It is essential to select a replacement capacitor with a voltage rating equal to or higher than the original. Choosing a capacitor with a lower voltage rating can lead to catastrophic failure and damage to the AC unit, impacting service reliability and increasing repair costs. -

Frequency Rating (Hz)

AC capacitors are rated for either 50 or 60 Hertz, depending on the electrical system’s design. Ensuring the frequency rating matches that of the original capacitor is vital for optimal performance. Mismatched frequency ratings can lead to inefficiencies and reduced lifespan of the AC unit. -

Terminal Types

The configuration of the terminals is crucial for installation. Capacitors can have one to four metal tabs, and it’s important to ensure that the replacement capacitor has the same number and configuration of terminals as the original. This ensures compatibility and ease of installation, minimizing downtime. -

Case Shape

Capacitors may come in various shapes, typically cylindrical or oval. While the shape does not impact functionality, it is essential to ensure that the physical dimensions fit within the designated space in the AC unit. This consideration can prevent installation issues and facilitate a smoother replacement process.

What Trade Terminology Should B2B Buyers Know for AC Capacitors?

Familiarity with industry-specific jargon can significantly enhance communication and negotiation in B2B transactions. Here are some common terms related to AC capacitors:

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that are sold under another company’s brand. Understanding OEM specifications is crucial for buyers looking for components that meet the original standards of quality and performance. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers plan their purchasing strategy, ensuring they meet the supplier’s requirements while managing inventory costs effectively. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For B2B buyers, issuing an RFQ can lead to better pricing and contract terms, allowing for more informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping goods. Understanding these terms is essential for managing logistics and ensuring that both parties are clear on shipping responsibilities, costs, and risks. -

Lead Time

Lead time refers to the amount of time it takes from placing an order until it is delivered. Knowing the lead time for capacitors is essential for project planning and inventory management, particularly in industries with tight deadlines. -

Warranties and Guarantees

These are assurances provided by manufacturers regarding the performance and reliability of their products. Familiarizing oneself with warranty conditions can help buyers make more confident decisions, ensuring they are protected against potential defects or failures.

By understanding these technical properties and trade terminologies, international B2B buyers can make informed decisions that enhance the efficiency and reliability of their air conditioning systems.

Navigating Market Dynamics and Sourcing Trends in the ac capacitor home depot Sector

What Are the Key Market Dynamics Affecting AC Capacitors for B2B Buyers?

The global market for AC capacitors, particularly in sectors like HVAC (Heating, Ventilation, and Air Conditioning), is experiencing significant growth driven by increasing urbanization and a rising demand for energy-efficient systems. International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, are increasingly seeking suppliers who can provide high-quality components that meet stringent performance standards. Key trends include the shift towards smart technologies and IoT-enabled HVAC systems, which require advanced capacitors that can handle variable loads and ensure consistent performance.

Emerging sourcing technologies, such as digital procurement platforms and AI-driven analytics, are enhancing supply chain efficiency by enabling buyers to access real-time data on pricing and inventory levels. This capability is particularly beneficial for buyers in developing markets, where reliable supply chains can be a challenge. Moreover, suppliers who offer flexible payment terms and localized support can significantly improve their attractiveness to international buyers, especially in regions with diverse economic conditions.

How Is Sustainability Influencing B2B Sourcing of AC Capacitors?

Sustainability has become a cornerstone of modern B2B sourcing strategies, and the AC capacitor sector is no exception. Environmental concerns surrounding electronic waste and energy consumption have prompted manufacturers to adopt more sustainable practices. For international buyers, especially those from regions like Nigeria and Saudi Arabia, selecting suppliers who prioritize eco-friendly materials and manufacturing processes is critical. This includes sourcing capacitors made from recyclable materials and utilizing production methods that minimize carbon footprints.

Furthermore, buyers are increasingly interested in suppliers who hold ‘green’ certifications, such as ISO 14001, which signifies a commitment to effective environmental management systems. These certifications not only enhance the credibility of suppliers but also align with the sustainability goals of many organizations. As global regulations tighten around environmental standards, B2B buyers who prioritize ethical sourcing will likely gain a competitive advantage in their respective markets.

How Has the AC Capacitor Market Evolved Over Time?

The evolution of the AC capacitor market has been shaped by technological advancements and changing consumer demands. Initially, capacitors were primarily used in basic electrical applications, but as HVAC technology advanced, the need for more sophisticated capacitors became apparent. Today, capacitors are integral to energy-efficient air conditioning systems, enabling them to operate at optimal efficiency and reliability.

The introduction of digital technologies and smart home systems has further transformed the landscape, leading to the development of capacitors that support variable frequency drives and other innovative applications. This evolution has created opportunities for international B2B buyers to engage with suppliers who are at the forefront of technological advancements, ensuring they can meet the demands of modern HVAC systems while adhering to sustainability practices.

Frequently Asked Questions (FAQs) for B2B Buyers of ac capacitor home depot

-

How do I determine the right AC capacitor for my air conditioning unit?

To select the appropriate AC capacitor, first identify the specifications of the existing capacitor, which include capacitance (measured in microfarads), voltage rating, frequency (50 or 60 Hz), and terminal types. Match these specifications with those of the replacement capacitor to ensure compatibility. Additionally, consider the physical shape of the capacitor, as it should fit within the unit’s housing. If you’re sourcing internationally, confirm that the manufacturer’s product complies with local electrical standards. -

What is the best way to ensure the quality of AC capacitors when buying from suppliers?

To ensure quality, source AC capacitors from reputable suppliers who provide certifications or quality assurance documentation. Request samples to test their performance, and verify that they meet the required industry standards, such as UL or CE certifications. It’s also beneficial to read reviews or testimonials from other B2B buyers, and engage in direct communication with the supplier to assess their responsiveness and expertise in the product. -

What are the typical minimum order quantities (MOQs) for AC capacitors?

Minimum order quantities can vary significantly based on the supplier and the type of capacitor. Typically, MOQs range from 50 to 100 units for standard products, but some manufacturers may offer lower MOQs for customized orders. When negotiating, consider your business’s demand forecast to ensure that the MOQ aligns with your inventory management and cash flow capabilities. -

What payment terms should I expect when sourcing AC capacitors internationally?

Payment terms for international transactions often include options such as wire transfers, letters of credit, and payment upon delivery. Standard practices involve a 30% deposit upfront, with the balance due before shipment. Always clarify payment terms during negotiations and ensure that they are documented in the contract to avoid misunderstandings. It’s also wise to consider currency fluctuations and potential fees associated with international transactions. -

How can I vet potential suppliers of AC capacitors?

To vet suppliers, conduct thorough research by checking their business credentials, industry certifications, and customer reviews. Request references from previous clients and inquire about their experience with product quality and delivery timelines. Additionally, consider visiting their manufacturing facilities if possible, or utilize third-party inspection services to verify their operations and product standards before placing a significant order. -

What logistics considerations should I keep in mind when importing AC capacitors?

When importing AC capacitors, consider factors such as shipping methods, customs duties, and delivery timelines. Choose a reliable freight forwarder who understands the complexities of international shipping and can assist with customs clearance. Be aware of the regulations and tariffs applicable to electrical components in your country, as these can impact costs and delivery schedules. Finally, ensure proper documentation accompanies your shipment to prevent delays. -

Can I customize AC capacitors for specific applications?

Yes, many manufacturers offer customization options for AC capacitors to meet specific application needs, such as unique capacitance values, voltage ratings, or terminal configurations. When requesting custom capacitors, provide detailed specifications and any relevant application data to ensure the manufacturer understands your requirements. Be prepared for longer lead times and potentially higher costs associated with custom production. -

What safety standards should AC capacitors comply with for international trade?

AC capacitors should comply with relevant safety standards such as UL (Underwriters Laboratories), CE (Conformité Européenne), or IEC (International Electrotechnical Commission) certifications, depending on the target market. Verify that the products meet local regulations and safety standards to ensure compliance and safety for end-users. Request documentation from suppliers to confirm adherence to these standards, which is crucial for maintaining product integrity and avoiding legal issues.

Top 2 Ac Capacitor Home Depot Manufacturers & Suppliers List

1. Capacitors – HVAC Solutions

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Electrical capacitors for HVAC use are not sold at Home Depot due to the variety of types and potential dangers associated with consumer replacement. Specialist stores and supply houses typically carry these products, catering to commercial customers and tradespeople. Online availability exists, but immediate needs for HVAC repairs often lead customers to seek local options.

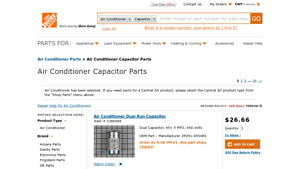

2. Home Depot – Air Conditioner Dual Run Capacitor

Domain: appliancerepair.homedepot.com

Registered: 1992 (33 years)

Introduction: [{‘name’: ‘Air Conditioner Dual Run Capacitor’, ‘price’: ‘$26.66’, ‘availability’: ‘In Stock’, ‘specifications’: ‘Dual Capacitor, 45+ 5 MFD, 440 volts’, ‘OEM Part’: ‘Manufacturer #P291-4554RS’}, {‘name’: ‘Air Conditioner Dual Run Capacitor’, ‘price’: ‘$24.50’, ‘availability’: ‘In Stock’, ‘specifications’: ‘Dual run capacitor round 440 V 35/5 uF’, ‘OEM Part’: ‘Manufacturer #P291-3554RS’}, {‘name’: …

Strategic Sourcing Conclusion and Outlook for ac capacitor home depot

In today’s competitive landscape, effective strategic sourcing for AC capacitors from Home Depot can significantly enhance operational efficiency and reduce costs for international B2B buyers. Understanding the critical specifications of AC capacitors, such as capacitance, voltage, and terminal types, enables procurement professionals to make informed purchasing decisions that align with their specific needs. Additionally, leveraging Home Depot’s extensive inventory and resources can streamline the replacement process, ensuring minimal downtime for HVAC systems.

As global markets evolve, it is crucial for businesses in regions like Africa, South America, the Middle East, and Europe to stay ahead of the curve by embracing strategic sourcing practices. This not only optimizes supply chains but also fosters long-term partnerships with reliable suppliers.

Looking ahead, B2B buyers should explore the potential of digital platforms and tools offered by Home Depot to enhance their sourcing strategies. By prioritizing quality and compatibility in capacitor selection, companies can ensure their HVAC systems operate at peak performance. Take the next step in your sourcing journey—partner with Home Depot to secure the best AC capacitors for your business needs.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.