Ab Twist Machine: The Ultimate B2B Sourcing Guide for Global Buyer

Introduction: Navigating the Global Market for ab twist machine

In today’s competitive fitness market, sourcing an effective ab twist machine can be a daunting challenge for international B2B buyers. With the increasing demand for innovative home fitness solutions, particularly in regions like Africa, South America, the Middle East, and Europe, understanding the nuances of this equipment is crucial. This guide serves as a comprehensive resource, offering insights into the various types of ab twist machines available, their applications in both commercial and residential settings, and the importance of supplier vetting to ensure quality and reliability.

As buyers navigate through the complexities of sourcing, they will find detailed sections that cover the cost implications, potential return on investment, and the latest trends in fitness technology. By arming themselves with this knowledge, B2B buyers can make informed purchasing decisions that not only meet their clients’ needs but also align with market demands. Whether you’re a fitness equipment distributor in Nigeria or a gym owner in Brazil, this guide is designed to empower you with actionable insights that enhance your competitive edge. Embrace the opportunity to elevate your offerings with the right ab twist machines and cater to a growing market of health-conscious consumers seeking effective workout solutions.

Understanding ab twist machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Portable Waist Twister | Compact design, foldable, foot massage feature | Home fitness, small gyms | Pros: Easy to store, quiet operation. Cons: Limited resistance options. |

| Abdominal Rotation Machine | Fixed seat with adjustable weights for resistance training | Commercial gyms, rehabilitation centers | Pros: Targets obliques effectively. Cons: Requires more space, higher cost. |

| Adjustable Torso Twister | Adjustable seat height and resistance levels | Fitness studios, personal training facilities | Pros: Versatile for all fitness levels. Cons: May be complex for beginners. |

| Motorized Twisting Machine | Automated twisting motion with programmable settings | High-end gyms, wellness centers | Pros: Engages users with varied workouts. Cons: Higher maintenance, cost. |

| Dual Function Twist Machine | Combines twisting with other core exercises | Multi-functional gyms, fitness franchises | Pros: Space-efficient, diverse workout options. Cons: Can compromise on specific muscle targeting. |

What are the Characteristics of a Portable Waist Twister?

The Portable Waist Twister is designed for convenience, making it ideal for home fitness enthusiasts or small gym setups. Its compact size allows for easy storage, and its foldable nature is perfect for limited spaces. The added foot massage feature enhances user comfort, making it suitable for a wide range of users, including beginners. When considering this machine, B2B buyers should evaluate the target market’s need for space-efficient equipment and potential customer preferences for quiet workout options.

How Do Abdominal Rotation Machines Function in Commercial Settings?

Abdominal Rotation Machines are robust, fixed-seat machines that allow users to perform core exercises against adjustable resistance. They are primarily used in commercial gyms and rehabilitation centers, targeting the obliques effectively. For B2B buyers, the durability and effectiveness of these machines can drive customer satisfaction and retention. However, they require more space and a higher investment, making it essential to assess the facility’s layout and budget before purchasing.

What Makes Adjustable Torso Twisters Suitable for Fitness Studios?

Adjustable Torso Twisters cater to a diverse clientele by offering adjustable seat heights and resistance levels. This versatility makes them suitable for fitness studios and personal training facilities where users of varying fitness levels can benefit. B2B buyers should consider the potential for increased membership satisfaction and retention through the availability of adaptable equipment. However, the complexity of the machine might pose a challenge for beginners, requiring staff training and clear instructions.

Why Invest in Motorized Twisting Machines for High-End Gyms?

Motorized Twisting Machines provide automated twisting motions and programmable settings that engage users with varied workouts. These machines are often found in high-end gyms and wellness centers, appealing to fitness enthusiasts looking for innovative workout experiences. B2B buyers should weigh the advantages of attracting a premium clientele against the higher initial investment and maintenance costs. Additionally, the unique features can serve as a marketing point to differentiate their facility from competitors.

Illustrative image related to ab twist machine

How Do Dual Function Twist Machines Enhance Multi-Functional Gyms?

Dual Function Twist Machines combine twisting exercises with other core workouts, making them a space-efficient option for multi-functional gyms and fitness franchises. This versatility allows users to engage in a broader range of exercises, appealing to diverse fitness goals. For B2B buyers, the ability to maximize floor space while providing varied workout options can enhance customer satisfaction. However, it is crucial to ensure that the machine does not compromise on targeting specific muscle groups effectively.

Key Industrial Applications of ab twist machine

| Industry/Sector | Specific Application of ab twist machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Fitness and Wellness Centers | Core strength training for clients | Enhances customer satisfaction and retention | Durability, ease of use, and space efficiency for small facilities |

| Rehabilitation Facilities | Rehabilitation for lower back injuries | Aids in recovery and improves patient outcomes | Safety features, weight capacity, and warranty for long-term use |

| Corporate Wellness Programs | Employee fitness initiatives | Promotes health, reduces healthcare costs | Compact design, affordability, and effectiveness for diverse users |

| Educational Institutions | Physical education and fitness programs | Encourages student engagement in physical fitness | Multi-user capability, safety standards, and ease of maintenance |

| Home Fitness Market | Personal training and home workouts | Increases accessibility to fitness solutions | Portability, noise levels, and price point for individual consumers |

How is the ab twist machine utilized in fitness and wellness centers?

In fitness and wellness centers, the ab twist machine serves as a vital tool for enhancing core strength among clients. By facilitating targeted workouts, it helps individuals engage their abdominal and oblique muscles effectively. This not only improves physical fitness but also contributes to customer satisfaction and retention. B2B buyers in this sector should prioritize machines that are durable, user-friendly, and compact to fit within often limited gym spaces.

What role does the ab twist machine play in rehabilitation facilities?

Rehabilitation facilities employ the ab twist machine to assist patients recovering from lower back injuries. The machine enables gentle, controlled movements that help strengthen core muscles without excessive strain. This application is crucial for improving patient outcomes and accelerating recovery times. Buyers in this industry must consider safety features, maximum weight capacity, and warranty options to ensure reliability and patient safety during use.

How can corporate wellness programs benefit from ab twist machines?

In corporate wellness programs, ab twist machines are integrated into fitness initiatives aimed at promoting employee health. These machines provide a convenient way for employees to engage in core-strengthening exercises, which can lead to reduced healthcare costs and improved productivity. When sourcing for corporate wellness, businesses should look for machines that are compact, affordable, and effective for a diverse range of users, accommodating varying fitness levels.

Illustrative image related to ab twist machine

Why are ab twist machines important for educational institutions?

Educational institutions utilize ab twist machines as part of their physical education and fitness programs to engage students in active lifestyles. These machines help foster a culture of fitness and health among students, making workouts fun and accessible. Buyers from this sector should focus on machines that can accommodate multiple users, meet safety standards, and require minimal maintenance to ensure longevity and usability in a school setting.

What advantages do ab twist machines offer in the home fitness market?

In the home fitness market, the ab twist machine provides individuals with an accessible and effective way to engage in core workouts. Its compact design makes it suitable for small living spaces, while its quiet operation allows for use without disturbing others. Buyers should prioritize portability, noise levels, and price points that cater to individual consumers looking for budget-friendly fitness solutions.

3 Common User Pain Points for ‘ab twist machine’ & Their Solutions

Scenario 1: Limited Space in Fitness Facilities

The Problem: Many B2B buyers, particularly those managing gyms or fitness studios in urban areas, face the challenge of limited floor space. This makes it difficult to incorporate larger fitness machines, leading to missed opportunities for providing a diverse workout experience. Buyers may worry that purchasing an ab twist machine will contribute to overcrowding and limit the variety of equipment available to clients.

The Solution: When sourcing an ab twist machine, prioritize compact and foldable models designed for easy storage. Look for machines that are lightweight yet sturdy, supporting a wide range of user weights without sacrificing durability. Suppliers should emphasize the dimensions and space-saving features of their products, such as the Merach Waist Twister, which measures only 21.3 x 13.6 x 5.1 inches and can easily fit into smaller workout areas. Additionally, consider options that can be used in multi-functional ways, allowing the machine to serve various fitness routines. By selecting space-efficient equipment, fitness facilities can enhance their offerings without compromising on the workout experience.

Scenario 2: User Safety and Stability Concerns

The Problem: Safety is a paramount concern for B2B buyers, especially in settings like gyms or rehabilitation centers where clients may have varying levels of fitness. An ab twist machine that lacks stability or has inadequate weight support can lead to accidents, discouraging users from trying it out. This can result in lost revenue and a tarnished reputation for the facility.

Illustrative image related to ab twist machine

The Solution: Invest in ab twist machines with high stability ratings and robust construction. Look for models with a maximum weight capacity that accommodates a broad range of users, ideally supporting up to 300 lbs. Machines with non-slip pedal surfaces and rubberized feet can enhance safety during use. Before making a purchase, request demonstration videos or user reviews to assess stability and user experiences. Additionally, consider providing training sessions for staff on how to properly demonstrate and guide users on the machine, ensuring that safety protocols are followed. By prioritizing safety features, B2B buyers can instill confidence in their clients and encourage them to incorporate the machine into their routines.

Scenario 3: Effective Marketing and Client Engagement

The Problem: After purchasing an ab twist machine, B2B buyers often struggle with effectively marketing the equipment to clients. They may find it challenging to communicate the benefits of the machine, leading to underutilization and insufficient engagement with clients who might not understand how to integrate it into their fitness routines.

The Solution: Develop a targeted marketing strategy that highlights the unique benefits of the ab twist machine. Create educational content, such as video tutorials or infographics, showcasing how the machine can enhance core strength, improve flexibility, and aid in weight loss. Leverage social media platforms to share user testimonials and before-and-after success stories that feature the machine. Additionally, consider hosting workshops or fitness classes that incorporate the ab twist machine, allowing potential clients to experience its benefits firsthand. Collaborate with fitness influencers or trainers to further boost visibility and credibility. By actively promoting the machine and providing engaging content, B2B buyers can drive client interest and increase usage, ultimately maximizing their investment in the equipment.

Strategic Material Selection Guide for ab twist machine

What Are the Best Materials for Manufacturing an Ab Twist Machine?

When selecting materials for manufacturing an ab twist machine, it is essential to consider factors such as durability, cost, and performance under various conditions. This guide analyzes four common materials used in the production of ab twist machines: steel, aluminum, polypropylene (PP), and rubber. Each material has unique properties and implications for performance, cost, and suitability for international markets.

How Does Steel Perform in Ab Twist Machine Construction?

Steel is a widely used material in fitness equipment due to its strength and durability. It typically has excellent resistance to wear and tear, making it suitable for high-stress applications. Steel’s temperature and pressure ratings are generally high, allowing it to maintain structural integrity under various conditions.

Illustrative image related to ab twist machine

Pros: Steel offers superior strength and durability, ensuring the longevity of the ab twist machine. It is also relatively cost-effective compared to other metals, making it an attractive option for manufacturers.

Cons: However, steel is susceptible to corrosion if not properly treated, which can be a significant drawback in humid environments. Additionally, the manufacturing complexity can increase due to the need for welding and finishing processes.

Impact on Application: Steel is compatible with various media, but its weight can make the final product less portable. International buyers should ensure compliance with relevant standards such as ASTM for structural steel.

Why Choose Aluminum for Ab Twist Machines?

Aluminum is another popular choice due to its lightweight nature and good corrosion resistance. It is often used in applications where portability is a priority, such as home fitness equipment.

Illustrative image related to ab twist machine

Pros: The primary advantage of aluminum is its lightweight property, which enhances portability. It also has a good strength-to-weight ratio and is resistant to rust, making it ideal for diverse climatic conditions.

Cons: The main limitation of aluminum is its lower tensile strength compared to steel, making it less suitable for heavy-duty applications. Additionally, aluminum can be more expensive than steel, which may impact overall production costs.

Impact on Application: Aluminum’s lightweight nature makes it ideal for users in regions where transportation costs are a concern, such as Africa and South America. Compliance with international standards like JIS for aluminum products is essential.

What Role Does Polypropylene Play in Ab Twist Machines?

Polypropylene (PP) is a thermoplastic polymer known for its durability and flexibility. It is often used for components that require a degree of flexibility and impact resistance.

Pros: PP is lightweight, resistant to moisture, and has good chemical resistance, making it suitable for various environments. It is also cost-effective, which can be beneficial for manufacturers looking to keep production costs low.

Cons: While PP is durable, it may not withstand extreme temperatures as well as metals. It can also be less stable under heavy loads, which may limit its use in structural components of the machine.

Impact on Application: PP is particularly suitable for regions with high humidity, as it does not absorb moisture. Buyers should ensure that the material meets relevant safety and quality standards in their respective markets.

Illustrative image related to ab twist machine

How Does Rubber Enhance Performance in Ab Twist Machines?

Rubber is primarily used for non-slip surfaces and cushioning in fitness equipment. Its unique properties make it an excellent choice for enhancing user comfort and safety.

Pros: Rubber provides excellent grip and shock absorption, which can enhance the user experience. It is also resistant to wear and can withstand varying temperatures.

Cons: The primary drawback of rubber is its susceptibility to degradation over time, especially when exposed to UV light or extreme temperatures. Additionally, it can be more expensive than other materials like PP.

Impact on Application: Rubber’s ability to provide a non-slip surface is crucial for safety, especially in regions where users may exercise on slick surfaces. Compliance with international safety standards is essential to ensure user safety.

Summary of Material Selection for Ab Twist Machines

| Material | Typical Use Case for ab twist machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Frame and structural components | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Portable parts and frames | Lightweight and corrosion-resistant | Lower tensile strength | High |

| Polypropylene | Non-structural components | Cost-effective and moisture-resistant | Limited load-bearing capability | Low |

| Rubber | Non-slip surfaces and cushioning | Excellent grip and shock absorption | Degrades over time | Medium |

This material selection guide offers actionable insights for international B2B buyers, helping them make informed decisions based on performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for ab twist machine

What Are the Key Manufacturing Processes for an Ab Twist Machine?

Manufacturing an ab twist machine involves several critical stages, each essential for ensuring the final product meets quality and performance standards. The primary stages of manufacturing include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Ab Twist Machine Production?

The manufacturing process begins with the careful selection and preparation of materials. Commonly used materials for ab twist machines include high-grade steel for structural components, durable plastic for non-slip surfaces, and rubber for foot grips. Suppliers often source these materials based on their strength, durability, and resistance to wear and tear.

Once selected, materials undergo a series of quality checks to ensure they meet specified standards. This may include testing for tensile strength, flexibility, and resistance to corrosion. Proper documentation of material specifications and test results is crucial for compliance with international standards, particularly for B2B buyers in diverse markets such as Africa, South America, the Middle East, and Europe.

What Techniques Are Used in Forming and Assembling the Machine?

The forming stage typically involves processes like cutting, bending, and welding. Advanced techniques such as laser cutting may be utilized for precision, ensuring that components fit together seamlessly. For metal parts, processes like CNC machining are common, allowing for intricate designs and exact specifications.

During assembly, components are brought together to create the final product. This stage often involves using automated systems and manual labor to ensure that parts fit correctly and function as intended. Careful attention is paid to the installation of rotating mechanisms, ensuring smooth operation during use.

How Is the Finishing Process Conducted?

Finishing is crucial for both aesthetic and functional purposes. This stage may involve powder coating or painting to enhance durability and protect against wear. Additionally, surface treatments such as anodizing or galvanizing can be applied to metal parts to prevent rust and corrosion.

Quality checks are performed at this stage to ensure that the finished product meets visual and functional standards. This includes inspecting the smoothness of surfaces, the effectiveness of coatings, and the overall appearance of the machine.

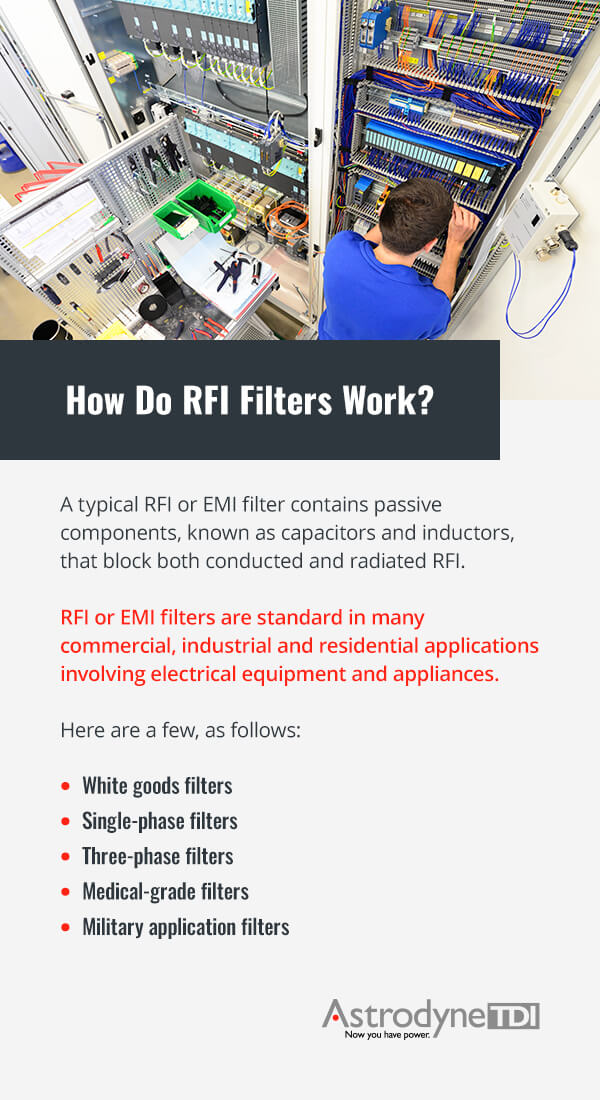

What Quality Assurance Standards Are Relevant for Ab Twist Machines?

Quality assurance is critical in ensuring that ab twist machines are safe, durable, and effective. Manufacturers often adhere to international standards such as ISO 9001, which sets the framework for quality management systems. This certification indicates that a company has established processes to ensure consistent quality in their products.

In addition to ISO 9001, specific certifications such as CE marking are essential for compliance in the European market. CE marking ensures that products meet safety, health, and environmental protection standards. For buyers in regions like Africa and South America, understanding these standards can be crucial for ensuring that products are not only compliant but also safe for use.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to catch any defects early. The typical QC checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival at the manufacturing facility. Checks include verifying material specifications, conducting initial tests, and ensuring compliance with quality standards.

-

In-Process Quality Control (IPQC): During production, continuous monitoring is essential. This may involve random sampling of products at various stages of assembly to ensure that they meet specified tolerances and quality standards.

-

Final Quality Control (FQC): Once the product is fully assembled, a comprehensive inspection is conducted. This includes testing the machine for functionality, safety, and durability. Common tests may include load testing to ensure the machine can support the specified weight and functional tests to ensure smooth operation.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those operating in international markets, verifying a supplier’s quality control processes is crucial. Here are some effective strategies:

Illustrative image related to ab twist machine

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing processes, quality control measures, and adherence to international standards. This can be done through on-site visits or remote assessments.

-

Requesting Quality Reports: Buyers should ask suppliers for detailed quality reports that outline testing methods, results, and compliance with relevant standards. These documents can provide confidence in the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the manufacturing process and final product quality. These services often include comprehensive reports that can be shared with stakeholders.

What Are the Nuances of Quality Control Certification for International Buyers?

International buyers must navigate various nuances when it comes to quality control certification. Different regions may have specific regulations and standards that must be adhered to. For example, while CE marking is essential for products sold in Europe, other markets may have different requirements.

Additionally, buyers should be aware of the implications of these certifications on product liability and safety. In regions like Africa and South America, understanding local regulations and how they align with international standards can be critical for successful market entry and long-term success.

In conclusion, the manufacturing processes and quality assurance for ab twist machines are complex and multifaceted. For B2B buyers, understanding these processes not only ensures they receive a high-quality product but also helps mitigate risks associated with compliance and safety. By investing time in evaluating suppliers and their quality assurance practices, buyers can make informed decisions that contribute to their business’s success.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ab twist machine’

In the competitive landscape of fitness equipment procurement, especially for products like the ab twist machine, making informed decisions is critical for ensuring quality, durability, and customer satisfaction. This guide offers a structured approach to sourcing ab twist machines, tailored for international B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Start by establishing clear specifications for the ab twist machine you wish to procure. Consider factors such as maximum weight capacity, dimensions, materials, and any special features like noise reduction or portability. This will help you narrow down your options and ensure that the machines meet the needs of your target market.

Illustrative image related to ab twist machine

- Weight Capacity: Ensure it can support a diverse range of users.

- Size and Portability: Compact designs are ideal for home use, while sturdier models may be preferred in gyms.

Step 2: Research Market Demand and Trends

Understanding market trends is crucial for making a strategic purchase. Analyze the demand for ab twist machines in your target regions, focusing on popular features and customer preferences. This insight will help you select products that resonate with your audience.

- Consumer Preferences: Look for trends in fitness equipment that emphasize convenience and effectiveness.

- Competitive Analysis: Review what competitors are offering to identify gaps in the market.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough research to evaluate their credibility and reliability. Request company profiles, product catalogs, and references from previous buyers. This step is vital to ensure you’re partnering with a reputable source.

- Supplier Background: Assess the supplier’s history and market presence.

- Customer Reviews: Look for testimonials that highlight product quality and service reliability.

Step 4: Request Samples and Conduct Quality Checks

Before placing a large order, request samples to assess the quality firsthand. This allows you to evaluate the machine’s construction, usability, and overall performance. Conduct a thorough inspection, focusing on the materials used and the stability of the machine during operation.

- Material Quality: Ensure that the machine is made from durable, non-toxic materials.

- Functional Testing: Test the machine for ease of use and comfort during workouts.

Step 5: Verify Certifications and Compliance

Check that the ab twist machines comply with relevant safety and quality standards in your target markets. Certifications can indicate that the product meets specific industry benchmarks, which is crucial for gaining consumer trust.

Illustrative image related to ab twist machine

- Safety Standards: Look for certifications such as ISO or CE that reflect adherence to safety guidelines.

- Warranty and Support: A solid warranty can indicate the manufacturer’s confidence in their product.

Step 6: Negotiate Pricing and Payment Terms

Once you have identified a suitable supplier, engage in negotiations to secure favorable pricing and payment terms. Consider bulk order discounts and flexible payment options, which can significantly impact your overall procurement costs.

- Volume Discounts: Ask about pricing tiers based on order size.

- Payment Flexibility: Explore options for payment plans that can ease cash flow management.

Step 7: Plan for Logistics and Distribution

Finally, develop a logistics plan for shipping and distribution. Consider shipping costs, delivery timelines, and potential customs duties, especially if importing from international suppliers. A well-organized logistics strategy will ensure timely delivery and customer satisfaction.

- Shipping Options: Evaluate various shipping methods for cost-effectiveness.

- Customs Regulations: Be aware of any import regulations that may affect your order.

By following this checklist, B2B buyers can confidently navigate the procurement process for ab twist machines, ensuring they select the best products to meet their business needs and customer expectations.

Comprehensive Cost and Pricing Analysis for ab twist machine Sourcing

What Are the Key Cost Components in Sourcing an Ab Twist Machine?

When sourcing ab twist machines, a comprehensive understanding of the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The selection of raw materials significantly influences the cost. High-quality steel and durable plastics may increase the initial cost but enhance longevity and performance, ultimately providing better value. For instance, machines that support higher weight capacities or include additional features like foot massage components typically require more robust materials.

-

Labor: Labor costs vary by region and can significantly affect pricing. In countries with lower labor costs, manufacturers may offer more competitive pricing. However, it’s essential to consider the skill level of the workforce, as skilled labor can lead to better quality products.

-

Manufacturing Overhead: This encompasses indirect costs such as utilities, rent, and equipment maintenance. Efficient production facilities can lower overhead costs, allowing suppliers to offer more competitive prices.

-

Tooling: The cost of molds and dies used in the manufacturing process can be substantial, especially for custom designs. Buyers should consider whether they require standard models or custom specifications, as the latter can lead to higher tooling costs.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability and safety, which can affect pricing. Machines with higher safety ratings or certifications will often command a premium.

-

Logistics: Transportation costs vary based on distance, mode of transport, and shipping terms. International buyers must consider import duties, taxes, and potential delays at customs, which can add to the total cost.

-

Margin: Suppliers typically add a profit margin to cover their risks and ensure business viability. Understanding the average industry margins can help buyers gauge whether a quoted price is reasonable.

What Influences Pricing for Ab Twist Machines?

Several factors can influence the pricing of ab twist machines, particularly in international B2B transactions:

-

Volume/MOQ: Bulk purchasing can lead to significant discounts. Manufacturers often have minimum order quantities (MOQs), and negotiating these terms can yield better pricing.

-

Specifications/Customization: Custom designs or features (like adjustable resistance or electronic displays) can increase costs. Buyers should weigh the benefits of customization against budget constraints.

-

Material Quality and Certifications: Higher-quality materials and certifications (like ISO or CE) may raise the price but can be essential for market acceptance in regions with stringent regulations.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established manufacturers may charge more due to their brand value and quality assurance.

-

Incoterms: The chosen Incoterms (International Commercial Terms) dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms can prevent unexpected costs.

What Are the Best Negotiation Tips for B2B Buyers of Ab Twist Machines?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation can lead to favorable pricing:

-

Research and Benchmarking: Conduct thorough market research to understand average pricing and features offered. This data can serve as leverage in negotiations.

-

Focus on Total Cost of Ownership (TCO): Evaluate not just the purchase price but also long-term costs such as maintenance, durability, and potential replacements. This approach can justify a higher upfront investment for better quality.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better terms and pricing flexibility. Trust can often lead to discounts and priority service.

-

Be Open to Alternatives: If a supplier cannot meet your price expectations, consider alternatives such as different models or materials that may fit your budget.

-

Understand Payment Terms: Negotiating favorable payment terms can enhance cash flow, allowing businesses to manage their finances more effectively.

Conclusion and Disclaimer

Pricing for ab twist machines can vary widely based on a multitude of factors, and buyers should approach sourcing with a comprehensive understanding of costs and pricing dynamics. It is crucial to note that the prices mentioned in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Conducting thorough due diligence will ensure that B2B buyers make informed decisions that align with their operational needs and budget constraints.

Alternatives Analysis: Comparing ab twist machine With Other Solutions

Exploring Alternatives to the Ab Twist Machine for Core Strengthening

In the realm of fitness equipment aimed at enhancing core strength and promoting a healthy lifestyle, the ab twist machine stands out as a popular choice. However, it is essential to consider various alternatives that may offer unique advantages depending on specific user needs, budget constraints, and fitness goals. Below, we compare the ab twist machine with other viable solutions: traditional abdominal exercises and the abdominal rotation machine.

Comparison Table

| Comparison Aspect | Ab Twist Machine | Traditional Abdominal Exercises | Abdominal Rotation Machine |

|---|---|---|---|

| Performance | Targets obliques and core effectively | Comprehensive core engagement | Primarily targets obliques |

| Cost | $59.99 – $99.98 | Low to no cost (bodyweight exercises) | $300 – $1,500 depending on model |

| Ease of Implementation | Simple setup and use | Requires guidance for effectiveness | Requires gym setting for best results |

| Maintenance | Low (occasional cleaning) | None (no equipment needed) | Moderate (depends on usage frequency) |

| Best Use Case | Home workouts, limited space | General fitness, no equipment access | Gym environments, targeted muscle training |

Detailed Breakdown of Alternatives

What Are the Pros and Cons of Traditional Abdominal Exercises?

Traditional abdominal exercises, such as crunches, planks, and leg raises, offer a low-cost alternative to specialized equipment like the ab twist machine. They engage multiple muscle groups, promoting overall core strength without the need for any equipment. However, these exercises require proper technique to prevent injury, and beginners may find it challenging to execute them correctly without guidance. Additionally, they may lack the fun element that some users seek in their workout routine.

How Does the Abdominal Rotation Machine Compare?

The abdominal rotation machine provides a more targeted approach to core training, focusing primarily on the obliques. This machine allows users to perform controlled movements against resistance, which can lead to improved muscle strength and definition. However, the initial investment is significantly higher, making it less accessible for home users or smaller fitness facilities. Moreover, it typically requires a larger space and is best suited for commercial gyms where users can benefit from a variety of equipment.

Illustrative image related to ab twist machine

Conclusion: How Should B2B Buyers Decide on the Right Solution?

When selecting the best core-strengthening solution, B2B buyers should carefully assess their target market’s needs, budget, and available space. The ab twist machine is ideal for home fitness enthusiasts or smaller gyms looking for affordable and space-efficient options. In contrast, traditional abdominal exercises can be promoted as a cost-effective, equipment-free alternative, appealing to a broader demographic. Finally, the abdominal rotation machine may suit larger commercial gyms that can accommodate more extensive equipment offerings and cater to clients seeking specialized training. By weighing these factors, buyers can make informed decisions that align with their business objectives and customer preferences.

Essential Technical Properties and Trade Terminology for ab twist machine

What Are the Essential Technical Properties of an Ab Twist Machine?

When considering the procurement of an ab twist machine, understanding its technical specifications is crucial for ensuring quality, safety, and performance. Here are some critical properties to evaluate:

-

Weight Capacity

– Definition: The maximum weight the machine can support during use, typically expressed in pounds or kilograms.

– Importance: A higher weight capacity (e.g., 300 lbs or 136 kg) ensures the machine can accommodate a wider range of users, enhancing market appeal and safety. -

Material Composition

– Definition: The materials used in the construction of the machine, commonly including high-grade plastics (like polypropylene) and metals (such as iron).

– Importance: Durable materials ensure longevity and resistance to wear and tear, reducing the need for frequent replacements. This is particularly important for B2B buyers looking for sustainable investment. -

Dimensions and Portability

– Definition: The size of the machine (length, width, height) and its weight, affecting its usability and storage.

– Importance: Compact designs (e.g., dimensions of 21.3 x 13.6 x 5.1 inches) are ideal for urban environments where space is limited. Portability is a key selling point for gyms and home users alike, as it allows for easy transportation and storage. -

Resistance Mechanism

– Definition: The type of resistance used during operation, which can be mechanical or hydraulic.

– Importance: Machines with adjustable resistance allow users to customize their workout intensity, appealing to both beginners and advanced fitness enthusiasts. This adaptability can enhance user experience and satisfaction. -

Safety Features

– Definition: Elements designed to prevent accidents during use, such as non-slip surfaces and stability enhancements.

– Importance: Safety features are crucial for minimizing the risk of injury, particularly in commercial settings like gyms. Machines equipped with non-slip textures and stable bases can provide peace of mind for both users and operators. -

Warranty and Support

– Definition: The terms of the manufacturer’s guarantee regarding defects and service.

– Importance: A robust warranty (e.g., two years) indicates confidence in the product’s durability and quality, which is a key consideration for B2B buyers. Comprehensive customer support can also enhance user experience and satisfaction.

What Are Common Trade Terminology and Industry Jargon Related to Ab Twist Machines?

Understanding industry jargon is essential for navigating B2B transactions effectively. Here are some common terms you may encounter:

-

OEM (Original Equipment Manufacturer)

– Definition: A company that produces parts or equipment that may be marketed by another manufacturer.

– Importance: Knowing whether a product is OEM can impact purchasing decisions, as it often reflects quality assurance and compatibility with existing equipment. -

MOQ (Minimum Order Quantity)

– Definition: The smallest quantity of a product that a supplier is willing to sell.

– Importance: Understanding MOQ helps buyers manage their inventory and budget effectively. It can influence purchasing strategies, especially for businesses looking to stock multiple units. -

RFQ (Request for Quotation)

– Definition: A document sent to suppliers to request pricing and terms for specific products or services.

– Importance: An RFQ is essential for comparing offers from different suppliers, ensuring that buyers get the best value for their investment. -

Incoterms (International Commercial Terms)

– Definition: A set of predefined international trade terms published by the International Chamber of Commerce, outlining the responsibilities of buyers and sellers.

– Importance: Understanding Incoterms is crucial for clarifying shipping responsibilities, costs, and risks associated with international transactions, thereby facilitating smoother import/export processes. -

Lead Time

– Definition: The total time it takes from placing an order to receiving the product.

– Importance: Knowing lead times can help businesses plan their inventory and avoid disruptions in operations, particularly when launching new products or services. -

Freight Forwarding

– Definition: The process of arranging the shipment of goods from one place to another via a single or multiple carriers.

– Importance: For international buyers, understanding freight forwarding is vital for managing logistics and ensuring timely delivery of products, which can significantly affect customer satisfaction and business operations.

By familiarizing yourself with these essential properties and terminologies, you can make more informed decisions when sourcing ab twist machines, ultimately leading to better business outcomes.

Navigating Market Dynamics and Sourcing Trends in the ab twist machine Sector

What Are the Key Market Trends Driving the Ab Twist Machine Sector?

The ab twist machine sector is witnessing a surge in demand, driven by an increasing global focus on health and fitness, particularly in emerging markets like Africa, South America, and the Middle East. Consumers are increasingly seeking compact, versatile fitness solutions that can be used at home, a trend fueled by the rise of remote work and home workouts. This shift has made portable ab twist machines a popular choice among international buyers looking to enhance their fitness offerings. Additionally, advancements in technology are facilitating the development of smart fitness equipment, integrating features such as app connectivity and performance tracking, appealing to tech-savvy consumers.

In terms of sourcing, buyers are increasingly prioritizing suppliers who can provide high-quality, durable machines at competitive prices. The market is also seeing a trend towards customization, where manufacturers offer bespoke solutions tailored to specific consumer needs, including weight capacities and design preferences. This flexibility is particularly appealing to B2B buyers in diverse markets, such as Nigeria and Brazil, where consumer preferences can vary widely. Furthermore, the emphasis on health and wellness has prompted suppliers to enhance their marketing strategies, focusing on the benefits of core strengthening and weight loss, thus attracting a broader customer base.

How Are Sustainability and Ethical Sourcing Impacting the Ab Twist Machine Market?

Sustainability is becoming a pivotal consideration for B2B buyers in the ab twist machine sector. As environmental awareness grows, companies are expected to minimize their ecological footprint, prompting a shift towards eco-friendly materials and production processes. Buyers are increasingly seeking manufacturers who utilize sustainable sourcing practices and materials, such as recycled plastics and sustainably sourced metals. These practices not only reduce environmental impact but also resonate with consumers who prioritize ethical consumption.

In addition, certifications such as ISO 14001 for environmental management systems are becoming essential for suppliers aiming to establish credibility in the market. Ethical sourcing and sustainability are not just trends; they are becoming critical components of brand reputation. B2B buyers, particularly in Europe and North America, are more likely to partner with suppliers who demonstrate a commitment to ethical practices, thereby enhancing their own brand’s sustainability narrative. This shift underscores the need for transparency in supply chains, allowing businesses to communicate their values effectively to their customers.

How Has the Ab Twist Machine Evolved Over Time?

The evolution of the ab twist machine reflects broader trends in fitness and consumer preferences. Initially, these machines were bulky and primarily found in commercial gyms. However, as home fitness gained traction, manufacturers began to innovate, creating compact, portable models that cater to home users. This transformation has allowed for greater accessibility, enabling consumers in diverse regions, including Africa and South America, to incorporate fitness into their daily routines.

Illustrative image related to ab twist machine

Today’s ab twist machines are designed with user comfort and safety in mind, featuring improved stability, non-slip surfaces, and ergonomic designs. The integration of technology, such as digital displays and smart connectivity, further enhances the user experience, allowing individuals to track their fitness progress conveniently. As the market continues to evolve, the focus remains on delivering high-quality, effective solutions that align with the growing global emphasis on health and wellness.

Frequently Asked Questions (FAQs) for B2B Buyers of ab twist machine

-

How do I evaluate the quality of an ab twist machine supplier?

To evaluate the quality of an ab twist machine supplier, start by assessing their manufacturing processes, materials used, and certifications (such as ISO). Look for suppliers with a proven track record of delivering durable and reliable products, ideally backed by customer testimonials or case studies. Request samples to assess quality firsthand, and inquire about warranties and after-sales support. Additionally, consider their compliance with international safety standards, which is especially crucial for buyers in regions with strict regulatory requirements. -

What is the best design for an ab twist machine for commercial use?

The best design for a commercial ab twist machine should prioritize durability, user comfort, and versatility. Look for machines with a robust frame that can support higher weight capacities and sustained use. Features like adjustable resistance levels, ergonomic seating, and non-slip surfaces enhance user experience. Additionally, machines that allow for multiple exercise variations can cater to a broader clientele, making them more appealing for gyms and fitness centers. -

What customization options are available for ab twist machines?

Many suppliers offer customization options for ab twist machines, including color, branding, and specific design features tailored to your market needs. You can request modifications in dimensions, weight capacities, and resistance types to suit different user demographics. Discussing your requirements during the initial stages can lead to better alignment with your business goals and provide a unique selling proposition in your market. -

What is the minimum order quantity (MOQ) for ab twist machines?

The minimum order quantity for ab twist machines varies by supplier and may depend on factors like manufacturing capacity and your specific customization requests. Generally, MOQs can range from 50 to several hundred units. It’s advisable to negotiate with suppliers to find a mutually beneficial arrangement, especially if you are a new buyer or looking to test market demand with a smaller batch. -

What payment terms should I expect when purchasing ab twist machines?

Payment terms can vary widely among suppliers, but common practices include a 30% deposit upfront with the balance due upon shipment or delivery. Some suppliers may offer flexible payment options such as letter of credit or installment payments, particularly for larger orders. Ensure you clarify payment terms in the contract to avoid misunderstandings and protect your investment. -

How can I ensure quality assurance (QA) for my order of ab twist machines?

To ensure quality assurance for your order, request a detailed QA process from your supplier. This should include pre-production samples, in-line inspections, and final product checks. You can also consider hiring a third-party inspection service to verify compliance with your specifications before shipment. Establishing clear quality standards and communication channels will help maintain product integrity and reduce the risk of defects. -

What logistics considerations should I keep in mind when importing ab twist machines?

When importing ab twist machines, consider shipping methods, customs regulations, and potential tariffs. Choose a reliable freight forwarder who understands the logistics involved in transporting fitness equipment. It’s crucial to factor in lead times for production and shipping, as well as to ensure compliance with local import regulations in your target market. Additionally, consider warehousing solutions if you anticipate delays in distribution. -

What are the common challenges faced when sourcing ab twist machines internationally?

Common challenges in international sourcing include language barriers, cultural differences, and varying standards of quality and safety. Additionally, navigating customs regulations and potential delays can pose issues. To mitigate these challenges, establish clear communication with suppliers, conduct thorough research on their reputation, and consider working with local agents who understand the market dynamics. Building strong relationships with suppliers can also foster better collaboration and problem-solving.

Top 2 Ab Twist Machine Manufacturers & Suppliers List

1. Merach – Waist Twister Fitness Tool

Domain: merachfit.com

Registered: 2022 (3 years)

Introduction: {“product_name”: “Waist Twister Fitness Tool”, “product_type”: “Waist Twister Exercise Machine”, “price”: “$59.99”, “original_price”: “$99.98”, “discount”: “$39.99”, “warranty”: “2 Years”, “shipping”: “Free Shipping”, “risk_free_trial”: “30-Day Risk-Free Trial”, “maximum_weight_capacity”: “300 lbs / 136 kg”, “item_dimensions”: “21.3 x 13.6 x 5.1 inches”, “net_weight”: “8.2 lbs / 3.7 kg”, “package_…

2. Mel Magazine – Torso Rotation Machine

Domain: melmagazine.com

Registered: 2015 (10 years)

Introduction: The torso rotation machine, also known as the torso twister, is designed to target the oblique muscles along the sides of the body. Users select a weight and either kneel or sit at the machine to perform trunk-twisting movements. It is promoted as an oblique training tool, but the article suggests that it may not be necessary for effective core training. The machine does not replicate natural move…

Strategic Sourcing Conclusion and Outlook for ab twist machine

What Are the Key Takeaways for Sourcing Ab Twist Machines?

In the competitive fitness equipment market, strategic sourcing of ab twist machines presents significant opportunities for international B2B buyers. Emphasizing durability, portability, and user-friendly design can enhance product appeal. Machines like the Merach Waist Twister exemplify these attributes, supporting diverse consumer needs from home fitness enthusiasts to commercial gym owners. By prioritizing quality and functionality, businesses can better meet market demand, particularly in regions like Africa, South America, the Middle East, and Europe, where fitness trends are rapidly evolving.

How Can Strategic Sourcing Enhance Your Business?

Investing in reliable and effective ab twist machines is not just about procurement; it’s about building a brand reputation for quality and customer satisfaction. With a growing emphasis on health and wellness, positioning your offerings to cater to this demand can lead to increased sales and customer loyalty. Engage with manufacturers who provide warranties and customer support, ensuring your clients have positive experiences that foster repeat business.

What Does the Future Hold for the Ab Twist Machine Market?

As fitness trends continue to evolve, the demand for innovative and effective workout solutions will only increase. By leveraging strategic sourcing practices, B2B buyers can capitalize on this growth, ensuring they offer top-tier products that resonate with their target markets. Now is the time to explore partnerships with reputable suppliers and invest in quality ab twist machines that meet the needs of today’s fitness-conscious consumers. Embrace this opportunity to lead in the fitness equipment market and drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.