A Deep Dive into Wiring Bracket Solution

Introduction: Navigating the Global Market for wiring bracket

In the ever-evolving landscape of global trade, sourcing reliable wiring brackets presents a significant challenge for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. The need for efficient, high-quality components that ensure the safe and organized routing of electrical and data cables is paramount. This guide serves as a comprehensive resource, delving into various types of wiring brackets, their applications across different industries, and the critical factors to consider when selecting suppliers.

With insights into the latest market trends, cost analysis, and best practices for vetting suppliers, this guide empowers international buyers to make informed purchasing decisions. Whether you are operating in Brazil, Vietnam, or any other emerging market, understanding the specifications and standards associated with wiring brackets can significantly impact operational efficiency and safety.

Additionally, we will explore the importance of compliance with regional regulations and certifications, which can vary widely across markets. By addressing these key considerations, this guide not only simplifies the sourcing process but also equips buyers with the knowledge needed to navigate the complexities of the global wiring bracket market effectively. Unlock the potential of your projects by leveraging this invaluable resource to enhance your procurement strategy.

Understanding wiring bracket Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cable Chase Wire Bracket | Multi-hole design, reduces friction, ETL/UL certified | Data centers, telecommunications | Pros: Reduces installation damage; future expansion options. Cons: Requires confirmation with local electrical codes. |

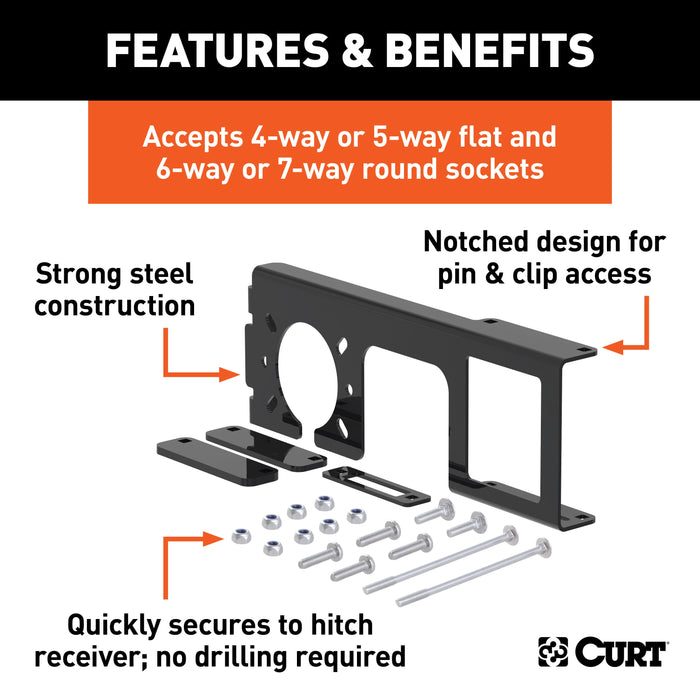

| Mounting Brackets for Connectors | Variety of sizes, compatibility with different plug types | Automotive, RV, and trailer wiring | Pros: Easy installation, various options available. Cons: May require additional hardware for specific applications. |

| Wall Mount Brackets | Designed for 66 wiring blocks, snap-in compatibility | Telecommunications, networking | Pros: Organized cable management, easy installation. Cons: Limited to specific wiring block types. |

| Universal Mounting Brackets | Adjustable design, fits multiple connector styles | Automotive, industrial applications | Pros: Versatile use across various devices. Cons: May not provide the most secure fit for all applications. |

| Heavy-Duty Mounting Brackets | Durable materials, designed for high-stress environments | Industrial, construction | Pros: High durability, suitable for demanding applications. Cons: Higher cost compared to standard brackets. |

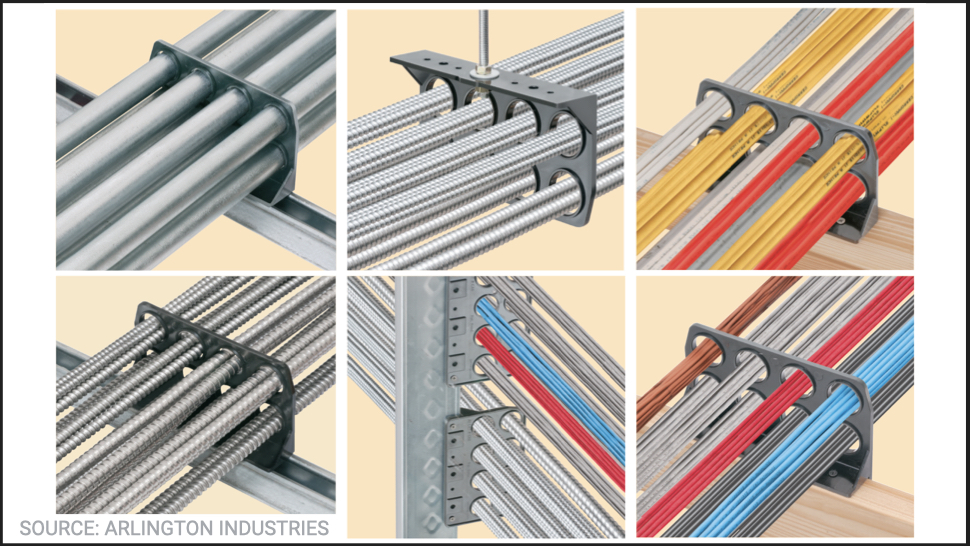

What are the Characteristics of a Cable Chase Wire Bracket?

The Cable Chase Wire Bracket is designed specifically for smooth cable routing, minimizing friction and stress on wires. Its multi-hole design allows for organized wiring without the need for drilling, which can damage structural elements like floor joists. This bracket is particularly suited for data centers and telecommunications installations where neatness and future expansion are essential. When purchasing, consider local electrical codes to ensure compliance, as this can affect installation.

Why Choose Mounting Brackets for Connectors?

Mounting brackets for connectors come in various sizes and are compatible with different plug types, making them ideal for automotive and trailer wiring applications. Their straightforward installation process allows for quick assembly, reducing labor costs. B2B buyers should assess the specific connector types they are working with to ensure compatibility and consider whether additional hardware is needed for installation.

What Makes Wall Mount Brackets Essential for Telecommunications?

Wall mount brackets are designed to hold 66 wiring blocks securely, providing a structured approach to cable management. They snap into place, allowing for easy installation and maintenance in telecommunications and networking environments. Buyers should evaluate the compatibility of these brackets with their existing wiring blocks and consider the space available for installation, as these factors will influence the effectiveness of the solution.

How Do Universal Mounting Brackets Provide Versatility?

Universal mounting brackets offer adjustable designs that accommodate various connector styles, making them a versatile option for automotive and industrial applications. Their adaptability means they can be used across multiple devices, which is a significant advantage for businesses looking to standardize components. However, buyers should be aware that while they provide flexibility, they may not always secure connectors as tightly as dedicated options.

When Should You Invest in Heavy-Duty Mounting Brackets?

Heavy-duty mounting brackets are constructed from robust materials to withstand high-stress environments, making them suitable for industrial and construction settings. Their durability ensures long-term reliability, which can justify a higher upfront cost. B2B buyers should consider the specific demands of their applications and the potential return on investment when selecting heavy-duty options, as these brackets can significantly reduce maintenance needs over time.

Key Industrial Applications of wiring bracket

| Industry/Sector | Specific Application of wiring bracket | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Telecommunications | Mounting brackets for data and telecom wiring in network setups | Enhances organization and accessibility of wiring, reducing downtime | Certifications (e.g., UL, CSA), material durability, compatibility with existing systems |

| Automotive | Wiring brackets for vehicle electrical systems | Ensures secure wiring connections, improving safety and performance | Temperature resistance, corrosion resistance, and fitment options for various vehicle models |

| Construction | Cable routing in commercial buildings | Minimizes damage to structural elements, facilitating easier installations | Compliance with local building codes, load capacity, and installation ease |

| Renewable Energy | Securing wiring for solar panel installations | Reduces maintenance costs by preventing wire damage and ensuring longevity | Weather resistance, UV stability, and adaptability to different mounting surfaces |

| Industrial Automation | Organizing control wiring in manufacturing facilities | Increases efficiency by streamlining wiring management and reducing errors | Customization options, scalability for future needs, and ease of installation |

How Are Wiring Brackets Used in Telecommunications?

In the telecommunications sector, wiring brackets are essential for organizing and securing data and telecom wiring in network setups. These brackets facilitate a clean and efficient installation, allowing for easy access and maintenance. By minimizing the risk of tangling and damage, businesses can significantly reduce downtime and improve operational efficiency. For international buyers, sourcing brackets that meet specific certifications, such as UL and CSA, is crucial to ensure compliance with local regulations and standards.

What Role Do Wiring Brackets Play in the Automotive Industry?

Wiring brackets in the automotive industry are utilized to secure electrical systems within vehicles. They ensure that wiring connections are stable and protected from wear and tear, which is vital for vehicle safety and performance. Buyers need to consider factors like temperature resistance and corrosion resistance, particularly in regions with harsh climates. Additionally, the fitment options must be compatible with various vehicle models to ensure broad applicability.

How Are Wiring Brackets Applied in Construction Projects?

In construction, wiring brackets are used to facilitate cable routing in commercial buildings, providing a systematic approach to electrical installations. By utilizing these brackets, contractors can minimize damage to structural elements, such as joists and walls, which can occur during traditional installation methods. For B2B buyers, it is essential to ensure that the selected brackets comply with local building codes and have adequate load capacity to support the electrical systems being installed.

What Benefits Do Wiring Brackets Offer in Renewable Energy?

In the renewable energy sector, particularly solar installations, wiring brackets are crucial for securing wiring and ensuring that connections remain intact over time. These brackets help reduce maintenance costs by preventing wire damage due to environmental factors. Buyers should focus on sourcing brackets that are UV stable and weather-resistant, as these qualities will enhance the longevity and reliability of the installations, especially in diverse climates across different regions.

How Do Wiring Brackets Enhance Industrial Automation?

Wiring brackets are integral in industrial automation, where they help organize control wiring in manufacturing facilities. An organized wiring system minimizes errors and enhances operational efficiency by streamlining the management of complex electrical systems. For businesses looking to source these brackets, customization options that allow for scalability and ease of installation are key considerations, ensuring that they can adapt to evolving automation needs.

3 Common User Pain Points for ‘wiring bracket’ & Their Solutions

Scenario 1: Managing Installation Challenges with Wiring Brackets

The Problem: When it comes to wiring installations, many B2B buyers encounter difficulties with ensuring the stability and safety of their wiring systems. Common issues arise from using inadequate mounting solutions that fail to support the weight and layout of the wiring. This can lead to sagging wires, which not only look unprofessional but also pose safety hazards. Buyers often struggle with choosing the right type of wiring bracket that adheres to local electrical codes while also providing easy access for future expansions or adjustments.

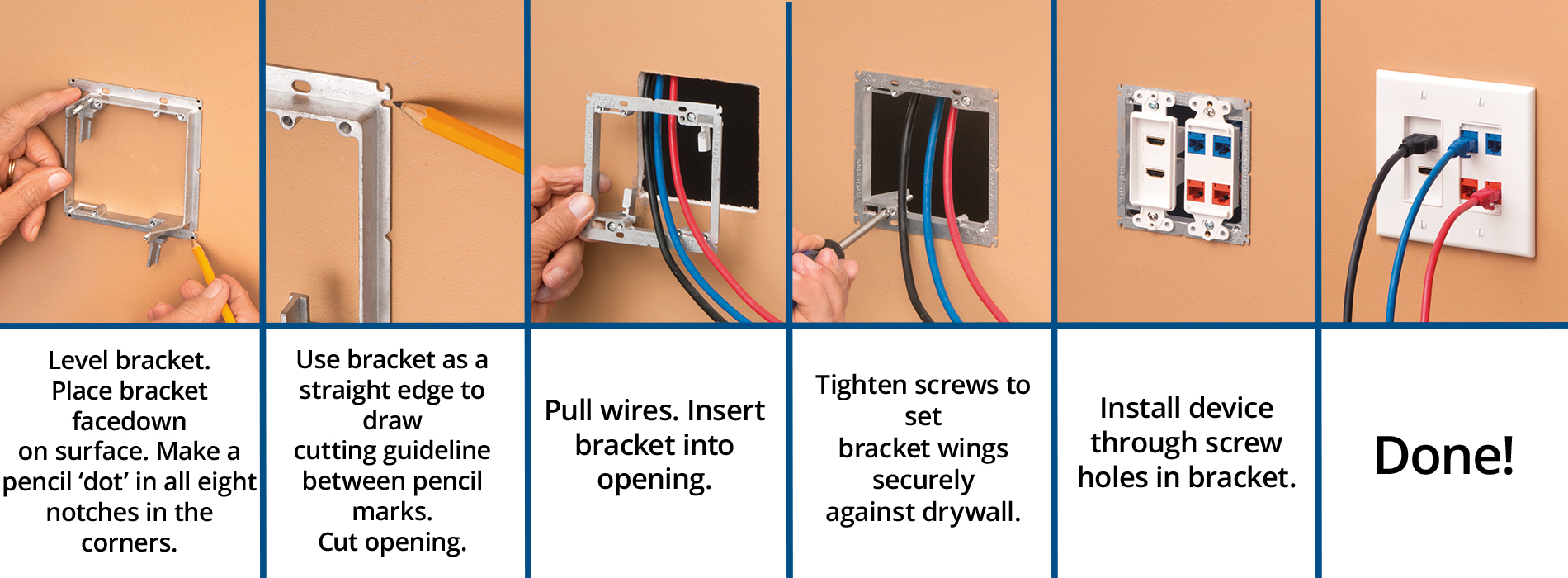

The Solution: To effectively address these challenges, buyers should prioritize sourcing wiring brackets that are specifically designed for their intended application. For instance, selecting brackets that are ETL Listed and compliant with UL standards ensures safety and reliability. Furthermore, consider using multi-hole cable brackets, such as the Cable Chase design, which allows for a clean and organized wire path while minimizing friction and stress on the cables. When planning the installation, it’s essential to consult with local electrical inspectors to confirm that your chosen products meet regulatory standards. Additionally, providing ample spacing between brackets—such as a maximum of 16 inches under floor joists—will enhance both the structural integrity and aesthetic appeal of the installation.

Scenario 2: Overcoming Space Constraints in Wiring Installations

The Problem: Space limitations are a frequent pain point for B2B buyers when installing wiring brackets, especially in older buildings or compact environments. Traditional mounting methods can require significant room for installation, leading to inefficient use of available space. This can also result in the need for excessive drilling, which may damage existing structures, create additional clean-up tasks, and extend project timelines.

The Solution: To mitigate space issues, buyers should opt for innovative wiring brackets that offer compact designs and flexible mounting options. For example, using wall-mount brackets for wiring blocks allows for efficient routing of cables without taking up valuable floor space. Additionally, products like the 89B Mounting Bracket for 66 wiring blocks can snap into place, simplifying installation and reducing the need for extensive drilling. When planning an installation, consider conducting a thorough site assessment to identify potential constraints and choose brackets that can adapt to those limitations. This proactive approach not only saves time but also reduces costs associated with rework or additional materials.

Scenario 3: Ensuring Future-Proofing with Wiring Brackets

The Problem: B2B buyers often face the challenge of future-proofing their wiring installations. As technology evolves, the demand for additional wiring and cabling is likely to increase. Buyers may worry that their current solutions will not accommodate future expansions, leading to costly retrofits and downtime.

The Solution: To ensure that wiring installations remain adaptable, it’s crucial to select wiring brackets that allow for scalability. Look for solutions that explicitly state their capacity for future wiring needs, such as those that provide ample room for additional cables. For instance, the Cable Chase bracket is designed not only for current installations but also allows for future expansion without needing to replace the existing infrastructure. Additionally, educate your teams about the benefits of planning for future wiring needs during the initial installation phase. Implementing a strategy that incorporates anticipated technology upgrades will save significant time and resources in the long run.

Strategic Material Selection Guide for wiring bracket

What Are the Key Properties of Common Materials for Wiring Brackets?

When selecting materials for wiring brackets, several factors must be considered, including performance, durability, cost, and specific applications. Below, we analyze four common materials used in the manufacturing of wiring brackets: steel, aluminum, plastic, and stainless steel. Each material has distinct properties that can influence its suitability for various environments and applications.

Steel: The Traditional Choice for Durability

Steel is a widely used material for wiring brackets due to its strength and durability. It can withstand high temperatures and pressures, making it suitable for heavy-duty applications. Steel brackets are also resistant to deformation under load, which is critical in environments where stability is paramount.

Pros: Steel brackets are highly durable and can support substantial weight. They are also relatively cost-effective, making them an excellent choice for bulk purchases.

Cons: However, steel is susceptible to corrosion if not properly treated or coated, which can be a significant drawback in humid or corrosive environments. Additionally, the manufacturing process can be complex, involving welding or machining.

Impact on Application: Steel brackets are ideal for indoor and outdoor applications where strength is required, such as in industrial settings. B2B buyers should ensure compliance with local standards (e.g., ASTM) for structural integrity.

Aluminum: Lightweight and Corrosion-Resistant

Aluminum is another popular choice for wiring brackets, especially in applications where weight is a concern. It offers excellent corrosion resistance, making it suitable for outdoor use or in environments where moisture is prevalent.

Pros: Aluminum brackets are lightweight, which simplifies installation and reduces shipping costs. They also have good thermal conductivity, which can be advantageous in electrical applications.

Cons: The main limitation of aluminum is its lower strength compared to steel, which may not be suitable for heavy-duty applications. Additionally, aluminum can be more expensive than steel.

Impact on Application: Aluminum is often preferred in the automotive and aerospace industries, where weight savings are critical. Buyers from regions with stringent environmental regulations may find aluminum brackets compliant with local standards.

Plastic: Versatile and Cost-Effective

Plastic materials, such as ABS and polycarbonate, are increasingly used for wiring brackets due to their versatility and cost-effectiveness. They are non-conductive, making them ideal for electrical applications.

Pros: Plastic brackets are lightweight, resistant to corrosion, and easy to manufacture. They can be produced in various colors and shapes, offering aesthetic flexibility.

Cons: However, plastic materials may not withstand high temperatures or heavy loads as well as metal options. They can also become brittle over time, especially when exposed to UV light.

Impact on Application: Plastic brackets are suitable for light-duty applications, such as in residential wiring or low-voltage installations. Buyers should check for compliance with relevant standards (e.g., UL) to ensure safety and performance.

Stainless Steel: The Premium Option for Harsh Environments

Stainless steel is known for its exceptional corrosion resistance and strength, making it ideal for harsh environments. It combines the durability of steel with the corrosion resistance of aluminum.

Pros: Stainless steel brackets can withstand extreme temperatures and are resistant to rust and corrosion, making them suitable for marine or chemical applications.

Cons: The primary drawback is the higher cost compared to other materials. Manufacturing stainless steel components can also be more complex, requiring specialized equipment.

Impact on Application: Stainless steel is often used in applications where hygiene and corrosion resistance are critical, such as in food processing or medical environments. International buyers should ensure compliance with standards such as ASTM or ISO for safety and quality assurance.

Summary Table of Material Selection for Wiring Brackets

| Material | Typical Use Case for Wiring Bracket | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty industrial applications | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Automotive and aerospace applications | Lightweight and corrosion-resistant | Lower strength than steel | High |

| Plastic | Residential and low-voltage wiring | Cost-effective and versatile | Limited temperature and load capacity | Low |

| Stainless Steel | Marine and chemical environments | Exceptional corrosion resistance | Higher cost and complex manufacturing | High |

This guide provides B2B buyers with a comprehensive overview of material selection for wiring brackets, aiding in informed decision-making tailored to specific applications and regional standards.

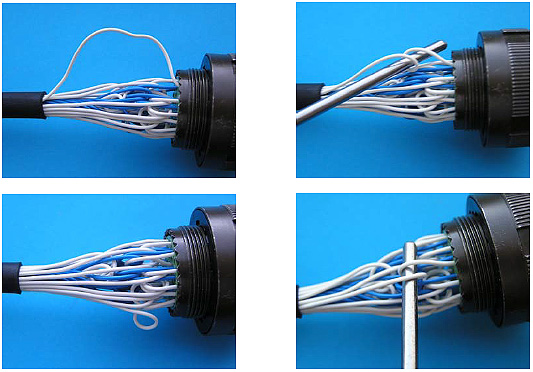

Illustrative image related to wiring bracket

In-depth Look: Manufacturing Processes and Quality Assurance for wiring bracket

What Are the Main Stages of Manufacturing Wiring Brackets?

The manufacturing process for wiring brackets typically involves several key stages: material preparation, forming, assembly, and finishing. Each stage is crucial for ensuring that the final product meets quality and performance standards.

Material Preparation: How Are Raw Materials Selected and Processed?

The first step in manufacturing wiring brackets is material selection. Common materials include high-grade steel, aluminum, and plastic composites, chosen for their strength, durability, and resistance to corrosion. Once selected, raw materials undergo processing, which may include cutting, shearing, or bending to create the initial shapes required for the brackets.

Material preparation also involves quality checks to ensure that the raw materials meet specific industry standards. This may include tests for tensile strength, elongation, and surface quality, which can help prevent defects in the final product.

Forming: What Techniques Are Used to Shape Wiring Brackets?

The forming stage involves shaping the prepared materials into the desired bracket configuration. Common techniques include stamping, laser cutting, and CNC machining.

- Stamping is often used for high-volume production, creating precise shapes rapidly and efficiently.

- Laser cutting allows for intricate designs and can accommodate varying thicknesses of material, making it ideal for custom orders.

- CNC machining offers high precision and flexibility, allowing manufacturers to produce complex geometries that may be needed for specific applications.

These techniques ensure that the brackets not only fit their intended purpose but also meet stringent dimensional tolerances required by industry standards.

Illustrative image related to wiring bracket

Assembly: How Are Different Components Integrated?

Once the individual components are formed, they move to the assembly stage. This may involve welding, riveting, or bolting different parts together to create the final bracket.

Automated assembly lines are increasingly common in the manufacturing of wiring brackets, as they enhance efficiency and consistency. However, manual assembly is still prevalent for specialized or low-volume products, where precision and craftsmanship are paramount.

Quality control checkpoints during assembly are crucial. Manufacturers often implement in-process quality checks (IPQC) to identify and rectify defects before the product moves to the finishing stage.

Finishing: What Processes Ensure Durability and Aesthetic Quality?

The finishing stage is essential for enhancing the durability and appearance of wiring brackets. Common finishing processes include:

- Painting or Powder Coating: This provides a protective layer against corrosion and improves aesthetics. Powder coating is often preferred for its durability and eco-friendliness.

- Plating: Electroplating can be applied to enhance corrosion resistance and improve the conductivity of metal components.

- Surface Treatment: Processes like anodizing for aluminum brackets can improve surface hardness and wear resistance.

Each of these finishing techniques contributes to the longevity of the wiring brackets, making them suitable for various environments, including those in humid or corrosive conditions.

What International Standards Govern Quality Assurance in Wiring Bracket Manufacturing?

Quality assurance in wiring bracket manufacturing is governed by several international standards, which are critical for B2B buyers seeking reliable suppliers.

What Are the Key International Quality Standards?

-

ISO 9001: This is the most recognized quality management standard globally. It ensures that manufacturers maintain consistent quality in their processes, which is essential for reliability and customer satisfaction.

-

CE Marking: For products sold within the European Economic Area, CE marking indicates conformity with health, safety, and environmental protection standards. This is crucial for buyers in Europe who need assurance of compliance.

-

API Standards: In industries like oil and gas, adherence to American Petroleum Institute (API) standards is vital for ensuring that products can withstand harsh operating conditions.

How Is Quality Control Implemented During Manufacturing?

Quality control (QC) involves multiple checkpoints throughout the manufacturing process to ensure that products meet established standards.

What Are the Common QC Checkpoints?

-

Incoming Quality Control (IQC): This is the first line of defense, where raw materials are inspected upon arrival to ensure they meet specifications.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, random samples may be tested to detect defects early, minimizing waste and rework.

-

Final Quality Control (FQC): Once the wiring brackets are assembled and finished, a final inspection is conducted to verify that they meet all dimensional and aesthetic requirements.

How Can B2B Buyers Verify Supplier Quality Assurance?

For international B2B buyers, verifying a supplier’s quality assurance processes is crucial for mitigating risks. Here are several strategies:

-

Conduct Supplier Audits: Regular audits help ensure that suppliers adhere to international standards and their internal QC protocols. Buyers should request audit reports to verify compliance.

-

Review Quality Assurance Documentation: Requesting documentation such as quality manuals, process flow charts, and testing protocols can provide insights into a supplier’s commitment to quality.

-

Utilize Third-Party Inspections: Engaging third-party inspection services can offer an impartial assessment of the supplier’s quality control processes and the final product.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers should be aware of specific nuances that may affect quality control:

-

Cultural Differences: Different regions may have varying approaches to quality assurance. Understanding these cultural differences can help in negotiating and ensuring adherence to quality standards.

-

Local Regulations: Buyers from regions like Africa and South America may encounter specific local regulations that affect product standards and certifications. It’s vital to ensure that suppliers are compliant with these regulations.

-

Logistics and Supply Chain Challenges: International shipping can introduce risks such as damage during transport. Buyers should consider including quality checks upon receipt of goods to ensure that products are delivered in satisfactory condition.

By understanding the manufacturing processes and quality assurance protocols for wiring brackets, B2B buyers can make informed decisions when selecting suppliers, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘wiring bracket’

In the complex world of B2B procurement, sourcing the right wiring bracket is crucial for ensuring efficiency, safety, and compliance with local standards. This guide serves as a step-by-step checklist to help international buyers navigate the procurement process, particularly in regions like Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Before initiating your search for wiring brackets, it’s essential to clarify your technical requirements. Consider the specific applications—are you using them for electrical installations, data cabling, or automotive purposes?

– Load Capacity: Ensure the brackets can support the weight and size of the wires or cables.

– Material Specifications: Decide on materials that will withstand environmental factors relevant to your location, such as humidity or temperature fluctuations.

Step 2: Identify Regulatory Compliance

Each region has specific regulations governing electrical components, including wiring brackets. Familiarize yourself with local standards to avoid compliance issues.

– Certification Requirements: Look for products that meet international standards such as UL, CSA, or CE markings.

– Regional Regulations: Consult with local authorities or industry experts to ensure your procurement aligns with national safety regulations.

Step 3: Evaluate Potential Suppliers

Once you have your specifications and compliance requirements, it’s time to identify potential suppliers. A thorough vetting process can prevent costly mistakes later on.

– Supplier Reputation: Research suppliers’ histories and customer reviews, especially from clients in similar industries.

– Case Studies: Request examples of previous projects that utilized their products to understand their capabilities and reliability.

Step 4: Request Samples

Before placing a bulk order, always request samples of the wiring brackets you are considering. This allows you to assess quality firsthand.

– Physical Testing: Evaluate the durability and functionality of the sample in your specific application.

– Fit and Compatibility: Ensure the sample fits with existing systems or components you plan to use.

Step 5: Negotiate Pricing and Terms

Pricing can vary significantly among suppliers, so it’s essential to negotiate to secure the best deal.

– Volume Discounts: Inquire about pricing structures for bulk orders, as many suppliers offer significant discounts.

– Payment Terms: Clarify payment conditions to align with your cash flow requirements, including any potential financing options.

Illustrative image related to wiring bracket

Step 6: Establish a Communication Channel

Effective communication with your supplier is vital throughout the procurement process. Set up a clear line of communication to address any concerns or questions.

– Regular Updates: Ensure that the supplier provides timely updates on order status and shipping.

– Point of Contact: Designate a specific representative for smoother interactions and problem resolution.

Step 7: Plan for Future Needs

As your business grows, so may your requirements for wiring brackets. Consider suppliers who can support future expansion.

– Scalability: Choose suppliers who offer a range of products that can adapt to changing needs.

– Long-term Relationships: Foster strong relationships with suppliers for better service and potential cost savings in future orders.

By following these steps, B2B buyers can streamline their sourcing process for wiring brackets, ensuring they make informed decisions that meet their technical and regulatory needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for wiring bracket Sourcing

What Are the Key Cost Components in Wiring Bracket Sourcing?

When sourcing wiring brackets, understanding the cost structure is crucial for making informed purchasing decisions. The primary components of cost include materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margin.

-

Materials: The choice of materials significantly impacts the cost. Common materials include metals like steel and aluminum, which offer durability and strength but vary in price based on market conditions. High-quality plastics may also be used for lighter applications, and their costs fluctuate based on resin prices.

-

Labor: Labor costs encompass both direct and indirect labor involved in the manufacturing process. This varies significantly by region, with labor being more affordable in developing countries, such as those in Africa or South America, compared to Europe or North America.

-

Manufacturing Overhead: This includes costs associated with running the production facility, such as utilities, maintenance, and salaries of support staff. These costs are often distributed across all products manufactured, making them a vital factor in pricing.

-

Tooling: Initial setup costs for molds and dies can be substantial, especially for custom or complex designs. These costs are amortized over the production volume, impacting unit pricing significantly for smaller orders.

-

Quality Control (QC): Ensuring the wiring brackets meet specific certifications (e.g., UL, CSA) is essential for compliance and safety. QC processes add to the overall cost but are necessary for maintaining product integrity.

-

Logistics: Shipping and handling costs vary widely based on the origin and destination of the products, as well as the chosen Incoterms. International shipping often involves additional tariffs and duties, which can further affect pricing.

-

Margin: Finally, the supplier’s profit margin is factored into the price. This can vary based on market competition, brand reputation, and the supplier’s operational efficiency.

How Do Price Influencers Affect Wiring Bracket Costs?

Several factors can influence the pricing of wiring brackets, making it essential for buyers to understand these nuances.

-

Volume/MOQ: Manufacturers often set a Minimum Order Quantity (MOQ) to ensure cost-effectiveness. Larger orders typically yield lower unit costs due to economies of scale, while smaller orders may incur higher per-unit prices.

-

Specifications and Customization: Customized brackets that meet specific requirements or unique designs can significantly increase costs. Buyers should weigh the necessity of customization against potential cost savings from standard products.

-

Material Selection: The choice of materials not only impacts the initial cost but also the durability and longevity of the product, which can affect the Total Cost of Ownership (TCO).

-

Quality and Certifications: Higher quality standards and certifications typically result in higher costs. However, investing in quality can lead to fewer failures and replacements, reducing overall expenses over time.

-

Supplier Factors: Supplier reliability, reputation, and location can also impact pricing. Suppliers with a strong track record may charge a premium, but they often provide better service and product quality.

-

Incoterms: Understanding Incoterms is crucial for international buyers. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect total landed costs, including shipping, insurance, and customs duties.

What Are the Best Negotiation Strategies for International B2B Buyers?

When negotiating prices for wiring brackets, especially in international contexts, buyers should consider several strategies to enhance cost-efficiency:

-

Research and Benchmarking: Gather pricing data from multiple suppliers to understand market rates and identify competitive pricing structures. This information can serve as leverage during negotiations.

-

Volume Commitments: If feasible, committing to larger orders can negotiate better pricing. Suppliers are often willing to lower prices for guaranteed bulk purchases.

-

Flexibility in Specifications: Being open to standard products instead of custom designs can lead to significant cost savings.

-

Evaluate Total Cost of Ownership: Consider not just the initial price but also long-term costs related to maintenance, durability, and potential failure rates. A higher upfront cost may be justified if the product lasts longer and performs better.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing, favorable terms, and priority treatment in future transactions.

By understanding these cost components, price influencers, and negotiation strategies, international B2B buyers can make more informed and strategic sourcing decisions regarding wiring brackets. Prices can vary widely based on numerous factors, and staying informed will ultimately lead to better procurement outcomes.

Alternatives Analysis: Comparing wiring bracket With Other Solutions

Exploring Alternatives to Wiring Brackets in Cable Management Solutions

When it comes to efficient cable management, choosing the right solution is crucial for ensuring durability, performance, and ease of installation. Wiring brackets are commonly used to secure and route cables, but there are alternative methods and products that may better suit specific needs. This analysis compares wiring brackets with two viable alternatives: cable trays and conduit systems.

| Comparison Aspect | Wiring Bracket | Cable Tray | Conduit System |

|---|---|---|---|

| Performance | Provides organized, neat routing; minimizes wire damage. | Supports a large volume of cables; easy access for maintenance. | Offers robust protection against environmental factors and physical damage. |

| Cost | Generally low-cost; affordable for large-scale installations. | Moderate initial investment; cost-effective for long runs. | Higher upfront cost; may require more labor for installation. |

| Ease of Implementation | Simple installation; can be mounted on various surfaces. | Requires planning for layout; installation can be more complex. | Involves more technical expertise; must adhere to electrical codes. |

| Maintenance | Minimal upkeep; easy to replace or adjust. | Low maintenance; easy to inspect and modify. | Requires regular inspections; potential for corrosion in some materials. |

| Best Use Case | Ideal for residential and small commercial applications. | Best suited for large industrial setups with extensive cabling. | Optimal for environments needing high protection, such as outdoor or hazardous areas. |

In-Depth Analysis of Alternatives

Cable Tray

Cable trays are an effective alternative for managing large volumes of cables, especially in commercial or industrial settings. They provide open access to the cables, making maintenance and upgrades straightforward. The primary advantage of cable trays is their ability to accommodate a wide range of cable types and sizes without the risk of overcrowding. However, the initial setup can be more complex, requiring careful planning to ensure they meet the layout of the building and comply with safety regulations.

Illustrative image related to wiring bracket

Conduit System

Conduit systems offer a robust solution for protecting electrical wiring from environmental factors and physical damage. They are particularly useful in outdoor applications or areas where cables are exposed to potential hazards. The main benefits of conduit systems include durability and compliance with safety codes, which can be critical in industrial environments. On the downside, the installation process is labor-intensive and requires skilled labor, resulting in higher upfront costs compared to wiring brackets and cable trays.

Making the Right Choice for Your Business Needs

When selecting the most suitable cable management solution, B2B buyers must consider several factors, including the specific application, budget constraints, and the environment in which the cables will be installed. Wiring brackets may be the best choice for straightforward installations with minimal cabling, while cable trays are advantageous for larger systems that require easy access for maintenance. For projects needing enhanced protection, a conduit system could be the ideal solution despite the higher costs and installation complexity.

Ultimately, understanding the unique requirements of your project will guide you to the most effective cable management strategy, ensuring long-term reliability and efficiency in your operations.

Essential Technical Properties and Trade Terminology for wiring bracket

Understanding the technical properties and terminology associated with wiring brackets is crucial for B2B buyers to make informed purchasing decisions. This knowledge helps ensure compatibility, compliance, and overall effectiveness in various applications.

What Are the Key Technical Properties of Wiring Brackets?

-

Material Grade

– Wiring brackets are commonly made from materials such as stainless steel, aluminum, or high-strength plastic (e.g., ABS). The choice of material affects durability, resistance to corrosion, and overall weight. For instance, stainless steel is favored for outdoor applications due to its rust resistance, while aluminum is lighter and easier to install. Selecting the right material grade is essential for ensuring longevity and reliability in various environments. -

Load Capacity

– This specification indicates the maximum weight a wiring bracket can support. Understanding load capacity is vital for ensuring that the brackets can adequately hold the wiring without risk of failure. Different applications may require different load capacities; for example, industrial settings might necessitate brackets that can bear heavier wiring loads compared to residential installations. -

Dimensions and Tolerances

– The dimensions of wiring brackets, including height, width, and depth, determine their fit within specific installations. Tolerances refer to acceptable variations in these dimensions, which are critical to ensure compatibility with other components. Proper sizing and tolerance are important for maintaining a clean installation and avoiding complications during assembly. -

Certification and Compliance Standards

– Many wiring brackets are certified to meet industry standards such as UL (Underwriters Laboratories) or CSA (Canadian Standards Association). These certifications ensure that the products have been tested for safety and performance. For B2B buyers, selecting certified products is important to comply with regulatory requirements and to ensure the safety of installations. -

Wire Fill Capacity

– This property defines the maximum number of wires that can be securely housed within a single bracket hole. It is crucial for maintaining organization and avoiding overheating due to excessive wire bundling. Understanding wire fill capacity helps buyers ensure that their installations adhere to electrical codes and safety guidelines. -

Installation Method

– Different wiring brackets may have various installation methods, including screw-on, snap-in, or adhesive options. Knowing the installation method is important for assessing the labor and time required for setup, which can impact project timelines and costs.

Which Trade Terms Should B2B Buyers Know When Dealing with Wiring Brackets?

-

OEM (Original Equipment Manufacturer)

– This term refers to a company that produces components or products that are used in another company’s end product. Understanding OEM relationships is crucial for buyers looking to source wiring brackets that are compatible with specific equipment or installations. -

MOQ (Minimum Order Quantity)

– MOQ denotes the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers as it affects purchasing strategies and inventory management. Knowing the MOQ can help in budgeting and ensuring that there is enough stock to meet project demands. -

RFQ (Request for Quotation)

– An RFQ is a formal document sent by buyers to suppliers requesting pricing and terms for specific products. This process is important for negotiating prices and understanding the full costs involved, including shipping and handling. -

Incoterms (International Commercial Terms)

– These terms define the responsibilities of buyers and sellers in international trade, including who pays for shipping, insurance, and tariffs. Familiarity with Incoterms is essential for B2B buyers engaged in cross-border transactions to avoid misunderstandings and ensure smooth logistics. -

Lead Time

– This term refers to the amount of time it takes for a supplier to fulfill an order after it has been placed. Understanding lead times is crucial for project planning and ensuring that materials arrive when needed, thus avoiding costly delays. -

Compatibility

– This refers to the ability of a wiring bracket to work seamlessly with other components in a system. Ensuring compatibility is essential for the overall effectiveness and safety of electrical installations, making it a key consideration for buyers.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing wiring brackets, leading to improved project outcomes and enhanced operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the wiring bracket Sector

What Are the Current Market Dynamics and Key Trends in the Wiring Bracket Sector?

The wiring bracket market is experiencing significant growth driven by several global trends. Increased urbanization and the expansion of infrastructure projects in regions like Africa, South America, and the Middle East are propelling demand for efficient and reliable wiring solutions. In Europe, the focus on smart buildings and energy-efficient technologies is creating opportunities for innovative wiring bracket designs that cater to modern electrical installations. Furthermore, advancements in materials technology are leading to the development of lighter, more durable wiring brackets that enhance installation efficiency and reduce costs.

Emerging technologies such as IoT and smart home systems are influencing sourcing trends as B2B buyers seek wiring brackets that can accommodate complex wiring needs. Buyers are increasingly looking for products that offer flexibility and scalability, enabling future expansions without significant additional costs. As a result, modular designs and easy-installation features are becoming standard expectations. Additionally, the rise of e-commerce platforms is changing how international buyers source wiring brackets, allowing for easier comparison of products and prices across different markets.

Illustrative image related to wiring bracket

How Is Sustainability and Ethical Sourcing Impacting the Wiring Bracket Market?

Sustainability has become a pivotal concern for B2B buyers in the wiring bracket sector. Increasing awareness of environmental issues is prompting buyers to prioritize products that are manufactured with minimal environmental impact. This includes the use of recycled materials and the reduction of waste throughout the production process. B2B buyers are now more inclined to partner with suppliers who demonstrate a commitment to sustainability through certifications such as ISO 14001 or adherence to green building standards.

Ethical sourcing is equally important, as buyers are concerned about the conditions under which products are manufactured. Companies that ensure fair labor practices and transparency in their supply chains are gaining a competitive edge. The demand for ‘green’ certifications is also rising, with buyers actively seeking wiring brackets that meet eco-friendly criteria. This shift not only addresses consumer demands but also enhances brand reputation, making sustainability a key factor in supplier selection.

What Is the Brief Evolution and History of Wiring Brackets in the B2B Context?

Wiring brackets have evolved significantly from their early days of simple metal or wooden supports used in basic electrical installations. Initially, these brackets were primarily functional, focusing on securing wires without much consideration for aesthetics or ease of installation. However, as electrical systems became more complex and the demand for organized wiring solutions grew, the design and functionality of wiring brackets advanced.

Illustrative image related to wiring bracket

The introduction of modular wiring systems in the late 20th century marked a turning point, allowing for easier installation and adaptability to changing technology. Today, modern wiring brackets are designed with user-friendliness in mind, featuring innovative designs that enhance efficiency and reduce installation time. This evolution reflects the broader trends within the electrical industry towards automation, smart technology, and sustainability, aligning with the needs and expectations of contemporary B2B buyers.

Frequently Asked Questions (FAQs) for B2B Buyers of wiring bracket

-

How do I solve issues related to wire damage during installation?

To mitigate wire damage during installation, consider using a wiring bracket designed to provide a smooth, unobstructed path for wires. Brackets such as the Cable Chase can help reduce friction and stress, minimizing the risk of damage from sharp edges or poorly drilled holes. Additionally, ensure that the bracket is installed according to local electrical codes and guidelines to maintain safety and compliance. Regular inspections and maintenance of wiring installations can also help identify potential issues before they escalate. -

What is the best wiring bracket for heavy-duty applications?

For heavy-duty applications, look for wiring brackets that are specifically designed to support larger gauge wires and provide robust structural integrity. Brackets that are UL listed and made from durable materials, such as ABS or steel, are ideal. Consider options that allow for easy access and future expansion, like those that accommodate multiple cable types and sizes, ensuring they meet the specific demands of your project. -

How can I customize wiring brackets for my specific needs?

Many manufacturers offer customization options for wiring brackets, allowing you to specify dimensions, materials, and hole configurations. When contacting suppliers, provide detailed specifications and any particular requirements, such as load capacity or environmental resistance. Ensure that the supplier can accommodate these requests and has a proven track record of delivering customized solutions for similar projects. -

What are the minimum order quantities (MOQ) for wiring brackets when sourcing internationally?

Minimum order quantities can vary significantly between suppliers and regions. Generally, larger manufacturers may have higher MOQs due to production efficiencies, while smaller suppliers may be more flexible. When sourcing internationally, inquire about MOQs early in the negotiation process and consider discussing options for smaller trial orders to assess product quality before committing to larger quantities. -

What payment terms are typically offered for B2B wiring bracket purchases?

Payment terms can range from upfront payment to net 30 or net 60 days, depending on the supplier’s policies and your business relationship. Some suppliers may offer discounts for early payment or flexible financing options for larger orders. It’s advisable to clarify payment terms in the contract to avoid misunderstandings and ensure that both parties are aligned on expectations. -

How can I ensure the quality of wiring brackets from international suppliers?

To ensure product quality, conduct thorough supplier vetting, including checking certifications, product samples, and customer references. Request documentation that outlines compliance with international standards, such as UL or CE certifications. Establishing a quality assurance (QA) process, including pre-shipment inspections, can further help maintain product integrity and reliability. -

What logistics considerations should I keep in mind when importing wiring brackets?

When importing wiring brackets, consider factors such as shipping methods, customs clearance, and local regulations. Choose a reliable freight forwarder who understands the nuances of international shipping and can assist with documentation and compliance. Additionally, plan for potential tariffs and duties that may apply to your imports, as these can impact overall costs. -

What are the common applications for wiring brackets in various industries?

Wiring brackets are widely used in telecommunications, construction, automotive, and industrial settings. They help organize and secure wiring in data centers, residential and commercial buildings, and vehicle electrical systems. Understanding the specific needs of your industry, such as load requirements and environmental factors, will help you select the right type of wiring bracket for optimal performance.

Top 4 Wiring Bracket Manufacturers & Suppliers List

1. ICC – 89B Mounting Bracket for 66 Wiring Block

Domain: icc.com

Registered: 1996 (29 years)

Introduction: {‘name’: ’89B Mounting Bracket for 66 Wiring Block’, ‘performance_connectors’: [‘8P8C’, ‘6P6C’, ‘6P4C’, ’25-Pair’, ’50-Pair’], ‘accessories’: [’89B Mounting Bracket’, ’89D Mounting Bracket’, ‘Bridging Clip’, ‘Cover’, ‘Cable Spool with Screw’, ‘Cable Spool without Screw’], ‘packaging_options’: [‘Single’, ’10-Pack’, ’25-Pack’, ‘100-Pack’], ‘sku’: ‘ICMB89B0WH’, ‘categories’: [’66 Wiring Blocks’, ‘Pat…

2. Jofemar – Wiring Harness Bracket

Domain: jofemarusa.com

Registered: 2006 (19 years)

Introduction: {“product_name”: “Wiring Harness Bracket”, “price”: “$15.76”, “quantity_in_stock”: 1, “product_code”: “6156550”}

3. Tow Ready – Mounting Bracket, 4-Way Flat

Domain: draw-tite.com

Registered: 1995 (30 years)

Introduction: {‘brand’: ‘Tow Ready’, ‘part_number’: ‘118144’, ‘description’: ‘Mounting Bracket, 4-Way Flat’, ‘features’: ‘Mounts electrical connector to attachment bracket; Includes screws and nuts; Attractive point-of-purchase packaging’, ‘warranty’: ‘Limited 1 Year Warranty’, ‘UPC’: ‘016118063608’, ‘dimensions’: ‘7.875″ x 4.75″ x 1.5″ (Shipping)’, ‘weight’: ‘0.2 lbs’, ‘finish’: ‘Black Powder Coat’, ‘prop_65_w…

4. Reese – Electrical Mounting Brackets

Domain: reese-hitches.com

Registered: 2002 (23 years)

Introduction: This company, Reese – Electrical Mounting Brackets, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for wiring bracket

Why is Strategic Sourcing Essential for Wiring Brackets?

In the competitive landscape of wiring brackets, strategic sourcing stands out as a crucial element for international B2B buyers. By focusing on quality, cost-efficiency, and compliance with global standards, businesses can enhance their operational effectiveness. Products like the Cable Chase wire bracket demonstrate how innovative designs can reduce installation time and costs while minimizing potential damage to infrastructure. This is particularly relevant for buyers in regions like Africa, South America, the Middle East, and Europe, where infrastructure development is rapidly evolving.

How Can International Buyers Leverage Market Trends?

Understanding market trends is vital. As the demand for efficient wiring solutions grows, sourcing from reliable manufacturers can ensure access to cutting-edge products that meet diverse needs. Buyers should prioritize partnerships that offer not only competitive pricing but also robust customer support and product warranties. This approach not only safeguards investments but also positions businesses favorably for future expansions.

Illustrative image related to wiring bracket

What’s Next for Wiring Bracket Solutions?

Looking ahead, international B2B buyers should remain proactive in exploring innovative wiring solutions that align with their operational goals. Engaging with suppliers who prioritize sustainability and technological advancements will be essential in navigating the evolving market landscape. As you consider your sourcing strategies, remember that the right wiring brackets can significantly impact both installation efficiency and long-term project success. Take the next step today by connecting with trusted suppliers and exploring the latest offerings in wiring bracket technology.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to wiring bracket