A Deep Dive into What Is The Isolation Transformer Solution

Introduction: Navigating the Global Market for what is the isolation transformer

In today’s interconnected world, sourcing reliable electrical components such as isolation transformers can present significant challenges for international B2B buyers. These critical devices not only provide electrical isolation between circuits but also enhance power quality and protect sensitive equipment from surges and noise. As industries across Africa, South America, the Middle East, and Europe increasingly rely on advanced technology, understanding the nuances of isolation transformers becomes essential for ensuring operational efficiency and safety.

This comprehensive guide delves into the various types of isolation transformers, including constant voltage, ultra-isolation, and drive isolation transformers, each tailored for specific applications. It also explores the benefits of using these transformers in diverse settings, from medical facilities to industrial operations, emphasizing their role in maintaining the integrity of electrical systems. Furthermore, we will provide insights on supplier vetting processes, cost considerations, and best practices for procurement.

By equipping B2B buyers with the knowledge needed to make informed purchasing decisions, this guide empowers organizations to navigate the global market with confidence. Whether you’re in Germany, Nigeria, or anywhere in between, understanding the critical features and applications of isolation transformers will enhance your sourcing strategy, ensuring you select the right solutions that meet your operational needs.

Understanding what is the isolation transformer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Constant Voltage Transformer | Maintains steady voltage output despite input fluctuations | Industrial equipment, data centers | Pros: Stabilizes voltage; protects sensitive equipment. Cons: May be more expensive than standard transformers. |

| Ultra Isolation Transformer | High levels of electrical isolation; minimizes noise | Medical devices, research labs | Pros: Enhanced protection against electrical noise; ideal for sensitive applications. Cons: Higher cost and size. |

| Drive Isolation Transformer | Designed for electric motors; reduces noise transfer | Manufacturing, automation systems | Pros: Provides clean power; improves motor efficiency. Cons: Limited to motor applications; may require specific configurations. |

| Galvanic Isolation Transformer | Complete electrical insulation between circuits | Medical equipment, industrial machinery | Pros: Ensures safety and reliability; prevents surges. Cons: May require complex installation; higher initial investment. |

| Dry Isolation Transformer | Utilizes dry air for insulation; compact design | Telecom, medical, industrial applications | Pros: Lightweight; suitable for various environments. Cons: May not be as durable in extreme conditions. |

What Are the Characteristics of Constant Voltage Transformers?

Constant Voltage Transformers (CVTs) are designed to maintain a consistent voltage output regardless of fluctuations in input voltage or load conditions. This feature is crucial for industries relying on sensitive equipment, such as data centers and manufacturing facilities. When purchasing CVTs, B2B buyers should consider the transformer’s voltage range, load capacity, and efficiency ratings to ensure it meets their operational needs.

How Do Ultra Isolation Transformers Enhance Electrical Safety?

Ultra Isolation Transformers provide superior levels of electrical isolation by utilizing advanced construction techniques that significantly reduce electrical noise transfer. This makes them particularly suitable for medical and research applications where precision is paramount. Buyers should evaluate the transformer’s specifications, including insulation materials and noise reduction capabilities, to ensure compliance with safety standards in their industry.

What Are the Benefits of Drive Isolation Transformers?

Drive Isolation Transformers are specifically engineered to power electric motors while minimizing electrical noise interference. Their design enhances motor performance and efficiency, making them a popular choice in manufacturing and automation sectors. B2B buyers should assess compatibility with existing motor systems, as well as the transformer’s ability to handle specific voltage and current requirements.

Why Choose Galvanic Isolation Transformers for Critical Applications?

Galvanic Isolation Transformers offer complete electrical insulation between circuits, which is essential for protecting sensitive equipment from electrical surges and noise. Commonly used in medical devices and industrial machinery, these transformers ensure operational safety and reliability. Buyers should consider the transformer’s isolation level, size, and installation requirements when making a purchasing decision.

What Are the Advantages of Dry Isolation Transformers?

Dry Isolation Transformers utilize dry air as an insulating medium, making them lighter and easier to install compared to traditional transformers. They are versatile and suitable for various applications, including telecommunications and medical environments. When purchasing, B2B buyers should evaluate the transformer’s environmental compatibility, insulation class, and maintenance requirements to ensure it meets their operational demands.

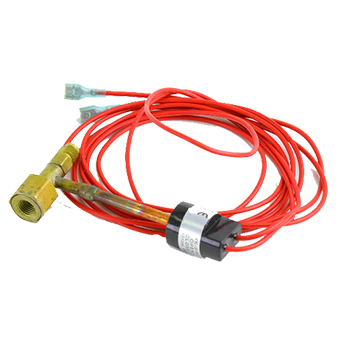

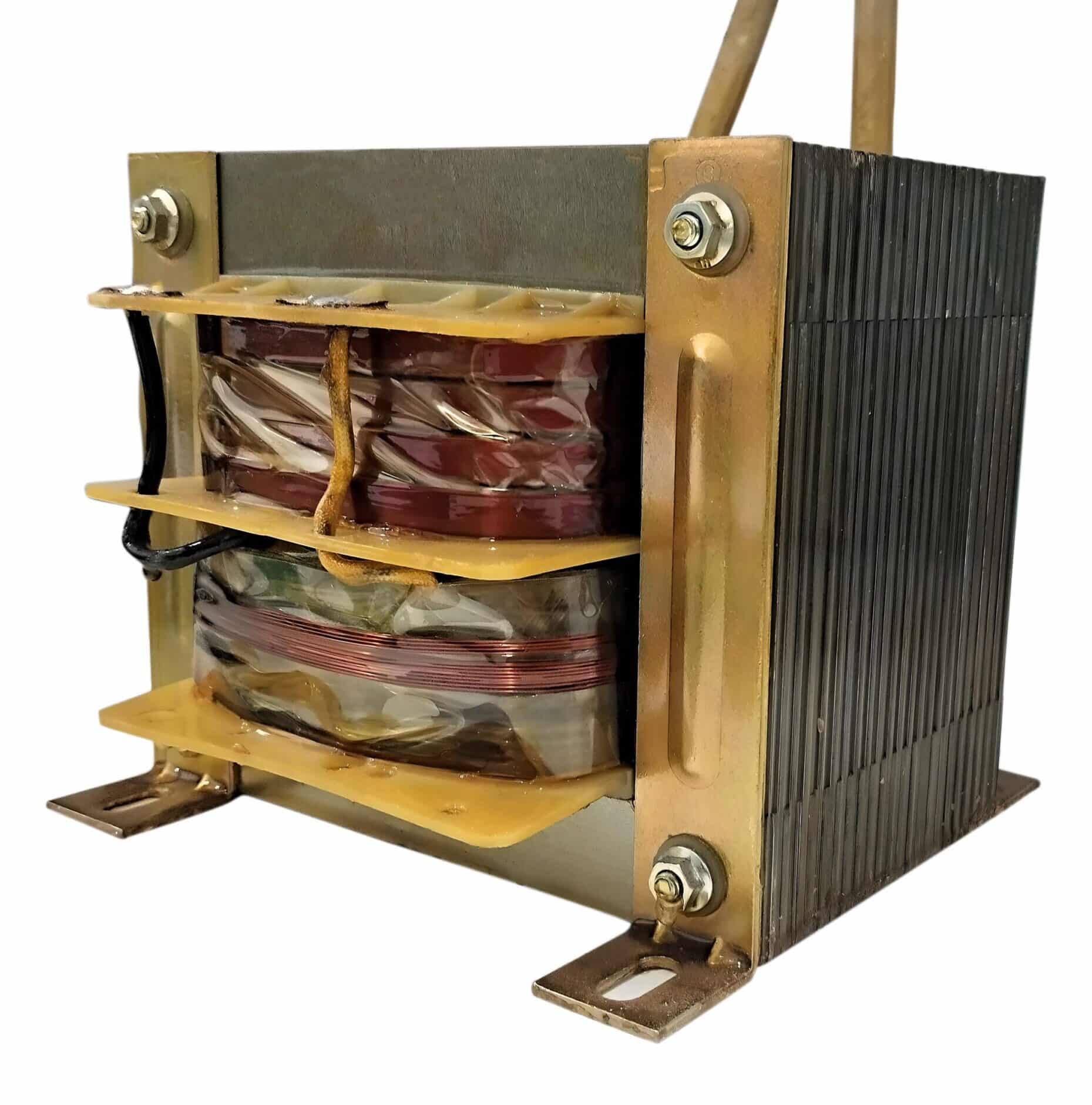

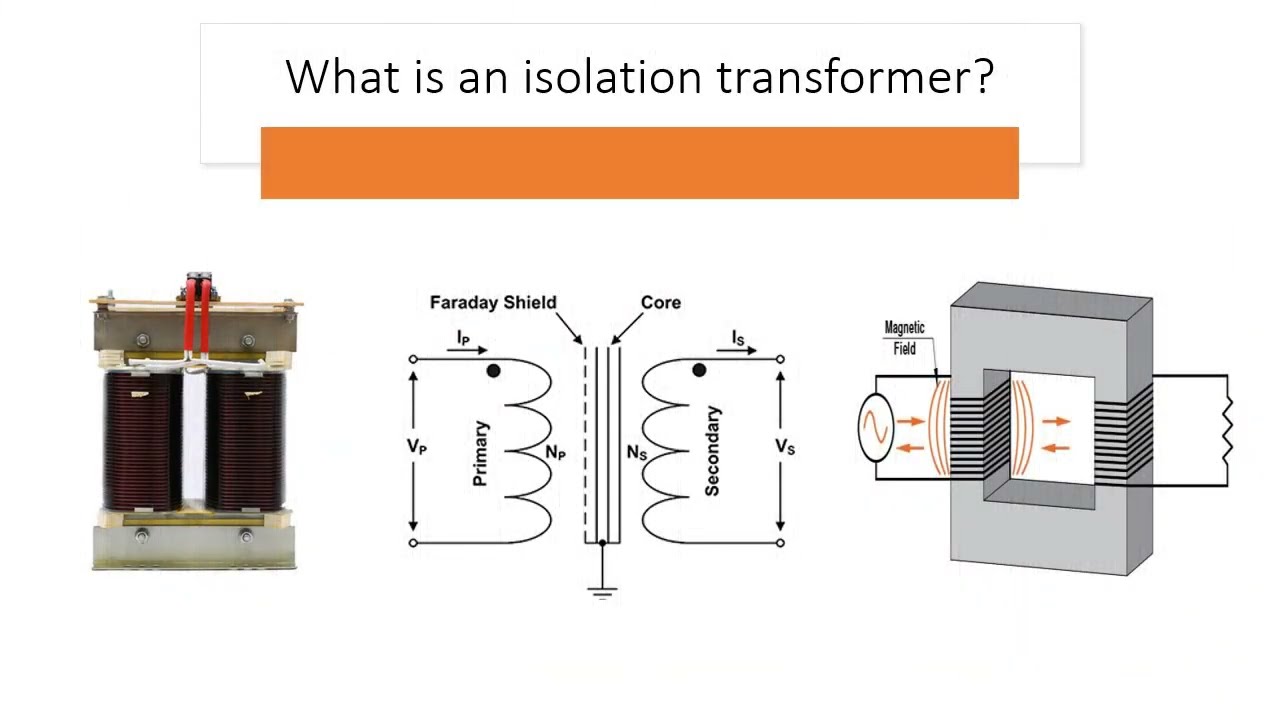

Illustrative image related to what is the isolation transformer

Key Industrial Applications of what is the isolation transformer

| Industry/Sector | Specific Application of what is the isolation transformer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Powering medical imaging equipment | Ensures reliable operation and safety of devices | Compliance with medical standards, voltage ratings |

| Manufacturing | Supplying clean power to CNC machines | Reduces electrical noise, enhancing machine accuracy | Durability under industrial conditions, efficiency |

| Telecommunications | Protecting telecom equipment from electrical surges | Increases equipment lifespan and reliability | Voltage capacity, environmental ratings |

| Research Laboratories | Isolation for sensitive electronic testing | Guarantees accurate measurements and data integrity | Precision in voltage output, thermal performance |

| Food Processing | Ensuring power quality for automated systems | Maintains product quality and operational efficiency | Hygiene compliance, energy efficiency |

How is an Isolation Transformer Used in Healthcare?

In the healthcare sector, isolation transformers are critical for powering medical imaging equipment like MRI and CT scanners. These devices require a stable and noise-free power supply to function correctly, as any electrical interference can lead to inaccurate readings or system failures. International buyers, especially in regions like Africa and South America, need to ensure that the transformers meet stringent medical standards and provide appropriate voltage ratings to ensure patient safety and equipment reliability.

What Role Does an Isolation Transformer Play in Manufacturing?

In manufacturing, particularly in CNC (Computer Numerical Control) machining, isolation transformers are used to supply clean power to machinery. By isolating electrical noise, these transformers enhance the precision of machining processes, resulting in higher quality outputs. For B2B buyers in Europe and the Middle East, sourcing transformers that can withstand harsh industrial environments while maintaining efficiency is crucial to minimizing downtime and maximizing production quality.

How Do Isolation Transformers Benefit Telecommunications?

Telecommunications infrastructure relies heavily on isolation transformers to protect sensitive equipment from electrical surges and spikes. These transformers ensure that telecom devices operate reliably, thereby increasing their lifespan and reducing maintenance costs. Buyers in regions like Nigeria and Brazil should prioritize sourcing transformers with appropriate voltage capacities and environmental ratings to withstand local conditions and ensure uninterrupted service.

Why Are Isolation Transformers Important in Research Laboratories?

Research laboratories utilize isolation transformers to provide a stable power supply for sensitive electronic testing equipment. These transformers help in maintaining accurate measurements and data integrity, which are vital for research outcomes. For international buyers, particularly in Europe, it is essential to consider the precision of voltage output and thermal performance to ensure that the equipment operates within the required parameters for reliable results.

What is the Significance of Isolation Transformers in Food Processing?

In the food processing industry, isolation transformers are employed to ensure high power quality for automated systems that handle food products. By providing a consistent and clean power supply, these transformers help maintain product quality and operational efficiency. Buyers in Africa and South America should focus on sourcing transformers that comply with hygiene standards and demonstrate energy efficiency to enhance sustainability in food production processes.

3 Common User Pain Points for ‘what is the isolation transformer’ & Their Solutions

Scenario 1: Ensuring Equipment Safety in Sensitive Environments

The Problem: Many B2B buyers in sectors like healthcare and research face the challenge of ensuring that their equipment operates safely in environments with high electrical noise. For instance, medical devices such as MRI machines or laboratory instruments are sensitive to voltage fluctuations and interference. These fluctuations can lead to inaccurate readings, equipment malfunction, or even endanger patient safety. Buyers need a solution that not only protects their equipment but also adheres to strict regulatory standards.

The Solution: To effectively mitigate these risks, B2B buyers should consider investing in ultra-isolation transformers. These transformers provide superior electrical isolation, significantly reducing the transfer of electrical noise and ensuring that sensitive devices receive stable, clean power. When sourcing ultra-isolation transformers, it’s crucial to evaluate specifications such as insulation class, voltage rating, and load capacity. Working closely with reputable suppliers who understand the specific needs of sensitive applications can help ensure compliance with industry standards, thereby safeguarding both equipment and users. Additionally, implementing regular maintenance checks on these transformers can further enhance their performance and longevity.

Scenario 2: Navigating Voltage Variability in Industrial Applications

The Problem: In industrial settings, buyers often grapple with fluctuating voltage levels that can cause significant operational disruptions. Machinery and equipment require a consistent voltage to operate efficiently; any deviation can lead to equipment damage, production downtime, and increased operational costs. This issue is particularly prevalent in regions with unstable power supply, where voltage spikes and sags are common.

The Solution: A viable solution for industrial buyers is to incorporate constant voltage transformers (CVTs) into their power distribution systems. CVTs are designed to maintain a steady voltage output despite input voltage fluctuations. Buyers should look for CVTs that offer features like feedback circuits for real-time voltage monitoring and adjustment capabilities. It’s advisable to conduct a thorough assessment of the plant’s power requirements and load characteristics before selecting a transformer. Collaborating with engineering consultants can further help in tailoring the CVT specifications to meet unique operational needs, ensuring that machinery operates smoothly and efficiently.

Scenario 3: Overcoming Grounding Issues in Complex Electrical Systems

The Problem: B2B buyers in sectors such as telecommunications and manufacturing often encounter grounding issues that can compromise the performance of their electrical systems. Poor grounding can lead to electrical noise, potential equipment damage, and even safety hazards. This is particularly true when multiple systems are interconnected, as it becomes challenging to ensure that all components are properly isolated from each other.

The Solution: Implementing galvanic isolation transformers can be an effective strategy to address grounding issues. These transformers create an isolated circuit that prevents any electrical current from passing directly between the primary and secondary coils, thereby eliminating ground loops and reducing electrical noise. When selecting a galvanic isolation transformer, buyers should consider the specific application requirements, such as power ratings, frequency, and insulation type. It’s beneficial to work with manufacturers who can provide tailored solutions and support in installation. Additionally, regular testing and monitoring of the electrical system can help identify potential grounding issues early, allowing for timely interventions to maintain system integrity.

Strategic Material Selection Guide for what is the isolation transformer

When selecting materials for isolation transformers, it is crucial to consider their properties, advantages, disadvantages, and specific applications. The choice of materials directly affects the performance, durability, and cost-effectiveness of the transformers, especially in diverse international markets such as Africa, South America, the Middle East, and Europe.

What Are the Key Materials Used in Isolation Transformers?

1. Silicon Steel

Key Properties: Silicon steel is known for its excellent magnetic properties, high electrical resistivity, and low core losses. It can withstand high temperatures, typically rated up to 150°C, making it suitable for various applications.

Pros & Cons: The primary advantage of silicon steel is its efficiency in reducing energy losses during operation, which is critical for power quality. However, it can be more expensive than other materials and may require complex manufacturing processes to achieve the desired magnetic characteristics.

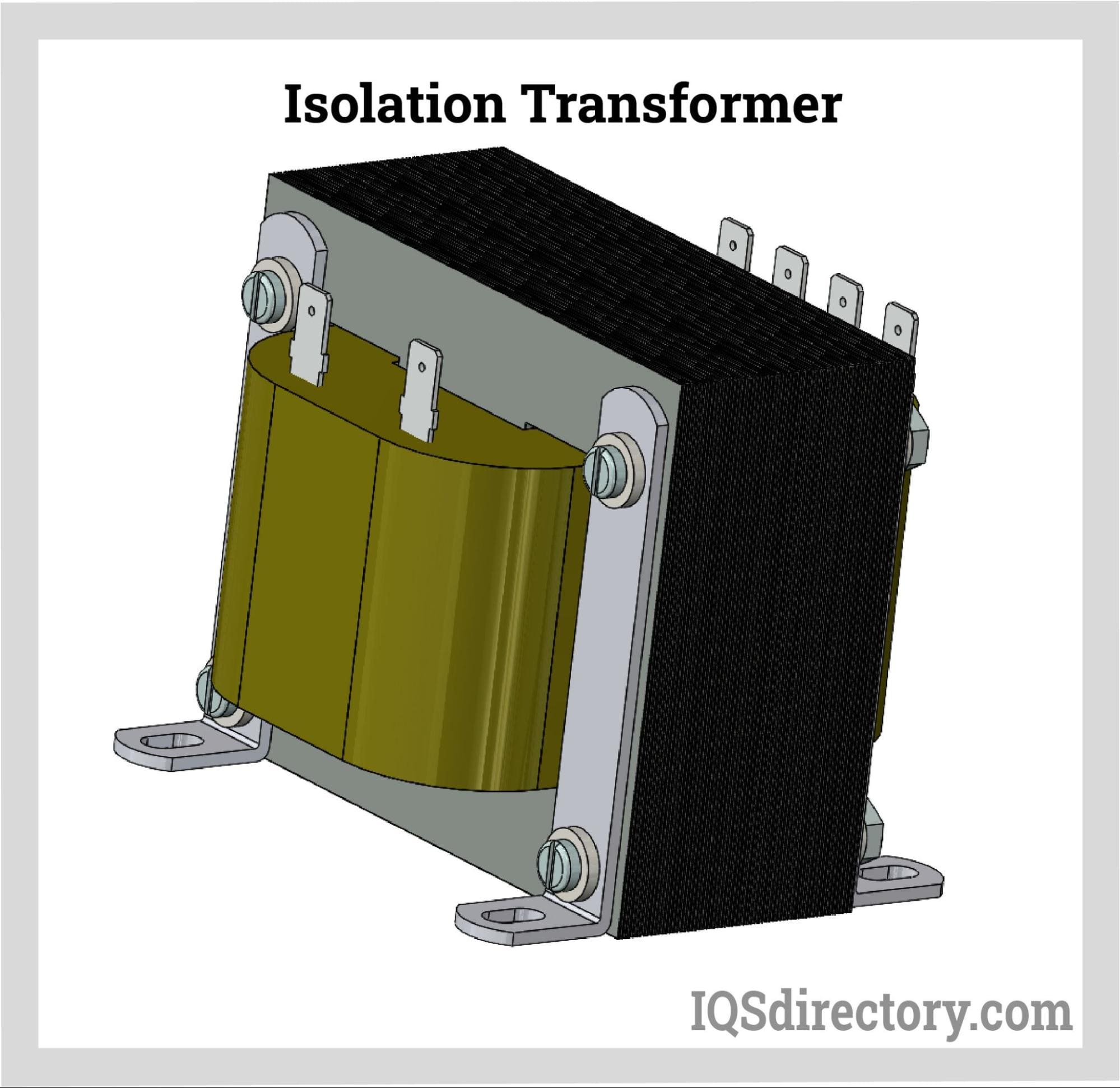

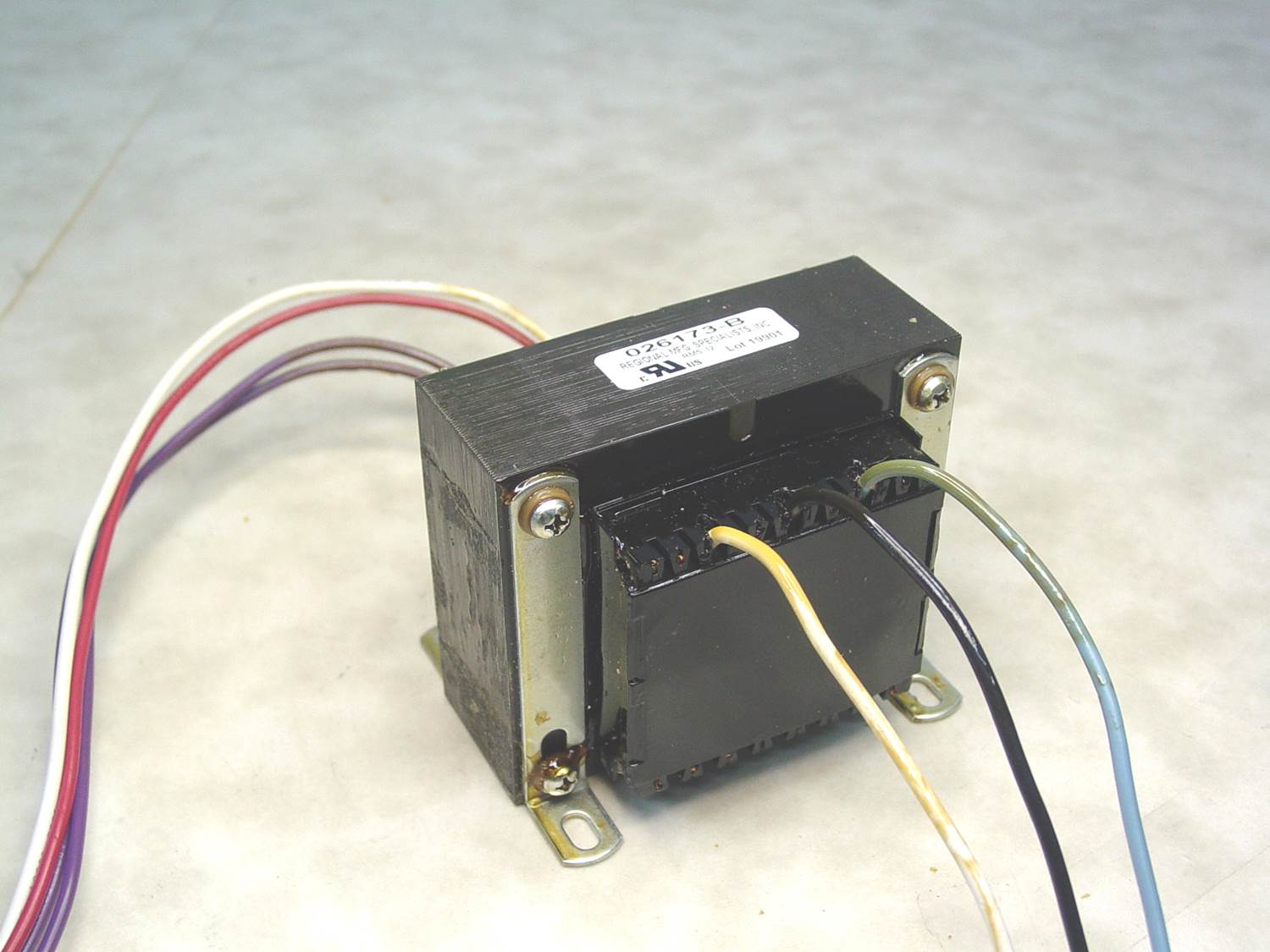

Illustrative image related to what is the isolation transformer

Impact on Application: Silicon steel is ideal for applications requiring high efficiency and low noise, such as in medical equipment and industrial applications. Its compatibility with high-frequency operations makes it a preferred choice in sensitive environments.

Considerations for International Buyers: Buyers should ensure compliance with international standards such as ASTM A677 or DIN 46212. In regions like Germany, where energy efficiency is paramount, silicon steel is often preferred.

2. Copper

Key Properties: Copper offers excellent electrical conductivity, thermal conductivity, and corrosion resistance. It can handle high current loads and has a melting point of around 1,085°C.

Pros & Cons: The main advantage of copper is its superior conductivity, which enhances the efficiency of the transformer. However, it is relatively expensive compared to alternatives like aluminum and can be prone to oxidation if not properly insulated.

Impact on Application: Copper is widely used in windings of isolation transformers, particularly in applications requiring high performance and reliability, such as telecommunications and industrial machinery.

Considerations for International Buyers: Compliance with standards such as IEC 60228 for conductors is essential. Buyers in regions with high humidity, like parts of Africa and South America, should consider protective coatings to prevent corrosion.

3. Aluminum

Key Properties: Aluminum is lightweight, has good electrical conductivity (about 60% that of copper), and exhibits excellent corrosion resistance. It is also cost-effective, making it a popular choice for various electrical applications.

Pros & Cons: The primary advantage of aluminum is its lower cost and lighter weight, which can reduce shipping and installation costs. However, it has lower conductivity than copper, which may necessitate larger wire sizes for equivalent performance.

Impact on Application: Aluminum is often used in larger transformers where weight and cost are critical factors. It is suitable for applications in commercial and industrial settings but may not be ideal for high-frequency uses.

Considerations for International Buyers: Buyers should be aware of the standards for aluminum conductors, such as ASTM B231. In regions like the Middle East, where extreme temperatures are common, thermal expansion properties must be considered.

4. Ferrite

Key Properties: Ferrite materials are ceramic compounds that exhibit high magnetic permeability and low electrical conductivity. They are effective at high frequencies and have good thermal stability.

Illustrative image related to what is the isolation transformer

Pros & Cons: Ferrite cores are advantageous for high-frequency applications due to their low eddy current losses. However, they can be brittle and may require careful handling during manufacturing and installation.

Impact on Application: Ferrite materials are commonly used in isolation transformers for electronic devices and RF applications, where size and weight are critical.

Considerations for International Buyers: Compliance with standards such as JIS C 5003 for ferrite materials is important. Buyers in Europe and Asia should also consider the environmental impact of ferrite production, as sustainability is becoming increasingly important.

Summary Table of Material Selection for Isolation Transformers

| Material | Typical Use Case for what is the isolation transformer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Silicon Steel | Medical equipment, industrial applications | High efficiency and low energy losses | Higher cost and complex manufacturing | High |

| Copper | Windings in telecommunications, industrial machinery | Superior conductivity | Expensive and oxidation-prone | High |

| Aluminum | Large transformers in commercial settings | Cost-effective and lightweight | Lower conductivity than copper | Medium |

| Ferrite | High-frequency electronic devices | Low eddy current losses | Brittle and requires careful handling | Medium |

This analysis provides a comprehensive overview of the materials used in isolation transformers, highlighting their properties and considerations for international B2B buyers. Understanding these factors is essential for making informed purchasing decisions that align with operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for what is the isolation transformer

What Are the Main Stages of Manufacturing Isolation Transformers?

The manufacturing process of isolation transformers involves several critical stages, each designed to ensure the final product meets the rigorous standards required for performance and safety. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Isolation Transformers?

Material preparation is the foundational step in manufacturing isolation transformers. The primary materials used include copper wire for the windings, silicon steel for the core, and insulation materials such as varnish or resin.

-

Copper Wire Selection: High-conductivity copper is chosen for its excellent electrical properties, which help minimize energy losses.

-

Core Material: The silicon steel used for the core is chosen for its magnetic properties, which are crucial for efficient energy transfer.

-

Insulation Materials: Various insulating materials are prepared to ensure that electrical isolation between the primary and secondary windings is maintained.

This stage involves rigorous quality checks to ensure that all materials meet international and industry-specific standards, as any defect at this stage can impact the transformer’s overall performance.

What Techniques Are Used in the Forming Process?

The forming process involves shaping the core and winding the copper wire. This stage is critical for ensuring the efficiency of the transformer.

-

Core Fabrication: The silicon steel is cut and shaped into the desired core configuration. This often involves stacking layers to reduce losses due to eddy currents.

-

Winding Techniques: The copper wire is wound around the core using automated winding machines. The precision of the winding process is vital, as it directly influences the transformer’s voltage regulation and efficiency. Techniques such as toroidal winding can also be employed for specific designs, which help reduce electromagnetic interference.

-

Insulation: After winding, insulation is applied to prevent electrical contact between the windings and the core. This step is crucial for maintaining the integrity of the isolation transformer.

How Does Assembly of Isolation Transformers Take Place?

The assembly stage involves integrating the core and windings into a complete unit.

-

Core Assembly: The assembled core is placed into a housing, which may be made of steel or aluminum for durability.

-

Winding Connection: The windings are connected to terminals, and care is taken to ensure that these connections are secure and well-insulated.

-

Final Assembly: All components, including any additional features such as circuit breakers or fuses, are installed.

This stage may also involve the application of protective coatings to the exterior of the transformer to enhance durability and resistance to environmental factors.

What Finishing Processes Are Involved in Manufacturing Isolation Transformers?

The finishing stage focuses on ensuring that the isolation transformer is ready for use.

-

Testing: Each transformer undergoes a series of tests to verify its performance and safety. These may include insulation resistance testing, power factor testing, and load testing.

-

Quality Control Inspections: Final inspections are conducted to ensure that the transformer meets all specifications and quality standards.

-

Certification: Transformers intended for international markets may require certification from recognized bodies, ensuring compliance with local regulations and standards.

What Quality Assurance Measures Are Commonly Used for Isolation Transformers?

Quality assurance is paramount in the manufacturing of isolation transformers. Adhering to international standards such as ISO 9001, as well as industry-specific certifications, helps ensure the reliability and safety of the final product.

Which International Standards Are Relevant for Isolation Transformers?

-

ISO 9001: This international standard focuses on quality management systems and ensures that manufacturers follow consistent processes to produce high-quality products. Compliance with ISO 9001 is often a prerequisite for B2B transactions.

-

CE Marking: For products sold in Europe, CE marking indicates compliance with health, safety, and environmental protection standards. This is particularly important for transformers used in sensitive applications, such as medical equipment.

-

API Standards: In regions where oil and gas applications are prevalent, adherence to American Petroleum Institute (API) standards may be required.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control checkpoints are strategically placed throughout the manufacturing process to catch any defects early. The main checkpoints include:

Illustrative image related to what is the isolation transformer

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections and tests are conducted to monitor the quality of the product at various stages, including during the forming and assembly processes.

-

Final Quality Control (FQC): After assembly, the transformer undergoes comprehensive testing to verify its performance against predefined criteria.

What Common Testing Methods Are Used for Isolation Transformers?

Various testing methods are utilized to ensure that isolation transformers operate safely and effectively:

-

Insulation Resistance Testing: This test measures the resistance of the insulation material to ensure it can withstand operational voltages.

-

Turn Ratio Testing: This test checks the ratio of the primary and secondary windings to confirm that the transformer will perform as expected.

-

Load Testing: This involves applying a load to the transformer to assess its performance under operational conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those in international markets, verifying the quality control processes of suppliers is crucial for ensuring product reliability.

-

Supplier Audits: Conducting on-site audits can provide insight into the supplier’s manufacturing processes, quality control measures, and compliance with standards.

-

Quality Assurance Reports: Requesting detailed reports from suppliers regarding their quality control processes, test results, and certifications can help assess their reliability.

-

Third-Party Inspections: Engaging third-party inspection agencies to evaluate the supplier’s facilities and processes can provide an unbiased assessment of their capabilities.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must be aware of regional differences in quality standards and regulations. For instance, while CE marking is essential for products sold in Europe, other regions may have different requirements. Understanding these nuances can help buyers navigate the complexities of international trade and ensure compliance with local regulations.

Moreover, buyers from regions like Africa and South America may face challenges related to logistics, communication, and supplier reliability. Building strong relationships with suppliers and establishing clear quality expectations can mitigate these challenges and lead to successful partnerships.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘what is the isolation transformer’

Introduction

This guide provides a practical checklist for B2B buyers interested in procuring isolation transformers. Isolation transformers are vital for ensuring electrical safety and maintaining power quality across various applications. By following these steps, you can make informed decisions and select the right isolation transformer that meets your specific needs.

Step 1: Define Your Technical Specifications

Before sourcing an isolation transformer, clearly outline your technical requirements. Consider factors such as voltage ratings, power capacity, and frequency. This step is crucial to ensure that the transformer aligns with your equipment and operational needs.

- Voltage Requirements: Identify the input and output voltage levels necessary for your application.

- Power Rating: Determine the kVA rating that your transformer must support based on the connected load.

Step 2: Identify the Appropriate Type of Isolation Transformer

Different types of isolation transformers serve specific purposes. Understanding these variations can help you choose the right type for your application.

- Constant Voltage Transformers (CVTs): Ideal for applications requiring stable voltage output despite fluctuating input.

- Ultra Isolation Transformers: Best suited for sensitive equipment in medical or research settings, offering enhanced electrical isolation.

Step 3: Evaluate Potential Suppliers

Thoroughly vet potential suppliers before making a commitment. This evaluation ensures that you partner with reputable manufacturers who can meet your specifications.

- Company Profiles and Case Studies: Request detailed information about the supplier’s experience and past projects in your industry.

- References: Seek testimonials from other businesses in similar sectors or geographical regions to assess reliability.

Step 4: Check Compliance and Certifications

Verify that the isolation transformers comply with relevant safety standards and certifications. This step is critical for ensuring the safety and reliability of the equipment.

- International Standards: Look for compliance with standards such as IEC, UL, or ISO, which indicate a commitment to quality and safety.

- Local Regulations: Ensure that the transformer meets any specific regulations applicable in your country or region.

Step 5: Assess Warranty and Support Services

Investigate the warranty and support services offered by the supplier. A robust warranty can protect your investment, while reliable support ensures operational continuity.

- Warranty Duration: Check the length and terms of the warranty to understand what is covered.

- Technical Support: Evaluate the availability of technical support for installation, troubleshooting, and maintenance.

Step 6: Consider Pricing and Payment Terms

Evaluate the pricing of isolation transformers while considering the total cost of ownership. This includes initial purchase price, installation costs, and long-term maintenance expenses.

- Transparent Pricing: Request detailed quotations that break down costs.

- Payment Flexibility: Discuss payment terms to ensure they align with your budgeting process.

Step 7: Finalize Your Purchase and Arrange Logistics

Once you have selected a supplier and confirmed your order, coordinate logistics for delivery and installation. This ensures that the transformer is installed correctly and efficiently.

- Delivery Timeframes: Confirm the expected delivery dates to align with your project timelines.

- Installation Requirements: Discuss installation support options to guarantee proper setup and operation of the transformer.

By following this checklist, B2B buyers can effectively navigate the sourcing process for isolation transformers, ensuring they choose the right solution for their electrical needs.

Comprehensive Cost and Pricing Analysis for what is the isolation transformer Sourcing

What Are the Key Cost Components of Sourcing Isolation Transformers?

When sourcing isolation transformers, understanding the cost structure is vital for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: The cost of raw materials, such as copper for windings and specialized insulation materials, can significantly influence the overall cost. Higher quality materials often lead to better performance and longevity, which can justify a higher upfront price.

-

Labor: Skilled labor is essential for the assembly and testing of isolation transformers. Labor costs can vary depending on the region and the complexity of the manufacturing process. Countries with lower labor costs may offer competitive pricing but could compromise on skill levels and quality.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce overhead costs, but these savings should not come at the expense of quality.

-

Tooling: The costs associated with the tools and machinery used in production can vary widely. Custom tooling for specialized transformer types can increase initial costs but may reduce per-unit costs for large orders.

-

Quality Control (QC): Rigorous QC processes are crucial for ensuring the reliability and safety of isolation transformers. While investing in QC can increase production costs, it also minimizes the risk of failures that could lead to costly downtimes or liability issues.

-

Logistics: Shipping and handling costs can be substantial, particularly for bulky items like transformers. The choice of shipping method and the distance to the buyer’s location can affect these costs significantly.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary based on market competition, brand reputation, and the perceived value of the product.

What Factors Influence Pricing for Isolation Transformers?

Several factors can influence the pricing of isolation transformers, including volume or minimum order quantity (MOQ), specifications and customization, material quality, certifications, supplier factors, and Incoterms.

-

Volume/MOQ: Bulk purchases typically reduce the per-unit cost, as manufacturers can achieve economies of scale. Understanding the supplier’s MOQ can help buyers negotiate better pricing.

-

Specifications and Customization: Customizing transformers for specific applications can increase costs. Buyers should balance the need for customization with the potential for higher prices.

-

Materials and Quality/Certifications: Transformers with higher quality materials and certifications (such as ISO or CE) may command higher prices. Buyers should assess the long-term benefits of investing in certified products versus cheaper alternatives.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge more due to their proven track record, while new entrants might offer lower prices to gain market share.

-

Incoterms: The choice of Incoterms can significantly impact the total cost. Understanding whether costs include shipping, insurance, and duties is crucial for accurate budgeting.

What Negotiation Strategies Can B2B Buyers Employ for Cost-Efficiency?

B2B buyers can implement several strategies to ensure cost-efficiency when sourcing isolation transformers.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Regular communication and transparency about needs and expectations can foster trust.

-

Conduct Competitive Analysis: Researching multiple suppliers and comparing their offerings can provide leverage in negotiations. Highlighting competitive quotes can encourage suppliers to offer better terms.

-

Focus on Total Cost of Ownership (TCO): Buyers should consider not just the purchase price but also the potential long-term savings from energy efficiency, maintenance, and operational reliability.

-

Understand Pricing Nuances for International Sourcing: When sourcing from different regions, be aware of currency fluctuations, import tariffs, and regional market conditions that can impact pricing.

Disclaimer for Indicative Prices

It is important to note that prices for isolation transformers can vary widely based on the aforementioned factors. As such, the figures discussed should be considered indicative rather than definitive. Buyers are encouraged to engage directly with suppliers for accurate quotes tailored to their specific requirements.

Alternatives Analysis: Comparing what is the isolation transformer With Other Solutions

Understanding Alternatives to Isolation Transformers

In the realm of electrical engineering, isolation transformers serve a unique purpose by transferring electrical power between circuits without direct electrical connection. However, various alternative solutions can also achieve similar objectives, often tailored to specific applications or environments. This analysis aims to compare isolation transformers with two viable alternatives: line reactors and surge protectors. By evaluating aspects such as performance, cost, ease of implementation, maintenance, and best use cases, businesses can make informed decisions when selecting the appropriate technology for their needs.

| Comparison Aspect | What Is The Isolation Transformer | Line Reactors | Surge Protectors |

|---|---|---|---|

| Performance | Provides excellent electrical isolation and noise reduction. | Improves power quality but does not isolate circuits. | Protects against voltage spikes but does not isolate. |

| Cost | Generally higher initial investment. | Moderate cost, often lower than isolation transformers. | Low to moderate cost, depending on specifications. |

| Ease of Implementation | Requires careful installation and configuration. | Easier to install with less complexity. | Simple installation, often plug-and-play. |

| Maintenance | Low maintenance; robust and long-lasting. | Minimal maintenance; check connections periodically. | Regular inspection recommended; replace after surges. |

| Best Use Case | Ideal for sensitive medical and industrial equipment. | Best for applications needing improved power quality. | Excellent for protecting electronic devices from surges. |

In-Depth Analysis of Alternatives

Line Reactors

Line reactors are inductive devices placed in series with a power supply. They work by limiting the rate of change of current and reducing harmonics, thus improving power quality. While they do not provide electrical isolation, they can effectively reduce electrical noise and protect equipment from voltage fluctuations. The cost of line reactors is generally lower than that of isolation transformers, making them a cost-effective solution for applications where complete isolation is not critical. However, businesses must consider that line reactors do not eliminate the risk of ground faults or provide the same level of protection as isolation transformers.

Surge Protectors

Surge protectors are devices designed to shield electronic equipment from voltage spikes, such as those caused by lightning strikes or power surges. They are typically easy to install and can be found at various price points, making them accessible for many businesses. While surge protectors excel at preventing damage from transient voltages, they do not provide electrical isolation or improve power quality in the same way isolation transformers do. Therefore, they are best suited for environments where electrical surges are a significant concern but where isolation is not a priority.

Conclusion: Choosing the Right Solution for Your Needs

When selecting between isolation transformers and their alternatives, B2B buyers must assess their specific application requirements. If electrical isolation, noise reduction, and protection against surges are paramount—especially in sensitive environments like hospitals or laboratories—an isolation transformer is likely the best choice. Conversely, for applications where improved power quality is desired without the need for complete isolation, line reactors may offer a more cost-effective solution. Surge protectors are ideal for businesses focused solely on safeguarding against voltage spikes without requiring isolation. Ultimately, understanding the distinct advantages and limitations of each option will empower buyers to make informed decisions that align with their operational needs and budget constraints.

Essential Technical Properties and Trade Terminology for what is the isolation transformer

What Are the Key Technical Properties of Isolation Transformers?

Understanding the technical properties of isolation transformers is vital for international B2B buyers to make informed purchasing decisions. Here are some critical specifications to consider:

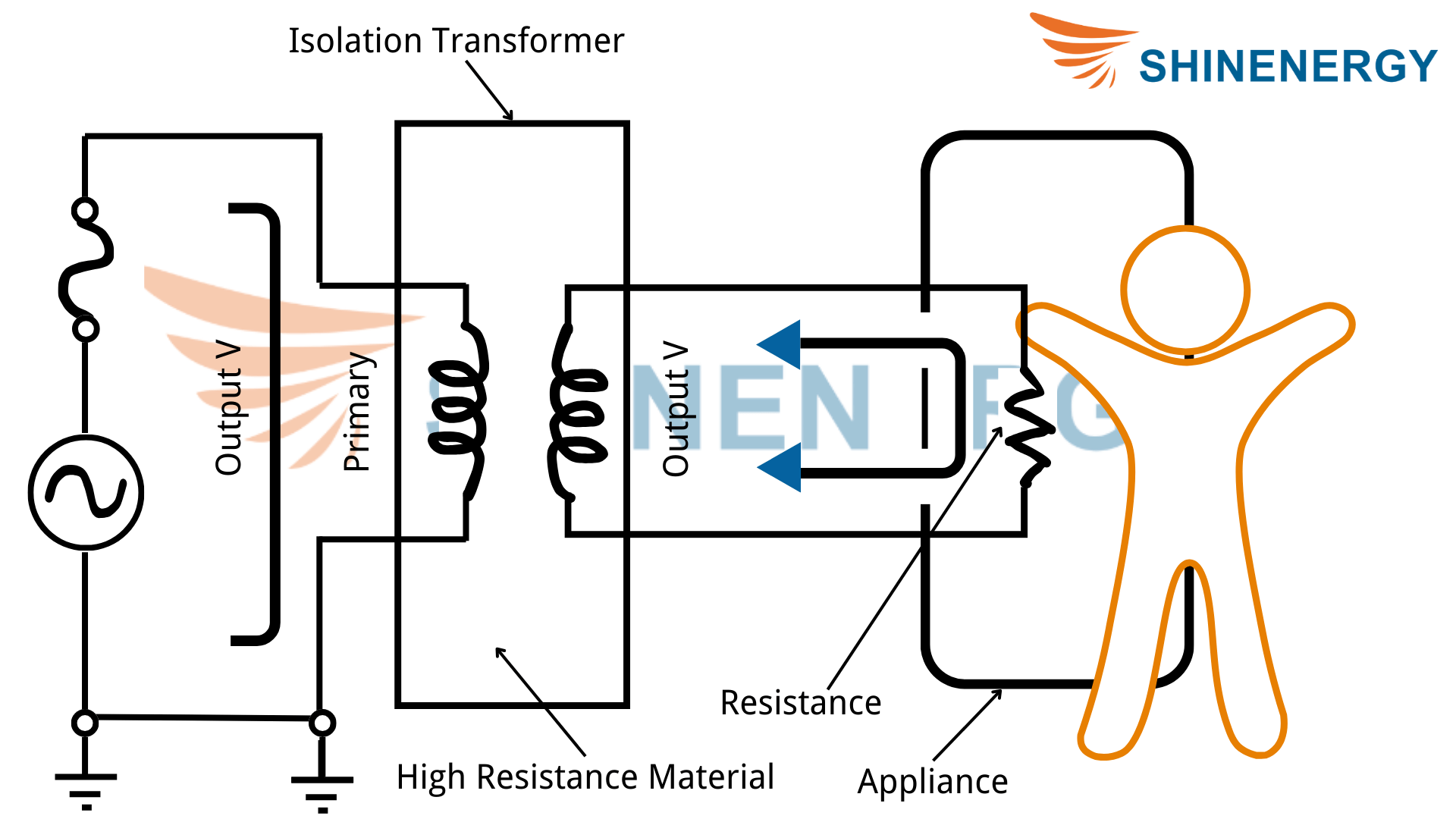

Illustrative image related to what is the isolation transformer

1. Winding Configuration

Isolation transformers typically utilize either a concentric or toroidal winding configuration. The choice affects efficiency and size. A toroidal transformer, for instance, offers lower electromagnetic interference and is often more compact, making it a preferred option for space-constrained applications.

2. Insulation Class

The insulation class of an isolation transformer indicates its temperature tolerance and operational reliability. Common classes include A, B, F, and H, with Class H offering the highest thermal resistance. Understanding insulation class is essential for ensuring that the transformer can operate efficiently in specific environmental conditions, especially in industrial settings.

3. Voltage Rating

The voltage rating specifies the maximum voltage the transformer can handle without risk of breakdown. Buyers should select transformers with voltage ratings that meet or exceed the application requirements to ensure safety and optimal performance. This is particularly crucial in regions with variable power supply conditions.

Illustrative image related to what is the isolation transformer

4. Frequency

Isolation transformers are designed to operate at specific frequencies, usually 50 Hz or 60 Hz, depending on the region. Selecting a transformer with the appropriate frequency rating is essential to prevent operational inefficiencies or equipment damage, especially in diverse markets like Africa and Europe, where frequency standards may differ.

5. Load Capacity

The load capacity, measured in VA (volt-amperes), indicates the maximum power the transformer can safely handle. Buyers must assess their load requirements accurately to avoid overheating and ensure long-term reliability. This is especially important in commercial and industrial applications where demand can fluctuate significantly.

6. Efficiency Rating

Efficiency ratings, often expressed as a percentage, indicate how much input energy is converted to output energy. Higher efficiency translates to lower energy costs and reduced heat generation, making it a crucial consideration for businesses aiming to optimize operational costs.

What Are Common Trade Terms Related to Isolation Transformers?

Familiarity with industry jargon can greatly enhance negotiations and purchasing processes. Here are essential terms to know:

1. OEM (Original Equipment Manufacturer)

An OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM partnerships can help buyers identify reliable sources of isolation transformers tailored to specific applications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for budgeting and inventory management, especially for international buyers who may face additional shipping costs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. A well-structured RFQ can streamline the procurement process, ensuring that buyers receive competitive pricing and clear terms.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions. They clarify who bears the risk and costs associated with shipping, making them essential for B2B transactions involving isolation transformers across borders.

Illustrative image related to what is the isolation transformer

5. CE Marking

CE marking indicates that a product conforms to European health, safety, and environmental protection standards. For buyers in Europe, ensuring that isolation transformers have CE marking is crucial for compliance and marketability.

6. UL Certification

UL (Underwriters Laboratories) certification signifies that a product meets specific safety standards in the United States. For buyers in North America, UL certification is a key factor in ensuring product safety and reliability.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing isolation transformers, ultimately leading to improved operational efficiency and safety in their applications.

Navigating Market Dynamics and Sourcing Trends in the what is the isolation transformer Sector

What Are the Key Market Dynamics Influencing the Isolation Transformer Sector?

The isolation transformer market is experiencing significant growth, driven by increasing demand for electrical safety and power quality across various industries. With the rise of industrial automation, medical devices, and data centers, the necessity for reliable power supply systems has never been more critical. Emerging markets in Africa and South America are particularly poised for growth, as infrastructure development and modernization efforts gain momentum. In Europe, especially in Germany, stringent regulations regarding electrical safety and energy efficiency are propelling the demand for isolation transformers.

Technological advancements are also shaping the market landscape. The integration of smart technologies into isolation transformers, such as IoT capabilities for monitoring and diagnostics, is becoming increasingly prevalent. Buyers are looking for solutions that not only provide electrical isolation but also enhance energy efficiency and reduce operational costs. Additionally, the trend towards modular and compact designs is appealing to industries seeking flexible solutions that can easily fit within existing setups.

Another significant trend is the rising emphasis on customization. International B2B buyers are seeking tailored solutions to meet their specific operational requirements, whether it be in healthcare, manufacturing, or telecommunications. As companies continue to prioritize their operational resilience, the focus on sourcing isolation transformers that align with their unique needs will intensify.

How Does Sustainability and Ethical Sourcing Impact Isolation Transformer Procurement?

Sustainability is becoming a cornerstone of procurement strategies across all sectors, including the isolation transformer market. The environmental impact of manufacturing processes, particularly concerning energy consumption and waste generation, is under scrutiny. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices, such as reducing carbon footprints and utilizing eco-friendly materials.

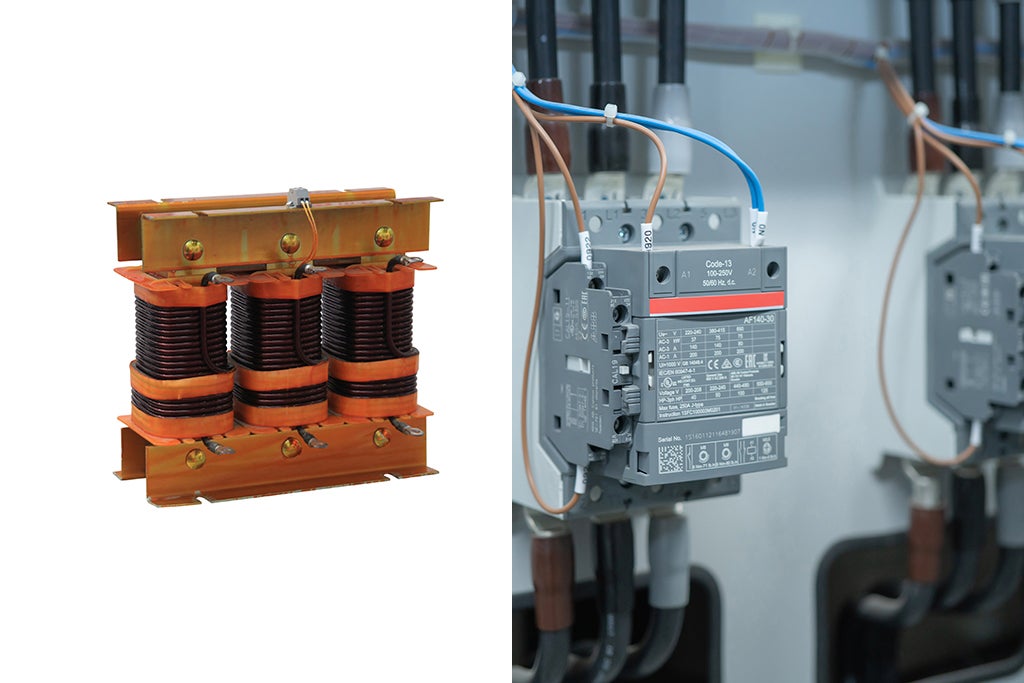

Illustrative image related to what is the isolation transformer

Ethical sourcing is equally important, as companies aim to ensure that their supply chains are transparent and responsible. This involves selecting manufacturers who adhere to fair labor practices and possess certifications that validate their commitment to ethical operations. Certifications such as ISO 14001 for environmental management and RoHS for hazardous materials can serve as indicators of a supplier’s dedication to sustainability.

Moreover, the trend towards “green” transformers—those designed with energy efficiency in mind—has gained traction. These products not only comply with environmental regulations but also offer long-term cost savings for businesses through reduced energy consumption. As such, B2B buyers should actively seek out suppliers who can provide isolation transformers that meet these sustainability criteria, thereby aligning their procurement practices with broader corporate social responsibility goals.

What Is the Historical Context of Isolation Transformers in B2B?

The evolution of isolation transformers dates back to the early 20th century, coinciding with the broader development of electrical power systems. Initially used to enhance safety in electrical installations, these transformers have transformed in complexity and application over the decades. The introduction of technologies such as constant voltage transformers and ultra-isolation transformers has allowed for a diverse range of applications, particularly in sensitive environments like hospitals and data centers.

As industries have become more reliant on sophisticated electronic equipment, the importance of isolation transformers has only increased. Their ability to provide electrical isolation not only protects sensitive equipment but also ensures compliance with international safety standards. This historical perspective highlights the ongoing relevance of isolation transformers in today’s B2B landscape, emphasizing the need for continuous innovation to meet evolving market demands.

Frequently Asked Questions (FAQs) for B2B Buyers of what is the isolation transformer

-

How do I solve electrical interference issues in my equipment?

Electrical interference can disrupt the performance of sensitive equipment. Using an isolation transformer is an effective solution, as it provides electrical isolation between circuits, minimizing noise and preventing surges from affecting connected devices. When sourcing isolation transformers, look for models that specifically address your equipment’s voltage and current specifications. Additionally, consider ultra-isolation transformers for applications requiring higher levels of noise reduction, especially in medical or research settings. -

What is the best isolation transformer for industrial applications?

The ideal isolation transformer for industrial use often depends on the specific requirements of your equipment. Drive isolation transformers are particularly suitable for powering electric motors, ensuring clean and consistent power. For environments sensitive to electrical noise, ultra-isolation transformers offer enhanced isolation. Assess your operational needs, including voltage, current capacity, and potential environmental factors, to choose the most appropriate transformer for your application. -

What factors should I consider when sourcing isolation transformers internationally?

When sourcing isolation transformers, consider factors such as the supplier’s reputation, product certifications, and compliance with international standards. Evaluate the quality assurance processes they have in place, and request samples if possible. Additionally, ensure that the supplier can accommodate your specific requirements, including voltage ratings and frequency specifications. It’s also crucial to understand their logistics capabilities, especially if you are importing from regions like Europe or Asia. -

How can I customize an isolation transformer to meet my specific needs?

Many manufacturers offer customization options for isolation transformers to fit specific applications. When discussing customization, be clear about your requirements, including voltage, current capacity, and physical dimensions. It’s also beneficial to inquire about the materials used and whether they can incorporate specific features such as enhanced insulation or special winding techniques. Ensure you collaborate closely with the supplier’s engineering team to align your expectations with their manufacturing capabilities. -

What are the minimum order quantities (MOQ) for isolation transformers?

Minimum order quantities for isolation transformers can vary significantly between manufacturers. Some suppliers may have low MOQs, while others might require bulk orders to justify production costs. When negotiating, clarify your needs and explore the possibility of smaller initial orders for testing purposes. This approach can help mitigate risk and ensure the product meets your expectations before committing to larger quantities. -

What payment terms are typical for purchasing isolation transformers?

Payment terms can differ widely among suppliers, especially in international transactions. Common arrangements include upfront payment, partial payments, or net 30/60/90 days after delivery. It’s essential to discuss these terms early in negotiations to ensure they align with your cash flow capabilities. Consider using secure payment methods, such as letters of credit or escrow services, particularly for large orders, to protect your investment. -

How do I ensure quality assurance for isolation transformers?

To ensure quality assurance, request detailed documentation from the supplier regarding their manufacturing processes and quality control measures. Look for certifications such as ISO 9001 or specific industry standards relevant to electrical equipment. Additionally, consider conducting factory visits or third-party inspections to verify production quality. Establishing a clear communication channel with the supplier for ongoing support and feedback can also enhance the quality assurance process. -

What logistics considerations should I keep in mind when importing isolation transformers?

Logistics play a critical role in the successful importation of isolation transformers. Consider shipping methods, lead times, and customs regulations specific to your country. Work with suppliers who have experience in international shipping to ensure compliance with documentation and tariffs. Additionally, plan for potential delays by allowing extra time in your project timelines. It’s also wise to evaluate local warehousing options to facilitate quicker access to the transformers upon arrival.

Top 7 What Is The Isolation Transformer Manufacturers & Suppliers List

1. IQS Directory – Isolation Transformers

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Isolation transformers are immobile devices designed to electrically and physically separate primary and secondary windings, ensuring complete isolation between circuits. They transfer energy through magnetic induction, adjusting voltage levels to ensure compatibility between coils’ voltage and current capacities. Key features include:

– Mitigation of voltage spikes in supply lines to prevent dis…

2. Payton Group – Isolation Transformers

Domain: paytongroup.com

Registered: 1997 (28 years)

Introduction: An isolation transformer is a type of transformer that transfers electrical power between two circuits without direct electrical connection, providing complete electrical isolation. Key types include: 1. Constant Voltage Transformers (CVTs) – maintain steady voltage output over varying input voltages. 2. Ultra Isolation Transformers – offer higher levels of electrical isolation, used in sensitive …

3. Aktif – Isolation Transformers

Domain: aktif.net

Registered: 1999 (26 years)

Introduction: Isolation transformers are static devices designed with separate primary and secondary windings, providing physical and electrical separation between circuits. They transfer electrical energy using magnetic induction and are employed in transmission and distribution networks to adjust voltage levels. Their main function is to eliminate voltage spikes in supply lines, protecting equipment and indiv…

4. Hammond Power Solutions – Isolation Transformers

Domain: americas.hammondpowersolutions.com

Registered: 2000 (25 years)

Introduction: Isolation transformers are transformers where the primary and secondary windings are physically isolated from each other, except for autotransformers. The transformation of voltage and current occurs through mutual inductance in the core.

5. Coilcraft – Isolation Transformers

Domain: coilcraft.com

Registered: 1995 (30 years)

Introduction: Coilcraft offers a variety of off-the-shelf isolation transformers with the following key specifications:

– Input voltages: 3.3 to 24 Volts

– Power ratings: up to 7.2 Watts

– Turns ratios: from 1:1 to 1:5

– Volt-time capabilities: from 8.64 to 134 Vµs

– Inductance: from 16 to 1000 µH

– Isolation: from 1500 to 5000 Vrms

Applications include low voltage isolated DC-DC power supplies, isolated…

6. Digi-Key – Isolation Transformers

Domain: digikey.com

Registered: 1995 (30 years)

Introduction: This company, Digi-Key – Isolation Transformers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Maddox – Drive Isolation Transformers

Domain: maddox.com

Registered: 1997 (28 years)

Introduction: Drive Isolation Transformers (DITs) are designed for applications with motor drives (VFDs & VSDs). They isolate the motor drive circuit from the power supply circuit, preventing electrical connection between primary and secondary sides. Key features include: 150% overload capacity for 60 seconds, 200% overload for 30 seconds, and standard kVA ratings sized to motor horsepower (e.g., 5 hp = 7.5 kVA…

Strategic Sourcing Conclusion and Outlook for what is the isolation transformer

As businesses across Africa, South America, the Middle East, and Europe seek to enhance operational efficiency and reliability, the role of isolation transformers becomes increasingly vital. These devices not only provide essential electrical isolation but also improve power quality and protect sensitive equipment from electrical surges and noise. By strategically sourcing isolation transformers tailored to specific applications—be it medical, industrial, or telecommunication—companies can achieve higher performance and longevity in their electrical systems.

Incorporating isolation transformers into your infrastructure ensures compliance with safety standards and optimizes the functionality of connected devices. As the demand for reliable power solutions continues to grow, investing in high-quality isolation transformers can offer a competitive advantage.

Looking ahead, B2B buyers are encouraged to evaluate their current power supply solutions and consider the long-term benefits of isolation transformers. Engaging with reputable suppliers who understand the nuances of different isolation transformer types will be crucial in making informed purchasing decisions. By prioritizing strategic sourcing, businesses can secure the reliable power solutions necessary for sustained growth and operational excellence.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.