A Deep Dive into Water Filter System Diagram Solution

Introduction: Navigating the Global Market for water filter system diagram

In today’s global landscape, sourcing effective water filter system diagrams poses a significant challenge for international B2B buyers. With increasing demands for clean water solutions across diverse markets, understanding the intricacies of various filtration systems is paramount. This guide serves as an essential resource, detailing the different types of water filter systems, their applications, and best practices for supplier vetting. By providing a comprehensive overview, we aim to empower decision-makers from regions such as Africa, South America, the Middle East, and Europe—including Germany and Brazil—to make informed purchasing decisions that align with their specific needs.

Navigating the complexities of water filtration technology can be daunting, especially when considering factors such as cost, installation requirements, and local regulations. This guide not only demystifies these elements but also highlights key considerations for selecting the right systems for various contexts, whether for residential, commercial, or industrial use. By leveraging actionable insights and expert recommendations, buyers will be equipped to identify reliable suppliers and negotiate favorable terms.

Ultimately, our goal is to facilitate a seamless procurement process for B2B stakeholders, ensuring that they can effectively address water quality challenges while enhancing operational efficiency and compliance in their respective markets.

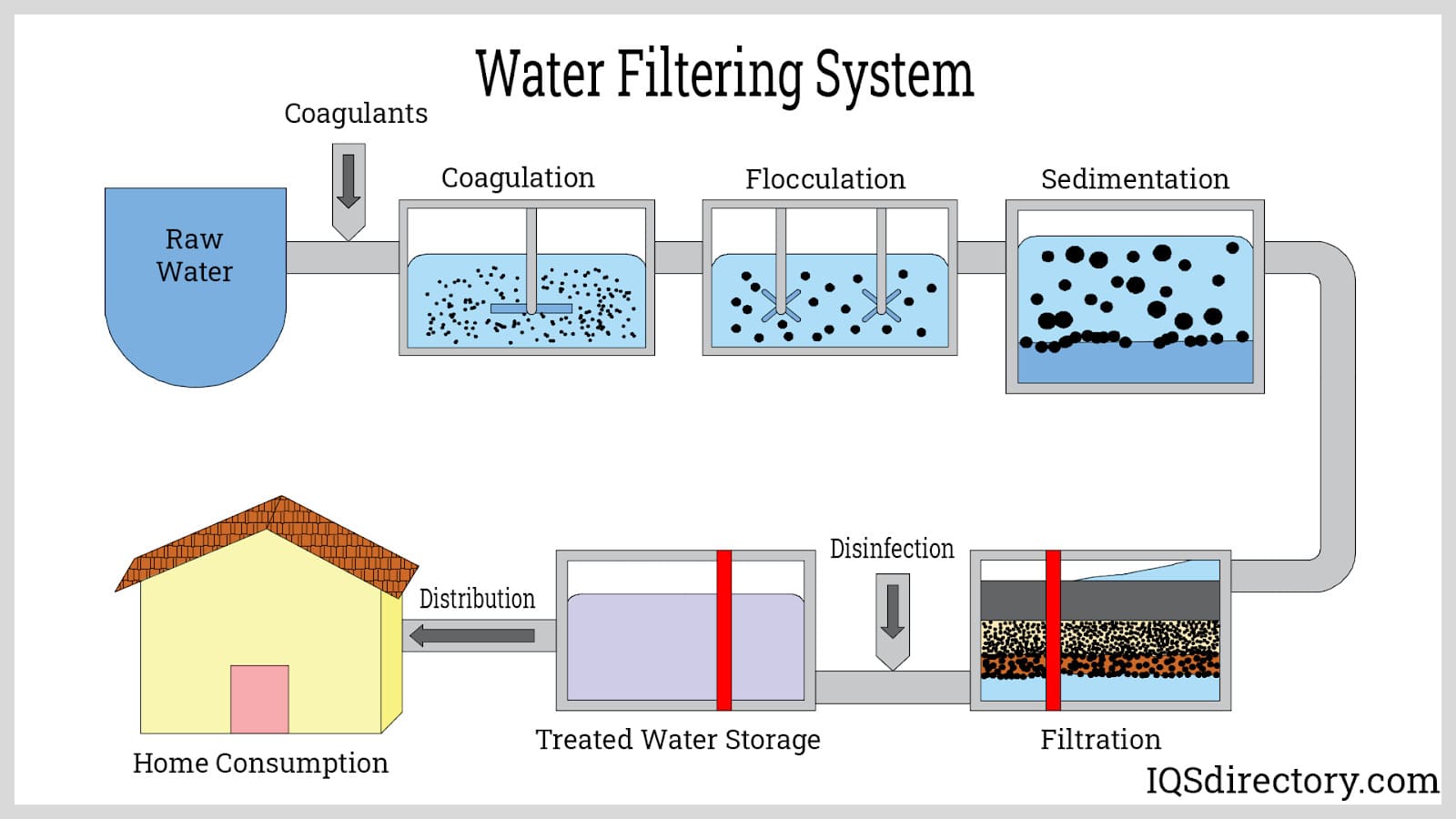

Understanding water filter system diagram Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Reverse Osmosis Systems | Uses semi-permeable membranes to remove contaminants | Water purification for industries, food & beverage | Pros: Highly effective; Cons: High initial cost |

| Activated Carbon Filters | Utilizes activated carbon to adsorb impurities | Residential and commercial water treatment | Pros: Cost-effective; Cons: Limited lifespan |

| UV Water Purification Systems | Employs ultraviolet light to eliminate microorganisms | Municipal water treatment, aquaculture | Pros: Chemical-free; Cons: Requires electricity |

| Multi-Stage Filtration Systems | Combines various filtration methods for comprehensive treatment | Industrial applications, large-scale facilities | Pros: Versatile; Cons: Complex installation |

| Gravity Filters | Operates without electricity, using gravity for filtration | Remote areas, emergency preparedness | Pros: Low maintenance; Cons: Slower filtration |

What are Reverse Osmosis Systems and Their Key B2B Applications?

Reverse osmosis (RO) systems are renowned for their ability to remove up to 99% of dissolved salts and contaminants through a semi-permeable membrane. This technology is particularly beneficial for industries that require high-quality water, such as pharmaceuticals and food & beverage production. When considering RO systems, B2B buyers should evaluate the initial investment, ongoing maintenance costs, and the system’s capacity to meet their specific water quality requirements.

How Do Activated Carbon Filters Work and Where Are They Used?

Activated carbon filters are designed to adsorb organic compounds and chlorine, making them ideal for residential and commercial water treatment. Their simplicity and cost-effectiveness make them a popular choice for businesses looking to enhance water quality without significant capital expenditure. However, buyers should be mindful of the filter’s lifespan and the need for regular replacements to ensure optimal performance.

What Are the Benefits of UV Water Purification Systems for B2B Buyers?

UV water purification systems utilize ultraviolet light to eradicate bacteria and viruses without the use of chemicals. This method is increasingly used in municipal water treatment facilities and aquaculture, where chemical residues can be problematic. B2B buyers should consider the operational costs, including energy consumption and bulb replacement, as well as the system’s capacity to handle their water volume needs.

Why Choose Multi-Stage Filtration Systems for Industrial Applications?

Multi-stage filtration systems integrate various filtration technologies to provide comprehensive water treatment. This versatility makes them suitable for industrial applications, including manufacturing and large-scale facilities. While they offer a broad range of filtration capabilities, potential buyers must assess the complexity of installation and the operational demands to ensure long-term effectiveness.

What Makes Gravity Filters Ideal for Remote Areas?

Gravity filters are a practical solution for water purification in remote areas or during emergencies, as they do not require electricity to operate. These systems are simple to use and maintain, making them accessible for various applications. However, B2B buyers should consider the slower filtration rate and ensure that the system meets their water demand adequately.

Key Industrial Applications of water filter system diagram

| Industry/Sector | Specific Application of water filter system diagram | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Filtration systems for beverage production | Ensures product quality and safety | Compliance with health regulations, material certifications |

| Agriculture | Irrigation water treatment systems | Enhances crop yield and sustainability | Local water quality analysis, system scalability |

| Pharmaceutical | Water purification for drug manufacturing | Guarantees high purity standards | Regulatory compliance, advanced filtration technologies |

| Hospitality | Water filtration for hotels and restaurants | Improves guest satisfaction and safety | Customization options, maintenance support |

| Industrial Manufacturing | Process water filtration for production lines | Reduces downtime and maintenance costs | System compatibility, after-sales service |

How is the Water Filter System Diagram Used in the Food and Beverage Industry?

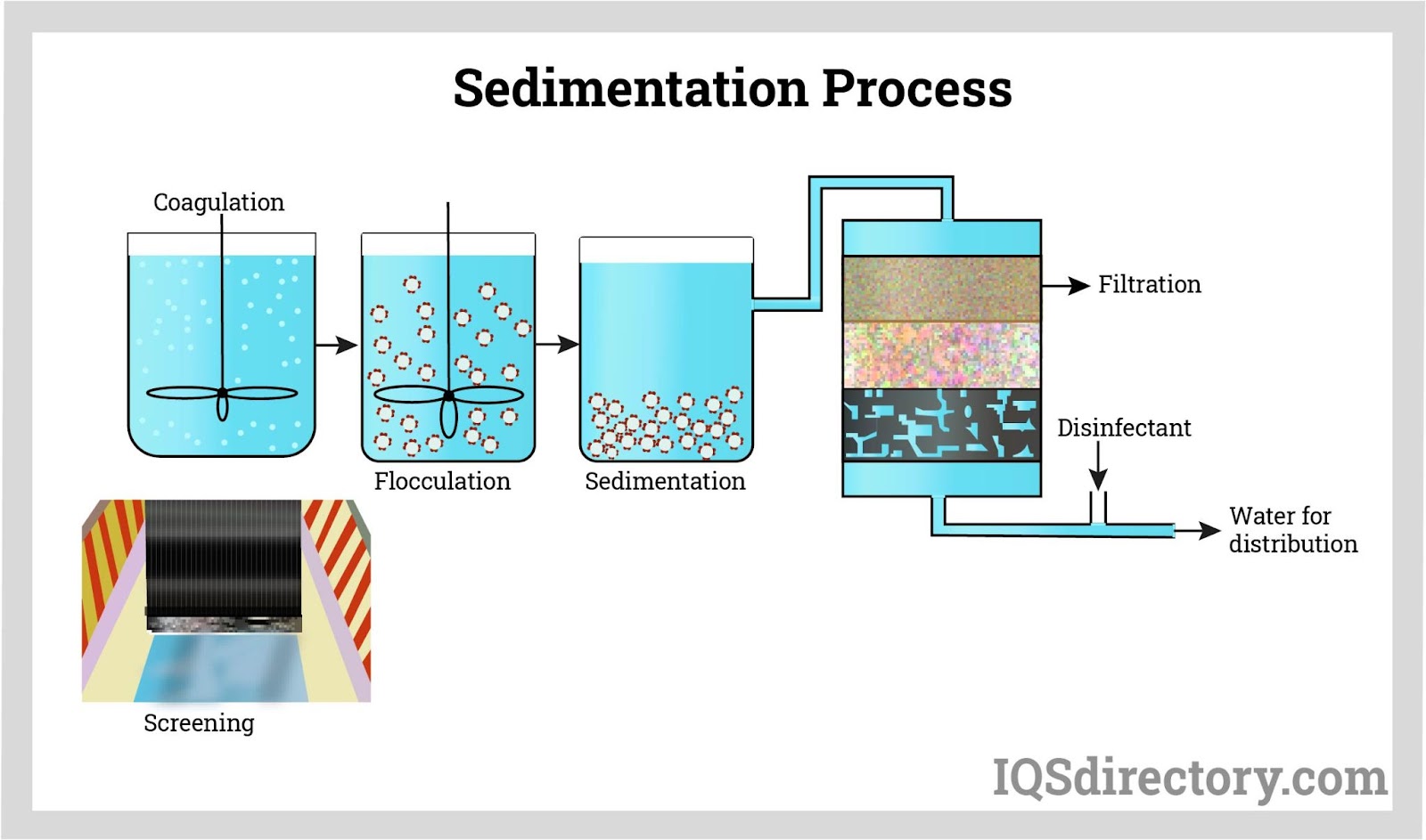

In the food and beverage sector, water filter system diagrams are critical for designing filtration systems that ensure the purity and safety of products. These diagrams help businesses implement systems that remove contaminants, such as bacteria and sediments, which can compromise product quality. For international buyers, especially those in regions like Africa and South America, understanding local water quality issues is essential. Compliance with local health regulations and obtaining certifications for materials used in the filtration systems are key considerations when sourcing these systems.

What Role Does Water Filtration Play in Agriculture?

Agriculture relies heavily on water quality for irrigation and livestock. Water filter system diagrams are utilized to design systems that treat and purify irrigation water, thereby enhancing crop yield and sustainability. For B2B buyers in the Middle East and Africa, where water scarcity is a pressing issue, sourcing filtration systems that can handle local water quality challenges is crucial. Additionally, scalability of the systems to accommodate different farm sizes and types of crops is a significant consideration when selecting a water filtration solution.

Why is Water Purification Important in the Pharmaceutical Sector?

In pharmaceutical manufacturing, water filter system diagrams serve as blueprints for creating high-purity water systems necessary for drug production. These systems must comply with stringent regulatory standards to ensure that the water used in processes meets the required purity levels. International buyers, especially in Europe, need to prioritize suppliers who can demonstrate compliance with Good Manufacturing Practices (GMP) and provide advanced filtration technologies. Understanding the specific filtration needs, such as reverse osmosis or UV treatment, is vital for sourcing the right systems.

How Does Water Filtration Enhance Guest Experience in Hospitality?

Hotels and restaurants utilize water filter system diagrams to design effective filtration systems that provide clean drinking water and improve the quality of food preparation. This not only enhances guest satisfaction but also ensures safety, as contaminated water can lead to health issues. For B2B buyers in the hospitality sector across Europe and South America, customization options that fit the specific needs of their establishments are essential. Moreover, ongoing maintenance and support services should be considered to ensure the longevity and efficiency of the filtration systems.

What Benefits Does Water Filtration Offer in Industrial Manufacturing?

In industrial manufacturing, water filter system diagrams are crucial for developing systems that provide clean process water, which is necessary for various production lines. Effective filtration helps reduce downtime caused by equipment malfunctions due to water impurities, ultimately leading to lower maintenance costs. For international buyers, especially in regions with varying water quality, it’s important to source systems that are compatible with existing infrastructure. Additionally, the availability of after-sales support and service is a key factor in ensuring operational efficiency.

3 Common User Pain Points for ‘water filter system diagram’ & Their Solutions

Scenario 1: Inadequate Understanding of System Components

The Problem: Many B2B buyers, especially those new to water filtration systems, struggle to grasp the complexities of various components within a water filter system diagram. This lack of understanding can lead to poor purchasing decisions, where essential parts are overlooked or mismatched. For instance, a company may order filters that do not fit their existing infrastructure, resulting in operational delays and increased costs.

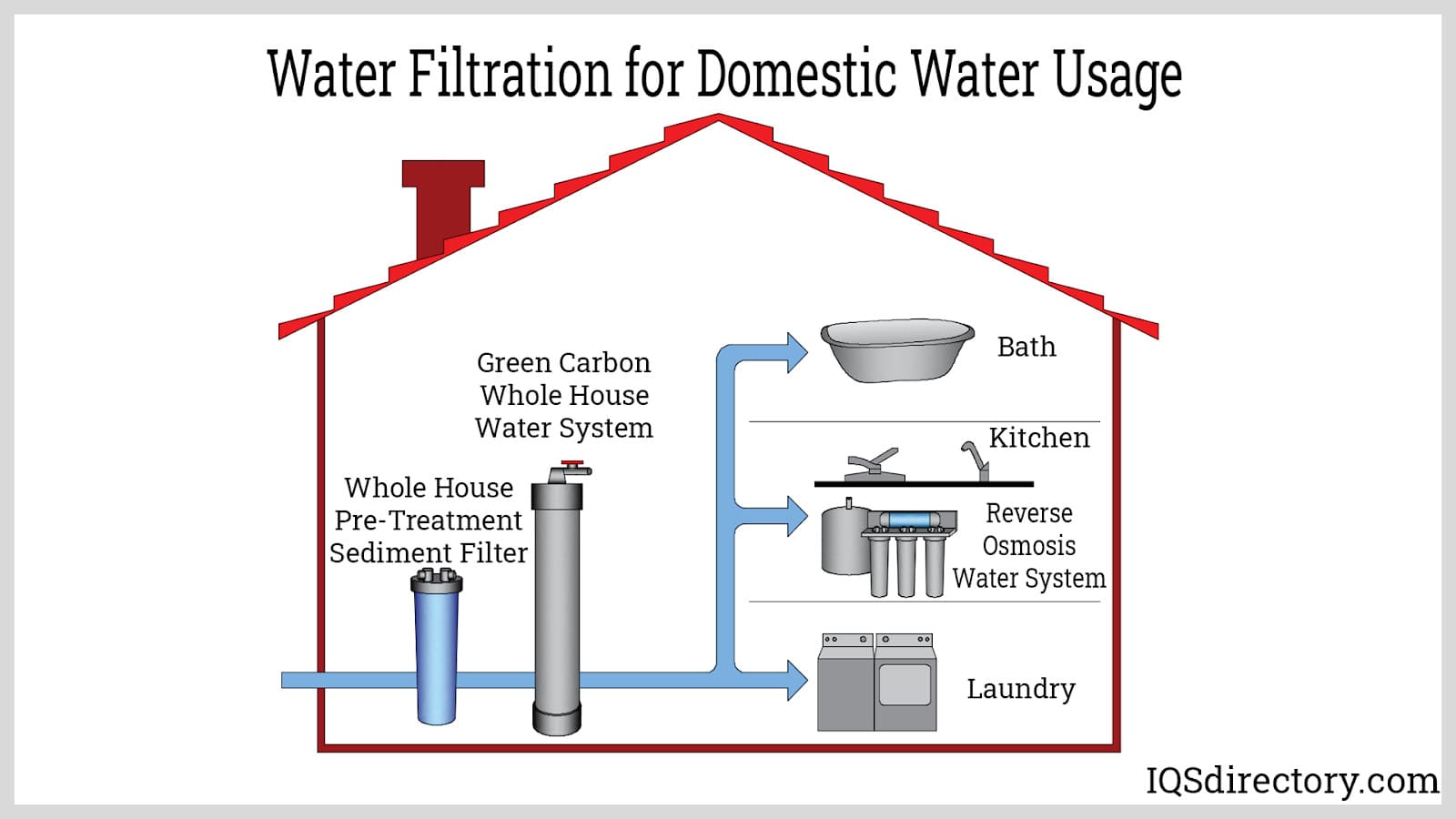

The Solution: To alleviate this issue, buyers should invest time in comprehensive training or workshops that focus on the components of water filtration systems. Suppliers should provide detailed diagrams accompanied by explanatory notes that outline the function of each component, such as pre-filters, reverse osmosis membranes, and UV sterilizers. Additionally, leveraging 3D visualizations or interactive diagrams can help buyers visualize how each part interacts within the system. B2B companies can also benefit from consulting with technical experts during the procurement process, ensuring that all components are compatible and correctly specified.

Scenario 2: Misalignment with Local Water Quality Standards

The Problem: B2B buyers often face challenges when local water quality standards differ significantly from the specifications of the water filter system they are considering. For example, a business in South America might be unaware that their region requires specific filtration standards for contaminants like heavy metals or bacteria, which could lead to regulatory non-compliance.

The Solution: To tackle this pain point, buyers must conduct thorough research on local water quality regulations and consult with local authorities or water quality experts. Additionally, suppliers should provide region-specific water filter system diagrams that highlight compliance features tailored to the local context. It’s beneficial for B2B buyers to engage in partnerships with manufacturers who have a proven track record of meeting local standards, ensuring that the systems they procure are compliant and effective. Moreover, implementing a feedback loop where users can report back on water quality outcomes can help suppliers refine their offerings.

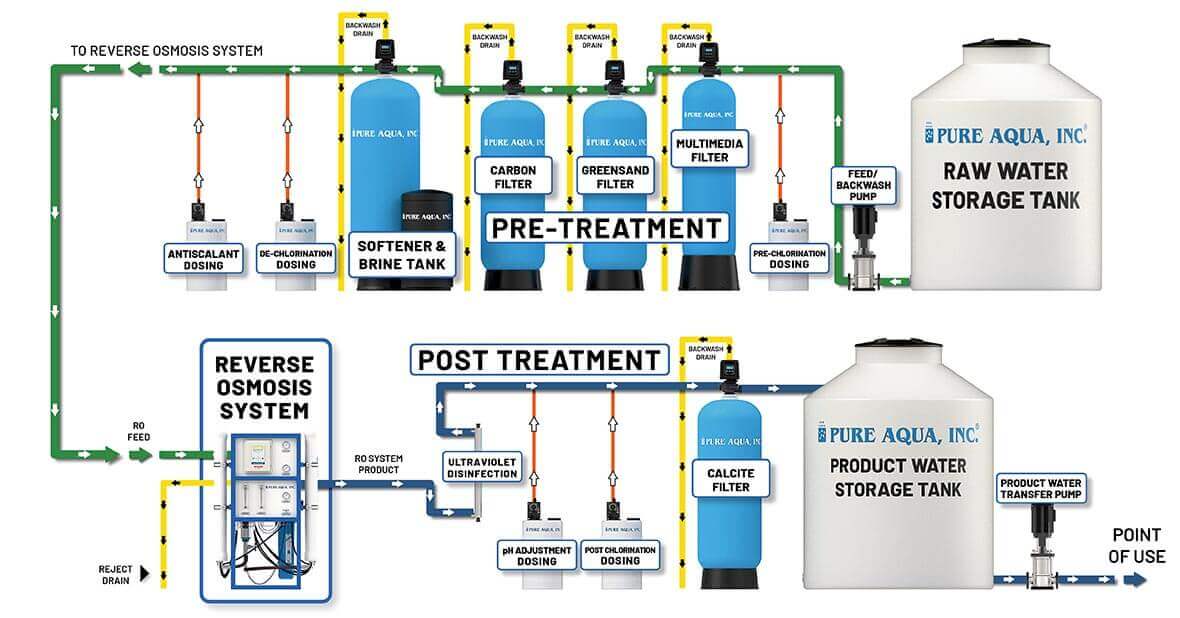

Illustrative image related to water filter system diagram

Scenario 3: Difficulties in Installation and Maintenance

The Problem: Installation and maintenance of water filter systems can be daunting for many B2B buyers, especially when diagrams lack clarity or detail. Companies may encounter issues such as improper installation leading to system inefficiencies, or difficulty in performing routine maintenance, which can affect water quality and operational costs.

The Solution: To improve installation and maintenance experiences, buyers should look for suppliers that offer comprehensive installation diagrams that include step-by-step instructions, color coding for different components, and troubleshooting tips. It’s also advantageous for buyers to request on-site training or virtual demonstrations from suppliers, allowing their technical teams to become familiar with the system. Implementing a maintenance schedule based on the diagram can also help ensure that routine checks are conducted, reducing the risk of system failure. Additionally, integrating digital tools, such as augmented reality applications, can provide real-time guidance during installation and maintenance tasks, enhancing user confidence and efficiency.

Strategic Material Selection Guide for water filter system diagram

When selecting materials for water filter systems, it is crucial to consider their properties, advantages, limitations, and compliance with international standards. Below is an analysis of four commonly used materials in water filter system diagrams, focusing on their performance characteristics and implications for B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe.

What Are the Key Properties of Polypropylene in Water Filter Systems?

Polypropylene (PP) is a thermoplastic polymer widely used in water filtration applications due to its excellent chemical resistance and low moisture absorption. It can withstand temperatures up to 100°C and pressures of around 10 bar, making it suitable for various filtration processes.

Pros and Cons: Polypropylene is lightweight, cost-effective, and easy to manufacture, which contributes to lower production costs. However, its mechanical strength is lower compared to other materials, which can limit its use in high-pressure applications. Additionally, while it is resistant to many chemicals, it may not be suitable for all aggressive solvents.

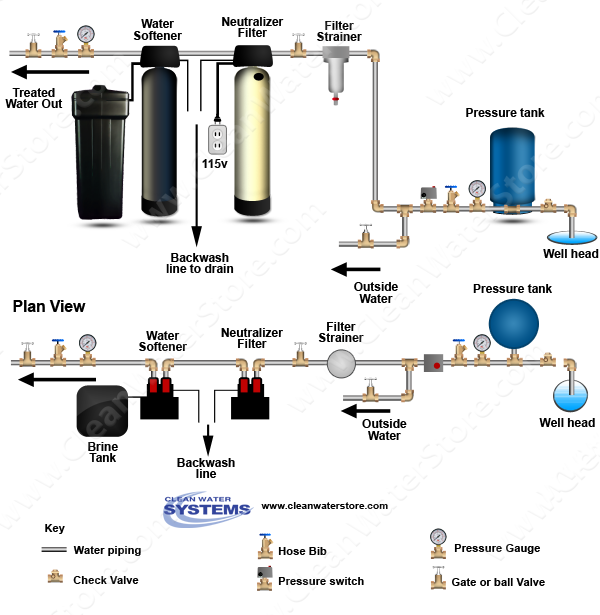

Illustrative image related to water filter system diagram

Impact on Application: Polypropylene is compatible with a wide range of filtration media, including activated carbon and ceramic filters. For international buyers, it’s essential to ensure that the polypropylene used complies with standards such as ASTM D4101 for impact resistance.

How Does Stainless Steel Enhance Durability in Water Filter Systems?

Stainless steel, particularly grades 304 and 316, is renowned for its durability and corrosion resistance, making it an excellent choice for water filter systems exposed to harsh environments. It can withstand high temperatures (up to 800°C) and pressures, making it suitable for both residential and industrial applications.

Pros and Cons: The primary advantage of stainless steel is its longevity and resistance to rust, which reduces maintenance costs over time. However, it is more expensive than other materials, which can impact the overall cost of the filtration system. Additionally, the manufacturing process can be more complex, requiring specialized equipment and skills.

Impact on Application: Stainless steel is compatible with various filtration media and is often used in reverse osmosis systems. For buyers in regions like Europe, compliance with EU regulations on materials in contact with drinking water is crucial.

What Role Does PVC Play in Water Filter Systems?

Polyvinyl Chloride (PVC) is another common material used in water filter systems, particularly for piping and structural components. It is known for its excellent chemical resistance and is suitable for temperatures up to 60°C.

Pros and Cons: PVC is cost-effective and easy to install, making it a popular choice for budget-conscious projects. However, it has limited temperature resistance compared to polypropylene and stainless steel, which may restrict its use in high-temperature applications. Additionally, PVC can become brittle over time when exposed to UV light.

Impact on Application: PVC is widely used in gravity-fed filtration systems and is compatible with various filtration media. Buyers should verify compliance with local regulations, such as ASTM D1784 for PVC pipe, to ensure safety and reliability.

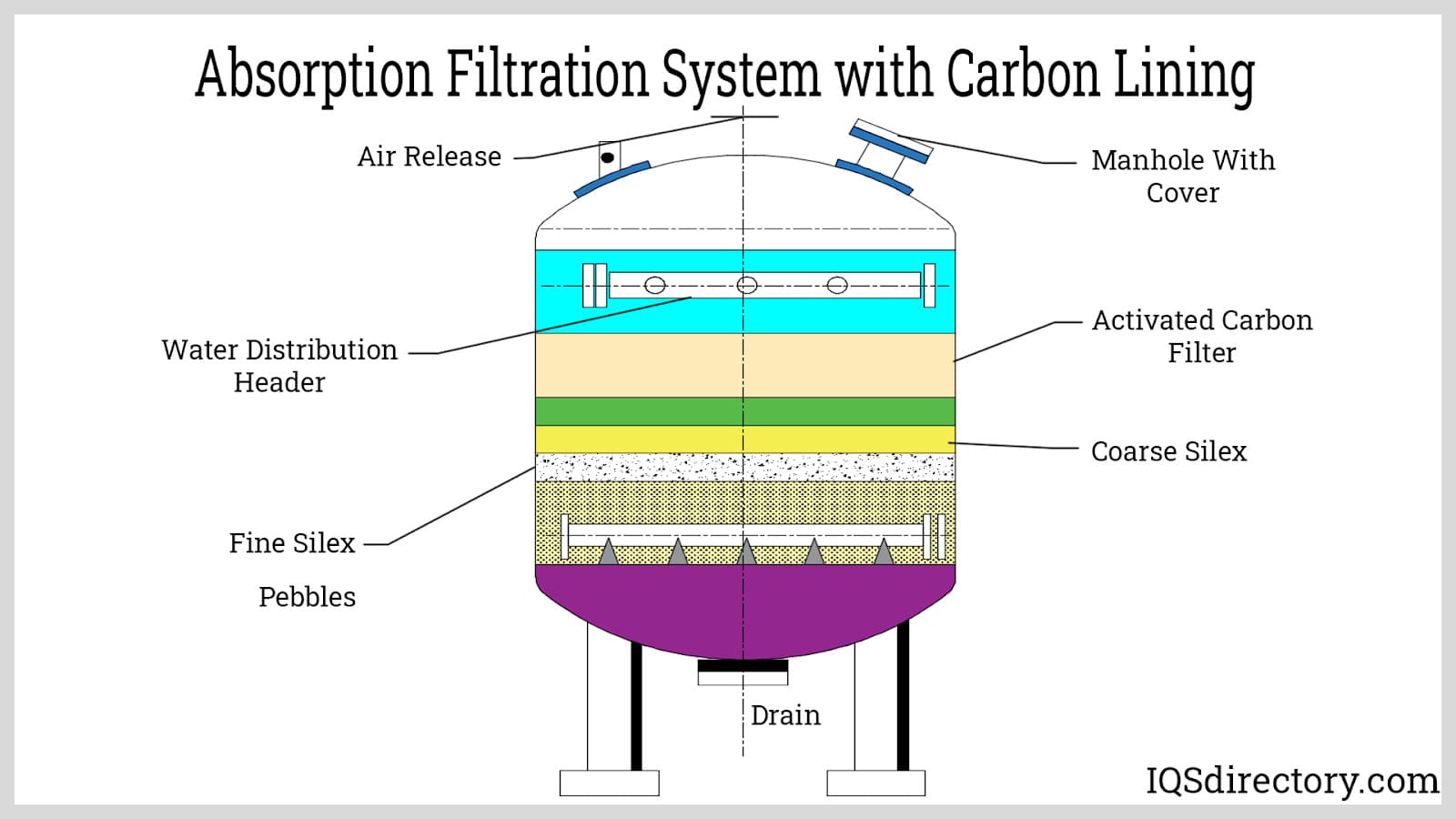

How Does Activated Carbon Improve Water Quality in Filtration Systems?

Activated carbon is a key material used in water filtration systems for its adsorption capabilities, effectively removing impurities and improving taste and odor. It is often used in combination with other materials to enhance filtration performance.

Pros and Cons: The primary advantage of activated carbon is its effectiveness in removing contaminants. However, it has a limited lifespan and requires regular replacement, which can increase long-term costs. Additionally, its performance can vary based on the specific contaminants present in the water.

Impact on Application: Activated carbon is suitable for both point-of-use and point-of-entry systems. International buyers should consider the specific standards for activated carbon, such as NSF/ANSI 61, to ensure compliance with health and safety regulations.

Summary Table

| Material | Typical Use Case for water filter system diagram | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene | Housing for filters and membranes | Lightweight and cost-effective | Lower mechanical strength | Low |

| Stainless Steel | Structural components in high-pressure systems | High durability and corrosion resistance | Higher cost and complex manufacturing | High |

| PVC | Piping and structural components | Cost-effective and easy to install | Limited temperature resistance | Low |

| Activated Carbon | Filtration media for taste and odor removal | Highly effective in contaminant removal | Limited lifespan and variable performance | Medium |

This strategic material selection guide provides B2B buyers with the essential insights needed to make informed decisions when sourcing materials for water filter systems, ensuring compliance with international standards and optimizing product performance.

In-depth Look: Manufacturing Processes and Quality Assurance for water filter system diagram

What Are the Main Stages of Manufacturing a Water Filter System Diagram?

Manufacturing a water filter system involves several critical stages that ensure the end product meets both quality and functional standards. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation: What Materials Are Used in Water Filter Systems?

The first step in the manufacturing process is material preparation. This involves sourcing high-quality raw materials suitable for water filtration, such as activated carbon, ceramic, or polymer membranes. The selection of materials is crucial as they directly influence the filtration efficiency and durability of the system. International buyers should inquire about the origin and quality certifications of these materials to ensure compliance with local regulations and standards.

How Is the Forming Process Conducted for Water Filter Systems?

Once the materials are prepared, the next stage is forming. This can involve various techniques, including extrusion for membranes, molding for filter housings, and cutting for filter elements. Advanced technology such as 3D printing may also be employed for custom components. Each technique has its advantages; for instance, extrusion allows for continuous production of filter membranes with uniform characteristics. Buyers should look for suppliers that utilize modern forming techniques to ensure precision and efficiency in production.

What Are the Key Aspects of the Assembly Process?

After forming, the components are assembled into the final water filter system. This stage may involve manual or automated processes, including fitting together various elements like the filter cartridges, housings, and connectors. Quality control during assembly is vital; any misalignment or improper sealing can lead to leaks or decreased filtration performance. Buyers should verify that manufacturers have a robust assembly process, including checklists and procedures to ensure consistency and quality.

How Is the Finishing Process Completed?

The finishing process encompasses any additional treatments or coatings that may be required to enhance the water filter system’s performance or aesthetic appeal. This can include surface treatments to prevent corrosion, apply antimicrobial coatings, or packaging for shipping. The finishing stage is also where final inspections occur, ensuring that all components meet the required specifications before they leave the factory.

What Quality Control Measures Are Essential for Water Filter Systems?

Quality assurance is a critical component in the manufacturing of water filter systems. It ensures that products not only meet customer expectations but also comply with international standards and regulations.

Which International Standards Are Relevant for Water Filter Systems?

For international B2B buyers, understanding the relevant quality standards is essential. ISO 9001 is a widely recognized standard that outlines quality management principles, ensuring consistency and continuous improvement. Additionally, industry-specific certifications such as CE (European Conformity) and API (American Petroleum Institute) can provide assurance regarding safety and performance. Buyers should request documentation of these certifications from suppliers to verify compliance.

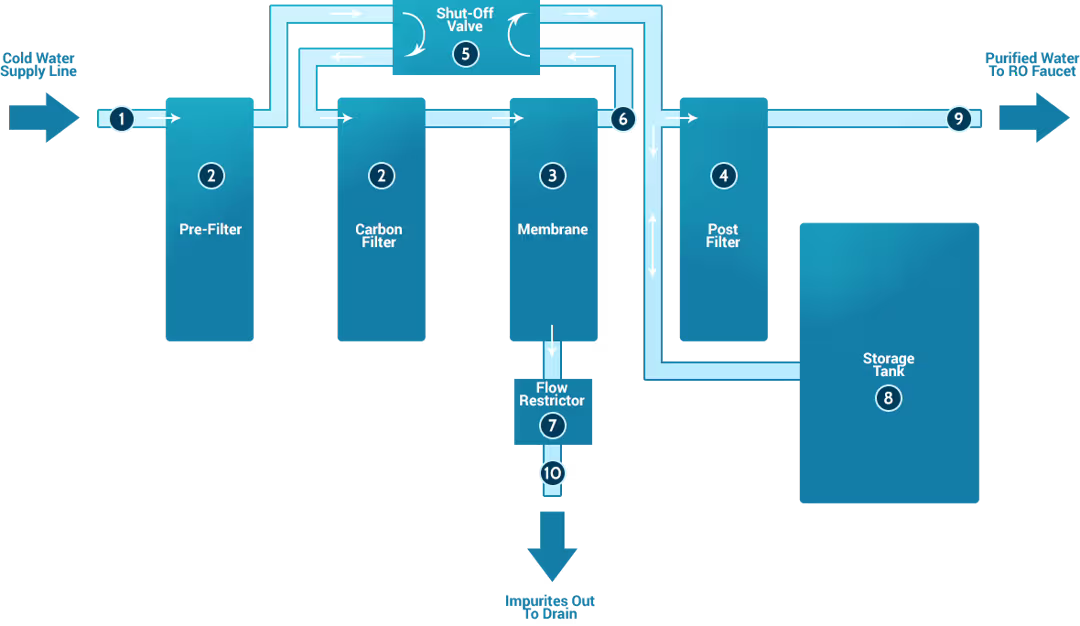

Illustrative image related to water filter system diagram

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are integrated throughout the manufacturing process. Key checkpoints include:

- Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify and rectify issues before they escalate.

- Final Quality Control (FQC): A comprehensive inspection of the finished product ensures it meets all specifications and is ready for distribution.

These checkpoints are crucial for maintaining product integrity and reliability.

How Can B2B Buyers Verify Supplier Quality Control?

Buyers should conduct due diligence when evaluating potential suppliers. Here are several effective strategies for verifying quality control processes:

What Types of Audits and Reports Should Buyers Request?

Buyers can request audits of the supplier’s manufacturing facilities to assess compliance with quality standards. These audits can be conducted by third-party organizations that specialize in quality assurance. Additionally, suppliers should provide detailed quality control reports that outline testing methodologies, results, and corrective actions taken for any discrepancies.

How Important Are Third-Party Inspections?

Third-party inspections add another layer of assurance for buyers. These inspections can occur at various stages of the manufacturing process and help confirm that suppliers adhere to quality standards. Engaging a reputable third-party inspection agency can provide buyers with unbiased evaluations and enhance trust in the supplier relationship.

What Are the Quality Control Nuances for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific quality control nuances. Different markets may have varying regulatory requirements and standards. For instance, the European Union has stringent regulations regarding water quality and safety, necessitating that suppliers demonstrate compliance with CE certification.

How Can Buyers Navigate Regional Differences in Quality Standards?

To navigate these regional differences, buyers should:

- Conduct thorough research on local regulations and standards applicable to water filtration systems in their respective countries.

- Engage with local representatives or consultants who understand the specific requirements and can facilitate compliance.

- Build relationships with suppliers who have experience exporting to the buyer’s region, as they will be more familiar with the necessary certifications and documentation.

Conclusion: Ensuring Quality in Water Filter System Manufacturing

For international B2B buyers, understanding the manufacturing processes and quality assurance measures for water filter systems is crucial for making informed purchasing decisions. By focusing on the main stages of manufacturing, relevant quality control standards, and strategies for supplier verification, buyers can ensure they source reliable and effective water filtration solutions that meet their specific needs. As the demand for clean water continues to grow globally, having a reliable supplier with robust quality assurance practices will be essential for success in the water filtration market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘water filter system diagram’

Introduction

Navigating the procurement of a water filter system diagram can be complex, especially for B2B buyers in diverse regions. This step-by-step checklist is designed to streamline the sourcing process, ensuring that you make informed decisions when selecting diagrams that fit your technical and operational requirements. By following these steps, you can ensure that you are aligned with best practices and industry standards.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, clearly outline your technical requirements. This includes the type of water filter system you need, the scale of operation, and specific filtration methods (e.g., reverse osmosis, UV filtration). Having precise specifications helps suppliers tailor their offerings to your needs and reduces the risk of miscommunication.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers of water filter system diagrams. Look for companies with a solid reputation in the industry, focusing on those that specialize in your specific filtration needs. Utilize online resources, industry forums, and trade shows to gather a list of qualified suppliers.

Step 3: Evaluate Supplier Credentials

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Check for certifications relevant to water filtration, such as NSF/ANSI standards, which demonstrate adherence to safety and performance criteria.

Step 4: Request Sample Diagrams

Once you have shortlisted suppliers, request sample diagrams that align with your specifications. Reviewing samples allows you to assess the clarity, accuracy, and usability of the diagrams. Ensure that the diagrams are comprehensive and easy to understand, as this will facilitate better implementation in your operations.

Step 5: Inquire About Customization Options

Not all projects are the same; therefore, inquire about customization capabilities. Many suppliers offer tailored diagrams to fit specific requirements or operational constraints. Understanding these options can significantly enhance the effectiveness of the water filtration system you plan to implement.

Step 6: Consider Support and Training

Evaluate the level of support and training offered by the supplier. A reliable supplier should provide technical assistance during installation and operation, as well as training for your team on how to interpret and utilize the diagrams effectively. This support can be invaluable in ensuring the success of your water filtration system.

Step 7: Negotiate Terms and Finalize Purchase

Once you’ve identified a suitable supplier, negotiate the terms of the purchase. Discuss pricing, delivery timelines, and any additional services included in the agreement. Ensure that all terms are clearly documented to prevent any misunderstandings in the future. A well-negotiated contract can lead to a fruitful long-term relationship with your supplier.

By following this checklist, B2B buyers can effectively navigate the complexities of sourcing water filter system diagrams, ensuring that they select the best solutions tailored to their operational needs.

Comprehensive Cost and Pricing Analysis for water filter system diagram Sourcing

Understanding the cost structure and pricing dynamics of water filter system diagrams is crucial for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis breaks down the key components that influence pricing and offers actionable insights for making informed purchasing decisions.

What Are the Key Cost Components in Water Filter System Diagram Sourcing?

The cost structure for sourcing water filter system diagrams encompasses several essential components:

-

Materials: The quality and type of materials used in the diagrams can significantly affect costs. High-quality paper, inks, and digital formats may incur higher expenses. Opting for eco-friendly materials can also impact pricing.

-

Labor: The expertise required to design and produce water filter system diagrams contributes to labor costs. Skilled designers and engineers command higher wages, particularly in regions with a strong emphasis on quality and innovation.

-

Manufacturing Overhead: This includes costs related to utilities, maintenance of equipment, and other indirect expenses that support the production process. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: For custom diagrams, the tooling costs can be substantial. This includes the expense of creating molds or specialized tools that are necessary for unique designs or specifications.

-

Quality Control (QC): Ensuring the accuracy and reliability of the diagrams necessitates a robust QC process, which can add to the overall costs. Investing in QC can prevent costly mistakes later in the supply chain.

-

Logistics: Shipping and handling costs vary based on the size and weight of the diagrams, as well as the distance to the buyer’s location. Understanding logistics is vital for calculating the total cost of ownership.

-

Margin: Suppliers typically add a profit margin that reflects their business model and market conditions. This margin can fluctuate based on competition and demand.

What Price Influencers Should Buyers Consider?

Several factors can influence the pricing of water filter system diagrams:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs. Buyers should consider their needs carefully to negotiate favorable terms.

-

Specifications and Customization: Custom diagrams tailored to specific applications or regulatory requirements may incur additional costs. Clearly defining specifications can help avoid unexpected expenses.

-

Quality and Certifications: Diagrams that meet specific industry standards or certifications may command higher prices. Buyers should assess the necessity of such certifications based on their operational needs.

-

Supplier Factors: The supplier’s reputation, reliability, and geographical location can impact pricing. Engaging with established suppliers may offer advantages in terms of quality assurance and service.

-

Incoterms: Understanding the terms of shipping and delivery is crucial. Different Incoterms can affect the final cost, including who bears the risk and responsibility during transit.

What Are Effective Buyer Tips for Cost-Efficiency?

To maximize cost-efficiency in sourcing water filter system diagrams, consider the following tips:

-

Negotiate Wisely: Leverage volume purchases to negotiate better pricing. Building long-term relationships with suppliers can also yield favorable terms.

-

Evaluate Total Cost of Ownership (TCO): Beyond initial costs, consider the long-term implications of your purchase, including maintenance, operational efficiency, and potential downtime.

-

Be Aware of Pricing Nuances: International buyers should account for currency fluctuations, import duties, and local market conditions. Understanding these factors can lead to better budgeting and planning.

-

Engage in Market Research: Regularly review market trends and competitor pricing to make informed decisions. This can help identify opportunities for cost savings or advantageous partnerships.

Conclusion

Navigating the complexities of cost and pricing analysis for water filter system diagrams requires a thorough understanding of various components and influencers. By leveraging these insights, international B2B buyers can enhance their sourcing strategies, optimize their investments, and ensure they procure high-quality diagrams that meet their specific needs. Always remember that the prices discussed are indicative and can vary based on market conditions and specific supplier negotiations.

Alternatives Analysis: Comparing water filter system diagram With Other Solutions

Exploring Alternatives to Water Filter System Diagrams

In the realm of water purification, various solutions exist beyond traditional water filter system diagrams. These alternatives not only offer different methodologies but also cater to diverse operational needs and geographical considerations. By comparing water filter system diagrams with other viable solutions, businesses can make informed decisions tailored to their specific requirements.

| Comparison Aspect | Water Filter System Diagram | Reverse Osmosis System | UV Water Purification System |

|---|---|---|---|

| Performance | Provides clear visual representation of filtration stages | Highly effective in removing contaminants, including bacteria and viruses | Kills microorganisms but may not remove chemical pollutants |

| Cost | Low initial cost; may require additional investment for installation and maintenance | Higher upfront cost; long-term savings on bottled water | Moderate cost; effective for small-scale operations |

| Ease of Implementation | Requires basic plumbing knowledge for installation | Requires professional installation | Easy to install; often comes with user-friendly guides |

| Maintenance | Regular maintenance needed for filter replacements | Membrane replacement needed every 2-3 years; requires periodic maintenance | Minimal maintenance; UV lamp replacement needed annually |

| Best Use Case | Ideal for residential and light commercial use | Suitable for areas with high TDS and microbial contamination | Best for disinfecting water in homes and small businesses |

What Are the Benefits and Drawbacks of a Reverse Osmosis System?

The reverse osmosis (RO) system is renowned for its superior filtration capabilities. It effectively eliminates a wide range of contaminants, making it a preferred choice in areas with high total dissolved solids (TDS) and microbial threats. However, the initial investment can be substantial, and the system requires professional installation. While RO systems offer long-term savings on bottled water, they may generate wastewater during the filtration process, which can be a concern in regions facing water scarcity.

Illustrative image related to water filter system diagram

How Does UV Water Purification Compare?

UV water purification systems are popular for their ease of use and maintenance. They utilize ultraviolet light to disinfect water by eliminating pathogens without the use of chemicals. This method is particularly effective for small-scale operations, such as residential settings, where chemical contamination is less of a concern. However, UV systems do not filter out chemical pollutants or sediment, which may require additional filtration solutions. The moderate cost and straightforward installation make UV systems an attractive option for many businesses, especially those prioritizing safety and simplicity.

Making the Right Choice for Your Water Purification Needs

When evaluating the best water purification solution, B2B buyers must consider specific operational needs, including the quality of the source water, regulatory compliance, and budget constraints. Water filter system diagrams offer an excellent visual aid for understanding filtration stages, making them suitable for businesses that prioritize education and straightforward implementation. Conversely, reverse osmosis and UV systems provide advanced solutions for specific contaminant challenges. By assessing these alternatives based on performance, cost, ease of implementation, maintenance, and use case, buyers can select the most effective system that aligns with their operational goals and regional requirements.

Essential Technical Properties and Trade Terminology for water filter system diagram

When navigating the complexities of water filtration systems, understanding essential technical properties and trade terminology is crucial for B2B buyers. This knowledge not only aids in selecting the right systems but also enhances communication with suppliers and manufacturers.

What Are the Critical Technical Properties of Water Filter Systems?

-

Material Grade

The material grade refers to the quality of the components used in the water filter system, such as plastic or metal. High-grade materials, like food-grade polypropylene or stainless steel, ensure durability and resistance to corrosion. For B2B buyers, selecting the right material grade is vital, as it directly impacts the lifespan and performance of the filtration system, particularly in diverse environments across Africa, South America, the Middle East, and Europe. -

Flow Rate

Flow rate is the volume of water that can be filtered per minute, typically measured in gallons per minute (GPM). This specification is critical for businesses that require a consistent supply of filtered water. Understanding the flow rate helps B2B buyers determine whether a particular system can meet their operational needs, particularly in high-demand settings like manufacturing plants or hospitality services. -

Filtration Efficiency

Filtration efficiency indicates the system’s ability to remove contaminants from water, often expressed as a percentage. A higher efficiency rating means that more impurities are removed, resulting in cleaner, safer water. B2B buyers should prioritize filtration efficiency to ensure compliance with local water quality regulations and to protect the health of employees and customers. -

Operating Pressure

Operating pressure is the pressure range within which the water filter system functions optimally. It is typically measured in pounds per square inch (PSI). Understanding the operating pressure is essential for B2B buyers, as systems designed for low-pressure environments may not perform well in regions with high water pressure, potentially leading to system failures or inefficiencies. -

Tolerance Levels

Tolerance levels refer to the acceptable limits of variation in the dimensions and performance of the components within the filtration system. High tolerance levels ensure that parts fit together correctly and function as intended. For B2B buyers, understanding tolerance levels is key to ensuring compatibility with existing systems and avoiding costly modifications.

What Are Common Trade Terms Related to Water Filter Systems?

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the water filtration industry, OEM components are often used to assemble complete systems. B2B buyers should consider OEM products for their reliability and compatibility with existing systems. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers, as it can impact inventory management and cash flow. Buyers should negotiate MOQs that align with their operational needs to avoid excess stock or supply shortages. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing and terms for specific products or services. In the water filtration sector, issuing an RFQ allows B2B buyers to compare different suppliers based on price, delivery time, and service. This process is essential for making informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce. They define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. For B2B buyers, understanding Incoterms is critical for managing logistics effectively and ensuring compliance with international trade regulations. -

Lead Time

Lead time refers to the amount of time between placing an order and receiving the product. In the context of water filtration systems, understanding lead times helps B2B buyers plan their procurement strategies and manage project timelines effectively.

By familiarizing themselves with these essential technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs, ensuring they invest in reliable and efficient water filtration systems.

Navigating Market Dynamics and Sourcing Trends in the water filter system diagram Sector

What Are the Key Market Dynamics and Trends Influencing Water Filter System Diagrams?

The global market for water filtration systems is witnessing significant growth, driven by rising concerns over water quality, health issues, and environmental sustainability. Key markets in Africa, South America, the Middle East, and Europe are experiencing a surge in demand due to increasing urbanization, industrial activities, and the pressing need for safe drinking water. In regions like Germany and Brazil, innovative technologies, including reverse osmosis and advanced filtration methods, are gaining traction, pushing manufacturers to create more sophisticated water filter system diagrams that provide clarity on installation and functionality.

Emerging B2B tech trends include the integration of digital solutions such as augmented reality (AR) for visualizing complex installations and remote monitoring systems that enhance operational efficiency. Additionally, the adoption of cloud-based platforms for data management and analytics allows for better decision-making, helping international buyers understand market demands and tailor solutions accordingly. The shift towards modular and customizable filtration systems is also notable, as businesses seek flexibility to adapt to diverse water quality challenges across different regions.

How Is Sustainability and Ethical Sourcing Impacting the Water Filter System Diagram Sector?

Environmental considerations are becoming increasingly critical in the sourcing of materials and components for water filtration systems. The demand for sustainable practices is prompting B2B buyers to prioritize suppliers who demonstrate a commitment to ethical sourcing and transparency in their supply chains. Manufacturers are increasingly focusing on using eco-friendly materials, such as biodegradable or recyclable components, in their water filter systems.

Certifications such as the Water Quality Association’s (WQA) Gold Seal and the International Organization for Standardization (ISO) standards are becoming essential benchmarks for buyers assessing the sustainability of water filtration products. These certifications not only validate the performance of the systems but also assure buyers of the environmental impact of their sourcing choices. As a result, businesses that align their sourcing strategies with sustainability goals are likely to gain a competitive advantage in the marketplace.

What Is the Evolution of Water Filter System Diagrams and Its Relevance for B2B Buyers?

Historically, water filtration systems have evolved from simple mechanical filters to complex multi-stage systems that incorporate advanced technologies such as ultraviolet (UV) light and nanofiltration. This evolution has led to an increased need for clear and detailed water filter system diagrams that can guide installation, maintenance, and troubleshooting.

Illustrative image related to water filter system diagram

For B2B buyers, understanding the historical context of these systems is crucial. It allows them to appreciate the advancements in technology and design that contribute to improved water quality and efficiency. As these systems become more sophisticated, the importance of comprehensive diagrams grows, serving as essential tools for engineers and technicians in ensuring proper implementation and maximizing system performance.

Frequently Asked Questions (FAQs) for B2B Buyers of water filter system diagram

-

How do I ensure the quality of a water filter system diagram from a supplier?

To ensure the quality of a water filter system diagram, start by verifying the supplier’s credentials and experience in the industry. Request samples of their previous work, including diagrams and schematics, to assess their accuracy and clarity. Additionally, inquire about their quality assurance processes, such as adherence to international standards and certifications. Engaging in direct communication to clarify technical details can also help establish trust and gauge their expertise in creating effective water filtration solutions. -

What is the best way to customize a water filter system diagram for my specific needs?

The best way to customize a water filter system diagram is to provide your supplier with detailed specifications regarding your project requirements, including the types of contaminants you wish to filter, flow rate, and installation constraints. Collaborate closely with the supplier to discuss potential modifications and ensure the diagram accurately reflects the system’s layout and components. Utilizing software tools that allow for real-time adjustments can also facilitate an iterative design process, ensuring that the final diagram meets your operational needs. -

What are the typical minimum order quantities (MOQ) for water filter system diagrams?

Minimum order quantities (MOQ) for water filter system diagrams can vary significantly based on the supplier and the complexity of the project. Some suppliers may not have an MOQ for digital diagrams, while others might require a minimum purchase when combined with physical products. It’s advisable to discuss your needs with the supplier directly to negotiate terms that work for both parties. Understanding your market demands can also help in setting realistic MOQs that align with your business objectives. -

How can I verify the credibility of a supplier providing water filter system diagrams?

To verify the credibility of a supplier, conduct thorough research including checking online reviews, ratings, and testimonials from previous clients. Request references and follow up to gain insights into their reliability and service quality. Additionally, assess their business certifications and compliance with industry standards. Engaging in a preliminary conversation can provide valuable information about their technical expertise and responsiveness, helping you make an informed decision. -

What payment terms should I expect when sourcing water filter system diagrams internationally?

Payment terms for international sourcing of water filter system diagrams typically include options such as advance payment, letters of credit, or payment upon delivery. It’s crucial to establish clear terms with the supplier upfront, including currency, payment methods, and deadlines. Some suppliers may offer discounts for early payment or larger orders. Always ensure that the terms are documented in a contract to protect both parties and to facilitate smoother transactions. -

What logistics considerations should I be aware of when sourcing water filter system diagrams from abroad?

When sourcing water filter system diagrams internationally, consider logistics factors such as shipping times, customs regulations, and potential tariffs. Understand the delivery methods available and choose a reliable shipping partner to ensure timely arrival. Additionally, factor in any time zone differences that might affect communication and project timelines. Planning for contingencies, such as delays or additional costs, can help mitigate risks associated with international sourcing. -

How can I ensure the diagrams comply with local regulations in my region?

To ensure that water filter system diagrams comply with local regulations, familiarize yourself with the specific standards and guidelines applicable in your region. Engage with local regulatory bodies or industry associations that can provide insights into compliance requirements. Collaborating with suppliers who are knowledgeable about these regulations can also help ensure that the diagrams meet necessary legal and operational standards, minimizing the risk of non-compliance. -

What should I look for in a supplier’s technical support for water filter system diagrams?

When evaluating a supplier’s technical support for water filter system diagrams, consider their responsiveness, availability, and expertise in water filtration technologies. Look for suppliers that offer comprehensive support, including troubleshooting assistance, installation guidance, and updates for diagram revisions. A strong technical support team can enhance your operational efficiency and ensure that any issues are resolved promptly, contributing to the overall success of your water filtration project.

Top 6 Water Filter System Diagram Manufacturers & Suppliers List

1. Clean Water Store – Water Treatment Solutions

Domain: cleanwaterstore.com

Registered: 1998 (27 years)

Introduction: Clean Water Store offers a wide range of water treatment products including:

– Drinking Water Systems (Faucets, Under-Sink Filters, Countertop Filters, Fluoride Filters, Reverse Osmosis)

– City Water Systems (Carbon Backwash Filters, Carbon Upflow Filters, Carbon Whole House Cartridge Filters, Salt-Free Water Conditioners, Water Softeners)

– Well Water Systems (Arsenic Filters, Acid Neutralizer…

2. Shutterstock – Home Water Purification System

Domain: shutterstock.com

Registered: 2003 (22 years)

Introduction: This company, Shutterstock – Home Water Purification System, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. H2O Distributors – Reverse Osmosis Systems

Domain: h2odistributors.com

Registered: 1997 (28 years)

Introduction: Reverse Osmosis Diagram – H2O Distributors. Most Orders Ship Today. Free Shipping On All Orders $150 And Over! Contact: 1-800-955-8561. Product Categories: Residential Reverse Osmosis Systems, Under Sink Systems, Countertop Water Filter Systems, Whole House Water Filter Systems, Water Softeners, Commercial Systems, Inline Shower Filter Systems, Replacement Filter Cartridges, Reverse Osmosis Filter…

4. Pinterest – Commercial Aquarium Filtration Systems

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: commercial aquarium filtration system drawings, Water treatment system, Well water system, Home water filtration, Sediment Filters, Sediment Backwash Filters, removes soluble inorganic contaminants and sediment from water, automatically back washing to extend usable life.

5. Facebook – Well Water Filtration System

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Well Water Filtration System, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Ukoke – Water Filtration System

Domain: ukoke.com

Registered: 2017 (8 years)

Introduction: Ukoke Water Filtration System, Installation diagram, Tags: sanitize, Ukoke, water filtration system, Categories: air condition connection instruction, portable ac power, garden tool, reverse osmosis water system, sanitize sprayer.

Strategic Sourcing Conclusion and Outlook for water filter system diagram

As the demand for clean water solutions continues to rise globally, strategic sourcing of water filtration systems becomes paramount for businesses seeking sustainable and effective solutions. By leveraging detailed diagrams and schematics, B2B buyers can make informed decisions regarding the installation and maintenance of water filter systems. Understanding the intricacies of these systems not only enhances operational efficiency but also ensures compliance with local regulations and quality standards.

Investing in high-quality filtration systems from reputable suppliers can significantly reduce long-term operational costs and improve product offerings. Buyers from regions such as Africa, South America, the Middle East, and Europe, including Germany and Brazil, should prioritize partnerships with manufacturers that provide comprehensive support, including installation guides and after-sales service. This approach will facilitate smoother integration of filtration systems into existing infrastructures.

Illustrative image related to water filter system diagram

Looking ahead, the focus on sustainability and health will likely drive innovation in water filtration technologies. B2B buyers are encouraged to stay ahead of the curve by exploring new advancements and considering strategic partnerships that align with their long-term goals. Embrace the opportunity to enhance your water management solutions today—your commitment to quality and sustainability will not only benefit your business but also the communities you serve.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.