A Deep Dive into Vibration Absorber Solution

Introduction: Navigating the Global Market for vibration absorber

In the fast-paced world of industrial applications, sourcing reliable vibration absorbers is a critical challenge for businesses across various sectors. These essential components are designed to mitigate the adverse effects of vibration, ensuring the longevity and efficiency of machinery in industries such as HVAC, refrigeration, and manufacturing. However, navigating the global market for vibration absorbers can be daunting, particularly for international B2B buyers from regions like Africa, South America, the Middle East, and Europe, including countries like Nigeria and Vietnam.

This comprehensive guide serves as a valuable resource for those seeking to enhance their purchasing decisions. We delve into the various types of vibration absorbers, such as gas springs, rubber and silicone molds, and their specific applications in different industries. Furthermore, we provide insights into supplier vetting processes, enabling buyers to identify reputable manufacturers and distributors who meet international quality standards.

Cost considerations are also addressed, offering a transparent view of pricing structures to help businesses budget effectively. By equipping B2B buyers with actionable insights and critical information, this guide empowers them to make informed purchasing decisions that optimize operational efficiency and enhance product reliability. Whether you are looking to reduce machinery wear or improve overall system performance, understanding the intricacies of vibration absorbers is essential for achieving your business objectives.

Understanding vibration absorber Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Gas Springs | Hydro-pneumatic design; stores potential energy | Machinery, automotive, HVAC systems | Pros: Lightweight, adjustable force. Cons: Limited to specific load requirements. |

| Rubber Molding | Durable, flexible rubber construction | Industrial machinery, automotive parts | Pros: Excellent vibration damping. Cons: Temperature sensitivity may limit use. |

| Stainless Steel Absorbers | High-pressure tolerance; corrosion-resistant | Refrigeration, air conditioning systems | Pros: Long lifespan, reliable under pressure. Cons: Higher initial cost. |

| Rubber Overmolding | Combines rubber with other materials for added strength | Consumer electronics, automotive components | Pros: Enhanced durability, customizability. Cons: More complex manufacturing process. |

| Grommet Edging | Flexible rubber or plastic strip for edge protection | Electrical installations, machinery | Pros: Protects sensitive components. Cons: Limited to edge applications. |

What Are Gas Springs and Their Applications in B2B Markets?

Gas springs are hydro-pneumatic devices that store energy by compressing gas within a sealed cylinder. They are widely utilized in machinery, automotive applications, and HVAC systems due to their lightweight and adjustable force characteristics. B2B buyers should consider load requirements and compatibility with existing systems when purchasing gas springs, as these factors can significantly influence performance and safety.

How Does Rubber Molding Benefit Industrial Applications?

Rubber molding involves the transformation of uncured rubber into usable products, offering excellent durability and flexibility. This type of vibration absorber is particularly effective in industrial machinery and automotive parts, where robust vibration damping is essential. Buyers should assess the temperature and environmental conditions of their application, as rubber can be sensitive to extreme heat or cold, impacting its performance.

Why Choose Stainless Steel Vibration Absorbers for Refrigeration?

Stainless steel vibration absorbers are designed to withstand high pressure and resist corrosion, making them ideal for refrigeration and air conditioning systems. Their long lifespan and reliability under pressure are significant advantages for B2B buyers seeking durable solutions. However, the higher initial cost may be a consideration, especially for budget-sensitive projects.

What Advantages Do Rubber Overmolding Techniques Offer?

Rubber overmolding combines rubber with other materials to enhance strength and durability, making it suitable for consumer electronics and automotive components. This method allows for increased customizability, which can be a selling point for B2B buyers looking for specific design requirements. However, the more complex manufacturing process can lead to longer lead times and higher costs.

How Does Grommet Edging Provide Protection in Electrical Installations?

Grommet edging is a flexible strip made of rubber or plastic that protects sensitive electrical components from rough edges and surfaces. Commonly used in electrical installations and machinery, it ensures the safety and longevity of wiring and cables. While grommet edging offers significant protective benefits, its application is limited to edge protection, which may not meet all vibration absorption needs.

Key Industrial Applications of vibration absorber

| Industry/Sector | Specific Application of Vibration Absorber | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| HVAC and Refrigeration | Installation in compressor suction and discharge lines | Reduces noise and extends equipment life | Compatibility with refrigerants, pressure ratings, and installation ease |

| Manufacturing and Machinery | Use in industrial machinery and equipment | Minimizes wear and tear, enhancing operational efficiency | Material durability, vibration frequency handling, and customization options |

| Automotive | Integration in vehicle suspension systems | Improves ride quality and reduces component fatigue | Compliance with automotive standards and performance specifications |

| Construction | Application in building foundations and structures | Enhances structural integrity and occupant comfort | Load-bearing capacity, material resilience, and environmental factors |

| Oil and Gas | Deployment in drilling rigs and offshore platforms | Protects sensitive equipment from vibrations and shocks | Resistance to harsh environments, pressure ratings, and maintenance requirements |

How Are Vibration Absorbers Utilized in HVAC and Refrigeration Systems?

In HVAC and refrigeration systems, vibration absorbers are crucial components installed in the suction and discharge lines of compressors. They help mitigate vibrations caused by the compressor’s operation, which can lead to noise and system inefficiencies. For international buyers, especially in regions like Africa and South America, sourcing vibration absorbers that are compatible with various refrigerants and have high-pressure ratings is essential. Additionally, ensuring easy installation can significantly reduce labor costs and downtime.

What Role Do Vibration Absorbers Play in Manufacturing and Machinery?

Vibration absorbers are extensively used in manufacturing and industrial machinery to minimize vibrations that can lead to wear and tear on components. By absorbing excess vibrations, these devices enhance the operational efficiency of equipment, resulting in lower maintenance costs and longer equipment life. Buyers in markets such as Europe and the Middle East should consider the durability of materials and the specific vibration frequencies they need to handle when sourcing these products, as different machinery may have varying requirements.

How Are Vibration Absorbers Integrated into Automotive Applications?

In the automotive sector, vibration absorbers are integrated into suspension systems to improve ride quality by dampening road vibrations. This not only enhances passenger comfort but also reduces fatigue on vehicle components, leading to lower maintenance costs. For B2B buyers in automotive manufacturing, it is vital to source vibration absorbers that comply with industry standards and performance specifications, especially when considering vehicles designed for rugged terrains in regions like Nigeria and Vietnam.

How Do Vibration Absorbers Enhance Construction Projects?

In construction, vibration absorbers are used to improve the integrity of building foundations and structures by dampening vibrations from external sources, such as traffic or machinery. This application is particularly valuable in urban areas where vibrations can affect occupant comfort and structural safety. Buyers should prioritize sourcing vibration absorbers with high load-bearing capacities and resilience to environmental factors, ensuring they meet local building codes and standards.

What Benefits Do Vibration Absorbers Provide in Oil and Gas Operations?

In the oil and gas industry, vibration absorbers are deployed in drilling rigs and offshore platforms to protect sensitive equipment from vibrations and shocks caused by drilling operations. This application is critical for maintaining operational efficiency and preventing costly equipment failures. Buyers in this sector should focus on sourcing vibration absorbers that are resistant to harsh environments, have appropriate pressure ratings, and require minimal maintenance to ensure longevity and reliability in challenging conditions.

3 Common User Pain Points for ‘vibration absorber’ & Their Solutions

Scenario 1: Ensuring Vibration Control in High-Pressure Systems

The Problem: Many B2B buyers in industries such as HVAC and refrigeration face the challenge of managing vibration in high-pressure systems. Vibration can lead to fatigue in piping, resulting in premature failures and costly downtimes. This is particularly critical in regions like Africa and the Middle East, where system reliability is essential due to limited maintenance resources. Buyers often struggle to find vibration absorbers that can withstand high pressures while maintaining flexibility and reliability.

The Solution: To effectively address this issue, buyers should prioritize sourcing vibration absorbers specifically designed for high-pressure applications. It is essential to evaluate the burst pressure ratings and compatibility with refrigerants used in their systems. For instance, models like the Packless VAFS series, constructed with stainless steel and designed for modern high-pressure refrigerants, offer enhanced durability and vibration absorption. Buyers should also consider installation practices, ensuring that absorbers are placed close to vibration sources and are installed perpendicular to the vibration axis. This positioning maximizes their effectiveness, reducing the risk of system failures.

Scenario 2: Navigating Compatibility with Different Refrigerants

The Problem: In the international market, B2B buyers often encounter difficulties when selecting vibration absorbers that are compatible with various refrigerants, including CO2 and HFCs. The challenge lies in ensuring that the materials used in the vibration absorbers do not degrade when exposed to different refrigerants, which can lead to leaks and system inefficiencies. This is particularly relevant for buyers in South America, where regulations may dictate specific refrigerant usage.

The Solution: Buyers should conduct thorough research on the chemical compatibility of vibration absorbers with the refrigerants they plan to use. It is advisable to consult technical datasheets and engage with manufacturers who can provide specific compatibility information. For example, vibration absorbers from Packless are engineered to be compatible with a wide range of refrigerants. Buyers can also request customized solutions, such as specific materials or coatings that enhance compatibility. This proactive approach not only ensures system reliability but also helps avoid costly regulatory penalties.

Scenario 3: Managing Installation Challenges and Performance Expectations

The Problem: Installation of vibration absorbers can pose significant challenges, especially in complex systems with limited space or awkward layouts. B2B buyers often report difficulties in achieving optimal performance due to improper installation techniques or lack of proper guidelines. This can lead to insufficient vibration damping and increased wear on equipment, affecting overall operational efficiency.

The Solution: To mitigate installation challenges, buyers should invest time in understanding best practices and seek out comprehensive installation guidelines from manufacturers. Proper training for installation teams can significantly improve outcomes. For instance, ensuring that vibration absorbers are installed in a straight line and are adequately anchored can prevent issues like static compression that may hinder performance. Additionally, utilizing installation tools that allow for precise alignment and securing can enhance effectiveness. Manufacturers often provide support, including installation videos and technical consultations, which can be invaluable for ensuring that absorbers perform as expected in real-world conditions.

Strategic Material Selection Guide for vibration absorber

What Are the Key Materials Used in Vibration Absorbers?

When selecting materials for vibration absorbers, several factors come into play, including performance characteristics, cost, and suitability for specific applications. Below is an analysis of four common materials used in vibration absorbers, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Stainless Steel Perform in Vibration Absorbers?

Stainless steel is a popular choice for vibration absorbers due to its excellent strength-to-weight ratio and resistance to corrosion. It typically has a high-temperature rating, making it suitable for applications in refrigeration and HVAC systems where temperature fluctuations are common.

Pros: Stainless steel offers high durability and can withstand harsh environmental conditions. It is also compliant with various international standards, making it a reliable choice for global applications.

Cons: The primary drawback is its cost, which is generally higher than other materials like brass or rubber. Manufacturing processes can also be complex, requiring specialized techniques such as welding or machining.

Impact on Application: Stainless steel is compatible with a wide range of refrigerants, including HFCs and CO2, making it versatile for various industries.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM or DIN, especially when exporting to regions like Europe or the Middle East.

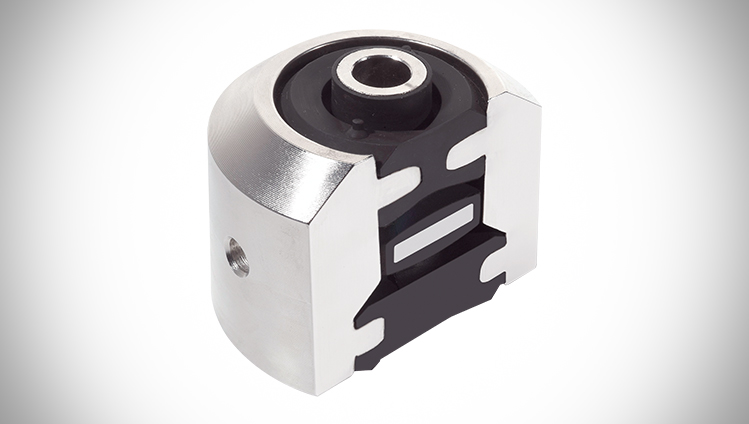

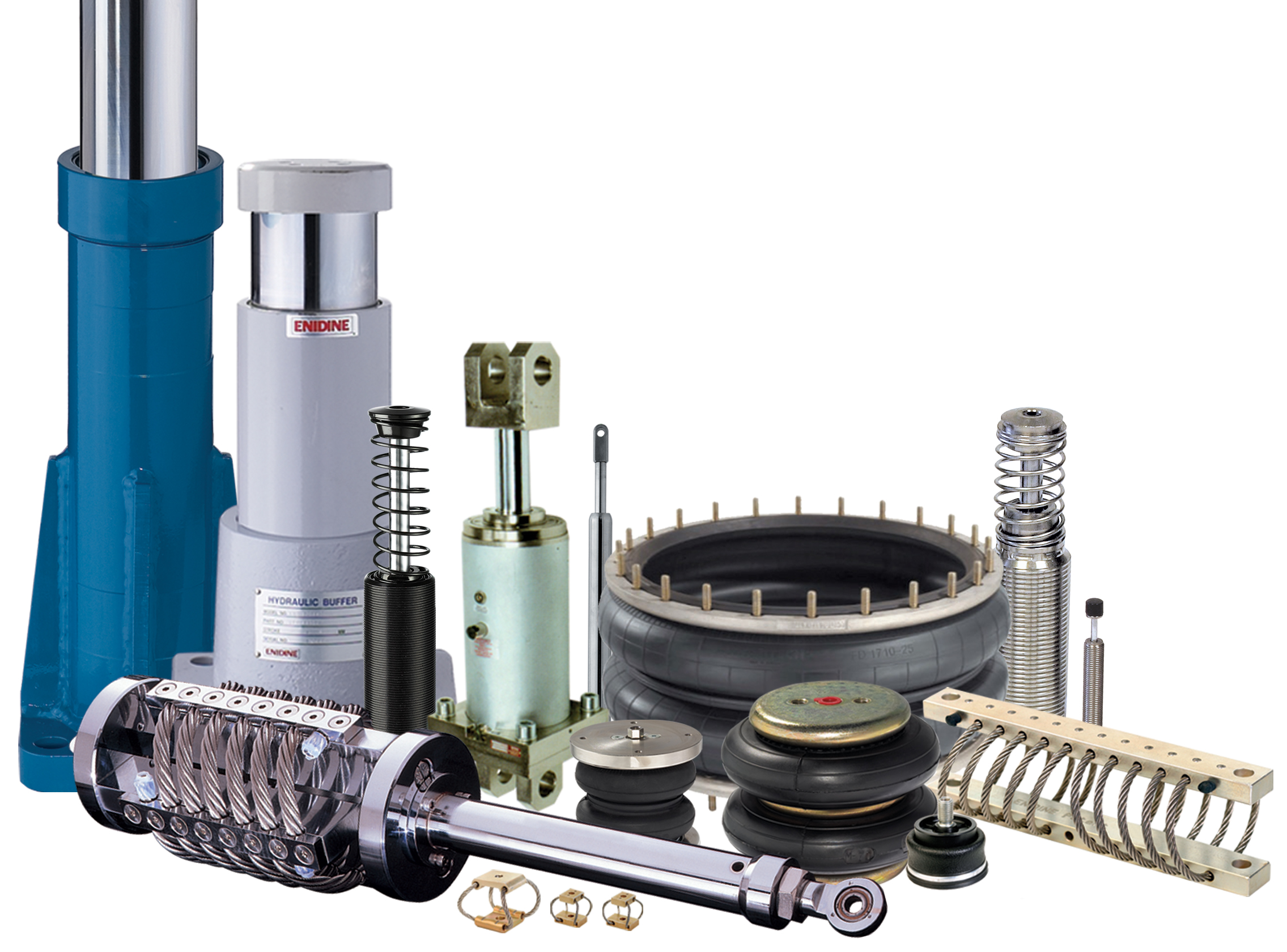

Illustrative image related to vibration absorber

What Role Does Brass Play in Vibration Absorbers?

Brass is another widely used material for vibration absorbers, particularly in lower-pressure applications. It provides good corrosion resistance and is relatively easy to manufacture.

Pros: Brass is generally more affordable than stainless steel and offers good mechanical properties, making it suitable for many applications.

Cons: While brass is durable, it may not perform as well under extreme temperature or pressure conditions compared to stainless steel. It is also susceptible to dezincification in certain environments, which can compromise its integrity.

Impact on Application: Brass is often used in HVAC systems but may not be the best choice for high-pressure refrigerants.

Illustrative image related to vibration absorber

Considerations for International Buyers: Compliance with local standards is crucial, particularly in regions like South America and Africa, where material specifications may vary.

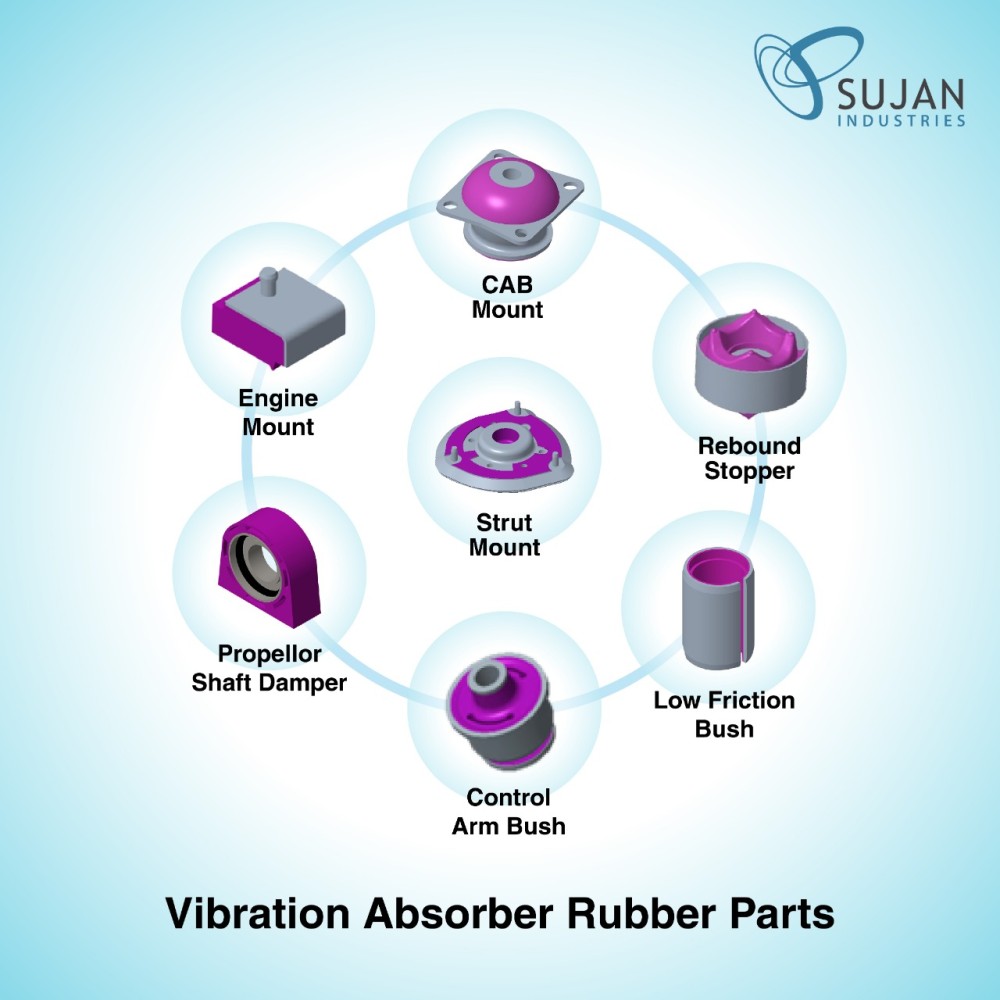

How Does Rubber Contribute to Vibration Absorbers?

Rubber, particularly synthetic variants like neoprene and silicone, is commonly used in vibration absorbers due to its excellent damping properties.

Pros: Rubber is highly effective at absorbing vibrations and is generally low-cost. It is also lightweight, making it easy to install.

Cons: However, rubber has limitations in temperature and pressure ratings, which may restrict its use in high-performance applications. Additionally, it can degrade over time due to environmental factors like UV exposure and ozone.

Illustrative image related to vibration absorber

Impact on Application: Rubber is suitable for applications where flexibility and vibration damping are critical, such as in automotive or industrial machinery.

Considerations for International Buyers: Buyers should consider the specific rubber type and its compatibility with various media, ensuring it meets local compliance standards.

What Advantages Do Gas Springs Offer in Vibration Absorbers?

Gas springs are hydro-pneumatic devices that store energy and provide a unique solution for vibration absorption. They are often used in applications requiring precise control of motion and vibration.

Pros: Gas springs offer high flexibility and can handle a wide range of pressures, making them suitable for various applications.

Cons: They can be more expensive than traditional materials and may require specialized installation techniques.

Illustrative image related to vibration absorber

Impact on Application: Gas springs are particularly effective in applications where dynamic loads and vibrations are common, such as in automotive and aerospace industries.

Considerations for International Buyers: Buyers should ensure that gas springs comply with relevant international standards, as variations in manufacturing and materials can affect performance.

Summary Table of Material Selection for Vibration Absorbers

| Material | Typical Use Case for Vibration Absorber | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | HVAC and refrigeration systems | High durability and corrosion resistance | Higher cost and complex manufacturing | High |

| Brass | Low-pressure HVAC applications | Affordable and easy to manufacture | Susceptible to dezincification | Medium |

| Rubber | Automotive and industrial machinery | Excellent vibration damping | Limited temperature and pressure ratings | Low |

| Gas Springs | Automotive and aerospace applications | High flexibility and pressure handling | More expensive and specialized installation | Medium |

This guide provides a comprehensive overview of the materials used in vibration absorbers, helping international B2B buyers make informed decisions tailored to their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for vibration absorber

What Are the Main Stages of Manufacturing Vibration Absorbers?

Manufacturing vibration absorbers involves several critical stages, ensuring that the final product meets stringent performance and quality standards. The main stages include material preparation, forming, assembly, and finishing. Each stage is vital for achieving the desired properties of the vibration absorber, which is essential in various applications, such as HVAC systems and industrial machinery.

Illustrative image related to vibration absorber

How Is Material Prepared for Vibration Absorbers?

The first step in the manufacturing process is the preparation of materials, which typically involves selecting high-quality elastomers, metals, or composites. For rubber-based absorbers, raw rubber materials are sourced and may undergo a curing process to enhance durability and elasticity. In contrast, metal components, like those used in gas springs, require selection based on tensile strength and corrosion resistance. This preparation phase often includes cutting and shaping the raw materials into manageable sizes for the next stages of production.

What Forming Techniques Are Used in Vibration Absorber Manufacturing?

Forming is a crucial phase that shapes the materials into the final product. Common techniques include:

-

Compression Molding: This method involves placing raw rubber or elastomer materials into a heated mold, where they are compressed to take the desired shape. It is particularly beneficial for creating complex geometries.

-

Injection Molding: This technique is used for producing rubber and silicone components by injecting the uncured material into a mold. The process allows for high precision and consistency in product dimensions.

-

Metal Forming: For components like gas springs, metal forming processes such as bending or rolling are used to create the desired shapes. The quality of the metal is critical, as it must withstand high pressures and stresses.

How Is Assembly Conducted in Vibration Absorber Production?

Once the individual components are formed, they proceed to the assembly stage. This involves joining various parts, such as rubber elements and metal casings, to create a complete vibration absorber. Techniques like welding, bonding, or mechanical fastening are utilized based on the design requirements and materials used. For instance, stainless steel models may require specialized welding to enhance strength and prevent leaks.

What Finishing Processes Are Essential for Vibration Absorbers?

The finishing stage includes several processes aimed at enhancing the product’s appearance and functionality. Common finishing techniques include:

Illustrative image related to vibration absorber

-

Surface Treatment: This may involve coating or treating the surface of the absorber to improve resistance to environmental factors such as corrosion or abrasion.

-

Quality Inspection: Post-manufacturing inspections are conducted to ensure that each product meets industry standards and specifications. This includes visual inspections, dimensional checks, and functional tests.

What International Standards Govern Vibration Absorber Quality Assurance?

Quality assurance in the manufacturing of vibration absorbers is paramount, particularly for B2B buyers. Compliance with international standards such as ISO 9001 ensures that manufacturers adhere to quality management principles. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) play critical roles in validating product safety and performance.

What Are the Key Quality Control Checkpoints in Vibration Absorber Manufacturing?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to catch defects early. These checkpoints typically include:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon delivery to ensure they meet specified standards before being used in production.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing checks are conducted to monitor parameters like dimensions and material properties. This helps in identifying any deviations from the expected quality.

-

Final Quality Control (FQC): After assembly, the completed products undergo rigorous testing to verify their performance and safety. This may include pressure testing for leaks, dimensional accuracy checks, and functional tests.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, it is crucial to verify the quality control practices of suppliers. Here are several methods to ensure that suppliers maintain high standards:

Illustrative image related to vibration absorber

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes and QC measures in place. This provides insights into the supplier’s adherence to international standards and best practices.

-

Quality Assurance Reports: Requesting detailed QC reports from suppliers can help buyers assess the consistency and reliability of the products. These reports should include information on testing methods, results, and any corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These inspections can be particularly valuable for buyers in regions with varying regulatory standards.

What QC Nuances Should International Buyers Consider?

International buyers, especially from diverse markets like Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control:

-

Regulatory Compliance: Different regions may have varying regulations affecting product safety and performance. Buyers must ensure that suppliers comply with local standards and international certifications relevant to their market.

-

Cultural Considerations: Understanding the cultural context of suppliers can influence communication and negotiation regarding quality expectations. Building a strong relationship can facilitate better adherence to quality standards.

-

Logistical Challenges: International shipping can introduce risks to product integrity. Buyers should discuss packaging and transport methods with suppliers to mitigate damage during transit.

By understanding these manufacturing processes and quality assurance measures, B2B buyers can make informed decisions when sourcing vibration absorbers, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘vibration absorber’

In today’s competitive landscape, sourcing high-quality vibration absorbers is essential for ensuring equipment longevity and operational efficiency. This guide provides a structured approach for B2B buyers to navigate the procurement process effectively.

Step 1: Define Your Technical Specifications

Start by clearly outlining the technical requirements of the vibration absorbers you need. Consider factors such as size, material (e.g., rubber, metal), pressure ratings, and the specific application environment (e.g., HVAC, industrial machinery). Detailed specifications will help you communicate effectively with suppliers and ensure compatibility with your existing systems.

Illustrative image related to vibration absorber

Step 2: Identify Your Application Needs

Understanding the specific applications for which the vibration absorbers will be used is crucial. Different applications—like air conditioning, refrigeration, or industrial equipment—may require different types of absorbers. For instance, vibration absorbers for refrigeration systems need to withstand high pressures and be compatible with various refrigerants, ensuring you select the right product for your needs.

Step 3: Evaluate Potential Suppliers

Before making a commitment, thoroughly vet potential suppliers. Request company profiles, case studies, and references from other buyers in similar industries or regions. Pay close attention to their experience with vibration absorbers and their ability to meet your technical specifications. This step helps mitigate risks associated with product quality and supplier reliability.

Step 4: Check for Compliance and Certifications

Ensure that the suppliers you are considering have the necessary certifications and comply with relevant industry standards. Look for certifications such as ISO 9001 or UL listings that indicate adherence to quality management systems and safety standards. Compliance is critical for ensuring product reliability and safety, especially in industries with stringent regulations.

Step 5: Request Samples for Testing

Always ask for samples of the vibration absorbers before placing a bulk order. Testing samples allows you to assess the product’s quality, fit, and performance in your specific application. This hands-on evaluation can help you identify any potential issues early on and reduce the risk of costly mistakes later.

Step 6: Negotiate Terms and Pricing

Once you have identified a suitable supplier, engage in negotiations regarding pricing, delivery times, and payment terms. Be clear about your budget constraints and any specific requirements regarding delivery timelines. A good negotiation can lead to favorable terms that benefit both parties and establish a solid foundation for a long-term partnership.

Step 7: Plan for After-Sales Support

Consider the level of after-sales support offered by the supplier. This includes warranty terms, technical support, and availability of spare parts. A reliable supplier should provide ongoing assistance to ensure your vibration absorbers perform optimally throughout their lifecycle. Adequate support can minimize downtime and enhance your operational efficiency.

Illustrative image related to vibration absorber

By following this step-by-step checklist, B2B buyers can effectively source vibration absorbers that meet their technical and application-specific needs, ensuring quality and reliability in their operations.

Comprehensive Cost and Pricing Analysis for vibration absorber Sourcing

When sourcing vibration absorbers, understanding the cost structure and pricing components is essential for international B2B buyers, particularly those operating in regions like Africa, South America, the Middle East, and Europe. This analysis delves into the various cost components, price influencers, and practical buyer tips to help businesses make informed purchasing decisions.

What Are the Key Cost Components for Vibration Absorbers?

The total cost of vibration absorbers encompasses several components:

-

Materials: The primary materials used in manufacturing vibration absorbers include rubber, silicone, and metals like stainless steel and brass. The choice of material significantly influences the overall cost. For instance, stainless steel models often come at a premium due to their durability and resistance to corrosion.

-

Labor: Labor costs can vary based on the manufacturing location. Regions with lower labor costs may offer competitive pricing, but this can affect quality. Skilled labor is essential for tasks like assembly and quality control, particularly in complex designs.

-

Manufacturing Overhead: This includes costs associated with factory operations, utilities, and equipment maintenance. Efficient manufacturing processes can lower these costs, allowing suppliers to offer better prices.

-

Tooling: Initial tooling costs for custom or specialized vibration absorbers can be substantial. Buyers should consider these costs when evaluating pricing, especially if they require unique specifications.

-

Quality Control (QC): The implementation of stringent QC measures ensures product reliability and safety. Suppliers that invest in robust QC processes may charge higher prices, but this can lead to long-term savings by reducing failure rates.

-

Logistics: Transportation and handling costs can significantly impact the final price, especially for international shipments. Factors such as shipping distance, mode of transport, and fuel prices should be factored into the total cost.

-

Margin: Suppliers typically build a profit margin into their pricing. Understanding the market dynamics can help buyers negotiate better terms.

What Influences the Pricing of Vibration Absorbers?

Several factors can influence the pricing of vibration absorbers:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to discounts. Buyers should negotiate MOQs that align with their operational needs to optimize costs.

-

Specifications and Customization: Custom designs or specific material requirements may incur additional costs. Buyers should clearly communicate their needs to suppliers to avoid unexpected expenses.

-

Quality Certifications: Products with recognized quality certifications may be priced higher but offer assurance of performance and safety, which can be critical in certain applications.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may command higher prices due to their track record but may also provide better support and warranties.

-

Incoterms: Understanding Incoterms is crucial for international buyers. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly impact the total landed cost of products.

What Are the Best Practices for Negotiating Vibration Absorber Prices?

International buyers should adopt several strategies to ensure cost-efficiency when sourcing vibration absorbers:

-

Conduct Comprehensive Market Research: Understanding market trends and competitor pricing can provide leverage during negotiations.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the purchase price but also potential maintenance, installation, and operational costs associated with the product over its lifecycle.

-

Build Long-Term Relationships: Establishing strong partnerships with suppliers can lead to better pricing and terms over time, as suppliers are more likely to accommodate loyal customers.

-

Be Aware of Pricing Nuances: International buyers should be mindful of currency fluctuations, import tariffs, and local regulations that can affect pricing.

Disclaimer on Indicative Prices

It is important to note that prices for vibration absorbers can vary widely based on the aforementioned factors. Buyers are encouraged to obtain multiple quotes and assess the value offered, rather than relying solely on price, to ensure they make the best purchasing decision for their business needs.

Illustrative image related to vibration absorber

Alternatives Analysis: Comparing vibration absorber With Other Solutions

Exploring Alternatives to Vibration Absorbers: What Are Your Options?

When considering solutions for vibration control in industrial applications, vibration absorbers are a common choice. However, there are several alternatives that may also meet the needs of B2B buyers. Understanding the strengths and weaknesses of these options is crucial for making informed purchasing decisions. Below, we will compare vibration absorbers with two viable alternatives: rubber mounts and viscoelastic dampers.

| Comparison Aspect | Vibration Absorber | Rubber Mounts | Viscoelastic Dampers |

|---|---|---|---|

| Performance | Effective in dampening compressor-induced vibrations | Good for isolating low-frequency vibrations | Excellent at absorbing a wide range of frequencies |

| Cost | Moderate to high (depends on type) | Generally lower cost | Higher initial investment |

| Ease of Implementation | Requires careful installation near vibration source | Simple installation, versatile | May require specialized installation |

| Maintenance | Low maintenance, durable | Low maintenance, but may degrade over time | Low maintenance, but sensitive to temperature changes |

| Best Use Case | HVAC and refrigeration systems | Machinery and equipment isolation | Automotive and aerospace applications |

What Are the Advantages and Disadvantages of Rubber Mounts?

Rubber mounts are widely used for vibration isolation due to their simplicity and cost-effectiveness. They are particularly beneficial in scenarios where low-frequency vibrations are prevalent, such as in machinery and equipment setups. Their installation is straightforward, making them a practical choice for many applications. However, rubber mounts can degrade over time, especially under extreme environmental conditions, leading to potential performance issues. They may not be as effective for high-frequency vibrations, limiting their applicability in certain scenarios.

How Do Viscoelastic Dampers Compare to Vibration Absorbers?

Viscoelastic dampers offer a sophisticated solution for vibration control, utilizing materials that absorb and dissipate energy across a wide frequency range. This makes them particularly effective in automotive and aerospace applications where varied vibration frequencies are common. While they provide excellent performance, the initial investment can be significant, which may deter some buyers. Additionally, installation can be more complex, requiring specialized knowledge. However, once in place, they require minimal maintenance, making them a long-term solution for vibration management.

Conclusion: How Should B2B Buyers Choose the Right Vibration Control Solution?

Selecting the right vibration control solution depends on various factors including application requirements, budget constraints, and installation capabilities. For instance, if cost is a primary concern and the application involves low-frequency vibrations, rubber mounts may be the most suitable option. Conversely, if a high-performance solution is necessary for complex systems, investing in viscoelastic dampers could yield better long-term results. Ultimately, B2B buyers should conduct a thorough analysis of their specific needs, weighing the pros and cons of each alternative to ensure they choose the most effective solution for their vibration control challenges.

Essential Technical Properties and Trade Terminology for vibration absorber

What Are the Key Technical Properties of Vibration Absorbers?

Understanding the technical properties of vibration absorbers is crucial for B2B buyers, especially when selecting products that meet specific application requirements. Here are some critical specifications that buyers should consider:

-

Material Grade

Vibration absorbers are typically made from materials such as stainless steel, brass, or specialized rubber compounds. The choice of material affects durability, flexibility, and resistance to corrosion. For instance, stainless steel is preferred in high-pressure applications due to its strength and resistance to environmental factors, making it ideal for refrigeration systems. -

Working Pressure

This specification indicates the maximum pressure the vibration absorber can withstand during operation. It is critical for ensuring safety and performance in systems like HVAC and refrigeration, where fluctuations in pressure can occur. Buyers must choose an absorber with a working pressure rating that exceeds the operational requirements of their specific application. -

Burst Pressure

The burst pressure is the maximum pressure the device can tolerate before failure. Understanding this property helps businesses assess the safety margins in their systems. A higher burst pressure offers additional assurance against unexpected pressure spikes, which can lead to catastrophic failures. -

Size and Dimensions

The outside diameter (OD) and length of vibration absorbers vary significantly. These dimensions must align with the specific installation requirements of the system, including available space and connection types. Ensuring the right fit is essential to prevent installation issues and operational inefficiencies. -

Tolerance Levels

Tolerance refers to the permissible variation in dimensions. Tight tolerances are crucial for ensuring a secure fit and optimal performance, especially in applications where precise alignment is necessary. Buyers should be aware of the tolerance levels in their vibration absorbers to ensure compatibility with existing systems. -

Temperature Range

The operational temperature range indicates the extremes within which the vibration absorber can function effectively. This property is particularly important in industrial applications where equipment may be subjected to high temperatures or thermal cycling. Selecting an absorber with an appropriate temperature range ensures reliable performance and longevity.

What Are Common Trade Terms Related to Vibration Absorbers?

Familiarity with industry terminology is essential for effective communication and negotiation in the B2B marketplace. Here are several common terms related to vibration absorbers:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that are sold under another company’s brand. In the context of vibration absorbers, an OEM may produce these components for larger HVAC systems or refrigeration units, emphasizing the importance of quality and compatibility. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is vital for B2B buyers to manage inventory and ensure they meet their operational needs without overcommitting financially. -

RFQ (Request for Quotation)

An RFQ is a formal document that buyers use to solicit price quotes from suppliers. This process is essential for comparing costs and ensuring that the buyer receives competitive pricing for vibration absorbers based on their specific requirements. -

Incoterms (International Commercial Terms)

These are standardized terms used in international trade that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps B2B buyers understand their obligations and rights in cross-border transactions involving vibration absorbers. -

Lead Time

This term refers to the time it takes from placing an order until the product is delivered. Knowing the lead time is crucial for B2B buyers to plan their projects and manage inventory effectively, especially in industries where downtime can be costly. -

Certification Standards

Certifications, such as those from Underwriter’s Laboratories (UL), signify that a product meets specific safety and performance standards. Buyers should seek vibration absorbers that carry relevant certifications to ensure compliance with industry regulations and enhance the reliability of their systems.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing vibration absorbers, ensuring that they meet their operational needs and industry standards.

Navigating Market Dynamics and Sourcing Trends in the vibration absorber Sector

What Are the Current Market Dynamics and Key Trends in the Vibration Absorber Sector?

The global vibration absorber market is experiencing significant growth, driven by the increasing demand for noise and vibration control solutions across various industries, including HVAC, automotive, and manufacturing. With the rise of urbanization and industrialization, particularly in regions such as Africa, South America, the Middle East, and Europe, businesses are seeking efficient ways to mitigate vibrations and enhance operational efficiency. In these markets, international buyers are increasingly interested in advanced technologies such as gas springs, rubber injection molding, and silicone rubber molding, which offer improved performance and durability.

Emerging B2B tech trends include the integration of IoT-enabled vibration monitoring systems, which allow for real-time data collection and analysis. This capability not only enhances predictive maintenance strategies but also supports the optimization of vibration absorber applications. Additionally, the shift towards customized solutions tailored to specific industrial needs is reshaping sourcing strategies. International buyers are now prioritizing suppliers who can provide bespoke products that align with their operational requirements.

Moreover, the competitive landscape is evolving, with an influx of manufacturers leveraging digital platforms for sourcing and procurement. This trend is particularly relevant for buyers in emerging markets, as it facilitates access to a broader range of suppliers and products, thereby enhancing their ability to negotiate favorable terms.

Illustrative image related to vibration absorber

How Is Sustainability Influencing Sourcing in the Vibration Absorber Market?

Sustainability and ethical sourcing are becoming paramount in the vibration absorber sector, as businesses are increasingly aware of their environmental impact. The production processes for vibration absorbers often involve materials that can have significant ecological footprints. Consequently, B2B buyers are now placing greater emphasis on sourcing from suppliers that prioritize eco-friendly practices and sustainable materials.

The adoption of ‘green’ certifications, such as ISO 14001 and LEED, is gaining traction among manufacturers of vibration absorbers. These certifications not only demonstrate a commitment to reducing environmental impact but also provide buyers with assurance regarding the sustainability of their supply chains. Furthermore, many suppliers are investing in recyclable materials and processes that minimize waste and energy consumption, appealing to environmentally conscious buyers.

Ethical sourcing is also increasingly critical in establishing trust and long-term relationships. Buyers are encouraged to conduct thorough due diligence on their suppliers, ensuring that they adhere to ethical labor practices and environmental standards. This vigilance not only enhances brand reputation but also aligns with the growing consumer demand for sustainability in industrial operations.

What Is the Evolution of Vibration Absorber Technology?

The evolution of vibration absorber technology dates back several decades, with significant advancements driven by industrial demands for efficiency and noise reduction. Initially, simple rubber mounts and pads were the primary solutions, providing basic vibration isolation. Over time, the development of more sophisticated materials and engineering techniques has transformed the sector.

In the late 20th century, innovations such as gas springs and advanced elastomers began to emerge, offering enhanced performance characteristics. These advancements have paved the way for modern solutions that not only mitigate vibrations but also improve the overall lifespan of machinery and reduce maintenance costs. Today, with the integration of smart technologies and a focus on sustainability, the vibration absorber market continues to evolve, promising exciting opportunities for international B2B buyers.

This historical perspective highlights the importance of continuous innovation and adaptation to meet the changing needs of various industries, further emphasizing the significance of reliable partnerships in sourcing high-quality vibration absorbers.

Frequently Asked Questions (FAQs) for B2B Buyers of vibration absorber

-

How do I choose the right vibration absorber for my application?

Selecting the appropriate vibration absorber depends on several factors, including the type of machinery, the frequency and amplitude of vibrations, and the specific application (e.g., HVAC systems, industrial machinery). Assess the operating conditions, such as pressure ratings and material compatibility, to ensure the absorber can handle the demands of your system. Consulting with suppliers about the specific requirements and potential customizations can help you find the most effective solution. -

What types of vibration absorbers are available in the market?

Vibration absorbers come in various forms, including rubber, metal, and gas springs. Rubber vibration absorbers are commonly used in HVAC applications due to their excellent damping properties. Metal absorbers, like those made from stainless steel, are preferred in high-pressure environments. Gas springs provide controlled motion and are often utilized in lifting and support applications. Understanding the pros and cons of each type will help you make an informed decision. -

What factors should I consider when vetting a supplier for vibration absorbers?

When evaluating suppliers, consider their manufacturing capabilities, quality certifications, and industry experience. Look for suppliers with a proven track record in your specific application area. Request samples and technical documentation to assess product quality. Additionally, check customer reviews and testimonials to gauge reliability and service levels. Establish clear communication to discuss your needs and expectations, which is crucial for successful partnerships. -

What is the minimum order quantity (MOQ) for vibration absorbers?

Minimum order quantities can vary significantly between suppliers and depend on the type of vibration absorber being ordered. Some manufacturers may have an MOQ of a few units for standard products, while custom or specialized absorbers may require larger orders to justify production costs. It’s advisable to discuss your requirements directly with suppliers to understand their MOQ policies and negotiate terms that align with your purchasing strategy. -

What are the payment terms typically offered by suppliers for vibration absorbers?

Payment terms can vary widely among suppliers and may include options like advance payments, net 30, or net 60 days. Some suppliers might offer discounts for early payments or bulk orders. It’s essential to clarify these terms before placing an order, especially in international transactions, where currency fluctuations and banking fees can impact overall costs. Establishing a mutually beneficial payment arrangement can foster a stronger supplier relationship. -

How can I ensure quality assurance when sourcing vibration absorbers?

To ensure quality, request documentation such as certifications, test reports, and manufacturing processes from your suppliers. Many manufacturers conduct routine quality checks and provide traceability for their products. Additionally, consider visiting the supplier’s facility or using third-party inspection services before shipment. Regular communication regarding quality expectations and adherence to industry standards can help mitigate risks associated with product performance. -

What logistics considerations should I keep in mind when importing vibration absorbers?

Logistics for importing vibration absorbers include evaluating shipping options, customs regulations, and import duties. Work with suppliers who have experience in international shipping to streamline the process. Ensure you have all necessary documentation, such as commercial invoices and certificates of origin, to avoid customs delays. Consider using freight forwarders to manage logistics efficiently, especially if you are ordering large quantities or specialized products. -

Can vibration absorbers be customized for specific applications?

Yes, many manufacturers offer customization options for vibration absorbers to meet specific application requirements. Customizations can include variations in size, material, and design features to optimize performance for unique operational conditions. Discuss your needs with suppliers early in the sourcing process to explore available options and ensure that the final product aligns with your application requirements. Custom solutions can enhance efficiency and prolong the lifespan of your machinery.

Top 8 Vibration Absorber Manufacturers & Suppliers List

1. IQS Directory – Vibration Absorbers

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Vibration absorbers are spring-mass systems designed to minimize or eliminate vibrations in systems affected by harmonic forces, such as engines, motors, and conveyors. They create ‘anti-resonance’ to counteract unwanted oscillations. Key components include rubber mounts, springs, pads, and hydraulic systems. Rubber is a preferred material due to its elasticity, durability, and resistance to high …

2. Packless – Vibration Absorbers

Domain: packless.com

Registered: 1997 (28 years)

Introduction: Packless vibration absorbers are designed for installation in the suction and discharge lines of air conditioning and refrigeration systems to dampen the transmission of compressor induced vibration. They are recognized under the component programs of Underwriter’s Laboratories for application on both refrigerant suction and discharge lines and are compatible with all CO2, HC, HFO, HFC, HCFC, and …

3. URI – Vibration Absorbers

Domain: uri.com

Registered: 1995 (30 years)

Introduction: This company, URI – Vibration Absorbers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Castel – Vibration Absorbers

Domain: castel.it

Registered: 1999 (26 years)

Introduction: Vibration absorbers are designed for commercial refrigerating systems and civil/industrial air conditioning systems to eliminate the transmission of compressor vibrations to refrigerating system pipes. They feature TIG-welded unions for resistance to overheating during installation. These absorbers can be installed on both the inlet and outlet lines, near the compressor. The product line includes …

5. Doucette Industries – Vibration Absorbers

Domain: doucetteindustries.com

Registered: 1996 (29 years)

Introduction: This company, Doucette Industries – Vibration Absorbers, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Mars Delivers – Vibration Isolators

Domain: marsdelivers.com

Registered: 2011 (14 years)

Introduction: This company, Mars Delivers – Vibration Isolators, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. VibraSystems – Machinery Vibration Dampers

Domain: vibrasystems.com

Registered: 1998 (27 years)

Introduction: Machinery Vibration Isolators/Dampers: VSCM – Engine/ Motor/ Marine Vibration Dampers, SML Heavy Duty Vibration Dampers, FMD – Fan/Pump/ Compressor Vibration Dampers, LF – Fan/Pump/ Compressor Vibration Dampers, VTM Heavy Duty Vibration Dampers, FSM/SM Channel & Sandwich Vibration Dampers, CRS/CRSL – Antivibration Mounts, NVS – Universal Antivibration Levelers, VM – Universal Antivibration Leveler…

8. ScienceDirect – Dynamic Vibration Absorber

Domain: sciencedirect.com

Registered: 1997 (28 years)

Introduction: A vibration absorber is a device that controls the vibration of a mass by adding an extra spring-mass element to a system, converting a single-degree-of-freedom (DOF) machine into a two-DOF vibration system. It minimizes the vibration experienced by the machine. The dynamic vibration absorber is a tuned spring-mass system that reduces or eliminates vibration of a harmonically excited system. The w…

Strategic Sourcing Conclusion and Outlook for vibration absorber

In navigating the complexities of vibration absorber sourcing, B2B buyers must prioritize strategic partnerships that enhance product quality and reliability. By leveraging advanced manufacturing techniques such as rubber injection molding and stainless steel construction, businesses can ensure the durability and efficiency of vibration absorbers in various applications, from HVAC systems to industrial machinery. Understanding the specifications—such as burst pressure and compatibility with refrigerants—will empower buyers to make informed decisions that meet their operational needs.

Strategic sourcing not only streamlines procurement processes but also fosters relationships with suppliers who can offer customization and technical support tailored to specific market demands. As global markets evolve, particularly in regions like Africa, South America, the Middle East, and Europe, the ability to source high-quality vibration absorbers will be crucial in enhancing operational efficiency and reducing downtime.

Looking ahead, international buyers are encouraged to engage with manufacturers who prioritize innovation and customer-centric solutions. By doing so, they can position themselves for growth in an increasingly competitive landscape, ensuring their operations remain resilient and responsive to future challenges.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.