A Deep Dive into V6 Engine For Sale Solution

Introduction: Navigating the Global Market for v6 engine for sale

In the dynamic landscape of global commerce, sourcing the right V6 engine for sale presents a unique set of challenges for B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. The complexity of this market—spanning various engine types, applications, and specifications—can make informed purchasing decisions daunting. This guide aims to demystify the process by offering comprehensive insights into the diverse range of V6 engines available, their applications in different industries, and critical factors to consider when selecting suppliers.

From understanding the nuances of engine specifications to evaluating supplier credibility, this guide equips international buyers with the knowledge necessary to make sound investments. It covers essential topics such as engine types—including remanufactured and crate engines—key performance metrics, and price ranges, allowing buyers to navigate the market with confidence. Furthermore, practical advice on vetting suppliers ensures that buyers can establish reliable partnerships that meet their operational needs.

By addressing common concerns and providing actionable insights, this guide empowers B2B buyers to not only source the right V6 engines but also to optimize their procurement strategies. Whether you are in Germany, Brazil, or elsewhere, understanding the global market for V6 engines will enhance your purchasing decisions and drive your business success.

Understanding v6 engine for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Crate V6 Engines | Pre-assembled, ready for installation, often remanufactured | Automotive repair, fleet maintenance | Pros: Quick installation, reliability. Cons: Limited customization options. |

| Marine V6 Engines | Designed for marine applications, corrosion-resistant materials | Boat manufacturers, marine repair shops | Pros: Durability in harsh environments. Cons: Higher cost due to specialized features. |

| Performance V6 Engines | Enhanced horsepower and torque, aftermarket modifications | Racing teams, performance upgrades | Pros: Increased performance, competitive edge. Cons: Potential for higher maintenance. |

| Industrial V6 Engines | Built for heavy-duty applications, robust construction | Construction, agriculture, manufacturing | Pros: High durability, power for demanding tasks. Cons: Heavier and less fuel-efficient. |

| Eco-friendly V6 Engines | Designed for improved fuel efficiency and lower emissions | Eco-conscious businesses, urban fleets | Pros: Cost savings on fuel, regulatory compliance. Cons: May sacrifice some power. |

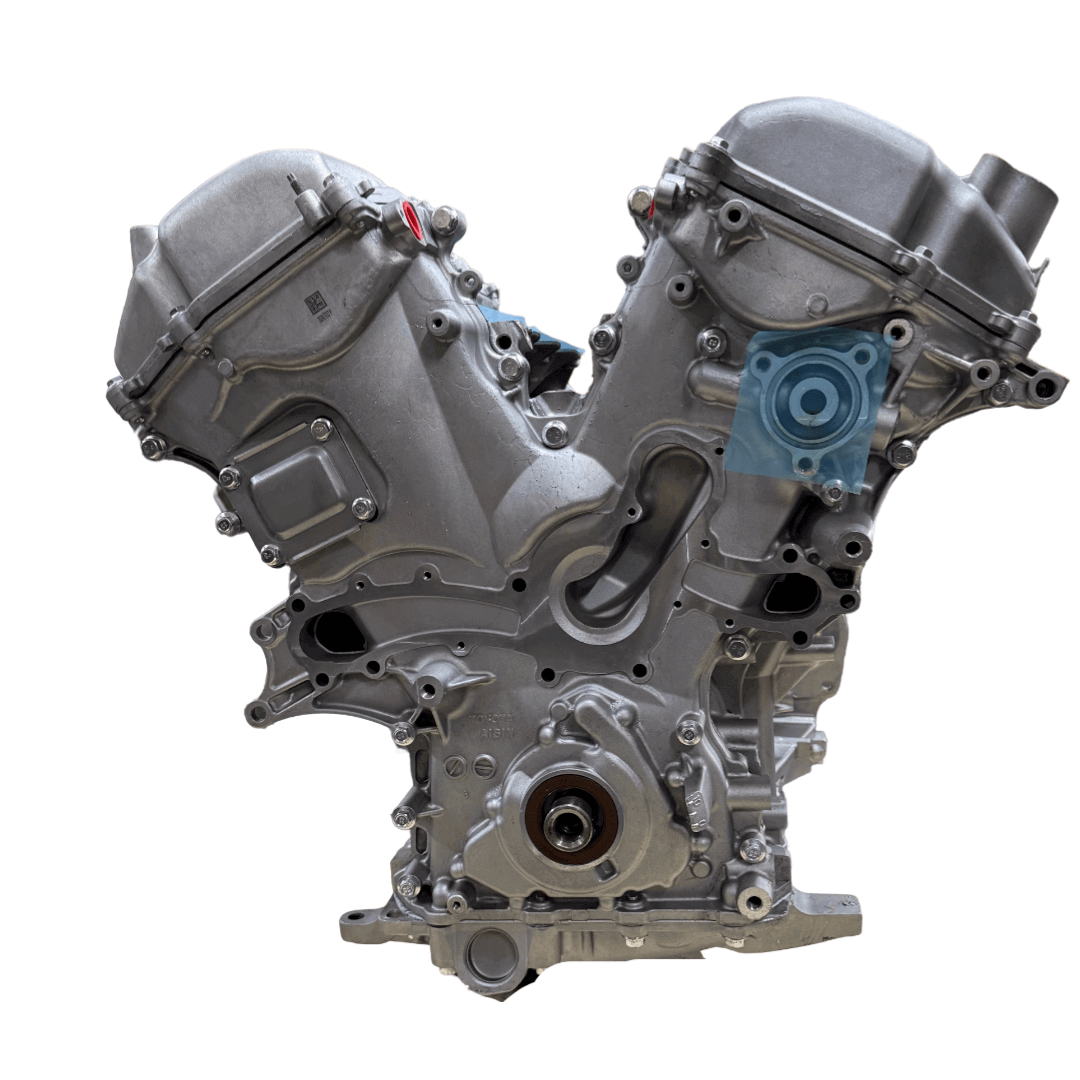

What Are the Key Characteristics of Crate V6 Engines?

Crate V6 engines are pre-assembled power units that are ready for immediate installation, making them ideal for automotive repair shops and fleet maintenance providers. Typically remanufactured, these engines offer a reliable solution for businesses needing to replace or upgrade their vehicle engines quickly. B2B buyers should consider factors such as compatibility with existing vehicles and warranty options, as these can significantly affect overall satisfaction and long-term performance.

How Do Marine V6 Engines Differ from Other Types?

Marine V6 engines are specifically engineered for use in boats and watercraft, featuring corrosion-resistant materials to withstand harsh marine environments. They cater primarily to boat manufacturers and marine repair shops. When purchasing, buyers should evaluate engine specifications, including power output and fuel efficiency, as these factors can impact operational costs and performance on the water.

What Advantages Do Performance V6 Engines Offer for B2B Buyers?

Performance V6 engines are designed for enhanced horsepower and torque, often featuring aftermarket modifications that appeal to racing teams and businesses focused on performance upgrades. While these engines provide a competitive edge, buyers must consider the potential for higher maintenance costs and the need for specialized knowledge in installation and tuning. Assessing the specific performance requirements and expected usage scenarios will help in making an informed purchase.

What Makes Industrial V6 Engines Suitable for Heavy-Duty Applications?

Industrial V6 engines are built to endure heavy-duty applications, making them suitable for construction, agriculture, and manufacturing sectors. Their robust construction ensures high durability and reliability under demanding conditions. B2B buyers should prioritize specifications related to power output and fuel efficiency, as these can influence operational effectiveness and costs in industrial settings.

Why Consider Eco-friendly V6 Engines for Urban Fleets?

Eco-friendly V6 engines focus on improved fuel efficiency and reduced emissions, making them an attractive option for eco-conscious businesses and urban fleets. These engines can lead to significant cost savings on fuel and help companies comply with environmental regulations. However, buyers should be aware that these engines may offer slightly reduced power compared to traditional V6 engines, necessitating a careful assessment of performance needs relative to sustainability goals.

Key Industrial Applications of v6 engine for sale

| Industry/Sector | Specific Application of v6 engine for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Replacement engines for mid-sized vehicles | Enhances vehicle reliability and performance, reducing downtime. | Ensure compatibility with existing models and compliance with local regulations. |

| Marine | Powering recreational and commercial boats | Provides efficient power-to-weight ratio, improving fuel efficiency. | Consider marine-grade components to withstand harsh environments. |

| Construction Equipment | Engines for heavy machinery like excavators | Increases operational efficiency and reduces maintenance costs. | Look for engines with robust support and warranty options. |

| Agricultural Machinery | Engines for tractors and harvesters | Enhances productivity in farming operations, ensuring consistent power. | Verify the engine’s adaptability to various agricultural applications. |

| Power Generation | Backup generators for industrial applications | Ensures continuous power supply, enhancing operational reliability. | Evaluate engine fuel type and efficiency based on regional availability. |

How is the V6 Engine Used in Automotive Manufacturing?

In the automotive sector, V6 engines are frequently utilized as replacement engines for mid-sized vehicles. Their design provides a balanced combination of power and efficiency, which is essential for both passenger cars and light trucks. International buyers, especially from regions like Africa and South America, may face challenges related to engine compatibility with local vehicle models. Therefore, sourcing engines that meet specific emission standards and are readily available for replacement parts is crucial for minimizing vehicle downtime.

What Role Does the V6 Engine Play in Marine Applications?

In the marine industry, V6 engines are commonly employed to power recreational and commercial boats. Their compact size and efficient power-to-weight ratio make them ideal for various marine applications, from fishing vessels to luxury yachts. For buyers in the Middle East and Europe, ensuring that the engine is marine-grade is vital, as it must withstand the corrosive effects of saltwater and provide reliable performance under varying conditions. Additionally, fuel efficiency is a significant concern for businesses operating in this sector, making it essential to consider engines that optimize fuel consumption.

How is the V6 Engine Beneficial for Construction Equipment?

V6 engines are also integral to heavy machinery in construction, such as excavators and bulldozers. These engines offer the necessary torque and power to handle demanding tasks, which is critical for enhancing operational efficiency on job sites. Buyers from Europe and Africa should focus on sourcing engines that come with strong support networks and warranties, as these can significantly reduce long-term maintenance costs. Furthermore, the ability to adapt to various machinery types is a key consideration in the sourcing process.

Why is the V6 Engine Important for Agricultural Machinery?

In agriculture, V6 engines power tractors and harvesters, providing the necessary strength to perform heavy-duty tasks. The reliability and efficiency of these engines can directly impact farming productivity, ensuring that operations run smoothly during critical planting and harvesting seasons. Buyers in South America may require engines that are not only powerful but also capable of operating in diverse environmental conditions. Therefore, sourcing engines that offer adaptability and compatibility with existing agricultural machinery is essential for maximizing productivity.

How Does the V6 Engine Contribute to Power Generation?

Finally, V6 engines are utilized in backup generators for industrial applications, providing a reliable power source during outages. This is particularly important for businesses that rely on continuous operations, such as manufacturing plants. For international buyers, evaluating the fuel type and efficiency of the engine is crucial, as these factors can influence operational costs. Additionally, ensuring that the engine complies with local energy regulations can help avoid potential legal issues and enhance long-term sustainability.

3 Common User Pain Points for ‘v6 engine for sale’ & Their Solutions

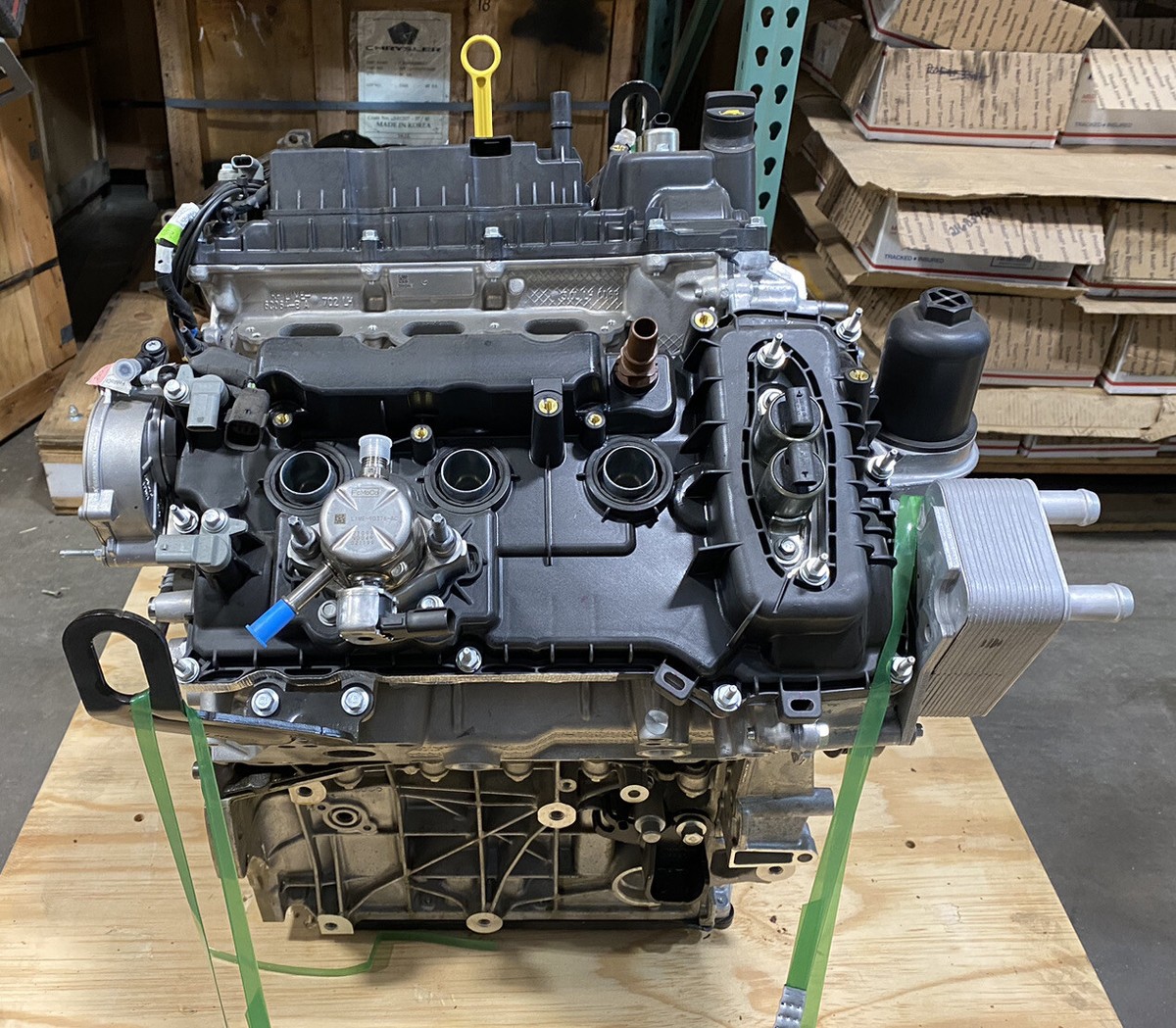

Scenario 1: Sourcing Quality V6 Engines for Diverse Applications

The Problem: Many B2B buyers, especially those in regions like Africa and South America, face significant challenges when sourcing quality V6 engines that meet specific performance and durability standards. These buyers often encounter difficulties in verifying the reliability of suppliers and the authenticity of the engines, leading to potential operational disruptions and increased costs due to poor engine performance or failures.

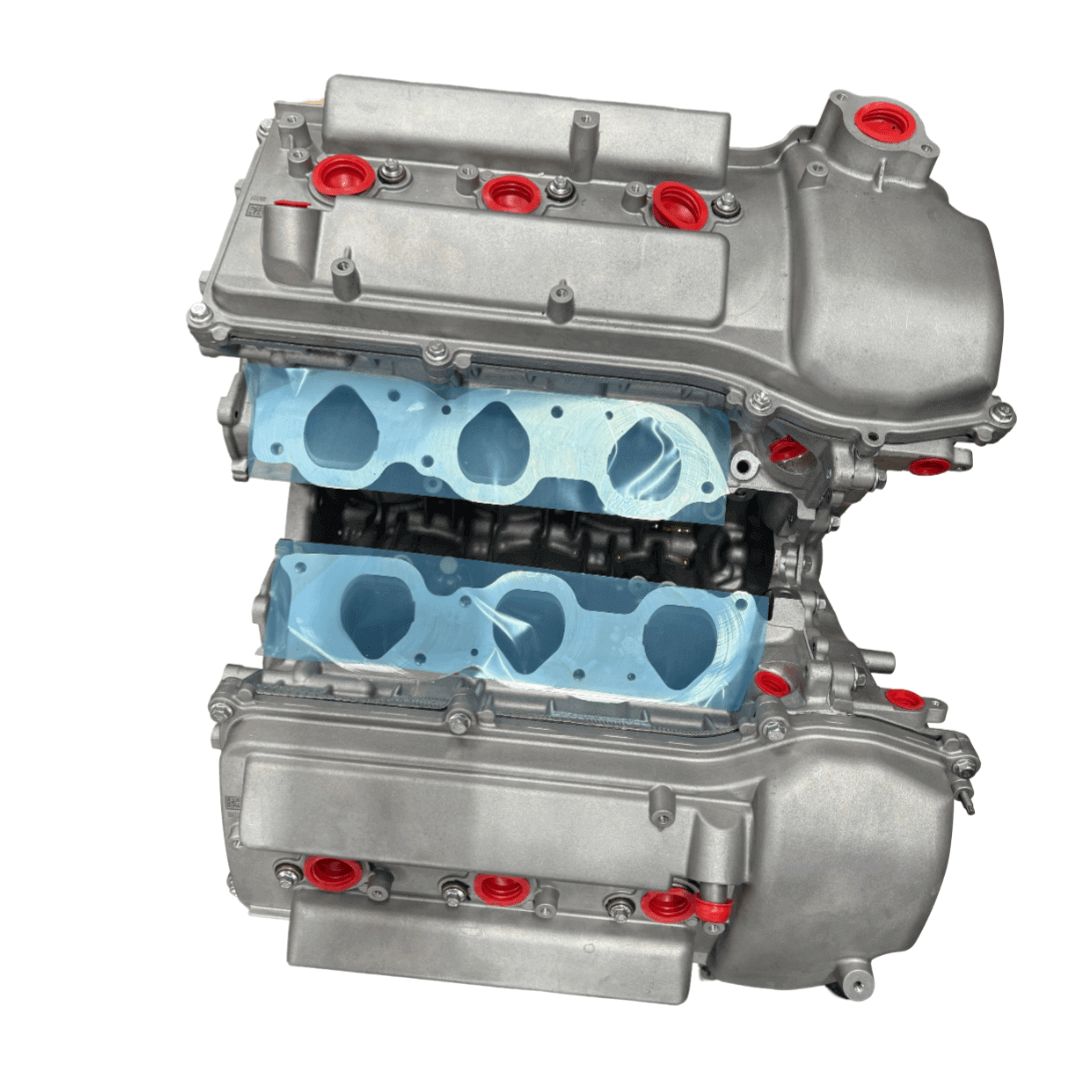

Illustrative image related to v6 engine for sale

The Solution: To effectively source quality V6 engines, buyers should prioritize partnerships with reputable suppliers who have established credibility in the market. Conducting thorough due diligence is crucial; this includes checking supplier certifications, customer reviews, and performance guarantees. It is advisable to request detailed specifications, including engine displacement, material composition, and assembly quality, to ensure the product aligns with the buyer’s operational requirements. Additionally, buyers can leverage platforms that provide verified supplier ratings and feedback, allowing for informed decision-making. Engaging in direct communication with suppliers can also clarify any doubts regarding engine applications and performance expectations, ensuring that the selected engine is fit for purpose.

Scenario 2: Understanding Engine Specifications and Compatibility

The Problem: Another common pain point for B2B buyers is navigating the complex landscape of engine specifications and compatibility with existing vehicle or machinery systems. Buyers often struggle to match the right V6 engine with their specific applications, leading to mismatches that can incur additional costs and operational downtime.

The Solution: To address this challenge, buyers should invest time in understanding the critical specifications of V6 engines relevant to their needs, such as horsepower, torque ratings, and fuel efficiency. Utilizing detailed product catalogs and technical sheets from suppliers can provide vital information on compatibility with different vehicle models or industrial applications. Furthermore, buyers should engage with technical experts or automotive engineers who can offer insights into the best engine choices based on intended use cases. Creating a checklist of required specifications before making a purchase can streamline the decision-making process and help avoid costly errors associated with incompatible engine selections.

Scenario 3: Managing Logistics and Shipping Challenges

The Problem: International B2B buyers often face logistical hurdles when ordering V6 engines, particularly concerning shipping times, costs, and customs regulations. These challenges can lead to delays in receiving engines, impacting project timelines and potentially causing financial losses for businesses reliant on timely engine availability.

Illustrative image related to v6 engine for sale

The Solution: To effectively manage logistics, buyers should work closely with suppliers who offer comprehensive shipping solutions, including clear timelines and transparent pricing structures. It is beneficial to inquire about available shipping methods and the expected delivery timeframes to align with project schedules. Buyers can also consider working with logistics providers who specialize in international shipping of automotive parts, as they can navigate customs regulations and ensure compliance with local import requirements. Establishing a buffer period in project planning can help mitigate the impact of any unforeseen shipping delays. Additionally, utilizing tracking systems can provide real-time updates on shipment status, allowing buyers to adjust their operations proactively if delays occur.

Strategic Material Selection Guide for v6 engine for sale

What Are the Key Materials Used in V6 Engine Manufacturing?

In the production of V6 engines, the choice of materials significantly influences performance, durability, and cost. Below, we analyze four common materials used in V6 engine components, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Cast Iron Perform in V6 Engine Applications?

Cast iron is a traditional choice for engine blocks and cylinder heads due to its excellent wear resistance and ability to withstand high temperatures. It can typically handle temperatures up to 600°F (315°C) and pressures of about 4000 psi.

Pros: Cast iron is highly durable, has good vibration damping properties, and is relatively inexpensive compared to other materials. Its manufacturing process is well-established, making it easier to source and produce.

Cons: However, cast iron is heavy, which can negatively impact engine weight and overall vehicle performance. Additionally, it is prone to rust if not properly coated or maintained.

Illustrative image related to v6 engine for sale

Impact on Application: Cast iron is compatible with a wide range of engine oils and fuels, making it versatile for various applications. However, its weight may be a concern for buyers focused on performance.

Considerations for International Buyers: Buyers from regions like Africa and South America should consider local climate conditions, as cast iron may require more maintenance in humid environments. Compliance with ASTM standards is essential for ensuring quality.

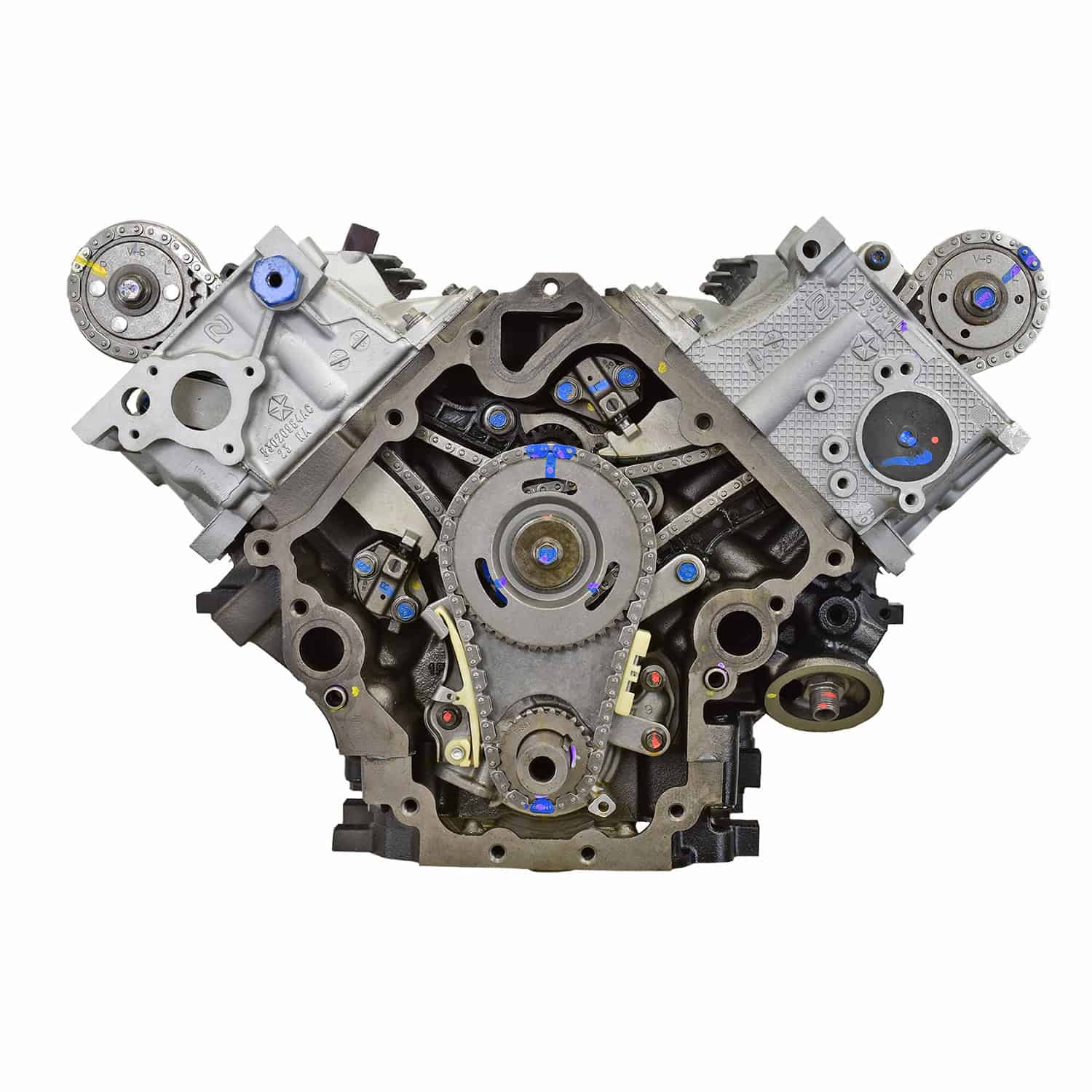

What Advantages Does Aluminum Offer in V6 Engine Manufacturing?

Aluminum is increasingly popular for engine components due to its lightweight nature and excellent thermal conductivity. It can withstand temperatures up to 500°F (260°C) and offers good corrosion resistance.

Pros: The primary advantage of aluminum is its reduced weight, which enhances fuel efficiency and performance. Additionally, aluminum engines heat up quickly, improving cold-start performance.

Illustrative image related to v6 engine for sale

Cons: The main disadvantage is that aluminum is generally more expensive than cast iron and can be less durable under extreme conditions. It may also require more complex manufacturing processes, which can increase production costs.

Impact on Application: Aluminum is suitable for high-performance applications, particularly in racing and sports vehicles. However, it may not be the best choice for heavy-duty applications where durability is paramount.

Considerations for International Buyers: Buyers in Europe, particularly Germany, may prefer aluminum engines for their performance benefits, while those in the Middle East may need to consider the effects of extreme heat on aluminum components.

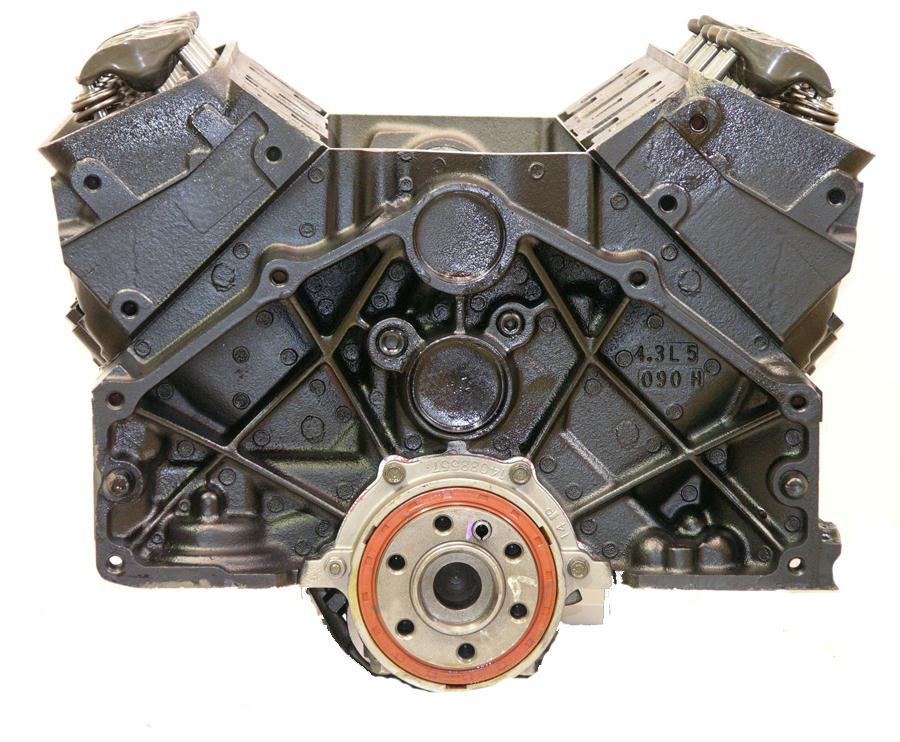

How Does Steel Compare as a Material for V6 Engine Components?

Steel is often used for crankshafts and connecting rods due to its high strength-to-weight ratio and resistance to fatigue. It can handle high temperatures and pressures, making it ideal for critical engine components.

Pros: Steel’s strength and durability make it suitable for high-performance applications, and it is generally less expensive than aluminum. It also offers good resistance to wear and deformation.

Illustrative image related to v6 engine for sale

Cons: The downside is that steel is heavier than aluminum, which can affect overall engine weight. Additionally, it may be more susceptible to corrosion if not properly treated.

Impact on Application: Steel components are essential for applications requiring high strength, such as in heavy-duty trucks or performance vehicles. However, the added weight could be a drawback for buyers focused on fuel efficiency.

Considerations for International Buyers: Compliance with international standards such as DIN and JIS is crucial for steel components. Buyers should also consider local availability and sourcing options.

Illustrative image related to v6 engine for sale

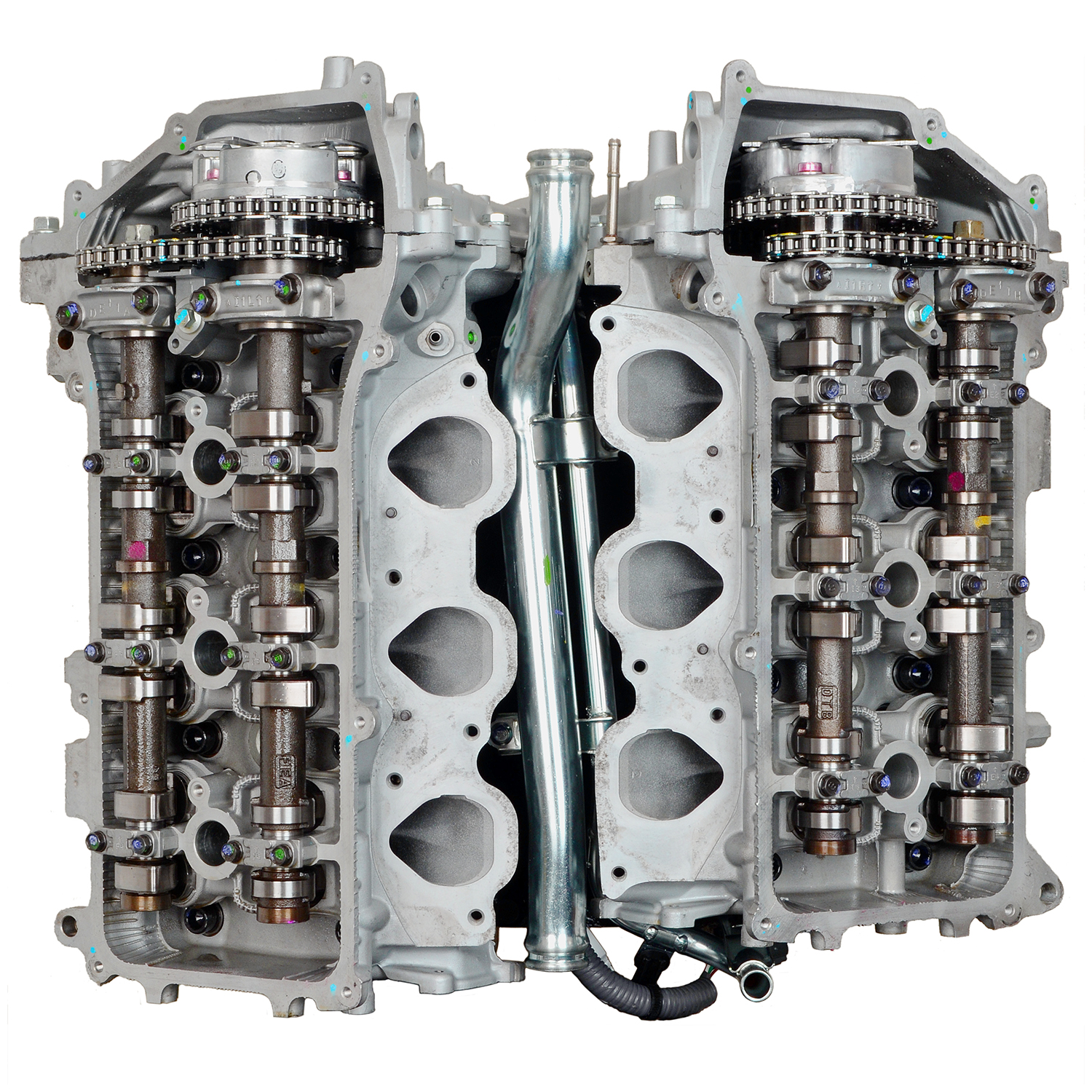

What Role Does Composite Material Play in V6 Engine Design?

Composite materials, including carbon-fiber-reinforced plastics, are emerging in engine design for specific components like intake manifolds and valve covers. They can withstand temperatures up to 400°F (204°C) and offer excellent corrosion resistance.

Pros: Composites are lightweight and can be molded into complex shapes, providing design flexibility. They also offer superior thermal insulation compared to metals.

Cons: The primary disadvantage is the higher cost and complexity of manufacturing. Additionally, composites may not be suitable for high-stress applications.

Impact on Application: Composites are ideal for applications where weight reduction is critical, such as in performance vehicles. However, they may not be appropriate for components that experience high mechanical loads.

Illustrative image related to v6 engine for sale

Considerations for International Buyers: Buyers should be aware of the varying standards for composites in different regions. Ensuring that materials meet local regulations is essential for compliance.

Summary Table of Material Selection for V6 Engines

| Material | Typical Use Case for v6 engine for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cast Iron | Engine blocks, cylinder heads | Excellent durability and wear resistance | Heavy and prone to rust | Low |

| Aluminum | Engine blocks, cylinder heads | Lightweight and good thermal conductivity | More expensive and less durable | Med |

| Steel | Crankshafts, connecting rods | High strength and durability | Heavier than aluminum | Low |

| Composite | Intake manifolds, valve covers | Lightweight and design flexibility | Higher cost and manufacturing complexity | High |

This guide provides a comprehensive overview of material selection for V6 engines, empowering international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for v6 engine for sale

What Are the Main Stages of Manufacturing a V6 Engine?

The manufacturing of a V6 engine involves several critical stages that ensure both performance and reliability. Understanding these stages can help B2B buyers make informed decisions when sourcing engines.

Material Preparation

The first step in the manufacturing process is material preparation, which involves selecting high-quality raw materials such as aluminum and cast iron. The choice of material is crucial, as it impacts the engine’s weight, durability, and thermal efficiency. Advanced material testing methods, such as spectrometry and tensile testing, are employed to verify that the materials meet the required specifications.

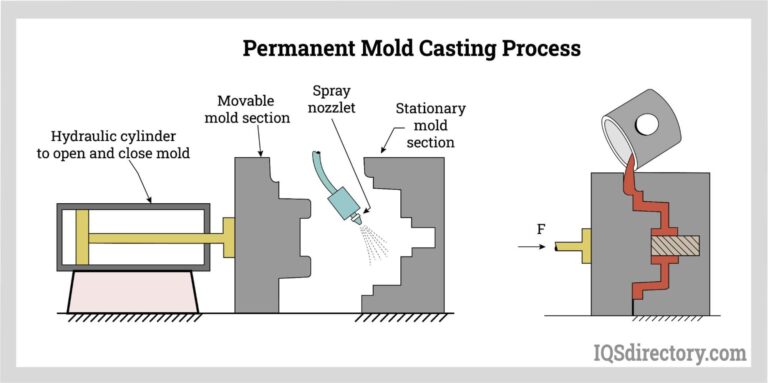

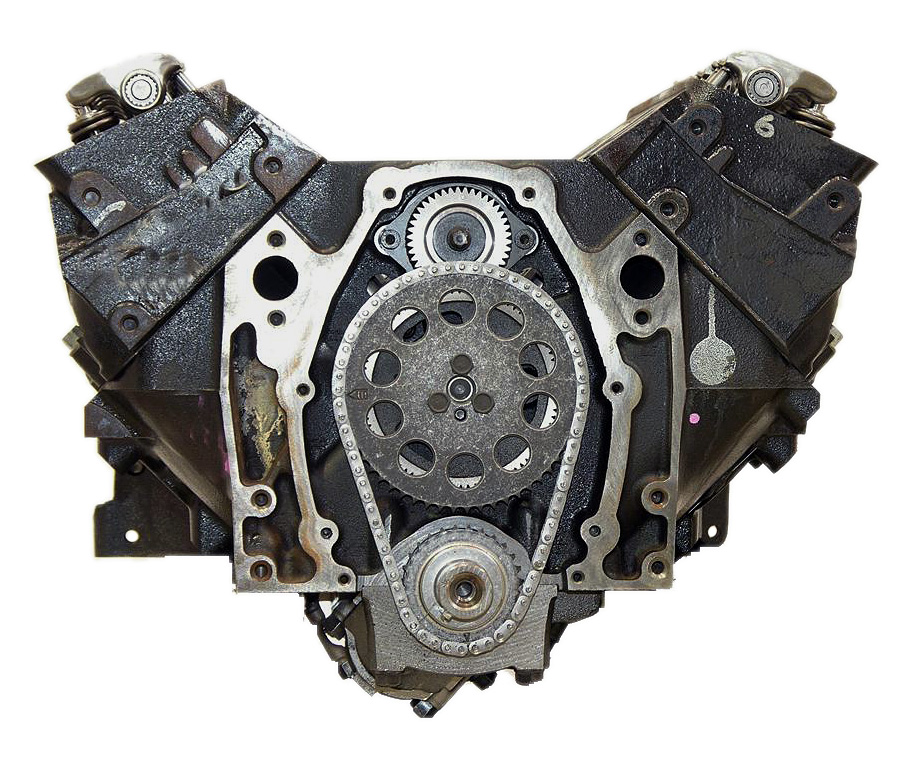

Forming Techniques Used in V6 Engine Production

Once the materials are prepared, they undergo various forming processes. Techniques such as casting, forging, and machining are commonly used:

Illustrative image related to v6 engine for sale

-

Casting: This technique involves pouring molten metal into a mold to create engine blocks and cylinder heads. It allows for complex shapes and is cost-effective for large production runs.

-

Forging: Used primarily for components that require high strength, such as crankshafts and connecting rods, forging shapes the material under pressure, enhancing its mechanical properties.

-

Machining: After forming, precision machining is performed to achieve exact tolerances on surfaces and dimensions. CNC (Computer Numerical Control) machines are often utilized for this purpose, ensuring high accuracy.

How Is V6 Engine Assembly Conducted?

The assembly stage is where individual components come together to form the complete engine. This process typically includes:

-

Component Inspection: Before assembly, all components undergo rigorous inspection to ensure they meet quality standards. This includes checking for dimensional accuracy and surface finishes.

-

Assembly Line Techniques: Modern assembly lines utilize automated systems alongside skilled labor to enhance efficiency. Each engine is assembled according to strict protocols, ensuring consistency across production.

-

Integration of Systems: During assembly, various systems, such as fuel injection, ignition, and lubrication, are integrated into the engine. This requires careful alignment and connection of components to ensure optimal performance.

What Quality Control Measures Are Essential for V6 Engines?

Quality control (QC) is a fundamental aspect of V6 engine manufacturing. It ensures that each engine meets international and industry-specific standards, providing reliability for B2B buyers.

What Are the International Standards for Quality Assurance in Engine Manufacturing?

Many manufacturers adhere to international standards such as ISO 9001, which outlines requirements for a quality management system. Compliance with these standards signifies that a manufacturer has implemented effective processes to enhance customer satisfaction and product quality. Additionally, for specific applications, engines may need to meet CE (Conformité Européenne) or API (American Petroleum Institute) standards, which indicate compliance with safety and performance regulations.

What QC Checkpoints Are Implemented During the Manufacturing Process?

Quality assurance involves multiple checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials and components upon arrival at the manufacturing facility to ensure they meet specified criteria.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted at various stages, such as after forming and before assembly. This helps identify any issues early in the process.

-

Final Quality Control (FQC): Once the engine is assembled, a final inspection is performed to verify overall quality. This may include performance testing and checks for leaks, noise, and emissions.

What Testing Methods Are Commonly Used for V6 Engines?

To ensure the functionality and safety of V6 engines, various testing methods are employed:

-

Performance Testing: Engines are subjected to dynamometer tests to assess power output, torque, and fuel efficiency under different operating conditions.

-

Durability Testing: Engines undergo extended testing cycles to evaluate their performance over time, simulating real-world conditions to identify potential failures.

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and X-ray inspection are used to detect internal defects without damaging the components.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For B2B buyers, especially those in regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control processes is crucial. Here are some effective strategies:

Illustrative image related to v6 engine for sale

-

Supplier Audits: Conducting regular audits of potential suppliers can provide insight into their manufacturing practices and quality management systems. This helps ensure they meet international standards.

-

Requesting Quality Reports: Buyers should request documentation of quality control processes, including inspection reports and compliance certifications. This transparency builds trust and allows for informed decision-making.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control measures. These inspections can be particularly beneficial for buyers entering new markets.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate specific quality control nuances that vary by region. For instance:

-

Regulatory Compliance: Buyers should be aware of the regulatory requirements in their region, such as emissions standards in Europe or safety regulations in South America. Non-compliance can lead to significant penalties.

-

Cultural Differences in Quality Perception: Quality expectations can vary significantly between cultures. Understanding these differences can help buyers communicate their requirements more effectively and avoid misunderstandings.

-

Logistical Considerations: The logistics of transporting engines across borders can introduce additional quality risks, such as damage during shipping. Buyers should work closely with suppliers to ensure proper packaging and handling.

In summary, understanding the manufacturing processes and quality assurance measures for V6 engines is vital for B2B buyers looking for reliable suppliers. By focusing on these aspects, buyers can make informed decisions that ensure they receive high-quality engines tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘v6 engine for sale’

This guide provides a structured approach for B2B buyers looking to procure V6 engines for sale, ensuring that you make informed decisions that align with your operational needs and budget. By following this checklist, you can streamline your sourcing process and mitigate risks associated with purchasing critical engine components.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential for ensuring that the V6 engine meets your specific requirements. Consider factors such as engine displacement, intended application (e.g., marine, automotive), and compatibility with existing systems. Documenting these specifications will help you communicate effectively with suppliers and avoid mismatches.

Illustrative image related to v6 engine for sale

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to identify reputable suppliers of V6 engines. Utilize industry directories, trade shows, and online marketplaces to compile a list of potential vendors. Focus on suppliers with experience in your target region, such as Africa, South America, the Middle East, and Europe, as they may better understand local regulations and logistics.

Step 3: Verify Supplier Certifications

Before entering negotiations, verify that potential suppliers hold relevant certifications and quality assurances. Look for certifications like ISO 9001 for quality management systems and any industry-specific certifications relevant to engine manufacturing. This ensures that the supplier adheres to industry standards and can deliver reliable products.

Step 4: Request Detailed Quotations

Once you have shortlisted suppliers, request detailed quotations that include pricing, lead times, and payment terms. Pay attention to the breakdown of costs, including shipping and handling fees, to avoid surprises later. Comparing multiple quotations will help you assess the market rate and make informed purchasing decisions.

Step 5: Evaluate Warranty and After-Sales Support

Understanding the warranty terms and after-sales support offered by the supplier is crucial. A robust warranty can protect your investment and mitigate risks associated with engine failures. Ensure you inquire about the duration of the warranty, coverage details, and the availability of technical support for installation and maintenance.

Illustrative image related to v6 engine for sale

Step 6: Conduct Reference Checks

Before finalizing any purchase, conduct reference checks with other businesses that have previously sourced engines from the suppliers you are considering. Ask about their experiences regarding product quality, delivery timelines, and customer service. This step can provide valuable insights into the reliability and reputation of the supplier.

Step 7: Finalize the Purchase Agreement

After thorough evaluation and due diligence, finalize your purchase agreement. Ensure that all terms, including specifications, pricing, delivery schedules, and warranty conditions, are clearly documented. This agreement serves as a binding contract and helps prevent disputes in the future.

By following this step-by-step checklist, you can navigate the complexities of sourcing V6 engines more effectively, ensuring that your procurement process is efficient and aligns with your business objectives.

Illustrative image related to v6 engine for sale

Comprehensive Cost and Pricing Analysis for v6 engine for sale Sourcing

What Are the Key Cost Components in Sourcing V6 Engines?

When sourcing V6 engines, understanding the cost structure is crucial for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margins.

Materials: The type of materials used, such as aluminum or cast iron for engine blocks and cylinder heads, significantly impacts the overall cost. Higher quality materials may lead to better performance and longevity but will also increase the initial purchase price.

Labor: Labor costs vary depending on the manufacturing location. Countries with lower labor costs may offer more competitive pricing, but this can sometimes compromise quality. It’s essential to balance cost savings with the assurance of skilled craftsmanship.

Illustrative image related to v6 engine for sale

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities and maintenance. Efficient manufacturing processes can reduce overhead costs, benefiting buyers in terms of price competitiveness.

Tooling: The investment in tooling is necessary for producing high-quality engines. Custom tooling for specialized designs may raise costs initially but can lead to better fit and performance, reducing long-term expenses.

Quality Control (QC): Implementing stringent QC processes ensures that engines meet specifications and standards. While this may add to upfront costs, it can save buyers from future warranty claims and repairs.

Logistics: Transporting engines internationally incurs costs that can vary widely based on distance, shipping method, and freight terms. Incoterms play a crucial role here, as they define who is responsible for shipping, insurance, and tariffs, directly affecting the total cost.

Margin: Suppliers typically add a profit margin to cover their risks and expenses. Understanding the supplier’s pricing strategy can provide insights into potential negotiation points.

How Do Price Influencers Affect V6 Engine Costs?

Several factors can influence the pricing of V6 engines in the international market, making it essential for buyers to conduct thorough research.

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for bulk purchases. Understanding MOQ policies can help buyers negotiate better pricing, especially when planning for long-term projects.

Specifications and Customization: Custom-engineered engines with specific features may command higher prices. Buyers should assess whether these customizations are necessary or if standard options suffice for their applications.

Quality and Certifications: Engines that meet international standards or possess certifications will typically be priced higher. However, these certifications can offer peace of mind regarding performance and reliability, making them a worthwhile investment.

Illustrative image related to v6 engine for sale

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers with a track record of quality may charge more but offer superior service and product assurance.

Incoterms: The choice of Incoterms can significantly impact the final price. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) dictate who bears the costs and risks during shipping, influencing the overall expenditure.

What Negotiation Strategies Can Buyers Employ?

Effective negotiation strategies are vital for international buyers to ensure cost-efficiency. Here are some actionable tips:

-

Leverage Volume: Buyers should consider ordering in larger quantities to negotiate better prices. This can also help in securing favorable payment terms.

-

Explore Alternatives: If a particular supplier’s prices are too high, it’s beneficial to explore multiple suppliers. This competitive analysis can provide leverage during negotiations.

-

Focus on Total Cost of Ownership (TCO): Emphasizing TCO rather than just the initial purchase price can help justify higher-quality options. Consider factors like maintenance costs, expected lifespan, and efficiency.

-

Understand Pricing Nuances: International buyers should be aware of currency fluctuations, import tariffs, and local market conditions, which can affect pricing.

-

Build Long-Term Relationships: Establishing a strong relationship with suppliers can lead to better pricing and terms over time. Consistent communication fosters trust and can yield future discounts.

Conclusion

While the initial price of V6 engines is important, buyers should consider the comprehensive cost structure and various influencing factors when sourcing. By understanding these components and employing effective negotiation strategies, international B2B buyers can make informed decisions that balance cost and quality, ultimately leading to more successful procurement outcomes.

Alternatives Analysis: Comparing v6 engine for sale With Other Solutions

Exploring Alternatives to V6 Engines for Sale

In the competitive landscape of engine procurement, understanding alternative solutions to the V6 engine can be crucial for B2B buyers. Companies must evaluate various options based on performance, cost, maintenance, and suitability for their specific applications. This section compares the V6 engine for sale with two alternative solutions: the inline-four (I4) engine and the turbocharged V8 engine.

Illustrative image related to v6 engine for sale

| Comparison Aspect | V6 Engine For Sale | Inline-Four Engine | Turbocharged V8 Engine |

|---|---|---|---|

| Performance | Moderate power and torque suitable for mid-sized vehicles | Lower power but better fuel efficiency | High power and torque, suitable for heavy-duty applications |

| Cost | $2,000 – $5,000 | $1,500 – $3,500 | $5,000 – $10,000 |

| Ease of Implementation | Generally straightforward installation | Easy installation; common in many vehicles | More complex installation, may require modifications |

| Maintenance | Moderate; parts availability can vary | Low; parts are widely available | High; specialized maintenance required |

| Best Use Case | Versatile for SUVs and light trucks | Ideal for compact cars and efficiency-focused applications | Best for performance vehicles and heavy-duty applications |

What Are the Benefits and Drawbacks of Using an Inline-Four Engine?

The inline-four engine is a popular alternative due to its compact size and efficiency. It typically offers better fuel economy than the V6, making it an excellent choice for companies focused on sustainability and cost savings. However, while it’s easier to install and maintain, its power output is significantly lower, which may not meet the demands of larger vehicles or heavy loads. This trade-off makes it best suited for smaller, lighter vehicles where efficiency is prioritized over raw power.

How Does a Turbocharged V8 Engine Compare to the V6 Engine?

The turbocharged V8 engine stands out for its impressive power and torque, making it ideal for heavy-duty applications such as trucks and performance vehicles. Its ability to deliver high performance can significantly enhance vehicle capabilities, especially in demanding conditions. However, the initial cost is higher, and installation can be more complex, requiring modifications to the vehicle. Additionally, maintenance costs can be significant due to the engine’s complexity, making it less attractive for companies with tighter budgets.

Choosing the Right Engine Solution for Your Business Needs

When considering the right engine solution, B2B buyers should assess their operational requirements and budget constraints. The V6 engine for sale provides a balanced option for those needing moderate power and versatility. In contrast, businesses prioritizing fuel efficiency may find the inline-four engine more suitable, while those requiring high performance for demanding tasks should consider the turbocharged V8.

Illustrative image related to v6 engine for sale

Ultimately, the decision should align with the specific use case, operational demands, and long-term maintenance capabilities of the business. By thoroughly evaluating these factors, companies can make informed decisions that enhance their operational efficiency and meet their performance needs.

Essential Technical Properties and Trade Terminology for v6 engine for sale

What Are the Key Technical Properties of a V6 Engine for Sale?

Understanding the technical specifications of a V6 engine is crucial for B2B buyers to ensure they select the right product for their needs. Here are some essential properties that should be considered:

-

Engine Displacement: This refers to the total volume of all the cylinders in the engine, typically measured in liters (L) or cubic centimeters (cc). A higher displacement often indicates a more powerful engine, which can lead to better performance in applications such as heavy-duty vehicles or machinery. Buyers should match the engine displacement to their operational requirements.

-

Material Composition: The materials used in the construction of engine components—such as the engine block and cylinder heads—affect durability and performance. Common materials include cast iron and aluminum. Cast iron is known for its strength and thermal stability, while aluminum offers a lighter weight and better heat dissipation. Selecting the appropriate material can impact maintenance costs and engine longevity.

-

Camshaft Configuration: The camshaft design (e.g., overhead cam or pushrod) influences engine efficiency and performance characteristics. Overhead cam engines generally provide better performance due to more precise control over valve timing. Understanding the camshaft configuration helps buyers assess the engine’s suitability for their applications.

-

Engine Balance: This specification indicates whether the engine is internally or externally balanced, impacting vibrations and overall smoothness of operation. Internally balanced engines tend to provide a smoother performance, making them suitable for high-end vehicles or machinery requiring minimal vibration.

-

Horsepower and Torque Ratings: These metrics measure an engine’s power output and its ability to perform work. High horsepower ratings are essential for speed and acceleration, while torque is crucial for hauling and towing capabilities. Buyers should consider their specific power requirements based on the intended use of the engine.

-

Fuel Type Compatibility: Different V6 engines may require specific fuel types, such as gasoline, diesel, or alternative fuels. Knowing the fuel compatibility is essential for ensuring that the engine operates efficiently and meets regulatory standards in various regions.

What Are Common Trade Terms Related to V6 Engines?

In the B2B context, familiarity with industry jargon can facilitate smoother transactions and negotiations. Here are several important terms to know:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM standards is vital for ensuring the compatibility and quality of engine components.

-

MOQ (Minimum Order Quantity): This specifies the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers plan their procurement strategies and manage inventory levels effectively.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to invite them to bid on the supply of goods or services. It outlines the requirements and specifications needed, allowing buyers to compare offers from multiple vendors.

-

Incoterms (International Commercial Terms): These are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms can help buyers negotiate shipping and delivery terms effectively.

-

Lead Time: This term refers to the amount of time it takes from placing an order to receiving the goods. Understanding lead times is essential for supply chain management and ensures that projects stay on schedule.

-

Warranty Terms: This encompasses the conditions under which a manufacturer will repair or replace defective parts or products. Buyers should always clarify warranty terms to mitigate risks associated with potential failures after purchase.

Familiarity with these properties and terms will empower B2B buyers to make informed decisions when purchasing V6 engines, ensuring they choose the right products for their operational needs.

Illustrative image related to v6 engine for sale

Navigating Market Dynamics and Sourcing Trends in the v6 engine for sale Sector

What Are the Current Market Dynamics and Key Trends Influencing the v6 Engine for Sale Sector?

The v6 engine market is experiencing notable shifts driven by various global factors. One of the primary drivers is the increasing demand for fuel-efficient vehicles, particularly in regions such as Africa and South America, where fuel prices can significantly impact operating costs. Additionally, the rise in electric vehicle (EV) technologies is prompting manufacturers to innovate, leading to hybrid models that incorporate v6 engines for better performance and efficiency.

Emerging trends in B2B tech are reshaping sourcing strategies, particularly through digital platforms that facilitate cross-border transactions. Buyers from Europe, especially Germany, are increasingly leveraging online marketplaces to access a broader range of v6 engines, allowing for better price comparisons and supplier evaluations. Moreover, advancements in supply chain technology, including blockchain and IoT, are enhancing transparency and traceability in sourcing, which is crucial for B2B buyers concerned about quality and origin.

As international buyers navigate these market dynamics, they must also be aware of shifting regulations and compliance standards, particularly related to emissions. Countries in the Middle East are tightening regulations on vehicle emissions, prompting buyers to source engines that not only meet local standards but are also aligned with global sustainability goals.

Illustrative image related to v6 engine for sale

How Can Sustainability and Ethical Sourcing Influence the v6 Engine Supply Chain?

Sustainability is becoming increasingly vital in the v6 engine supply chain, with buyers prioritizing suppliers who demonstrate environmental responsibility. The production and disposal of traditional engines have significant environmental impacts, leading to a growing focus on ethical sourcing practices. B2B buyers should seek partners who utilize recycled materials and sustainable manufacturing processes.

Certifications such as ISO 14001, which focuses on effective environmental management systems, can serve as key indicators of a supplier’s commitment to sustainability. Additionally, materials that reduce the carbon footprint, such as lightweight alloys or biodegradable components, are gaining traction. Buyers who prioritize these ‘green’ certifications not only contribute to environmental preservation but also enhance their brand reputation in an increasingly eco-conscious market.

In regions with stringent environmental regulations, such as Europe, sourcing from suppliers committed to sustainability can ensure compliance and reduce the risk of penalties. This proactive approach not only benefits the environment but also positions companies favorably in the eyes of consumers and stakeholders.

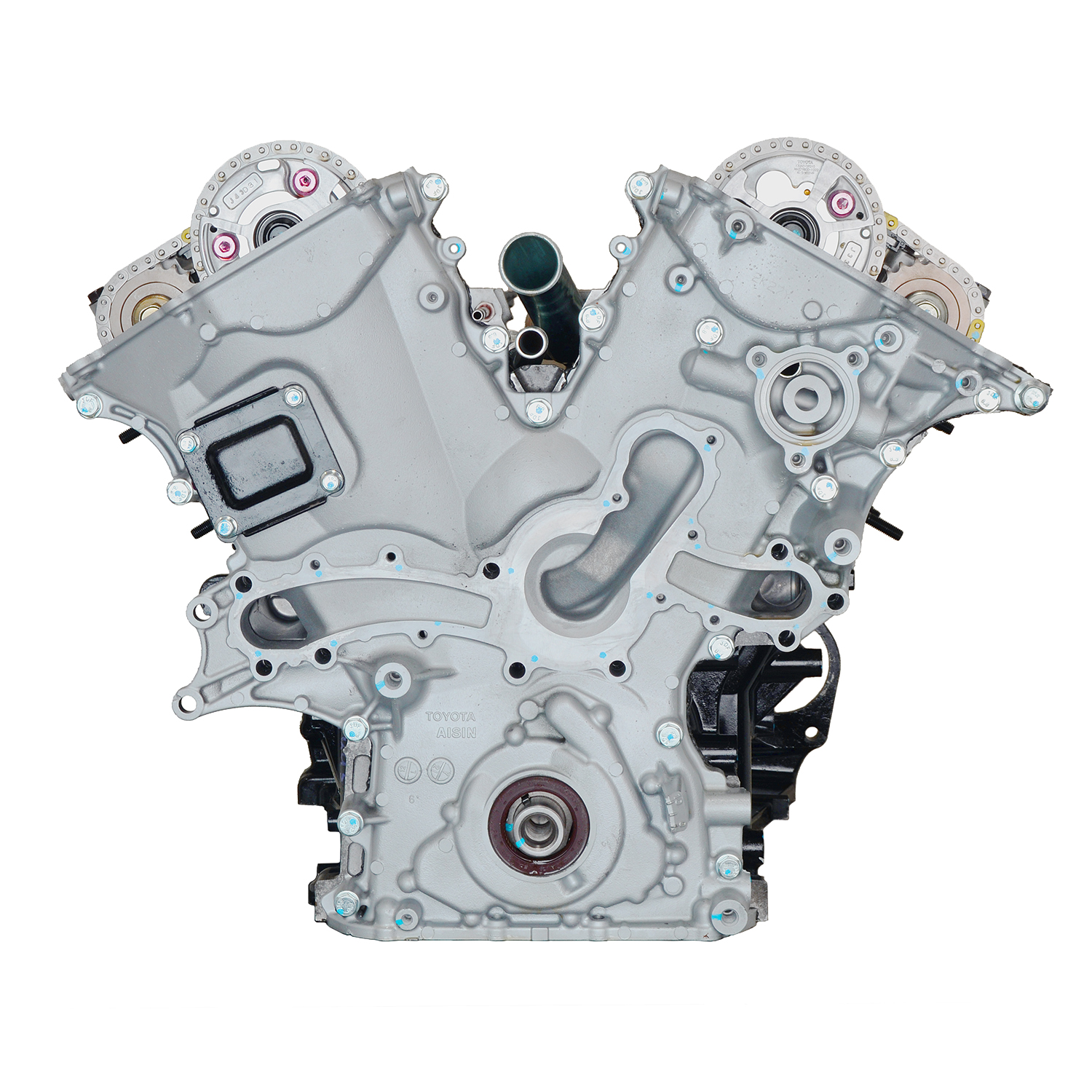

What Is the Historical Context of the V6 Engine Market in the B2B Landscape?

The v6 engine has evolved significantly since its introduction, originally designed to provide a balance between performance and fuel efficiency. In the early days, the focus was primarily on power output, but as fuel prices rose and environmental concerns became more prevalent, the industry shifted towards producing more efficient and cleaner engines.

Over the decades, technological advancements have enabled manufacturers to enhance the performance and reduce the emissions of v6 engines. Innovations such as turbocharging and direct fuel injection have made these engines more appealing to both manufacturers and consumers. As a result, the v6 engine has remained a popular choice across various vehicle categories, including sedans, SUVs, and trucks.

Illustrative image related to v6 engine for sale

Today, the legacy of the v6 engine continues to influence the B2B landscape, as international buyers seek reliable, efficient, and compliant options for their fleets. Understanding this evolution helps buyers appreciate the current offerings and future potential of v6 engines, ensuring informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of v6 engine for sale

-

1. How do I select the right V6 engine for my business needs?

When selecting a V6 engine, consider factors such as the engine’s specifications (displacement, horsepower, and torque), intended application (automotive, marine, or industrial), and compatibility with existing equipment. Assess your operational requirements, including power needs and fuel efficiency. It’s also essential to review the manufacturer’s reputation and warranty offerings, as these can impact the reliability and overall value of the engine. -

2. What are the advantages of purchasing remanufactured V6 engines?

Remanufactured V6 engines offer several advantages, including cost savings compared to new engines, while still providing high-quality performance. These engines are typically rebuilt to meet or exceed original equipment manufacturer (OEM) specifications, ensuring reliability. Additionally, sourcing remanufactured engines can be more sustainable, as it reduces waste and the environmental impact associated with producing new engines. -

3. What should I consider when vetting suppliers for V6 engines?

When vetting suppliers, focus on their industry reputation, experience, and certifications. Request references from previous clients and assess their customer service responsiveness. Evaluate the supplier’s quality assurance processes and warranty terms. It’s also beneficial to check their logistics capabilities, including shipping options and timelines, especially for international transactions to ensure timely delivery to your location. -

4. What are the typical minimum order quantities (MOQ) for V6 engines?

Minimum order quantities can vary significantly among suppliers and depend on factors such as the engine type and market demand. Generally, MOQs for V6 engines can range from a single unit to several dozen. Discuss your specific needs with potential suppliers to determine if they can accommodate smaller orders, especially if you are a new buyer or testing a new market. -

5. How can I customize a V6 engine to suit my application?

Customization options for V6 engines often include modifications to performance characteristics, such as tuning for horsepower or torque output, as well as changes to components like the intake and exhaust systems. Work closely with your supplier to explore available customization options, including any necessary engineering support. Ensure that all modifications comply with local regulations and standards in your target market. -

6. What payment terms are commonly offered in international V6 engine transactions?

Payment terms in international transactions typically include options such as letters of credit, advance payments, or payment upon delivery. Discuss terms with your supplier early in negotiations, considering factors such as your creditworthiness and the supplier’s policies. Ensure that payment methods are secure and provide protection against fraud or non-delivery, particularly when dealing with significant investments. -

7. How do I ensure quality assurance for V6 engines sourced internationally?

To ensure quality assurance, request detailed product specifications and certifications from suppliers. It’s advisable to establish a clear quality control process, including inspections and testing protocols before shipment. Consider third-party inspections or audits to verify product quality. Additionally, maintaining open communication with the supplier throughout the production process can help address any potential issues early. -

8. What logistics considerations should I keep in mind when importing V6 engines?

Logistics considerations include shipping methods, customs regulations, and import tariffs in your country. Choose a reliable freight forwarder with experience in handling automotive parts to navigate these complexities. Additionally, factor in lead times for production and shipping, and ensure that the supplier can provide necessary documentation for customs clearance. Proper planning can help avoid delays and additional costs in the import process.

Top 5 V6 Engine For Sale Manufacturers & Suppliers List

1. Chevrolet – Engine Blocks

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Car & Truck Engines 6 Cylinders for sale on eBay. Brands include Chevrolet, Ford, Toyota, Dodge, BMW, Jeep, Cummins, Mercedes-Benz, Porsche, Nissan, Honda, Hyundai. Categories include Connecting Rods & Parts, Crankshafts, Cylinder Heads, Engine Bearings, Engine Blocks, Engine Mounts, Engine Rebuild Kits, Engine Sensors & Switches, Gaskets, Seals & Hardware, Oil Drain Plugs, Filler Caps & Dipsticks…

2. Chevrolet Performance – 4.3L V6 Crate Engine

Domain: summitracing.com

Registered: 1995 (30 years)

Introduction: {“category”:”Crate Engines”,”engine_type”:”V6″,”availability”:”In Stock”,”shipping”:”Free Shipping on Orders Over $109″,”brands”:[“VEGE”,”ATK Marine Engine”,”Chevrolet Performance”,”Quicksilver”],”engine_family”:”Chevy 90º V6″,”engine_displacement”:[{“size”:”4.3L/262″,”count”:31},{“size”:”4.0L/245″,”count”:11},{“size”:”3.0L/182″,”count”:9},{“size”:”2.7L/167″,”count”:5},{“size”:”3.0L/2995cc”,”count…

3. Mountune USA – High-Performance Racing Crate Engines

Domain: mountuneusa.com

Registered: 2013 (12 years)

Introduction: Racing Crate Engines from Mountune USA include high-performance engine options such as: 1. High Performance 2.3L MRX Focus RS Long Block – Sale Price: $16,149.05 (Regular Price: $16,999.00) 2. High Performance 2.0L MRX Focus ST Long Block – Sale Price: $13,774.05 (Regular Price: $14,499.00) 3. High Performance 1.6L MRX Fiesta ST Long Block – Sale Price: $13,650.00 (Regular Price: $13,999.00) 4. Hi…

4. Facebook – 3.5L V6 Motor Under $650

5. Ford – M-6007-D347SR Engine

Domain: performanceparts.ford.com

Registered: 1988 (37 years)

Introduction: This company, Ford – M-6007-D347SR Engine, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for v6 engine for sale

In the dynamic landscape of the V6 engine market, strategic sourcing is paramount for international B2B buyers seeking to optimize their procurement processes. The diverse range of V6 engines available, from remanufactured long blocks to high-performance crate engines, underscores the importance of aligning sourcing strategies with specific project requirements and budget constraints. By leveraging supplier networks that span various geographical regions, buyers can access competitive pricing, timely delivery, and specialized technical support.

Additionally, understanding regional market trends and supply chain dynamics can enhance decision-making, ensuring that buyers select engines that meet both performance standards and regulatory compliance in their respective markets. As demand for efficient and reliable engines continues to rise, particularly in sectors such as automotive and marine, the ability to source strategically will distinguish successful businesses from their competitors.

Looking ahead, international buyers from Africa, South America, the Middle East, and Europe should proactively engage with trusted suppliers and manufacturers to secure their V6 engine needs. Embracing a strategic approach to sourcing not only facilitates operational efficiency but also positions businesses for sustainable growth in an evolving marketplace. Take the next step in your sourcing journey today and explore the vast opportunities within the V6 engine sector.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to v6 engine for sale

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.