A Deep Dive into Used Tire Machine Solution

Introduction: Navigating the Global Market for used tire machine

Navigating the global market for used tire machines presents a unique challenge for B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe. Sourcing reliable and cost-effective used tire machines can significantly impact operational efficiency, yet the complexities of international trade, varying quality standards, and supplier credibility often complicate this process. This guide aims to demystify the intricacies of purchasing used tire machines by providing a comprehensive overview of the different types available, their applications in various industries, and essential factors to consider when vetting suppliers.

In this resource, we delve into critical elements such as cost considerations, the nuances of different machine models, and the importance of warranties and after-sales support. By equipping international buyers with actionable insights and strategies, this guide empowers them to make informed purchasing decisions that align with their business needs. Whether you are looking to enhance your automotive service capabilities in Nigeria, expand operations in Saudi Arabia, or optimize tire recycling processes in Brazil, understanding the global landscape of used tire machines is crucial. With the right knowledge, you can confidently navigate the market, ensuring you invest in equipment that delivers both value and performance.

Understanding used tire machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tire Changer | Mechanically or hydraulically operated, clamps tires for removal and installation. | Automotive repair shops, tire retailers | Pros: Efficient tire changing; Cons: Can be bulky, requiring ample workspace. |

| Tire Balancer | Balances tires to ensure even wear and optimal performance; may be manual or automatic. | Automotive service centers, tire shops | Pros: Enhances vehicle performance; Cons: Requires calibration and maintenance. |

| Wheel Alignment Machine | Adjusts wheel angles to manufacturer specifications for better handling. | Auto repair shops, fleet maintenance | Pros: Increases tire lifespan; Cons: High initial investment. |

| Tire Repair Machine | Specialized for patching or sealing punctured tires; may include vulcanizing features. | Tire shops, roadside assistance services | Pros: Cost-effective repair solutions; Cons: Limited to specific tire conditions. |

| Mobile Tire Service Unit | A portable setup that includes tire changing and repair tools for on-site services. | Fleet services, emergency tire repair | Pros: Flexibility and convenience; Cons: May lack advanced features of stationary units. |

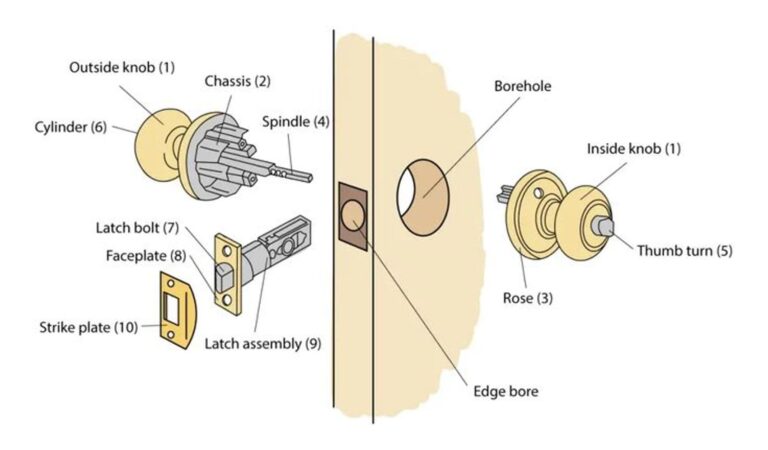

What are the Key Characteristics of Tire Changers?

Tire changers are essential for any automotive workshop focused on tire services. These machines can be hydraulic or mechanical, designed to securely clamp tires for quick removal and installation. Their efficiency makes them invaluable for high-volume tire retailers. When purchasing, consider the machine’s size and compatibility with different tire types. Ensure it meets your shop’s operational capacity while also evaluating the warranty and service options available.

How Do Tire Balancers Enhance Vehicle Performance?

Tire balancers are crucial for ensuring that tires wear evenly and provide a smooth ride. These machines come in both manual and automatic variants, allowing for precise weight distribution on the wheels. They are commonly used in automotive service centers and tire shops to enhance vehicle handling and safety. Buyers should assess the balancer’s speed, accuracy, and ease of use, as well as any necessary calibration or maintenance requirements.

Why is a Wheel Alignment Machine Important for Tire Longevity?

Wheel alignment machines adjust the angles of the wheels to match manufacturer specifications, significantly impacting vehicle handling and tire longevity. They are typically used in auto repair shops and fleet maintenance facilities. While they require a substantial initial investment, the long-term benefits include reduced tire wear and improved fuel efficiency. Buyers should consider the machine’s technology, ease of use, and the training needed for staff to operate it effectively.

What are the Advantages of Using a Tire Repair Machine?

Tire repair machines focus on patching or sealing tires that have been punctured. These machines can include vulcanizing features, making them suitable for tire shops and roadside assistance services. They offer cost-effective solutions for tire repairs, extending the lifespan of tires. However, buyers should be aware that these machines are limited to specific tire conditions and may not be suitable for all types of damage.

How Does a Mobile Tire Service Unit Provide Flexibility?

Mobile tire service units are designed for on-site tire changing and repair, making them ideal for fleet services and emergency tire repair. These portable setups enhance operational flexibility, allowing businesses to serve customers wherever they are. However, they may lack some advanced features found in stationary units. When considering a mobile unit, assess its equipment, size, and how well it can handle the range of services you plan to offer.

Key Industrial Applications of used tire machine

| Industry/Sector | Specific Application of used tire machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Repair | Tire changing and balancing for vehicles | Increased efficiency and reduced labor costs | Availability of parts, local support, and machine reliability |

| Recycling and Waste Management | Processing used tires for recycling | Sustainable waste management and cost savings | Compliance with local regulations and recycling capabilities |

| Transportation and Logistics | Maintenance of fleet vehicles | Enhanced vehicle uptime and safety | Machine compatibility with various tire sizes and types |

| Construction and Heavy Machinery | Tire servicing for construction equipment | Improved equipment performance and longevity | Robustness of the machine for heavy-duty applications |

| Retail Tire Sales | Retail tire installation and service | Increased customer satisfaction and loyalty | Speed of service and ease of use for staff training |

How is a Used Tire Machine Applied in the Automotive Repair Sector?

In the automotive repair sector, used tire machines are essential for efficiently changing and balancing tires on various vehicles. They enable workshops to perform tire installations quickly, minimizing vehicle downtime for customers. For international buyers, especially in regions like Africa and South America, sourcing machines that accommodate diverse tire sizes and types is crucial. Reliability and availability of spare parts are key considerations to ensure continuous operations without interruptions.

What Role Does a Used Tire Machine Play in Recycling and Waste Management?

Used tire machines are pivotal in recycling and waste management industries, where they help process discarded tires into reusable materials. These machines can efficiently break down tires, facilitating the production of rubber crumbs or fuel-grade oil, which can be used in various applications. Buyers from the Middle East and Europe should focus on machines that comply with local environmental regulations and have a track record of effective recycling capabilities to ensure sustainable operations.

How Can Used Tire Machines Benefit Transportation and Logistics Companies?

In the transportation and logistics sector, maintaining fleet vehicles is paramount for operational efficiency. Used tire machines allow companies to service their fleets on-site, ensuring quick tire changes and balancing, which enhances vehicle safety and performance. B2B buyers in this sector must consider the machine’s ability to handle a variety of tire sizes and its durability to withstand frequent use, as well as the availability of local technical support.

Why Are Used Tire Machines Important for Construction and Heavy Machinery?

Construction companies rely on used tire machines to maintain their heavy machinery, ensuring that equipment remains operational and safe. These machines facilitate quick tire changes, which is essential given the demanding nature of construction work. Buyers should prioritize machines that are robust enough to handle the heavy-duty tires typically used in this sector. Additionally, sourcing machines with a strong warranty and local service options can mitigate downtime.

How Do Retail Tire Sales Benefit from Used Tire Machines?

In the retail tire sales industry, used tire machines are vital for providing installation services that meet customer expectations. The efficiency of these machines can significantly enhance service speed, leading to higher customer satisfaction and repeat business. For B2B buyers, ease of use and the ability to train staff quickly are important factors. Ensuring the machine can accommodate a wide range of tire types will also help retailers cater to diverse customer needs effectively.

3 Common User Pain Points for ‘used tire machine’ & Their Solutions

Scenario 1: Difficulty in Assessing the Condition of Used Tire Machines

The Problem: B2B buyers often struggle to accurately evaluate the condition of used tire machines before making a purchase. This challenge can stem from the lack of detailed inspection reports or warranties, leading to uncertainty about the machine’s reliability and longevity. In regions like Africa and South America, where access to quality service and spare parts can be limited, the risk of investing in a subpar machine is significant. Buyers may fear that they will face costly repairs soon after the purchase or that the machine will not meet their operational needs.

The Solution: To mitigate this risk, buyers should prioritize sourcing used tire machines from reputable dealers who offer comprehensive inspection reports and guarantees. Before finalizing a purchase, buyers can request a video walkthrough of the machine, highlighting its key features and operational status. Additionally, they should consider obtaining an independent technician’s evaluation to verify the machine’s condition. Establishing clear communication with the seller regarding maintenance history and potential future issues can also provide peace of mind. Finally, investing in a machine that comes with a return policy can further protect the buyer’s interests.

Illustrative image related to used tire machine

Scenario 2: Incompatibility with Existing Equipment

The Problem: Another common pain point for B2B buyers is the potential incompatibility of a used tire machine with their existing setup. For instance, a tire shop may already have specific tools or systems in place, such as tire balancers or alignment equipment, that are not compatible with the new machine. This issue can lead to additional costs, as buyers might need to purchase new equipment or make modifications to their workspace, which can disrupt operations and affect profitability.

The Solution: To avoid compatibility issues, buyers should conduct thorough research on the specifications and requirements of the used tire machine they intend to purchase. This includes checking the machine’s dimensions, power requirements, and any necessary accessories. Creating a comprehensive list of existing equipment and comparing it against the specifications of the used machine can help identify potential conflicts. Engaging with industry professionals or consultants can also provide insights into compatibility and integration. Furthermore, buyers should consider purchasing machines from the same manufacturer as their existing equipment, as this often ensures better interoperability.

Scenario 3: Limited Availability of Spare Parts and Support

The Problem: A frequent concern for B2B buyers in regions like the Middle East and Africa is the limited availability of spare parts and technical support for used tire machines. If a machine requires repairs or maintenance, the inability to source the necessary components can lead to extended downtimes, which can severely impact business operations. This is particularly critical in markets where local support is minimal, and shipping parts from overseas can be time-consuming and expensive.

The Solution: To address this issue, buyers should prioritize machines from manufacturers known for their robust supply chains and global reach. Before purchasing, they can research the availability of spare parts in their region or consult with local distributors to ensure that they can obtain necessary components without significant delays. Additionally, establishing a relationship with a reliable service provider who specializes in tire machinery can help streamline repair processes. Buyers can also consider joining industry forums or associations to connect with other businesses facing similar challenges, thus gaining insights into best practices for sourcing parts and support. Implementing a proactive maintenance plan can also extend the lifespan of the machine and minimize the frequency of repairs needed.

Illustrative image related to used tire machine

Strategic Material Selection Guide for used tire machine

What Are the Key Materials Used in Tire Machines?

When selecting materials for used tire machines, it’s crucial to consider their properties and how they align with the operational demands of tire changing and balancing tasks. Here, we analyze four common materials: steel, aluminum, rubber, and composite materials.

How Does Steel Perform in Tire Machine Applications?

Steel is a primary material used in the construction of tire machines, particularly for structural components and critical load-bearing parts. Its key properties include high tensile strength, excellent durability, and the ability to withstand significant pressure and temperature variations. Steel’s corrosion resistance can be enhanced through galvanization or coatings, making it suitable for various environments.

Pros: Steel is highly durable and offers a long service life, which is essential for machines that undergo heavy usage. It is also cost-effective compared to other materials, making it an attractive option for manufacturers.

Cons: The weight of steel can be a disadvantage, as it may increase shipping costs and complicate installation. Additionally, if not properly treated, steel can corrode, especially in humid or saline environments, which may be a concern for buyers in coastal regions.

Impact on Application: Steel components are well-suited for high-stress applications, such as clamping and lifting mechanisms in tire changers. However, buyers should ensure that the steel used complies with international standards, such as ASTM or DIN, to guarantee quality and safety.

Illustrative image related to used tire machine

What Role Does Aluminum Play in Tire Machine Construction?

Aluminum is increasingly used in tire machines for parts that benefit from its lightweight and corrosion-resistant properties. It is particularly advantageous in components that require mobility, such as portable tire changers.

Pros: The primary advantage of aluminum is its lightweight nature, which facilitates easier handling and reduces shipping costs. It also resists corrosion naturally, making it ideal for use in diverse climates.

Cons: Aluminum is generally less strong than steel, which may limit its application in high-load areas. It is also more expensive, which can affect overall manufacturing costs.

Impact on Application: Aluminum is suitable for components that do not experience extreme stress, such as outer casings or non-load-bearing frames. Buyers in regions with high humidity or corrosive environments, such as coastal areas in the Middle East, may prefer aluminum for its longevity.

Why Is Rubber Important for Tire Machines?

Rubber is predominantly used in tire machines for seals, gaskets, and cushioning components. Its key properties include excellent elasticity, resistance to wear, and the ability to absorb vibrations.

Pros: Rubber’s elasticity allows for effective sealing, preventing air leaks in tire inflation systems. Its vibration-dampening properties enhance the user experience by reducing noise and mechanical shock.

Cons: Rubber can degrade over time, particularly when exposed to extreme temperatures or UV light. This degradation can lead to increased maintenance costs and potential downtime.

Impact on Application: Rubber components are critical for ensuring the proper functioning of tire machines. B2B buyers should consider the specific rubber grades and compounds used, as compliance with international standards can vary significantly.

How Do Composite Materials Enhance Tire Machines?

Composite materials, often a blend of plastics and fibers, are becoming popular in tire machine manufacturing due to their unique properties. They offer a combination of lightweight, strength, and resistance to environmental factors.

Pros: Composites are lightweight and can be molded into complex shapes, offering design flexibility. They also exhibit excellent corrosion resistance and thermal stability.

Cons: The cost of composite materials can be higher than traditional options, and their manufacturing processes can be more complex. Additionally, not all composites are suitable for high-stress applications.

Impact on Application: Composites are often used in non-structural components, such as housing or covers. For buyers in regions with strict environmental regulations, composites can be an attractive option due to their recyclability.

Summary Table of Material Selection for Used Tire Machines

| Material | Typical Use Case for used tire machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components, load-bearing parts | High durability and cost-effectiveness | Heavy weight, potential for corrosion | Medium |

| Aluminum | Portable tire changers, non-load-bearing frames | Lightweight and corrosion-resistant | Lower strength, higher cost | High |

| Rubber | Seals, gaskets, cushioning components | Excellent elasticity and vibration absorption | Degradation over time | Medium |

| Composite | Non-structural components, housing | Lightweight and design flexibility | Higher cost and complex manufacturing | High |

By understanding the properties, advantages, and limitations of these materials, international B2B buyers can make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for used tire machine

What Are the Main Stages of Manufacturing a Used Tire Machine?

The manufacturing process for used tire machines involves several critical stages, each designed to ensure the machine’s durability, efficiency, and overall quality. Understanding these stages can help B2B buyers make informed decisions when sourcing equipment.

Material Preparation: What Materials Are Used?

The manufacturing process begins with material preparation. High-quality steel is the primary material used in constructing tire changers, given its strength and resilience. Suppliers often source steel that meets international standards to ensure safety and performance.

In addition to steel, other materials such as rubber and various polymers may be used in components that require flexibility and durability. The choice of materials can significantly affect the machine’s lifespan and performance, making it crucial for buyers to inquire about the specific materials used by manufacturers.

How Is the Forming Process Executed?

Once materials are prepared, the forming process begins. This typically involves cutting, bending, and shaping steel sheets into the various components of the tire machine. Techniques such as laser cutting and CNC (Computer Numerical Control) machining are commonly employed to achieve precise dimensions and high-quality finishes.

The forming stage is critical as it lays the groundwork for the machine’s functionality. Components like the tire changer arm and rim clamps are crafted during this stage, and their accuracy directly impacts the machine’s efficiency.

What Does the Assembly Stage Involve?

After forming, the next step is assembly. During this phase, all the individual components are brought together to create the final product. This process can be labor-intensive and may involve both automated systems and manual labor.

Quality control checkpoints are integrated at this stage to ensure that each component fits correctly and functions as intended. For instance, the alignment of the tire changer arm is crucial for its operation, and any misalignment can lead to increased wear and tear or operational failures.

How Is the Finishing Process Conducted?

The finishing stage involves painting and coating the assembled tire machine. This not only enhances aesthetics but also provides protection against corrosion and wear. Manufacturers often use powder coating or electrostatic painting for durability.

Illustrative image related to used tire machine

Quality assurance continues into this phase, where the finish is inspected for consistency and coverage. A well-finished tire machine can withstand harsh operating conditions, making it a valuable investment for businesses.

What Are the Key Quality Assurance Standards for Used Tire Machines?

Quality assurance (QA) is a vital component of the manufacturing process, especially for used tire machines that must meet specific performance and safety standards. Understanding these standards can help international B2B buyers ensure they are investing in reliable equipment.

Which International Standards Should Buyers Be Aware Of?

International standards such as ISO 9001 serve as benchmarks for quality management systems. Compliance with ISO 9001 ensures that manufacturers follow established procedures for quality control and continuous improvement. Buyers should request certification documents to verify a manufacturer’s compliance with these standards.

In addition to ISO, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may also be relevant, depending on the machine’s intended use. CE marking indicates compliance with European safety, health, and environmental protection standards, while API certification may be necessary for machines used in specific industrial applications.

Illustrative image related to used tire machine

What Are the Key Quality Control Checkpoints?

Quality control involves multiple checkpoints throughout the manufacturing process to ensure that products meet the required specifications. Key checkpoints include:

-

Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials and components upon arrival at the manufacturing facility. Suppliers must demonstrate that materials meet specified standards before production begins.

-

In-Process Quality Control (IPQC): During manufacturing, IPQC monitors the production process to identify any deviations from quality standards. This includes inspection of formed components and assembly techniques.

-

Final Quality Control (FQC): Once assembly is complete, FQC involves a comprehensive inspection of the final product. This includes functionality tests and visual inspections to ensure all components are working correctly and that the machine meets safety standards.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control processes of suppliers is crucial to ensure they receive high-quality used tire machines. Here are several actionable steps to consider:

What Should Buyers Request from Suppliers?

Buyers should request detailed documentation regarding the manufacturer’s quality control processes. This includes:

-

Quality Assurance Manuals: These documents should outline the QA processes, standards, and certifications that the manufacturer adheres to.

-

Test Reports: Buyers can ask for test results of previous batches, demonstrating the machine’s performance under various conditions.

-

Inspection Records: Suppliers should provide records of inspections performed during the manufacturing process.

How Can Buyers Conduct Audits?

Conducting audits is an effective way for buyers to assess a supplier’s quality control measures. This can involve:

Illustrative image related to used tire machine

-

On-Site Visits: Buyers can visit manufacturing facilities to observe the production process and quality control measures firsthand.

-

Third-Party Inspections: Engaging third-party inspectors can provide an unbiased assessment of the manufacturer’s compliance with quality standards.

What Nuances Should International Buyers Consider?

International buyers, particularly those from Africa, South America, the Middle East, and Europe, should be aware of certain nuances when sourcing used tire machines:

-

Regulatory Compliance: Different regions may have varying regulations regarding machinery safety and environmental impact. Buyers must ensure that the machines comply with local regulations in their respective countries.

-

Cultural Considerations: Understanding cultural differences can aid in building strong supplier relationships. Clear communication regarding quality expectations and standards is essential.

-

Logistics and Supply Chain: Buyers should consider logistics when sourcing equipment internationally, including shipping times, costs, and potential tariffs. Establishing strong communication with suppliers can help mitigate potential issues.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing used tire machines, ensuring they invest in equipment that meets their operational needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘used tire machine’

When sourcing a used tire machine, it’s essential to navigate the complexities of international procurement effectively. This guide provides a structured checklist to help B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, make informed decisions.

Step 1: Define Your Technical Specifications

Before initiating your search, clearly outline the specifications required for your used tire machine. Consider the type of tire services you will be providing, whether it’s changing, balancing, or repairing tires.

– Key considerations: Size, capacity, and compatibility with different tire types.

– Example: If you primarily service larger vehicles, ensure the machine can accommodate truck tires.

Step 2: Research Market Trends and Pricing

Understanding current market trends and pricing for used tire machines is crucial. This knowledge will empower you to negotiate effectively and avoid overpaying.

– Resources: Utilize online marketplaces, industry reports, and auction sites to gauge average prices.

– Tip: Keep an eye on market fluctuations that may affect availability and pricing.

Step 3: Evaluate Potential Suppliers

Thoroughly vet suppliers to ensure they meet your standards. Request detailed company profiles, including their history, client testimonials, and case studies relevant to your industry.

– Additional checks: Look for reviews or feedback from other buyers in your region to validate the supplier’s reputation.

– Considerations: Assess their responsiveness and willingness to provide after-sales support.

Step 4: Verify Equipment Condition and Certifications

Before finalizing any purchase, assess the condition of the used tire machine. Request detailed photographs and maintenance records to evaluate wear and tear.

– Certifications: Ensure the machine complies with safety and operational standards relevant to your country.

– Inspection: If possible, arrange for a physical inspection or hire a local expert to evaluate the machine’s functionality.

Illustrative image related to used tire machine

Step 5: Understand Shipping and Import Regulations

Given the international nature of your procurement, familiarize yourself with shipping logistics and import regulations in your country.

– Documentation: Ensure you have all necessary documentation, including customs clearance papers and proof of purchase.

– Shipping options: Evaluate shipping methods and costs, and factor these into your overall budget.

Step 6: Negotiate Payment Terms

Establish clear payment terms before proceeding with the transaction. Discuss options such as letters of credit, escrow services, or payment upon delivery to mitigate risks.

– Flexibility: Be open to negotiating terms that may provide additional security, especially when dealing with international suppliers.

– Documentation: Ensure all agreed-upon terms are documented to avoid misunderstandings later.

Step 7: Plan for Installation and Training

After purchase, consider how the machine will be installed and whether training will be required for your staff.

– Installation support: Some suppliers may offer installation services or guidance, which can be beneficial.

– Training resources: Look for training manuals or online resources to help your team maximize the machine’s capabilities.

By following this checklist, B2B buyers can streamline the sourcing process for used tire machines, ensuring they make informed and strategic decisions that align with their operational needs.

Comprehensive Cost and Pricing Analysis for used tire machine Sourcing

What Are the Key Cost Components for Sourcing Used Tire Machines?

When sourcing used tire machines, understanding the cost structure is vital for making informed purchasing decisions. The primary cost components include:

-

Materials: This encompasses the raw materials used in the machine’s construction. For used tire machines, factors such as the type of steel, electronic components, and hydraulic systems can significantly influence costs.

-

Labor: Labor costs can vary depending on the location of the supplier and the complexity of the machine. Skilled technicians may be required for assembly and maintenance, impacting the overall cost.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and administrative expenses that are allocated to the production of the machines. A supplier with higher overhead might pass those costs onto buyers.

-

Tooling: Custom tooling for specific machine types can add to costs, particularly if the supplier has invested in specialized equipment for a unique model.

-

Quality Control (QC): Rigorous QC processes ensure the machines meet safety and operational standards, which can add to the overall cost but is essential for reliability.

-

Logistics: Shipping and handling costs can vary widely, especially for international shipments. Factors such as distance, mode of transport, and local tariffs will affect logistics costs.

-

Margin: Suppliers typically include a profit margin in their pricing, which can fluctuate based on market demand and competition.

How Do Price Influencers Affect Used Tire Machine Costs?

Several factors can influence the final price of used tire machines:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Suppliers may offer discounts for bulk purchases, making it advantageous for businesses planning to acquire multiple machines.

-

Specifications and Customization: Customized machines tailored to specific operational needs can incur additional costs. Buyers should weigh the benefits of customization against budget constraints.

-

Materials and Quality Certifications: Machines made from high-quality materials or those that come with industry certifications may command higher prices. However, investing in quality can lead to lower maintenance costs over time.

-

Supplier Factors: The reputation and reliability of the supplier can significantly impact pricing. Established suppliers may charge more due to their proven track record and after-sales support.

-

Incoterms: The terms of delivery can influence costs. Understanding Incoterms (International Commercial Terms) is crucial for international buyers to avoid unexpected charges related to shipping and customs.

What Are Some Effective Buyer Tips for Sourcing Used Tire Machines?

Navigating the purchasing process for used tire machines can be complex, especially for international buyers. Here are some tips to enhance negotiation and cost-efficiency:

-

Negotiation: Always be prepared to negotiate. Understanding the market value of the machine and being aware of competitors’ pricing can strengthen your position.

-

Total Cost of Ownership (TCO): Consider the TCO, which includes not just the initial purchase price but also maintenance, operational costs, and potential downtime. A slightly higher upfront cost may be justified if the machine offers better reliability and efficiency.

-

Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import duties, and local taxes that can impact the final cost. It’s advisable to work with suppliers who have experience exporting to your region.

-

Request Detailed Quotations: Always ask for a comprehensive breakdown of costs, including all components and services. This transparency will help you make more informed decisions and identify any hidden costs.

Disclaimer on Indicative Prices

Prices for used tire machines can vary significantly based on the factors outlined above. The figures provided in this analysis are indicative and may fluctuate based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough market research and supplier evaluations before making purchasing decisions.

Alternatives Analysis: Comparing used tire machine With Other Solutions

Introduction to Alternative Solutions for Tire Changing

In the dynamic landscape of automotive service equipment, the choice of tire-changing solutions is critical for businesses looking to maximize efficiency and reduce costs. While used tire machines offer a practical option for many, it’s essential to explore alternative technologies that may better suit specific operational needs. This analysis will compare used tire machines with other viable solutions, including automated tire changers and manual tire-changing kits, allowing B2B buyers to make informed decisions.

Comparison Table

| Comparison Aspect | Used Tire Machine | Automated Tire Changer | Manual Tire-Changing Kit |

|---|---|---|---|

| Performance | High for standard tires | Exceptional for all tire types | Moderate, labor-intensive |

| Cost | Moderate initial investment | Higher upfront cost | Low cost |

| Ease of Implementation | Requires setup and training | Plug-and-play installation | Requires skill and effort |

| Maintenance | Moderate | Low maintenance required | High wear and tear |

| Best Use Case | Small to mid-sized shops | High-volume tire shops | Mobile service providers |

Detailed Breakdown of Alternatives

Automated Tire Changer

Automated tire changers represent a cutting-edge solution for businesses focused on maximizing productivity. These machines significantly reduce the time needed to change tires, often completing the task in a matter of minutes. While the initial investment is higher compared to used tire machines, the efficiency gained can lead to increased throughput and reduced labor costs. Furthermore, they typically require less maintenance, making them a long-term cost-effective solution. However, their complexity may necessitate specialized training for staff, which could lead to additional operational downtime during the learning phase.

Illustrative image related to used tire machine

Manual Tire-Changing Kit

For businesses operating on a tighter budget or those that provide mobile tire services, a manual tire-changing kit can be an attractive option. These kits are inexpensive and easy to transport, making them suitable for on-site services. However, they require significant physical effort and skill from the operator, which can lead to longer service times and potential safety risks. The wear and tear on tools can also lead to increased costs over time. This solution is best suited for low-volume operations or as a supplementary option for emergency tire changes.

Conclusion: Choosing the Right Tire Changing Solution

Selecting the right tire-changing solution requires careful consideration of various factors, including performance, cost, and the specific needs of your business. Used tire machines offer a balanced approach for many small to mid-sized automotive shops, providing reliable performance at a reasonable cost. However, for high-volume operations, automated tire changers may yield better long-term returns despite the higher initial investment. Conversely, manual tire-changing kits serve well in niche markets or mobile services but come with limitations in efficiency and ease of use. Ultimately, B2B buyers should assess their operational goals, budget constraints, and service requirements to determine the most suitable tire-changing solution for their business.

Essential Technical Properties and Trade Terminology for used tire machine

What Are the Key Technical Properties of Used Tire Machines?

When considering the purchase of used tire machines, several technical properties are crucial for ensuring optimal performance and longevity. Understanding these specifications can help B2B buyers make informed decisions.

-

Material Grade

The material grade of a tire machine significantly affects its durability and performance. Common materials include high-grade steel and aluminum, which offer strength and resistance to wear. For buyers, selecting machines made of higher-grade materials often translates to lower maintenance costs and extended service life, which is critical in high-demand environments like tire shops. -

Operating Capacity

This specification refers to the maximum tire size and weight the machine can handle. Operating capacity varies widely among models, with some designed for passenger vehicles and others for heavy-duty trucks. Buyers must assess their specific needs, as a machine with insufficient capacity may lead to inefficiencies or damage. -

Power Requirements

Understanding the power requirements, including voltage and amperage, is essential for operational compatibility. Many tire changers are electrically powered, requiring specific electrical setups. This information is vital for buyers to ensure that their facilities can accommodate the equipment without incurring additional costs for electrical upgrades. -

Cycle Time

Cycle time refers to the duration needed for the machine to complete a tire change. Faster cycle times can increase productivity, making it a critical metric for tire service businesses. Buyers should evaluate their expected workload and choose a machine that balances speed with reliability to meet customer demands effectively. -

Precision Tolerance

Precision tolerance indicates how accurately the machine can perform tasks such as balancing tires. Higher precision tolerances reduce the risk of vibration and improve vehicle handling. For B2B buyers, investing in a machine with superior precision can enhance service quality and customer satisfaction.

What Are Common Trade Terms Related to Used Tire Machines?

In the used tire machine market, understanding industry terminology is essential for effective negotiation and transaction management. Here are several key terms:

-

OEM (Original Equipment Manufacturer)

OEM refers to equipment produced by the original manufacturer. In the used tire machine market, OEM parts are often preferred for their compatibility and reliability. Buyers should ensure that any used machines they consider use OEM parts to maintain quality and performance standards. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of units a supplier is willing to sell. For buyers looking to purchase multiple tire machines or parts, understanding MOQ is crucial to avoid unexpected costs and ensure they meet supplier requirements. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products. This is particularly useful for B2B buyers seeking competitive bids for used tire machines, as it allows for apples-to-apples comparisons across multiple vendors. -

Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. They specify who bears the costs and risks associated with shipping, delivery, and customs clearance. Familiarity with Incoterms is essential for B2B buyers, especially when importing used tire machines from different countries, as they can significantly impact total landed costs. -

Lead Time

Lead time is the period between placing an order and receiving the product. Understanding lead times can help buyers plan inventory and manage customer expectations effectively. For used tire machines, lead times can vary based on location, availability, and shipping methods, making it a crucial factor in procurement planning.

By grasping these technical properties and trade terms, B2B buyers can navigate the complexities of purchasing used tire machines more effectively, ensuring they choose the right equipment to meet their operational needs.

Navigating Market Dynamics and Sourcing Trends in the used tire machine Sector

What are the Current Market Dynamics and Key Trends Affecting the Used Tire Machine Sector?

The global used tire machine market is experiencing notable growth, driven by increasing demand for cost-effective equipment and sustainability initiatives. Key markets in Africa, South America, the Middle East, and Europe are witnessing a surge in the adoption of used tire machines due to rising vehicle ownership and the corresponding need for efficient tire maintenance solutions. For instance, countries like Nigeria and Saudi Arabia are investing heavily in automotive services, creating a robust demand for tire changers and balancers.

Emerging B2B technologies, such as online auction platforms and digital marketplaces, are revolutionizing how buyers source used tire machines. These platforms not only provide a wider selection but also enhance transparency in pricing and equipment condition through user reviews and certification programs. Buyers can leverage these technologies to compare various makes and models, ensuring they find the best fit for their operational needs.

Market dynamics are also shifting towards more localized sourcing strategies. International buyers are increasingly focusing on suppliers that can provide fast shipping and local support. This trend is particularly pronounced in regions with developing automotive industries, where timely access to equipment is critical for service continuity. As a result, international buyers should prioritize partnerships with suppliers that have established logistics capabilities in their respective regions.

How Does Sustainability and Ethical Sourcing Impact the Used Tire Machine Sector?

Sustainability is becoming a central theme in the used tire machine sector as businesses increasingly recognize the environmental impact of their sourcing decisions. The lifecycle of tire machines often involves significant energy consumption and resource use; therefore, opting for used equipment can substantially reduce waste and carbon footprints. This shift towards sustainability aligns with global initiatives to reduce environmental harm, making it a key consideration for B2B buyers.

Moreover, ethical sourcing practices are gaining traction. Buyers are now looking for suppliers that prioritize responsible manufacturing processes and adhere to environmental regulations. Certifications such as ISO 14001 (Environmental Management) and partnerships with organizations focused on sustainability can enhance a supplier’s credibility and attract eco-conscious buyers. This trend is particularly relevant in regions like Europe, where regulatory frameworks are increasingly stringent regarding environmental impact.

Buyers should also consider the materials used in the manufacturing of tire machines. Those that utilize recycled materials or have energy-efficient designs not only contribute to sustainability but also often offer long-term cost savings through reduced operational expenses. By prioritizing suppliers with ‘green’ certifications and sustainable practices, international buyers can align their purchasing decisions with their corporate social responsibility goals.

What is the Evolution of the Used Tire Machine Sector?

The used tire machine sector has evolved significantly over the past few decades. Initially, the market was dominated by a few manufacturers who produced equipment primarily for local markets. However, as the automotive industry expanded globally, the demand for more versatile and efficient tire machines grew, prompting manufacturers to innovate.

Illustrative image related to used tire machine

In recent years, the rise of digital marketplaces has further transformed the sector. Buyers can now easily access a global inventory of used tire machines, leading to increased competition and better pricing. This evolution has not only improved availability but has also encouraged manufacturers to enhance the quality and features of their equipment to meet the diverse needs of international buyers.

As the sector continues to develop, trends such as automation and connectivity are expected to shape the future of tire maintenance. The integration of smart technologies into tire machines can streamline operations and improve efficiency, making it essential for buyers to stay informed about these advancements when sourcing used equipment.

Frequently Asked Questions (FAQs) for B2B Buyers of used tire machine

-

How do I choose the right used tire machine for my business needs?

Choosing the right used tire machine involves assessing your specific operational requirements, such as the types of tires you handle (e.g., passenger, commercial, or specialty tires), volume of service, and available space. It’s crucial to evaluate the machine’s specifications, including its capabilities, speed, and ease of use. Consult with suppliers to understand the machine’s maintenance history and any potential refurbishing options. Additionally, consider the availability of spare parts and after-sales support, which can significantly affect your operational efficiency. -

What are the key factors to consider when sourcing used tire machines internationally?

When sourcing used tire machines internationally, focus on factors such as the supplier’s reputation, compliance with international quality standards, and shipping logistics. Verify the supplier’s credentials and experience in exporting equipment to your region. It’s also essential to understand the local regulations regarding machinery imports, including customs duties and any necessary certifications. Engage in clear communication about warranties, return policies, and the machine’s operational condition to avoid potential disputes. -

What is the average lead time for receiving a used tire machine after placing an order?

The lead time for receiving a used tire machine can vary significantly based on factors like the supplier’s location, shipping method, and customs clearance processes. Generally, expect a timeframe of 4 to 12 weeks from order placement to delivery. To ensure timely receipt, confirm the supplier’s estimated delivery schedule and stay informed about any potential delays in shipping or customs. Establishing a clear line of communication with the supplier can help mitigate unforeseen issues. -

What are the typical payment terms for purchasing used tire machines?

Payment terms for used tire machines can vary widely among suppliers. Common arrangements include full upfront payment, a deposit followed by the balance upon delivery, or installment payments. Be sure to clarify the payment terms before finalizing the purchase. It’s advisable to use secure payment methods that provide some level of buyer protection. For larger transactions, consider negotiating terms that allow for a partial payment upon machine inspection before full payment. -

How can I ensure the quality and functionality of a used tire machine before purchase?

To ensure the quality and functionality of a used tire machine, request detailed photographs, videos, and operational history from the supplier. If possible, arrange for an on-site inspection or a third-party evaluation to assess the machine’s condition. Inquire about any previous repairs or refurbishments and request documentation of maintenance records. Additionally, consider purchasing from suppliers that offer warranties or guarantees, which can provide peace of mind regarding the machine’s reliability. -

Are there customization options available for used tire machines?

Yes, many suppliers offer customization options for used tire machines to better fit your specific operational needs. Customizations may include modifications to accommodate different tire sizes, additional features like automatic tire changers, or enhancements for increased efficiency. Engage with suppliers about your requirements and explore any available options. Customizing a used machine can improve its performance and integration into your existing workflow. -

What is the minimum order quantity (MOQ) for purchasing used tire machines?

Minimum order quantities (MOQs) for used tire machines can vary by supplier and are often influenced by factors such as the type of machine and the supplier’s business model. Some suppliers may allow single unit purchases, while others may require a minimum order of two or more machines. Clarify the MOQ with potential suppliers during your initial discussions to align your purchasing strategy with their terms. -

What logistics considerations should I keep in mind when importing used tire machines?

When importing used tire machines, consider logistics aspects such as shipping methods, insurance, and customs clearance. Choose a reliable freight forwarder familiar with handling heavy machinery to ensure safe transport. Calculate all associated costs, including shipping fees, customs duties, and taxes, to determine the total investment. Additionally, familiarize yourself with your country’s import regulations and ensure that all necessary documentation is prepared to facilitate a smooth customs process.

Top 7 Used Tire Machine Manufacturers & Suppliers List

1. COATS – Tire Balancer 850

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, COATS – Tire Balancer 850, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Coats – Automotive Tire Changer

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Automotive Tire Changers for sale on eBay include various brands such as Coats, Hunter, Snap-on, and Atlas. They are suitable for different vehicle types including passenger vehicles, motorcycles, and heavy-duty/commercial vehicles. Related products include tire balancing machines and wheel balancers. Popular searches include manual tire changers, tire changer tool sets, and heavy-duty tire change…

3. Tire Changer – Used Models Available at IronPlanet

Domain: ironplanet.com

Registered: 1999 (26 years)

Introduction: Tire Changer for Sale at IronPlanet. Various makes and models available, including AGT, Agriquip, Coats, and more. Types include used tire changers with options for auction or buy now. Models include HIT 9000, R980XR, LHR-TC24, and others. Locations include the United States and Canada. Price range varies, with some items listed from $1,000 to $4,999. IronClad Assurance available for select items.

4. Equipment City – Quality Equipment

Domain: equipmentcity.net

Registered: 2007 (18 years)

Introduction: This company, Equipment City – Quality Equipment, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. AllStates – Tire Changers

Domain: allstates.com

Registered: 1997 (28 years)

Introduction: Tire changers (new & used), including Coats rim clamp, John Bean mag changer, Hunter tire changer, and Coats 40-40 used tire changer. Over 200 units in stock. Motorcycle models available. Coats rim clamp tire changers reconditioned with various models and prices: 50-60 AX remanufactured ($2,300), 50-60AX robo arm reconditioned ($2,700), used 50-60AX ($1,700), used with Robo Arm ($2,500), heavy-dut…

6. TireTech – Manual Tire Changer System

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Manual tire changer and balance system, used tire machines, requires a healthy compressor, needs to be bolted to the floor, can scrape the lip of the wheels, requires significant force to operate, suitable for changing one tire maybe once a year.

7. COATS – Tire Changing Machines

Domain: automotiveequipmentspecialists.com

Registered: 2014 (11 years)

Introduction: COATS Tire Machines for Sale – COATS Tire Changing Machines. Categories include Tire Changers and Wheel Balancers. Brands available: COATS, CORGHI, ATLAS, HOFMANN, RANGER, TUX Equipment. Various types of lifts and equipment also offered, including 2 Post Lifts, 4 Post Lifts, Alignment Lifts, and Specialty Lifts. Financing options available.

Strategic Sourcing Conclusion and Outlook for used tire machine

The used tire machine market presents a wealth of opportunities for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. By strategically sourcing used tire machines, businesses can significantly reduce capital expenditures while acquiring high-quality equipment that meets operational needs. Understanding the nuances of market dynamics—such as auction formats, equipment condition, and regional availability—enables buyers to make informed decisions that align with their growth strategies.

Investing in used tire machines not only enhances operational efficiency but also promotes sustainability by extending the lifecycle of existing equipment. As global demand for tire services rises, securing reliable machinery becomes paramount. Buyers should leverage platforms that facilitate transparent transactions and provide assurances on equipment quality, such as IronPlanet and Ritchie Bros. Auctioneers.

Looking ahead, the strategic sourcing of used tire machines is set to gain momentum as businesses prioritize cost-effectiveness and sustainability. We encourage potential buyers to engage proactively with suppliers, explore diverse marketplaces, and evaluate the long-term benefits of integrating used machinery into their operations. Seize the opportunity to elevate your business by investing wisely in the right equipment today.

Illustrative image related to used tire machine

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.