A Deep Dive into Tumble Vibe Solution

Introduction: Navigating the Global Market for tumble vibe

In the increasingly competitive landscape of metal finishing and rock polishing, sourcing the right vibratory tumblers, specifically the Tumble Vibe, poses a significant challenge for international B2B buyers. Businesses across Africa, South America, the Middle East, and Europe are seeking effective solutions to enhance production efficiency and achieve high-quality finishes. This guide offers a comprehensive overview of the Tumble Vibe, exploring its various types, applications, and the nuances of supplier vetting, enabling you to make informed purchasing decisions.

The Tumble Vibe is not just a tool; it represents a pivotal investment in the operational capabilities of your business. From polishing metal and plastic parts to deburring and descaling, understanding the diverse functionalities of these machines is crucial for maximizing their potential. This guide will delve into the essential factors to consider, including cost implications, maintenance requirements, and the critical aspects of selecting reliable suppliers who can meet your specific needs.

By providing actionable insights and expert recommendations, this resource empowers B2B buyers to navigate the complexities of sourcing Tumble Vibe machines effectively. Whether you are a manufacturer in Vietnam or a distributor in Saudi Arabia, leveraging this guide will equip you with the knowledge to enhance your procurement strategy, ensuring you acquire the right equipment to elevate your business’s productivity and quality standards.

Understanding tumble vibe Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tumble-Vibe 5 | Compact size, 8-inch bowl, affordable price | Hobbyist markets, small-scale production | Pros: Cost-effective, versatile. Cons: Limited capacity, potential noise issues. |

| Tumble-Vibe 10 | Larger capacity, available with or without drain | Mid-sized operations, jewelry polishing | Pros: Greater capacity, more efficient. Cons: Higher price point, requires more space. |

| Adjusta-Vibe 18 | Adjustable vibration settings, robust design | Industrial applications, heavy-duty use | Pros: Customizable settings, durable. Cons: Higher initial investment, maintenance may be needed. |

| Tumble-Dump 40 | Large capacity, designed for bulk processing | Mass production, large-scale manufacturing | Pros: High throughput, efficient for bulk. Cons: Requires significant floor space, higher cost. |

| Tumble-Dump 75 | Extra-large capacity, dual-drum design | High-volume operations, specialized finishing | Pros: Exceptional capacity, time-saving. Cons: High initial cost, complex operation. |

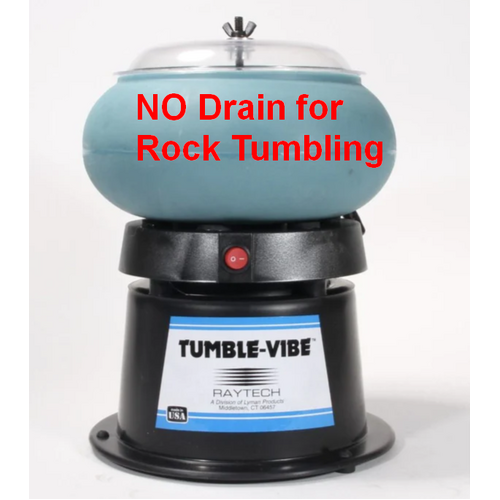

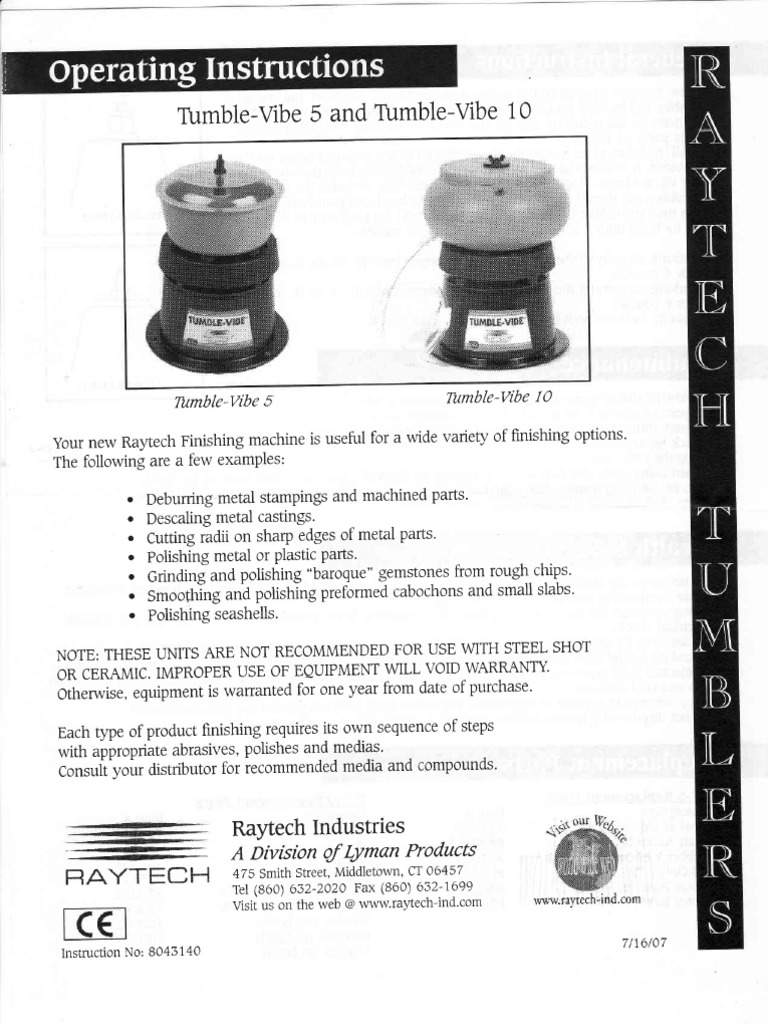

What Are the Key Characteristics of Tumble-Vibe 5?

The Tumble-Vibe 5 is an entry-level model designed for both hobbyists and small commercial applications. With an 8-inch bowl, it holds about 4 pounds of material, making it ideal for smaller batches. Its affordable price point is attractive for new businesses, although buyers should note that it may produce significant noise and requires careful monitoring during operation. This model is suitable for deburring and polishing small metal and plastic parts, making it a versatile choice for various applications.

How Does the Tumble-Vibe 10 Differ from Other Models?

The Tumble-Vibe 10 offers a larger bowl capacity compared to the Tumble-Vibe 5, accommodating more substantial loads, which is beneficial for mid-sized operations. It is available in versions with and without a drain, allowing for easier media and part removal. This model is particularly favored in jewelry polishing and small-scale manufacturing. While it does come at a higher price, the increased efficiency and capacity can justify the investment for businesses looking to scale operations.

What Advantages Does the Adjusta-Vibe 18 Provide for Industrial Applications?

The Adjusta-Vibe 18 stands out due to its adjustable vibration settings, which allow users to customize the intensity based on the material and desired finish. Its robust design makes it suitable for industrial applications, where durability and reliability are paramount. While the initial investment is higher than other models, the ability to fine-tune operations can lead to better end results and reduced processing times, making it a worthwhile consideration for businesses focused on quality.

Why Choose the Tumble-Dump 40 for Bulk Processing?

The Tumble-Dump 40 is engineered for high-volume processing, featuring a large capacity that accommodates bulk materials. This model is perfect for mass production environments, where efficiency and throughput are critical. While it requires more floor space and comes with a higher price tag, the benefits of increased productivity can significantly outweigh these drawbacks for companies engaged in large-scale manufacturing.

What Makes the Tumble-Dump 75 Ideal for Specialized Finishing?

The Tumble-Dump 75 is designed for operations requiring specialized finishing processes, featuring a dual-drum design that enhances efficiency. Its exceptional capacity allows for processing large quantities simultaneously, making it ideal for high-volume operations. However, potential buyers should be aware of the complexity in operation and the significant upfront costs. For businesses focused on maximizing output and minimizing labor, this model can provide substantial long-term benefits.

Key Industrial Applications of tumble vibe

| Industry/Sector | Specific Application of tumble vibe | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Deburring metal components | Enhances product quality by removing sharp edges | Voltage compatibility (115V/230V) for local standards |

| Jewelry | Polishing metal and plastic parts | Improves aesthetic appeal, increasing market value | Size capacity and media type for different materials |

| Rock and Mineral Industry | Polishing and finishing of rocks and gemstones | Boosts product quality, making them more marketable | Media selection for specific stone types |

| Automotive | Surface finishing of machined parts | Reduces production time and improves surface integrity | Durability and reliability of the tumbler machine |

| Electronics | Cleaning and finishing electronic components | Ensures optimal performance and longevity of parts | International certifications and safety standards |

How is Tumble Vibe Used in Manufacturing for Deburring Metal Components?

In the manufacturing sector, tumble vibe machines are primarily employed for deburring metal components. This process involves using vibratory tumblers to remove sharp edges and burrs from metal stampings and machined parts. By using a tumbler, businesses can ensure higher product quality and consistency, which is crucial for maintaining competitive advantage. For international buyers, it is essential to consider the voltage compatibility of the equipment, as different regions may have varying electrical standards (e.g., 115V for the U.S. and 230V for Europe and other areas).

What is the Role of Tumble Vibe in Jewelry Polishing?

In the jewelry industry, tumble vibe machines are utilized to polish both metal and plastic parts, enhancing their aesthetic appeal. This is particularly important in a market where visual presentation can significantly affect sales. Buyers should focus on the size capacity of the tumbler to accommodate various jewelry pieces and the type of polishing media used, as different materials require specific media for optimal results. This consideration helps ensure that the final product meets customer expectations.

How Does Tumble Vibe Benefit the Rock and Mineral Industry?

For the rock and mineral industry, tumble vibe machines serve a critical role in polishing and finishing rocks and gemstones. This application improves the quality of the stones, making them more appealing to consumers and increasing their market value. Buyers in this sector should pay attention to the selection of polishing media, as certain stones require specific types to achieve the desired finish. Additionally, understanding the machine’s capacity to handle different rock sizes is vital for efficient operations.

Illustrative image related to tumble vibe

Why is Tumble Vibe Important in Automotive Surface Finishing?

In the automotive industry, tumble vibe machines are used for surface finishing of various machined parts, ensuring they meet stringent quality standards. This process not only reduces production time but also enhances the integrity of the components, which is vital for vehicle performance and safety. When sourcing these machines, businesses must consider the durability and reliability of the tumbler, as automotive components often undergo rigorous testing and use.

How Does Tumble Vibe Enhance Electronic Component Cleaning?

In electronics manufacturing, tumble vibe machines are essential for cleaning and finishing electronic components. This application ensures that parts are free from contaminants, which can adversely affect their performance and longevity. For international buyers, it is crucial to check for certifications and safety standards to ensure compliance with local regulations. Understanding the specific requirements for electronic components, such as the need for non-abrasive media, is also key to successful sourcing.

3 Common User Pain Points for ‘tumble vibe’ & Their Solutions

Scenario 1: Overcoming Noise Issues in Tumble Vibe Operations

The Problem: One of the most common challenges faced by B2B buyers when using vibratory tumblers, such as the Tumble Vibe, is the excessive noise generated during operation. This can be particularly problematic in environments where noise control is essential, such as in workshops located near residential areas or in shared industrial spaces. The loud operation can not only be a nuisance but also lead to complaints from employees or neighbors, potentially affecting business relationships and workplace morale.

The Solution: To mitigate noise issues, consider implementing several strategies. First, evaluate the placement of the tumbler; positioning it on vibration-absorbing mats can significantly reduce noise levels. Additionally, consider enclosing the tumbler within a soundproof box or cabinet, ensuring that there is adequate ventilation to prevent overheating. Another effective approach is to use sound-dampening materials, such as acoustic foam, around the work area. Regular maintenance of the tumbler can also help; ensuring that all components are tight and in good condition can reduce rattling and vibrations that contribute to noise.

Scenario 2: Ensuring Consistent Polishing Results

The Problem: B2B buyers often encounter inconsistency in the polishing results when using vibratory tumblers for metal or plastic parts. Factors such as uneven media distribution, incorrect media selection, or varying batch sizes can lead to uneven finishes, resulting in additional time and costs to rework items. This is particularly concerning for manufacturers who rely on high-quality finishes for customer satisfaction and brand reputation.

The Solution: To achieve consistent polishing results, start by standardizing the processes and materials used in the tumbling operation. Ensure that the media used is appropriate for the specific materials being polished; for instance, using silicon carbide for harder metals and softer media for delicate plastics. It is advisable to weigh the media and workpieces before each batch to maintain a consistent ratio, typically around 2:1 or 3:1, depending on the material. Regularly monitor and replace the media to avoid contamination, as worn-out media can lead to poor finishes. Implementing a quality control process after tumbling, such as visually inspecting or using measurement tools, can help identify issues early and ensure that the desired results are consistently achieved.

Scenario 3: Managing Machine Overheating and Performance

The Problem: Overheating is a significant concern for users of Tumble Vibe machines, particularly in high-demand environments where machines operate continuously. Overheating can lead to machine failure, decreased efficiency, and increased repair costs. This issue can be exacerbated in regions with higher ambient temperatures, making it crucial for B2B buyers to understand how to manage this risk effectively.

The Solution: To prevent overheating, it is essential to implement a regular maintenance schedule that includes checking motor performance, cleaning the tumbler, and ensuring proper airflow. Consider installing a timer or a temperature monitoring system that can alert operators if the machine exceeds safe operating temperatures. Additionally, when using the tumbler, avoid overloading it beyond its specified capacity, as this can strain the motor and increase the likelihood of overheating. If the tumbler is used for extended periods, consider periodic breaks to allow it to cool down. For buyers in hotter climates, investing in a cooling system or fan to circulate air around the tumbler can also be beneficial in maintaining optimal operating temperatures and prolonging the lifespan of the machine.

Strategic Material Selection Guide for tumble vibe

What Are the Key Materials Used in Tumble Vibe Manufacturing?

When selecting materials for tumble vibe applications, it is essential to consider the specific properties and performance characteristics that will impact the effectiveness and efficiency of the tumbling process. Below are analyses of four common materials used in tumble vibe manufacturing, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

How Does Plastic Impact Tumble Vibe Performance?

Plastic is a widely used material for the bowls and components of tumble vibe machines. It offers excellent corrosion resistance and is lightweight, making it easy to handle. However, plastics can have lower durability compared to metals, particularly under high-temperature conditions. This can limit their use in applications requiring extended operational periods or high-stress environments.

Pros: Lightweight, corrosion-resistant, cost-effective, and easy to mold into complex shapes.

Cons: Lower durability, potential for wear over time, and sensitivity to high temperatures.

For international buyers, particularly those in regions with varying climate conditions, it’s crucial to ensure that the selected plastic can withstand local environmental factors, such as humidity and temperature fluctuations. Compliance with international standards, such as ASTM for materials, is also a consideration.

Illustrative image related to tumble vibe

What Role Does Stainless Steel Play in Tumble Vibe Applications?

Stainless steel is often chosen for its exceptional durability and resistance to corrosion, making it suitable for heavy-duty applications. Its high strength allows it to withstand the rigors of continuous operation, which is particularly beneficial for commercial users. However, stainless steel can be more expensive and may require additional manufacturing processes, such as welding or machining.

Pros: High durability, excellent corrosion resistance, and suitable for high-stress applications.

Cons: Higher cost, potential for rust in certain environments, and more complex manufacturing processes.

For buyers in Africa and the Middle East, where corrosion from saline environments can be a concern, selecting high-grade stainless steel that meets specific standards (e.g., ASTM A240) is advisable to ensure long-term performance.

How Does Rubber Enhance Tumble Vibe Efficiency?

Rubber is often used in the construction of vibration dampening pads and seals in tumble vibe machines. Its inherent flexibility and shock-absorbing properties help reduce noise and vibration, improving user comfort and machine longevity. However, rubber can degrade over time, especially when exposed to certain chemicals or extreme temperatures.

Pros: Excellent vibration dampening, cost-effective, and easy to install.

Cons: Limited lifespan under harsh conditions, potential for chemical degradation, and may require frequent replacement.

For B2B buyers in regions with high temperatures or exposure to chemicals, it is critical to choose rubber compounds that are specifically designed for durability and resistance to environmental factors.

What Advantages Does Aluminum Offer in Tumble Vibe Equipment?

Aluminum is a lightweight yet strong material that is often used in the frames and structural components of tumble vibe machines. It provides a good balance of strength and weight, allowing for easier mobility and installation. However, aluminum can be prone to scratching and denting, which may affect its aesthetic and functional performance over time.

Illustrative image related to tumble vibe

Pros: Lightweight, good strength-to-weight ratio, and resistant to corrosion.

Cons: Susceptible to surface damage, higher cost compared to plastic, and may require protective coatings.

International buyers should consider the specific grades of aluminum that comply with regional standards (such as JIS in Japan or DIN in Europe) to ensure compatibility with their applications.

Summary Table of Material Selection for Tumble Vibe

| Material | Typical Use Case for tumble vibe | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Plastic | Bowls and components | Lightweight and corrosion-resistant | Lower durability under stress | Low |

| Stainless Steel | Heavy-duty applications | High durability and corrosion resistance | Higher cost and complex manufacturing | High |

| Rubber | Vibration dampening pads | Excellent vibration dampening | Limited lifespan under harsh conditions | Med |

| Aluminum | Structural components | Lightweight with good strength | Susceptible to surface damage | Med |

This comprehensive analysis of materials used in tumble vibe applications will assist international B2B buyers in making informed decisions that align with their operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for tumble vibe

What Are the Key Stages in the Manufacturing Process of Tumble Vibe Machines?

The manufacturing process of tumble vibe machines, particularly in the context of B2B operations, involves several critical stages: material preparation, forming, assembly, and finishing. Each stage is designed to ensure that the final product meets stringent quality standards suitable for various industrial applications.

-

Material Preparation:

The first step is the selection and preparation of raw materials, typically high-grade plastics and metals that can withstand the rigors of vibration and wear. Suppliers often utilize advanced cutting and shaping techniques to ensure that materials are sized correctly. Quality checks during this stage ensure that materials are free from defects, as any imperfections can compromise the machine’s functionality. -

Forming:

In this stage, the prepared materials are shaped into the components of the tumbler. This process may include injection molding for plastic parts and machining for metal components. Precision is critical; tolerances must be adhered to closely to facilitate smooth assembly and operation. Techniques such as CNC machining are commonly employed to achieve the necessary accuracy. -

Assembly:

Once the parts are formed, they are assembled into the final product. This process typically involves the integration of the motor, bowl, and vibration mechanism. During assembly, each component’s fit and function are verified to ensure optimal performance. Automated assembly lines may be used for consistency, but manual inspection remains vital, especially for intricate parts. -

Finishing:

The final stage involves surface treatment and finishing processes, such as polishing or coating, to enhance durability and aesthetics. This may include applying anti-corrosive coatings to metal parts or surface treatment to reduce noise during operation. Quality assurance checks are performed to ensure that the finish meets customer expectations and industry standards.

How Is Quality Assurance Implemented in Tumble Vibe Manufacturing?

Quality assurance (QA) is an integral part of the manufacturing process for tumble vibe machines, ensuring that each unit meets international and industry-specific standards. Understanding these QA protocols is essential for B2B buyers to ensure they receive high-quality products.

Illustrative image related to tumble vibe

-

Adhering to International Standards:

Compliance with international quality standards, such as ISO 9001, is crucial. ISO 9001 provides a framework for consistent quality management systems, ensuring that organizations meet customer and regulatory requirements. In addition, certifications like CE mark are essential for products sold in Europe, indicating that they meet safety, health, and environmental protection standards. -

Key Quality Control Checkpoints:

– Incoming Quality Control (IQC): This initial checkpoint examines raw materials and components upon arrival at the manufacturing facility. Any substandard materials are rejected, ensuring that only high-quality inputs enter the production process.

– In-Process Quality Control (IPQC): Throughout the manufacturing stages, IPQC checks are implemented to monitor production processes. This includes measuring tolerances and inspecting assembly integrity to catch defects early.

– Final Quality Control (FQC): Before shipping, FQC involves comprehensive testing of the finished products. This may include operational testing, noise level assessments, and durability tests to ensure that the machines perform as expected under real-world conditions. -

Common Testing Methods for Tumble Vibe Machines:

Various testing methods are employed to evaluate the performance and safety of tumble vibe machines. These include:

– Vibration Testing: Ensures that the machine operates effectively without excessive noise or instability.

– Load Testing: Verifies that the machine can handle the specified weight and workload without failure.

– Electrical Safety Testing: Checks for compliance with electrical safety standards to prevent hazards during operation.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must take proactive steps to ensure that suppliers adhere to high-quality standards in the manufacturing of tumble vibe machines. Here are actionable strategies for buyers:

-

Conducting Supplier Audits:

Regular audits of suppliers can provide insight into their manufacturing processes and quality control measures. Buyers should evaluate the supplier’s compliance with international standards and their internal QA protocols. This can be done through on-site visits or third-party audit services. -

Requesting Quality Assurance Reports:

Suppliers should be able to provide documentation of their quality assurance processes, including IQC, IPQC, and FQC results. These reports can detail the testing methods used and the outcomes, giving buyers confidence in the product quality. -

Utilizing Third-Party Inspection Services:

Engaging third-party inspection services can provide an unbiased assessment of the manufacturing process and the final product. This is particularly valuable for international buyers who may not have the resources to conduct on-site inspections.

What Are the Unique Quality Control Considerations for International B2B Buyers?

International buyers, especially those from regions such as Africa, South America, the Middle East, and Europe, face unique challenges in ensuring quality control. Understanding these nuances is critical for successful procurement.

-

Cultural and Regulatory Differences:

Different regions may have varying standards and regulations that affect product quality. Buyers should familiarize themselves with local compliance requirements and ensure that suppliers can meet these standards. -

Logistical Challenges:

Shipping and handling can introduce risks to product quality. B2B buyers should ensure that suppliers have robust packaging and shipping practices to prevent damage during transit. -

Communication and Transparency:

Maintaining clear communication with suppliers is essential for effective quality assurance. Buyers should establish channels for feedback and reporting to address any concerns quickly.

By understanding the manufacturing processes and quality assurance practices surrounding tumble vibe machines, B2B buyers can make informed decisions, ensuring they invest in high-quality equipment that meets their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘tumble vibe’

In the competitive landscape of sourcing ‘tumble vibe’ machinery, B2B buyers must adopt a structured approach to ensure they make informed decisions. This guide provides a step-by-step checklist to streamline the procurement process, helping you navigate technical specifications, supplier evaluations, and post-purchase support.

Illustrative image related to tumble vibe

Step 1: Define Your Technical Specifications

Before initiating your search, clearly outline the technical requirements for the tumble vibe machine. Consider factors such as bowl capacity, motor specifications, and voltage compatibility (e.g., 115V for domestic use and 230V for international).

– Bowl Size: Ensure the bowl size meets your production needs—larger capacities can accommodate more material, which is essential for efficiency.

– Material Compatibility: Identify whether the tumbler will be used for metal, plastic, or rock polishing, as different materials may require specific types of tumblers.

Step 2: Research Potential Suppliers

Conduct thorough research on manufacturers and suppliers that specialize in tumble vibe equipment. Look for reputable companies with a proven track record in your target market regions.

– Online Reviews and Ratings: Check platforms like Trustpilot or industry-specific forums for customer feedback.

– Company History: Investigate how long the supplier has been in business and their market presence in regions like Africa, South America, or Europe.

Step 3: Evaluate Supplier Certifications

Verification of supplier certifications is crucial to ensure compliance with international standards. Look for certifications like CE marking, which indicates that the equipment meets EU safety, health, and environmental requirements.

– Quality Assurance: Ensure that suppliers follow quality management systems such as ISO 9001, which signifies commitment to quality and continuous improvement.

– Environmental Compliance: Check for certifications that demonstrate adherence to environmental regulations, especially if you operate in regions with stringent environmental laws.

Step 4: Request Quotes and Compare Pricing

Gather quotes from multiple suppliers to compare pricing effectively. Ensure that quotes include all costs, such as shipping, taxes, and potential import duties.

– Transparent Breakdown: A detailed quote helps you identify any hidden costs and understand the total investment required.

– Bulk Discounts: Inquire about discounts for bulk purchases, which can significantly reduce your overall costs.

Step 5: Assess After-Sales Support and Warranty Options

Before finalizing your purchase, investigate the after-sales support provided by the supplier. Strong support can mitigate potential issues after installation and operation.

– Warranty Terms: Understand the warranty duration and what it covers. A robust warranty can protect your investment and ensure peace of mind.

– Technical Support: Confirm the availability of technical support, including troubleshooting assistance and replacement parts.

Step 6: Finalize Payment and Shipping Arrangements

Once you have selected a supplier, finalize the payment terms and shipping arrangements. Ensure that the payment method is secure and that the shipping timeline aligns with your operational needs.

– Payment Options: Evaluate various payment methods (e.g., bank transfer, credit terms) to choose what works best for your financial strategy.

– Shipping Method: Discuss shipping options, including express or standard shipping, to determine the best choice for your timeline and budget.

Step 7: Plan for Installation and Training

Finally, ensure you have a plan for the installation and operation of the tumble vibe machine. Some suppliers may offer installation services or training for your team.

– Installation Support: Clarify whether the supplier provides installation assistance, which can help avoid operational delays.

– Training Programs: Consider training sessions for your staff to maximize the efficiency and longevity of the equipment.

By following this checklist, you can navigate the procurement process for tumble vibe machinery with confidence, ensuring that you make informed decisions that align with your business needs.

Comprehensive Cost and Pricing Analysis for tumble vibe Sourcing

What Are the Key Cost Components in Tumble Vibe Manufacturing?

When sourcing Tumble Vibe equipment, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The raw materials used in constructing Tumble Vibe units, such as high-quality plastics and metals, significantly influence pricing. The choice of durable materials can impact both the longevity and performance of the tumbler, making it essential for buyers to consider quality over cost.

-

Labor: Labor costs vary depending on the region and the skill level required for assembly. Regions with lower labor costs may offer competitive pricing, but this can sometimes come at the expense of quality control.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help minimize these costs, allowing suppliers to offer more competitive pricing.

-

Tooling: The initial investment in tooling and molds for production can be substantial. These costs are typically amortized over the production volume, meaning that larger orders may benefit from reduced per-unit costs.

-

Quality Control (QC): Rigorous quality assurance processes add to the overall cost but are critical for ensuring product reliability and customer satisfaction. Certifications such as CE or ISO can also elevate costs but are essential for compliance in certain markets.

-

Logistics: Shipping costs can vary significantly based on the destination. Factors such as distance, mode of transport, and local tariffs or duties should be considered when calculating total costs.

-

Margin: Suppliers will add a markup to cover their costs and profit. This margin can fluctuate based on market demand and competitive pressures.

How Do Price Influencers Affect Tumble Vibe Costs?

Several factors can influence the pricing of Tumble Vibe equipment:

-

Volume/MOQ: Larger orders often qualify for discounts, which can significantly reduce the cost per unit. Buyers should negotiate minimum order quantities (MOQ) to optimize pricing.

-

Specifications and Customization: Custom features or specific technical requirements can increase costs. Buyers should clearly define their needs to avoid unexpected expenses.

-

Materials: The choice of materials directly impacts the price. High-performance materials may cost more initially but can result in lower maintenance and replacement costs over time.

-

Quality and Certifications: Products that meet higher quality standards or come with certifications may carry a premium price but can provide assurance of durability and safety.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with proven track records may command higher prices but often provide better service and reliability.

-

Incoterms: Understanding the terms of shipping, such as FOB (Free on Board) or CIF (Cost Insurance and Freight), is crucial for calculating total landed costs. These terms dictate who bears responsibility for shipping costs and risks.

What Are the Best Negotiation Tips for B2B Buyers in Tumble Vibe Sourcing?

Effective negotiation can lead to cost savings and better terms for buyers:

-

Research and Preparation: Understand market prices and competitor offerings. Having a solid grasp of costs will empower you during negotiations.

-

Leverage Volume Discounts: If your business can commit to larger volumes, leverage this to negotiate better pricing.

-

Consider Total Cost of Ownership (TCO): Evaluate not just the upfront price but also long-term costs related to maintenance, durability, and performance. A higher initial investment may yield lower operational costs.

-

Be Open to Alternatives: If a supplier cannot meet your price point, explore alternative specifications or materials that may help bridge the gap.

-

Build Relationships: Establishing a strong relationship with suppliers can lead to better pricing and more favorable terms in the long run.

What Should International Buyers Consider When Sourcing Tumble Vibe Equipment?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, several unique factors come into play:

-

Currency Fluctuations: Be mindful of currency exchange rates, as they can significantly impact final costs.

-

Import Duties and Taxes: Understand the applicable tariffs and taxes in your country to accurately calculate total costs.

-

Regulatory Compliance: Ensure that the products meet local safety and quality standards to avoid costly delays or penalties.

-

Shipping and Delivery Times: International logistics can introduce delays, so factor in lead times when planning your inventory.

-

Cultural Differences: Being aware of cultural norms in business practices can facilitate smoother negotiations and partnerships.

By understanding these cost components, pricing influencers, and negotiation strategies, B2B buyers can make informed decisions when sourcing Tumble Vibe equipment, ultimately leading to better value and operational efficiency.

Alternatives Analysis: Comparing tumble vibe With Other Solutions

Exploring Alternative Solutions to Tumble Vibe

When considering options for vibratory tumbling, it’s essential to evaluate various alternatives that can meet specific metal finishing needs. Each solution has unique advantages and drawbacks, making it crucial for international B2B buyers to analyze these factors carefully.

Comparison Table

| Comparison Aspect | Tumble Vibe | Rotary Tumblers | Ultrasonic Cleaners |

|---|---|---|---|

| Performance | Effective for deburring and polishing small parts. | Slower, but excellent for uniform finishing of larger items. | Highly effective for intricate cleaning, especially in tight spaces. |

| Cost | Affordable starting at $133.90 for basic models. | Generally higher initial investment, starting around $300. | Higher cost, with units typically starting at $1,000. |

| Ease of Implementation | Simple setup; plug-and-play functionality. | Requires more space and setup time. | Often requires additional training for optimal use. |

| Maintenance | Low maintenance; occasional bowl replacement needed. | Moderate maintenance; periodic motor checks and lubrication required. | Higher maintenance; requires regular cleaning and maintenance of tanks and filters. |

| Best Use Case | Ideal for small batches of items, particularly in jewelry or hobbyist applications. | Best for larger batches and heavier items like automotive parts. | Suitable for delicate components that need thorough cleaning without abrasion. |

Detailed Breakdown of Alternatives

1. Rotary Tumblers

Rotary tumblers operate on a different principle compared to Tumble Vibe units. They rotate items within a barrel, providing a more uniform finish. This method is particularly advantageous for larger parts, as it can handle heavier loads without compromising the integrity of the items being polished. However, the process is slower, which may not be ideal for businesses requiring quick turnaround times. Additionally, rotary tumblers often require more space and setup time, making them less convenient for smaller operations.

2. Ultrasonic Cleaners

Ultrasonic cleaners utilize high-frequency sound waves to agitate a cleaning solution, effectively removing contaminants from surfaces, including intricate designs. This technology is especially beneficial for complex items that are difficult to clean using traditional methods. While ultrasonic cleaners offer superior cleaning capabilities, they come with a higher price tag and may necessitate operator training to achieve optimal results. Their maintenance requirements are also more demanding, as they require regular cleaning of the tanks and filters to maintain efficiency.

Conclusion: Choosing the Right Solution for Your Needs

When selecting the right tumbling solution, B2B buyers should carefully consider their specific operational needs and constraints. Tumble Vibe offers an economical and straightforward option for small-scale operations, particularly in jewelry and hobbyist sectors. For businesses dealing with larger components, rotary tumblers may provide the necessary performance despite slower processing times. On the other hand, if intricate cleaning is a priority, investing in ultrasonic cleaners could yield the best results, albeit at a higher cost and maintenance commitment. Ultimately, understanding the unique requirements of your business will guide you in making an informed decision that aligns with both your budget and operational goals.

Essential Technical Properties and Trade Terminology for tumble vibe

What Are the Key Technical Properties of Tumble Vibe Machines?

When investing in tumble vibe machinery, understanding the essential technical properties can significantly impact operational efficiency and product quality. Here are some critical specifications to consider:

-

Bowl Capacity

Bowl capacity refers to the volume of material the tumbler can handle, typically measured in cubic feet. For example, a unit with a .05 cubic foot bowl can process approximately four pounds of rocks or 25 ring castings. This specification is vital for B2B buyers to ensure they select a machine that meets their production needs without overloading, which could lead to mechanical failure or subpar finishes. -

Voltage and Power Ratings

Tumble vibe machines often come in different voltage options, such as 115V for domestic use and 230V for international markets. The power rating, measured in watts (e.g., 50W for 115V and 40W for 230V), indicates the machine’s efficiency and suitability for continuous operation. Knowing the correct voltage for your region is crucial to avoid electrical issues and ensure optimal performance. -

Noise Level

Noise levels, typically measured in decibels (dB), are particularly important in commercial settings where noise regulations may apply. Many vibratory tumblers operate at around 82 dB, which can be loud in a workspace. Buyers should consider purchasing noise-reduction accessories or soundproofing solutions to maintain a comfortable working environment. -

Motor Specifications

The motor’s horsepower and amperage ratings are essential for understanding the machine’s durability and suitability for specific tasks. For instance, a 0.07 horsepower motor for a 115V machine indicates a robust design capable of handling intensive workloads. This detail is crucial for B2B buyers to ensure they invest in a machine that meets their operational demands without frequent breakdowns. -

Material Composition

The material used in the construction of the tumbler, such as high-density plastic or stainless steel, influences durability and maintenance. Units made from high-quality materials are less prone to wear and tear, thereby reducing long-term operational costs. Buyers should assess material grades to ensure longevity and reliability in demanding environments.

Which Trade Terminology Should B2B Buyers Know Regarding Tumble Vibe Machines?

Understanding industry jargon can enhance communication and negotiation during the procurement process. Here are some common terms relevant to tumble vibe machines:

Illustrative image related to tumble vibe

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reputable suppliers and aftermarket support for their equipment. -

MOQ (Minimum Order Quantity)

MOQ specifies the minimum number of units a supplier is willing to sell. Knowing the MOQ is essential for budgeting and inventory planning, especially for businesses looking to scale their operations without overcommitting resources. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to obtain pricing and terms for specific products. For tumble vibe machines, submitting an RFQ can help buyers compare offers from different manufacturers and ensure they receive the best value for their investment. -

Incoterms (International Commercial Terms)

These are standardized terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for international buyers to avoid unexpected costs and ensure smooth logistics. -

CE Certification

CE marking indicates compliance with European safety standards. For international buyers, especially in Europe, ensuring that tumble vibe machines are CE certified can help guarantee product safety and regulatory compliance.

By understanding these technical properties and terminology, B2B buyers can make informed decisions, optimize their purchasing processes, and ultimately enhance their operational efficiencies in metal finishing applications.

Navigating Market Dynamics and Sourcing Trends in the tumble vibe Sector

What are the Current Market Dynamics and Key Trends in the Tumble Vibe Sector?

The global market for tumble vibe machinery is being driven by increasing demand for efficient metal finishing and polishing solutions across various industries, including jewelry manufacturing, automotive parts, and electronics. As businesses strive for higher quality output and faster production cycles, the adoption of vibratory tumblers has surged. Key trends include the integration of smart technologies such as IoT-enabled devices that allow for real-time monitoring and automation of the finishing process. This is particularly relevant for international buyers from regions like Africa, South America, the Middle East, and Europe, where operational efficiency is paramount.

Moreover, there is a growing emphasis on customization and versatility in tumbler design. Manufacturers are responding by offering machines with adjustable settings and multiple bowl configurations, catering to specific needs such as polishing, deburring, and descaling. In regions like Saudi Arabia and Vietnam, the focus on local sourcing and reduced lead times has prompted buyers to seek out suppliers who can offer both quality products and responsive service.

Another significant trend is the shift towards compact and energy-efficient models, which are becoming increasingly important in markets with high energy costs. As sustainability becomes a priority, buyers are looking for machines that not only perform well but also consume less power and generate less waste.

How are Sustainability and Ethical Sourcing Influencing B2B Decisions in the Tumble Vibe Sector?

Sustainability and ethical sourcing are becoming critical factors for B2B buyers in the tumble vibe sector. Companies are increasingly aware of their environmental impact, prompting them to choose suppliers who prioritize sustainable practices. This includes sourcing materials that are recyclable or made from renewable resources, as well as ensuring that manufacturing processes are eco-friendly.

Certification programs such as ISO 14001 for environmental management systems and other green certifications are gaining traction among suppliers. Buyers are now more inclined to partner with manufacturers who can demonstrate compliance with these standards, reflecting their commitment to reducing carbon footprints.

Illustrative image related to tumble vibe

Additionally, the trend towards transparency in the supply chain is encouraging buyers to inquire about the origins of materials used in the production of tumblers. Ethical sourcing practices not only enhance brand reputation but also align with consumer expectations for corporate responsibility. As a result, B2B buyers are now evaluating suppliers based on their social and environmental impact, making ethical sourcing a pivotal part of procurement strategies.

How Has the Tumble Vibe Sector Evolved Over Time?

The tumble vibe sector has evolved significantly from its early days of basic tumbling machines to the advanced technology seen today. Initially, vibratory tumblers were simple devices used primarily by hobbyists for rock polishing. However, as industries recognized the efficiency and effectiveness of vibratory finishing, the technology was adapted for commercial use.

Over the past few decades, innovations have led to the development of more sophisticated machines capable of handling various materials and complex finishing tasks. The integration of digital controls and automation has further enhanced operational capabilities, enabling manufacturers to achieve consistent results while reducing labor costs. This evolution reflects broader trends in manufacturing where efficiency, customization, and sustainability are driving the development of new technologies.

As the market continues to grow, international B2B buyers are encouraged to stay abreast of technological advancements and trends that can impact their sourcing decisions. Understanding these dynamics is essential for making informed choices that align with their business goals and sustainability commitments.

Frequently Asked Questions (FAQs) for B2B Buyers of tumble vibe

-

How do I choose the right tumble vibe for my business needs?

Choosing the right tumble vibe involves assessing your specific applications, such as polishing, deburring, or descaling. Consider the size and type of materials you will process; for instance, smaller tumblers like the TV-5 are suitable for hobbyist use and small batches, while larger units like the Adjusta-Vibe series cater to higher capacity commercial needs. Additionally, check the voltage compatibility with your region to avoid operational issues. -

What is the best way to maintain and care for my tumble vibe?

Regular maintenance is essential for optimal performance of your tumble vibe. Clean the bowl and lid after each use to prevent media contamination, and check for any wear on the motor and components. Ensure the tumbler is placed on a stable surface to minimize vibration-related wear. Additionally, refer to the manufacturer’s guidelines for any specific maintenance schedules or replacement parts to ensure longevity. -

What are the typical lead times for ordering tumble vibes internationally?

Lead times for international orders can vary based on the supplier, shipping method, and destination. Generally, you can expect a processing time of 1-2 weeks, with shipping taking an additional 2-6 weeks depending on the logistics involved. It’s advisable to communicate with your supplier regarding estimated delivery times and to plan for potential customs delays, particularly when importing equipment into regions with strict regulations. -

What are the common payment terms for purchasing tumble vibes in bulk?

Payment terms can differ by supplier and region. Common arrangements include upfront payment, a deposit with the balance due upon shipment, or payment upon delivery. For international transactions, it’s vital to clarify whether payment will be made via bank transfer, letter of credit, or other methods. Always confirm if any additional fees, such as currency conversion or international transaction fees, apply. -

How can I vet suppliers for tumble vibes effectively?

To vet suppliers, consider their reputation, customer reviews, and industry experience. Request references from other clients and check for certifications that validate their quality standards. Engage in direct communication to assess their responsiveness and willingness to address your concerns. Additionally, inquire about their after-sales support and warranty policies to ensure they stand behind their products. -

What customization options are available for tumble vibes?

Many suppliers offer customization options for tumble vibes to meet specific operational needs. This can include modifications in bowl size, additional features like drainage systems, or specialized media for different finishing processes. Discuss your requirements with potential suppliers to explore available customizations that can enhance efficiency and output quality in your production line. -

What are the minimum order quantities (MOQs) for tumble vibes?

Minimum order quantities can vary significantly among suppliers, often influenced by production costs and shipping logistics. While some suppliers may allow orders of a single unit, others may set MOQs at 5 to 10 units or more. It’s essential to clarify MOQs during initial discussions to plan your procurement strategy accordingly and to understand any pricing implications associated with larger orders. -

How do I handle quality assurance for tumble vibes from international suppliers?

Quality assurance is crucial when sourcing tumble vibes internationally. Implement a quality control process that includes pre-shipment inspections and testing of the equipment upon arrival. Request product certifications and compliance documentation from your supplier. If feasible, consider visiting the manufacturing facility or hiring a third-party inspection service to ensure that the equipment meets your quality standards before finalizing the purchase.

Top 5 Tumble Vibe Manufacturers & Suppliers List

1. Stuller – RAYTECH TUMBLE-VIBE™ Vibratory Tumbler

Domain: stuller.com

Registered: 1996 (29 years)

Introduction: RAYTECH TUMBLE-VIBE™ Vibratory Tumbler; Expedite available; 3 items per request; Unavailable for sizing, engraving, and other customization services; Commodity bands in 14K gold only; $25.00 fee per request; 100% payout in Stuller account credit for gold clean scrap until September 30, 2025.

2. Flinn Scientific – Tumble-Vibe® Rock Tumbler

Domain: flinnsci.com

Registered: 1997 (28 years)

Introduction: Rock Tumbler, Tumble-Vibe®

Item #: AP5263

Price: $204.60

In Stock

Description: The Tumble-Vibe® Rock Tumbler is designed for geology and Earth science applications, useful for smoothing and polishing a wide variety of rocks. It guarantees success in achieving good finishing results when following the provided four-step finishing process. The tumbler can process up to four pounds of rocks at one ti…

3. Aussie Sapphire – Tumble-Vibe 10 Tumbler

Domain: aussiesapphire.com.au

Introduction: The Tumble-Vibe 10 Tumbler (TV10) requires simple assembly and includes the following components: tumbler base, bowl and lid, drainage hose, a plastic bag of nuts, and a centre bolt. Assembly steps include: 1) screwing the threaded rod into the centre hole and securing with a washer and nut; 2) using a rubber-backed washer and nut to secure the bowl to the tumbler base without over-tightening; 3) …

4. Raytech – Tumble-Vibe 10 Polisher

Domain: orchid.ganoksin.com

Registered: 1996 (29 years)

Introduction: Raytech tumble-vibe 10, used for polishing jewelry; recommended media includes green polish shine and cobb meal; issues reported with green polish build-up and potential damage to fragile stones; suggested cleaning methods include using a toothbrush with 409 or Windex, and a small cardboard box for shaking to remove debris; alternative cleaning solution mentioned is an ionic cleaning machine (Spee…

5. Ray Tech – Tumble-Vibe

Strategic Sourcing Conclusion and Outlook for tumble vibe

As the demand for efficient and cost-effective metal and stone finishing solutions continues to grow, the strategic sourcing of vibratory tumblers, particularly Tumble Vibe models, presents a significant opportunity for international B2B buyers. These machines offer versatility in applications such as deburring, polishing, and descaling, making them essential tools in various industries, including jewelry, metalworking, and hobbyist markets.

Illustrative image related to tumble vibe

Investing in high-quality Tumble Vibe units not only enhances operational efficiency but also ensures consistent product quality. The availability of different models caters to diverse needs, from small hobbyist operations to larger commercial enterprises. Buyers should prioritize suppliers who offer robust customer support, warranty options, and replacement parts to maximize their investment and ensure uninterrupted operations.

Looking ahead, the market for vibratory tumblers is poised for growth, driven by advancements in technology and increasing global demand. By engaging in strategic sourcing, businesses can secure competitive pricing and reliable supply chains. International buyers from Africa, South America, the Middle East, and Europe are encouraged to explore partnerships with reputable suppliers to capitalize on these trends and enhance their operational capabilities. Embrace the opportunity to streamline your processes and elevate your product quality today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to tumble vibe

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.