A Deep Dive into Titanium Carbide Vs Tungsten Carbide Solution

Introduction: Navigating the Global Market for titanium carbide vs tungsten carbide

In today’s competitive manufacturing landscape, sourcing the right materials, such as titanium carbide and tungsten carbide, is crucial for optimizing performance and cost efficiency. With both materials boasting exceptional durability and unique properties, international B2B buyers face the challenge of navigating their distinct advantages and applications. This guide serves as a comprehensive resource that delves into the types, applications, and performance characteristics of titanium carbide and tungsten carbide, equipping decision-makers with the insights needed to make informed purchasing decisions.

As the global market continues to evolve, understanding the nuances of these two materials is essential, especially for buyers from regions like Africa, South America, the Middle East, and Europe, including countries such as Nigeria and Brazil. This guide will explore critical factors such as supplier vetting processes, cost analysis, and environmental impacts to help you identify the most suitable material for your specific applications.

By providing actionable insights and a detailed comparison of titanium carbide and tungsten carbide, this guide empowers B2B buyers to enhance their sourcing strategies, ultimately leading to improved product quality, reduced production costs, and a competitive edge in the marketplace. Whether you are involved in manufacturing, aerospace, or heavy machinery, understanding the right applications for these materials will significantly impact your operational success.

Understanding titanium carbide vs tungsten carbide Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tungsten Carbide (WC) | High density, exceptional hardness (8.5-9 Mohs) | Cutting tools, drill bits, jewelry | Pros: Extremely durable, wear-resistant; Cons: Heavier, less cost-effective for some applications. |

| Titanium Carbide (TiC) | Lower density, higher hardness (9-9.5 Mohs), good chemical stability | Coatings, biomedical applications | Pros: Excellent wear resistance, lightweight; Cons: Higher production costs, lower toughness. |

| Cemented Carbides | Composite materials combining tungsten carbide or titanium carbide with a metal binder | Mining, machining, manufacturing | Pros: Tailored properties, improved toughness; Cons: May require more complex manufacturing processes. |

| Titanium Carbide Coatings | Thin layers of TiC applied to surfaces for enhanced properties | Aerospace, automotive, electronics | Pros: Enhanced surface hardness, corrosion resistance; Cons: Application costs may be high. |

| Tungsten Carbide Composites | Mixtures of tungsten carbide with other materials for specific applications | Oil & gas, construction, military | Pros: Customizable properties, high performance; Cons: Potentially higher costs and complexity in sourcing. |

What Are the Key Characteristics of Tungsten Carbide (WC) for B2B Buyers?

Tungsten carbide is characterized by its remarkable hardness and density, making it ideal for high-stress applications such as cutting tools and drill bits. With a Mohs hardness of 8.5-9, it excels in wear resistance, ensuring longevity in demanding environments. B2B buyers should consider its weight and production costs, as tungsten carbide can be heavier and more expensive than alternatives, which might influence the choice for specific applications like jewelry or industrial tools.

How Does Titanium Carbide (TiC) Stand Out in Industrial Applications?

Titanium carbide offers a unique combination of lower density and superior hardness, rated between 9-9.5 on the Mohs scale. This makes it particularly suitable for applications requiring high wear resistance, such as coatings in aerospace and biomedical fields. Buyers should be aware of its higher production costs and relatively lower toughness compared to tungsten carbide, which can affect its suitability for certain applications.

What Are Cemented Carbides and Their Benefits for B2B Buyers?

Cemented carbides are composite materials that combine tungsten or titanium carbide with a metal binder, enhancing toughness and wear resistance. These materials are widely used in mining and manufacturing, where durability is paramount. Buyers should evaluate the tailored properties of cemented carbides against their specific requirements, as the complex manufacturing processes may introduce additional costs.

Why Consider Titanium Carbide Coatings for Advanced Applications?

Titanium carbide coatings provide a thin, durable layer that enhances the hardness and chemical stability of various substrates. Commonly used in aerospace and automotive sectors, these coatings improve wear resistance and reduce friction. B2B buyers must consider the application costs and the need for specialized equipment to apply these coatings, which can impact overall project budgets.

How Do Tungsten Carbide Composites Meet Diverse Industry Needs?

Tungsten carbide composites combine tungsten carbide with other materials to create tailored solutions for industries such as oil and gas, construction, and military applications. These composites offer customizable properties, making them suitable for specific performance requirements. Buyers should consider the potential higher costs and sourcing complexities associated with these materials, as they often demand specialized manufacturing capabilities.

Illustrative image related to titanium carbide vs tungsten carbide

Key Industrial Applications of titanium carbide vs tungsten carbide

| Industry/Sector | Specific Application of titanium carbide vs tungsten carbide | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Mining & Drilling | Tungsten carbide drill bits for oil and gas exploration | Enhanced durability and wear resistance | Availability of high-quality tungsten carbide sources; certifications for harsh environments |

| Manufacturing | Titanium carbide coatings for cutting tools | Improved tool life and cutting efficiency | Sourcing from reputable manufacturers with proven performance in high-speed machining |

| Aerospace & Defense | Titanium carbide components in aerospace applications | Weight reduction without compromising strength | Compliance with aerospace standards and regulations; material traceability |

| Medical Devices | Titanium carbide in surgical instruments | Biocompatibility and long-lasting sharpness | Certifications for biocompatibility; sourcing from suppliers with medical-grade materials |

| Automotive | Tungsten carbide inserts for engine components | Increased performance and longevity | Supplier reliability and ability to meet production schedules; cost-effectiveness in bulk orders |

How is Tungsten Carbide Used in Mining and Drilling?

In the mining and drilling sectors, tungsten carbide is predominantly used for manufacturing drill bits and other cutting tools. Its exceptional hardness and wear resistance make it ideal for penetrating tough geological formations. This application solves the challenge of frequent tool replacements, thereby enhancing operational efficiency and reducing downtime. For international buyers, especially in Africa and South America, sourcing tungsten carbide drill bits requires attention to quality certifications and the ability to withstand extreme conditions typical in mining operations.

What Role Does Titanium Carbide Play in Manufacturing?

Titanium carbide is often employed as a coating for cutting tools in manufacturing settings. This application enhances tool life and increases cutting efficiency by providing superior wear resistance. The use of titanium carbide coatings allows manufacturers to achieve tighter tolerances and better finishes on machined parts. Buyers in Europe and the Middle East should prioritize sourcing from suppliers who demonstrate proven performance metrics and compatibility with various machining processes, ensuring that the coatings can withstand high-speed operations.

How is Titanium Carbide Beneficial in Aerospace and Defense?

In aerospace applications, titanium carbide is utilized for components that require high strength-to-weight ratios. The material’s lightweight nature combined with its durability is critical for enhancing fuel efficiency in aircraft. This application addresses the challenges of weight reduction while maintaining structural integrity. International buyers, particularly those in the Middle East, must ensure that their suppliers comply with stringent aerospace standards and can provide material traceability to meet regulatory requirements.

Why is Titanium Carbide Important in Medical Devices?

Titanium carbide is increasingly being used in the production of surgical instruments due to its biocompatibility and ability to maintain sharpness over time. This application solves the problem of instrument wear in surgical settings, thus ensuring precision and safety during procedures. Buyers in the medical sector, especially in regions like Europe, should focus on sourcing from manufacturers that offer certified medical-grade titanium carbide products, ensuring compliance with health regulations and standards.

How Does Tungsten Carbide Enhance Automotive Performance?

In the automotive industry, tungsten carbide is frequently used for inserts in engine components. Its high density and strength contribute to enhanced performance and longevity of parts, thereby reducing maintenance costs. This application addresses the need for durable components that can withstand high-stress environments. B2B buyers in South America should prioritize reliable suppliers who can meet production demands and provide cost-effective solutions for bulk orders, ensuring that they maintain competitive pricing in the market.

3 Common User Pain Points for ‘titanium carbide vs tungsten carbide’ & Their Solutions

Scenario 1: Navigating Cost-Effectiveness in Material Selection

The Problem: When sourcing materials for manufacturing, many B2B buyers grapple with the cost differential between titanium carbide and tungsten carbide. Titanium carbide, while offering superior hardness and wear resistance, often comes with a higher production cost. Buyers in regions like Africa and South America may find it challenging to justify the increased expense when sourcing materials for cutting tools or industrial applications, particularly when budget constraints are a primary concern.

The Solution: To tackle this cost-related challenge, buyers should conduct a comprehensive cost-benefit analysis that factors in not only the initial purchase price but also the long-term performance and lifecycle costs of each material. For instance, while titanium carbide may have a higher upfront cost, its extended service life and reduced maintenance needs can offset this initial investment in high-demand applications. Collaborating with suppliers who offer bulk purchasing agreements or loyalty discounts can also help mitigate costs. Additionally, leveraging advanced manufacturing techniques such as additive manufacturing may allow for more efficient use of materials, reducing waste and maximizing the utility of both titanium carbide and tungsten carbide.

Illustrative image related to titanium carbide vs tungsten carbide

Scenario 2: Assessing Material Performance in Extreme Conditions

The Problem: Buyers in industries such as aerospace or mining often face the daunting task of selecting the right carbide material that can withstand extreme environmental conditions. For example, while tungsten carbide is recognized for its toughness in high-impact scenarios, titanium carbide may perform better in high-temperature settings due to its superior wear resistance. This duality can lead to uncertainty in decision-making, especially when specifications are not clearly understood.

The Solution: To address this issue, it is crucial for buyers to collaborate closely with material scientists or engineers who can provide insights into the specific properties of each carbide. Conducting material testing under simulated operational conditions can yield valuable data that informs the selection process. Additionally, utilizing detailed product specifications from suppliers can help buyers understand the performance limits of titanium carbide and tungsten carbide under different stresses. Developing a clear set of criteria based on application requirements—such as temperature resistance, wear patterns, and mechanical stress—will enable buyers to make informed decisions that align with their operational needs.

Scenario 3: Understanding Environmental Impact and Sustainability

The Problem: As businesses worldwide increasingly prioritize sustainability, B2B buyers are challenged to select materials that align with environmentally responsible practices. The production processes for titanium carbide and tungsten carbide can be energy-intensive and may contribute to a larger carbon footprint. Buyers in Europe and the Middle East, where environmental regulations are stringent, may struggle to find materials that meet both performance and sustainability criteria.

The Solution: To navigate these sustainability concerns, buyers should seek suppliers who prioritize eco-friendly production methods and offer detailed information about their environmental impact. This includes requesting lifecycle assessments (LCA) that evaluate the carbon footprint of both titanium carbide and tungsten carbide from extraction to end-of-life. Additionally, buyers can explore the option of recycled carbide materials, which not only reduce environmental impact but also often come at a lower cost. Forming partnerships with suppliers committed to sustainable practices can enhance a company’s reputation and align with broader corporate social responsibility goals. Furthermore, buyers can engage in dialogue with manufacturers to push for innovations in production techniques that minimize energy consumption and waste.

Strategic Material Selection Guide for titanium carbide vs tungsten carbide

When evaluating titanium carbide (TiC) and tungsten carbide (WC) for industrial applications, understanding their key properties, advantages, and limitations is essential for international B2B buyers. This analysis will focus on these two materials, providing insights relevant to buyers from regions such as Africa, South America, the Middle East, and Europe.

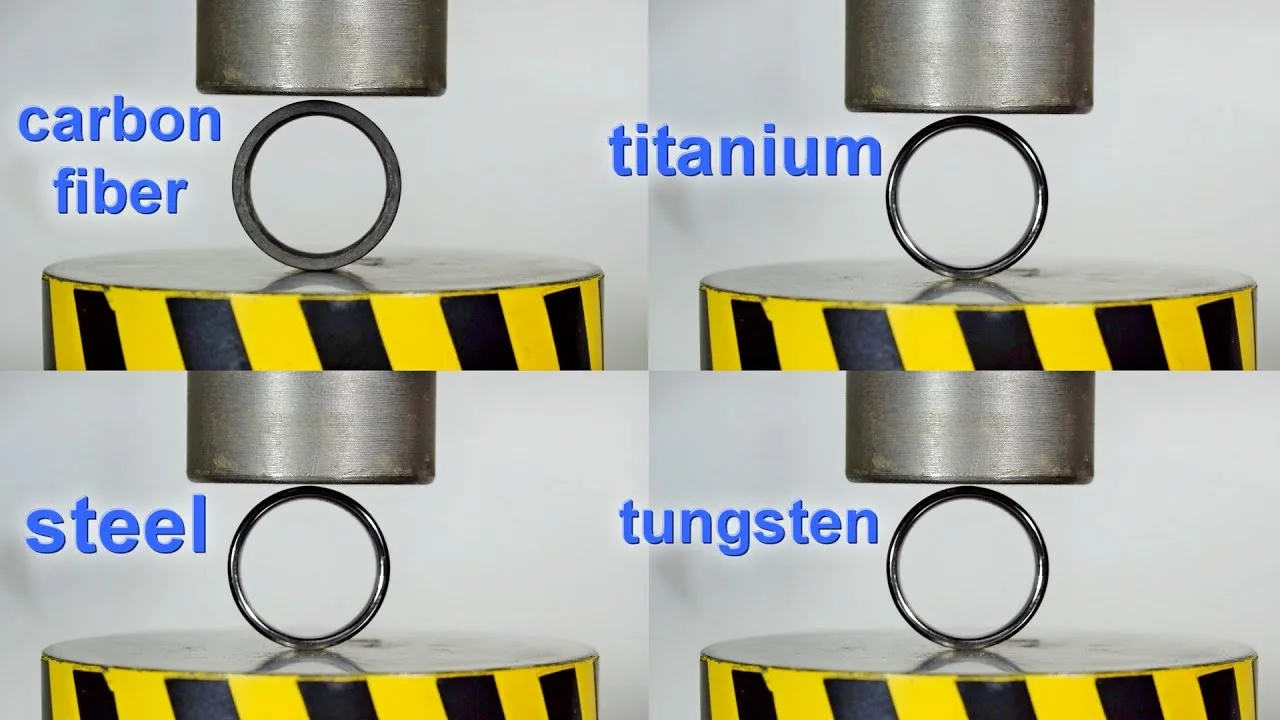

What Are the Key Properties of Titanium Carbide and Tungsten Carbide?

Titanium Carbide (TiC) is known for its high hardness, rated between 9 and 9.5 on the Mohs scale, and excellent wear resistance, particularly in high-temperature environments. It has a lower density (4.93 g/cm³) compared to tungsten carbide, making it suitable for applications where weight is a concern. TiC also exhibits good chemical stability, which is advantageous in corrosive environments.

Tungsten Carbide (WC), on the other hand, boasts a hardness of 8.5 to 9 on the Mohs scale and a higher density (15.63 g/cm³). This material is renowned for its toughness, making it ideal for heavy-duty applications such as cutting tools and drilling equipment. With a higher melting point (2870 °C) than TiC, tungsten carbide can withstand extreme temperatures, which is crucial in high-stress applications.

What Are the Pros and Cons of Each Material?

Pros of Titanium Carbide:

– High Wear Resistance: TiC outperforms WC in wear resistance, particularly in high-temperature conditions, making it suitable for applications in aerospace and automotive sectors.

– Lower Density: The lightweight nature of TiC can lead to reduced operational costs in applications where weight savings are critical.

Cons of Titanium Carbide:

– Higher Production Costs: The manufacturing process for TiC is more complex and energy-intensive, leading to higher costs that may impact pricing strategies.

– Lower Toughness: While hard, TiC is less tough than WC, which can limit its use in applications requiring high impact resistance.

Pros of Tungsten Carbide:

– Exceptional Toughness: WC is highly durable and can withstand significant mechanical stress, making it a preferred choice for cutting tools and wear-resistant applications.

– Cost-Effectiveness: Generally, WC is less expensive to produce than TiC, making it a more budget-friendly option for many industries.

Cons of Tungsten Carbide:

– Higher Density: The weight of WC can be a disadvantage in applications where lightweight materials are preferred.

– Limited Corrosion Resistance: While WC is tough, it may not perform as well as TiC in corrosive environments, which could limit its application in certain sectors.

How Do These Materials Impact Specific Applications?

The choice between TiC and WC significantly impacts application performance. For instance, in industries like mining and drilling, where tools face extreme wear and tear, tungsten carbide’s toughness and durability are crucial. Conversely, in sectors such as aerospace, where weight and heat resistance are paramount, titanium carbide’s properties may offer a better solution.

What Should International B2B Buyers Consider?

When sourcing these materials, international buyers must consider compliance with industry standards such as ASTM, DIN, or JIS, which can vary by region. For example, buyers in Nigeria and Brazil may face different regulatory environments compared to those in Europe. Additionally, understanding local market preferences and the availability of materials can influence procurement strategies.

Illustrative image related to titanium carbide vs tungsten carbide

Summary Table of Material Selection

| Material | Typical Use Case for titanium carbide vs tungsten carbide | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Titanium Carbide (TiC) | Aerospace components, high-performance coatings | High wear resistance at elevated temperatures | Higher production costs | High |

| Tungsten Carbide (WC) | Cutting tools, mining equipment | Exceptional toughness and durability | Heavier and less corrosion-resistant | Medium |

This strategic material selection guide provides a clear comparison between titanium carbide and tungsten carbide, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for titanium carbide vs tungsten carbide

What Are the Main Stages of the Manufacturing Process for Titanium Carbide and Tungsten Carbide?

The manufacturing processes for titanium carbide (TiC) and tungsten carbide (WC) involve several critical stages, each essential for ensuring the final product meets the rigorous demands of various applications. Understanding these processes allows B2B buyers to make informed decisions when selecting suppliers.

1. Material Preparation

Raw Material Selection: The production of both TiC and WC begins with the careful selection of raw materials. For titanium carbide, titanium dioxide (TiO2) and carbon sources (such as petroleum coke) are used. In contrast, tungsten carbide is primarily produced from tungsten metal and carbon.

Sourcing and Quality Control: Reliable sourcing of raw materials is crucial. Suppliers should provide certifications for the purity and quality of the materials, typically in compliance with international standards such as ISO 9001. This is important for ensuring consistent performance in the final products.

2. Forming Techniques

Powder Metallurgy: Both TiC and WC are predominantly manufactured using powder metallurgy. This process involves mixing the powdered raw materials in precise ratios. For tungsten carbide, the typical ratio is 6-8% carbon to tungsten, while for titanium carbide, the carbon content can vary based on the desired properties.

Compaction: The mixed powders undergo cold pressing, where they are compacted into desired shapes under high pressure. This step is critical as it determines the density and mechanical properties of the final product.

Sintering: Following compaction, the formed pieces are sintered in a controlled atmosphere furnace. This process involves heating the compacted powders to high temperatures without reaching their melting points, allowing them to bond together. The sintering temperature for WC is typically around 1400-1600°C, while TiC requires slightly lower temperatures.

3. Assembly and Finishing

Machining: After sintering, the components may require additional machining to achieve specific dimensions and surface finishes. This can involve grinding, milling, or turning processes. Given the hardness of both materials, specialized equipment is often necessary.

Coating and Surface Treatments: For titanium carbide, additional surface coatings may be applied to enhance properties such as wear resistance or corrosion protection. Techniques like chemical vapor deposition (CVD) or physical vapor deposition (PVD) are commonly used.

How Is Quality Assurance Implemented in the Manufacturing of Titanium Carbide and Tungsten Carbide?

Quality assurance (QA) is integral to the manufacturing process of titanium and tungsten carbide. Implementing rigorous QA processes ensures that the final products meet the required specifications and standards.

International Standards for Quality Assurance

ISO 9001 Compliance: Many manufacturers adhere to ISO 9001 standards, which provide a framework for quality management systems. Compliance ensures that processes are standardized, documented, and continuously improved.

Illustrative image related to titanium carbide vs tungsten carbide

Industry-Specific Certifications: Depending on the application, additional certifications may be necessary. For example, products intended for the oil and gas sector may require API (American Petroleum Institute) certification, while those used in medical applications might need CE marking.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is an ongoing process throughout the manufacturing lifecycle of TiC and WC. Key checkpoints include:

1. Incoming Quality Control (IQC)

Before production begins, raw materials undergo inspection and testing to verify compliance with specifications. This can involve chemical analysis to check for impurities and consistency in material properties.

2. In-Process Quality Control (IPQC)

During the manufacturing process, periodic checks are performed at various stages. This includes monitoring the compaction process to ensure uniform density and verifying sintering conditions to prevent defects.

3. Final Quality Control (FQC)

Once the products are finished, they undergo final inspections. Common testing methods include:

- Hardness Testing: To ensure that the materials meet the required hardness specifications.

- Microstructure Analysis: Using scanning electron microscopy (SEM) to assess the grain structure and detect any anomalies.

- Dimensional Checks: Verifying that the final dimensions adhere to the specified tolerances.

How Can B2B Buyers Verify Supplier Quality Control Measures?

To ensure that suppliers maintain high-quality standards, B2B buyers can take several proactive steps:

1. Conduct Audits

Regular audits of potential suppliers can provide insights into their manufacturing processes and quality control systems. This includes reviewing their compliance with international standards and assessing the effectiveness of their QA protocols.

2. Request Documentation

Buyers should request documentation, including quality certificates, inspection reports, and compliance records. This documentation serves as proof of adherence to required standards and can help in evaluating the supplier’s reliability.

3. Utilize Third-Party Inspections

Engaging third-party inspection services can add an extra layer of assurance. These independent entities can conduct inspections and testing to verify that the products meet specified standards before shipment.

What Are the Quality Control Nuances for International Buyers from Africa, South America, the Middle East, and Europe?

International B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, face unique challenges and considerations:

- Regulatory Compliance: Different regions may have specific regulations regarding the import and use of carbide materials. Buyers should familiarize themselves with local regulations to ensure compliance.

- Supply Chain Transparency: Given the global nature of supply chains, it is essential to establish clear communication with suppliers regarding sourcing practices and material quality.

- Cultural and Language Barriers: Buyers should consider cultural differences and potential language barriers when negotiating contracts and quality expectations with international suppliers.

By understanding the manufacturing processes and quality assurance measures for titanium carbide and tungsten carbide, B2B buyers can make informed decisions that align with their operational requirements and standards. This knowledge not only enhances product reliability but also fosters stronger supplier relationships, ensuring long-term success in their industries.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘titanium carbide vs tungsten carbide’

Introduction

Navigating the procurement process for titanium carbide (TiC) and tungsten carbide (WC) can be complex, given their distinct properties and applications. This guide serves as a practical checklist for international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, to ensure a thorough and informed sourcing decision. By following these steps, you can align your procurement strategy with your technical requirements and business goals.

Step 1: Define Your Technical Specifications

Clearly outlining your technical specifications is the first step in the sourcing process. Identify the specific properties you need—such as hardness, wear resistance, and thermal stability. This clarity will help you compare the materials effectively and ensure they meet your application requirements.

- Determine Application Requirements: Consider the intended use, whether for cutting tools, coatings, or biomedical applications.

- Specify Performance Metrics: Include details like hardness ratings and temperature tolerance to facilitate precise comparisons.

Step 2: Conduct Market Research

Understanding the market landscape is essential for effective sourcing. Research the current trends, pricing, and availability of titanium carbide and tungsten carbide in your target regions. This knowledge will empower you to make informed decisions and negotiate better terms.

- Identify Leading Suppliers: Look for suppliers with a strong reputation and a proven track record in your industry.

- Assess Regional Variations: Prices and availability can vary significantly across regions; consider local suppliers for better logistics and support.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s crucial to vet them thoroughly. Request company profiles, case studies, and references from buyers in similar industries or regions. A solid supplier partnership can significantly impact your product quality and supply chain reliability.

- Check Certifications: Ensure the supplier adheres to international quality standards and possesses relevant certifications.

- Review Customer Feedback: Analyze reviews and testimonials to gauge supplier reliability and service quality.

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of both titanium carbide and tungsten carbide. Testing samples allows you to evaluate the material’s performance against your specifications in real-world conditions.

Illustrative image related to titanium carbide vs tungsten carbide

- Conduct Performance Tests: Assess key properties such as hardness, wear resistance, and thermal stability through standardized tests.

- Evaluate Consistency: Ensure that the samples represent the quality you expect from bulk orders.

Step 5: Analyze Cost-Effectiveness

Cost is a critical factor in the procurement process. Analyze the total cost of ownership, including production costs, expected service life, and potential recycling options. This analysis will help you determine the best value for your investment.

- Compare Production Costs: Understand how material properties affect the overall cost, factoring in both TiC and WC options.

- Consider Long-Term Value: Evaluate which material offers the best performance and longevity for your specific application to justify the initial expenditure.

Step 6: Negotiate Terms and Conditions

Once you’ve selected a supplier, the next step is to negotiate terms and conditions. Ensure that all aspects of the agreement align with your business needs, including pricing, delivery schedules, and payment terms.

- Establish Clear Expectations: Define quality standards, delivery timelines, and support services in the contract.

- Discuss Future Collaboration: Explore possibilities for long-term partnerships, which can lead to better pricing and priority service.

Step 7: Monitor Supplier Performance Post-Procurement

After procurement, it’s essential to monitor the supplier’s performance regularly. Establish metrics to evaluate their reliability, quality, and responsiveness to any issues that may arise.

- Implement Feedback Mechanisms: Regularly review supplier performance and provide feedback to ensure continuous improvement.

- Adapt Procurement Strategies: Be prepared to adjust your sourcing strategy based on supplier performance and market changes.

By following this checklist, B2B buyers can confidently navigate the complexities of sourcing titanium carbide and tungsten carbide, ensuring they select the right materials for their needs.

Illustrative image related to titanium carbide vs tungsten carbide

Comprehensive Cost and Pricing Analysis for titanium carbide vs tungsten carbide Sourcing

When evaluating the cost and pricing dynamics of titanium carbide (TiC) versus tungsten carbide (WC), B2B buyers must consider a multitude of cost components and price influencers that can significantly impact their sourcing decisions.

What Are the Key Cost Components in Sourcing Titanium and Tungsten Carbide?

-

Materials: The base materials for both titanium carbide and tungsten carbide play a crucial role in determining the overall cost. Tungsten carbide generally has a lower production cost due to the more abundant availability of tungsten compared to titanium. Conversely, titanium carbide, while offering superior wear resistance, incurs higher material costs linked to titanium’s extraction and refinement processes.

-

Labor: Labor costs can vary significantly based on the complexity of manufacturing processes. Titanium carbide, often requiring more sophisticated processing techniques, may have higher labor costs associated with its production compared to tungsten carbide.

-

Manufacturing Overhead: This includes expenses related to machinery, utilities, and facility maintenance. Given the specialized equipment required for producing both materials, overhead costs can be substantial. However, tungsten carbide production may benefit from established manufacturing efficiencies, potentially lowering overhead costs.

-

Tooling: The tooling required for each material can differ. Titanium carbide often demands more advanced tooling due to its hardness, leading to higher initial tooling costs. Tungsten carbide, being more common, may have more readily available tooling options, which can reduce costs.

-

Quality Control (QC): The need for stringent quality control processes can add to the overall cost. Titanium carbide’s applications in high-tech and medical fields necessitate rigorous QC measures, which can drive up the price compared to tungsten carbide.

-

Logistics: Shipping costs can vary based on the material’s density and weight. Tungsten carbide, being denser, may incur higher shipping costs relative to its volume. Additionally, international logistics can be affected by local regulations and tariffs, particularly relevant for buyers in regions like Africa and South America.

-

Margin: Supplier margins can vary based on market conditions and competition. Buyers should be aware of the typical margins in their region to better understand the pricing landscape.

What Influences the Pricing of Titanium and Tungsten Carbide?

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically result in lower per-unit costs. Buyers should negotiate for bulk pricing, especially when sourcing from suppliers that operate on a tiered pricing model.

-

Specifications and Customization: Tailoring specifications for unique applications can lead to increased costs. Buyers should clearly define their requirements to avoid unexpected price escalations.

-

Quality Certifications: Materials that meet specific quality standards (ISO, ASTM, etc.) may command higher prices. Buyers should assess whether these certifications are necessary for their applications to avoid unnecessary costs.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge a premium for their products due to perceived quality and service, while newer entrants might offer competitive pricing to gain market share.

-

Incoterms: Understanding the terms of shipping and delivery (e.g., FOB, CIF) is crucial as they can significantly affect total costs. Buyers should clarify these terms with suppliers to avoid misunderstandings that could lead to increased expenses.

What Tips Can Help Buyers Optimize Costs?

-

Negotiation: Engage in open discussions with suppliers about pricing, especially for larger orders. Building a relationship can lead to better terms and discounts.

-

Cost-Efficiency Analysis: Consider the total cost of ownership (TCO), which includes not just the purchase price but also maintenance, replacement, and potential downtime costs. This analysis can help justify higher upfront costs for longer-lasting materials.

-

Pricing Nuances for International Buyers: Buyers from regions like Nigeria and Brazil should factor in currency fluctuations and local economic conditions when assessing prices. Additionally, understanding local market dynamics can provide leverage in negotiations.

-

Disclaimer for Indicative Prices: Always request quotes tailored to your specific needs, as prices can vary widely based on the aforementioned factors.

By comprehensively analyzing these cost structures and pricing influences, B2B buyers can make informed decisions that align with their operational requirements and budget constraints when sourcing titanium carbide and tungsten carbide.

Alternatives Analysis: Comparing titanium carbide vs tungsten carbide With Other Solutions

In the industrial landscape, selecting the right material is critical for enhancing performance, reducing costs, and ensuring longevity in applications. While titanium carbide and tungsten carbide are popular choices for their hardness and wear resistance, it is essential to evaluate them against alternative materials that may offer specific benefits depending on the application.

Comparison Table

| Comparison Aspect | Titanium Carbide Vs Tungsten Carbide | Ceramic Composites | Cobalt-Chromium Alloys |

|---|---|---|---|

| Performance | High hardness and wear resistance; TiC is better at high temperatures | Excellent hardness; good thermal resistance | Good wear resistance; more ductile than carbides |

| Cost | Higher production cost for TiC; WC is generally more affordable | Moderate cost; can vary based on composition | Generally lower cost compared to TiC |

| Ease of Implementation | Requires specialized machining | Can be complex due to brittleness | Easier to machine than carbides |

| Maintenance | Low maintenance; resistant to wear | May require frequent inspections due to brittleness | Moderate maintenance; good durability |

| Best Use Case | High-performance applications like cutting tools and aerospace components | High-temperature applications and cutting tools | Dental and biomedical applications |

Detailed Breakdown of Alternatives

Ceramic Composites

Ceramic composites are known for their exceptional hardness and thermal stability, making them ideal for high-temperature applications such as aerospace and automotive industries. They can resist wear effectively but are often brittle, which can pose challenges during machining or in high-impact scenarios. Their moderate cost makes them a viable alternative, but the complexity of implementation and potential fragility may limit their use in certain high-stress applications.

Cobalt-Chromium Alloys

Cobalt-chromium alloys are widely used in dental and biomedical applications due to their excellent corrosion resistance and biocompatibility. They offer good wear resistance and are easier to machine than both titanium carbide and tungsten carbide. This can lead to lower production costs and faster turnaround times for manufacturers. However, they may not achieve the same hardness levels as carbide materials, making them less suitable for extremely abrasive environments.

Conclusion

When determining the best material for industrial applications, B2B buyers must consider specific performance requirements, cost implications, and ease of implementation. Titanium carbide and tungsten carbide are excellent choices for high-performance needs, particularly in cutting and drilling applications. However, alternatives like ceramic composites and cobalt-chromium alloys may provide suitable benefits for different contexts, such as high-temperature resilience or biocompatibility. Ultimately, understanding the unique properties and trade-offs of each material will empower buyers to make informed decisions that align with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for titanium carbide vs tungsten carbide

What Are the Key Technical Properties of Titanium Carbide and Tungsten Carbide?

When evaluating titanium carbide (TiC) and tungsten carbide (WC) for industrial applications, understanding their essential technical properties is crucial for making informed purchasing decisions. Here are some critical specifications that B2B buyers should consider:

Illustrative image related to titanium carbide vs tungsten carbide

-

Density

– Definition: Density refers to the mass per unit volume of a material, typically measured in grams per cubic centimeter (g/cm³).

– Importance: Tungsten carbide has a density of approximately 15.63 g/cm³, making it significantly denser than titanium carbide, which has a density of around 4.93 g/cm³. This difference affects the weight and strength of components made from these materials, influencing their suitability for specific applications, such as cutting tools versus lightweight coatings. -

Hardness

– Definition: Hardness is a measure of a material’s resistance to deformation or scratching, commonly quantified using the Mohs scale or GPa (gigapascals).

– Importance: Titanium carbide exhibits higher hardness (28-35 GPa) compared to tungsten carbide (18-22 GPa). This property is essential for applications requiring superior wear resistance, such as in high-performance cutting tools and protective coatings. -

Melting Point

– Definition: The melting point is the temperature at which a solid becomes a liquid.

– Importance: Titanium carbide has a melting point of 3160°C, whereas tungsten carbide has a melting point of 2870°C. Higher melting points indicate better performance under extreme heat, making titanium carbide suitable for high-temperature applications, such as aerospace and military sectors. -

Toughness

– Definition: Toughness is the ability of a material to absorb energy and plastically deform without fracturing.

– Importance: Although titanium carbide is harder, tungsten carbide is generally tougher. This quality makes tungsten carbide ideal for applications where impact resistance is crucial, such as drilling and mining tools. -

Wear Resistance

– Definition: Wear resistance refers to the ability of a material to withstand abrasion and erosion.

– Importance: Titanium carbide typically offers superior wear resistance, especially at elevated temperatures, making it a preferred choice for high-wear environments. This property can lead to longer service life and reduced maintenance costs in industrial applications.

What Are Common Trade Terms Used in the Titanium and Tungsten Carbide Market?

Understanding trade terminology is essential for navigating the procurement process effectively. Here are some common terms that B2B buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

– Definition: An OEM is a company that manufactures products that may be marketed under another company’s brand.

– Importance: Buyers often source titanium and tungsten carbide components from OEMs to ensure quality and compatibility with their existing systems. -

MOQ (Minimum Order Quantity)

– Definition: MOQ is the smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ is vital for budgeting and inventory management, especially for buyers in regions like Africa and South America, where shipping costs can significantly impact overall expenses. -

RFQ (Request for Quotation)

– Definition: An RFQ is a document used to solicit price quotes from suppliers for specific products or services.

– Importance: Submitting an RFQ allows buyers to compare prices and terms from multiple suppliers, facilitating better negotiation and decision-making. -

Incoterms (International Commercial Terms)

– Definition: Incoterms are a set of international rules that define the responsibilities of buyers and sellers in international transactions.

– Importance: Familiarity with Incoterms helps buyers understand shipping costs, risks, and responsibilities, ensuring clarity in cross-border transactions involving titanium and tungsten carbide. -

Lead Time

– Definition: Lead time refers to the amount of time it takes from placing an order to receiving the product.

– Importance: Understanding lead times is crucial for project planning and inventory management, particularly in industries where timely delivery of titanium and tungsten carbide products can impact production schedules.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions when sourcing titanium carbide and tungsten carbide products for their operations.

Navigating Market Dynamics and Sourcing Trends in the titanium carbide vs tungsten carbide Sector

What Are the Current Market Dynamics and Key Trends for Titanium Carbide vs. Tungsten Carbide?

The global market for titanium carbide (TiC) and tungsten carbide (WC) is experiencing notable growth, driven by increasing demand in various industrial sectors such as manufacturing, aerospace, and construction. Key trends include the adoption of advanced manufacturing technologies, such as 3D printing and laser sintering, which enhance the production capabilities and cost-effectiveness of these materials. Additionally, the rising focus on high-performance materials that can withstand extreme conditions is propelling the use of both TiC and WC in cutting tools, wear-resistant coatings, and other applications.

Illustrative image related to titanium carbide vs tungsten carbide

International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of regional market dynamics that influence sourcing strategies. For instance, the increasing industrialization in Africa and South America is creating a burgeoning demand for durable materials in mining and construction. In Europe and the Middle East, stringent regulations regarding material performance and environmental standards are shaping buyer preferences. This shift towards quality over cost necessitates a thorough understanding of material properties, including wear resistance and toughness, to make informed procurement decisions.

Moreover, the supply chain landscape is evolving, with a growing emphasis on local sourcing and partnerships to mitigate risks associated with global supply disruptions. Buyers are encouraged to seek suppliers who can provide not only high-quality materials but also reliable logistics and support services.

How Does Sustainability and Ethical Sourcing Impact the Titanium Carbide vs. Tungsten Carbide Market?

As sustainability becomes a cornerstone of corporate responsibility, both titanium carbide and tungsten carbide sectors are under increasing pressure to adopt ethical sourcing practices. The production of these materials is energy-intensive, contributing to environmental concerns. Buyers are urged to consider the environmental impact of their sourcing decisions, including energy consumption during production and the lifecycle of the materials.

Ethical supply chains are increasingly important, particularly in regions like Africa and South America, where mining practices can significantly impact local communities and ecosystems. International buyers should prioritize suppliers who adhere to ethical mining practices and offer transparency regarding their sourcing methods. Certifications such as ISO 14001 for environmental management can serve as benchmarks for evaluating suppliers’ commitment to sustainability.

Illustrative image related to titanium carbide vs tungsten carbide

Additionally, the demand for “green” materials is on the rise. Buyers can explore options for recycled tungsten carbide, which not only reduces waste but also lessens the environmental footprint associated with new material production. This trend towards sustainability not only aligns with global environmental goals but can also enhance brand reputation and customer loyalty.

What Is the Brief Evolution of Titanium Carbide and Tungsten Carbide in Industrial Applications?

The use of titanium carbide and tungsten carbide has evolved significantly since their introduction in industrial applications. Tungsten carbide, discovered in the early 20th century, quickly became a go-to material for cutting tools due to its exceptional hardness and wear resistance. Its applications expanded into various sectors, including mining, construction, and jewelry, where durability is paramount.

On the other hand, titanium carbide emerged later, gaining traction in the 1970s and 1980s as industries sought lighter, yet robust alternatives for high-temperature applications. Its unique properties, such as lower density and good chemical stability, made it ideal for coatings and certain high-performance applications, particularly in the aerospace and biomedical fields.

Today, both materials are critical to modern manufacturing, with ongoing research and technological advancements promising to enhance their applications further. The evolution of these carbides reflects broader trends in industrial innovation, with both materials continuously adapting to meet the demands of new technologies and market needs.

Frequently Asked Questions (FAQs) for B2B Buyers of titanium carbide vs tungsten carbide

-

How do I choose between titanium carbide and tungsten carbide for my applications?

When selecting between titanium carbide (TiC) and tungsten carbide (WC), consider the specific requirements of your application. TiC is known for its superior wear resistance and high hardness, making it suitable for high-temperature environments and applications requiring longevity. Conversely, WC excels in toughness and is commonly used in cutting tools and abrasives. Evaluate the operational conditions, such as temperature and stress, to determine which material aligns best with your needs. -

What are the key differences in properties between titanium carbide and tungsten carbide?

Titanium carbide boasts a higher hardness (28-35 GPa) compared to tungsten carbide (18-22 GPa), but WC is generally tougher and better suited for applications involving impact. TiC has a lower density (4.93 g/cm³) and better chemical stability, making it ideal for coatings and specialized applications. In contrast, WC’s higher density (15.63 g/cm³) contributes to its effectiveness in cutting tools. Understanding these differences is crucial for selecting the right material for your industrial needs. -

What factors should I consider when sourcing titanium carbide and tungsten carbide internationally?

When sourcing these materials, consider supplier reputation, production capabilities, and compliance with international quality standards. Assess the supplier’s ability to provide documentation such as material certifications and test reports. Additionally, consider logistical aspects like shipping costs, delivery times, and customs regulations in your region, especially if you’re importing from suppliers in Europe or Asia. -

What are the minimum order quantities (MOQ) for titanium carbide and tungsten carbide products?

MOQs can vary significantly based on the supplier and the type of product. Generally, for bulk industrial applications, MOQs might range from 100 kg to several tons. For smaller projects or custom orders, some suppliers may offer lower MOQs. Always confirm with the supplier to ensure that their MOQ aligns with your purchasing needs and budget. -

What payment terms are common when purchasing titanium carbide and tungsten carbide?

Common payment terms in B2B transactions include net 30, net 60, or payment upfront, especially for custom orders. Some suppliers may accept letters of credit or escrow services for larger transactions to mitigate risk. It’s essential to negotiate terms that suit your cash flow while ensuring the supplier’s confidence in fulfilling the order. -

How can I ensure quality assurance (QA) for titanium carbide and tungsten carbide products?

To ensure quality, request detailed QA documentation from suppliers, including material certificates, hardness tests, and wear resistance data. Establish clear specifications and performance criteria before placing an order. Additionally, consider conducting third-party inspections or audits of the manufacturing facility, especially when dealing with new suppliers to verify their adherence to quality standards. -

What are the logistics considerations for shipping titanium carbide and tungsten carbide internationally?

Logistics for shipping these materials involve understanding the regulations governing hazardous materials, as some carbide products may require special handling. Consider the shipping method (air, sea, or land) based on cost and urgency. Collaborate with logistics partners experienced in international shipping to navigate customs clearance and ensure timely delivery to your location. -

Can I customize titanium carbide and tungsten carbide products for specific applications?

Yes, many suppliers offer customization options for titanium carbide and tungsten carbide products, including variations in size, shape, and coating. Discuss your specific requirements with potential suppliers to determine their capabilities in producing tailored solutions. Customization may involve additional lead time and costs, so it’s important to factor these into your project planning.

Top 5 Titanium Carbide Vs Tungsten Carbide Manufacturers & Suppliers List

1. Xometry – Titanium Solutions

Domain: xometry.com

Registered: 2015 (10 years)

Introduction: Titanium (Ti):

– Transition metal with a silvery-white exterior.

– Corrosion-resistant, strong, and water-resistant.

– Used in aerospace, medical sectors, and jewelry.

– Processed using the Kroll method from minerals like rutile, ilmenite, or sphene.

– Commonly CNC machined or 3D printed (DMLS process).

– Types of Titanium:

– Ti 6Al-4V (Grade 5): Strongest alloy, used in aerospace, medical, mari…

2. Reddit – Blade Tip Materials and Fusing Techniques

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The discussion revolves around identifying whether a specific blade tip is made of tungsten carbide or titanium carbide. It also questions the method of fusing the blade tip to the body, suggesting induction heating or resistance heating as possible techniques. The blade tip appears to be brazed onto the blade body, with a filler metal used in the process. The conversation highlights that titanium…

3. Ferro-Tic – Titanium Carbide (TiC) Properties

Domain: ferro-tic.com

Registered: 2008 (17 years)

Introduction: Titanium Carbide (TiC):

– Hardness: 2800-3200 HV

– Melting Point: 3160°C

– Oxidation Resistance: Up to 800°C

– Density: 4.9 g/cm³

– Compressive Strength: 4000-5000 MPa

– Thermal Conductivity: 21-25 W/m·K

– Electrical Conductivity: Insulator (resistivity > 10^6 µΩ.cm)

– Manufacturing Cost: Up to three times more expensive than WC due to energy-intensive synthesis and reliance on high-purity titaniu…

4. Just Men’s Rings – Titanium and Tungsten Carbide Jewelry

Domain: justmensrings.com

Registered: 2006 (19 years)

Introduction: Titanium and tungsten carbide are popular materials for men’s jewelry. Key differences include:

1. **Price**: Both are affordable alternatives to precious metals, with prices varying based on style and quality.

2. **Composition**: Titanium is alloyed with elements like aluminum and vanadium, while tungsten carbide is a compound of tungsten mixed with nickel or cobalt.

3. **Hardness**: Tungsten ca…

5. Carbide Provider – Tungsten Carbide vs Titanium

Domain: carbideprovider.com

Registered: 2023 (2 years)

Introduction: Tungsten Carbide vs Titanium: Tungsten Carbide is extremely hard (8.5-9 on Mohs scale) and durable, offering excellent scratch resistance, making it ideal for tools and jewelry. Titanium is lighter (4.5 g/cm³) and more impact-resistant, scoring about 6 on the Mohs scale. Tungsten Carbide has good corrosion resistance but can oxidize, while Titanium excels in corrosion resistance, especially in mar…

Strategic Sourcing Conclusion and Outlook for titanium carbide vs tungsten carbide

In evaluating titanium carbide (TiC) and tungsten carbide (WC), it’s clear that both materials offer distinct advantages tailored to specific applications. Tungsten carbide is prized for its exceptional toughness and cost-effectiveness, making it ideal for cutting tools and heavy-duty applications. Conversely, titanium carbide shines in high-temperature environments and wear-resistant coatings due to its superior hardness and lighter weight.

For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, understanding these differences is crucial for strategic sourcing decisions. Prioritizing the right material can lead to improved operational efficiency, reduced costs, and enhanced product longevity.

As technological advancements continue to evolve, the potential for innovative applications of both tungsten and titanium carbide is expanding. Buyers are encouraged to stay informed about these developments and consider partnerships with reputable suppliers who can provide high-quality materials tailored to their specific needs. By doing so, businesses can position themselves for success in a competitive global market. Embrace the opportunity to leverage these materials strategically, ensuring that your sourcing decisions align with your long-term goals.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.