A Deep Dive into Telescoping Locking Mechanisms Solution

Introduction: Navigating the Global Market for telescoping locking mechanisms

In the ever-evolving landscape of global manufacturing, sourcing reliable telescoping locking mechanisms can present significant challenges for international B2B buyers. As industries across Africa, South America, the Middle East, and Europe increasingly seek efficient solutions for adjustable structures—from industrial machinery to recreational equipment—the importance of selecting the right locking mechanism cannot be overstated. This comprehensive guide delves into the diverse types of telescoping locking mechanisms, their applications, and best practices for supplier vetting, ensuring that buyers can make informed decisions tailored to their specific operational needs.

Throughout this guide, we will explore various locking styles, including button pins, flip locks, and custom-engineered solutions, while highlighting their unique advantages across multiple sectors such as construction, automotive, and healthcare. Additionally, we will provide insights into pricing structures and cost-saving strategies that can enhance your procurement process. By understanding the intricacies of telescoping locking mechanisms, B2B buyers can optimize their purchasing decisions, ultimately driving efficiency and innovation in their projects. Whether you are based in Saudi Arabia, Germany, or beyond, this guide equips you with the knowledge needed to navigate the global market confidently and effectively.

Understanding telescoping locking mechanisms Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Quick Release Ball Lock Pin | Easy insertion and removal; spring-loaded mechanism | Photography stands, adjustable poles, scaffolding | Pros: Quick setup, reliable locking; Cons: May require regular maintenance. |

| Button Clip | Compact design; fits various tube diameters | Flagpoles, antenna masts, adjustable equipment | Pros: Lightweight, versatile; Cons: Limited load capacity compared to other types. |

| Flip and Twist Locking Clamp | Secure locking with a twist mechanism; robust construction | Industrial applications, construction, healthcare | Pros: Strong hold, suitable for heavy-duty use; Cons: Slightly more complex operation. |

| Snap Button | Spring-loaded for easy operation; available in multiple sizes | Camping gear, recreational equipment, safety devices | Pros: Simple to use, lightweight; Cons: Potential wear over time with frequent use. |

| Custom Telescoping Locks | Tailored solutions for specific applications; diverse materials | Specialized equipment, custom engineering projects | Pros: Perfect fit for unique needs; Cons: Higher initial investment and lead time. |

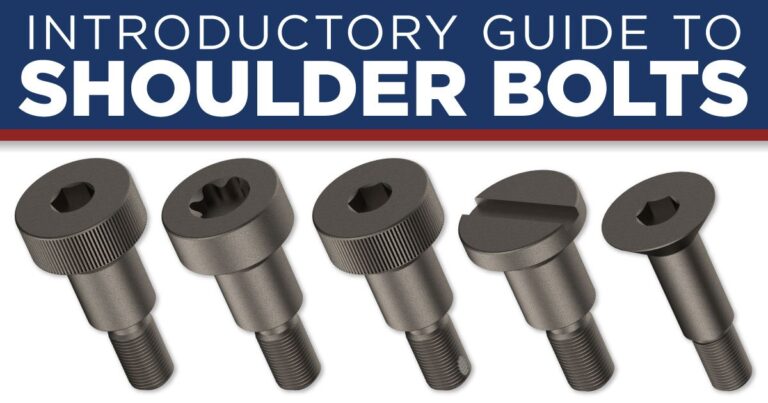

What Are the Key Characteristics of Quick Release Ball Lock Pins?

Quick release ball lock pins are designed for rapid engagement and disengagement, making them ideal for applications requiring frequent assembly and disassembly, such as photography stands and scaffolding. Their spring-loaded mechanism ensures a reliable locking action, which is critical for safety in dynamic environments. B2B buyers should consider the pin’s load rating and compatibility with existing equipment to ensure optimal performance.

How Do Button Clips Function in Telescoping Applications?

Button clips are compact locking mechanisms that fit within various tube diameters, making them versatile for applications like flagpoles and antenna masts. Their lightweight design facilitates ease of use, yet they offer limited load capacity compared to other locking mechanisms. When sourcing button clips, businesses should assess the specific tube dimensions and environmental conditions, such as exposure to moisture, which may affect material choice.

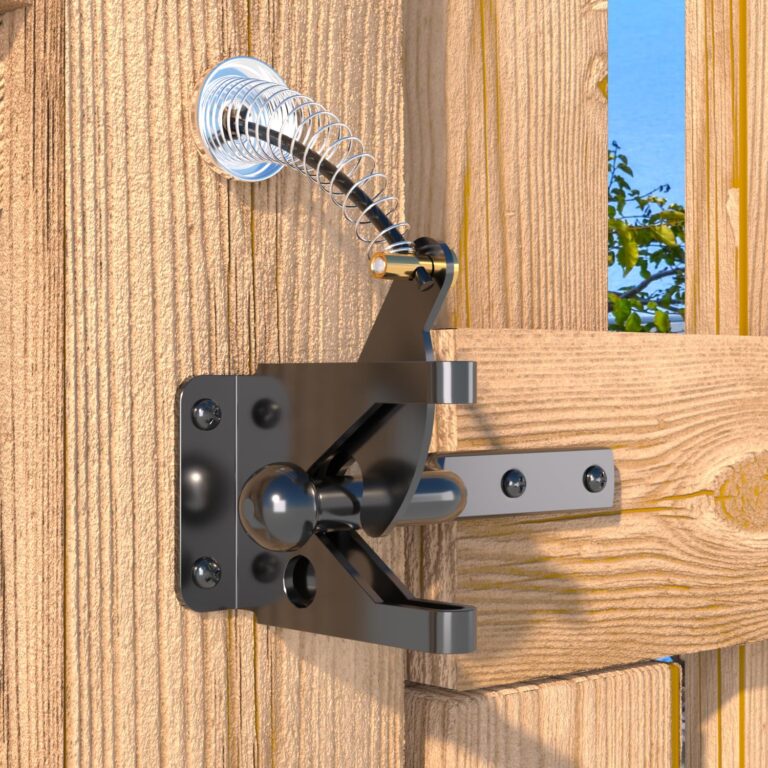

What Advantages Do Flip and Twist Locking Clamps Offer?

Flip and twist locking clamps provide a robust locking mechanism that is particularly effective in industrial and healthcare settings where stability is paramount. These clamps ensure a secure hold even under heavy loads, making them suitable for construction and engineering applications. Buyers should evaluate the ease of operation and the clamp’s compatibility with their specific telescoping systems to maximize efficiency.

Why Choose Snap Buttons for Recreational Equipment?

Snap buttons are spring-loaded devices that facilitate easy operation and are commonly used in camping gear and safety devices. Their lightweight nature makes them an attractive option for portable applications. However, B2B buyers should be aware of potential wear over time, especially in high-frequency use scenarios. Selecting snap buttons with durable materials can mitigate this concern.

How Can Custom Telescoping Locks Benefit Specialized Projects?

Custom telescoping locks are tailored to meet unique specifications, providing solutions for specialized equipment and custom engineering projects. These locks can be made from various materials, allowing for adaptability in different environments. While they offer a perfect fit for specific applications, buyers should consider the higher initial costs and longer lead times associated with custom orders, ensuring that the investment aligns with project requirements.

Key Industrial Applications of telescoping locking mechanisms

| Industry/Sector | Specific Application of telescoping locking mechanisms | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Adjustable scaffolding systems | Enhances safety and flexibility on job sites | Material durability, load capacity, and ease of use |

| Aerospace | Extendable aircraft maintenance platforms | Optimizes maintenance access and workspace efficiency | Weight specifications, corrosion resistance, and compliance with aviation standards |

| Medical Devices | Adjustable hospital beds and equipment | Improves patient comfort and operational efficiency | Hygiene standards, customization options, and reliability |

| Outdoor Recreation | Telescoping camping gear (e.g., poles, canopies) | Increases portability and user convenience | Weight, compactness, and weather resistance |

| Telecommunications | Adjustable antenna masts | Facilitates optimal signal reception and adjustment | Stability under wind loads, material choice, and installation ease |

How Are Telescoping Locking Mechanisms Used in Construction?

In the construction industry, telescoping locking mechanisms are integral to adjustable scaffolding systems. These systems allow workers to modify the height and reach of scaffolding as needed, enhancing safety and efficiency on job sites. B2B buyers should prioritize sourcing mechanisms that offer high load capacities and are made from durable materials to withstand harsh conditions. Additionally, ease of operation is crucial, as it minimizes downtime during projects.

What Role Do Telescoping Locking Mechanisms Play in Aerospace?

In aerospace applications, telescoping locking mechanisms are used in extendable maintenance platforms that provide technicians with adjustable access to various parts of an aircraft. This flexibility is essential for conducting thorough inspections and repairs efficiently. Buyers in this sector must consider weight specifications, as any additional weight can impact aircraft performance. Moreover, materials must resist corrosion and meet stringent aviation standards to ensure safety and reliability.

How Are Telescoping Locking Mechanisms Beneficial for Medical Devices?

Telescoping locking mechanisms are increasingly used in adjustable hospital beds and other medical equipment, allowing for easy height adjustments to improve patient comfort and accessibility for healthcare providers. For international buyers, sourcing mechanisms that comply with hygiene standards is vital, as medical environments require strict cleanliness. Additionally, customization options may be necessary to meet specific equipment designs and operational needs.

What Applications Do Telescoping Locking Mechanisms Have in Outdoor Recreation?

In the outdoor recreation sector, telescoping locking mechanisms are found in camping gear, such as adjustable tent poles and canopies. These mechanisms enhance portability and user convenience, allowing campers to set up and take down their equipment with ease. Buyers should focus on weight, compactness, and weather resistance when sourcing these products, especially for markets in regions prone to diverse weather conditions.

How Are Telescoping Locking Mechanisms Used in Telecommunications?

Telecommunications industries utilize telescoping locking mechanisms in adjustable antenna masts, enabling technicians to optimize signal reception by adjusting the height of antennas as needed. This adaptability is crucial for ensuring consistent communication services. When sourcing for this application, stability under wind loads and material choice are critical factors, as these masts must endure varying environmental conditions while maintaining functionality.

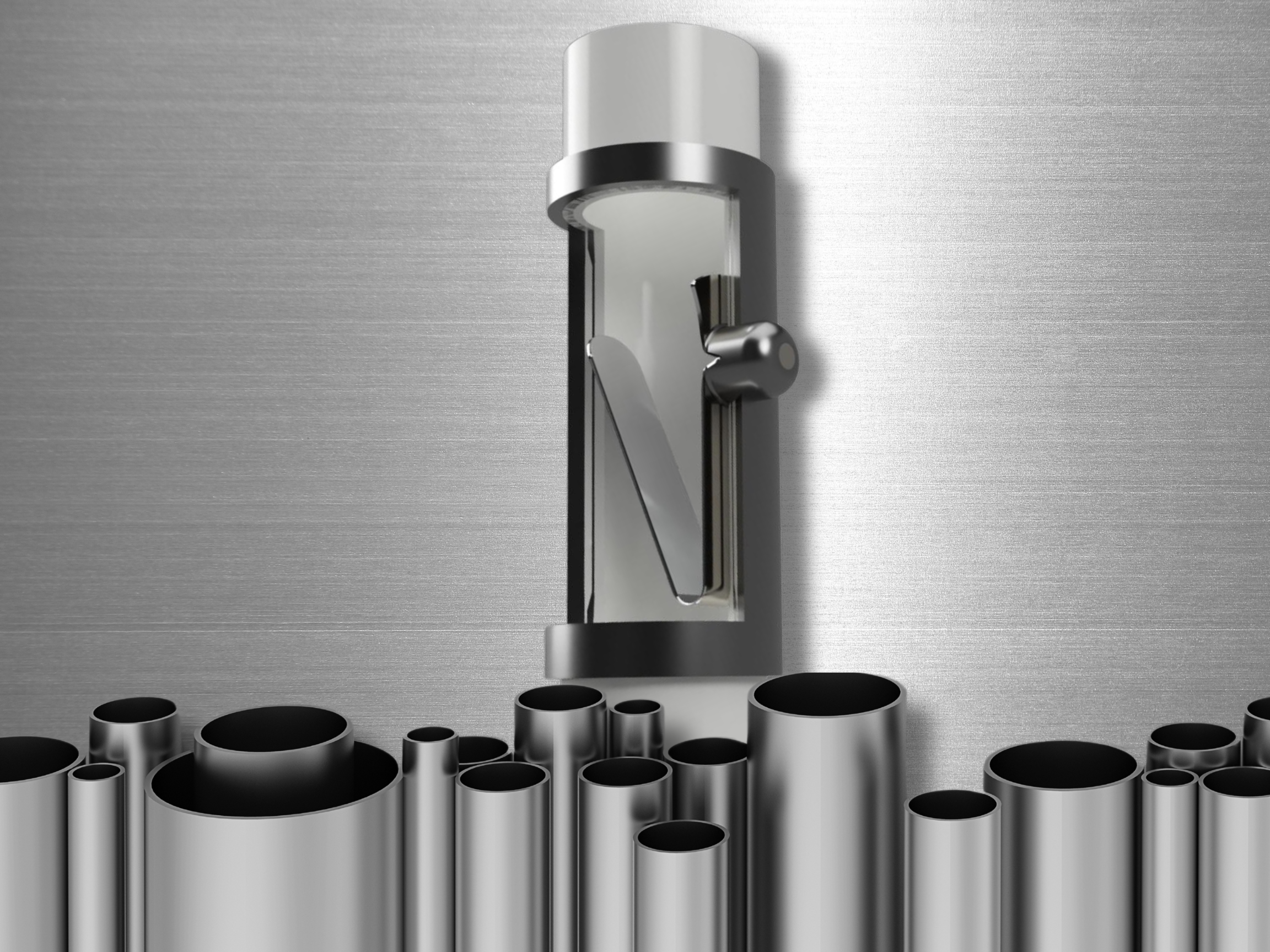

Illustrative image related to telescoping locking mechanisms

3 Common User Pain Points for ‘telescoping locking mechanisms’ & Their Solutions

Scenario 1: Difficulty in Ensuring Stability in Mobile Equipment

The Problem: Many B2B buyers in industries such as construction and photography encounter issues with the stability of telescoping structures, particularly when used in dynamic environments. For example, a construction company may utilize telescoping poles for temporary structures or safety barriers. However, if the locking mechanisms do not securely hold the poles in place, this can lead to unsafe conditions, damaging equipment or injuring personnel. The frustration often stems from a lack of understanding of which locking mechanism will provide the necessary stability in varying conditions.

The Solution: To address this challenge, buyers should prioritize the selection of high-quality, durable locking mechanisms specifically designed for their application’s environmental conditions. For instance, opting for stainless steel button clips or quick-release ball lock pins can enhance stability due to their robust construction and resistance to environmental factors such as corrosion or heavy load. It is crucial to consult with suppliers to identify locking mechanisms that are tested for the specific loads and conditions they will face. Additionally, conducting on-site trials with different locking mechanisms before committing to a bulk order can help ensure the chosen solution meets stability and safety requirements.

Scenario 2: Complexity in Customizing Locking Mechanisms for Unique Applications

The Problem: Buyers often face challenges when attempting to customize telescoping locking mechanisms for specialized applications, such as medical equipment or unique industrial setups. Each application may require different locking styles, diameters, or materials, leading to confusion and potential mismatches in functionality. This complexity can result in project delays and increased costs, especially when the wrong components are ordered.

The Solution: To simplify the customization process, buyers should engage with suppliers that offer a comprehensive range of locking mechanisms along with customization services. For example, firms like Valco provide tailored solutions and engineering support for unique requirements. Buyers should clearly outline their specifications, including the intended use, material preferences, and load requirements. Requesting samples of various locking mechanisms can facilitate the selection process, allowing buyers to test compatibility and functionality before finalizing their orders. Furthermore, establishing a close relationship with the supplier can lead to more efficient problem-solving and faster turnaround times for custom orders.

Scenario 3: Challenges with Sourcing Reliable Locking Mechanisms Internationally

The Problem: International B2B buyers, especially from regions like Africa and South America, often struggle with sourcing reliable telescoping locking mechanisms due to logistical challenges and a lack of local suppliers. This can lead to delays in project timelines and increased shipping costs, causing frustration and uncertainty about the quality of products received.

The Solution: To mitigate sourcing challenges, buyers should consider partnering with reputable manufacturers who have a global distribution network. Conducting thorough research on suppliers that specialize in telescoping locking mechanisms can yield valuable insights into their product quality and customer service. Buyers should look for suppliers that offer clear shipping policies, reliable lead times, and the ability to handle customs efficiently. Additionally, utilizing platforms that connect buyers with verified manufacturers can streamline the sourcing process. Establishing a long-term relationship with a trusted supplier can also provide leverage for better pricing and priority service, ensuring that locking mechanisms are consistently available when needed.

Strategic Material Selection Guide for telescoping locking mechanisms

When selecting materials for telescoping locking mechanisms, several factors must be considered to ensure optimal performance, durability, and cost-effectiveness. Below, we analyze four common materials used in these applications, focusing on their properties, advantages, disadvantages, and specific considerations for international B2B buyers.

What are the Key Properties of Aluminum in Telescoping Locking Mechanisms?

Aluminum is a lightweight metal known for its excellent strength-to-weight ratio and corrosion resistance. It typically performs well in a range of temperatures and pressures, making it suitable for various environments. Its natural oxide layer provides additional protection against corrosion, particularly in humid or saline conditions.

Pros and Cons: Aluminum is durable and cost-effective, making it a popular choice for many applications. However, it can be less rigid than other metals, which may limit its use in high-stress environments. Manufacturing complexity is relatively low, allowing for easy machining and fabrication.

Impact on Application: Aluminum is compatible with a variety of media, including water and air, making it ideal for applications like adjustable stands and outdoor equipment.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as EN 573 for aluminum alloys. In countries like Germany, preference may lean towards high-quality aluminum alloys that meet stringent performance criteria.

How Does Stainless Steel Compare for Telescoping Locking Mechanisms?

Stainless steel is renowned for its exceptional corrosion resistance and strength. It can withstand high temperatures and pressures, making it suitable for demanding applications. The material is available in various grades, with 304 and 316 being the most common for locking mechanisms.

Pros and Cons: The primary advantage of stainless steel is its durability and resistance to rust, which is crucial for outdoor applications. However, it is generally more expensive than aluminum and can be heavier, which may impact the overall weight of the telescoping structure.

Impact on Application: Stainless steel is ideal for applications exposed to harsh environments, such as marine or industrial settings, where corrosion resistance is paramount.

Considerations for International Buyers: Buyers should be aware of compliance with ASTM A240 for stainless steel products. In regions like South America and Africa, local sourcing of stainless steel may also influence cost and availability.

What Role Does Plastic Play in Telescoping Locking Mechanisms?

Plastic, particularly high-density polyethylene (HDPE) and polycarbonate, is often used in telescoping locking mechanisms due to its lightweight nature and resistance to chemicals. These materials can handle moderate temperatures and pressures, making them suitable for various applications.

Illustrative image related to telescoping locking mechanisms

Pros and Cons: The main advantages of plastic are its low cost and ease of manufacturing, which allows for complex shapes and designs. However, plastics may not offer the same level of durability as metals and can be more susceptible to wear over time.

Impact on Application: Plastic locking mechanisms are often used in consumer products, such as adjustable furniture or lightweight outdoor equipment, where weight savings are critical.

Considerations for International Buyers: Buyers should consider compliance with international standards such as ISO 9001 for quality management. In regions like Africa, the availability of specific plastics may vary, impacting sourcing decisions.

How Does Composite Material Stand Out in Telescoping Locking Mechanisms?

Composite materials, such as fiberglass or carbon fiber, are gaining popularity for their high strength-to-weight ratio and resistance to environmental factors. They can withstand varying temperatures and pressures, making them versatile for many applications.

Pros and Cons: Composites offer excellent durability and are lightweight, which is advantageous for portable applications. However, they can be more expensive to manufacture and may require specialized equipment for fabrication.

Impact on Application: Composites are particularly useful in high-performance applications, such as aerospace or advanced sporting equipment, where weight and strength are critical.

Considerations for International Buyers: Buyers should be aware of compliance with industry-specific standards, such as ASTM D3039 for composite materials. In Europe, the preference for composites may be influenced by environmental regulations and sustainability considerations.

Illustrative image related to telescoping locking mechanisms

Summary Table of Material Selection for Telescoping Locking Mechanisms

| Material | Typical Use Case for telescoping locking mechanisms | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Adjustable stands, outdoor equipment | Lightweight and corrosion-resistant | Less rigid than other metals | Medium |

| Stainless Steel | Marine and industrial applications | Exceptional durability and corrosion resistance | Higher cost and weight | High |

| Plastic | Consumer products, lightweight equipment | Low cost and easy to manufacture | Less durable than metals | Low |

| Composite | Aerospace and high-performance sporting equipment | High strength-to-weight ratio | Expensive and requires specialized manufacturing | High |

This analysis provides a comprehensive overview of the materials commonly used in telescoping locking mechanisms, empowering international B2B buyers to make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for telescoping locking mechanisms

What Are the Main Stages in the Manufacturing Process of Telescoping Locking Mechanisms?

The manufacturing process for telescoping locking mechanisms involves several critical stages, each designed to ensure the final product meets the necessary specifications for quality and performance. Understanding these stages can help B2B buyers assess the reliability of their suppliers.

Material Preparation: How Are Raw Materials Selected and Processed?

The manufacturing process begins with material selection. Common materials used for telescoping locking mechanisms include stainless steel, aluminum, and various high-strength plastics. The choice of material depends on the application requirements, such as weight, strength, and corrosion resistance. Once selected, raw materials undergo processes such as cutting, machining, and surface treatment to prepare them for forming.

For instance, stainless steel components may be subjected to processes like heat treatment to enhance their strength and durability, while aluminum parts might be anodized to improve corrosion resistance. Ensuring that the materials meet industry standards is crucial, as it directly impacts the performance of the locking mechanisms.

What Techniques Are Used in the Forming Stage of Production?

The forming stage involves shaping the prepared materials into the desired components of the telescoping locking mechanisms. Key techniques include:

-

CNC Machining: This method allows for high precision in creating complex shapes and components. CNC machines can produce parts with tight tolerances, ensuring consistent quality across batches.

-

Stamping and Forging: These techniques are often used for mass production of locking pins and clips. Stamping is cost-effective for high-volume production, while forging enhances the strength of the metal components.

-

Injection Molding: For plastic components, injection molding is a common technique. It allows for the mass production of intricate shapes and is highly efficient.

By employing these techniques, manufacturers can optimize production efficiency while maintaining the integrity of the components.

How Are the Components Assembled and Finished?

Once the individual components are formed, the next step is assembly. This may involve manual labor or automated processes, depending on the complexity of the locking mechanism. Assemblies often include the integration of springs, buttons, and locking pins, which must fit together precisely to ensure functionality.

After assembly, finishing processes such as polishing, coating, or painting are applied to enhance the aesthetic appeal and protect against environmental factors. For example, coatings may be applied to enhance corrosion resistance, which is particularly important for applications exposed to harsh conditions.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is critical in the manufacturing of telescoping locking mechanisms, as it ensures the reliability and safety of the products. International standards such as ISO 9001 provide a framework for quality management systems. This certification indicates that the manufacturer adheres to best practices in quality assurance.

In addition to ISO standards, industry-specific certifications may be relevant depending on the application of the locking mechanisms. For instance:

-

CE Marking: Essential for products sold in the European market, ensuring compliance with safety and environmental regulations.

-

API Certification: Important for manufacturers supplying components to the oil and gas industry, ensuring adherence to rigorous safety and performance standards.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are integral to maintaining product integrity throughout the manufacturing process. Key checkpoints include:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified standards. Any materials that do not pass inspection are rejected or sent back.

-

In-Process Quality Control (IPQC): During production, various checks are conducted to monitor the manufacturing process. This may include measuring dimensions, testing material properties, and verifying assembly integrity.

-

Final Quality Control (FQC): The final inspection occurs after assembly and finishing. This step typically includes functional testing of locking mechanisms to ensure they operate as intended and meet safety requirements.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers should take proactive steps to ensure their suppliers maintain high-quality standards. Here are several methods to verify supplier QC practices:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control measures, and overall operational effectiveness of potential suppliers.

-

Quality Reports: Requesting documentation of quality control processes, including inspection reports and testing results, can provide insight into the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging independent inspection agencies can offer an unbiased evaluation of the supplier’s quality control practices. These inspections can validate compliance with international standards and industry-specific certifications.

-

Certifications: Ensuring that suppliers possess relevant certifications (ISO, CE, API) can provide additional assurance of their quality management practices.

What Are the Specific QC Considerations for International B2B Buyers?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific QC nuances:

-

Cultural Differences: Understanding cultural approaches to quality and manufacturing can impact communication and expectations. It’s essential to establish clear quality standards and ensure mutual understanding.

-

Regulatory Compliance: Different regions have varying regulations regarding product safety and quality. Buyers must ensure that their suppliers can meet these requirements to avoid compliance issues in their markets.

-

Logistical Challenges: International shipping can introduce risks to product quality. Buyers should discuss how suppliers manage these risks, including packaging, handling, and transport conditions.

By considering these factors and actively engaging in the quality assurance process, B2B buyers can enhance their procurement strategies and foster successful partnerships with suppliers of telescoping locking mechanisms.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘telescoping locking mechanisms’

To successfully procure telescoping locking mechanisms, it’s essential to follow a structured approach that ensures you meet your specific needs while also aligning with industry standards. This guide provides a step-by-step checklist to help you navigate the sourcing process effectively.

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements for the telescoping locking mechanisms you need. This includes dimensions, materials (such as metal or plastic), load capacity, and specific locking mechanisms (e.g., button clips or ball lock pins). Defining these specifications helps narrow down your options and ensures that you select a solution tailored to your application.

- Consider the application: Different industries (e.g., construction, aerospace) may have unique requirements for strength and durability.

- Account for environmental factors: Consider the conditions in which the locking mechanisms will be used, such as exposure to moisture or extreme temperatures.

Step 2: Research Potential Suppliers

Conduct comprehensive research to identify suppliers who specialize in telescoping locking mechanisms. Utilize online platforms, industry directories, and trade shows to compile a list of potential vendors. A well-informed selection process can lead to better pricing and quality.

- Look for industry experience: Suppliers with a proven track record in your specific industry are more likely to understand your needs.

- Read reviews and testimonials: Customer feedback can provide insights into product quality and supplier reliability.

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify that your chosen suppliers hold relevant certifications that ensure compliance with industry standards. This could include ISO certifications or specific quality assurance processes that relate to their locking mechanisms.

- Request documentation: Ask suppliers for copies of their certifications and quality assurance protocols.

- Confirm compliance: Ensure that the products meet the necessary safety and regulatory standards applicable in your region.

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of the locking mechanisms you are considering. Testing these samples in real-world conditions allows you to evaluate their performance and suitability for your application.

- Conduct thorough testing: Assess factors like ease of use, durability, and locking reliability.

- Gather feedback from your team: Involve relevant stakeholders in the testing process to ensure that the mechanisms meet operational needs.

Step 5: Assess Customization Options

If your application requires specific features not available in standard products, inquire about customization options. Many suppliers offer tailored solutions to meet unique requirements, which can provide significant advantages in functionality.

- Discuss material and design flexibility: Ensure that the supplier can accommodate your specific needs, whether it’s a unique size, shape, or locking mechanism.

- Understand lead times and costs: Custom solutions may have different timelines and pricing structures, which should be factored into your decision-making process.

Step 6: Negotiate Terms and Pricing

After selecting a supplier, engage in negotiations regarding terms, pricing, and delivery schedules. Clear communication at this stage can prevent misunderstandings and ensure a successful partnership.

- Discuss bulk order discounts: If you plan to order large quantities, ask about potential discounts.

- Clarify payment terms: Establish payment schedules that align with your cash flow needs.

Step 7: Finalize the Purchase and Monitor Performance

After negotiations, finalize your purchase agreement and place your order. Once the products are delivered, monitor their performance closely to ensure they meet your expectations and specifications.

- Implement a feedback loop: Regularly assess the performance of the locking mechanisms and communicate any issues to the supplier for resolution.

- Maintain documentation: Keep records of your purchase, including specifications and supplier communications, for future reference.

By following this structured checklist, you can streamline the sourcing process for telescoping locking mechanisms, ensuring that you find a solution that meets your needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for telescoping locking mechanisms Sourcing

What Are the Key Cost Components in Sourcing Telescoping Locking Mechanisms?

When sourcing telescoping locking mechanisms, understanding the cost structure is essential for effective budgeting and procurement. The primary components influencing the total cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of materials significantly impacts costs. Common materials include various grades of stainless steel, aluminum, and durable plastics. For instance, stainless steel components often command higher prices due to their strength and corrosion resistance, whereas plastic parts may be more cost-effective but can compromise durability in demanding applications.

-

Labor: Labor costs can vary based on the complexity of manufacturing processes and the location of production. In regions with higher labor costs, such as parts of Europe, you may see a corresponding increase in pricing. Conversely, sourcing from countries with lower labor costs may reduce overall expenses, but quality assurance must be prioritized.

-

Manufacturing Overhead: This encompasses indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient production processes can minimize overhead, but buyers should be wary of hidden costs that could inflate final pricing.

-

Tooling: Tooling expenses arise when specialized equipment is necessary for manufacturing specific locking mechanisms. Custom tooling can be expensive, and these costs are often amortized over production runs, influencing per-unit pricing.

-

Quality Control (QC): Rigorous QC processes ensure product reliability, especially in critical applications such as aerospace or medical devices. However, enhanced QC measures can add to the overall cost. Certifications, such as ISO or industry-specific standards, may also incur additional costs but can enhance product credibility.

-

Logistics: Shipping and handling costs must be considered, especially for international buyers. Factors such as distance, shipping method, and Incoterms (International Commercial Terms) play a crucial role in determining logistics costs.

-

Margin: Supplier margins can vary widely depending on the market position and competitiveness. Understanding the supplier’s pricing strategy can help buyers negotiate better terms.

How Do Price Influencers Affect Sourcing Decisions for Telescoping Locking Mechanisms?

Several factors influence the pricing of telescoping locking mechanisms, which can significantly affect sourcing decisions.

-

Volume/MOQ (Minimum Order Quantity): Higher order volumes often lead to lower per-unit costs due to economies of scale. Buyers should assess their needs to negotiate favorable terms with suppliers, potentially reducing the overall cost.

-

Specifications and Customization: Customized locking mechanisms tailored to specific applications may incur additional costs. Clearly defining specifications can help suppliers provide accurate quotes and avoid unexpected expenses.

-

Quality and Certifications: Products with industry certifications often come at a premium. However, investing in higher-quality products can lead to lower Total Cost of Ownership (TCO) by reducing maintenance and replacement needs.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers with a track record of quality may charge more but offer assurance in terms of product consistency and support.

-

Incoterms: Understanding Incoterms is crucial for international buyers. Terms such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can significantly influence overall costs, including shipping and insurance.

What Are Effective Buyer Tips for Negotiating Prices for Telescoping Locking Mechanisms?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to substantial savings.

Illustrative image related to telescoping locking mechanisms

-

Negotiate Based on Total Cost of Ownership: Instead of focusing solely on the purchase price, consider the long-term costs associated with maintenance, durability, and performance. This approach can justify a higher upfront cost if it results in lower TCO.

-

Leverage Volume Discounts: If your organization requires large quantities, use this leverage to negotiate better pricing or terms. Suppliers often have flexibility in pricing for bulk orders.

-

Request Multiple Quotes: Engaging multiple suppliers can provide competitive pricing options. This not only aids in cost comparison but can also give buyers leverage during negotiations.

-

Be Aware of Pricing Nuances: International buyers should understand local market dynamics, currency fluctuations, and trade regulations that could impact pricing. Building relationships with suppliers can also lead to better insights and potential discounts.

-

Inspect Quality Before Committing: For significant investments, consider requesting samples or conducting quality inspections. This can prevent costly mistakes and ensure the locking mechanisms meet your operational requirements.

Disclaimer on Indicative Prices

Prices for telescoping locking mechanisms can vary widely based on the factors discussed. The indicative prices mentioned are subject to change based on market conditions, supplier negotiations, and specific buyer requirements. Always consult with suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing telescoping locking mechanisms With Other Solutions

Exploring Alternatives to Telescoping Locking Mechanisms

In the world of adjustable structures and equipment, telescoping locking mechanisms are widely recognized for their versatility and effectiveness. However, alternative solutions exist that may better suit specific applications, particularly for international B2B buyers looking for tailored solutions. Understanding these alternatives can guide companies in selecting the most appropriate locking mechanism for their needs.

| Comparison Aspect | Telescoping Locking Mechanisms | Mechanical Clamps | Ratchet Straps |

|---|---|---|---|

| Performance | High stability and adjustability; prevents accidental collapse | Provides strong grip; stable but limited adjustability | Good for securing items but less stable for height adjustments |

| Cost | Moderate, varying by material and design | Generally lower cost; varies based on complexity | Low cost; inexpensive and widely available |

| Ease of Implementation | Requires precise installation; user-friendly once set up | Simple installation; often requires tools | Easy to use; requires no permanent installation |

| Maintenance | Low maintenance; occasional lubrication needed | Moderate maintenance; periodic checks for wear | Minimal maintenance; check for fraying |

| Best Use Case | Ideal for adjustable poles, stands, and equipment | Best for fixed applications requiring strength | Suitable for securing loads or temporary setups |

What Are the Advantages and Disadvantages of Mechanical Clamps?

Mechanical clamps serve as a solid alternative to telescoping locking mechanisms, especially in environments where a fixed, strong hold is necessary. They are often used in industrial settings for securing pipes or beams. The primary advantages of mechanical clamps include their robustness and ease of use. However, they may lack the flexibility of telescoping systems, as they do not allow for height or length adjustments after installation. This can limit their applicability in scenarios where variable dimensions are required.

How Do Ratchet Straps Compare to Telescoping Locking Mechanisms?

Ratchet straps are another alternative, primarily used for securing loads rather than providing structural support. Their ease of use is a significant advantage; they can quickly secure items without the need for permanent installation. Ratchet straps are cost-effective, making them a popular choice for temporary setups or logistics. However, they do not provide the same stability or adjustability as telescoping locking mechanisms, particularly for applications that require consistent support over time, such as flagpoles or adjustable stands.

Illustrative image related to telescoping locking mechanisms

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting the right locking mechanism for your business needs, consider the specific application requirements, including performance, cost, and ease of implementation. Telescoping locking mechanisms are advantageous for adjustable applications requiring stability, while mechanical clamps are ideal for fixed setups needing strength. Ratchet straps offer a low-cost, user-friendly option for securing loads temporarily. By carefully analyzing these alternatives, B2B buyers can make informed decisions that align with their operational needs and budget constraints.

Essential Technical Properties and Trade Terminology for telescoping locking mechanisms

What Are the Essential Technical Properties of Telescoping Locking Mechanisms?

Understanding the technical properties of telescoping locking mechanisms is crucial for B2B buyers, particularly when selecting components that ensure the performance and durability of their applications. Here are several critical specifications to consider:

1. Material Grade

The material used in locking mechanisms can significantly impact their performance and longevity. Common materials include stainless steel, aluminum, and high-strength plastics. For instance, stainless steel offers excellent corrosion resistance and strength, making it suitable for outdoor applications. Buyers should assess the material grade to ensure it meets the environmental conditions and mechanical demands of their specific use case.

2. Tensile Strength

Tensile strength refers to the maximum amount of tensile (pulling) stress that a material can withstand before failure. This property is vital for ensuring that the locking mechanism can handle the loads and forces exerted during operation. B2B buyers must consider the tensile strength to prevent premature failure in demanding applications such as construction or industrial equipment.

3. Tolerance

Tolerance is the permissible limit of variation in a physical dimension. For telescoping mechanisms, precise tolerances are crucial to ensure a snug fit between components, which enhances stability and functionality. Poor tolerance can lead to misalignment, resulting in operational inefficiencies and potential safety hazards. Buyers should specify tolerances that align with their operational requirements to achieve optimal performance.

4. Weight Capacity

Each locking mechanism comes with a specified weight capacity, indicating the maximum load it can securely hold. This specification is especially important in applications such as photography equipment, flagpoles, and adjustable stands. Understanding weight capacity helps buyers select the right locking mechanism that can safely support their intended application without risk of failure.

5. Locking Mechanism Type

Different locking mechanisms—such as button pins, quick-release ball locks, or clamps—offer various advantages based on the application. For instance, quick-release mechanisms allow for fast adjustments, while clamps provide a more permanent hold. Buyers should evaluate the type of locking mechanism that best suits their operational needs and ease of use.

What Are Common Trade Terms Used in the Telescoping Locking Mechanisms Industry?

Familiarity with industry terminology is essential for effective communication and decision-making in B2B transactions. Here are some common terms related to telescoping locking mechanisms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is critical for buyers seeking components that fit seamlessly into their existing systems or products.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is particularly relevant for B2B buyers when negotiating purchases, as it can affect overall project costs and inventory management.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. This process helps buyers compare options and negotiate better pricing or terms based on their requirements.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in global trade. Understanding these terms is crucial for B2B transactions, as they dictate shipping costs, risk transfer, and delivery obligations.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For locking mechanisms, lead time can vary based on customization and supplier capabilities. Buyers should consider lead times when planning projects to avoid delays.

By grasping these essential technical properties and trade terms, B2B buyers can make informed decisions when selecting telescoping locking mechanisms, ensuring they meet their operational needs and project specifications.

Navigating Market Dynamics and Sourcing Trends in the telescoping locking mechanisms Sector

What Are the Key Market Trends Impacting the Telescoping Locking Mechanisms Sector?

The telescoping locking mechanisms market is currently experiencing robust growth, driven by the increasing demand for lightweight, durable, and adjustable equipment across various industries. In regions such as Africa, South America, the Middle East, and Europe, particularly in countries like Saudi Arabia and Germany, there is a notable trend towards enhanced customization and versatility in product offerings. Industries like construction, automotive, and aerospace are increasingly adopting telescoping mechanisms for their ability to provide space-saving solutions and facilitate quick adjustments in height and length.

Emerging technologies, such as smart locking systems integrated with IoT capabilities, are redefining traditional locking mechanisms. These innovations allow for real-time monitoring and remote control, appealing particularly to industries that prioritize efficiency and security. Moreover, as manufacturers enhance their offerings, the focus is shifting towards modular designs that allow for easy assembly and disassembly, catering to diverse applications from industrial equipment to consumer products.

Additionally, the rise of e-commerce platforms is transforming sourcing dynamics, allowing international buyers to access a broader range of suppliers and products. This trend is particularly beneficial for small and medium-sized enterprises (SMEs) in emerging markets, enabling them to source high-quality telescoping locking mechanisms without the limitations of traditional procurement methods.

How Important Is Sustainability and Ethical Sourcing for Telescoping Locking Mechanisms?

Sustainability has become a paramount concern for B2B buyers in the telescoping locking mechanisms sector. The environmental impact of manufacturing processes, particularly in terms of resource consumption and waste generation, is under scrutiny. International buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices, such as using recycled materials and reducing carbon footprints.

Ethical sourcing plays a critical role in ensuring that materials are obtained responsibly. Companies that can provide certifications for green materials, such as eco-friendly plastics or sustainably sourced metals, are likely to gain a competitive edge. This is particularly relevant in Europe and North America, where regulatory frameworks are becoming more stringent regarding environmental compliance.

Furthermore, embracing sustainability is not just about compliance; it can also lead to cost savings and improved brand reputation. Buyers are encouraged to engage with suppliers who are transparent about their supply chains and can provide detailed documentation regarding their sustainability efforts. Ultimately, aligning with environmentally conscious suppliers can enhance a company’s market position while contributing positively to global sustainability goals.

What Is the Historical Context of Telescoping Locking Mechanisms in B2B Applications?

The evolution of telescoping locking mechanisms can be traced back to their initial use in simple applications such as flagpoles and adjustable stands. Over the decades, as industries evolved, so did the designs and functionalities of these mechanisms. The introduction of advanced materials and manufacturing techniques in the late 20th century paved the way for more robust and versatile locking solutions.

The shift from traditional materials to composites and lightweight alloys has allowed for significant enhancements in performance and durability. Today, telescoping locking mechanisms are integral in numerous applications, ranging from medical devices to aerospace components, reflecting their adaptability and importance in modern manufacturing and design. As the industry continues to innovate, the focus remains on creating solutions that are not only functional but also sustainable and ethically sourced, ensuring they meet the evolving demands of a global market.

Frequently Asked Questions (FAQs) for B2B Buyers of telescoping locking mechanisms

-

How do I ensure the quality of telescoping locking mechanisms before purchase?

To ensure quality, request samples from potential suppliers to assess their performance and durability. Additionally, inquire about the manufacturer’s quality assurance processes, certifications, and testing methods. It is also advisable to check customer reviews and case studies to understand the reliability of the locking mechanisms in real-world applications. Engaging with suppliers who have a strong track record in your industry can provide further assurance of product quality. -

What is the best locking mechanism for adjustable poles used in outdoor applications?

For outdoor applications, quick-release ball lock pins and flip-lock clamps are ideal due to their ease of use and reliability. These mechanisms provide secure locking while allowing for quick adjustments, which is crucial in dynamic environments. Additionally, consider materials resistant to corrosion and UV exposure, such as stainless steel or treated aluminum, to ensure longevity and functionality in varying weather conditions. -

How can I customize telescoping locking mechanisms for specific applications?

Many manufacturers offer customization options, including materials, dimensions, and locking styles tailored to your needs. When discussing customization, provide detailed specifications about your application, including load requirements and environmental conditions. Collaborating with the engineering team of the supplier can also yield innovative solutions that enhance product performance for your specific use case. -

What are the minimum order quantities (MOQs) for telescoping locking mechanisms?

MOQs can vary significantly among suppliers, often depending on the complexity of the product and the customization options. Standard products may have lower MOQs, while custom solutions could require larger quantities. Always clarify MOQs upfront and negotiate terms that align with your purchasing capabilities to ensure a cost-effective supply chain. -

What payment terms should I expect when sourcing telescoping locking mechanisms internationally?

Payment terms can range from upfront payment to net 30, 60, or 90 days after delivery. Suppliers may also accept letters of credit or escrow services for larger transactions. It is essential to establish clear payment terms before finalizing orders to avoid potential cash flow issues, especially when dealing with international suppliers where currency fluctuations may impact costs. -

How do I evaluate suppliers for telescoping locking mechanisms?

Evaluate suppliers based on their industry experience, production capabilities, and customer references. Request information about their manufacturing processes, quality control measures, and delivery timelines. Additionally, consider their ability to provide after-sales support and warranty services, as these factors significantly influence your long-term satisfaction and partnership. -

What logistics considerations should I keep in mind when importing telescoping locking mechanisms?

When importing, consider shipping methods, customs regulations, and potential tariffs that may apply to your products. It’s crucial to work with a logistics partner familiar with international trade to streamline the shipping process. Additionally, factor in lead times for production and shipping to ensure timely delivery aligned with your project schedules. -

What certifications should I look for in telescoping locking mechanisms?

Look for certifications such as ISO 9001 for quality management systems and any industry-specific standards that may apply. These certifications indicate that the manufacturer adheres to high-quality production practices. Additionally, check for compliance with safety and environmental regulations applicable in your region, especially if the locking mechanisms will be used in sensitive or high-stakes applications.

Top 6 Telescoping Locking Mechanisms Manufacturers & Suppliers List

1. Rock West Composites – Telescoping Tube Locking Mechanisms

Domain: rockwestcomposites.com

Registered: 2009 (16 years)

Introduction: Locking mechanisms for telescoping tubes include various components that work with Rock West Composites’ telescoping tubing products. The available mechanisms are: 1. Clamps for Telescoping Tubes 2. Button Clips 3. Quick Release Ball Lock Pins 4. Tube Plugs & Tape Joints 5. Carbon Fiber Joints 6. Push Button Ratchet Joints. The telescoping tubing products are categorized into three lineups: TW (ta…

2. Reddit – Telescopic Twist Lock Mechanism

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Telescopic twist lock mechanism; utilizes two free sliding telescopic tubes; inner tube locks to prevent movement in the outer tube; locking achieved by rotating the inner tube; mechanism involves a cam that locks the inner tube in place; design considerations include a plastic nut with a split and conical thread; requires radial expansion to lock tubes together; various design options discussed, …

3. Testrite – Telescoping Tubing Locks

Domain: testriteoem.com

Registered: 2017 (8 years)

Introduction: Testrite Instrument Co., Inc. offers a variety of round telescoping tubing locks, including:

1. A Style Clutch Lock – Aluminum with knurl for easy turning, internally threaded with a split plastic sleeve.

2. B Style Split Collar – Strong and stiff, suitable for aluminum or steel tubing.

3. L Lever Lock – Strong one-handed flip lock for custom assemblies.

4. C Style Cam Lock – Internal cam lock…

4. Valco Cleve – Telescoping Pipe Locks

Domain: valcocleve.com

Registered: 1996 (29 years)

Introduction: Key Takeaways About Our Telescoping Pipe Locks: Comprehensive Range of Lock Styles, Versatile Diameter Compatibility, Customization and Material Options, Tailored Solutions for Specialized Applications. Industries served include Industrial Construction, Mining, Aerospace, Automotive, Healthcare, and more. Specific uses include flagpoles, antenna masts, adjustable stands, and handles. Advantages in…

5. Testrite – L Lever Lock Telescopic Tube Clamp

Domain: testritealuminum.com

Registered: 2022 (3 years)

Introduction: L Lever Lock 7/8″ to 1″ Telescopic Tube Clamp; SKU: LLOCK0875-1000; Price: $8.00 USD; Material: Glass reinforced nylon and 304 stainless steel; Features: One-handed flip lock, adjustable tension via 2.5MM allen screw, non-marring; Compatibility: Fits round 7/8″ OD tube on one end and 1″ tube on the other; Usage: Can be used with various tubing materials including DOM steel, stainless steel, carbon…

6. Evacuums and More – Locking Mechanism for Telescopic Tube

Domain: evacuumsandmore.com

Registered: 2024 (1 years)

Introduction: Locking Mechanism for Telescopic Tube on D1, K2, E1, E2, C1-1, and C2-1 models.

Strategic Sourcing Conclusion and Outlook for telescoping locking mechanisms

The landscape of telescoping locking mechanisms offers significant opportunities for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. By strategically sourcing these essential components, businesses can enhance product versatility and adaptability, ultimately driving operational efficiency. Whether your needs are for industrial applications or specialized products, selecting the right locking mechanism can lead to substantial cost savings and improved design flexibility.

Incorporating a variety of locking styles and materials—ranging from stainless steel to custom-engineered solutions—will allow companies to meet diverse industry demands. The ability to customize locking mechanisms further ensures that specific functional requirements are met, fostering innovation and competitive advantage.

As we look to the future, the demand for reliable, adjustable, and space-saving solutions will only increase. International B2B buyers are encouraged to explore partnerships with suppliers who can provide quality telescoping locking mechanisms tailored to their unique needs. This strategic sourcing approach not only secures a stable supply chain but also positions businesses to capitalize on the growing market potential. Embrace the opportunity to enhance your product offerings today!

Illustrative image related to telescoping locking mechanisms

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.