A Deep Dive into Ss Grating Solution

Introduction: Navigating the Global Market for ss grating

In today’s competitive landscape, sourcing high-quality stainless steel grating (ss grating) can pose significant challenges for international B2B buyers. Factors such as varying standards, material specifications, and supplier reliability can complicate the procurement process, especially for businesses operating in diverse regions like Africa, South America, the Middle East, and Europe. This comprehensive guide is designed to navigate these complexities, offering insights into the different types of ss grating available, their applications across various industries, and strategies for effectively vetting suppliers.

Throughout this guide, we delve into the nuances of stainless steel grating, including its corrosion-resistant properties, various construction types, and the importance of load-bearing specifications. Buyers will gain a thorough understanding of critical considerations such as cost, maintenance, and compliance with international standards, enabling them to make informed purchasing decisions.

By equipping B2B buyers with actionable insights and best practices, this resource aims to streamline the sourcing process, ensuring that businesses can select the right products to meet their specific needs. Whether you are looking to enhance safety in industrial settings or seeking sustainable solutions for architectural applications, this guide is your essential tool for mastering the global market for stainless steel grating.

Understanding ss grating Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Welded Bar Grating | Strong, durable construction; welded joints | Industrial flooring, catwalks, platforms | Pros: High load capacity, low maintenance. Cons: Heavier, may require more installation effort. |

| Swage-Locked Grating | Lightweight, corrosion-resistant, versatile design | Architectural applications, safety treads | Pros: Easier installation, aesthetically pleasing. Cons: Lower load capacity compared to welded. |

| Press-Locked Grating | Cost-effective, customizable spacing options | Commercial spaces, walkways, stair treads | Pros: Affordable, quick to produce. Cons: Less robust than welded or swage-locked options. |

| Riveted Grating | Traditional design with riveted connections | Heavy-duty applications, industrial environments | Pros: Excellent load distribution, durable. Cons: Heavier, potential corrosion at rivet points. |

| Dovetail Grating | Unique design for improved drainage and aesthetics | Outdoor environments, parks, and recreation areas | Pros: Enhanced drainage, attractive finish. Cons: Limited load capacity, more expensive. |

What Are the Characteristics and Suitability of Welded Bar Grating?

Welded bar grating is characterized by its robust construction, where bearing bars are welded to crossbars, creating a solid structure. This type is ideal for heavy-duty applications, such as industrial flooring and catwalks, due to its high load-bearing capacity. When considering this option, buyers should evaluate the installation requirements and the weight of the product, as it may require additional support structures.

How Does Swage-Locked Grating Differ in Design and Use?

Swage-locked grating features a lightweight design that utilizes swaged connections, making it easier to handle and install. This type is particularly suitable for architectural applications where aesthetics matter, such as safety treads and decorative walkways. Buyers should consider the load requirements of their projects, as swage-locked grating typically has a lower load capacity compared to welded options, but offers a visually appealing solution.

What Are the Benefits of Press-Locked Grating for Commercial Spaces?

Press-locked grating is known for its cost-effectiveness and customizable spacing options, making it popular in commercial settings like walkways and stair treads. This type is manufactured quickly and offers a range of designs to meet specific project needs. However, buyers should be aware that while it is affordable, it may not provide the same durability and load capacity as heavier-duty options, making it essential to assess the anticipated traffic and usage.

Why Choose Riveted Grating for Heavy-Duty Applications?

Riveted grating is a traditional option that utilizes riveted connections to provide excellent load distribution and durability. This type is well-suited for heavy-duty environments, such as factories and warehouses. While it offers significant strength, buyers must consider the potential for corrosion at the rivet points and the added weight, which may necessitate additional support in the installation process.

What Makes Dovetail Grating an Attractive Option?

Dovetail grating features a unique design that enhances both drainage and aesthetics, making it ideal for outdoor applications like parks and recreation areas. It is often chosen for its attractive appearance and functionality. However, buyers should keep in mind that while it offers enhanced drainage, it typically has a lower load capacity and may come at a higher price point compared to other types.

Key Industrial Applications of ss grating

| Industry/Sector | Specific Application of ss grating | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Water & Wastewater | Grating for treatment plants | Enhances safety and efficiency in harsh environments | Corrosion resistance, load-bearing capacity, compliance with environmental standards |

| Construction | Walkways and platforms | Provides durable, slip-resistant surfaces | Custom sizing, ADA compliance, and finish options |

| Food & Beverage | Hygiene-centric flooring | Ensures cleanliness and prevents contamination | Material certification, hygienic design, and ease of cleaning |

| Oil & Gas | Catwalks and support structures | Supports heavy loads and withstands extreme conditions | Heavy-duty specifications, anti-slip features, and resistance to chemicals |

| Architecture | Decorative grilles and facades | Enhances aesthetic appeal while maintaining functionality | Design flexibility, finish options, and integration with other materials |

How is Stainless Steel Grating Used in Water & Wastewater Treatment Facilities?

In water and wastewater treatment plants, stainless steel grating serves as flooring and walkways, offering a robust solution that withstands corrosive environments. Its inherent resistance to rust and degradation ensures longevity, which is vital for maintaining operational efficiency. Buyers in this sector must prioritize sourcing grating that meets specific load-bearing requirements and complies with environmental standards, ensuring safety and functionality.

What Role Does Stainless Steel Grating Play in Construction Projects?

In the construction industry, stainless steel grating is widely used for walkways, platforms, and stair treads, where safety and durability are paramount. The grating provides slip resistance, reducing the risk of accidents on job sites. Buyers should consider custom sizing and ADA compliance options to accommodate diverse project specifications and ensure accessibility for all workers, particularly in international markets with varying regulations.

Why is Stainless Steel Grating Essential in the Food & Beverage Sector?

In food processing and beverage manufacturing, stainless steel grating is crucial for flooring systems that prioritize hygiene. Its smooth surface is easy to clean, preventing contamination and promoting safety. Buyers should look for products that are certified for food safety and designed for easy maintenance, as these factors significantly impact operational efficiency and compliance with health regulations.

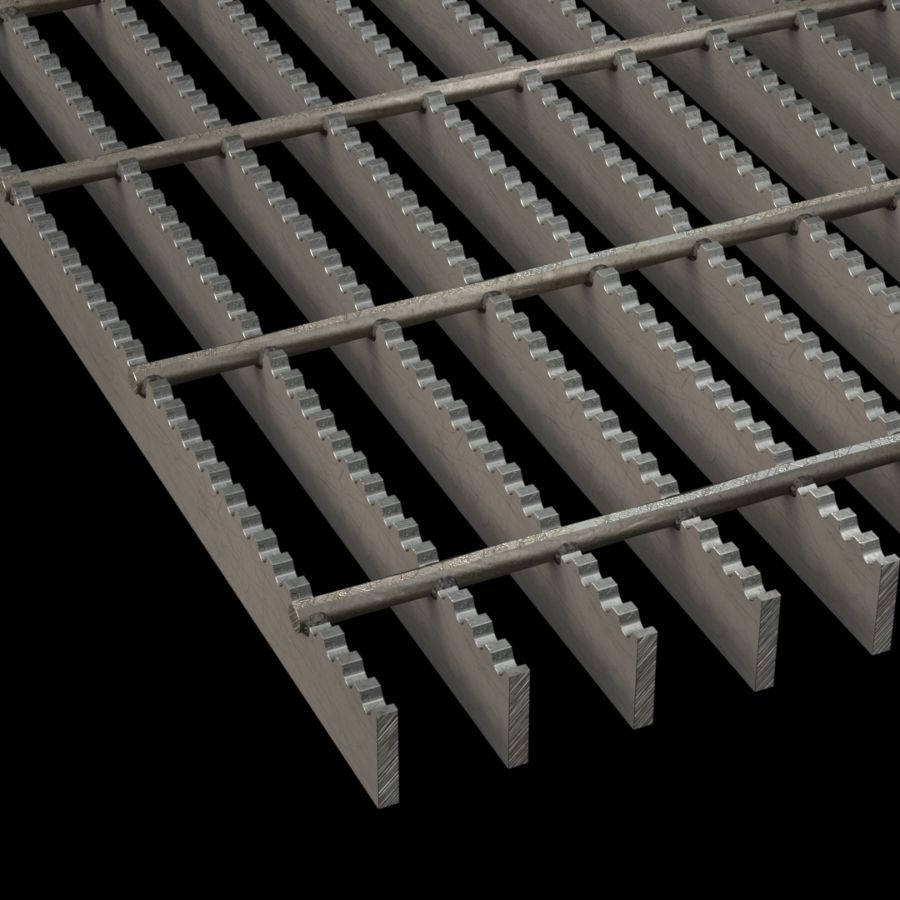

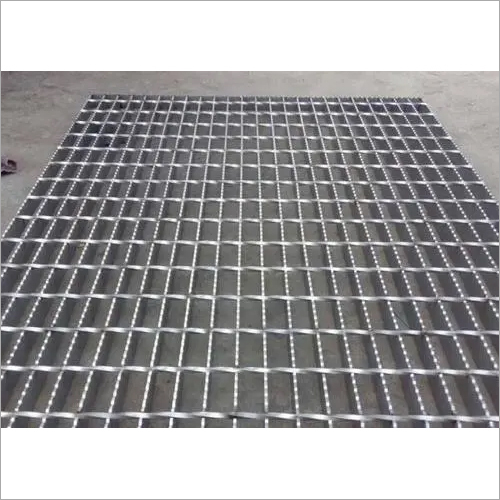

Illustrative image related to ss grating

How Does Stainless Steel Grating Enhance Safety in Oil & Gas Operations?

In the oil and gas industry, stainless steel grating is utilized in catwalks and support structures, providing the strength required to handle heavy equipment and extreme conditions. The material’s resistance to chemicals and corrosion is essential for maintaining structural integrity in challenging environments. When sourcing for this application, buyers should focus on heavy-duty specifications and anti-slip features to ensure worker safety.

What Are the Aesthetic and Functional Benefits of Stainless Steel Grating in Architecture?

In architectural applications, stainless steel grating is often used for decorative grilles and facades, merging form with function. It enhances the visual appeal of buildings while providing practical benefits such as ventilation and light penetration. Buyers in this sector should consider design flexibility and finish options, allowing for customization that meets both aesthetic desires and structural requirements in various international markets.

3 Common User Pain Points for ‘ss grating’ & Their Solutions

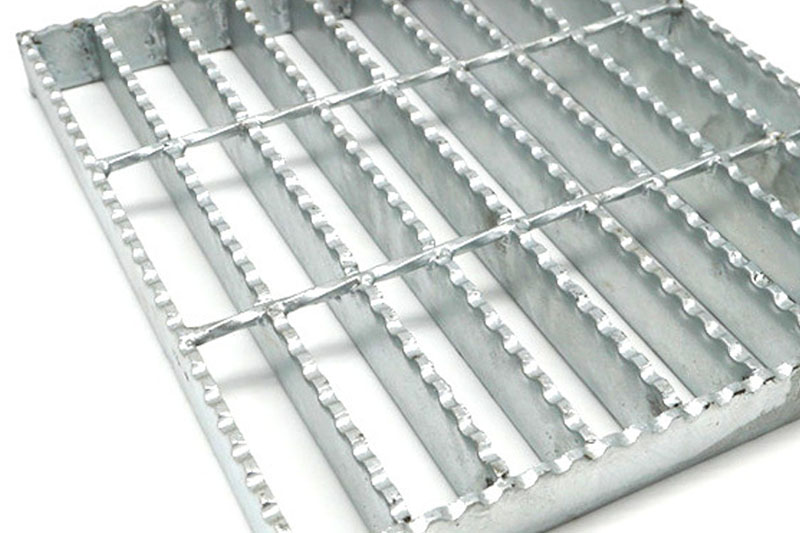

Scenario 1: Navigating Corrosion Resistance Challenges in Harsh Environments

The Problem: Many B2B buyers in industries such as food processing, pharmaceuticals, and marine applications face significant challenges with corrosion when selecting stainless steel grating. For instance, buyers operating in coastal regions may find that traditional stainless steel products do not hold up against saline environments, leading to premature deterioration and costly replacements. The challenge intensifies when buyers are also required to comply with strict hygiene standards, necessitating a grating solution that is not only corrosion-resistant but also easy to clean and maintain.

The Solution: To effectively combat corrosion, buyers should prioritize sourcing high-grade stainless steel grating specifically designed for harsh environments, such as those using 316 stainless steel, known for its superior resistance to saltwater. It is essential to consult with suppliers about the specific alloy composition and corrosion ratings of the products they offer. Additionally, integrating a regular maintenance schedule can significantly prolong the lifespan of the grating. Using a mild detergent and water can help maintain the hygiene and appearance of the grating without compromising its structural integrity. Finally, consider specifying grating with surface finishes that enhance traction and reduce slip risks, particularly in wet environments.

Scenario 2: Ensuring Load-Bearing Capacity Meets Safety Standards

The Problem: B2B buyers in sectors such as construction and manufacturing often struggle with selecting the appropriate stainless steel grating that can safely support the intended load without compromising safety. Many are faced with the daunting task of balancing cost, strength, and compliance with local regulations regarding load-bearing capacities, which can vary significantly from one region to another.

Illustrative image related to ss grating

The Solution: To address this concern, buyers should conduct a thorough load analysis before purchasing stainless steel grating. Begin by determining the specific weight load requirements based on the application, whether for pedestrian traffic or heavy machinery. Collaborate closely with manufacturers to understand the different construction types available—such as welded, swage-locked, or press-locked grating—and their respective load ratings. It’s also advisable to review detailed load tables provided by suppliers to ensure that the selected product meets or exceeds the required safety standards. Furthermore, discussing potential custom solutions with suppliers can yield grating tailored to unique load conditions, which can enhance safety and performance.

Scenario 3: Balancing Aesthetic Appeal with Functional Requirements

The Problem: In sectors like architecture and landscaping, B2B buyers often face the challenge of finding stainless steel grating that not only meets functional requirements but also aligns with aesthetic goals. Many traditional grating solutions can appear industrial and unattractive, which may not meet the design intentions of upscale commercial projects or public spaces.

The Solution: To successfully balance aesthetics with functionality, buyers should explore various design options and finishes available for stainless steel grating. Customizable solutions, such as patterned or decorative grating, can enhance visual appeal while maintaining strength and durability. Buyers should consult with suppliers about available finishes that can improve both aesthetics and performance, such as powder coating or brushed finishes, which can provide a modern look while enhancing traction. Additionally, consider the integration of stainless steel grating within broader design elements, such as landscaping or architectural features, to create a cohesive look that supports the project’s overall vision. Engaging with designers or architects who specialize in industrial aesthetics can also yield innovative ideas on incorporating grating into the design effectively.

Strategic Material Selection Guide for ss grating

What Are the Key Properties of Stainless Steel Grating Materials?

Stainless steel grating is increasingly favored for its unique properties that enhance performance across various applications. The primary materials used in stainless steel grating include 304 stainless steel, 316 stainless steel, and aluminum. Each material has distinct characteristics that influence its suitability for specific environments and applications.

1. 304 Stainless Steel: A Versatile Choice

Key Properties:

304 stainless steel is known for its excellent corrosion resistance and high-temperature tolerance, making it suitable for a wide range of applications. It can withstand temperatures up to 870°C (1600°F) intermittently.

Pros & Cons:

The advantages of 304 stainless steel include its affordability and ease of fabrication. However, it is less resistant to chlorides compared to 316 stainless steel, which can lead to pitting in marine or highly saline environments.

Impact on Application:

304 stainless steel grating is ideal for general industrial use, including walkways and platforms in environments where exposure to moisture is limited. However, it may not be suitable for coastal applications or areas with high chloride exposure.

Considerations for International Buyers:

Buyers from regions like Africa and South America should consider local environmental conditions when selecting 304 stainless steel. Compliance with regional standards (e.g., ASTM) is crucial for ensuring product reliability.

2. 316 Stainless Steel: Enhanced Corrosion Resistance

Key Properties:

316 stainless steel offers superior corrosion resistance, particularly against chlorides and harsh chemicals. It maintains its integrity in temperatures up to 925°C (1700°F).

Pros & Cons:

While 316 stainless steel is more expensive than 304, its durability in corrosive environments justifies the cost. The primary disadvantage is its weight, which can complicate transport and installation.

Impact on Application:

This material is particularly suitable for marine environments, chemical processing, and food processing applications where hygiene and corrosion resistance are paramount.

Considerations for International Buyers:

For buyers in the Middle East and coastal regions, 316 stainless steel grating is often a preferred choice due to its longevity in harsh conditions. Familiarity with local compliance standards is essential for procurement.

3. Aluminum Grating: Lightweight and Cost-Effective

Key Properties:

Aluminum grating is lightweight, corrosion-resistant, and can handle moderate loads. It is typically rated for temperatures up to 200°C (392°F).

Pros & Cons:

The main advantage of aluminum grating is its low weight, which reduces shipping costs and simplifies installation. However, it may not be suitable for heavy-duty applications, and its cost can be higher than carbon steel alternatives.

Impact on Application:

Aluminum grating is commonly used in pedestrian walkways, platforms, and areas requiring lightweight solutions. It is less ideal for heavy industrial applications.

Considerations for International Buyers:

In regions like Europe and Brazil, where environmental regulations are stringent, aluminum grating can be an excellent option due to its recyclability and lower environmental impact.

Summary Table of Material Selection for Stainless Steel Grating

| Material | Typical Use Case for ss grating | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 304 Stainless Steel | General industrial walkways and platforms | Cost-effective and easy to fabricate | Limited corrosion resistance in saline environments | Medium |

| 316 Stainless Steel | Marine, chemical processing, and food industries | Superior corrosion resistance | Higher cost and weight | High |

| Aluminum | Pedestrian walkways and lightweight platforms | Lightweight and easy to install | Not suitable for heavy-duty use | Medium |

| 304 Stainless Steel | General industrial walkways and platforms | Cost-effective and easy to fabricate | Limited corrosion resistance in saline environments | Medium |

This guide serves as a strategic resource for international B2B buyers, helping them make informed decisions regarding the material selection for stainless steel grating based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for ss grating

What Are the Key Stages in the Manufacturing Process of Stainless Steel Grating?

The manufacturing of stainless steel (SS) grating involves several critical stages, each designed to ensure the final product meets stringent quality and performance standards.

1. Material Preparation

The process begins with the selection of high-quality stainless steel, typically categorized as 304 or 316 grades due to their corrosion resistance and durability. The material is then cut into appropriate sizes using precision cutting tools. This stage is crucial as the quality of the raw materials directly influences the performance of the final product.

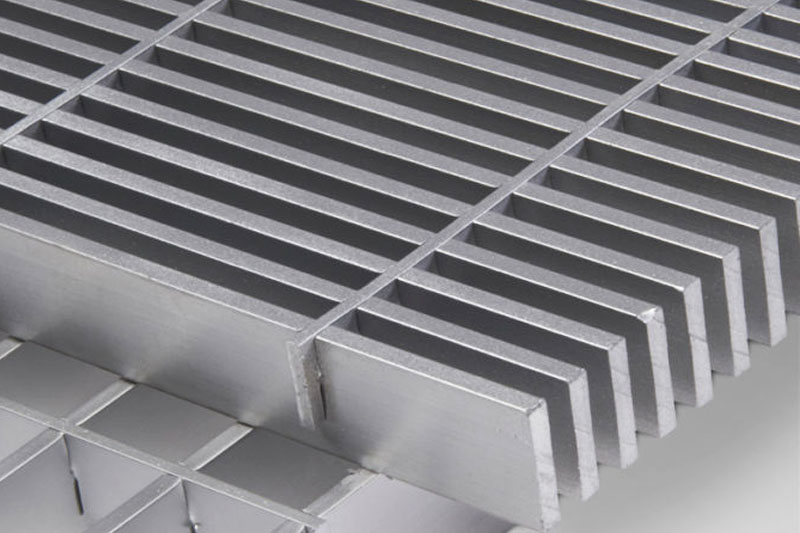

2. Forming Techniques

Once prepared, the stainless steel sheets are subjected to various forming techniques. The most common methods include:

-

Welding: This is widely used for creating welded grating, where bearing bars are welded to cross bars to form a robust grid structure. This technique ensures strength and stability.

-

Swage-Locking: This method involves locking the bars together without welding, which can enhance the load-bearing capacity and reduce manufacturing stress.

-

Press-Locking: Utilized for lighter-duty applications, this technique involves mechanically pressing the bars together, ensuring a secure fit while allowing for some flexibility.

Each method has its advantages depending on the intended application of the grating, whether it’s for pedestrian walkways or heavy vehicular loads.

3. Assembly

Following the forming process, the grating panels are assembled. This involves placing the formed bars in the correct orientation and securing them to create a complete panel. Depending on the design specifications, additional features like toeboards or custom cutouts may also be integrated at this stage.

4. Finishing

The final stage is finishing, which may involve surface treatments to enhance durability and aesthetics. Options include:

Illustrative image related to ss grating

-

Mill Finish: This is the natural state of stainless steel, which provides a clean, modern appearance.

-

Powder Coating: This adds color and enhances surface protection, particularly useful in environments that require additional corrosion resistance.

-

Textured Finishes: These are applied to increase traction, making the grating safer for pedestrian use.

What Quality Assurance Measures Are Essential for Stainless Steel Grating?

Quality assurance (QA) is critical in the production of stainless steel grating, ensuring that the final products meet international standards and customer expectations.

International Standards to Consider

B2B buyers should be aware of various international standards that govern the quality of stainless steel grating. Key certifications include:

-

ISO 9001: This is the international standard for quality management systems, ensuring that manufacturers maintain consistent quality in their processes.

-

CE Marking: Essential for products sold in the European Economic Area, CE marking indicates compliance with health, safety, and environmental protection standards.

-

API Standards: Particularly relevant for grating used in oil and gas applications, API standards ensure that products can withstand harsh environmental conditions.

What Are the Key Quality Control Checkpoints?

Quality control (QC) is typically divided into several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon receipt to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor critical parameters, such as the accuracy of dimensions and the integrity of welds.

-

Final Quality Control (FQC): The finished products undergo rigorous testing, including load testing and surface inspections, to confirm they meet performance specifications.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are several methods to ensure supplier reliability:

Conducting Supplier Audits

Regular audits of suppliers can provide insight into their manufacturing practices and quality assurance processes. Buyers should request to review their QC protocols, certifications, and any non-conformance reports.

Requesting Quality Assurance Reports

Buyers can ask suppliers to provide detailed quality assurance reports that outline testing methods, results, and any corrective actions taken. This transparency is vital for assessing the reliability of the supplier.

Engaging Third-Party Inspections

Utilizing third-party inspection services can provide an unbiased evaluation of the supplier’s products. This is particularly important for large orders or when entering new markets where local regulations may differ.

What Specific Quality Control Nuances Should International Buyers Be Aware Of?

International B2B buyers should be cognizant of specific nuances in quality control that may differ by region:

-

Regulatory Compliance: Different countries have varying regulations regarding materials and safety standards. It’s crucial to ensure that the supplier’s products comply with local laws in the buyer’s country.

-

Cultural Differences in Quality Expectations: Understanding cultural differences in quality perception can influence how products are evaluated. Buyers should communicate their quality expectations clearly to avoid discrepancies.

-

Supply Chain Transparency: Buyers should seek suppliers that maintain transparency throughout their supply chain. This includes the sourcing of materials, manufacturing processes, and distribution channels.

By understanding the manufacturing processes and quality assurance measures in stainless steel grating production, B2B buyers can make informed decisions, ensuring they procure high-quality products that meet their specific needs.

Illustrative image related to ss grating

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ss grating’

To assist international B2B buyers in sourcing stainless steel (SS) grating, this guide provides a clear, actionable checklist designed to streamline the procurement process. By following these steps, buyers can ensure that they select the right products that meet their specific needs while also maintaining quality and compliance with industry standards.

Step 1: Define Your Technical Specifications

Clearly outline the specific technical requirements for your SS grating. This includes load-bearing capacity, dimensions, and environmental conditions it must withstand. Identifying these specifications upfront helps narrow down options and ensures that the products sourced will meet the operational demands of your project.

- Load Requirements: Determine whether the grating will support pedestrian traffic, heavy machinery, or both.

- Environmental Factors: Consider factors such as exposure to corrosive substances, extreme temperatures, or hygienic requirements, especially for industries like food processing or pharmaceuticals.

Step 2: Research Material Types and Finishes

Stainless steel grating comes in various grades and finishes, each offering different properties and aesthetics. Understanding these options is vital to selecting the best product for your application.

- Material Grades: Familiarize yourself with common grades of stainless steel, such as 304 and 316, which differ in corrosion resistance and strength.

- Finishing Options: While stainless steel is inherently corrosion-resistant, additional finishes like serrated or coated surfaces can enhance traction or aesthetic appeal.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conducting a thorough evaluation is essential. This ensures that you partner with a reliable vendor who can deliver quality products consistently.

- Supplier Credentials: Request certifications, such as ISO or ASTM compliance, to verify the supplier’s quality standards.

- Customer Feedback: Seek references or reviews from other clients in similar industries to gauge their reliability and service quality.

Step 4: Request Samples and Specifications

Always ask for samples of the SS grating before making a bulk order. This allows you to assess the quality and suitability of the product firsthand.

- Physical Assessment: Inspect the sample for structural integrity, finish quality, and compliance with your specifications.

- Documentation: Ensure that the supplier provides detailed product specifications, including load tables and installation guidelines.

Step 5: Confirm Compliance with Local Regulations

Ensure that the SS grating meets any local regulatory standards or industry-specific guidelines applicable to your region or sector.

Illustrative image related to ss grating

- Safety Standards: Verify that the grating complies with safety regulations, such as ADA compliance for public applications.

- Environmental Regulations: Check for adherence to any environmental standards relevant to your industry, particularly for waste management or construction projects.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, negotiate favorable terms that include pricing, lead times, and payment conditions.

- Pricing Structures: Discuss bulk purchase discounts or payment terms that can benefit your cash flow.

- Delivery Schedules: Confirm lead times and shipping logistics to ensure timely delivery that aligns with your project timelines.

Step 7: Finalize the Order and Monitor Delivery

After negotiations, finalize your order and establish a monitoring system for delivery. This ensures that you receive the correct products on time.

- Order Confirmation: Ensure all specifications and terms are documented in the purchase order.

- Delivery Tracking: Keep in contact with the supplier to monitor the shipment and address any potential issues proactively.

By following this checklist, B2B buyers can efficiently navigate the sourcing process for stainless steel grating, ensuring they obtain the right products that meet their operational and regulatory needs.

Comprehensive Cost and Pricing Analysis for ss grating Sourcing

What Are the Key Cost Components in Sourcing Stainless Steel Grating?

When sourcing stainless steel (ss) grating, understanding the cost structure is critical for B2B buyers. The main components that contribute to the overall cost include:

-

Materials: Stainless steel is the primary material, and its cost can fluctuate based on market demand, alloy composition, and global supply chain dynamics. The choice between different grades of stainless steel (like 304 vs. 316) can also significantly affect pricing due to variations in corrosion resistance and strength.

-

Labor: Labor costs are influenced by the complexity of the manufacturing process. Products requiring intricate designs or customizations may incur higher labor costs. Additionally, labor rates vary by region, impacting overall expenses.

-

Manufacturing Overhead: This includes costs associated with facilities, utilities, equipment maintenance, and administrative expenses. For manufacturers with advanced technology or automation, overhead may be lower, but this can vary widely.

-

Tooling: The initial setup for production, including molds and jigs, can be a significant upfront cost, especially for custom or specialized grating. Tooling costs are amortized over the production run, making larger orders more cost-effective.

-

Quality Control (QC): Ensuring that the stainless steel grating meets industry standards requires investment in quality control processes. Certifications (like ISO) can further influence costs but are essential for compliance and customer satisfaction.

-

Logistics: Transportation and handling costs are critical, especially for international shipping. Factors such as distance, mode of transport, and local tariffs can affect logistics expenses.

-

Margin: Suppliers typically add a margin to cover their costs and profit, which can vary based on market competition and supplier reputation.

How Do Price Influencers Impact the Cost of Stainless Steel Grating?

Several factors can influence pricing in the stainless steel grating market:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower unit prices due to economies of scale. Suppliers may set MOQs that affect pricing flexibility, especially for small or medium-sized businesses.

-

Specifications and Customization: Custom designs or specific load-bearing requirements can increase costs. Buyers should consider whether standard products meet their needs or if customization is necessary.

-

Material Quality and Certifications: Higher quality materials or certifications can lead to increased costs but provide assurance of durability and compliance, which is crucial for many applications.

-

Supplier Factors: The reputation, reliability, and location of the supplier can affect pricing. Established suppliers may offer better quality but at a premium price.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is vital for managing logistics costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can influence the total landed cost.

What Tips Can Help Buyers Negotiate Better Prices for Stainless Steel Grating?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, strategic approaches can enhance cost efficiency:

-

Negotiate Volume Discounts: Leverage order size to negotiate better pricing. Suppliers are often willing to offer discounts for larger orders.

-

Evaluate Total Cost of Ownership (TCO): Consider not just the initial purchase price but the total cost over the product’s life cycle, including maintenance and replacement costs.

-

Research Market Trends: Understanding market conditions can provide leverage in negotiations. Keeping abreast of stainless steel prices and demand fluctuations can help in timing purchases effectively.

-

Seek Multiple Quotes: Obtaining quotes from several suppliers can provide insights into competitive pricing and help in negotiations.

-

Consider Local Suppliers: For buyers in regions like Africa or South America, sourcing from local suppliers may reduce logistics costs and lead times, despite potential higher material costs.

-

Understand Pricing Nuances for International Transactions: Be aware of currency fluctuations, taxes, and tariffs that could affect the final price when sourcing internationally.

Disclaimer on Pricing

Prices for stainless steel grating can vary significantly based on the factors discussed. It is recommended that buyers conduct thorough market research and request detailed quotes from suppliers to obtain the most accurate and competitive pricing information.

Alternatives Analysis: Comparing ss grating With Other Solutions

Understanding Alternatives to Stainless Steel Grating

When considering grating solutions for industrial or architectural applications, stainless steel (SS) grating stands out due to its durability and resistance to corrosion. However, various alternatives may suit specific needs, providing different benefits and drawbacks. This analysis will compare SS grating against two viable alternatives: aluminum grating and fiberglass reinforced plastic (FRP) grating.

Comparison Table

| Comparison Aspect | SS Grating | Aluminum Grating | Fiberglass Reinforced Plastic (FRP) Grating |

|---|---|---|---|

| Performance | High load-bearing capacity, slip-resistant, corrosion-resistant | Lightweight, good load capacity, corrosion-resistant | Excellent chemical resistance, lightweight, non-slip surfaces |

| Cost | Higher initial investment | Moderate cost, more affordable than SS | Lower upfront cost, but may have higher lifecycle costs |

| Ease of Implementation | Requires specific tools for installation | Easier to handle and install due to lower weight | Requires specialized installation techniques |

| Maintenance | Low maintenance; resistant to rust and staining | Low maintenance; may require periodic inspections | Very low maintenance; resistant to chemicals but may degrade over time |

| Best Use Case | Heavy-duty applications, outdoor environments, and areas exposed to harsh conditions | Medium-duty applications, environments where weight is a concern | Chemical processing plants, wastewater treatment facilities, and environments with corrosive substances |

Pros and Cons of Alternatives

Aluminum Grating

Aluminum grating offers a lightweight alternative to SS grating, making it easier to handle and install. Its cost-effectiveness makes it an attractive option for projects with budget constraints. However, while aluminum is corrosion-resistant, it may not withstand heavy loads as effectively as stainless steel, making it more suitable for medium-duty applications. Buyers should consider the specific load requirements of their projects when evaluating aluminum grating.

Illustrative image related to ss grating

Fiberglass Reinforced Plastic (FRP) Grating

FRP grating is designed for environments that require excellent chemical resistance, such as chemical processing plants and wastewater treatment facilities. Its lightweight nature allows for easy handling, and it can be customized to provide non-slip surfaces, enhancing safety. While FRP grating typically has a lower initial cost, its long-term durability can be a concern, as it may degrade over time under certain conditions. Organizations must weigh the advantages of FRP in corrosive environments against the potential need for replacements or repairs.

Making the Right Choice for Your Grating Needs

When selecting the most appropriate grating solution, B2B buyers should assess their specific operational needs, including load requirements, environmental conditions, and budget constraints. Stainless steel grating excels in high-load, outdoor environments where durability is paramount. In contrast, aluminum grating is suitable for lighter applications where weight and cost are significant factors. For chemical exposure, FRP grating may offer the best solution, provided that its long-term resilience aligns with project expectations. Ultimately, the right choice will depend on a careful evaluation of performance needs and financial considerations, ensuring a sustainable and effective grating solution.

Essential Technical Properties and Trade Terminology for ss grating

What are the Key Technical Properties of Stainless Steel Grating for B2B Buyers?

Understanding the essential technical properties of stainless steel (SS) grating is vital for B2B buyers looking to make informed purchasing decisions. Here are some critical specifications to consider:

-

Material Grade

Stainless steel grating is available in various grades, primarily 304 and 316. Grade 304 is commonly used for general applications due to its excellent corrosion resistance and affordability. Grade 316, however, offers superior corrosion resistance, especially in marine environments. Selecting the right grade can significantly affect the longevity and performance of the grating in specific applications, such as wastewater treatment or food processing. -

Load-Bearing Capacity

This specification indicates how much weight the grating can support without bending or breaking. Load-bearing capacities are typically categorized into light, medium, and heavy-duty options. For B2B buyers, understanding the required load capacity is crucial to ensure safety and functionality in applications ranging from pedestrian walkways to heavy vehicular traffic areas. -

Tolerance

Tolerance refers to the permissible limits of variation in dimensions and properties of the grating. Common tolerances for stainless steel grating products can range from ±1/16 inch to ±1/8 inch. Proper tolerances ensure that the grating fits seamlessly into existing structures, reducing the need for costly adjustments during installation. -

Open Area Percentage

This specification indicates the ratio of open space to the total surface area of the grating. A higher open area percentage improves drainage and reduces weight, making it suitable for applications where water runoff is crucial, such as in drainage systems or walkways. Buyers should evaluate the open area percentage based on the intended use to optimize performance. -

Finish Type

While stainless steel does not require a protective finish against corrosion, finishes can enhance traction and aesthetics. Common finishes include mill finish, polished, and powder-coated options. Selecting the appropriate finish is essential for both functionality and meeting design specifications, especially in architectural applications.

What are Common Industry Terms Related to Stainless Steel Grating?

Familiarity with industry jargon is important for effective communication and negotiation. Here are some commonly used terms in the stainless steel grating market:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that are used as components in another company’s end product. Understanding OEM relationships can help B2B buyers assess the reliability and quality of the grating products they are sourcing. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for B2B buyers to budget their purchases and manage inventory effectively. It can also impact the overall cost of procurement. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing for specific products or services. In the context of stainless steel grating, issuing an RFQ allows buyers to compare costs and specifications from multiple suppliers, facilitating better purchasing decisions. -

Incoterms (International Commercial Terms)

These are standardized terms that define the responsibilities of buyers and sellers in international transactions. Common Incoterms include FOB (Free on Board) and CIF (Cost, Insurance, and Freight). Understanding these terms helps B2B buyers clarify shipping costs, risks, and responsibilities, ensuring smoother transactions. -

Slip Resistance

This property refers to the ability of the grating surface to prevent slips and falls. It is especially important in environments where water or debris may accumulate. Buyers should look for specifications on slip resistance to ensure safety in pedestrian areas, especially in industrial settings.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions regarding stainless steel grating, enhancing their procurement processes and ensuring the successful execution of their projects.

Navigating Market Dynamics and Sourcing Trends in the ss grating Sector

What Are the Current Market Dynamics and Key Trends in the Stainless Steel Grating Sector?

The global stainless steel grating market is experiencing notable growth driven by several key factors. An increase in infrastructure development across Africa, South America, the Middle East, and Europe has heightened demand for durable and versatile materials. In particular, the construction and manufacturing sectors are adopting stainless steel grating for applications ranging from pedestrian walkways to industrial flooring, owing to its strength and corrosion resistance. Furthermore, the rise of smart technology integration in sourcing—such as digital platforms and automated procurement processes—has streamlined the purchasing experience for international B2B buyers.

Emerging sourcing trends include a shift towards online marketplaces where buyers can compare products, prices, and suppliers more efficiently. This is particularly beneficial for buyers in developing regions, where accessibility to quality materials can be challenging. Additionally, manufacturers are increasingly offering customized solutions to meet specific project requirements, such as ADA compliance and unique load-bearing specifications, which cater to diverse market needs. The focus on cost-effectiveness and rapid delivery also drives competition among suppliers, pushing them to optimize their logistics and inventory management.

How Are Sustainability and Ethical Sourcing Becoming Integral in the Stainless Steel Grating Sector?

Sustainability is becoming a critical consideration in the sourcing of stainless steel grating. The environmental impact of production processes and the lifecycle of materials are under scrutiny, compelling manufacturers to adopt greener practices. Stainless steel itself is an eco-friendly option due to its durability and recyclability, which aligns with the growing emphasis on sustainable construction methods.

Illustrative image related to ss grating

Ethical sourcing practices are also gaining traction. B2B buyers are increasingly looking for suppliers who can demonstrate transparency in their supply chains and adherence to environmental regulations. Certifications such as ISO 14001 for environmental management and LEED for green building projects are becoming essential benchmarks. Buyers should prioritize suppliers who actively engage in sustainable practices, such as utilizing recycled materials or minimizing waste in their manufacturing processes. This not only enhances the credibility of the buyer’s projects but also contributes to a positive brand image in an increasingly eco-conscious market.

What Is the Historical Context of Stainless Steel Grating in B2B Applications?

The use of stainless steel grating dates back several decades, evolving from simple metal frameworks to sophisticated, engineered solutions. Initially utilized in industrial settings for safety and load-bearing applications, its properties have made it a favored choice across various sectors. The material’s resistance to corrosion and high temperatures has facilitated its adoption in more diverse environments, including architectural applications and public infrastructure.

Over the years, technological advancements in manufacturing processes, such as welding and swaging, have enhanced the performance and versatility of stainless steel grating. This evolution has allowed for greater customization, enabling suppliers to meet specific client needs while maintaining cost-effectiveness. As markets continue to expand, the historical context of stainless steel grating underlines its essential role in modern infrastructure and construction, making it a reliable choice for B2B buyers seeking durable solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of ss grating

-

How do I select the right stainless steel grating for my application?

Selecting the appropriate stainless steel grating involves assessing your specific application needs, including load requirements, environment, and aesthetic preferences. Consider factors such as the type of traffic (pedestrian or vehicular), the required slip resistance, and whether the grating must meet any specific regulatory standards, such as ADA compliance. Additionally, evaluate the construction type (welded, swage-locked, or press-locked) and material finish to ensure durability and maintenance ease in your intended setting. -

What is the best type of stainless steel grating for outdoor applications?

For outdoor applications, especially those exposed to harsh weather or corrosive environments, welded stainless steel grating is often the best choice. It provides exceptional strength and resistance to rust, making it suitable for platforms, walkways, and drainage covers. The choice of finish can also impact performance; opting for a non-slip surface can enhance safety in wet conditions, while a polished finish may enhance aesthetics in architectural settings. -

What are the common customization options available for stainless steel grating?

Customization options for stainless steel grating often include dimensions, load capacity, surface finishes, and specific shapes or configurations. Buyers can request cut-to-size panels, unique shapes for specific installations, or finishes that enhance traction or match architectural designs. Additionally, some suppliers offer the ability to add features like banding, notching, or custom cut-outs to meet unique project specifications. -

What is the minimum order quantity (MOQ) for stainless steel grating?

The minimum order quantity for stainless steel grating can vary significantly based on the manufacturer and specific product lines. Typically, MOQs may range from a few panels to several hundred square feet. It’s advisable for buyers to communicate their needs directly with suppliers, as many manufacturers are willing to accommodate smaller orders for first-time clients or pilot projects, especially when establishing a long-term relationship. -

How can I ensure the quality of stainless steel grating products?

To ensure product quality, start by verifying that the supplier adheres to industry standards and certifications. Request detailed product specifications, including load ratings and material composition, and inquire about their quality assurance processes. It may also be beneficial to ask for samples or conduct site visits to the manufacturing facility. Establishing a reliable communication channel with the supplier can facilitate transparency regarding production practices and quality control measures. -

What payment terms are typically offered for international orders of stainless steel grating?

Payment terms for international orders can vary widely depending on the supplier and the buyer’s location. Common practices include partial upfront payments (30-50%) with the balance due upon shipment or delivery. Some suppliers may offer letters of credit or payment upon receipt of goods. It’s crucial to negotiate terms that protect both parties and to ensure clarity on currency, payment methods, and any potential tariffs or duties involved in the transaction. -

What logistics considerations should I be aware of when sourcing stainless steel grating internationally?

Logistics considerations include shipping methods, lead times, customs clearance, and freight costs. Ensure that your supplier can provide a clear timeline for production and delivery, and discuss shipping options that align with your project schedule. Additionally, familiarize yourself with import regulations in your country, including any necessary documentation for customs clearance. Collaborating with a freight forwarder can streamline the logistics process and mitigate potential delays. -

How do I vet suppliers of stainless steel grating effectively?

Vetting suppliers effectively involves researching their reputation, production capabilities, and customer reviews. Look for certifications that demonstrate compliance with international standards, such as ISO certifications. Request references from previous clients and analyze their project portfolios to assess quality and reliability. Engaging in direct communication can also provide insights into their responsiveness and customer service, which are critical for a successful long-term partnership.

Top 10 Ss Grating Manufacturers & Suppliers List

1. Metals Depot – Stainless Steel Bar Grating

Domain: metalsdepot.com

Registered: 1999 (26 years)

Introduction: Stainless Steel Bar Grating is strong, durable, and highly corrosive resistant, suitable for pedestrian and light vehicle traffic. Ideal for walkways, flooring, trench grates, mezzanines, platforms, and stair treads. Best for corrosive environments like chemical, food, salt and fresh water marine, and acidic environments. Available in precut or mill sizes, custom cut to size, and wholesale prices….

2. McNichols – Stainless Steel Bar Grating

Domain: mcnichols.com

Registered: 1996 (29 years)

Introduction: {‘item_number’: ‘6801312732’, ‘product_line’: ‘Bar Grating’, ‘construction_type’: ‘Standard-Duty Welded’, ‘bearing_bar_shape’: ‘Rectangular Bar’, ‘series_type’: ‘GW-100 (19-W-4)’, ‘product_spacing’: ’19-W-4′, ‘primary_material’: ‘Stainless Steel (SS)’, ‘alloy_grade’: ‘Type 304 (304)’, ‘material_finish’: ‘Mill Finish’, ‘bearing_bar_size’: ‘1″ Height x 3/16″ Thick Rectangular Bar’, ‘bearing_bar_heig…

3. McMaster – Stainless Steel Grating

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Stainless Steel Grating, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Ohio Gratings – Stainless Steel Grating Solutions

Domain: ohiogratings.com

Registered: 1996 (29 years)

Introduction: Stainless Steel Grating Products: Corrosion-resistant, hygienic, sustainable, and modern appearance. Unique properties prevent rust and surface stains. Infinitely recyclable and sustainable. Highly durable and easy to maintain. Types available: Standard Series (light-duty, lower load-bearing) and Strong Series (heavy-duty, higher load-bearing). Grating types include Dovetail (DTSS), Riveted (RSS),…

5. P&R Metals – Grating Products

Domain: prmetals.com

Registered: 2001 (24 years)

Introduction: Grating Products from P&R Metals include various types such as Bar Grating, Fiberglass Grating, Plank Grating, Walkway Grating, and Expanded Metal Grating. Available materials include Carbon Steel, Stainless Steel, Aluminum, and Fiberglass. Key specifications include widths of 24″, depths ranging from 3/4″ to 6″, bar thicknesses from 1/8″ to 3/8″, and surface finishes like Smooth, Serrated, and Gr…

6. Grating Pacific – Stainless Steel Bar Grating

Domain: gratingpacific.com

Registered: 1997 (28 years)

Introduction: Stainless Steel Bar Grating is manufactured from alloy types 304, 304L, 316, and 316L, making it ideal for sanitary or highly corrosive environments and architectural applications. It is available in three construction methods: type “WS” welded, type “SLS” swage locked, and type “DTS” dovetail. Bearing bar spacings range from 19/16″ (1-3/16″) to 7/16″ on center, with cross bars at 4″ or 2″ on cent…

7. Amarco Products – ST-58 Stainless Steel Grating

Domain: amarcoproducts.com

Registered: 2005 (20 years)

Introduction: {“model”:”ST-58″,”type”:”Stainless Steel Grating”,”thickness”:”5/8 inch”,”material”:”304 Type Stainless Steel”,”rolling_load”:”1,000 pounds”,”tread_spacing”:”0.233 inches on center”,”applications”:[“High-Traffic Entryways”,”Commercial Vestibules”,”Corporate Office Entrances”],”dimensions”:{“max_width”:”94 inches”,”max_length”:”61 inches”,”custom_fabrication”:”available”},”features”:[“Unique design…

8. Interstate Gratings – Welded Bar Grating

Domain: interstategratings.com

Registered: 2007 (18 years)

Introduction: Welded Bar Grating is an economical design ideal for industrial applications, manufactured by forge welding rectangular bearing bars and drawn cross bars. Available in type ‘W’ Welded Steel or type ‘WS’ Welded Stainless Steel, with bearing bar spacing from 19/16″ to 7/16″ on center and cross bars at 4″ or 2″ on center. Type ‘W’ is the most economical steel grating, with type 19-W-4 recommended for…

9. China Steel Grating – Stainless Steel Grating

Domain: chinasteelgrating.com

Registered: 2009 (16 years)

Introduction: Stainless Steel Grating for Corrosive Platforms or Flooring. Available in 304 and 316 stainless steel grades. Features include: strong, durable, and corrosion-resistant for load-bearing applications; suitable for pedestrian and light vehicle traffic; options for smooth or serrated surfaces; various bearing bar sizes and pitches; special discounts for large orders; ISO certified factory; CAD or 3D …

10. Brown-Campbell – Stainless Steel Bar Grating

Domain: brown-campbell.com

Registered: 1996 (29 years)

Introduction: Stainless Steel Bar Grating available in welded, press-locked, and swaged constructions. Suitable for corrosive environments such as chemical, food, and hydro processing areas. Key product specifications include:

– Item# BS118: 19SW4, 1″ x 1/8″, Welded, Smooth, Stainless Steel, Mill Finish, Sizes: 24″ x 288″, 36″ x 288″.

– Item# BS1316: 19SW4, 1″ x 3/16″, Welded, Smooth, Stainless Steel, Mill Fi…

Strategic Sourcing Conclusion and Outlook for ss grating

As international B2B buyers consider the procurement of stainless steel grating, understanding the strategic sourcing landscape is crucial. Stainless steel grating offers exceptional durability, low maintenance, and corrosion resistance, making it ideal for diverse applications across industries such as construction, transportation, and environmental services. Buyers should prioritize specifications that align with their operational needs, including load-bearing requirements and compliance with local regulations, particularly those pertaining to safety and accessibility.

The strategic sourcing process not only enhances cost-effectiveness but also fosters long-term supplier relationships, enabling businesses to secure quality products while navigating fluctuating market conditions. Engaging suppliers who can provide tailored solutions and innovative products can significantly impact project success and operational efficiency.

Looking ahead, the demand for sustainable and hygienic materials will continue to rise, especially in regions like Africa, South America, the Middle East, and Europe. By investing in high-quality stainless steel grating, companies can position themselves at the forefront of industry advancements. Take the next step in your sourcing journey by exploring reliable suppliers that align with your business goals and sustainability initiatives. Your proactive approach today will pave the way for future success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.