A Deep Dive into Snowflake Machine Solution

Introduction: Navigating the Global Market for snowflake machine

In the competitive landscape of the food and beverage industry, sourcing the right snowflake machine can be a daunting task for international B2B buyers. With diverse options flooding the market, it is essential to navigate through features, pricing, and supplier reliability to make an informed decision. This guide serves as a comprehensive resource, detailing various types of snowflake machines, their applications across different culinary settings, and crucial aspects of supplier vetting. Whether you’re operating in bustling urban centers in Brazil or expanding your food service business in Saudi Arabia, understanding the nuances of these machines can significantly impact your operational efficiency and product quality.

This guide empowers B2B buyers by providing actionable insights into the specifications and functionalities of snowflake machines. From evaluating the production capacity suited for your business model to comparing costs across suppliers, we address the critical questions that arise during the purchasing process. Additionally, we offer strategies for assessing supplier credibility, ensuring that your investment is secure and aligned with your quality standards. As you explore the options available in the global market, this guide will equip you with the knowledge necessary to make strategic purchasing decisions that can enhance your product offerings and drive customer satisfaction.

By focusing on the unique needs of buyers from Africa, South America, the Middle East, and Europe, this resource aims to bridge the gap between diverse market demands and the solutions available through advanced snowflake machines.

Understanding snowflake machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electric Snowflake Ice Machine | Automatic operation, high output capacity | Restaurants, food trucks, dessert shops | Pros: High efficiency, consistent quality. Cons: Higher initial investment. |

| Manual Snowflake Ice Shaver | Hand-operated, compact design | Small cafes, home use | Pros: Lower cost, portable. Cons: Labor-intensive, slower output. |

| Commercial Snow Cone Machine | Specialized for snow cones, often includes multiple flavors | Amusement parks, festivals, event catering | Pros: Versatile flavor options, attracts customers. Cons: Limited to snow cone applications. |

| Bingsu Machine | Designed for Korean-style shaved ice, fine texture | Asian restaurants, dessert bars | Pros: Unique product offering, high demand in specific markets. Cons: Niche appeal, may require specific ice types. |

| Ice Crusher Machine | Focused on crushing ice for various uses | Bars, restaurants, smoothie shops | Pros: Multi-functional, can be used for cocktails and food. Cons: May lack specialized features for snowflake ice. |

What Are the Key Characteristics of Electric Snowflake Ice Machines?

Electric snowflake ice machines are designed for high efficiency and high output, making them suitable for businesses with significant ice demands. They typically feature automatic operation, allowing for consistent ice quality and reducing labor costs. These machines are ideal for restaurants, food trucks, and dessert shops that require quick service. When considering a purchase, buyers should evaluate the machine’s output capacity and energy efficiency, as these factors directly impact operational costs.

How Do Manual Snowflake Ice Shavers Work and Who Should Use Them?

Manual snowflake ice shavers offer a compact, hand-operated solution for businesses with lower ice production needs. Their portability makes them perfect for small cafes or home use. While they come at a lower initial cost, buyers should consider the labor-intensive nature of operation and slower output compared to electric machines. Manual shavers are ideal for businesses testing the market or those wanting to offer a unique, artisanal product without a large investment.

Why Choose a Commercial Snow Cone Machine?

Commercial snow cone machines are specialized equipment designed to create snow cones with various flavor options. They are popular in amusement parks, festivals, and catering for events. The ability to offer multiple flavors can attract more customers and increase sales. However, potential buyers should note that these machines may have limited applications beyond snow cones, making them less versatile compared to other types of ice machines.

What Makes Bingsu Machines Unique for Certain Markets?

Bingsu machines are tailored for producing the fine-textured shaved ice typical of Korean desserts. They cater primarily to Asian restaurants and dessert bars, where there is a growing demand for unique and authentic offerings. While they can command a premium price due to their specialized nature, businesses should assess whether their target market has a significant interest in such products. Additionally, these machines may require specific ice types, which could affect operational logistics.

How Do Ice Crusher Machines Fit into the B2B Landscape?

Ice crusher machines are versatile tools that can crush ice for various applications, including cocktails, smoothies, and food preparation. They are commonly used in bars, restaurants, and smoothie shops. While they provide multi-functional benefits, buyers should be aware that they may lack the specialized features found in dedicated snowflake ice machines. Evaluating the primary use case and potential demand for crushed ice is essential for making an informed purchasing decision.

Key Industrial Applications of snowflake machine

| Industry/Sector | Specific Application of snowflake machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Ice production for beverages and desserts | Enhances product offerings and customer satisfaction | Energy efficiency, production capacity, and ease of maintenance |

| Hospitality | Serving snowflake ice desserts at restaurants and cafes | Attracts customers with unique dessert options | Size, portability, and durability for high-volume use |

| Retail | Ice production for retail food displays | Improves product presentation and freshness | Compliance with food safety standards and energy usage |

| Events and Catering | On-site snowflake ice for catering events | Provides a unique experience for guests | Mobility, speed of ice production, and ease of use |

| Health and Wellness | Ice-based health products like smoothies | Supports health trends with refreshing options | Quality of ice texture and ease of cleaning |

How is the Snowflake Machine Used in the Food and Beverage Industry?

In the food and beverage sector, snowflake machines are vital for producing finely shaved ice for beverages and desserts, such as cocktails and snow cones. This ice enhances the presentation and taste of drinks, driving customer satisfaction. International buyers should consider energy efficiency and production capacity to meet local demand, especially in regions like Brazil and Saudi Arabia where warm climates boost beverage sales.

What Role Does the Snowflake Machine Play in Hospitality?

Restaurants and cafes leverage snowflake machines to create visually appealing desserts that attract customers. By offering unique snowflake ice desserts, establishments can differentiate themselves in a competitive market. Buyers in the hospitality industry should prioritize the machine’s size and portability, ensuring it fits within kitchen constraints while maintaining durability for high-volume service.

How is Snowflake Ice Beneficial for Retail Food Displays?

In retail, snowflake machines are used to produce ice for food displays, maintaining the freshness of perishable items like seafood and produce. This not only enhances visual appeal but also extends product shelf life, encouraging consumer purchases. Retailers must ensure that their chosen machines comply with food safety standards and are energy-efficient to reduce operational costs.

Why Are Snowflake Machines Important for Events and Catering?

For catering events, snowflake machines provide on-site ice production, allowing caterers to serve refreshing, chilled dishes and drinks. This capability enhances guest experiences at parties and large gatherings. Key considerations for event-based buyers include the mobility of the machine, speed of ice production, and user-friendliness, ensuring seamless service during events.

How Do Snowflake Machines Support Health and Wellness Trends?

Snowflake machines are increasingly used in health and wellness sectors to create ice-based smoothies and health drinks that cater to health-conscious consumers. The fine texture of snowflake ice enhances the mouthfeel of these products, making them more appealing. Buyers should focus on the quality of the ice produced and ease of cleaning to maintain hygiene standards, particularly in health-focused markets across Europe and the Middle East.

3 Common User Pain Points for ‘snowflake machine’ & Their Solutions

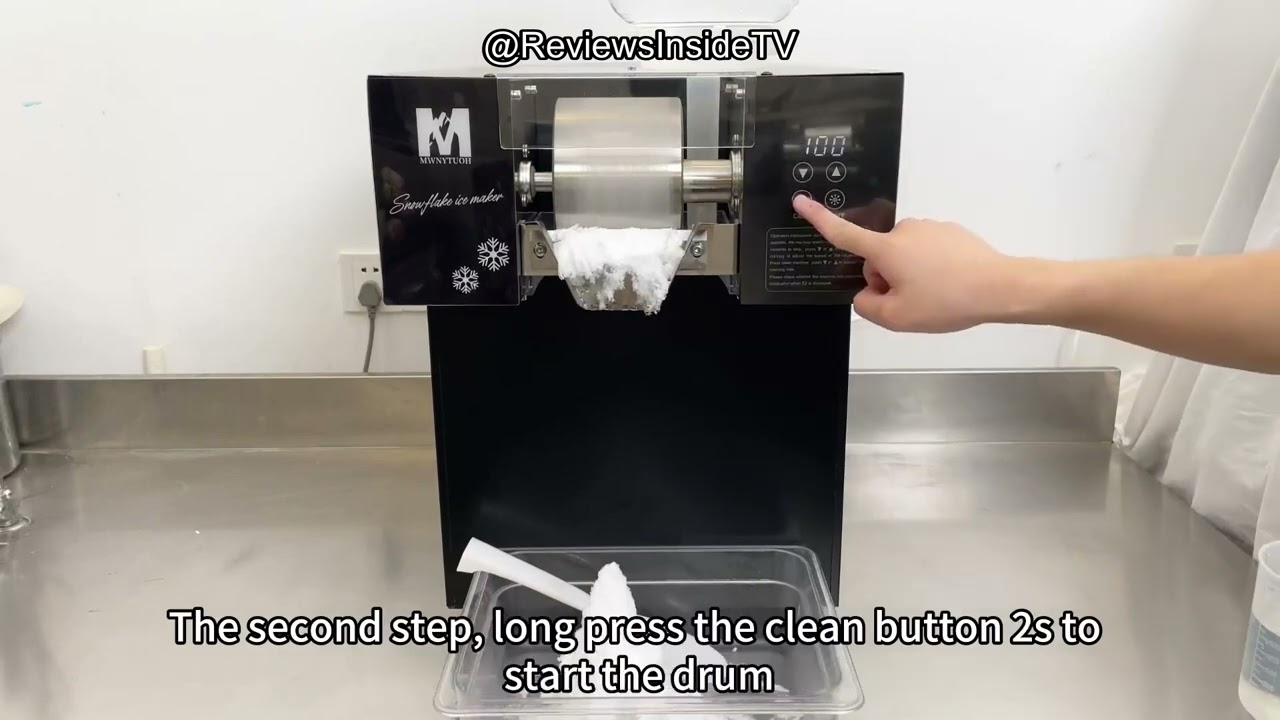

Scenario 1: Difficulty in Achieving Consistent Ice Quality

The Problem: B2B buyers, especially those in the food service industry, often struggle with maintaining the quality and texture of the ice produced by snowflake machines. Inconsistent ice quality can lead to customer dissatisfaction, particularly in businesses that rely on the aesthetics and texture of ice in products like bingsu or snow cones. This inconsistency may stem from factors like improper machine settings, inadequate maintenance, or using substandard ice blocks.

The Solution: To ensure consistent ice quality, buyers should invest in machines that offer adjustable settings for ice thickness and texture. It’s crucial to regularly maintain the machines, including cleaning the blades and ensuring proper coolant levels. Buyers should also consider sourcing ice blocks specifically designed for snowflake machines. Collaborating with reliable suppliers who provide high-quality ice blocks can significantly enhance the end product. Furthermore, training staff on the proper operation and maintenance of the machines will help in achieving the desired consistency in ice production.

Scenario 2: High Operating Costs and Energy Consumption

The Problem: Many businesses find that the operating costs associated with snowflake machines can be unexpectedly high. This may be due to excessive energy consumption or frequent breakdowns that require costly repairs. For B2B buyers, especially those in competitive markets, managing operating costs is critical to maintaining profitability.

The Solution: To address high operating costs, buyers should seek energy-efficient models that are designed to consume less electricity while maintaining performance. Researching and selecting machines that have a good energy rating can significantly reduce monthly utility bills. Additionally, implementing a regular maintenance schedule can prevent costly repairs and downtime. Investing in a machine with durable components can reduce the frequency of repairs, thereby lowering overall operational costs. Buyers should also consider negotiating long-term service agreements with suppliers to ensure ongoing support and maintenance at a reduced rate.

Scenario 3: Challenges in Sourcing Replacement Parts and Service Support

The Problem: A common issue faced by B2B buyers is the difficulty in sourcing replacement parts and obtaining service support for their snowflake machines. This can lead to prolonged downtime, affecting business operations and customer service. For international buyers, logistical challenges in acquiring parts can exacerbate the problem, leading to increased frustration and financial loss.

The Solution: To mitigate this challenge, buyers should prioritize purchasing snowflake machines from reputable manufacturers who offer comprehensive service agreements and readily available replacement parts. Before making a purchase, it’s advisable to inquire about the availability of parts in their region and the manufacturer’s support infrastructure. Establishing a direct relationship with the manufacturer or authorized distributors can streamline the process of obtaining parts and service. Additionally, buyers can consider joining industry forums or networks where they can share experiences and recommendations on reliable suppliers and service providers, ensuring they have access to essential support when needed.

Strategic Material Selection Guide for snowflake machine

What Materials Are Commonly Used in Snowflake Machines?

When selecting materials for snowflake machines, it is crucial to consider properties that affect performance, durability, and compliance with international standards. The following analysis covers four common materials: stainless steel, aluminum, plastic, and copper. Each material has unique properties, advantages, and limitations that can significantly impact the machine’s performance and suitability for various applications.

Illustrative image related to snowflake machine

How Does Stainless Steel Perform in Snowflake Machines?

Stainless steel is a popular choice for snowflake machines due to its high corrosion resistance and strength. It can withstand low temperatures without becoming brittle, making it ideal for ice production. The material is also easy to clean, which is essential in food-related applications. However, the manufacturing complexity can increase costs, and certain grades may not be suitable for all environments.

Pros: High durability, excellent corrosion resistance, easy maintenance.

Cons: Higher cost compared to other materials, potential for thermal conductivity issues if not properly insulated.

Impact on Application: Stainless steel is compatible with various media, including water and flavored syrups, ensuring that the end product remains uncontaminated.

Considerations for International Buyers: Compliance with standards such as ASTM A240 for stainless steel is critical. Buyers from regions like Europe and the Middle East should ensure that the material meets local food safety regulations.

What Advantages Does Aluminum Offer for Snowflake Machines?

Aluminum is lightweight and has good thermal conductivity, which can enhance the efficiency of snowflake machines. It is easier to manufacture than stainless steel, which can lower production costs. However, aluminum may not be as durable as stainless steel, particularly in harsh environments where corrosion is a concern.

Pros: Cost-effective, lightweight, good thermal properties.

Cons: Lower corrosion resistance, may require protective coatings for certain applications.

Impact on Application: Aluminum is suitable for machines that produce snowflakes quickly but may not be ideal for long-term use in high-humidity environments.

Considerations for International Buyers: Compliance with international standards such as ASTM B221 is essential. Buyers should also consider the material’s lifecycle and recycling potential, especially in regions with stringent environmental regulations.

How Does Plastic Compare for Snowflake Machine Construction?

Plastic materials, particularly food-grade polymers, are often used in snowflake machines for components like hoppers and casings. They are lightweight, cost-effective, and resistant to corrosion. However, plastics may not withstand extreme temperatures as effectively as metals, which can limit their application in high-performance machines.

Pros: Low cost, lightweight, resistant to corrosion.

Cons: Limited temperature resistance, potential for wear over time.

Impact on Application: Suitable for non-critical components, but may not be ideal for parts that directly contact ice or water.

Considerations for International Buyers: Ensure compliance with food safety standards such as FDA regulations in the U.S. and EU food contact material regulations in Europe.

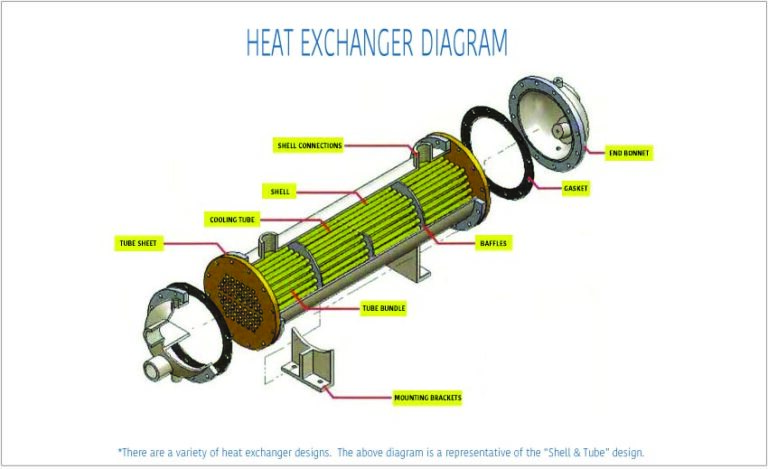

What Role Does Copper Play in Snowflake Machines?

Copper is known for its excellent thermal conductivity, making it a good choice for heat exchangers in snowflake machines. It can help maintain optimal temperatures for ice production. However, copper is more expensive and can corrode if not properly treated, which may affect its long-term viability.

Pros: Exceptional thermal conductivity, effective in heat transfer applications.

Cons: Higher cost, potential for corrosion without proper treatment.

Impact on Application: Best suited for components requiring efficient heat exchange but may require additional coatings or treatments for long-term use.

Considerations for International Buyers: Compliance with standards such as ASTM B370 is necessary. Buyers should also be aware of the implications of copper’s environmental impact, particularly in regions with strict regulations.

Summary Table of Material Selection for Snowflake Machines

| Material | Typical Use Case for snowflake machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Main body and ice contact components | High durability and corrosion resistance | Higher cost, thermal conductivity issues | High |

| Aluminum | Structural components and casings | Lightweight and cost-effective | Lower corrosion resistance | Medium |

| Plastic | Hoppers and non-critical components | Low cost and corrosion-resistant | Limited temperature resistance | Low |

| Copper | Heat exchangers | Excellent thermal conductivity | Higher cost, potential for corrosion | High |

In conclusion, the selection of materials for snowflake machines is critical to their performance, durability, and compliance with international standards. Each material offers unique advantages and disadvantages that should be carefully considered based on the specific application and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for snowflake machine

What Are the Key Stages in the Manufacturing Process of a Snowflake Machine?

The manufacturing process of a snowflake machine involves several critical stages designed to ensure the production of high-quality, reliable equipment. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation

The initial stage focuses on sourcing high-quality materials, primarily stainless steel and food-grade plastics, which are essential for the durability and hygiene of the machine. Suppliers often conduct rigorous testing to ensure that materials meet industry standards, including corrosion resistance and thermal conductivity. Material specifications must align with international food safety regulations, ensuring that the equipment is safe for food contact.

Forming Techniques

Once the materials are prepared, various forming techniques are employed, including CNC machining, stamping, and injection molding. CNC machining allows for precise shaping of components, ensuring that parts fit together seamlessly. Stamping is often used for creating flat parts, while injection molding is used for plastic components. Each technique is chosen based on the design requirements and expected machine performance.

Assembly Process

The assembly stage is critical, as it combines all the individual components into a functional unit. This process often employs automation to enhance precision and efficiency. Skilled technicians are also involved to ensure that the assembly meets specifications, particularly for critical parts like the motor and blade systems. During assembly, various checks are conducted to ensure that parts are correctly installed and aligned.

Finishing Touches

Finishing processes, such as polishing and coating, enhance the machine’s aesthetics and protect it from wear and corrosion. This stage may involve surface treatments that comply with food safety standards, ensuring that the final product is not only visually appealing but also safe for consumers. Quality control measures during this stage verify that the finish meets the desired specifications.

Illustrative image related to snowflake machine

How Is Quality Assurance Managed in Snowflake Machine Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that the final products meet both international and industry-specific standards. A robust QA system can significantly affect a buyer’s confidence in a supplier.

Which International Standards Apply to Snowflake Machines?

International standards such as ISO 9001 play a crucial role in QA for manufacturing processes. ISO 9001 outlines requirements for a quality management system, focusing on continuous improvement and customer satisfaction. Additionally, certifications like CE mark indicate compliance with European safety, health, and environmental protection standards, while other regions may have specific certifications relevant to their markets.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are critical throughout the manufacturing process to identify and rectify issues early. Common checkpoints include:

- Incoming Quality Control (IQC): This phase involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): This ongoing assessment takes place during the manufacturing process, monitoring operations and ensuring that each stage adheres to quality standards.

- Final Quality Control (FQC): At this stage, the completed machines undergo thorough testing to ensure they perform according to specifications. This may include performance tests, safety checks, and compliance verification.

What Testing Methods Are Commonly Used for Snowflake Machines?

Various testing methods are employed to verify the functionality and safety of snowflake machines. These tests ensure that the machines operate effectively under different conditions.

- Performance Testing: This assesses the machine’s ability to produce snowflake ice at specified capacities. It evaluates factors such as ice texture, cooling efficiency, and energy consumption.

- Safety Testing: Ensures that the machine complies with safety regulations, including electrical safety, mechanical safety, and food safety standards.

- Durability Testing: Simulates long-term use to ensure that components can withstand regular operation without failure.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are several strategies:

- Supplier Audits: Conducting on-site audits can provide insights into the supplier’s manufacturing practices and quality control measures. This includes assessing their adherence to international standards and their internal QA processes.

- Requesting Quality Reports: Buyers should ask for detailed quality reports that outline testing results, compliance certifications, and any corrective actions taken in case of failures.

- Third-Party Inspections: Engaging third-party inspection services can add an additional layer of verification, ensuring that the products meet the required standards before shipment.

What Are the Quality Control Nuances for International Buyers?

International buyers must navigate specific nuances related to quality control when sourcing snowflake machines. These include:

- Understanding Local Regulations: Different countries have varying regulations regarding food safety and machinery standards. Buyers must ensure that their suppliers comply with both local and international standards.

- Cultural Considerations: Communication styles and business practices may vary significantly across regions. Buyers should be aware of these differences to effectively negotiate quality expectations.

- Supply Chain Transparency: Buyers should seek suppliers who provide transparency in their supply chains, allowing for better tracking of materials and processes, which can enhance trust and accountability.

Conclusion

The manufacturing processes and quality assurance measures for snowflake machines are intricate and essential for delivering reliable and safe equipment. By understanding these processes and implementing thorough verification strategies, B2B buyers can enhance their procurement decisions and ensure they partner with reputable suppliers. This knowledge not only aids in securing quality products but also fosters long-term business relationships built on trust and compliance.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘snowflake machine’

To successfully procure a snowflake machine for your business, it’s essential to follow a structured approach. This guide provides a practical checklist to help international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, navigate the sourcing process effectively.

1. Identify Your Business Needs

Understanding your specific requirements is the first step. Consider the volume of production you expect, the types of products you will create (e.g., bingsu, snow cones), and the space available for the machine. This clarity will guide you in selecting a machine that meets your operational needs and budget.

2. Define Your Technical Specifications

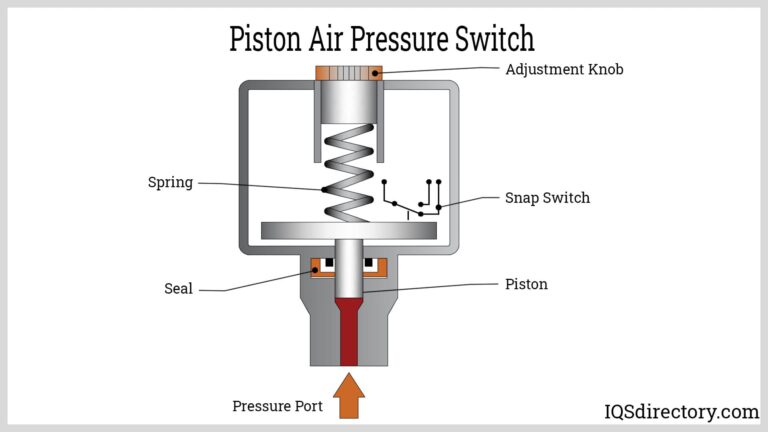

Clearly outline the technical specifications required for your snowflake machine. Key factors to consider include:

– Production Capacity: Determine the pounds of ice the machine can shave per hour.

– Cooling Method: Choose between air-cooled or water-cooled systems based on your operational environment.

– Power Supply: Ensure compatibility with local voltage and electrical standards.

3. Research Potential Suppliers

Conduct thorough research on potential suppliers. Look for manufacturers or distributors with a proven track record in the industry. Important aspects to investigate include:

– Reputation: Check online reviews and testimonials from other B2B buyers.

– Experience: Favor suppliers who specialize in ice machines and have experience in your target market.

Illustrative image related to snowflake machine

4. Request Quotes and Compare Pricing

Once you have shortlisted potential suppliers, request detailed quotes. When comparing pricing, consider not only the initial cost but also:

– Shipping Fees: Factor in international shipping costs to your location.

– Warranty and After-sales Service: Understand the warranty terms and what support is available post-purchase.

5. Verify Supplier Certifications

Confirm that your chosen suppliers possess the necessary certifications and compliance with international standards. This step is crucial to ensure:

– Quality Assurance: Certifications like ISO or CE indicate adherence to quality management systems.

– Safety Standards: Compliance with safety regulations protects your business and customers.

6. Assess Customer Support and Maintenance Options

Evaluate the level of customer support offered by the supplier. Effective customer service can be a significant advantage, especially for machinery maintenance. Look for:

– Technical Support: Availability of support in your time zone and language.

– Maintenance Plans: Check if they offer maintenance packages or training for your staff.

7. Finalize the Purchase Agreement

After selecting a supplier, carefully review the purchase agreement before signing. Ensure it covers:

– Payment Terms: Understand the payment schedule and methods accepted.

– Delivery Timeline: Confirm the expected delivery date and any penalties for delays.

Illustrative image related to snowflake machine

By following this structured checklist, you can confidently navigate the procurement process for a snowflake machine, ensuring that you make an informed decision that aligns with your business goals.

Comprehensive Cost and Pricing Analysis for snowflake machine Sourcing

What Are the Key Cost Components for Snowflake Machine Sourcing?

When sourcing snowflake machines, understanding the cost structure is vital for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The quality of raw materials directly affects the durability and performance of the snowflake machine. Stainless steel and high-grade plastics are common in manufacturing, impacting both cost and longevity.

-

Labor: Labor costs vary based on the region of manufacturing. Countries with lower labor costs may offer competitive pricing, but this could compromise quality.

-

Manufacturing Overhead: This includes expenses related to utilities, rent, and equipment maintenance. Overhead costs can vary significantly between manufacturers, influencing the final price.

-

Tooling: Initial tooling costs for custom designs can be substantial. If a buyer requires unique specifications, these costs should be factored into the overall budget.

-

Quality Control (QC): Investing in robust QC processes ensures product reliability. Manufacturers with stringent QC protocols may charge higher prices, but the long-term benefits can outweigh these initial costs.

-

Logistics: Shipping costs can vary greatly based on distance, mode of transport, and the chosen Incoterms. International shipping often incurs additional fees that can affect the total cost.

-

Margin: Supplier profit margins can fluctuate based on market demand and competition. Understanding the typical margins within the industry can help buyers negotiate better prices.

How Do Price Influencers Impact Snowflake Machine Costs?

Several factors influence the pricing of snowflake machines, making it crucial for buyers to evaluate their purchasing strategy.

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly impact pricing. Larger orders often lead to volume discounts, making it more cost-effective for buyers planning to resell or utilize multiple machines.

-

Specifications and Customization: Customized machines tailored to specific needs may incur additional costs. It is essential to balance the need for customization with budget constraints.

-

Material Quality and Certifications: Machines that meet international quality standards often come at a premium. Buyers should assess whether these certifications align with their market requirements.

-

Supplier Factors: The reputation and reliability of suppliers can influence price negotiations. Established suppliers may charge more due to their proven track record, while newer entrants may offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is critical for international transactions. They dictate the responsibilities of buyers and sellers concerning shipping costs, insurance, and delivery, which can affect the overall pricing.

What Buyer Tips Should Be Considered for Cost-Efficiency?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, there are several strategies to ensure cost-efficiency in sourcing snowflake machines:

-

Negotiation: Engage in negotiations with suppliers to secure better terms. Understanding the supplier’s cost structure can provide leverage during discussions.

-

Total Cost of Ownership (TCO): Evaluate TCO instead of just upfront costs. Consider maintenance, energy consumption, and potential downtime to assess the overall value of the machine.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and tariffs that may affect the final cost. It’s advisable to conduct thorough research on local regulations and market conditions.

-

Supplier Diversification: Establish relationships with multiple suppliers to compare pricing and service levels. This can lead to better deals and reduce dependency on a single source.

-

Request for Quotes (RFQ): Issuing RFQs to several suppliers can provide a clearer picture of the market price and help identify the best offers.

Disclaimer on Indicative Prices

Prices for snowflake machines can vary widely based on specifications, supplier, and market conditions. The figures mentioned in this analysis are indicative and should be validated through direct communication with suppliers. Always request detailed quotes to ensure a comprehensive understanding of costs involved.

Alternatives Analysis: Comparing snowflake machine With Other Solutions

When considering the acquisition of a snowflake machine, it’s essential to evaluate various alternatives that can meet similar operational needs in the food service and beverage industries. By comparing different technologies, buyers can make informed decisions based on performance, cost, ease of implementation, maintenance, and the specific use case for their business.

Comparison Table

| Comparison Aspect | Snowflake Machine | Bingsu Machine | Ice Shaving Machine |

|---|---|---|---|

| Performance | Produces fine, fluffy snow-like ice quickly | Versatile; can create various ice textures | High output; suitable for large volumes |

| Cost | $650 – $1,890 USD | $378 – $2,180 USD | $500 – $1,500 USD |

| Ease of Implementation | User-friendly setup; minimal training required | Generally straightforward; some models require more setup | Typically easy to use; needs some initial adjustments |

| Maintenance | Regular cleaning; few moving parts | Moderate; depends on model complexity | Low to moderate; requires routine cleaning |

| Best Use Case | Ideal for desserts, milkshakes, and cocktails | Best for shaved ice desserts and Asian desserts | Perfect for high-volume ice serving in events |

What Are the Benefits and Drawbacks of a Bingsu Machine?

The Bingsu machine is designed for making Korean-style shaved ice desserts, offering versatility in ice texture and flavor options. It excels in producing fluffy ice ideal for topping with various ingredients, making it a popular choice for dessert shops and restaurants. However, its higher price point and potential complexity in setup might deter some buyers. Additionally, while it can handle a variety of recipes, it may not be as effective for high-volume ice production compared to snowflake machines.

How Does an Ice Shaving Machine Compare?

Ice shaving machines are another viable alternative, known for their ability to produce a consistent and fine ice texture quickly. They are often used in settings that require large volumes of shaved ice, such as events and festivals. The ease of use and lower maintenance needs make them attractive for businesses focused on efficiency. However, they may lack the specialized features that snowflake machines offer for specific applications, such as cocktail preparation or dessert presentations, which could limit their versatility.

Conclusion: Which Solution Should B2B Buyers Choose for Their Needs?

Choosing the right machine depends on the specific requirements of your business. If you’re focused on creating unique dessert offerings and cocktails, a snowflake machine might be your best bet due to its specialized capabilities. On the other hand, if your operations demand a versatile machine that can handle various ice styles for a broader menu, consider the Bingsu or ice shaving machines. Assessing your target market, volume needs, and budget will ultimately guide you to the solution that best fits your operational goals.

Essential Technical Properties and Trade Terminology for snowflake machine

What Are the Key Technical Properties of a Snowflake Machine?

When investing in a snowflake machine, understanding its technical specifications is crucial for making informed purchasing decisions. Here are several key properties to consider:

-

Production Capacity

The production capacity of a snowflake machine is typically measured in pounds of ice produced per hour (e.g., 374 lbs/day or 540 lbs/day). This specification is vital for businesses to assess whether the machine can meet their operational demands, especially in high-traffic environments like restaurants, food trucks, or events. -

Cooling System Type

Snowflake machines often utilize either air cooling or water cooling systems. Air-cooled machines are generally more energy-efficient and easier to maintain, while water-cooled systems might provide faster ice production but can incur higher operational costs due to water usage. Understanding the cooling system type can influence long-term operational costs and environmental impact. -

Material Grade

The materials used in constructing the machine, often stainless steel or food-grade plastic, impact durability and hygiene. High-grade materials are essential for compliance with health regulations, especially in food service. B2B buyers should ensure that the machine’s materials are suitable for the intended application and can withstand regular usage. -

Power Consumption

Measured in watts, power consumption directly affects the operational costs of running a snowflake machine. Low-energy machines may have a higher initial cost but can lead to significant savings over time. It’s essential for businesses to evaluate the energy efficiency of the machine to optimize their overall expenditure. -

Size and Footprint

The physical dimensions of the snowflake machine are critical for space planning in commercial kitchens or service areas. A machine that is too large may not fit within the allocated space, while a compact design can enhance operational efficiency. B2B buyers should consider the available space when selecting a model. -

Maintenance Requirements

Regular maintenance is necessary to ensure optimal performance and longevity. Some machines come with self-cleaning features or easy-access components for routine maintenance. Understanding the maintenance requirements can help businesses avoid unexpected downtime and associated costs.

Which Trade Terms Should B2B Buyers Understand for Snowflake Machines?

Navigating the purchasing process for snowflake machines involves familiarizing oneself with industry terminology. Here are several common trade terms:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is crucial for ensuring compatibility and quality, particularly when sourcing replacement parts or accessories for snowflake machines. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is important for B2B buyers to understand their purchasing power and negotiate terms effectively, especially when considering bulk purchases or supplier relationships. -

RFQ (Request for Quotation)

An RFQ is a formal process used by buyers to solicit price offers from suppliers. This document outlines specifications, quantities, and terms, allowing buyers to compare offers comprehensively. Familiarity with the RFQ process can help businesses secure the best pricing and terms. -

Incoterms (International Commercial Terms)

These are standardized trade terms used in international shipping that define the responsibilities of buyers and sellers. Understanding Incoterms is crucial for B2B buyers, as they clarify who is responsible for shipping, insurance, and tariffs, thereby mitigating risks during cross-border transactions. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For businesses that rely on snowflake machines for seasonal or high-demand periods, understanding lead time can help in planning inventory and ensuring operational readiness. -

Warranty and Service Agreement

This term encompasses the commitments made by the manufacturer regarding the repair or replacement of the snowflake machine within a specified period. Knowing the warranty terms and service agreements helps buyers understand their rights and obligations, ensuring peace of mind in their investment.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when procuring snowflake machines, ultimately enhancing their operational efficiency and service offerings.

Navigating Market Dynamics and Sourcing Trends in the snowflake machine Sector

What are the Current Market Dynamics and Key Trends in the Snowflake Machine Sector?

The snowflake machine market has witnessed significant growth, driven by increasing demand for innovative dessert options across various regions, particularly in Africa, South America, the Middle East, and Europe. The rise in consumer preferences for unique and visually appealing desserts, such as bingsu and snow cones, has propelled the market forward. Additionally, the rapid expansion of food service sectors, including restaurants, food trucks, and cafes, has created a robust demand for snowflake machines.

Emerging trends indicate a shift towards automation and advanced technology in snowflake machines. Automatic ice shavers that enhance efficiency and reduce labor costs are becoming increasingly popular. Furthermore, manufacturers are focusing on creating machines that offer versatility, enabling businesses to serve a variety of frozen desserts while optimizing space and resources. As international B2B buyers look for competitive advantages, sourcing machines with high production capacities and energy-efficient designs is becoming paramount.

Regional dynamics also play a crucial role in shaping market trends. For instance, in Brazil, the popularity of street food culture has led to an uptick in the demand for portable snowflake machines. Similarly, in Saudi Arabia, the growing inclination towards gourmet food experiences is driving the adoption of high-quality, premium snowflake machines. Understanding these regional nuances is essential for B2B buyers to make informed sourcing decisions that align with local consumer preferences.

How Can B2B Buyers Prioritize Sustainability and Ethical Sourcing in the Snowflake Machine Sector?

Sustainability is becoming a pivotal factor for businesses in the snowflake machine sector. The environmental impact of manufacturing and operating these machines necessitates a focus on eco-friendly practices. B2B buyers should prioritize suppliers who demonstrate a commitment to sustainability through the use of energy-efficient components and environmentally friendly materials. This not only helps reduce carbon footprints but also appeals to the growing consumer demand for sustainable products.

Ethical sourcing is equally important in establishing a responsible supply chain. Buyers should seek manufacturers that adhere to fair labor practices and transparency in their operations. Certifications such as ISO 14001 for environmental management and ISO 9001 for quality management can serve as indicators of a supplier’s commitment to sustainability and ethical practices. Furthermore, considering suppliers that utilize recyclable or biodegradable materials in their machines can enhance a company’s reputation and align with corporate social responsibility goals.

By integrating sustainability and ethical sourcing into their procurement strategies, international B2B buyers can position themselves as leaders in the market, meeting consumer expectations while contributing positively to the environment and society.

How Has the Snowflake Machine Market Evolved Over Time?

The snowflake machine market has evolved significantly since its inception, transitioning from simple manual ice shavers to sophisticated automated machines. Initially, these machines were primarily used in local markets and street vendors, offering basic ice-shaved treats. However, as global culinary trends began to embrace innovative dessert options, the technology behind snowflake machines advanced rapidly.

The introduction of electric and programmable machines has revolutionized the industry, allowing for increased efficiency and consistency in ice production. This evolution has enabled businesses to cater to a broader audience, from casual consumers to gourmet enthusiasts. Today, snowflake machines are not just a tool for making desserts; they represent a fusion of technology and culinary art, paving the way for new business opportunities across diverse markets. As the sector continues to grow, the focus on quality, efficiency, and sustainability will likely shape its future trajectory.

Frequently Asked Questions (FAQs) for B2B Buyers of snowflake machine

1. How do I choose the right snowflake machine for my business needs?

Selecting the ideal snowflake machine depends on your production requirements, space constraints, and budget. Assess the machine’s output capacity, typically measured in pounds of ice produced per hour, to match your expected demand. Consider the machine’s design—whether countertop or floor-standing—based on available space. Additionally, evaluate energy efficiency, maintenance needs, and whether the machine can produce different ice textures to meet diverse customer preferences. Engaging with suppliers for demonstrations can also help inform your decision.

2. What are the key features to look for in a snowflake machine?

When evaluating snowflake machines, prioritize features such as production capacity, cooling method (air or water), and ease of use. Look for models with robust safety features, such as automatic shut-off mechanisms, and those that offer adjustable blade settings for different ice textures. Additionally, consider machines with easy-to-clean designs and reliable customer support. Energy efficiency ratings can also impact long-term operational costs, making them an essential factor in your selection process.

3. What are the minimum order quantities (MOQ) for snowflake machines?

Minimum order quantities for snowflake machines vary by manufacturer and supplier. Generally, MOQs can range from a single unit for small businesses to multiple units for bulk orders. It’s essential to discuss your specific needs with suppliers, especially if you’re interested in customizing machines. Some suppliers may offer lower MOQs for first-time buyers or promotional periods, while others might provide tiered pricing based on volume. Always inquire about potential discounts for larger orders to maximize your investment.

4. What payment terms should I expect when purchasing a snowflake machine?

Payment terms for snowflake machines can vary significantly depending on the supplier and the size of the order. Common terms include a deposit upon order confirmation (usually 30-50% of the total cost) with the balance due before shipment. Some suppliers might offer flexible financing options or payment plans for larger purchases. It’s vital to clarify the payment methods accepted, such as bank transfers, credit cards, or letters of credit, particularly for international transactions, to ensure a smooth purchasing process.

5. How can I vet suppliers for snowflake machines?

Vetting suppliers involves assessing their reputation, product quality, and customer service. Start by researching online reviews and testimonials from other businesses. Request references and case studies to understand the supplier’s experience in your industry. Verify their manufacturing capabilities, certifications, and compliance with international standards. Additionally, consider requesting samples or visiting their facilities if feasible. Engaging in direct communication can also provide insights into their responsiveness and willingness to support your needs.

6. What logistics considerations should I be aware of when importing snowflake machines?

When importing snowflake machines, consider shipping costs, lead times, and customs regulations in your country. Work with a freight forwarder experienced in handling machinery to navigate logistics efficiently. It’s essential to understand the total landed cost, including shipping, insurance, and duties, to avoid unexpected expenses. Ensure that the supplier provides all necessary documentation, such as invoices, packing lists, and compliance certificates, to facilitate smooth customs clearance. Additionally, plan for potential delays due to customs processes.

Illustrative image related to snowflake machine

7. Can I customize my snowflake machine to fit my business requirements?

Many manufacturers offer customization options for snowflake machines to meet specific business needs. Customizations can include modifications to the machine’s size, color, production capacity, and additional features like branding or specialized controls. Discuss your requirements with potential suppliers during the sourcing process to understand the extent of customization they can provide and any associated costs. Keep in mind that custom orders may have longer lead times, so plan accordingly to align with your business launch or expansion timeline.

8. What quality assurance measures should I consider when purchasing a snowflake machine?

Quality assurance is crucial when sourcing snowflake machines to ensure reliability and performance. Look for suppliers that conduct rigorous testing on their products before shipment, including functionality tests and safety inspections. Inquire about warranties and return policies to safeguard your investment. Suppliers should also provide detailed specifications and certifications indicating compliance with industry standards. Regular maintenance and service support from the supplier are essential for ensuring the longevity and efficiency of the equipment.

Top 2 Snowflake Machine Manufacturers & Suppliers List

1. VEVOR – Commercial Snowflake Ice Machine

Domain: vevor.com

Registered: 2009 (16 years)

Introduction: {“Product Name”: “VEVOR Commercial Snowflake Ice Machine”, “Ice Production”: “176.4 lbs / 80 kg per 24 hours”, “Cooling Method”: “Air Cooling”, “Power”: “360W”, “Main Material”: “SUS201 / SUS304 / 5CR15 Stainless Steel / PC”, “Bucket Capacity”: “3 L / 0.8 gal”, “Refrigeration Speed”: “40 seconds”, “Product Weight”: “51.4 lbs / 23.3 kg”, “Product Size”: “18.1 x 12.6 x 15.7 in / 460 x 320 x 400 mm”,…

2. Facebook – Snowflake Ice Machine

Domain: facebook.com

Registered: 1997 (28 years)

Introduction: This company, Facebook – Snowflake Ice Machine, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for snowflake machine

In the evolving landscape of the food and beverage industry, the snowflake machine stands out as a pivotal asset for businesses looking to enhance their offerings. By prioritizing strategic sourcing, international B2B buyers can capitalize on the growing demand for innovative dessert options, particularly in emerging markets across Africa, South America, the Middle East, and Europe. Key takeaways include the importance of evaluating suppliers for quality, efficiency, and scalability, ensuring that the chosen snowflake machine aligns with operational needs and market trends.

Investing in high-quality snowflake machines not only boosts customer satisfaction through superior product offerings but also enhances operational efficiency, allowing businesses to meet peak demand without compromising service quality. As the market for unique frozen desserts continues to expand, now is the time for businesses to act decisively.

Illustrative image related to snowflake machine

Leverage strategic sourcing to secure the best technology and partnerships in this niche. By doing so, you position your business to thrive in a competitive marketplace, offering products that resonate with diverse consumer preferences. Embrace the future of dessert innovation and explore the myriad opportunities that snowflake machines bring to your business strategy.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.