A Deep Dive into Sling Types Solution

Introduction: Navigating the Global Market for sling types

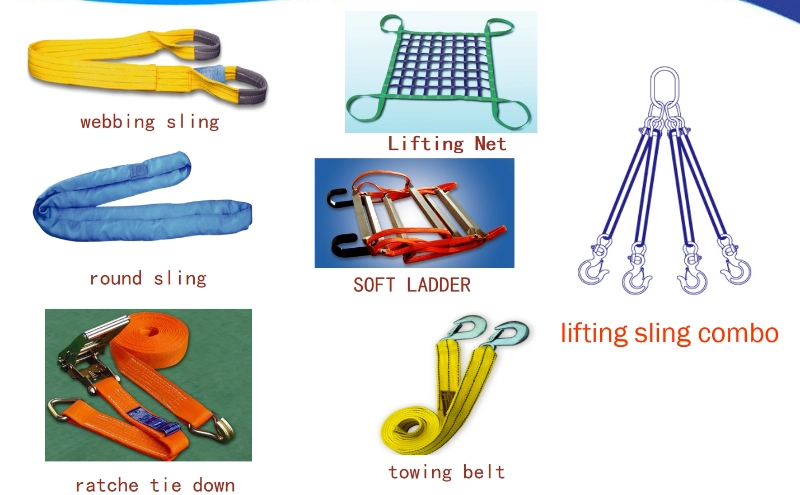

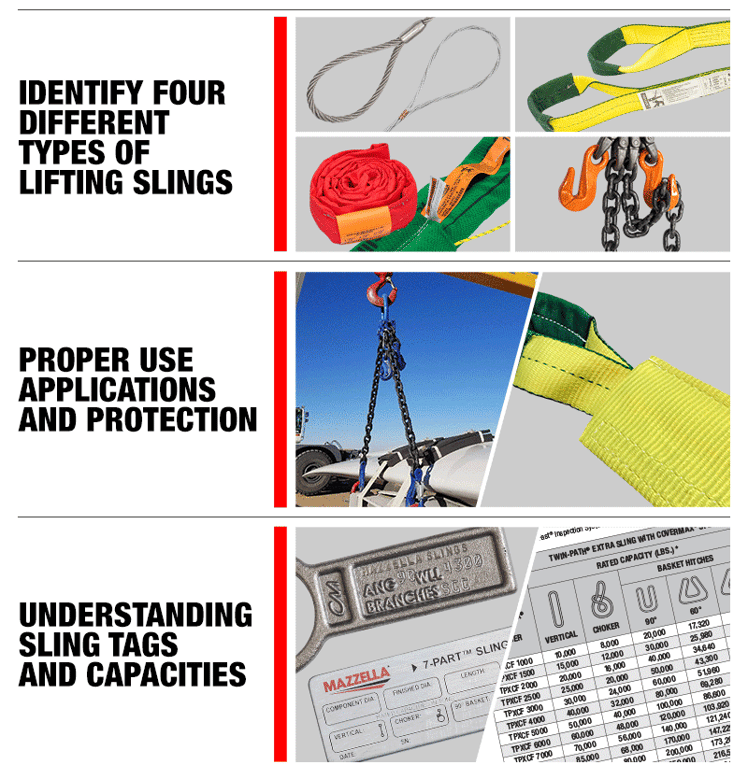

In an increasingly interconnected world, sourcing the right types of slings can be a daunting challenge for international B2B buyers, particularly those operating in diverse markets such as Nigeria and Brazil. With a plethora of sling types available, ranging from webbing to wire rope and chain slings, understanding their specific applications and limitations is crucial for ensuring safety and efficiency in operations. This guide offers a comprehensive exploration of various sling types, detailing their advantages, disadvantages, and ideal use cases.

Additionally, we delve into essential aspects such as supplier vetting processes, cost considerations, and compliance with international safety standards. By equipping buyers with in-depth knowledge and actionable insights, this resource empowers businesses to make informed purchasing decisions tailored to their unique operational needs. Whether you’re in the construction industry in the Middle East or involved in logistics in South America, understanding the nuances of sling types can significantly impact your operational efficiency and safety standards.

Join us as we navigate the complexities of the global sling market, ensuring you have the tools and insights necessary to optimize your procurement strategy and enhance your business operations.

Understanding sling types Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

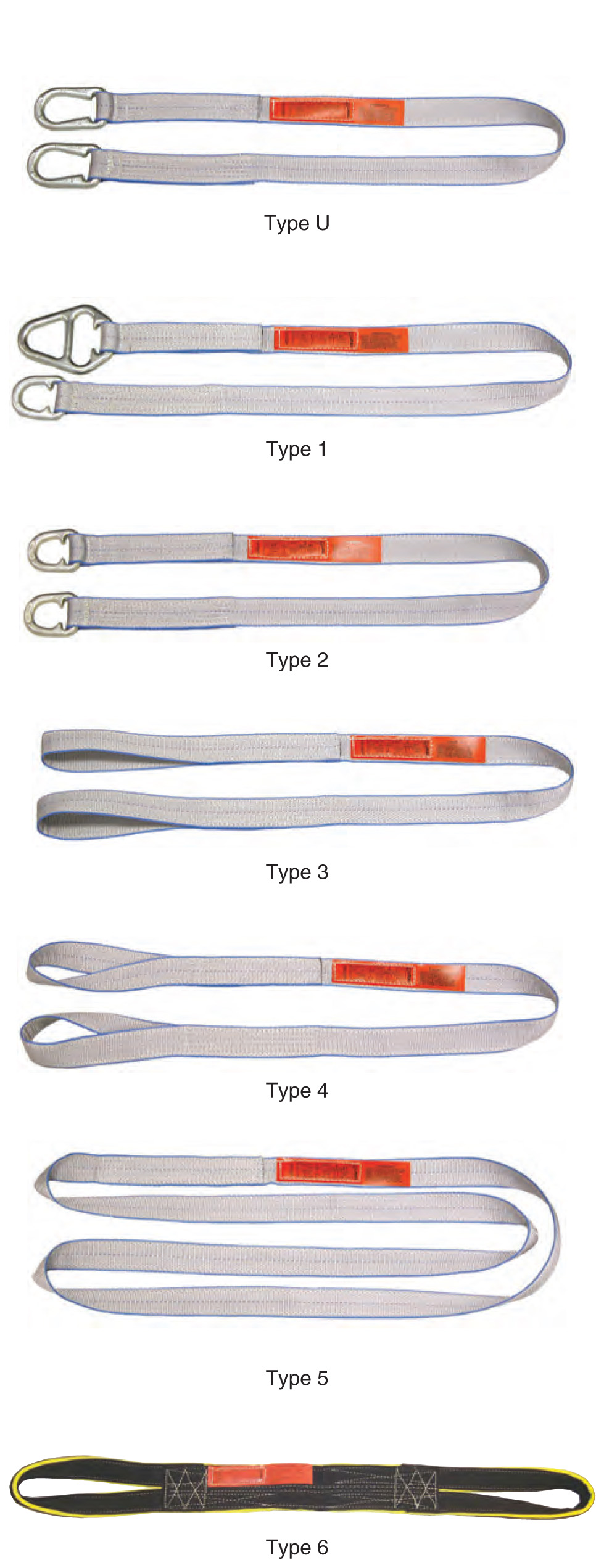

| Webbing Slings | Made from high-strength polyester or nylon, lightweight, flexible | General cargo handling, lifting moderate loads | Pros: Affordable, minimal load abrasion; Cons: Lower load limits, not moisture-resistant. |

| Round Slings | Woven tubular jacket, available in flat and tube types | Rigging, lifting, and securing loads | Pros: Versatile configurations, higher load limits than webbing; Cons: Less stretch, lower limits than steel slings. |

| Wire Rope Slings | Constructed from wire rope, available with different eye configurations | Heavy-duty lifting in industrial settings | Pros: High load limits, durable; Cons: Prone to corrosion and kinking, heavier than fabric slings. |

| Chain Slings | Made from high tensile chains, robust construction | Heavy machinery lifting, construction | Pros: Very high load limits, suitable for harsh environments; Cons: Heavy, can cause load abrasion, more expensive. |

What Are the Characteristics of Webbing Slings for B2B Buyers?

Webbing slings are crafted from durable polyester or nylon, making them lightweight and flexible. This type is particularly suitable for general cargo handling and lifting moderate loads in various sectors, including logistics and construction. Buyers should consider the weight limits, as these slings are not ideal for heavy loads. Additionally, their susceptibility to moisture makes them less effective in damp environments. However, their affordability and minimal abrasion to loads make them a preferred choice for many operations.

How Do Round Slings Stand Out in the Market?

Round slings feature a woven tubular design that offers flexibility and adaptability in lifting applications. They are commonly used in rigging and load securing due to their ability to evenly distribute weight. Available in flat and tube types, round slings can handle higher working load limits than standard webbing slings, making them a versatile option for various industries. Buyers should evaluate their specific lifting needs, as these slings provide excellent configuration options but have limitations compared to steel-based alternatives.

Why Choose Wire Rope Slings for Heavy-Duty Applications?

Wire rope slings are designed for heavy-duty lifting, utilizing strong wire materials that provide significant load capacity. They are ideal for industrial applications, such as construction and manufacturing, where heavy machinery or materials are frequently lifted. Buyers should be aware that while wire rope slings offer high durability and flexibility, they can be prone to corrosion and kinking, which may affect their longevity. The weight of these slings can also be a consideration for transportation and handling.

What Benefits Do Chain Slings Offer for Heavy Machinery Lifting?

Chain slings are constructed from high tensile chains, making them exceptionally robust and ideal for lifting heavy machinery in construction and industrial environments. Their high working load limits and resistance to harsh conditions make them a go-to choice for demanding applications. However, buyers must consider their weight and potential for causing abrasion to loads, which may not be suitable for more delicate items. The investment in chain slings is generally higher, but their durability can lead to long-term savings in heavy-duty operations.

Key Industrial Applications of sling types

| Industry/Sector | Specific Application of sling types | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Lifting heavy machinery and materials | Enhances safety and efficiency in material handling | Ensure compliance with local regulations and load capacity ratings |

| Shipping & Logistics | Securing cargo during transportation | Reduces damage to goods and improves transportation reliability | Select slings suitable for environmental conditions, such as moisture resistance |

| Oil & Gas | Rigging equipment for offshore drilling operations | Increases operational safety and reduces downtime | Consider durability and resistance to harsh chemicals |

| Manufacturing | Handling and moving large components in assembly lines | Optimizes workflow and minimizes manual handling risks | Evaluate the working load limits based on specific load requirements |

| Mining | Transporting heavy equipment and materials underground | Improves operational efficiency and worker safety | Assess the sling’s abrasion resistance and suitability for rough terrain |

How Are Sling Types Used in the Construction Industry?

In the construction sector, slings are essential for lifting heavy machinery and materials, such as steel beams and concrete blocks. They facilitate safe material handling, reducing the risk of accidents and injuries on-site. Buyers in this industry must prioritize slings that comply with local safety regulations and can handle specific load capacities, especially in regions like Nigeria and Brazil where construction standards may vary.

What Role Do Sling Types Play in Shipping and Logistics?

In shipping and logistics, slings are crucial for securing cargo during transportation. They help minimize damage to goods, ensuring that products arrive at their destination in good condition. Businesses must consider environmental factors, such as moisture exposure, when sourcing slings, particularly in humid climates found in parts of Africa and South America. Selecting the right sling type can significantly enhance transportation reliability.

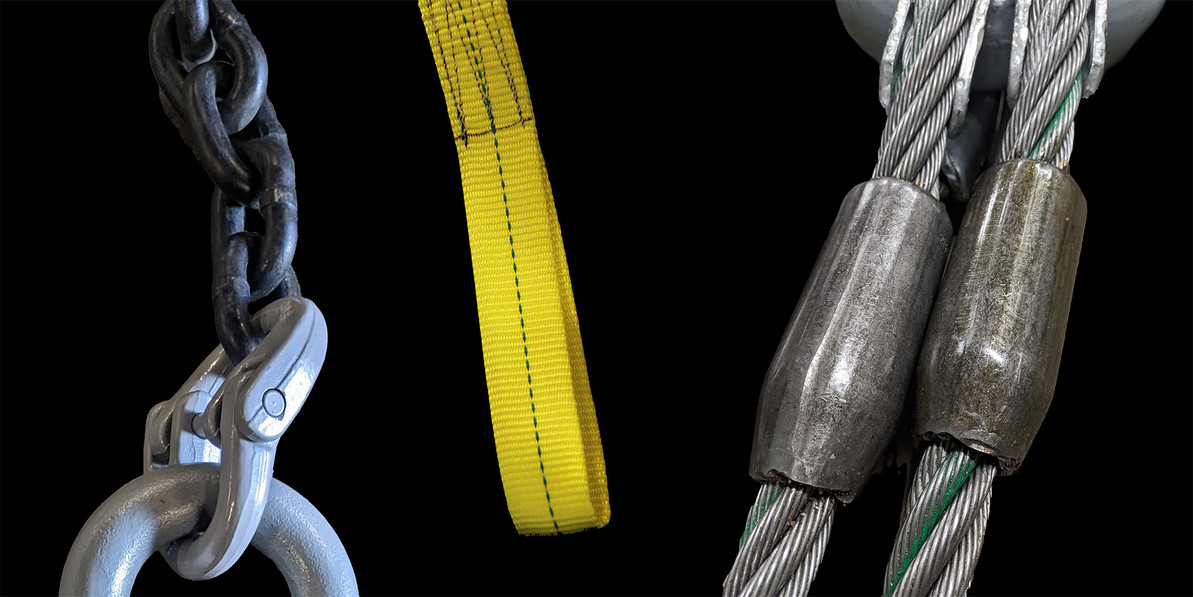

Illustrative image related to sling types

Why Are Sling Types Important in Oil & Gas Operations?

In the oil and gas industry, slings are utilized for rigging equipment during offshore drilling operations. Their role is vital in enhancing operational safety and reducing downtime caused by equipment failure. Buyers should focus on sourcing slings that offer high durability and resistance to harsh chemicals, which are common in this sector, particularly in the Middle East where drilling operations are extensive.

How Do Sling Types Improve Manufacturing Processes?

In manufacturing, slings assist in handling and moving large components along assembly lines. This optimizes workflow and minimizes risks associated with manual handling, leading to increased productivity. Companies should evaluate slings based on their working load limits to ensure they meet specific load requirements, particularly in European manufacturing plants where precision and safety are paramount.

What Are the Benefits of Sling Types in Mining Operations?

In mining, slings are employed for transporting heavy equipment and materials underground. They significantly improve operational efficiency and enhance worker safety by reducing the physical strain on personnel. When sourcing slings for mining applications, businesses must assess the abrasion resistance and suitability of the sling for rough terrain, ensuring they can withstand the demanding conditions typical in mining environments.

3 Common User Pain Points for ‘sling types’ & Their Solutions

Scenario 1: Choosing the Right Sling Type for Heavy Loads

The Problem: Many B2B buyers face the daunting task of selecting the appropriate sling type for lifting heavy loads, especially when dealing with diverse materials and environments. Misjudgments can lead to inadequate lifting solutions, resulting in operational delays and increased safety risks. For instance, a construction manager in Nigeria might struggle to decide between a chain sling and a wire rope sling for transporting heavy machinery, fearing that the wrong choice could compromise safety and efficiency.

The Solution: To mitigate this challenge, buyers should conduct a thorough assessment of their lifting requirements, including the weight, shape, and material of the load, as well as the environment in which the lifting will occur. It is crucial to understand the specific advantages of each sling type. For heavy loads, wire rope slings offer superior strength and flexibility, making them ideal for industrial applications. Conversely, chain slings provide robustness for heavy-duty tasks but can cause abrasion to delicate loads. Buyers should also consider environmental factors—choosing corrosion-resistant materials for humid conditions or selecting webbing slings for lighter, more fragile loads. Consulting with sling manufacturers or distributors can provide insights into the best options tailored to individual needs.

Scenario 2: Managing Sling Maintenance and Longevity

The Problem: Another common pain point is the maintenance of slings, which directly impacts their longevity and safety. B2B buyers often neglect regular inspections and maintenance, leading to potential failures during critical lifting operations. For example, a logistics manager in Brazil might overlook the wear and tear of webbing slings used in transporting goods, unaware that such negligence could lead to costly accidents and liability issues.

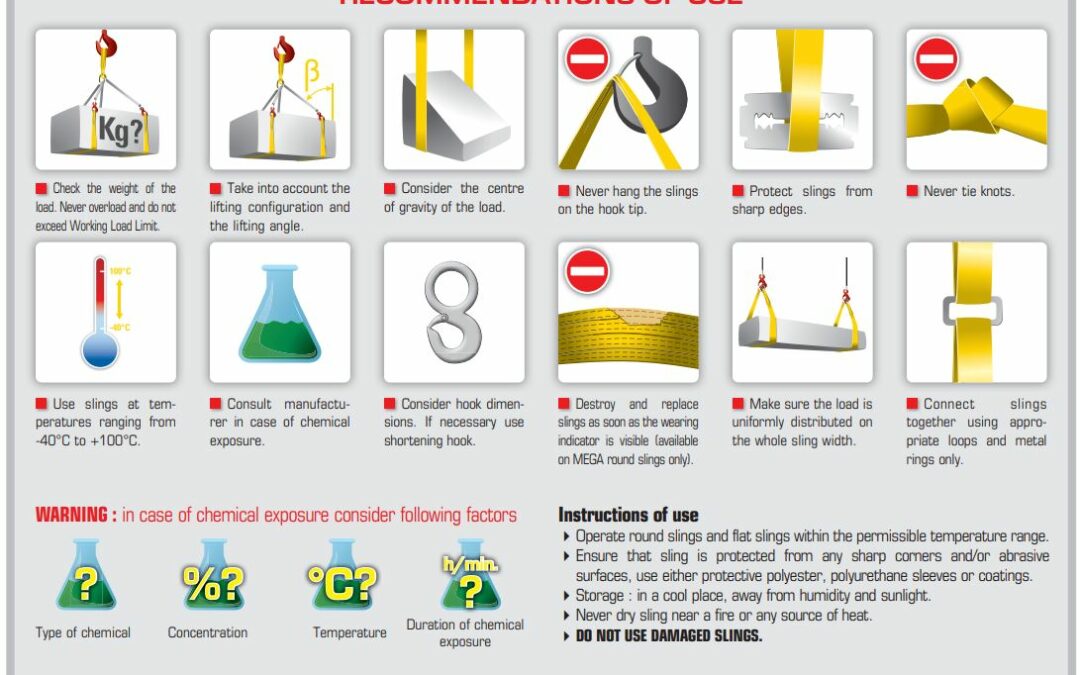

The Solution: To address this issue, organizations should implement a comprehensive sling inspection and maintenance program. This includes establishing a routine inspection schedule, ideally before each use, to check for signs of wear, fraying, or damage. Training employees on proper sling handling and storage can also prevent premature wear. Furthermore, buyers should invest in slings that come with detailed manufacturer guidelines regarding care and usage. For instance, it is essential to store webbing slings away from direct sunlight and moisture to prolong their lifespan. Regularly documenting inspections and maintenance activities can enhance accountability and ensure compliance with safety regulations.

Scenario 3: Understanding Load Capacity and Safety Standards

The Problem: A significant concern for B2B buyers is the confusion surrounding load capacity and safety standards associated with different sling types. Miscalculating load limits can lead to catastrophic failures, endangering workers and damaging equipment. A construction site supervisor in the Middle East, for instance, may misinterpret the color coding on webbing slings, inadvertently using a sling rated for a lower capacity than required, posing serious safety risks.

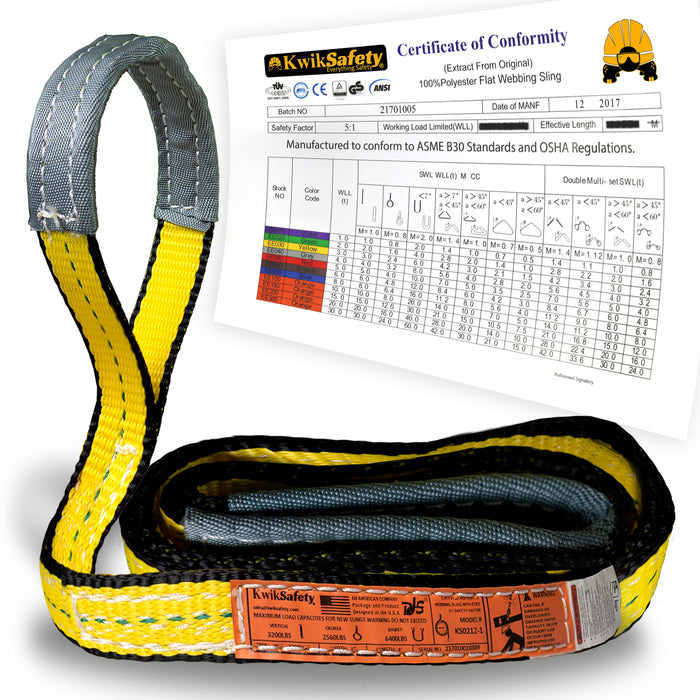

Illustrative image related to sling types

The Solution: To prevent such scenarios, buyers must familiarize themselves with the working load limits (WLL) of each sling type and the relevant safety standards. Training sessions should be organized for staff to educate them on how to interpret color codes and understand the implications of using slings outside their rated capacity. Additionally, it is advisable to keep a comprehensive inventory of slings, complete with their specifications, easily accessible on-site. Buyers should also consider partnering with reputable suppliers who can provide clear information on safety standards and guidelines. Regularly reviewing and updating training programs will further ensure that all personnel are aware of the latest best practices in sling usage and safety compliance.

Strategic Material Selection Guide for sling types

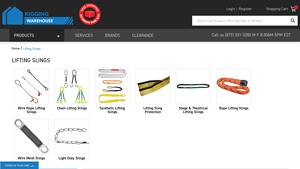

What are the Key Properties of Common Sling Materials?

When selecting slings for lifting and securing loads, the choice of material is critical to ensure optimal performance and safety. Here, we analyze four common materials used in sling manufacturing: polyester, nylon, wire rope, and steel chain. Each material has unique properties that influence its suitability for various applications.

How Does Polyester Perform in Sling Applications?

Polyester is a widely used material for webbing slings due to its excellent strength-to-weight ratio and flexibility. It can typically withstand temperatures up to 100°C (212°F) and is resistant to UV degradation, making it suitable for outdoor applications. However, polyester is not ideal for environments with high moisture levels, as it can absorb water and weaken over time.

Pros: Polyester slings are lightweight, affordable, and have a soft exterior that reduces the risk of load damage. They are also color-coded for easy identification of working load limits.

Cons: The main limitation is their lower working load limit compared to other materials, making them unsuitable for heavy-duty applications.

Impact on Application: Polyester slings are ideal for lifting and securing lighter loads in dry conditions, such as in warehouses or construction sites.

What Advantages Does Nylon Offer for Sling Manufacturing?

Nylon is another popular choice for slings, known for its exceptional elasticity and strength. It can handle temperatures up to 80°C (176°F) and provides excellent shock absorption, which is beneficial when lifting dynamic loads. However, nylon is more susceptible to UV damage and can degrade faster when exposed to sunlight.

Pros: The elasticity of nylon allows it to stretch under load, providing a cushioning effect that can help prevent sudden load drops.

Cons: Like polyester, nylon can absorb moisture, which can compromise its integrity over time. Additionally, it is generally more expensive than polyester.

Impact on Application: Nylon slings are well-suited for applications requiring shock absorption, such as lifting heavy machinery or in construction scenarios.

How Do Wire Rope Slings Compare in Terms of Durability?

Wire rope slings are constructed from high-strength steel wires, making them ideal for heavy-duty lifting applications. They can withstand extreme temperatures and are resistant to abrasion and corrosion, which is particularly important in harsh environments. However, wire rope slings can be heavier and more cumbersome to handle.

Pros: They offer a high working load limit and are durable, making them suitable for lifting heavy loads in industrial settings.

Illustrative image related to sling types

Cons: Wire rope slings can kink or become damaged if not handled properly, and they may cause abrasion to the loads being lifted.

Impact on Application: These slings are perfect for lifting heavy machinery or construction materials, especially in environments where durability is paramount.

What Role Does Steel Chain Play in Sling Applications?

Steel chain slings are made from high-tensile steel and are known for their robustness and high load capacities. They are resistant to corrosion, making them suitable for use in wet or harsh environments. However, their weight can make them less convenient for transport and handling.

Illustrative image related to sling types

Pros: Steel chain slings have the highest working load limits among sling types and can withstand extreme conditions.

Cons: They are typically more expensive and can cause damage to delicate loads due to their rigid structure.

Impact on Application: Steel chain slings are ideal for heavy lifting in construction, mining, and other industrial applications where durability and load capacity are critical.

Summary Table of Sling Materials

| Material | Typical Use Case for sling types | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Lifting lighter loads in dry conditions | Lightweight and affordable | Lower working load limit | Low |

| Nylon | Lifting heavy machinery requiring shock absorption | Excellent elasticity and strength | Susceptible to UV damage | Medium |

| Wire Rope | Heavy-duty industrial lifting | High working load limit | Can kink and cause abrasion | Medium |

| Steel Chain | Heavy lifting in harsh environments | Very high load capacity | Heavy and can damage loads | High |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of various sling materials. Understanding these factors is crucial for making informed purchasing decisions that align with specific operational needs and environmental conditions.

Illustrative image related to sling types

In-depth Look: Manufacturing Processes and Quality Assurance for sling types

What Are the Main Stages of Manufacturing Sling Types?

The manufacturing process for slings involves several critical stages, each essential for ensuring the final product meets the necessary performance and safety standards. The main stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Sling Production?

Material preparation is the first step in the manufacturing process. This involves selecting the appropriate materials based on the type of sling being produced. For webbing slings, high-strength polyester or nylon is used, while wire rope slings require steel or nylon wire rope. The materials undergo rigorous testing to confirm their tensile strength and durability, ensuring they can withstand the required working loads.

Once the materials are selected, they are cut to the specified lengths and treated to enhance their properties. For example, steel wire ropes may be galvanized to prevent corrosion, while polyester webbing might be treated for UV resistance. This stage is crucial, as the integrity of the materials directly impacts the sling’s performance.

Illustrative image related to sling types

What Techniques Are Employed in Sling Forming?

The forming stage involves shaping the prepared materials into the desired sling configuration. For webbing slings, this typically includes sewing the ends to create loops or eyelets. Industrial sewing machines equipped with heavy-duty needles and threads are used to ensure strong seams that can bear significant loads.

In the case of wire rope slings, the wire is looped and secured using specialized equipment that can apply the necessary tension and secure the ends with fittings or thimbles. Chain slings are formed by linking high-tensile chain segments, which are then welded or connected using hooks.

How Are Sling Components Assembled?

Assembly is the stage where all components are brought together. For fabric-based slings, this may involve attaching additional safety features, such as protective sleeves, that enhance durability and reduce wear on the load. For wire rope and chain slings, the final assembly involves the attachment of hooks, shackles, or other hardware that will be used in the lifting process.

Quality at this stage is critical; manufacturers often employ automated systems for precision and consistency, ensuring that every sling produced meets the same high standards.

What Finishing Processes Are Used for Slings?

The finishing stage includes several processes that enhance the sling’s usability and longevity. This may involve applying protective coatings, such as paint or anti-corrosion sprays, particularly for metal slings, to increase resistance to environmental factors.

Additionally, slings are often color-coded or labeled to indicate their working load limits (WLL), making it easier for operators to select the appropriate sling for specific tasks. Final inspections are conducted to ensure that all slings meet the required specifications and safety standards.

What Quality Assurance Standards Should B2B Buyers Look For?

Quality assurance is a vital aspect of the sling manufacturing process, ensuring that the products meet international safety and performance standards. B2B buyers should be familiar with several key standards, including ISO 9001, which outlines requirements for a quality management system, and other industry-specific standards such as CE marking for compliance with European regulations and API standards for oil and gas applications.

Illustrative image related to sling types

How Are Quality Control Checkpoints Established?

Quality control (QC) checkpoints are integrated throughout the manufacturing process. Common checkpoints include:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specified quality standards.

- In-Process Quality Control (IPQC): Ongoing inspections during the manufacturing process check for defects and adherence to specifications.

- Final Quality Control (FQC): The final product undergoes comprehensive testing to verify that it meets all performance and safety requirements before being shipped.

Testing methods may include tensile testing, fatigue testing, and inspections for visual defects. These tests are essential for certifying that the slings can safely perform under their intended loads.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must actively verify their suppliers’ quality control measures to ensure they are sourcing reliable and safe products. Here are several strategies:

Illustrative image related to sling types

-

Supplier Audits: Conducting on-site audits provides insight into the manufacturing processes, quality control systems, and compliance with international standards. Buyers should assess the supplier’s facilities, equipment, and quality management practices.

-

Requesting Quality Reports: Suppliers should be willing to provide detailed quality reports that outline their testing methodologies, inspection results, and compliance with relevant standards. These documents are critical for transparency and accountability.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s manufacturing processes and product quality. This step is particularly valuable for international transactions, where local regulations and standards may differ.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding quality control nuances is essential. Buyers must be aware of regional standards and regulations that may affect product compliance.

Additionally, language barriers and cultural differences can impact communication regarding quality expectations. Establishing clear, documented agreements on quality standards and expectations can mitigate misunderstandings.

Lastly, buyers should consider the logistics of sourcing materials and products across borders. Ensuring that suppliers maintain consistent quality throughout their supply chains is crucial for avoiding delays and ensuring reliability in operations.

Conclusion

Understanding the manufacturing processes and quality assurance protocols for sling types is crucial for B2B buyers seeking reliable lifting solutions. By focusing on the key stages of production, relevant quality standards, and effective verification methods, buyers can make informed decisions that ensure the safety and efficiency of their operations. Investing time in understanding these processes not only safeguards their investments but also enhances operational reliability in lifting and securing cargo.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘sling types’

Introduction

This practical sourcing guide aims to equip B2B buyers with a comprehensive checklist for procuring various sling types. Understanding the specific requirements of slings is essential for ensuring safety, efficiency, and cost-effectiveness in lifting operations. With numerous options available, this guide will help you navigate the selection process with confidence.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly define your technical specifications for the slings you need. Consider factors such as load capacity, environmental conditions, and intended use. This clarity will help you identify the right sling type—whether webbing, round, wire rope, or chain—tailored to your operational requirements.

- Load Capacity: Determine the maximum weight the sling will need to lift.

- Environment: Assess whether the sling will be used indoors, outdoors, or in wet conditions.

Step 2: Research Available Sling Types

Familiarize yourself with the various sling types and their unique properties. Each type has specific advantages and disadvantages that may influence your decision. Understanding these nuances will enable you to make an informed choice based on your operational needs.

- Webbing Slings: Lightweight and flexible but limited in load capacity.

- Chain Slings: Extremely durable and high load capacity but may cause abrasion.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations to ensure they meet your quality and service standards. Review their company profiles, request case studies, and seek references from other buyers in your industry. This due diligence minimizes risks associated with poor quality or unreliable service.

- Certifications: Check for relevant industry certifications that validate their compliance with safety standards.

- Experience: Prioritize suppliers with proven expertise in your specific industry.

Step 4: Request Samples and Specifications

Once you’ve shortlisted suppliers, request samples or detailed specifications of the slings they offer. This step allows you to assess the quality and suitability of the products firsthand. Look for material strength, construction quality, and any additional features that may enhance performance.

- Testing: If possible, conduct load tests to verify the sling’s performance under conditions similar to your operational environment.

- Documentation: Ensure that suppliers provide comprehensive product data sheets.

Step 5: Compare Pricing and Terms

After evaluating the slings and suppliers, compare pricing structures and payment terms. Ensure that you are getting value for your investment without compromising on quality. Be wary of prices that seem too good to be true, as they may indicate inferior products.

- Bulk Discounts: Inquire about pricing tiers for larger orders.

- Warranty and Support: Understand the warranty terms and after-sales support offered by the supplier.

Step 6: Finalize Your Purchase Agreement

Once you have selected a supplier, finalize the purchase agreement with clear terms regarding delivery timelines, payment, and any contingencies. Having a well-documented agreement protects both parties and sets expectations for the transaction.

Illustrative image related to sling types

- Delivery Schedule: Confirm the expected delivery dates to align with your project timelines.

- Return Policy: Clarify the return policy in case the slings do not meet your specifications upon arrival.

Conclusion

By following this step-by-step checklist, B2B buyers can streamline their sourcing process for sling types, ensuring they choose the right products for their specific lifting needs. With a focus on quality and reliability, you can enhance operational safety and efficiency in your lifting operations.

Comprehensive Cost and Pricing Analysis for sling types Sourcing

What Are the Key Cost Components in Sling Types Sourcing?

When sourcing slings, understanding the cost structure is crucial for effective budgeting and decision-making. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Materials: The choice of materials significantly impacts the overall cost. For instance, webbing slings made from polyester or nylon are generally more affordable than wire rope or chain slings, which require higher-grade steel. Round slings also incorporate specialized woven jackets that add to their cost.

Labor: Labor costs vary based on the complexity of the sling design and the manufacturing location. In regions with lower labor costs, such as parts of Africa or South America, the overall production cost can be reduced. However, this must be balanced with the quality of craftsmanship.

Manufacturing Overhead: This encompasses costs related to factory operations, including utilities, equipment maintenance, and facility management. High overhead can increase prices, particularly in regions with stringent operational costs.

Illustrative image related to sling types

Tooling: Initial tooling costs for specialized or custom sling designs can be significant. Buyers should inquire about these costs upfront, especially if they require non-standard sizes or configurations.

Quality Control (QC): Implementing robust QC measures ensures product reliability but can add to costs. Certifications for safety standards, which are critical for lifting equipment, also influence pricing.

Logistics: Transportation and handling costs can vary widely based on distance, shipping methods, and local tariffs. International buyers must consider these factors in their total cost assessments.

Illustrative image related to sling types

Margin: Suppliers typically include a profit margin in their pricing, which can vary depending on market conditions and competition.

How Do Price Influencers Affect Sling Types Pricing?

Several factors can influence the pricing of slings, including volume or minimum order quantity (MOQ), specifications and customization, materials used, quality certifications, supplier factors, and Incoterms.

Volume/MOQ: Larger orders often come with volume discounts. Buyers should assess their needs carefully; purchasing in bulk can lead to significant savings but requires upfront capital.

Illustrative image related to sling types

Specifications/Customization: Custom slings designed for specific applications may incur higher costs due to additional materials and engineering. Standard slings are generally more cost-effective.

Materials: The type of sling material directly affects pricing. For example, while webbing slings are typically less expensive, chain slings may provide greater durability and higher load limits, justifying their premium price.

Quality/Certifications: Products that meet international safety standards or have undergone rigorous testing often come at a higher price point. This is crucial for industries where safety is paramount.

Supplier Factors: The reliability and reputation of the supplier can also impact pricing. Established suppliers may charge more due to their proven track record, while newer suppliers might offer lower prices to gain market share.

Incoterms: Understanding Incoterms is essential for international transactions. Different terms can affect shipping costs and responsibilities, influencing the final price.

Illustrative image related to sling types

What Buyer Tips Can Help with Cost-Efficiency in Sling Sourcing?

To maximize cost-efficiency when sourcing slings, buyers should consider the following tips:

Negotiate Terms: Always negotiate pricing, payment terms, and delivery schedules. Suppliers may have flexibility, especially if you’re a repeat customer or placing a large order.

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider long-term costs associated with maintenance, replacement, and operational efficiency. For example, investing in higher-quality slings may reduce downtime and replacement frequency.

Understand Pricing Nuances for International Buyers: Buyers from Africa, South America, the Middle East, and Europe should be aware of regional differences in pricing structures. Factors such as local demand, shipping costs, and import tariffs can significantly impact overall expenses.

Research and Compare Suppliers: Don’t settle for the first quote. Conduct thorough research and compare multiple suppliers to ensure you are getting the best price and quality for your requirements.

Illustrative image related to sling types

Request Samples: Before committing to a large order, request samples to assess quality and suitability for your specific applications. This can prevent costly mistakes down the line.

Disclaimer on Indicative Prices

Prices for slings can vary widely based on the above factors and market conditions. It is advisable for buyers to conduct thorough market research and request multiple quotes to obtain accurate pricing tailored to their specific needs.

Alternatives Analysis: Comparing sling types With Other Solutions

Exploring Alternative Lifting Solutions to Sling Types

When it comes to lifting and securing heavy loads, slings are a popular choice due to their versatility and ease of use. However, businesses should also consider alternative solutions that may offer distinct advantages based on their specific operational needs. This analysis compares various sling types with two viable alternatives: Lifting Beams and Forklifts, helping B2B buyers make informed decisions.

Illustrative image related to sling types

Comparison Table

| Comparison Aspect | Sling Types | Lifting Beams | Forklifts |

|---|---|---|---|

| Performance | High flexibility and load distribution | Excellent for heavy lifting; stable | Great for heavy loads, but limited to horizontal movement |

| Cost | Generally low cost | Moderate initial investment | High initial cost and ongoing maintenance |

| Ease of Implementation | Quick to set up and operate | Requires understanding of rigging | Requires training and certification |

| Maintenance | Minimal, mostly visual checks | Moderate, regular inspections needed | High, requires regular servicing |

| Best Use Case | Rigging and securing loads | Heavy lifting in fixed locations | Transporting loads over distances |

What Are the Advantages and Disadvantages of Lifting Beams?

Lifting beams are horizontal beams that allow for the even distribution of load weight when lifting. Their primary advantage is the ability to stabilize loads and provide a safe lifting point when dealing with heavy machinery or awkwardly shaped objects. They are especially useful in environments where multiple lifting points are necessary. However, lifting beams require a solid understanding of rigging techniques and safety protocols to implement correctly, which could pose a challenge for companies without skilled personnel. Additionally, while they are cost-effective for heavy lifting, the initial investment can be higher than slings, and they require regular inspections to ensure safety and compliance.

How Do Forklifts Compare to Sling Types?

Forklifts are widely recognized for their capability to lift and transport heavy loads across distances within warehouses and construction sites. They provide excellent lifting capacity and speed, making them suitable for operations that require moving materials quickly. However, their use is limited to flat surfaces and horizontal transport, which can be a significant drawback in certain applications. The upfront cost of purchasing or leasing a forklift is considerable, and ongoing maintenance can be expensive, requiring regular servicing and compliance with safety regulations. Moreover, operators need specialized training and certification, which may not be feasible for all businesses.

Making the Right Choice: How Can B2B Buyers Determine the Best Lifting Solution?

In choosing the right lifting solution, B2B buyers should consider several factors, including the nature of their operations, the types of loads they handle, and the specific lifting environment. For businesses that prioritize flexibility and cost-effectiveness, slings may be the ideal choice. In contrast, companies that frequently deal with heavy, awkward loads in fixed locations might find lifting beams more advantageous. Meanwhile, those requiring mobility and speed in transporting materials may opt for forklifts despite the higher costs and training requirements. Ultimately, understanding the unique demands of your operations will guide you to the most suitable lifting solution, ensuring efficiency, safety, and cost-effectiveness in your lifting processes.

Essential Technical Properties and Trade Terminology for sling types

What Are the Key Technical Properties of Sling Types?

When selecting slings for lifting and securing loads, understanding their technical specifications is crucial. Here are some critical properties that buyers should consider:

Illustrative image related to sling types

1. Material Grade

The material used in slings—such as polyester, nylon, steel, or chain—affects their strength, durability, and suitability for specific applications. For example, polyester webbing slings are favored for their lightweight and flexibility, while wire rope slings provide higher strength for heavy loads. Understanding material grades helps businesses select slings that match their operational requirements and safety standards.

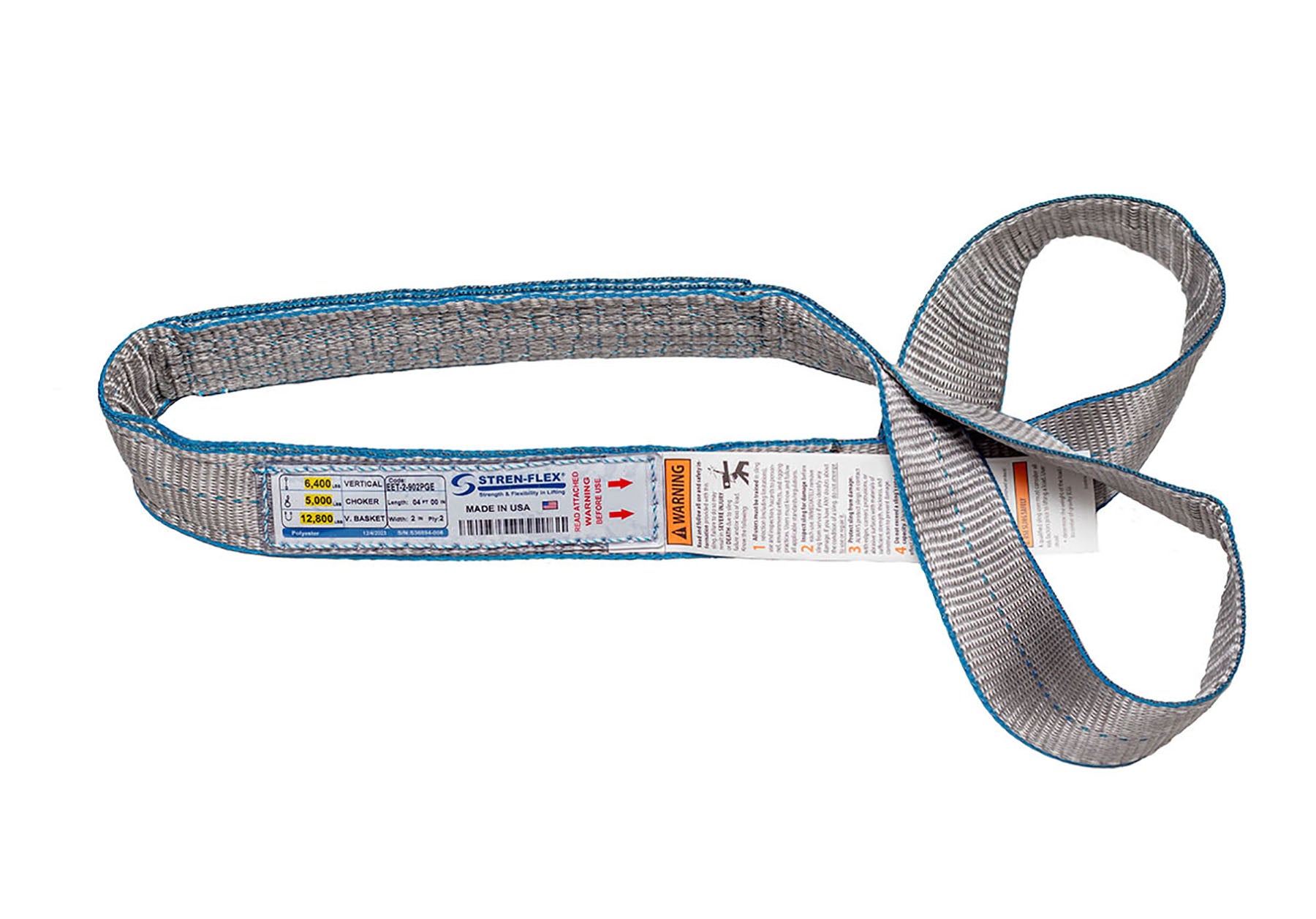

2. Working Load Limit (WLL)

The WLL indicates the maximum weight a sling can safely lift. This specification is critical for ensuring safety and compliance with industry regulations. Selecting a sling with an appropriate WLL minimizes the risk of accidents and equipment failure, protecting both personnel and assets.

3. Stretch Rate

Different sling types exhibit varying degrees of elasticity. Webbing slings, for instance, have a higher stretch rate, allowing for shock absorption during lifting. Knowing the stretch characteristics helps buyers choose slings that can accommodate dynamic loads without risking damage or instability.

Illustrative image related to sling types

4. Length and Configuration

The length of a sling impacts its lifting capability and versatility. Longer slings can accommodate bulky loads but may reduce the WLL. Additionally, the ability to configure slings (e.g., single or double leg) allows for flexibility in lifting applications. Buyers should assess their specific lifting scenarios to determine the ideal sling length and configuration.

5. Abrasion Resistance

Sling materials vary in their resistance to wear and tear, particularly when used with rough or sharp-edged loads. For example, round slings often feature protective jackets that enhance abrasion resistance. Understanding this property is vital to extending the lifespan of slings and ensuring consistent performance.

6. Environmental Resistance

Certain slings are designed to withstand harsh conditions, such as moisture, chemicals, or extreme temperatures. For instance, chain slings are ideal for industrial environments due to their corrosion resistance. Buyers must consider the operating environment when selecting slings to ensure longevity and reliability.

What Are Common Trade Terms Related to Sling Types?

Familiarity with industry jargon can streamline procurement processes and enhance communication between buyers and suppliers. Here are some essential trade terms:

1. OEM (Original Equipment Manufacturer)

An OEM produces parts or equipment that are used in another company’s product. In the context of slings, knowing the OEM can ensure quality and compatibility with existing lifting systems.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier is willing to sell. Understanding MOQs helps businesses plan their purchasing strategies and manage inventory effectively, especially when sourcing from international suppliers.

3. RFQ (Request for Quotation)

An RFQ is a formal request to suppliers for pricing and terms on specific products or services. Submitting an RFQ for slings allows businesses to compare options and negotiate favorable terms, ensuring they get the best value.

4. Incoterms (International Commercial Terms)

Incoterms are standardized shipping terms that define the responsibilities of buyers and sellers in international trade. Familiarity with Incoterms helps businesses understand shipping costs, risks, and delivery obligations when purchasing slings from global suppliers.

5. Compliance Standards

Compliance standards, such as those set by OSHA or ISO, dictate safety and quality benchmarks for lifting equipment. Being aware of these standards is essential for ensuring that slings meet regulatory requirements, thereby reducing liability risks.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that enhance safety, efficiency, and cost-effectiveness in their lifting operations.

Navigating Market Dynamics and Sourcing Trends in the sling types Sector

What Are the Current Market Dynamics and Key Trends in the Sling Types Sector?

The sling types sector is experiencing significant growth driven by globalization, urbanization, and the increasing demand for safe lifting solutions across various industries. In regions like Africa, South America, the Middle East, and Europe, the need for reliable lifting equipment is amplified by ongoing construction projects, infrastructure developments, and industrial activities. The rising focus on worker safety and stringent regulations surrounding lifting operations further propel the market.

Technological advancements are reshaping the sourcing landscape. The integration of Industry 4.0 technologies, such as IoT and AI, is enhancing the operational efficiency and safety of sling applications. For instance, smart slings equipped with sensors can provide real-time data on load conditions, enabling better decision-making and minimizing risks. Additionally, e-commerce platforms and digital sourcing tools are streamlining procurement processes, allowing international buyers to easily compare products, prices, and suppliers.

Emerging trends also include the increasing popularity of lightweight and high-strength materials, such as synthetic fibers, which offer superior performance and durability. As businesses look to optimize their supply chains, sourcing strategies are shifting towards more localized suppliers to mitigate risks and enhance responsiveness. This is particularly relevant for B2B buyers in Africa and South America, where logistical challenges can impact supply chain efficiency.

How Is Sustainability Shaping the Sling Types Market?

Sustainability has become a critical focus in the sling types sector, driven by growing environmental concerns and the need for ethical sourcing practices. The environmental impact of manufacturing and disposing of lifting equipment is prompting companies to adopt more sustainable practices. Buyers are increasingly seeking products made from recycled or environmentally friendly materials, which can help minimize their carbon footprint.

Ethical supply chains are gaining importance, with B2B buyers prioritizing suppliers that demonstrate a commitment to social responsibility. This includes ensuring fair labor practices, safe working conditions, and responsible sourcing of materials. Certifications such as ISO 14001 for environmental management and OHSAS 18001 for occupational health and safety are becoming essential for suppliers aiming to attract international buyers.

The demand for ‘green’ slings made from sustainable materials is on the rise. Products that utilize biodegradable or recyclable materials not only cater to eco-conscious buyers but can also enhance a company’s brand reputation. As regulations around sustainability tighten globally, B2B buyers must evaluate their supply chains and consider the long-term implications of their sourcing decisions.

What Is the Evolution of Sling Types in the B2B Context?

The evolution of sling types has been significantly influenced by advancements in materials and technology. Historically, slings were primarily made from natural fibers like hemp and manila, which were later supplemented by the introduction of metal-based options, such as wire and chain slings, for heavier lifting tasks. These traditional materials offered strength but often lacked flexibility and could be susceptible to wear and tear.

The late 20th century marked a turning point with the development of synthetic materials, leading to the introduction of webbing and round slings. These innovations provided greater flexibility, lighter weight, and enhanced durability, making them popular choices in various lifting applications. As industries continue to evolve, so too do the demands on sling types, prompting ongoing research and development aimed at improving safety, performance, and sustainability. This historical context is crucial for B2B buyers, as understanding the evolution of sling types can inform better purchasing decisions based on current and future needs.

Frequently Asked Questions (FAQs) for B2B Buyers of sling types

-

How do I determine the right sling type for my lifting needs?

To select the appropriate sling type, assess the load’s weight, shape, and material. Webbing slings are ideal for lighter, flexible loads, while wire rope and chain slings suit heavy, industrial applications. Consider the environmental conditions; for instance, avoid webbing slings in damp areas. Additionally, evaluate the sling’s working load limit, which should exceed your load’s weight. Consulting with suppliers about specific applications can also provide valuable insights tailored to your requirements. -

What are the key factors to consider when sourcing slings internationally?

When sourcing slings internationally, consider quality, certifications, and compliance with local regulations. Verify suppliers’ reputations through reviews and past client testimonials. Also, assess their manufacturing capabilities and whether they provide customization options. Understanding payment terms, shipping costs, and lead times is crucial to ensure a smooth procurement process. Lastly, ensure clear communication regarding product specifications to avoid misunderstandings. -

What is the minimum order quantity (MOQ) for slings from suppliers?

Minimum order quantities (MOQ) for slings vary by supplier and product type. Many manufacturers set an MOQ to cover production costs, often ranging from 50 to 100 units. However, some suppliers may offer flexibility for first-time buyers or smaller businesses. It’s advisable to discuss your needs directly with suppliers to negotiate favorable terms or explore options for bulk purchasing to reduce costs. -

What payment terms should I expect when buying slings internationally?

Payment terms for international sling purchases typically include options such as upfront payment, partial payment upon order confirmation, or payment on delivery. Common methods include wire transfers, letters of credit, or online payment platforms. Ensure you clarify terms during negotiations to prevent cash flow issues. It’s also wise to assess the supplier’s financial stability, as this can impact their ability to fulfill orders. -

How can I ensure the quality of slings from international suppliers?

To ensure quality, request samples before placing a bulk order. Verify that the slings meet relevant industry standards and certifications, such as ISO or ASTM. Conduct quality assurance checks, including load testing, to confirm that the slings can handle specified weights. Additionally, consider third-party inspection services for added assurance, especially for large orders or complex applications. -

What customization options are available for slings?

Many manufacturers offer customization options for slings, including length, color coding, and specific fittings or attachments. Customization may also extend to unique material specifications or branding elements. When discussing customization, provide detailed requirements and inquire about any additional costs or lead times associated with bespoke orders. This ensures the slings meet your specific operational needs. -

How do logistics and shipping impact sling procurement?

Logistics and shipping play a critical role in sling procurement, affecting delivery times and costs. Assess the supplier’s shipping capabilities, including their experience with international freight and customs clearance. Consider the incoterms that define responsibilities for shipping, insurance, and duties. Planning for potential delays and understanding the logistics chain can help mitigate risks associated with international procurement. -

What are the common uses for different sling types in various industries?

Different sling types serve various industries based on their unique properties. Webbing slings are popular in construction and events for lighter loads, while wire rope slings are common in heavy industrial settings like mining and manufacturing. Chain slings are often used in construction and heavy machinery applications. Understanding these applications can guide your selection process, ensuring you choose the right sling type for your specific industry needs.

Top 2 Sling Types Manufacturers & Suppliers List

1. US Cargo Control – Lifting Slings

Domain: uscargocontrol.com

Registered: 2005 (20 years)

Introduction: Lifting Slings are categorized into five types: nylon, plasma, polyester, wire rope, and chain. Styles include eye and eye slings and endless slings available in nylon and polyester. All web slings are made from high-quality materials. US Cargo Control offers proof testing for crane rigging slings prior to shipment. Plasma, high performance roundslings, and chain slings are proof-tested at no extr…

2. Rigging Warehouse – Lifting Slings

Domain: riggingwarehouse.com

Registered: 2006 (19 years)

Introduction: Lifting slings are designed to move large and heavy loads. Types of lifting slings available include: 1. Wire Rope Lifting Slings: Durable and robust, with higher temperature limits but can be difficult to inspect. 2. Synthetic Lifting Slings: Made from nylon or polyester, lightweight and flexible, but not suitable for high-heat applications and susceptible to cuts. Protective gear like sleeves or…

Strategic Sourcing Conclusion and Outlook for sling types

In navigating the diverse landscape of slings, it is crucial for international B2B buyers to understand the unique characteristics and applications of each type. From the lightweight flexibility of webbing and round slings to the robust strength of wire rope and chain slings, selecting the right sling can significantly impact operational efficiency and safety. By leveraging strategic sourcing practices, companies can not only optimize their supply chain but also ensure they are equipped with the most suitable lifting solutions tailored to their specific needs.

As markets in Africa, South America, the Middle East, and Europe continue to evolve, the demand for reliable and high-quality lifting equipment will only increase. This presents an opportunity for businesses to forge partnerships with trusted suppliers who can provide insight and expertise in sling selection.

Investing in the right sling type not only enhances productivity but also mitigates risks associated with lifting operations. We encourage international buyers to explore diverse sling options and engage with industry experts to make informed purchasing decisions. The future of lifting solutions is bright, and your proactive approach today will position your business for success tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.