A Deep Dive into Shoulder Bolts Solution

Introduction: Navigating the Global Market for shoulder bolts

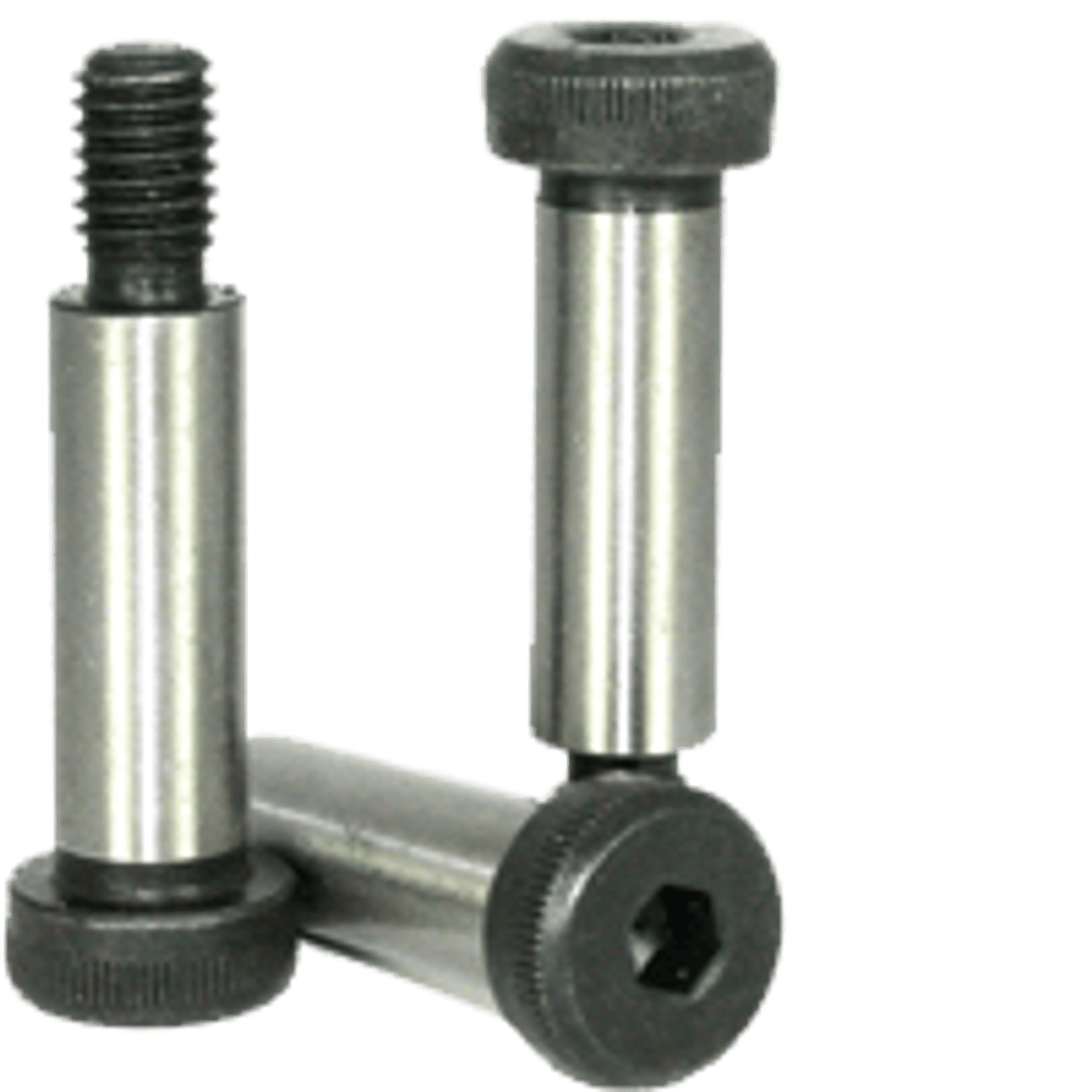

In the fast-paced world of manufacturing and assembly, sourcing the right shoulder bolts can pose a significant challenge for international B2B buyers. These specialized fasteners, often referred to as stripper bolts or axle bolts, are essential for applications ranging from automotive to industrial machinery. With diverse specifications, including metric sizing and various materials, the complexity of selecting the appropriate shoulder bolts can lead to costly errors and project delays.

This comprehensive guide will equip you with the knowledge needed to navigate the global market for shoulder bolts effectively. We delve into various types and sizes, their specific applications, and best practices for vetting suppliers. Additionally, we explore cost considerations and shipping logistics tailored for buyers in Africa, South America, the Middle East, and Europe, including key markets like Germany and Saudi Arabia.

By providing actionable insights and expert guidance, this resource empowers B2B buyers to make informed purchasing decisions, ensuring that you procure the right shoulder bolts to meet your operational needs. Whether you are scaling production or enhancing product reliability, our guide is designed to streamline your sourcing process and optimize your supply chain management.

Understanding shoulder bolts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Socket Shoulder Screws | Smooth, unthreaded shoulder with a modified fillister head | Machinery, automotive, electronics | Pros: High precision, versatile; Cons: May require specific tools for installation. |

| Stripper Bolts | Similar to socket shoulder screws, often used for guiding | Automated machinery, robotics | Pros: Effective for alignment; Cons: Limited thread engagement can affect strength. |

| Metric Shoulder Screws | Available in various metric sizes, shoulder and thread sizes | Global manufacturing, engineering | Pros: Standardized sizes for international use; Cons: May have longer lead times for custom sizes. |

| Flanged Shoulder Bolts | Integrated flange for added stability and load distribution | Construction, heavy machinery | Pros: Enhanced load-bearing capacity; Cons: Bulkier design may limit space in tight applications. |

| Captive Shoulder Screws | Designed to remain attached to the component after loosening | Electronics, assembly lines | Pros: Prevents loss of components; Cons: Slightly higher cost due to specialized design. |

What Are the Characteristics of Socket Shoulder Screws?

Socket shoulder screws feature a smooth, unthreaded shoulder that provides a precise fit for rotational applications, such as bearings and bushings. The modified fillister head allows for a larger surface area for tools, enhancing torque application. These screws are ideal for high-precision assemblies in machinery and automotive sectors, where exact alignment is crucial. When purchasing, buyers should consider compatibility with existing components and the specific torque requirements for their applications.

How Do Stripper Bolts Function in Automated Machinery?

Stripper bolts, akin to socket shoulder screws, are primarily used for guiding and aligning components in automated machinery and robotics. Their design facilitates quick assembly and disassembly, making them suitable for high-volume production environments. Buyers should evaluate the specific alignment needs of their machinery, as improper sizing can lead to misalignment and operational inefficiencies. Additionally, understanding the load requirements is essential for optimal performance.

Why Choose Metric Shoulder Screws for International Applications?

Metric shoulder screws are available in a range of standardized sizes, making them suitable for global manufacturing and engineering applications. Their compatibility with international standards simplifies procurement and inventory management for businesses operating across multiple regions, including Africa, South America, and Europe. Buyers should assess the availability of specific sizes and any potential lead times for custom orders, as these factors can impact project timelines.

What Advantages Do Flanged Shoulder Bolts Offer?

Flanged shoulder bolts come with an integrated flange that enhances stability and load distribution, making them ideal for applications in construction and heavy machinery. This design minimizes the risk of loosening under vibration, which is crucial in high-stress environments. Buyers should consider the space constraints of their applications, as the bulkier design may not fit in tighter assemblies. Additionally, evaluating the load requirements is important to ensure the selected bolt can handle operational stresses.

How Do Captive Shoulder Screws Enhance Assembly Efficiency?

Captive shoulder screws are engineered to remain attached to components even after loosening, which minimizes the risk of loss during maintenance or assembly processes. This feature is particularly beneficial in electronic and assembly line applications where components are frequently handled. When considering captive screws, buyers should evaluate the cost versus the potential savings in reduced replacement parts and assembly time, as the initial investment can lead to long-term efficiency gains.

Key Industrial Applications of shoulder bolts

| Industry/Sector | Specific Application of Shoulder Bolts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Used in assembly lines as pivot points for machinery | Enhances operational efficiency and reduces downtime | Require high tensile strength; consider material corrosion resistance. |

| Automotive | Function as axle bolts in vehicle assemblies | Ensures safety and reliability in vehicle performance | Must meet stringent automotive standards; look for precision sizing. |

| Aerospace | Act as dowels for aligning components in aircraft | Critical for safety and performance under extreme conditions | Compliance with aerospace regulations; focus on lightweight materials. |

| Construction | Serve as fasteners in structural framing | Provides durability and stability in building structures | Need for high load-bearing capacity; assess environmental factors. |

| Telecommunications | Used in mounting and securing telecom equipment | Supports infrastructure reliability and longevity | Consider custom lengths and diameters for specific applications; check for vibration resistance. |

How Are Shoulder Bolts Utilized in Manufacturing?

In the manufacturing sector, shoulder bolts are integral to assembly lines, serving as pivot points for machinery. Their smooth, unthreaded shoulders allow for rotational movement, which is essential in conveyor systems and robotic arms. By utilizing shoulder bolts, manufacturers can enhance operational efficiency, reduce wear on moving parts, and minimize downtime caused by maintenance. International buyers should prioritize sourcing bolts with high tensile strength and consider materials that resist corrosion, especially in humid or harsh environments.

What Role Do Shoulder Bolts Play in the Automotive Industry?

In the automotive industry, shoulder bolts are crucial components in vehicle assemblies, specifically as axle bolts. They ensure the proper alignment and secure attachment of critical parts, which directly impacts vehicle safety and performance. The need for precision in sizing and compliance with strict automotive standards makes sourcing these fasteners a critical task for manufacturers. Buyers should look for shoulder bolts that meet industry specifications and are made from durable materials to withstand the rigors of road conditions.

Why Are Shoulder Bolts Important in Aerospace Applications?

Shoulder bolts are essential in the aerospace sector, acting as dowels for aligning various components in aircraft. Their reliability is paramount, as any failure can lead to catastrophic consequences. These bolts must comply with rigorous aerospace regulations, ensuring they can withstand extreme temperatures and pressures. Buyers in this sector should focus on lightweight materials that do not compromise strength, as well as sourcing from suppliers with a proven track record in aerospace fasteners.

How Are Shoulder Bolts Utilized in Construction?

In construction, shoulder bolts are used as fasteners in structural framing, providing the necessary stability and durability for buildings. They can handle high loads and are often employed in critical structural applications, where safety is a concern. When sourcing shoulder bolts for construction projects, it’s essential to evaluate their load-bearing capacity and consider environmental factors, such as exposure to moisture or chemicals, which could affect material integrity over time.

What Applications Do Shoulder Bolts Have in Telecommunications?

In the telecommunications industry, shoulder bolts are utilized for mounting and securing various telecom equipment, ensuring that infrastructure remains stable and reliable. These bolts often need to accommodate specific lengths and diameters to fit unique mounting systems, making customization a key consideration. Buyers should also ensure that the shoulder bolts are resistant to vibration, as telecom installations can be subject to movement and stress, which could lead to equipment failure if not properly secured.

3 Common User Pain Points for ‘shoulder bolts’ & Their Solutions

Scenario 1: Sizing Confusion in Shoulder Bolts

The Problem: A common challenge faced by B2B buyers is determining the correct size and specifications for shoulder bolts. With various standards and sizes available, including metric and imperial units, it can be overwhelming to ensure that the selected bolt will fit seamlessly into existing machinery or assembly setups. Errors in sizing can lead to costly delays and operational inefficiencies, as incompatible components may require rework or replacement.

The Solution: To mitigate sizing confusion, B2B buyers should take a systematic approach to specification. Start by measuring the existing components or assemblies where the shoulder bolts will be used. Utilize calipers to measure both the shoulder diameter and the length accurately. When sourcing, consult manufacturers’ catalogs that provide detailed dimensions and specifications for each bolt type. Pay special attention to the thread diameter, which should always be smaller than the shoulder diameter. Additionally, consider reaching out to suppliers for assistance in selecting the right size based on application requirements. Building a strong relationship with suppliers can also facilitate better support for future orders, ensuring consistency in quality and specifications.

Scenario 2: Material Selection for Environmental Conditions

The Problem: Many B2B buyers encounter difficulties when selecting the appropriate material for shoulder bolts, especially when their applications involve exposure to harsh environmental conditions. For instance, shoulder bolts used in marine equipment may be subjected to corrosion from saltwater, while those in industrial machinery might face extreme temperatures or chemical exposure. Choosing the wrong material can lead to premature failure, safety risks, and increased maintenance costs.

The Solution: To address material selection challenges, buyers should conduct a thorough assessment of the environmental conditions where the shoulder bolts will be utilized. Consider factors such as humidity, temperature fluctuations, and the presence of corrosive substances. For marine applications, stainless steel or marine-grade materials are typically recommended due to their resistance to rust and corrosion. In industrial settings, look for shoulder bolts made from high-strength alloys that can withstand temperature extremes and chemical exposure. Collaborating with material specialists or suppliers can provide valuable insights into the best materials for specific applications. It’s also wise to request samples for testing before making bulk purchases to ensure compatibility and performance in the intended environment.

Scenario 3: Ensuring Proper Installation and Alignment

The Problem: Another prevalent pain point for B2B buyers involves the installation and alignment of shoulder bolts within their assemblies. Misalignment can occur if the shoulder bolts are not installed correctly, leading to operational inefficiencies or even mechanical failure. This is particularly critical in applications where precision is paramount, such as in automotive or aerospace components.

The Solution: To ensure proper installation and alignment of shoulder bolts, buyers should adopt best practices during the assembly process. Start by using alignment tools such as dowels or guide pins to achieve accurate positioning before securing the bolts. It’s essential to tighten the bolts to the manufacturer’s recommended torque specifications to avoid over-tightening, which could compromise the integrity of the assembly. Additionally, consider implementing a quality control checklist that includes inspection of alignment and torque settings as part of the assembly process. Training assembly staff on proper techniques and the importance of precision can further enhance outcomes. Leveraging technology, such as digital torque wrenches, can provide real-time feedback during installation, ensuring that every bolt is correctly aligned and secured.

Strategic Material Selection Guide for shoulder bolts

What are the Key Properties of Common Materials Used for Shoulder Bolts?

When selecting shoulder bolts for various applications, the choice of material significantly impacts performance, durability, and overall suitability. Below, we analyze four common materials used in the manufacturing of shoulder bolts: steel, stainless steel, aluminum, and plastic.

Steel: A Versatile Choice for Strength and Durability

Steel is one of the most commonly used materials for shoulder bolts due to its high tensile strength and durability. It typically offers excellent performance under high pressure and temperature conditions, making it suitable for heavy-duty applications. However, steel is prone to corrosion, especially in humid or saline environments, which can limit its use without proper coatings or finishes.

Pros: High strength, cost-effective, widely available.

Cons: Susceptible to corrosion, heavier than alternatives.

Impact on Application: Ideal for mechanical assemblies where strength is critical, but may require protective coatings in corrosive environments.

Considerations for International Buyers: Compliance with standards such as ASTM A307 or DIN 931 is crucial, especially in regions with stringent quality regulations.

Stainless Steel: Corrosion Resistance and Aesthetic Appeal

Stainless steel shoulder bolts are favored for their corrosion resistance and aesthetic qualities. They maintain structural integrity in harsh environments, making them suitable for marine and outdoor applications. The material’s resistance to rust and staining enhances longevity, although it comes at a higher cost than standard steel.

Pros: Excellent corrosion resistance, good aesthetic finish, durable.

Cons: Higher cost, may be more challenging to machine.

Impact on Application: Perfect for applications exposed to moisture or chemicals, such as in the food and beverage industry.

Considerations for International Buyers: Ensure compliance with international standards like ASTM A276 or JIS G4303, which are often required in regions like Europe and the Middle East.

Aluminum: Lightweight and Versatile

Aluminum shoulder bolts are known for their lightweight properties, making them ideal for applications where weight reduction is a priority. They offer good corrosion resistance and are easier to machine than steel. However, aluminum has lower tensile strength compared to steel, which may limit its use in high-stress applications.

Pros: Lightweight, good corrosion resistance, easy to machine.

Cons: Lower strength, can be more expensive than steel.

Impact on Application: Suitable for aerospace and automotive applications where weight is a critical factor.

Considerations for International Buyers: Look for compliance with standards such as ASTM B211 or DIN 1725, especially in industries focused on weight efficiency.

Plastic: Cost-Effective and Non-Conductive

Plastic shoulder bolts are increasingly popular in applications requiring non-conductive properties or resistance to chemical exposure. They are lightweight and cost-effective, making them suitable for various industries, including electronics and consumer goods. However, plastic bolts may not withstand high temperatures or heavy loads.

Pros: Lightweight, non-corrosive, cost-effective.

Cons: Limited temperature and load-bearing capacity, less durable than metal options.

Impact on Application: Ideal for electronic assemblies or applications where insulation is required.

Considerations for International Buyers: Ensure compliance with relevant standards for plastics, such as ASTM D638, especially in regions with strict safety regulations.

Summary of Material Selection for Shoulder Bolts

| Material | Typical Use Case for shoulder bolts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy machinery, automotive applications | High strength | Susceptible to corrosion | Medium |

| Stainless Steel | Marine equipment, food processing machinery | Excellent corrosion resistance | Higher cost | High |

| Aluminum | Aerospace, automotive lightweight applications | Lightweight | Lower strength | Medium |

| Plastic | Electronics, consumer goods | Non-conductive, cost-effective | Limited load-bearing capacity | Low |

This strategic material selection guide provides a comprehensive overview for B2B buyers, helping them make informed decisions based on specific application requirements and regional compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for shoulder bolts

What Are the Key Stages in the Manufacturing Process of Shoulder Bolts?

Shoulder bolts, also known as socket shoulder screws or stripper bolts, are precision fasteners used in various applications, from machinery to automotive components. The manufacturing process of shoulder bolts involves several critical stages to ensure that they meet the required specifications and quality standards.

Material Preparation

The first step in manufacturing shoulder bolts is material selection and preparation. Common materials include stainless steel, carbon steel, and alloy steel, chosen for their mechanical properties and corrosion resistance. The raw materials are typically supplied in the form of rods or bars. These materials undergo cutting to size, where the bars are cut into lengths suitable for the specific shoulder bolt dimensions.

Forming Techniques: How Are Shoulder Bolts Shaped?

Once the material is prepared, it moves to the forming stage. This involves several techniques, including:

-

Cold Heading: This process involves deforming the metal at room temperature to form the head and shoulder of the bolt. Cold heading is efficient and produces strong components with minimal waste.

shoulder bolts related image

-

Machining: After cold heading, machining is performed to create the threaded portion and ensure precise dimensions. CNC (Computer Numerical Control) machines are commonly employed for this purpose, allowing for high accuracy and repeatability.

-

Heat Treatment: To enhance the mechanical properties of the bolts, heat treatment processes such as quenching and tempering are often applied. This increases strength and hardness, making the bolts suitable for demanding applications.

Finishing Processes: What Ensures the Durability of Shoulder Bolts?

After forming, the bolts undergo finishing processes. These may include:

-

Surface Treatment: Common treatments include galvanizing, plating, or anodizing to improve corrosion resistance and aesthetic appeal.

-

Deburring: This process removes sharp edges and burrs that may have formed during machining, ensuring safety and ease of handling.

-

Quality Inspection: Before packaging, the bolts are subject to rigorous quality inspections to ensure they meet specifications.

What Quality Assurance Measures Are Important for Shoulder Bolts?

Quality assurance (QA) is a vital aspect of shoulder bolt manufacturing. It ensures that the final products are reliable, safe, and compliant with international standards.

Which International Standards Should B2B Buyers Consider?

B2B buyers should be aware of relevant international standards that govern the manufacturing of shoulder bolts, including:

-

ISO 9001: This standard specifies requirements for a quality management system (QMS). Manufacturers certified to ISO 9001 demonstrate a commitment to quality and continuous improvement.

-

CE Marking: In Europe, CE marking indicates compliance with health, safety, and environmental protection standards. This is crucial for buyers in the European market.

-

API Standards: For buyers in the oil and gas industry, compliance with American Petroleum Institute (API) standards is essential, particularly for applications requiring high reliability under extreme conditions.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints throughout the manufacturing process include:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials to ensure they meet specified standards before production begins.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, various inspections are conducted to monitor dimensions, tolerances, and material properties. This ensures that any deviations are caught early.

-

Final Quality Control (FQC): After production, a final inspection is performed to verify that the shoulder bolts meet all specifications before they are packaged and shipped.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify the quality control measures of their suppliers:

-

Supplier Audits: Conducting on-site audits of potential suppliers allows buyers to assess manufacturing practices, quality control systems, and compliance with relevant standards.

-

Quality Reports: Requesting detailed quality reports, including inspection records and test results, can provide insights into the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the quality and compliance of shoulder bolts before they are shipped.

What Testing Methods Are Commonly Used for Shoulder Bolts?

Several testing methods are employed to ensure shoulder bolts meet the required performance standards:

-

Tensile Testing: This test measures the strength of the material and its ability to withstand pulling forces.

-

Hardness Testing: Hardness tests determine the resistance of the material to deformation, which is crucial for the longevity of the bolts.

-

Dimensional Inspection: Using precision measuring tools, manufacturers verify that the dimensions of the shoulder bolts conform to specified tolerances.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

International buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, should be aware of specific nuances in quality control and certification:

-

Regulatory Compliance: Different regions may have unique regulatory requirements. Understanding local regulations and standards is essential for compliance and market entry.

-

Documentation: Buyers should ensure that all certifications, test reports, and compliance documentation are in order and available for review.

-

Cultural Differences: In some regions, personal relationships play a significant role in business. Building trust and rapport with suppliers can enhance collaboration and ensure better quality assurance practices.

By understanding the manufacturing processes and quality assurance measures associated with shoulder bolts, B2B buyers can make informed decisions when selecting suppliers, ensuring they receive reliable and high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘shoulder bolts’

Introduction

This practical sourcing guide is designed to assist B2B buyers in the procurement of shoulder bolts, ensuring a streamlined and efficient purchasing process. Shoulder bolts, also known as socket shoulder screws or stripper bolts, are critical components used in various applications, including machinery and automotive parts. By following this checklist, buyers can secure high-quality fasteners that meet their technical requirements while optimizing their supply chain.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential before sourcing shoulder bolts. Consider the dimensions, materials, and mechanical properties required for your application.

– Key factors to define include:

– Shoulder diameter and length

– Thread size and type (e.g., metric or imperial)

– Material grade (e.g., stainless steel, alloy) for corrosion resistance or strength.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in shoulder bolts. Utilize industry directories, trade shows, and online marketplaces to compile a list of potential partners.

– When researching, focus on:

– Supplier experience in your specific industry.

– Customer reviews and ratings to gauge reliability and quality.

Step 3: Evaluate Supplier Certifications

Before proceeding with a supplier, verify their certifications and quality management systems. This step ensures that the supplier adheres to industry standards and regulations, which is crucial for maintaining product integrity.

– Look for certifications such as:

– ISO 9001 for quality management.

– Specific certifications relevant to your industry, such as AS9100 for aerospace components.

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of their shoulder bolts for testing. This hands-on evaluation allows you to assess the quality and performance of the fasteners in your application.

– During testing, consider:

– Dimensional accuracy and consistency.

– Mechanical properties under operational conditions.

Step 5: Discuss Pricing and Terms

Initiate discussions on pricing, payment terms, and lead times. Understanding the total cost of procurement will help you budget effectively and avoid unexpected expenses.

– Be sure to clarify:

– Bulk purchase discounts.

– Shipping and handling fees, especially for international orders.

Step 6: Check for Customization Options

If your application requires specific modifications, inquire about the supplier’s capabilities for custom shoulder bolts. Many suppliers offer customization to meet unique specifications, which can enhance performance in your specific use case.

– Customization can include:

– Altered dimensions or shapes.

– Specific coatings or finishes for enhanced durability.

Step 7: Finalize Contracts and Agreements

Once you have chosen a supplier, finalize the contracts and agreements. Ensure that all terms, including delivery schedules, quality assurance processes, and warranties, are clearly outlined to protect your interests.

– Key elements to include:

– Penalties for late delivery.

– Procedures for handling defective products.

By adhering to this sourcing checklist, B2B buyers can effectively navigate the procurement process for shoulder bolts, ensuring they secure reliable, high-quality fasteners tailored to their specific needs.

Comprehensive Cost and Pricing Analysis for shoulder bolts Sourcing

What Are the Key Cost Components in Shoulder Bolt Sourcing?

Understanding the cost structure of shoulder bolts is crucial for B2B buyers aiming to optimize their procurement process. The primary cost components include:

-

Materials: The choice of material significantly impacts the cost. Common materials for shoulder bolts include stainless steel, alloy steel, and brass. Stainless steel (18-8 or 300 series) is preferred for its corrosion resistance but can be more expensive than other materials.

-

Labor: Labor costs vary depending on the manufacturing location. Countries with lower labor costs, such as those in Asia or Eastern Europe, may offer more competitive pricing compared to Western Europe or North America.

-

Manufacturing Overhead: This includes costs associated with the production facility, utilities, and equipment maintenance. Efficient manufacturing processes can help reduce overhead, which can be reflected in the final price of the bolts.

-

Tooling: Custom tooling can be a significant upfront cost for specialized shoulder bolts. Buyers should consider whether the investment in custom tooling will be justified by the volume of orders.

-

Quality Control (QC): Rigorous quality assurance processes are necessary to ensure that the shoulder bolts meet required specifications. The costs associated with QC can vary, impacting the overall pricing.

-

Logistics: Shipping and handling costs, including international freight and customs duties, play a significant role, especially for buyers in regions like Africa or South America. Understanding Incoterms can help buyers manage these costs effectively.

-

Margin: Suppliers will add their profit margin on top of the production costs. This margin can vary widely based on market conditions and supplier relationships.

How Do Price Influencers Affect the Cost of Shoulder Bolts?

Several factors influence the final pricing of shoulder bolts beyond the basic cost components:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to lower per-unit costs. Buyers should inquire about price breaks at various order volumes.

-

Specifications and Customization: Custom designs or specific requirements can lead to increased costs. Buyers should weigh the necessity of customization against potential price increases.

-

Materials: As mentioned, the type of material used will influence pricing. Specialty materials or those with certifications may carry a premium.

-

Quality and Certifications: Certifications such as ISO or ASTM can affect pricing. Suppliers that meet these standards may charge more, but they also provide assurance of quality.

-

Supplier Factors: Established suppliers with a good reputation may charge higher prices due to perceived reliability and quality assurance. Conversely, newer suppliers may offer lower prices to build their customer base.

-

Incoterms: The agreed terms of shipment can significantly impact total costs. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can help buyers negotiate better deals.

What Tips Can Help B2B Buyers Negotiate Better Prices for Shoulder Bolts?

-

Negotiation: Always negotiate pricing and terms. Suppliers may have flexibility, especially if they want to secure a long-term relationship.

-

Cost Efficiency: Analyze the Total Cost of Ownership (TCO), which includes purchase price, shipping, duties, and potential costs associated with quality issues. A lower initial price might lead to higher costs down the line.

-

Pricing Nuances for International Buyers: For buyers in Africa, South America, the Middle East, and Europe, consider currency fluctuations, local regulations, and import duties that can affect overall costs.

-

Build Relationships: Establishing a strong relationship with suppliers can lead to better pricing and terms over time. Trust can often lead to discounts and priority service.

-

Stay Informed: Keep abreast of market trends and material costs. Knowledge of the market can provide leverage in negotiations and help in making informed purchasing decisions.

Disclaimer on Pricing

Prices for shoulder bolts can fluctuate based on market conditions, material availability, and geopolitical factors. It’s advisable for buyers to request quotes and conduct thorough market research to obtain the most accurate and competitive pricing.

Alternatives Analysis: Comparing shoulder bolts With Other Solutions

Exploring Alternative Solutions to Shoulder Bolts

In the realm of fasteners, shoulder bolts serve a unique function, particularly as spacers and bearing surfaces in mechanical assemblies. However, businesses often face a choice between various fastening solutions depending on their specific applications, performance requirements, and cost considerations. This section delves into viable alternatives to shoulder bolts, allowing international B2B buyers to make informed decisions based on performance, cost, and practicality.

| Comparison Aspect | Shoulder Bolts | Alternative 1: Dowel Pins | Alternative 2: Hex Bolts |

|---|---|---|---|

| Performance | High precision, effective as pivot points | Adequate for alignment, limited load capacity | High tensile strength, versatile in many applications |

| Cost | Moderate cost per unit | Generally lower cost | Cost-effective, especially in bulk |

| Ease of Implementation | Requires precise machining for fit | Easy to install with minimal tools | Standardized sizes, compatible with many designs |

| Maintenance | Low maintenance; durable | Low maintenance, but potential for misalignment | Requires regular inspection for integrity |

| Best Use Case | Ideal for rotating components | Best for fixed alignment applications | Suitable for heavy load-bearing applications |

What are the Pros and Cons of Dowel Pins as an Alternative to Shoulder Bolts?

Dowel pins are cylindrical rods used to align and connect two components. Their primary advantage is cost-effectiveness and ease of installation, as they typically require only basic tools for placement. However, dowel pins have limitations in terms of load-bearing capacity and are less effective in applications requiring rotational movement. For applications where precise alignment is crucial but rotational movement is not required, dowel pins can be a suitable alternative.

How Do Hex Bolts Compare to Shoulder Bolts?

Hex bolts are widely used fasteners known for their strength and adaptability. They excel in applications requiring high tensile strength and can be used in a variety of mechanical assemblies. Hex bolts are generally easy to source and can be found in various grades, making them suitable for diverse applications. However, they may not provide the same level of precision as shoulder bolts in applications requiring smooth rotation or spacing. For heavy-duty applications where load-bearing capacity is paramount, hex bolts are often the go-to choice.

How Should B2B Buyers Choose the Right Fastening Solution?

Choosing the right fastening solution hinges on several factors, including the specific application, required precision, load-bearing needs, and budget constraints. Shoulder bolts are ideal for applications demanding high precision and rotational movement, while dowel pins offer a cost-effective solution for fixed alignments. Conversely, hex bolts provide robust strength for heavy-duty applications. By evaluating these alternatives against their unique operational requirements, B2B buyers can select the most suitable fastening solution to enhance the efficiency and reliability of their projects.

Essential Technical Properties and Trade Terminology for shoulder bolts

What Are the Essential Technical Properties of Shoulder Bolts?

When considering shoulder bolts for your applications, understanding their technical properties is crucial for ensuring performance and reliability. Here are some key specifications:

1. Material Grade

Shoulder bolts are commonly manufactured from various materials, including stainless steel, alloy steel, and brass. The choice of material affects the bolt’s strength, corrosion resistance, and thermal properties. For instance, stainless steel offers excellent corrosion resistance, making it suitable for marine or outdoor applications, while alloy steel is often chosen for its superior strength in high-stress environments. Selecting the right material grade ensures that the bolts can withstand the specific demands of your application.

2. Shoulder Diameter

The shoulder diameter of a shoulder bolt is critical for its function as a pivot or bearing. This measurement determines the load-bearing capacity and compatibility with other components, such as bushings or bearings. A proper fit is essential to prevent wear and ensure smooth operation. B2B buyers should consider the shoulder diameter when designing or sourcing assemblies to ensure that components will work together effectively.

3. Thread Diameter

Typically, the thread diameter is the next standard size down from the shoulder diameter. This specification is important for ensuring a secure fit within the assembly, allowing for proper torque application and load distribution. For example, an M10 shoulder bolt will have an M8 thread diameter. Understanding this relationship helps buyers select the appropriate bolts for their applications, minimizing the risk of failure.

4. Tolerance

Tolerance refers to the permissible limit of variation in the dimensions of the shoulder bolt. Tight tolerances are critical in applications where precision is necessary, such as in aerospace or automotive industries. A high tolerance can lead to improved assembly quality and reduce the likelihood of mechanical failure. Buyers should pay attention to tolerance specifications to ensure that the shoulder bolts will meet the exacting demands of their applications.

5. Length

The length of the shoulder bolt is also a key property, as it influences how the bolt interacts with other components in an assembly. The length should be chosen based on the specific application requirements, taking into account factors such as the thickness of materials being fastened and the need for thread engagement. Ensuring the correct length prevents issues related to insufficient grip or excess protrusion.

Which Trade Terminology Should Buyers Understand When Sourcing Shoulder Bolts?

Familiarity with industry jargon can streamline the sourcing process and improve communication with suppliers. Here are some common terms relevant to shoulder bolts:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is vital for buyers who require shoulder bolts that meet the exact standards of their machinery or equipment. This ensures compatibility and performance in the final assembly.

2. MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units that a supplier is willing to sell. Knowing the MOQ is essential for budget planning and inventory management. Buyers should consider their project needs and whether they can meet the supplier’s MOQ without overcommitting resources.

3. RFQ (Request for Quote)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products, including shoulder bolts. Submitting an RFQ allows buyers to compare options and negotiate better deals. Clarity in RFQs can lead to more accurate quotes and improved supplier relationships.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for buyers to know who is responsible for shipping, insurance, and tariffs, which can significantly impact total costs.

5. Customization

Customization refers to the ability to tailor shoulder bolts to specific requirements, including dimensions, materials, and finishes. This is often necessary for specialized applications where standard products may not suffice. Engaging with suppliers who offer customization can lead to more effective solutions for unique engineering challenges.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing shoulder bolts, ensuring that they meet the specific requirements of their applications while optimizing their procurement processes.

Navigating Market Dynamics and Sourcing Trends in the shoulder bolts Sector

What Are the Current Market Dynamics and Key Trends Impacting Shoulder Bolts?

The shoulder bolts sector is witnessing significant growth driven by various global factors, including the rapid advancement of manufacturing technologies and increased demand across diverse industries such as automotive, electronics, and machinery. Key trends influencing the market include the rising adoption of automation and robotics, which necessitate precise and reliable fasteners like shoulder bolts for enhanced performance. Furthermore, the expansion of electric vehicles (EVs) and renewable energy systems is generating new applications for shoulder bolts, particularly in battery packs and other critical components.

International buyers from Africa, South America, the Middle East, and Europe must navigate a complex landscape of sourcing trends. The shift towards digital procurement tools and e-commerce platforms is becoming increasingly prominent, enabling buyers to access a broader range of suppliers and products. Additionally, the emergence of Industry 4.0 technologies is reshaping supply chains, fostering real-time data sharing, and improving inventory management. This not only optimizes sourcing processes but also enhances responsiveness to market fluctuations.

Furthermore, geopolitical factors and trade regulations are influencing sourcing strategies, compelling buyers to diversify their supplier bases to mitigate risks associated with supply chain disruptions. As such, understanding local market conditions and establishing strong relationships with suppliers in key regions is crucial for securing a competitive advantage.

How Does Sustainability and Ethical Sourcing Affect the Shoulder Bolts Market?

As environmental concerns continue to rise, sustainability and ethical sourcing have become paramount for B2B buyers in the shoulder bolts sector. The production of fasteners can have a significant environmental impact, from resource extraction to manufacturing processes. Buyers are increasingly prioritizing suppliers who demonstrate a commitment to minimizing their carbon footprint through energy-efficient practices and sustainable materials.

Incorporating ‘green’ certifications and materials into sourcing strategies is essential for buyers looking to enhance their brand reputation and meet regulatory requirements. Certifications such as ISO 14001 (Environmental Management) and adherence to REACH (Registration, Evaluation, Authorisation, and Restriction of Chemicals) regulations are becoming critical benchmarks for assessing suppliers. Additionally, the use of recycled metals and eco-friendly coatings in shoulder bolt production is gaining traction, reflecting a broader industry shift towards sustainability.

Adopting ethical sourcing practices not only aids in compliance with emerging regulations but also resonates with consumers increasingly concerned about the sustainability of the products they purchase. This trend is particularly relevant in European markets, where regulatory frameworks are stringent, and consumer expectations for corporate social responsibility are high.

What Is the Historical Context of Shoulder Bolts in the B2B Sector?

Shoulder bolts have evolved significantly since their inception in the early industrial era. Originally designed for basic fastening applications, their unique geometry, characterized by a smooth, unthreaded shoulder, has allowed them to serve as pivotal components in various machinery and equipment. Over the decades, advancements in materials science have led to the development of high-performance alloys and coatings, enhancing their durability and corrosion resistance.

As industries have diversified, shoulder bolts have found their way into specialized applications, ranging from automotive to aerospace, showcasing their versatility and reliability. The evolution of manufacturing processes, including precision machining and automated production, has further improved the quality and consistency of shoulder bolts, making them indispensable in modern engineering and production environments. This historical context underscores the importance of shoulder bolts in facilitating innovation and efficiency across multiple sectors, providing B2B buyers with a rich legacy of performance and adaptability.

Frequently Asked Questions (FAQs) for B2B Buyers of shoulder bolts

-

How do I choose the right shoulder bolt for my application?

Selecting the appropriate shoulder bolt involves understanding the specific requirements of your application. Consider the shoulder diameter, length, and the material (such as stainless steel or carbon steel) based on environmental factors like corrosion resistance. Additionally, assess the load requirements and whether the bolt will act as a dowel or bearing. Consulting with suppliers for technical specifications and compatibility with your machinery can provide tailored solutions that meet your operational needs. -

What are the common uses of shoulder bolts in industrial applications?

Shoulder bolts, also known as stripper bolts or axle bolts, are versatile fasteners primarily used in applications requiring rotation or alignment. They serve as spacers, bearings, and pivots in machinery, automotive parts, and conveyor systems. Industries like construction, electronics, and marine equipment frequently use these bolts due to their ability to accommodate dynamic loads and facilitate smooth movement, making them essential in assembly processes. -

What is the minimum order quantity (MOQ) for shoulder bolts?

Minimum order quantities for shoulder bolts can vary significantly among suppliers. Typically, MOQs may range from 100 to 1,000 pieces, depending on the manufacturer and the specific type of shoulder bolt required. For custom orders or specialized materials, MOQs may be higher. It’s advisable to discuss your requirements with suppliers to negotiate terms that suit your purchasing needs, particularly if you are looking to source for larger projects. -

How can I ensure the quality of shoulder bolts from international suppliers?

To ensure quality, request detailed product specifications and certifications from potential suppliers, including ISO certifications or material test reports. Conducting factory visits or audits can also provide insight into manufacturing processes. Utilize third-party inspection services if necessary, especially for bulk orders. Establishing a clear quality assurance process that includes sampling and testing can mitigate risks associated with sourcing from international markets. -

What payment terms should I expect when sourcing shoulder bolts internationally?

Payment terms can vary widely depending on the supplier and the transaction’s size. Common terms include advance payment, 30% deposit with the balance due before shipment, or net 30 days after delivery. For larger orders, consider negotiating letters of credit or escrow services to protect your investment. Always clarify the payment methods accepted (e.g., wire transfer, PayPal) and any potential fees associated with currency conversion or international transactions. -

How do I vet suppliers for shoulder bolts in international markets?

To vet suppliers, start by researching their reputation through online reviews, industry forums, and references from past clients. Verify their business credentials and manufacturing capabilities, ensuring they meet international standards. Request samples of shoulder bolts to evaluate quality and performance. Establish clear communication channels and assess their responsiveness to inquiries, as this reflects their commitment to customer service. -

What logistics considerations should I keep in mind when importing shoulder bolts?

When importing shoulder bolts, consider shipping methods, lead times, and customs regulations in your country. Assess the total landed cost, including freight, insurance, and customs duties. Work with logistics providers experienced in handling industrial components to ensure smooth transportation and delivery. Additionally, factor in potential delays due to customs clearance and plan your inventory accordingly to avoid production disruptions. -

Can shoulder bolts be customized for specific applications?

Yes, many manufacturers offer customization options for shoulder bolts, including variations in size, material, and thread specifications. Customization allows you to tailor the bolts to meet unique application requirements, such as specific load capacities or environmental conditions. Discuss your needs with suppliers and request quotes for custom designs, keeping in mind that this may affect lead times and MOQs.

Top 6 Shoulder Bolts Manufacturers & Suppliers List

1. McMaster – Shoulder Bolts

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Shoulder Bolts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Bolt Depot – Stainless Steel 316 Shoulder Bolts

Domain: boltdepot.com

Registered: 1999 (26 years)

Introduction: {“Product Name”:”Shoulder bolts”,”Material”:”Stainless steel 316″,”Shoulder Diameter”:”5/32 inch”,”Thread Diameter”:”#6″,”Length”:”1/2 inch”,”Product Number”:”19978″,”Grade”:”316″,”Corrosion Resistance”:”Highly corrosion resistant, ideal in salt water and chlorine environments”,”Thread Count”:”32″,”Domestically Produced”:”Yes”,”Brand Name”:”AMPG”,”Dimensional Standard”:”AMPG 2012 ZS.01″,”Drive Siz…

3. HOLO-KROME – Socket Shoulder Bolts

Domain: holo-krome.com

Registered: 2003 (22 years)

Introduction: Socket Shoulder Bolts, also known as “stripper bolts”, are used in punch and die operations. They serve as fulcrums or pivots in machine designs involving links and levers. HOLO-KROME offers over 73 stock sizes with diameters from ¼” to ¾” and shoulder lengths from 1″ to 6″, along with a full line of metric and non-standard sizes. Significant features include: 1) “Tru-Ground” surfaces for smooth, …

4. Ondrives – Precision Shoulder Screws

Domain: ondrivesus.com

Registered: 2007 (18 years)

Introduction: Precision Shoulder Screws, also known as Shoulder Bolts or Stripper Bolts, feature undersized shoulder diameters and oversized shoulder lengths, allowing for free rotational or axial motion when mounted. Available in both inch and metric sizes, they come in various styles including hex socket head, star socket head, and slotted head. Key specifications include:

– Materials: 303 stainless steel an…

5. Albany County Fasteners – Stainless Steel Shoulder Bolt

Domain: albanycountyfasteners.com

Registered: 2007 (18 years)

Introduction: {‘Product_Name’: ‘Shoulder Bolts, Stainless Steel 18-8, 1/2″ Shoulder (3/8″-16 Thread)’, ‘Shoulder_Diameter’: ‘1/2″‘, ‘Thread_Size’: ‘3/8″-16’, ‘Material’: ‘304 Stainless Steel’, ‘Corrosion_Resistant’: ‘Yes’, ‘Drive_Style’: ‘Internal Hex (Allen)’, ‘Head_Diameter’: ‘3/4″‘, ‘Head_Height’: ‘5/16″‘, ‘Head_Style’: ‘Socket Cap’, ‘Hex_Drive’: ‘1/4″‘, ‘Thread_Direction’: ‘Right Hand’, ‘Thread_Pitch’: ’16 …

6. RC Fastener – Socket Shoulder Screws

Domain: rcfastener.com

Registered: 2015 (10 years)

Introduction: Socket Shoulder Screws available in Alloy and Stainless Steel options.

Strategic Sourcing Conclusion and Outlook for shoulder bolts

How Can Strategic Sourcing Enhance Your Procurement of Shoulder Bolts?

In today’s competitive landscape, the strategic sourcing of shoulder bolts is paramount for international B2B buyers. By understanding the unique applications and specifications of shoulder bolts, businesses can streamline their procurement processes and enhance operational efficiency. Leveraging partnerships with reliable suppliers ensures access to high-quality materials, which is critical for industries ranging from automotive to marine equipment.

Furthermore, the importance of customization cannot be overstated; tailored solutions can lead to improved product performance and durability. Buyers should prioritize suppliers who offer a wide range of sizes and materials, allowing for greater flexibility in meeting specific application requirements.

Looking ahead, the demand for shoulder bolts is poised to grow, especially in emerging markets across Africa, South America, the Middle East, and Europe. As industries evolve, so too will the specifications of fasteners, necessitating proactive engagement with suppliers to stay ahead of trends.

Take the next step in optimizing your supply chain. Engage with trusted manufacturers and suppliers today to ensure your projects are equipped with the best shoulder bolts, setting the foundation for success in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.