A Deep Dive into Shock Cord Solution

Introduction: Navigating the Global Market for shock cord

In the dynamic landscape of global commerce, sourcing high-quality shock cord can present significant challenges for B2B buyers. Whether you’re looking to procure durable elastic cords for outdoor gear, marine applications, or manufacturing processes, understanding the nuances of shock cord types and specifications is crucial. This guide will delve into the diverse varieties of shock cord available, their applications across various industries, and the essential factors to consider when selecting suppliers.

International buyers from regions such as Africa, South America, the Middle East, and Europe—particularly Germany and Saudi Arabia—will find actionable insights tailored to their specific market needs. By exploring supplier vetting processes, cost considerations, and quality assurance practices, this comprehensive resource empowers businesses to make informed purchasing decisions.

Navigating the complexities of shock cord procurement doesn’t have to be daunting. With the right information and a strategic approach, you can streamline your sourcing process, ensuring that you acquire the most suitable products for your operations. This guide serves as your roadmap, providing the knowledge needed to enhance your supply chain and support your business goals in an increasingly competitive environment.

Understanding shock cord Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Shock Cord | Braided nylon sheath with a rubber core | Clothing, DIY projects, light-duty tie-downs | Pros: Versatile, cost-effective. Cons: Limited durability for heavy loads. |

| Marine-Grade Shock Cord | Made with Dacron polyester, resistant to moisture and UV | Boating, outdoor sports, staging | Pros: High durability, weather-resistant. Cons: Higher cost than standard options. |

| Heavy-Duty Shock Cord | Thicker diameter and stronger elastic core | Industrial applications, heavy cargo tie-downs | Pros: Superior strength, reliable for heavy use. Cons: May be overkill for lighter tasks. |

| Custom Shock Cord | Tailored lengths and colors available | Specialized applications, custom projects | Pros: Tailored solutions, ideal for unique needs. Cons: Longer lead times, potentially higher cost. |

| Reflective Shock Cord | Includes reflective materials for visibility | Night-time use, outdoor events | Pros: Enhanced safety, visibility in low light. Cons: Limited color options, may not suit all aesthetics. |

What Are the Key Characteristics of Standard Shock Cord?

Standard shock cord is characterized by its braided nylon sheath that encases a rubber core, offering flexibility and stretch. This type is commonly used for various applications such as clothing repairs and light-duty tie-downs. When purchasing standard shock cord, B2B buyers should consider factors such as the required length, diameter, and load capacity, as it may not be suitable for heavy-duty use.

How Does Marine-Grade Shock Cord Stand Out?

Marine-grade shock cord is designed for durability in harsh environments, featuring a Dacron polyester sheath that withstands moisture and UV exposure. It is ideal for applications in boating, outdoor sports, and staging setups. Buyers in sectors requiring high-performance materials should prioritize marine-grade shock cord for its reliability, even though it comes at a premium price compared to standard options.

What Makes Heavy-Duty Shock Cord a Reliable Choice?

Heavy-duty shock cord is distinguished by its thicker diameter and a robust elastic core, making it suitable for industrial applications and heavy cargo tie-downs. This type is essential for businesses that require dependable strength in demanding situations. When selecting heavy-duty shock cord, B2B buyers should assess the specific load requirements to ensure safety and performance.

Why Consider Custom Shock Cord Solutions?

Custom shock cord offers tailored solutions in terms of length, diameter, and color, making it a perfect fit for specialized applications or unique projects. This flexibility allows businesses to meet specific requirements efficiently. However, buyers should be prepared for potentially longer lead times and higher costs associated with custom orders.

What Are the Advantages of Reflective Shock Cord?

Reflective shock cord includes materials that enhance visibility in low-light conditions, making it suitable for nighttime use and outdoor events. This feature provides an added layer of safety for users. B2B buyers should consider the visibility benefits, but they may find limited color options, which could affect aesthetic alignment with their brand or project.

Key Industrial Applications of shock cord

| Industry/Sector | Specific Application of Shock Cord | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Marine and Boating | Securing gear and equipment on boats | Enhances safety and prevents loss of equipment at sea | Look for marine-grade materials that resist UV and saltwater corrosion. |

| Construction and Scaffolding | Temporary tie-downs for scaffolding and tarps | Provides reliable tensioning for safety and stability | Ensure compliance with safety standards and load-bearing requirements. |

| Outdoor Recreation | Replacement for tent poles and securing hammocks | Increases durability and reliability of camping gear | Consider elasticity and weather resistance, especially in varying climates. |

| Automotive | Custom bungee cords for securing loads in vehicles | Improves cargo security and reduces damage during transport | Evaluate the cord’s tensile strength and compatibility with vehicle applications. |

| Textiles and Apparel | Elastic components in clothing and gear | Enhances product functionality and user experience | Focus on stretchability and durability, particularly for high-wear items. |

In the marine and boating industry, shock cord is essential for securing gear and equipment on vessels. Its elasticity allows it to absorb shock and tension, which is crucial in preventing loss of equipment during rough waters. For international buyers, particularly those in coastal regions of Africa and South America, sourcing marine-grade shock cord that can withstand UV exposure and saltwater corrosion is vital for ensuring longevity and reliability in harsh maritime conditions.

In construction and scaffolding, shock cord is used for temporary tie-downs to secure scaffolding and tarps. This application enhances safety by providing reliable tensioning, which is critical for maintaining stability at heights. Buyers from Europe, especially Germany, should prioritize sourcing shock cord that meets local safety standards and can handle specific load-bearing requirements to ensure compliance and worker safety on construction sites.

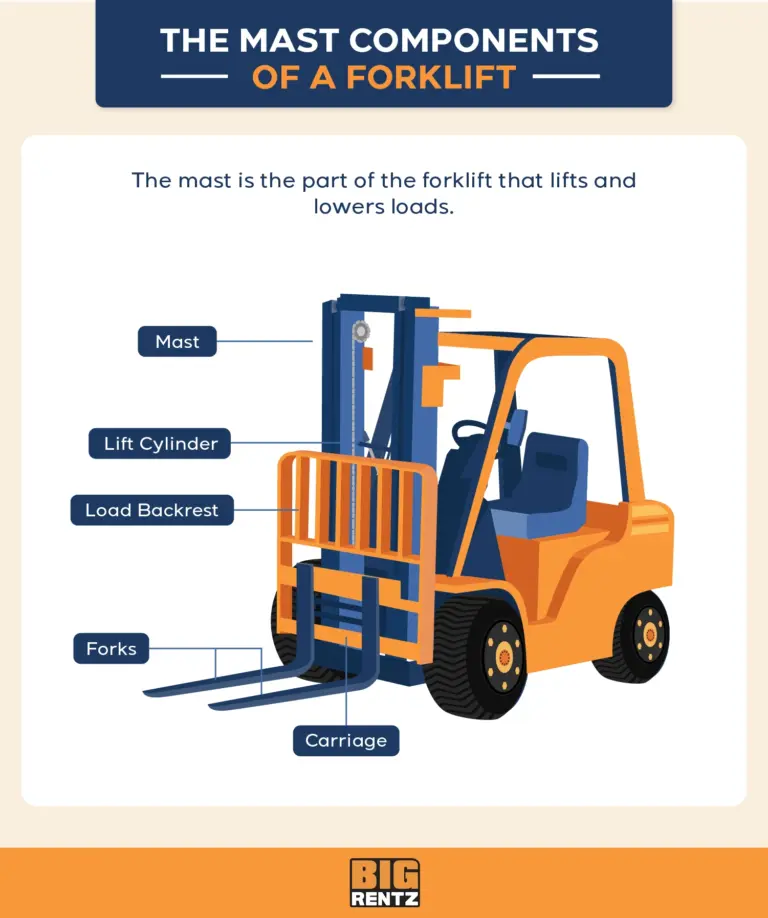

shock cord related image

For the outdoor recreation sector, shock cord serves as a replacement for tent poles and a means to secure hammocks. This application significantly increases the durability and reliability of camping gear, allowing for a better user experience during outdoor activities. Buyers in regions with diverse climates, such as the Middle East, must consider the elasticity and weather resistance of shock cord to ensure it performs well in extreme conditions.

In the automotive industry, shock cord is customarily used for creating bungee cords to secure loads in vehicles. This application improves cargo security, reducing the risk of damage during transport. International B2B buyers should evaluate the tensile strength of shock cords to ensure they can handle the specific demands of their vehicles, particularly in regions with rough terrain.

Lastly, in textiles and apparel, shock cord is incorporated into clothing and gear for added elasticity and comfort. This enhances product functionality, making items more user-friendly. Buyers, especially from Europe and the Middle East, should focus on sourcing shock cord that offers excellent stretchability and durability, particularly for high-wear items, to meet consumer expectations for quality and performance.

3 Common User Pain Points for ‘shock cord’ & Their Solutions

Scenario 1: Ensuring Durability in Harsh Environments

The Problem: B2B buyers, especially those in industries like marine, outdoor recreation, and logistics, often face challenges with shock cords that fail under extreme conditions. This can lead to equipment damage, safety hazards, and increased operational costs. For instance, a company using shock cords for securing cargo on shipping vessels may find their cords deteriorating due to saltwater exposure and UV radiation, resulting in frequent replacements and operational downtime.

The Solution: To address this issue, it’s essential to invest in marine-grade shock cords specifically designed to withstand harsh environments. Look for products made from Dacron polyester, which offers superior resistance to moisture and UV rays. When sourcing, request samples to test the elasticity and durability under your specific conditions. Ensure that the shock cords you choose are rated for the load and stretch requirements of your applications. Additionally, consider establishing a partnership with suppliers who can provide ongoing support and bulk pricing for high-quality shock cords, thus minimizing replacement frequency and costs.

Scenario 2: Customizing Shock Cord Applications for Diverse Needs

The Problem: Many B2B buyers struggle with the versatility of shock cords when trying to meet diverse operational needs. For instance, a manufacturer of outdoor gear may require shock cords that can be easily adapted for different products, such as tents, backpacks, and tarps. The challenge lies in finding a single type of shock cord that can effectively perform across these varied applications without compromising strength or durability.

The Solution: To overcome this challenge, buyers should focus on shock cords that offer customizable features. Opt for shock cords available in various diameters, lengths, and elasticity levels. This allows for easy customization to fit specific products. When sourcing shock cords, inquire about options for bulk purchasing in different specifications. Furthermore, consider suppliers who provide technical support to help you determine the best shock cord configuration for your unique product requirements. Using standardized shock cord components across different products can also streamline your supply chain and reduce inventory complexity.

Scenario 3: Managing Supply Chain Fluctuations and Quality Assurance

The Problem: Global supply chain disruptions can lead to inconsistent quality and availability of shock cords, which poses a significant risk for businesses relying on these materials for production or service delivery. For example, a logistics company may experience delays in securing shipments due to unreliable shock cord supplies, affecting their ability to maintain schedules and customer satisfaction.

The Solution: To mitigate supply chain risks, B2B buyers should establish relationships with multiple suppliers across different regions. This diversification ensures that if one supplier faces disruptions, alternatives are available. Additionally, implement a quality assurance program that includes rigorous testing of shock cords upon receipt. Look for suppliers that provide certification and traceability of their materials, ensuring that only high-quality products are used in your operations. Engage in regular communication with suppliers to stay informed about market trends and potential disruptions, allowing you to proactively manage your inventory levels and quality standards.

Strategic Material Selection Guide for shock cord

What Are the Key Materials Used in Shock Cord Production?

When selecting shock cord for industrial applications, understanding the materials involved is crucial. Different materials offer distinct properties that impact performance, durability, and suitability for various environments. Below is an analysis of four common materials used in shock cord manufacturing: nylon, polyester, rubber, and Dacron.

How Does Nylon Influence Shock Cord Performance?

Nylon is a popular choice for shock cord due to its excellent elasticity and strength. It boasts a high tensile strength, making it suitable for applications that require significant stretching without breaking. Nylon shock cords can typically withstand temperatures ranging from -40°F to 200°F, offering versatility in various climates.

Pros: Nylon shock cords are durable and resistant to abrasion, making them ideal for outdoor applications. They are also relatively lightweight, which is advantageous for portable gear.

Cons: However, nylon can absorb moisture, leading to potential degradation over time, especially in humid environments. Additionally, its UV resistance is moderate, which may limit its lifespan in prolonged sunlight exposure.

International Considerations: Buyers from regions with high humidity or UV exposure, such as Africa and the Middle East, should evaluate the longevity of nylon shock cords. Compliance with standards like ASTM D638 for tensile properties may also be relevant.

Why Choose Polyester for Shock Cord Applications?

Polyester shock cords are known for their strength and durability, particularly in outdoor and marine environments. They exhibit excellent resistance to UV rays and moisture, making them suitable for long-term exposure to harsh conditions.

Pros: The key advantage of polyester is its low stretch under load, which provides consistent performance. It is also resistant to mildew and rot, making it a reliable choice for marine applications.

Cons: On the downside, polyester shock cords can be less elastic than nylon, which may limit their use in applications requiring significant stretch. They are also typically more expensive than nylon options.

International Considerations: For buyers in Europe, adherence to EN 1492-1 standards for lifting slings may be necessary. The marine-grade polyester is particularly favored in coastal regions, such as parts of South America and the Middle East.

What Role Does Rubber Play in Shock Cord Design?

Rubber is the core material in many shock cords, providing the essential elasticity that defines their functionality. It offers excellent stretchability and recovery, making it ideal for applications requiring repeated tensioning.

Pros: Rubber shock cords can withstand a wide range of temperatures and maintain their elasticity over time. They are also resistant to many chemicals, enhancing their versatility.

Cons: However, rubber can degrade when exposed to UV light and ozone, which may limit its outdoor applications. Additionally, it is typically heavier than nylon or polyester, which could be a disadvantage in portable applications.

International Considerations: Buyers should consider the compliance with international standards such as ASTM D412 for rubber properties. Regions with high UV exposure should assess the suitability of rubber shock cords for long-term outdoor use.

How Does Dacron Enhance Shock Cord Durability?

Dacron, a type of polyester, is often used for shock cords due to its exceptional strength and resistance to environmental factors. It is particularly favored in marine applications due to its durability against saltwater and UV rays.

Pros: Dacron shock cords are non-absorbent, which prevents mold and mildew growth. They also maintain their elasticity over time, making them suitable for repeated use in demanding environments.

Cons: The primary limitation of Dacron is its higher cost compared to standard polyester, which may deter budget-conscious buyers. Additionally, it may not offer the same level of stretch as rubber-based shock cords.

International Considerations: Compliance with marine standards is crucial for buyers in coastal regions, particularly in the Middle East and South America. Understanding local regulations regarding marine-grade materials can influence purchasing decisions.

Summary Table of Shock Cord Materials

| Material | Typical Use Case for Shock Cord | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | Outdoor gear, tents, and backpacks | High tensile strength and elasticity | Moisture absorption may reduce lifespan | Medium |

| Polyester | Marine applications, outdoor use | Excellent UV and moisture resistance | Less elastic than nylon | Medium to High |

| Rubber | General-purpose elastic applications | Superior stretchability and recovery | UV degradation limits outdoor use | Low to Medium |

| Dacron | Marine environments, heavy-duty use | Exceptional durability and non-absorbent | Higher cost and limited stretch | High |

This analysis provides B2B buyers with critical insights into the properties and applications of various shock cord materials, enabling informed purchasing decisions tailored to specific operational needs and environmental conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for shock cord

What Are the Key Stages in the Manufacturing Process of Shock Cord?

The manufacturing process of shock cord involves several critical stages, each designed to ensure the final product meets the quality and performance standards required by diverse applications. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation:

The first stage involves sourcing high-quality raw materials. Typically, shock cords consist of a rubber core surrounded by a durable outer sheath made of nylon or polyester. Suppliers often utilize Dacron polyester for its resistance to UV light and moisture, making it suitable for marine applications. During this stage, materials are inspected for defects and consistency in quality. -

Forming:

The next stage is forming the rubber core. The rubber is extruded into the desired diameter and elasticity specifications. This process is crucial, as the performance characteristics of the shock cord, such as stretchability and resilience, depend heavily on the quality of the rubber used. Advanced manufacturing techniques, such as precision extrusion, ensure uniformity in the core. -

Assembly:

Once the core is formed, it is encased in the outer sheath. This is typically achieved through braiding or weaving techniques that provide additional strength and flexibility. The braiding process must be executed with precision to ensure that the sheath maintains its integrity during use. Additionally, if hooks or other attachments are required, they are integrated into this stage. -

Finishing:

The final stage involves cutting the shock cord to specified lengths, applying any additional treatments (such as waterproofing), and performing a thorough quality check. The finishing process also includes packaging, which is essential for protecting the product during shipping and storage.

How Is Quality Assurance Implemented in Shock Cord Manufacturing?

Quality assurance (QA) is a critical component in the production of shock cords, ensuring that products meet both international standards and customer specifications. Key elements of QA include adherence to relevant international standards, implementing quality control checkpoints, and employing various testing methods.

-

International Standards Compliance:

Many manufacturers adhere to ISO 9001 standards, which outline a framework for quality management systems. Compliance with these standards not only helps in maintaining product quality but also enhances customer trust. Additionally, industry-specific certifications, such as CE for European markets or API for certain technical applications, may also be applicable depending on the intended use of the shock cord. -

Quality Control Checkpoints:

Quality control is integrated at various stages of production through Inspection Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

– IQC involves inspecting raw materials before production begins to ensure they meet quality specifications.

– IPQC monitors the manufacturing process to identify and rectify any issues in real-time.

– FQC is conducted on the finished products to ensure they conform to all quality standards before shipment. -

Common Testing Methods:

Various testing methods are employed to assess the elasticity, tensile strength, and durability of shock cords. These may include:

– Tensile Testing: Measures how much force the shock cord can withstand before breaking.

– Fatigue Testing: Evaluates the shock cord’s performance over repeated stretching and contracting cycles.

– Environmental Testing: Assesses the cord’s resistance to UV exposure and moisture absorption, especially important for marine-grade products.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those operating in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential for ensuring product reliability.

-

Supplier Audits:

Conducting regular audits of potential suppliers can provide insights into their manufacturing processes and quality control systems. An audit should assess compliance with international standards, the effectiveness of their quality management systems, and their ability to meet delivery timelines. -

Quality Reports and Documentation:

Requesting detailed quality reports and documentation from suppliers can help buyers understand the quality measures in place. This documentation should include results from IQC, IPQC, and FQC, as well as any certifications obtained. -

Third-Party Inspections:

Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control measures. These inspectors can verify compliance with international standards and ensure that products meet specified requirements before shipment.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate several nuances when it comes to quality control in the shock cord manufacturing sector. Understanding these nuances can help mitigate risks associated with product quality.

-

Regional Standards Variability:

Different regions may have varying standards and regulations governing the quality of shock cords. For instance, European buyers may prioritize CE certification, while buyers in the Middle East may look for compliance with local regulations. Understanding these differences is crucial for ensuring compliance and avoiding potential legal issues. -

Cultural and Communication Challenges:

Cultural differences can impact communication regarding quality expectations. B2B buyers should establish clear lines of communication with suppliers and consider employing local representatives who understand the regional market dynamics and can bridge any communication gaps. -

Logistical Considerations:

The logistics of transporting shock cords internationally can affect their quality. Buyers should ensure that suppliers have robust packaging and shipping procedures in place to prevent damage during transit. Additionally, understanding the import regulations and quality inspections required in the buyer’s country is essential for a smooth transaction.

By comprehensively understanding the manufacturing processes and quality assurance mechanisms in place for shock cord production, B2B buyers can make informed decisions and foster successful partnerships with suppliers.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘shock cord’

Introduction

Navigating the procurement process for shock cord can be challenging, especially for B2B buyers operating in diverse global markets. This guide provides a structured checklist to help you source high-quality shock cord efficiently. By following these steps, you can ensure that you choose the right products and suppliers that meet your business needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications for the shock cord you require. Consider factors such as diameter, elasticity, tensile strength, and material composition (e.g., nylon, Dacron polyester). These specifications will guide your selection and help you communicate effectively with suppliers.

- Diameter and Length: Determine the required dimensions based on your intended application, whether for marine use, outdoor gear, or industrial applications.

- Material Quality: Assess whether you need marine-grade materials that can withstand harsh environments or lightweight options for simpler tasks.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in shock cord products. Look for companies with a strong track record in your industry and positive customer reviews.

- Supplier Directories: Utilize online platforms like Alibaba, ThomasNet, or industry-specific directories to find qualified suppliers.

- Network Recommendations: Leverage your professional network to gather insights and recommendations about reliable suppliers.

Step 3: Evaluate Supplier Certifications

Verifying supplier certifications is essential to ensure quality and compliance with industry standards. This step is particularly important if you are sourcing from international suppliers.

- ISO Certifications: Check if the supplier holds ISO certifications relevant to manufacturing quality.

- Material Safety: Ensure that the materials used comply with safety regulations applicable in your region or industry.

Step 4: Request Samples for Quality Assessment

Before placing a bulk order, request samples of the shock cord to evaluate its quality and performance. This step can save you from costly mistakes down the line.

- Testing Durability: Assess the stretch capacity, elasticity, and overall durability of the sample.

- Compatibility Check: Ensure that the shock cord meets your application requirements, such as fitting with existing hardware or systems.

Step 5: Negotiate Terms and Conditions

Once you have identified a suitable supplier and approved the sample, it’s time to negotiate terms and conditions. This includes pricing, payment terms, delivery schedules, and warranties.

- Bulk Pricing: Discuss bulk pricing options to ensure you receive competitive rates.

- Lead Times: Clarify production and delivery lead times to avoid disruptions in your supply chain.

Step 6: Review Shipping and Customs Considerations

When sourcing internationally, be aware of shipping logistics and customs regulations that may impact your order.

- Shipping Methods: Choose between air freight for speed or sea freight for cost-effectiveness, depending on your urgency.

- Customs Documentation: Ensure that all necessary customs documentation is prepared to prevent delays during importation.

Step 7: Establish a Long-Term Partnership

Consider the potential for a long-term partnership with your supplier. Building a reliable relationship can lead to better pricing, priority service, and improved product offerings over time.

- Regular Communication: Maintain open lines of communication to address any issues or changes in your requirements promptly.

- Feedback Mechanism: Provide feedback on product performance to help your supplier improve their offerings and service.

Following this practical sourcing checklist will empower you to make informed decisions and secure high-quality shock cord that meets your business needs.

Comprehensive Cost and Pricing Analysis for shock cord Sourcing

What Are the Key Cost Components in Shock Cord Manufacturing?

When considering shock cord sourcing, understanding the cost structure is crucial for effective budgeting and negotiation. The primary cost components include:

-

Materials: The core of shock cords typically consists of high-quality rubber, often encased in a durable nylon or polyester sheath. The choice of materials can significantly influence pricing, with marine-grade options commanding higher costs due to their enhanced durability and resistance to environmental factors.

-

Labor: Labor costs vary by region and the complexity of the manufacturing process. Countries with lower labor costs may offer competitive pricing but might compromise on quality. Skilled labor is essential for ensuring the proper assembly and quality control of shock cords.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and administrative expenses. Efficient manufacturing processes can help reduce overhead costs, impacting the final price.

-

Tooling: The initial investment in specialized tooling for producing various shock cord specifications can be substantial. This cost is often amortized over the production volume, making it critical for buyers to consider minimum order quantities (MOQs).

-

Quality Control (QC): Ensuring product quality through rigorous testing and inspection is vital, especially for applications that demand reliability. QC processes add to the overall cost but are essential for maintaining standards.

-

Logistics: Shipping costs can vary significantly based on the distance, weight, and mode of transport. For international buyers, understanding Incoterms is vital as they dictate the responsibilities of buyers and sellers in shipping arrangements.

-

Margin: Suppliers typically add a margin to cover costs and generate profit. This margin can vary widely based on market conditions, supplier reputation, and relationship dynamics.

How Do Price Influencers Impact Shock Cord Sourcing Decisions?

Several factors can influence the pricing of shock cords, making it essential for buyers to be aware of these variables:

-

Volume/MOQ: Bulk purchasing often leads to lower per-unit costs. Negotiating for larger quantities can result in significant savings, especially for consistent supply needs.

-

Specifications/Customization: Custom lengths, diameters, and material choices can drive costs up. Buyers should clearly define their requirements to avoid unexpected price hikes.

-

Material Quality and Certifications: Higher-quality materials or certifications (like ISO or marine-grade standards) typically come with a higher price tag. However, investing in quality can lead to lower total costs over time due to durability and reduced replacement frequency.

-

Supplier Factors: The supplier’s location, reputation, and production capacity can influence pricing. Established suppliers with robust quality assurance processes may charge more, but the reliability often justifies the expense.

-

Incoterms: Understanding the terms of shipping can significantly affect overall costs. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can shift financial responsibility and risk between the buyer and seller, impacting the final price.

What Are the Best Tips for Negotiating Shock Cord Prices?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to favorable outcomes:

-

Understand Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider logistics, potential tariffs, and long-term durability when evaluating costs.

-

Build Relationships: Establishing a rapport with suppliers can lead to better pricing and terms. Loyal partnerships often yield benefits in negotiations, including discounts and priority service.

-

Leverage Market Knowledge: Being informed about market prices and trends can empower buyers during negotiations. Utilize industry reports and competitor pricing to strengthen your position.

-

Consider Alternative Suppliers: Exploring multiple suppliers can help identify competitive pricing and better terms. However, ensure that quality standards are not compromised for cost savings.

-

Be Clear and Specific: When negotiating, clearly outline your needs and expectations. This clarity can prevent misunderstandings and help suppliers provide accurate quotes.

Conclusion

Understanding the comprehensive cost structure and price influencers in shock cord sourcing is paramount for international B2B buyers. By leveraging strategic negotiation techniques and being mindful of the total cost of ownership, buyers can secure favorable pricing while ensuring quality and reliability in their supply chains. Always consider the nuances specific to your region and industry to make informed sourcing decisions.

Alternatives Analysis: Comparing shock cord With Other Solutions

Exploring Alternatives to Shock Cord: A Comprehensive Comparison

In the realm of securing and fastening solutions, shock cord stands out for its versatility and elasticity. However, it is essential for B2B buyers to consider alternative solutions that may better suit specific applications or operational environments. This analysis compares shock cord with two viable alternatives: Webbing and Straps. Each option has distinct characteristics that can influence the decision-making process for international buyers.

| Comparison Aspect | Shock Cord | Webbing | Straps |

|---|---|---|---|

| Performance | Excellent elasticity and stretch | Strong tensile strength, low stretch | Good for heavy loads, adjustable |

| Cost | Moderate (varies by quality) | Generally lower cost | Varies widely based on material |

| Ease of Implementation | Easy to use and customize | Requires sewing or securing methods | Quick to deploy and adjust |

| Maintenance | Low maintenance, durable | Moderate; can fray over time | Low; replace when worn |

| Best Use Case | Securing lightweight items, DIY | Heavy-duty applications, outdoor gear | Cargo securing, automotive uses |

In-Depth Analysis of Alternatives

1. Webbing

Webbing is a flat, strong fabric designed to withstand heavy loads, making it a favored choice for applications requiring high tensile strength. Its durability and resistance to wear make it ideal for outdoor gear, such as harnesses and slings. However, webbing lacks the elasticity of shock cord, which may be a disadvantage when flexibility is required. Additionally, while webbing is generally more affordable, it often necessitates additional hardware (like buckles or loops) for securing items, which can complicate the setup process.

Pros:

– High strength-to-weight ratio.

– Cost-effective for large-scale applications.

– Versatile for various uses with different types of hardware.

Cons:

– Requires more complex setup than shock cord.

– Limited flexibility, unsuitable for applications needing stretch.

2. Straps

Straps, often made of nylon or polyester, are another alternative that excels in securing heavier loads. Adjustable and easy to use, straps can quickly adapt to different sizes, making them an excellent choice for cargo transport or securing items in vehicles. However, while they offer strength and adjustability, straps lack the inherent elasticity of shock cord, which may be necessary for certain applications like outdoor gear that require dynamic tension adjustments.

Pros:

– Quick to use and adjust.

– Strong and reliable for heavy-duty tasks.

– Ideal for automotive and cargo applications.

Cons:

– Less versatile for lightweight or dynamic applications.

– May require additional components for secure fastening.

Making the Right Choice for Your Needs

When considering which solution to implement, B2B buyers should assess their specific requirements, including the types of loads to be secured, the operational environment, and budget constraints. Shock cord is ideal for applications requiring elasticity and ease of use, such as securing lightweight items or DIY projects. In contrast, webbing and straps offer robust alternatives for heavy-duty needs but may necessitate more complex setups. Ultimately, understanding the unique advantages and limitations of each option will empower buyers to make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for shock cord

What Are the Key Technical Properties of Shock Cord?

Understanding the technical properties of shock cord is essential for B2B buyers to make informed purchasing decisions. Here are several critical specifications to consider:

-

Material Composition

Shock cord is typically made from a combination of a rubber core and a nylon or polyester sheath. The rubber provides elasticity, while the outer sheath adds durability and resistance to abrasion and environmental factors. For instance, marine-grade shock cord often uses Dacron polyester, which is designed to withstand moisture and UV exposure, making it suitable for outdoor applications. Selecting the right material ensures that the shock cord will perform effectively in specific environments. -

Diameter and Length Options

Shock cords come in various diameters, commonly ranging from 1/8 inch to 3/8 inch, and lengths that can extend from 10 feet to 1000 feet. The diameter affects the tensile strength and stretch capacity of the cord, while the length determines its usability in different applications, from securing lightweight items to heavy-duty tie-downs. Buyers should assess their specific requirements to choose the most appropriate size for their needs. -

Tensile Strength

This property refers to the maximum amount of tensile (pulling) stress that the shock cord can withstand before failing. It’s essential for applications where the cord will bear significant loads. For instance, a higher tensile strength is crucial for marine applications or heavy-duty use, ensuring safety and reliability. Buyers should inquire about the tensile strength ratings when sourcing shock cord for demanding environments. -

Elastic Recovery

Elastic recovery measures how well the shock cord returns to its original length after being stretched. This property is vital for maintaining consistent performance in applications like securing cargo or providing tension in tents. A cord with excellent elastic recovery will ensure that it remains functional over time, reducing the need for frequent replacements. -

UV and Weather Resistance

Especially for outdoor applications, the ability of shock cord to resist degradation from UV exposure and harsh weather conditions is critical. Marine-grade options often have enhanced properties to withstand saltwater and moisture. Understanding these characteristics can help buyers select cords that will not only last longer but also provide reliable performance in challenging conditions. -

Color Options and Customization

Many manufacturers offer shock cords in various colors, which can be important for branding or identifying specific applications. Customization options may also be available, allowing businesses to order shock cord tailored to their specific needs. This flexibility can enhance operational efficiency and safety in various environments.

What Are Common Trade Terms Related to Shock Cord?

Familiarity with industry jargon is crucial for effective communication and negotiation. Here are several common terms relevant to shock cord procurement:

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of shock cord, an OEM might supply shock cord components for various products, such as tents or outdoor gear, ensuring compatibility and quality. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to determine if they can meet the supplier’s requirements and whether it aligns with their purchasing needs, especially for bulk orders. -

RFQ (Request for Quotation)

An RFQ is a document that potential buyers send to suppliers to obtain price quotes for specific products or services. By issuing an RFQ for shock cord, buyers can compare pricing, material specifications, and delivery terms from different vendors, ensuring they make the best purchasing decision. -

Incoterms (International Commercial Terms)

These are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is crucial for B2B buyers to clarify shipping responsibilities, costs, and risks associated with transporting shock cord across borders. -

Lead Time

This term refers to the amount of time it takes from placing an order to receiving the product. Lead time can vary based on factors such as the supplier’s production capacity and the complexity of the order. Knowing the lead time helps buyers plan their inventory and production schedules effectively. -

Durability Ratings

Durability ratings indicate how well a shock cord can resist wear and tear over time. These ratings are vital for buyers looking for long-lasting solutions that can withstand specific environmental challenges, ensuring that their investment is protected.

Understanding these technical properties and trade terminology will empower B2B buyers to make informed decisions, ensuring they procure the right shock cord for their applications while optimizing costs and performance.

Navigating Market Dynamics and Sourcing Trends in the shock cord Sector

What Are the Current Market Dynamics and Key Trends in the Shock Cord Sector?

The global shock cord market is experiencing robust growth driven by increasing demand across various sectors, including outdoor recreation, automotive, and marine industries. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe (notably Germany and Saudi Arabia) seek reliable and versatile fastening solutions, the emphasis on high-quality, durable shock cords has intensified. Current trends indicate a shift toward heavy-duty marine-grade products, which are designed to withstand harsh environmental conditions, making them ideal for both land and nautical applications.

Emerging technologies are also influencing sourcing strategies. The incorporation of advanced materials such as Dacron polyester is gaining traction due to its durability and resistance to UV radiation and moisture. Additionally, there is a growing interest in customizable shock cord solutions, allowing businesses to tailor products to specific needs, such as color and diameter. International buyers are increasingly leveraging e-commerce platforms to streamline procurement processes, ensuring they can source products quickly and efficiently.

Furthermore, an emphasis on transparency in supply chains is reshaping market dynamics. Buyers are now more informed and demand accountability from suppliers regarding product origin and manufacturing practices. This trend highlights the importance of building strong relationships with manufacturers who can provide documentation and certifications to verify product quality and compliance with international standards.

How Are Sustainability and Ethical Sourcing Influencing the Shock Cord Industry?

Sustainability is becoming a pivotal concern in the shock cord sector, particularly for B2B buyers focused on minimizing environmental impact. The production of shock cords, traditionally reliant on synthetic materials, poses challenges regarding resource consumption and waste generation. As a result, there is a growing demand for eco-friendly alternatives, including shock cords made from recycled materials or natural fibers.

Ethical sourcing practices are equally important, as companies increasingly seek suppliers who adhere to fair labor practices and environmentally responsible manufacturing processes. Certifications such as OEKO-TEX and Global Recycle Standard are gaining importance, as they assure buyers that products meet stringent environmental and social criteria. This shift not only enhances brand reputation but also aligns with the values of consumers who prioritize sustainability.

In the context of sourcing, international buyers are encouraged to engage with manufacturers who demonstrate a commitment to sustainability. Establishing partnerships with suppliers that prioritize ethical practices can lead to long-term benefits, including improved product quality, reduced environmental footprint, and enhanced customer loyalty.

What Is the Evolution of the Shock Cord and Its Significance for B2B Buyers?

The shock cord has evolved significantly since its inception, originally designed for military applications and outdoor gear. Its versatile nature has led to widespread adoption in various industries, including automotive, marine, and recreational sectors. Historically, shock cords were primarily made from natural rubber, but advancements in materials science have introduced synthetic alternatives that offer improved elasticity and durability.

For B2B buyers, understanding the evolution of shock cords is crucial for making informed purchasing decisions. The shift from traditional materials to modern composites reflects advancements in technology and manufacturing processes that enhance product performance. This evolution underscores the importance of sourcing from reputable suppliers who can provide innovative solutions tailored to the specific needs of various applications, ensuring reliability and effectiveness in their use.

Frequently Asked Questions (FAQs) for B2B Buyers of shock cord

-

How do I select the right shock cord for my application?

Selecting the right shock cord involves assessing the specific requirements of your application, including load capacity, length, and environmental exposure. Consider the diameter and material of the cord; for instance, marine-grade shock cords are ideal for outdoor use due to their resistance to UV rays and moisture. Evaluate the tensile strength and elasticity needed for your project, whether it’s for securing cargo, repairing gear, or creating custom bungee systems. Consulting with suppliers about your intended use can also help you make an informed decision. -

What types of shock cord materials are available and their benefits?

Shock cords are typically made from materials like nylon, polyester, and rubber. Nylon shock cords are known for their strength and durability, making them suitable for heavy-duty applications. Polyester offers excellent UV resistance and is ideal for outdoor use, while rubber provides superior elasticity for applications requiring significant stretch. Understanding these materials’ properties will help you choose the best shock cord for your specific needs, whether it’s for marine applications, camping gear, or industrial uses. -

What are common applications for shock cord in B2B settings?

Shock cords are versatile and widely used in various B2B applications, including securing cargo in transportation, creating custom bungee systems, and providing tension in tents and outdoor gear. They are also employed in manufacturing processes for packaging and assembly lines. Understanding the various uses of shock cord can help businesses leverage its benefits for efficiency and cost-effectiveness in their operations. -

What is the typical minimum order quantity (MOQ) for shock cord?

Minimum order quantities (MOQs) for shock cord can vary significantly between suppliers and depend on the type of cord, customization, and intended application. Generally, MOQs can range from as low as 100 meters for standard products to several hundred meters for specialized or custom cords. It’s advisable to discuss your specific needs with suppliers to negotiate MOQs that align with your business requirements. -

How can I ensure quality assurance when sourcing shock cord?

To ensure quality assurance when sourcing shock cord, consider suppliers who provide certifications for their products, such as ISO or ASTM standards. Request samples to evaluate the material’s performance, elasticity, and durability. Additionally, inquire about the supplier’s manufacturing processes, quality control measures, and return policies. Establishing clear communication regarding your quality expectations can also help mitigate risks. -

What payment terms should I expect when purchasing shock cord internationally?

Payment terms for international purchases of shock cord may vary based on the supplier’s policies and your negotiation skills. Common terms include upfront payments, letters of credit, or payment upon delivery. It’s crucial to clarify these terms before finalizing any agreements, considering factors like currency exchange rates and transaction fees. Establishing a mutually agreeable payment structure can facilitate smoother transactions and build trust with your supplier. -

How do I vet suppliers when sourcing shock cord from different regions?

Vetting suppliers involves several steps: first, research their reputation through online reviews and industry referrals. Second, request references from other clients, particularly those in your region or industry. Third, assess their production capabilities and compliance with international standards. Finally, consider visiting their facilities if possible or utilizing third-party inspection services to ensure quality and reliability before placing large orders. -

What logistics considerations should I keep in mind when importing shock cord?

When importing shock cord, consider shipping options, lead times, and customs regulations specific to your country. Determine the best shipping method based on urgency and cost-effectiveness, and ensure that the supplier provides necessary documentation for customs clearance. Additionally, factor in any potential tariffs or duties that may apply to your order. Collaborating with a logistics partner experienced in international trade can help navigate these complexities efficiently.

Top 3 Shock Cord Manufacturers & Suppliers List

1. SGT Knots – Durable Marine Grade Shock Cord

Domain: sgtknots.com

Registered: 2010 (15 years)

Introduction: Durable Marine Grade Shock Cord – Heavy-Duty Bungee for Outdoors; Available Colors: Black, Brown, Emerald Green, Kelly Green, Maroon, Midnight Blue, Neon Green, Neon Orange, Neon Yellow, OD Green, Pink, Purple, Red, Royal Blue, Silver, Tan, White, Woodland Camo, Yellow; Available Sizes: 1/8″ x 10ft, 1/8″ x 25ft, 1/8″ x 50ft, 1/8″ x 100ft, 1/8″ x 500ft, 3/16″ x 10ft, 3/16″ x 25ft, 3/16″ x 50ft, 3/1…

2. TITAN Survival – Shock Cord

Domain: titansurvival.com

Registered: 2013 (12 years)

Introduction: Shock Cord – TITAN Survival

– Guaranteed for life

– Free shipping on all U.S. orders

– Elastic ShockCord with 100% stretch

– Tensile strength of ~100 LBS

– Ideal for creating bungee cords and securing or tethering items

– Available in 1000 foot spools

– Colors: Black, Coyote Brown, Olive-Drab

– Size: 1/8″

– Price: £87.00 GBP (originally £94.00 GBP)

3. Litesmith – Shock Cord

Domain: litesmith.com

Registered: 2014 (11 years)

Introduction: Shock Cord available in three sizes: 1/16 in. (1.6 mm), 5/64 in. (2 mm), and 3/32 in. (2.4 mm). Sold by the foot in one continuous piece. Maximum purchase of 100 units. Six color options: Neon Yellow, Neon Orange, Neon Green, Blue, Red, Black. Reflective options available. Weight per foot varies by diameter: 1/16 in. – 0.027 oz (0.77 g), 5/64 in. – 0.038 oz (1.07 g), 3/32 in. – 0.054 oz (1.53 g). …

Strategic Sourcing Conclusion and Outlook for shock cord

In today’s competitive global market, effective strategic sourcing of shock cord can significantly enhance operational efficiency and product quality. As industries across Africa, South America, the Middle East, and Europe increasingly rely on durable and versatile materials, understanding the various applications of shock cord—from outdoor gear to industrial uses—becomes paramount.

B2B buyers should prioritize sourcing from reputable manufacturers that offer marine-grade options, ensuring longevity and resilience against environmental challenges. By leveraging insights on specifications such as material composition, diameter, and elasticity, businesses can tailor their purchases to meet specific operational needs.

Looking ahead, the demand for high-quality shock cord is poised to grow, driven by trends in outdoor recreation, construction, and automotive sectors. International buyers are encouraged to establish strategic partnerships with suppliers who not only provide superior products but also offer customization options. This proactive approach will ensure that businesses remain competitive and responsive to market shifts.

Embrace the opportunity to enhance your supply chain today by exploring diverse sourcing options for shock cord, and secure a reliable foundation for your future projects.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.