A Deep Dive into Roton Continuous Hinge Solution

Introduction: Navigating the Global Market for roton continuous hinge

In the dynamic landscape of global trade, sourcing reliable solutions like Roton continuous hinges presents unique challenges for B2B buyers across diverse markets, including Africa, South America, the Middle East, and Europe. As businesses expand their operations and enhance infrastructure, the demand for durable and efficient door hardware is rising. Roton continuous hinges stand out due to their design, which distributes the weight of heavy doors evenly, significantly reducing wear and tear, and thus prolonging the lifespan of both the door and frame.

This comprehensive guide serves as an essential resource for international buyers seeking to navigate the complexities of purchasing Roton continuous hinges. It covers a variety of hinge types, including light, standard, and heavy-duty options, and delves into their specific applications across different sectors. Additionally, the guide provides critical insights into supplier vetting processes, pricing structures, and the latest innovations in hinge technology, ensuring that buyers can make informed decisions tailored to their operational needs.

By empowering B2B buyers with actionable knowledge and strategic insights, this guide is designed to facilitate successful sourcing decisions, ultimately leading to enhanced operational efficiency and project success. Whether you are in Saudi Arabia, Vietnam, or elsewhere, the information contained within will equip you with the tools needed to secure the best products for your specific requirements.

Understanding roton continuous hinge Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 500 Series – Light Duty | Designed for lighter doors; economical choice | Interior doors in commercial buildings | Pros: Cost-effective; easy installation. Cons: Limited load capacity; not suitable for heavy traffic. |

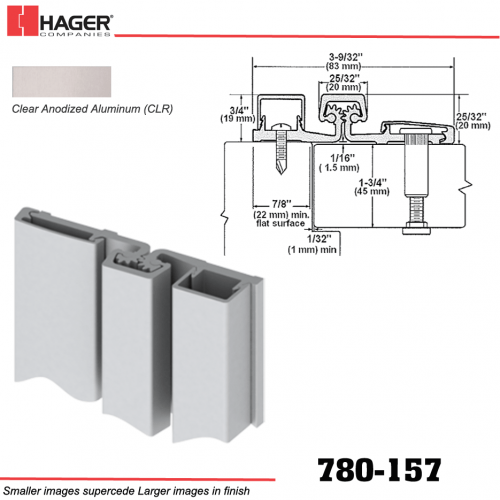

| 780 Series – Heavy Duty | Robust construction; accommodates heavy usage | High-traffic doors in schools and hospitals | Pros: Durable and reliable; minimizes wear. Cons: Higher initial cost; requires precise installation. |

| 1200 Series – Extra Heavy Duty | Maximum strength; ideal for extreme conditions | Industrial facilities and warehouses | Pros: Exceptional load-bearing; long lifespan. Cons: Heavier weight; may require custom fittings. |

| Concealed Leaf | Hidden hinge design; aesthetic appeal | Modern architectural designs | Pros: Enhanced aesthetics; reduces visible hardware. Cons: Potentially more expensive; installation complexity. |

| Electrified Roton Hinge | Integrated electrical components for access control | Security-sensitive environments | Pros: Facilitates electronic access; enhances security. Cons: Higher maintenance; requires electrical expertise. |

What are the Characteristics of the 500 Series – Light Duty Roton Continuous Hinge?

The 500 Series is designed for lighter doors, making it an economical choice for various interior applications. It is particularly suitable for commercial settings where doors experience minimal traffic. Buyers should consider its ease of installation and cost-effectiveness, though it is essential to note that its load capacity is limited, making it unsuitable for heavy-duty applications.

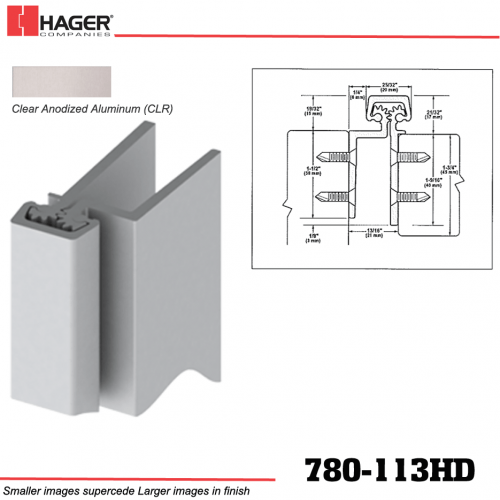

How Does the 780 Series – Heavy Duty Roton Continuous Hinge Stand Out?

The 780 Series is engineered for durability, accommodating heavy usage in high-traffic areas such as schools and hospitals. Its robust construction minimizes wear and tear, ensuring longevity. While it may come with a higher initial investment, the long-term reliability and reduced maintenance needs make it a worthwhile investment for businesses needing dependable door solutions.

Why Choose the 1200 Series – Extra Heavy Duty Roton Continuous Hinge?

The 1200 Series offers maximum strength, making it ideal for extreme conditions found in industrial settings and warehouses. This hinge can support significant weight, ensuring that even the heaviest doors function smoothly. Buyers should weigh the advantages of its exceptional load-bearing capabilities against the potential need for custom fittings and its heavier weight during installation.

What are the Benefits of the Concealed Leaf Roton Continuous Hinge?

The concealed leaf design of this hinge offers an aesthetically pleasing option for modern architectural projects. By hiding the hinge, it enhances the overall appearance of the door and frame. While it provides a sophisticated look, potential buyers should be aware of the higher costs and the installation complexity that may arise compared to traditional hinges.

When to Consider an Electrified Roton Hinge?

Electrified Roton hinges integrate electrical components, making them ideal for environments where access control and security are paramount. These hinges can facilitate electronic locking mechanisms, enhancing security measures. However, buyers should consider the increased maintenance requirements and the necessity for electrical expertise during installation, which can add to the overall project cost.

Key Industrial Applications of roton continuous hinge

| Industry/Sector | Specific Application of roton continuous hinge | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Healthcare | Door systems in hospitals and clinics | Enhanced durability and reduced maintenance costs | Compliance with health regulations and ease of cleaning required. |

| Educational Institutions | Classroom and laboratory doors | Improved safety and accessibility for high-traffic areas | Need for custom sizes and finishes to match institutional branding. |

| Commercial Construction | Entrances and exits in office buildings | Long-lasting performance in high-traffic environments | Availability of heavy-duty options for large doors and retrofit compatibility. |

| Retail | Storefront and interior doors | Aesthetic appeal and functionality for customer access | Requirement for varied finishes and styles to enhance store design. |

| Industrial Facilities | Access doors in warehouses and factories | Load distribution minimizes wear, extending door lifespan | Consideration for heavy-duty variants and potential electrification needs. |

How is Roton Continuous Hinge Used in Healthcare Settings?

In healthcare facilities, roton continuous hinges are crucial for door systems in hospitals and clinics. These hinges support heavy doors that experience frequent use, ensuring smooth operation and longevity. By evenly distributing the weight of the door, they minimize wear and tear, which is vital in environments that require strict hygiene standards. Buyers in this sector must ensure the hinges comply with health regulations and are easy to clean, as they play a significant role in maintaining sanitary conditions.

What Role Do Roton Continuous Hinges Play in Educational Institutions?

Educational institutions often utilize roton continuous hinges for classroom and laboratory doors. These hinges provide enhanced safety and accessibility, accommodating the movement of students and staff in busy environments. Their ability to withstand heavy use without compromising performance is essential in schools. Buyers should consider custom sizes and finishes to align with institutional branding while ensuring the hinges meet safety standards and facilitate easy operation.

How Are Roton Continuous Hinges Beneficial in Commercial Construction?

In commercial construction, roton continuous hinges are commonly installed on entrances and exits of office buildings. Their durability is a significant advantage, as they perform reliably in high-traffic areas, reducing the need for frequent replacements. These hinges help in load distribution, which is crucial for large doors. Buyers should look for heavy-duty options and ensure compatibility with existing frames for retrofit projects, as well as consider electrified variants for enhanced functionality.

Why Are Roton Continuous Hinges Important for Retail Spaces?

Retail environments benefit from roton continuous hinges on storefront and interior doors, where aesthetics and functionality are paramount. These hinges not only enhance the visual appeal of the entrance but also provide smooth operation for customer access. Retailers should prioritize varied finishes and styles to match their store design while ensuring that the hinges can withstand the rigors of constant use. Sourcing hinges that align with brand identity can significantly impact customer experience.

How Do Industrial Facilities Utilize Roton Continuous Hinges?

In industrial facilities, roton continuous hinges are essential for access doors in warehouses and factories. Their design allows for even load distribution, which minimizes wear and extends the lifespan of heavy doors subject to constant use. Buyers in this sector should consider heavy-duty variants and evaluate any electrification needs for automated doors. Ensuring that the hinges can handle the specific environmental conditions of the facility is critical for long-term performance.

3 Common User Pain Points for ‘roton continuous hinge’ & Their Solutions

Scenario 1: Weight Distribution Issues in Heavy-Duty Applications

The Problem: In high-traffic environments, such as hospitals or industrial facilities, doors experience significant wear due to their weight and frequent use. Traditional hinges may not adequately support heavy doors, leading to misalignment, excessive strain on the hinge, and potential damage to the door frame over time. Buyers often face challenges in selecting the right hinge that can withstand such conditions while ensuring smooth operation.

The Solution: To address weight distribution challenges, consider sourcing Roton continuous hinges specifically designed for heavy-duty applications. These hinges distribute the door’s weight evenly along the full length of the frame, minimizing stress on any single point. When selecting a hinge, opt for the 1200 Series of Roton continuous hinges, which are built for extra-heavy-duty use. Additionally, ensure that you consult with your supplier about the specific weight and usage conditions of your doors to get recommendations tailored to your needs. Proper installation is also crucial; engage a professional installer who understands the nuances of heavy-duty door applications to ensure optimal performance and longevity.

Scenario 2: Difficulty in Retrofitting Existing Door Frames

The Problem: Businesses often face the challenge of retrofitting existing door frames with modern hardware, including continuous hinges, without the need for extensive renovations. Retrofitting can be particularly difficult in older buildings where door frames may not accommodate standard hinge sizes, leading to gaps, misalignments, and operational inefficiencies.

The Solution: To effectively retrofit existing door frames, select Roton continuous hinges that offer flexible installation options, such as the 750 Series, which features concealed leaf designs. These hinges are designed to fit various door sizes and configurations, making them ideal for retrofitting projects. Before purchasing, take precise measurements of the existing door and frame to ensure compatibility. Moreover, consider consulting with a specialist who can provide advice on hinge sizes and installation techniques specific to your building’s architecture. This proactive approach will help prevent misalignment and ensure a seamless transition to modern hinge solutions.

Scenario 3: Electrical Integration Concerns for Automated Systems

The Problem: As businesses move towards automation, integrating electrical components with traditional hardware like hinges can present significant challenges. Buyers often struggle with finding continuous hinges that support electrification for door access systems, resulting in operational bottlenecks and increased costs.

The Solution: For facilities looking to integrate electrical systems, Roton continuous hinges that offer electrified options are essential. Specifically, the electric prep options available in the Roton series allow for seamless integration with electronic access controls. When sourcing these hinges, it’s vital to work closely with your supplier to understand the electrical specifications and compatibility with your existing systems. Additionally, enlist the help of a qualified electrician during installation to ensure that all components function correctly together, thus enhancing security and operational efficiency without compromising door functionality. By prioritizing these considerations, businesses can ensure that their automated systems operate smoothly and effectively.

Strategic Material Selection Guide for roton continuous hinge

What Are the Key Materials for Roton Continuous Hinges?

When selecting materials for Roton continuous hinges, it’s essential to consider the specific requirements of the application, such as durability, environmental conditions, and compliance with international standards. Below are analyses of four common materials used in the manufacturing of these hinges.

How Does Steel Perform as a Material for Roton Continuous Hinges?

Key Properties: Steel is known for its high tensile strength and durability. It typically has a temperature rating of up to 300°F (149°C) and can withstand significant pressure.

Pros & Cons: The primary advantage of steel is its robustness and long lifespan, making it suitable for heavy-duty applications. However, it is prone to corrosion unless treated with coatings or galvanization, which can increase manufacturing complexity and costs.

Impact on Application: Steel hinges are ideal for environments with high traffic and heavy doors, such as commercial buildings. However, in humid or coastal regions, corrosion-resistant options should be prioritized.

Considerations for International Buyers: Buyers in regions such as the Middle East and South America should ensure compliance with local standards like ASTM A36 for structural steel. The cost of steel can vary significantly based on local market conditions.

What Role Does Stainless Steel Play in Roton Continuous Hinges?

Key Properties: Stainless steel offers excellent corrosion resistance, making it suitable for various environments. It can handle temperatures up to 500°F (260°C) and is less likely to corrode or rust compared to carbon steel.

Pros & Cons: The key advantage of stainless steel is its durability and aesthetic appeal, making it suitable for visible applications. However, it is generally more expensive than carbon steel, which could be a limiting factor for budget-conscious projects.

Impact on Application: Stainless steel hinges are particularly effective in environments exposed to moisture, such as kitchens, hospitals, and coastal areas. They maintain their integrity and appearance over time, reducing maintenance costs.

Considerations for International Buyers: Compliance with standards like ASTM A240 for stainless steel grades is crucial. Buyers from Europe and Africa should consider the availability of specific grades, such as 304 or 316, based on local conditions.

Why Choose Aluminum for Roton Continuous Hinges?

Key Properties: Aluminum is lightweight and has a natural resistance to corrosion. It can withstand temperatures up to 400°F (204°C) and is often anodized for additional protection.

Pros & Cons: The lightweight nature of aluminum makes it ideal for applications where weight is a concern. However, it is less durable than steel and may not be suitable for heavy-duty applications.

Impact on Application: Aluminum hinges are often used in residential or light commercial settings where ease of installation is a priority. They are not recommended for high-traffic environments.

Considerations for International Buyers: Buyers should ensure that the aluminum meets standards like ASTM B221. In regions like Africa, where aluminum may be less common, sourcing can be a challenge.

How Does Plastic Compare as a Material for Roton Continuous Hinges?

Key Properties: Plastic hinges are lightweight, resistant to corrosion, and can handle temperatures up to 200°F (93°C).

Pros & Cons: The main advantage of plastic is its cost-effectiveness and low weight. However, plastic hinges have lower load-bearing capabilities and may not withstand heavy use.

Impact on Application: Plastic hinges are suitable for lightweight doors and applications where moisture is a concern, such as in outdoor settings.

Considerations for International Buyers: Buyers should verify compliance with local regulations regarding plastic materials, especially in regions with strict environmental policies.

Summary Table of Material Selection for Roton Continuous Hinges

| Material | Typical Use Case for roton continuous hinge | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty commercial doors | High strength and durability | Prone to corrosion | Medium |

| Stainless Steel | Moisture-prone environments (e.g., kitchens) | Excellent corrosion resistance | Higher cost compared to carbon steel | High |

| Aluminum | Residential or light commercial applications | Lightweight and easy to install | Less durable for heavy-duty use | Medium |

| Plastic | Lightweight doors in outdoor settings | Cost-effective and corrosion-resistant | Lower load-bearing capacity | Low |

This strategic material selection guide aims to assist international B2B buyers in making informed decisions regarding the most suitable materials for Roton continuous hinges based on their specific applications and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for roton continuous hinge

What Are the Key Stages in the Manufacturing Process of Roton Continuous Hinges?

Manufacturing Roton continuous hinges involves several critical stages designed to ensure high-quality performance and durability. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with sourcing high-grade materials, typically stainless steel or aluminum, known for their strength and resistance to corrosion. Suppliers must ensure that materials meet industry specifications and standards. This phase involves cutting the raw materials to the required dimensions and conducting initial quality checks to eliminate defects before progressing to forming.

-

Forming Techniques: In this stage, advanced machinery is employed to shape the hinges. Techniques such as CNC machining, stamping, and bending are utilized to achieve precise dimensions and design specifications. For instance, CNC machining allows for intricate designs and ensures uniformity across batches. Key considerations during this phase include maintaining tolerances and surface finishes that will affect both functionality and aesthetics.

-

Assembly Processes: Following forming, the various components of the hinge are assembled. This includes integrating gears and other moving parts that are essential for the hinge’s functionality. Precision during assembly is paramount to ensure that the hinge operates smoothly and withstands heavy usage. Automated assembly lines may be used to enhance efficiency and reduce human error.

-

Finishing Touches: The final stage involves applying protective coatings and finishes. This could include anodizing for aluminum hinges or powder coating for added durability and aesthetic appeal. The finishing process is essential as it not only enhances the appearance but also provides corrosion resistance, crucial for hinges used in diverse environments, including humid or coastal regions.

How Is Quality Assurance Implemented in the Manufacturing of Roton Continuous Hinges?

Quality assurance (QA) is an integral part of the manufacturing process for Roton continuous hinges, ensuring that products meet both international standards and customer expectations.

-

What International Standards Should B2B Buyers Be Aware Of?:

– ISO 9001: This standard is crucial for manufacturers aiming to demonstrate their ability to consistently provide products that meet customer and regulatory requirements. Adherence to ISO 9001 indicates a commitment to quality management systems.

– CE Marking: For products sold in the European market, CE marking is essential, indicating compliance with health, safety, and environmental protection standards.

– API Certification: For applications in specific industries, such as oil and gas, API certification may be necessary, ensuring that products meet rigorous industry standards. -

What Are the Key Quality Control Checkpoints?:

– Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet specified standards before they enter the production process.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify any deviations from quality standards. This may involve checking dimensions, surface finishes, and assembly integrity.

– Final Quality Control (FQC): Before shipment, hinges undergo rigorous testing to ensure they function correctly and meet all specifications. This may include load testing, cycle testing, and visual inspections. -

What Common Testing Methods Are Used?:

– Load Testing: To assess the hinge’s performance under weight, simulating real-world conditions.

– Cycle Testing: This tests the hinge’s durability by opening and closing it repeatedly to ensure it can withstand extensive use without failure.

– Corrosion Resistance Testing: Particularly important for hinges used in harsh environments, this testing evaluates how well the finish holds up against corrosive elements.

How Can B2B Buyers Verify Supplier Quality Assurance?

For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, ensuring that suppliers adhere to stringent quality assurance processes is vital. Here are actionable steps buyers can take:

-

Conduct Supplier Audits: Regular audits of manufacturing facilities can provide insights into the production processes, quality control measures, and compliance with international standards. Buyers should consider scheduling these audits as part of their procurement process.

-

Request Quality Reports and Certifications: Buyers should always request documentation demonstrating compliance with quality standards such as ISO 9001 and CE marking. These documents provide assurance of the supplier’s commitment to quality.

-

Engage Third-Party Inspection Services: Utilizing third-party inspection services can offer an unbiased assessment of the manufacturing processes and final products. These services can validate the claims made by suppliers regarding their quality assurance practices.

-

Understand QC and Certification Nuances for Different Regions: Buyers must be aware that quality standards can vary significantly by region. For example, while CE marking is essential in Europe, it may not be recognized in other markets. Engaging with local experts or consultants can help navigate these complexities effectively.

Conclusion

The manufacturing and quality assurance processes for Roton continuous hinges are designed to meet high-performance standards while ensuring durability and reliability. By understanding these processes and actively verifying supplier compliance with international standards, B2B buyers can make informed decisions, reducing the risk of product failure and enhancing their operational efficiency. This knowledge not only fosters better supplier relationships but also contributes to the overall success of projects involving continuous hinges in various applications across diverse markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘roton continuous hinge’

To assist B2B buyers in procuring Roton continuous hinges, this step-by-step checklist provides a structured approach to ensure informed decision-making. This guide focuses on critical aspects of sourcing these essential hardware components, particularly for high-traffic environments.

Step 1: Define Your Technical Specifications

Begin by establishing the specific requirements for your continuous hinges. Consider factors such as door weight, dimensions, and usage frequency. This step is crucial as it ensures that the hinges you choose can withstand the operational demands without compromising performance or safety.

- Door Type: Identify if the hinge will be for a standard door, bi-fold, or heavy-duty application.

- Material Requirements: Consider materials that offer durability and corrosion resistance, especially for environments with high humidity or exposure to chemicals.

Step 2: Research Supplier Credentials

Verify the credentials of potential suppliers to ensure reliability and quality. Look for certifications and industry standards that align with your project requirements.

- ISO Certification: Suppliers with ISO certifications typically adhere to international quality management standards.

- Customer Testimonials: Seek reviews or case studies from other buyers in your region or industry to gauge supplier performance.

Step 3: Evaluate Product Variants and Features

Examine the different series and models of Roton continuous hinges available. Each series may offer unique features tailored to specific applications.

- Weight Ratings: Understand the weight capacities of different hinge series (light, standard, heavy-duty, and extra heavy-duty) to match your needs.

- Electric Prep Options: For applications requiring electronic access control, ensure the hinges come with the necessary prep options.

Step 4: Request Samples for Testing

Before finalizing your order, it’s advisable to request samples of the hinges. Testing samples in real-world conditions can help you assess their functionality and durability.

- Installation Testing: Check how easily the hinges can be installed and whether they perform as expected under load.

- Operational Testing: Evaluate the hinge’s operation over time to ensure smooth functionality without wear.

Step 5: Understand Pricing and Payment Terms

Discuss pricing structures and payment terms with suppliers to ensure they align with your budget and financial processes.

- Bulk Discounts: Inquire about volume pricing if you plan to order in large quantities.

- Payment Flexibility: Look for suppliers who offer flexible payment terms, which can be beneficial for cash flow management.

Step 6: Confirm Delivery and Lead Times

Establish clear expectations regarding delivery schedules and lead times. This is vital for project planning and avoiding potential delays.

- Shipping Options: Discuss available shipping methods and costs, especially for international deliveries.

- Order Tracking: Ensure that the supplier provides tracking information for your order to monitor its progress.

Step 7: Review After-Sales Support and Warranty

Finally, assess the after-sales support offered by the supplier. A strong support system can be invaluable for addressing any issues that may arise post-purchase.

- Warranty Coverage: Understand the warranty terms for the hinges, including what it covers and the duration.

- Customer Support Availability: Check if the supplier offers readily available customer service for inquiries or troubleshooting.

By following this checklist, B2B buyers can effectively navigate the procurement process for Roton continuous hinges, ensuring they select the right products from reputable suppliers that meet their specific needs.

Comprehensive Cost and Pricing Analysis for roton continuous hinge Sourcing

What Are the Key Cost Components for Roton Continuous Hinges?

When sourcing Roton continuous hinges, understanding the cost structure is crucial for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly impacts the price. Stainless steel, aluminum, or specialized alloys will vary in cost based on availability and market demand. Heavy-duty options typically use higher-grade materials, resulting in increased prices.

-

Labor: Manufacturing labor costs can fluctuate based on geographic location. Regions with higher labor costs may lead to increased prices for hinges, while locations with lower labor rates can offer cost advantages.

-

Manufacturing Overhead: This encompasses expenses related to factory operations, such as utilities, rent, and administrative costs. Manufacturers with advanced machinery may have higher overhead but can produce hinges more efficiently.

-

Tooling: Custom tooling for specific hinge designs or sizes can add to the upfront costs. However, investing in quality tooling can improve production efficiency and product quality over time.

-

Quality Control (QC): Rigorous QC measures ensure that products meet specified standards. This includes testing for durability, load-bearing capabilities, and compliance with industry certifications, all of which can affect the final price.

-

Logistics: Shipping costs can vary significantly based on the distance, mode of transport, and the size of the order. Import duties and taxes also play a role in the total cost, especially for international buyers.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary widely based on competition, brand reputation, and market demand.

What Influences the Pricing of Roton Continuous Hinges?

Several factors can influence the pricing of Roton continuous hinges:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically benefit from economies of scale, resulting in lower per-unit prices. Suppliers may offer discounts for bulk purchases.

-

Specifications and Customization: Custom designs, finishes, or specific load capacities can increase costs. Buyers should consider whether standard options meet their needs to avoid unnecessary expenses.

-

Quality and Certifications: Products that meet specific industry standards or certifications may carry a premium price. However, investing in higher-quality hinges can lead to lower maintenance costs and longer lifespans.

-

Supplier Factors: The reputation and reliability of the supplier can also affect pricing. Established suppliers with a proven track record may charge more but offer greater assurance of product quality and service.

-

Incoterms: Understanding shipping terms (Incoterms) is vital, as they define the responsibilities of buyers and sellers. Costs can vary significantly depending on whether the buyer is responsible for shipping, insurance, and customs clearance.

How Can International B2B Buyers Optimize Their Costs?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, can leverage several strategies to optimize costs:

-

Negotiation: Engage suppliers in discussions about pricing, especially for larger orders. Establishing a good relationship may lead to better terms and conditions.

-

Cost-Efficiency: Consider the total cost of ownership (TCO) rather than just the initial purchase price. Assess how durability and maintenance requirements can impact overall costs over the product’s lifecycle.

-

Pricing Nuances: Be aware that international shipping can introduce delays and additional costs. Factor these into your purchasing decision. Understanding local market conditions can also provide leverage in negotiations.

-

Supplier Diversity: Explore multiple suppliers to compare prices and terms. This can provide insights into market rates and help identify the best options for your specific needs.

Disclaimer

Prices for Roton continuous hinges can vary significantly based on specifications, order volume, and supplier factors. The prices mentioned in various sources range widely, with some hinges priced between $138.00 to over $500.00, depending on the model and features. Always confirm current pricing directly with suppliers to ensure accuracy and avoid unexpected costs.

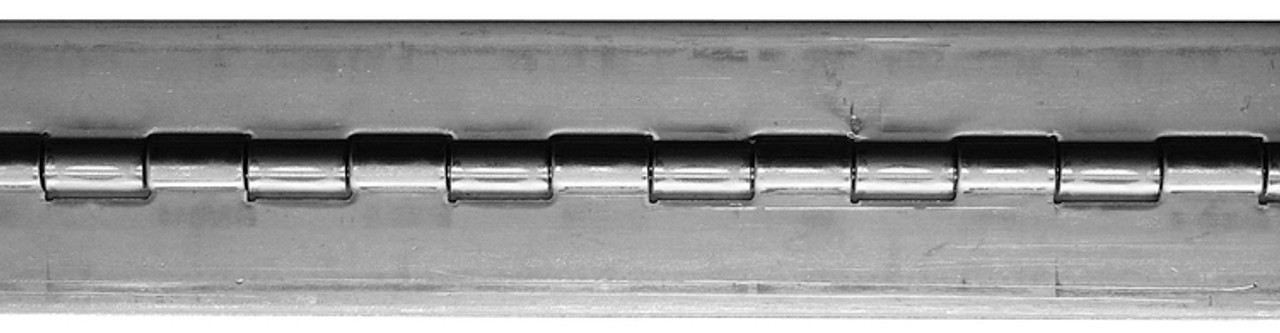

Illustrative image related to roton continuous hinge

Alternatives Analysis: Comparing roton continuous hinge With Other Solutions

Understanding Alternatives to Roton Continuous Hinges

When it comes to selecting the right hinge solution for commercial applications, buyers often encounter various options beyond the widely recognized Roton continuous hinge. This section explores alternative hinge solutions that can serve similar functions, helping B2B buyers make informed decisions based on their specific needs and operational environments.

| Comparison Aspect | Roton Continuous Hinge | Alternative 1: Standard Butt Hinges | Alternative 2: Pivot Hinges |

|---|---|---|---|

| Performance | Superior load distribution, ideal for heavy doors; minimizes wear over time | Good for lighter doors; uneven weight distribution can lead to wear | Excellent for space-saving designs; allows for smooth operation |

| Cost | Higher initial investment ($150-$500 depending on type) | Lower cost per unit ($20-$50) | Moderate cost ($50-$150) |

| Ease of Implementation | May require professional installation for optimal performance | Easy installation; can be DIY | Requires precise alignment; professional installation recommended |

| Maintenance | Low maintenance; durable and long-lasting | Moderate; may require periodic adjustments | Low to moderate; depends on usage intensity |

| Best Use Case | High-traffic areas, heavy doors in commercial settings | Residential or light commercial use | Spaces where door swing needs to be optimized, e.g., small rooms |

What Are the Advantages and Disadvantages of Standard Butt Hinges?

Standard butt hinges are a common alternative for many applications, particularly in residential settings or light commercial use. Their affordability and ease of installation make them attractive for budget-conscious projects. However, their performance can be limited when supporting heavy doors, as they typically distribute weight unevenly. Over time, this can lead to wear on the hinges and potential door misalignment. For environments with low foot traffic and lighter doors, standard butt hinges can be an adequate choice, but they may not hold up well in high-demand scenarios.

How Do Pivot Hinges Compare to Roton Continuous Hinges?

Pivot hinges offer a unique solution for door operation, allowing the door to pivot at a single point rather than along a traditional hinge line. This design can save space and create a sleek aesthetic, making them suitable for modern architectural designs. While pivot hinges can provide smooth operation, their installation can be more complex, requiring precise alignment and potentially professional assistance. They are best suited for environments where space is at a premium, but they may not provide the same load-bearing capacity as Roton continuous hinges, especially for heavy doors.

Illustrative image related to roton continuous hinge

Choosing the Right Hinge Solution for Your Needs

When evaluating hinge solutions, B2B buyers should consider their specific requirements, including door weight, frequency of use, and installation capabilities. While the Roton continuous hinge excels in high-traffic, heavy-duty applications, alternatives like standard butt hinges and pivot hinges can be viable options depending on the project’s context. Understanding the pros and cons of each solution will empower buyers to select the most appropriate hinge for their operational needs, ensuring durability and performance in their environments.

Essential Technical Properties and Trade Terminology for roton continuous hinge

What Are the Key Technical Properties of Roton Continuous Hinges?

When selecting Roton continuous hinges for commercial applications, understanding their technical specifications is crucial for ensuring durability, functionality, and suitability for specific projects. Here are some essential technical properties:

-

Material Grade

Roton continuous hinges are typically made from high-grade stainless steel, which offers resistance to corrosion and wear. The choice of material directly impacts the hinge’s longevity and performance, especially in environments exposed to moisture or chemicals. For B2B buyers, selecting the right material grade can mean the difference between frequent replacements and long-term reliability. -

Load Capacity

Each series of Roton continuous hinges is rated for specific load capacities, which determine the maximum weight they can support. Light-duty hinges may accommodate doors weighing up to 150 lbs, while heavy-duty variants can support doors exceeding 400 lbs. Understanding load capacity is essential for ensuring that the selected hinge meets the demands of the application, thus preventing premature failure. -

Tolerance Specifications

Tolerance levels indicate the acceptable range of deviation in hinge dimensions. This property is critical in ensuring that hinges fit perfectly with door and frame installations. A tighter tolerance may require more precise manufacturing processes but can result in smoother operation and enhanced performance, making it a key consideration for B2B buyers focused on quality and efficiency. -

Finish Options

Roton continuous hinges come with various finish options, such as brushed or polished stainless steel, which not only affect aesthetic appeal but also the hinge’s resistance to environmental factors. A suitable finish can enhance durability and minimize maintenance needs, making it an important factor for decision-makers who prioritize longevity and appearance. -

Installation Type

Roton hinges are available in different installation styles, including full surface, half surface, and concealed options. The installation type affects visibility and security, as concealed hinges provide a cleaner appearance and can be more difficult to tamper with. Understanding the implications of each installation type allows buyers to choose the best fit for their specific security and design needs. -

Electrification Options

Some Roton continuous hinges offer electrification options for access control systems. These features enable integration with electronic locking mechanisms, enhancing security in commercial settings. For buyers in industries where security is paramount, such as healthcare or government, electrified hinges can provide added functionality.

What Are Common Trade Terms Related to Roton Continuous Hinges?

Understanding industry jargon is essential for effective communication and negotiation in B2B transactions. Here are some common terms associated with Roton continuous hinges:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For buyers, knowing if the hinge is an OEM product can assure them of quality and compatibility with existing systems. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is crucial for budgeting and inventory planning, as it affects the total cost of procurement. Buyers should clarify MOQ requirements to avoid unexpected expenses. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing for specific products or services. For B2B buyers, issuing an RFQ can help compare costs and terms across multiple vendors, facilitating informed purchasing decisions. -

Incoterms (International Commercial Terms)

These terms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Understanding Incoterms is vital for buyers to manage risks and clarify who bears costs at different points in the supply chain. -

Lead Time

Lead time is the period between placing an order and receiving the goods. For B2B buyers, knowing the lead time is essential for project planning and ensuring timely delivery of products, particularly in construction or renovation projects. -

Warranty

A warranty is a guarantee from the manufacturer regarding the product’s performance and durability over a specified period. Understanding warranty terms can help buyers assess the reliability of the hinges and the level of support they can expect post-purchase.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that align with their project needs and operational requirements.

Navigating Market Dynamics and Sourcing Trends in the roton continuous hinge Sector

What Are the Key Drivers and Trends Impacting the Global Roton Continuous Hinge Market?

The global market for Roton continuous hinges is experiencing dynamic shifts driven by several key factors. Increased urbanization and infrastructure development across regions such as Africa, South America, the Middle East, and Europe are propelling demand for durable and efficient door hardware solutions. In high-traffic environments, the need for continuous hinges that can withstand wear and tear while providing consistent performance is becoming paramount. This trend is particularly relevant in sectors such as commercial construction, healthcare, and education, where heavy doors are commonplace.

Emerging technologies are also transforming the sourcing landscape. The integration of smart technology in continuous hinges, such as electrified options for door access control, is gaining traction. Buyers are increasingly looking for suppliers who offer innovative features, such as automatic closing mechanisms and biometric access integration, which can enhance security and operational efficiency.

Furthermore, the shift towards e-commerce platforms is altering the traditional procurement process, allowing international buyers to access a wider range of products and suppliers. This change is particularly beneficial for businesses in regions like Saudi Arabia and Vietnam, where digital procurement tools can streamline sourcing and reduce lead times. Buyers are advised to leverage these technologies to gain competitive advantages and ensure they are sourcing from reputable manufacturers who meet their quality standards.

How Is Sustainability Influencing Sourcing Decisions for Roton Continuous Hinges?

Sustainability and ethical sourcing are becoming increasingly important in the B2B landscape, especially for buyers concerned about environmental impacts. The production of Roton continuous hinges can involve significant material consumption and waste generation. As such, many manufacturers are adopting sustainable practices, such as using recycled materials and minimizing energy consumption during production.

Buyers are encouraged to seek out suppliers who have achieved ‘green’ certifications, as these can indicate a commitment to environmentally friendly practices. Certifications such as ISO 14001 or LEED compliance can provide assurance that a manufacturer prioritizes sustainability in their operations. Additionally, sourcing hinges made from sustainable materials—such as aluminum or recycled steel—can significantly reduce the carbon footprint of a project.

Illustrative image related to roton continuous hinge

Incorporating sustainability into sourcing strategies not only aligns with corporate social responsibility goals but can also appeal to a growing demographic of environmentally conscious consumers. As markets in Europe and the Middle East increasingly prioritize sustainability, businesses that adopt these practices may find themselves at a competitive advantage.

What Is the Historical Context Behind Roton Continuous Hinges?

The evolution of Roton continuous hinges can be traced back to the need for more robust and efficient door hardware solutions. Traditional hinges often suffered from uneven weight distribution, leading to premature wear and damage. In response, manufacturers developed continuous hinges that run the full length of the door, effectively distributing weight and minimizing stress on individual components.

Over the years, innovations in materials and manufacturing processes have enhanced the durability and functionality of these hinges. Today, they are available in a variety of configurations, including heavy-duty and electrified options, catering to diverse application needs. This historical progression reflects an ongoing commitment to improving performance and reliability, making Roton continuous hinges a preferred choice in modern construction and architectural design.

Frequently Asked Questions (FAQs) for B2B Buyers of roton continuous hinge

-

How do I choose the right Roton continuous hinge for my application?

Selecting the appropriate Roton continuous hinge involves assessing your specific needs. Consider factors like door weight, frequency of use, and environmental conditions. For high-traffic areas, opt for heavy-duty options, such as the 1200 Series, which can withstand significant wear. Additionally, evaluate whether you need concealed, full surface, or half surface designs based on aesthetic preferences and installation requirements. Collaborating with your supplier can also provide insights tailored to your operational context, ensuring optimal performance. -

What are the advantages of using Roton continuous hinges over traditional hinges?

Roton continuous hinges distribute the weight of the door evenly along their length, minimizing wear and tear on both the hinge and the door frame. This design enhances durability, making them ideal for heavy and frequently used doors. They also reduce maintenance costs over time due to their longevity. Furthermore, the innovative gearing mechanism decreases lateral wear, ensuring smoother operation and extending the lifespan of the hinge compared to traditional multi-hinge systems. -

What customization options are available for Roton continuous hinges?

Roton continuous hinges offer various customization options to meet specific project needs. Buyers can choose from different sizes, finishes, and load capacities, including light, standard, and heavy-duty models. Additionally, features such as electric prep options for electrified hinges can be specified. Discussing your requirements with suppliers will help identify suitable modifications, ensuring that the hinges align with design and functionality objectives. -

What is the minimum order quantity (MOQ) for Roton continuous hinges?

The minimum order quantity (MOQ) for Roton continuous hinges typically varies by supplier and region. For larger suppliers, MOQs can range from a few pieces to several dozen, depending on the specific hinge model and customization options. It’s advisable to check with your chosen distributor for exact MOQs, as they may offer flexibility for bulk purchases or special arrangements for larger projects. -

How do I vet suppliers for Roton continuous hinges?

Vetting suppliers involves a comprehensive evaluation of their credentials, product quality, and customer service. Start by researching their reputation in the industry through reviews and testimonials. Verify their certifications and compliance with international standards, particularly for markets in Africa, South America, the Middle East, and Europe. Request product samples to assess quality firsthand and inquire about their supply chain practices and lead times to ensure reliability. -

What payment terms should I expect when sourcing Roton continuous hinges?

Payment terms can vary significantly depending on the supplier and the nature of the transaction. Many suppliers offer options such as upfront payments, net 30/60 days, or letter of credit arrangements for larger orders. It’s essential to clarify these terms before finalizing your order. Additionally, consider discussing payment flexibility, especially if you are a first-time buyer or if your order volume is substantial. -

What quality assurance measures should I look for in Roton continuous hinges?

When sourcing Roton continuous hinges, inquire about the supplier’s quality assurance (QA) processes. Look for suppliers that adhere to international quality standards, such as ISO certifications, and have established protocols for testing their products. Ensure they provide documentation regarding material specifications and performance testing results. This information will help confirm that the hinges meet your operational requirements and industry standards. -

How can I manage logistics for importing Roton continuous hinges?

Effective logistics management involves coordinating shipping, customs clearance, and delivery timelines. Work closely with your supplier to establish a clear shipping plan, including Incoterms (e.g., FOB, CIF) to determine responsibilities. Consider partnering with a freight forwarder familiar with international shipping regulations to streamline the process. Be aware of potential tariffs and import duties in your region, and ensure proper documentation is in place to avoid delays at customs.

Top 4 Roton Continuous Hinge Manufacturers & Suppliers List

1. Hager – Roton® Continuous Geared Hinges

Domain: hagerco.com

Registered: 2001 (24 years)

Introduction: Hager’s Roton® continuous geared hinges provide superior performance in high-traffic areas. They feature unique gears to minimize lateral wear and evenly distribute door weight along the frame. Suitable for new construction and retrofit applications, they are available in various duty ratings: light, standard, heavy-duty, and extra heavy duty. Options include full surface, half surface, and concea…

2. Hager – Heavy Duty Roton Continuous Hinges

Domain: hagersupply.com

Registered: 2014 (11 years)

Introduction: Hager 780-041HD Roton Continuous Hinge Heavy Duty Concealed Leaf for 1-3/4 in. Thick Door Swing Clear Action Price: $406.61 to $539.68; Hager 780-054HD Roton Continuous Hinge Heavy Duty Half Surface Price: $345.58 to $425.02; Hager 780-057HD Roton Continuous Hinge Heavy Duty Full Surface for Bi-Fold Doors Price: $369.14 to $521.28; Hager 780-111 Roton Continuous Hinge Concealed Leaf Price: $183.34…

3. Qualified Hardware – Roton Continuous Hinges

Domain: qualifiedhardware.com

Registered: 2006 (19 years)

Introduction: Roton Continuous Hinges:

1. **Roton 780-053HD Heavy Duty Half Surface Continuous Hinge**

– Usage: Heavy Duty

– Price: Starting at $227.00

– Features: Low temperature and corrosion resistant.

2. **Roton 780-053 Standard Duty Half Surface Continuous Hinge**

– Usage: Standard Duty

– Price: Starting at $181.00

– Features: Frame leaf concealed between the rabbet of the f…

4. TM Hardware – Roton 780-124HD Continuous Hinge

Domain: tmhardware.com

Registered: 2011 (14 years)

Introduction: This company, TM Hardware – Roton 780-124HD Continuous Hinge, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for roton continuous hinge

The strategic sourcing of Roton continuous hinges offers significant advantages for B2B buyers across various industries, particularly in high-traffic environments. These hinges, designed to distribute weight evenly, enhance durability, and reduce maintenance costs, are ideal for both new construction and retrofit applications. By leveraging the different series available—ranging from light to extra heavy-duty—buyers can select the appropriate solution tailored to their specific needs and operational demands.

In a global marketplace, particularly in regions like Africa, South America, the Middle East, and Europe, investing in high-quality continuous hinges is vital for ensuring long-term performance and reliability. As industries evolve and adapt, the importance of sourcing durable, innovative hardware becomes increasingly clear.

Looking ahead, international buyers should prioritize partnerships with reputable suppliers who can provide not only high-quality products but also comprehensive support and expertise. By making informed sourcing decisions today, businesses can secure a competitive edge and enhance operational efficiency. Explore your options and connect with local distributors to find the perfect Roton continuous hinge solution for your projects.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.