A Deep Dive into Pvc Board 4X8 Solution

Introduction: Navigating the Global Market for pvc board 4×8

In today’s competitive landscape, sourcing high-quality PVC board 4×8 can present a significant challenge for international B2B buyers. This versatile material, known for its durability and resistance to moisture, is essential across various industries, including construction, signage, and interior design. However, navigating the complexities of global suppliers, varying material standards, and fluctuating costs can be daunting.

This comprehensive guide is designed to equip B2B buyers from Africa, South America, the Middle East, and Europe—specifically regions like Saudi Arabia and Germany—with the insights necessary to make informed purchasing decisions. We will explore different types of PVC boards, their applications, and the critical factors to consider when vetting suppliers. Additionally, we will delve into cost analysis, ensuring you understand pricing structures and potential hidden fees that may affect your bottom line.

By the end of this guide, you will have a clear roadmap for sourcing PVC board 4×8 that aligns with your project requirements, enabling you to leverage this material effectively for enhanced operational efficiency and product quality. Whether you are looking to enhance your product line or streamline your supply chain, this resource will empower you to navigate the global market confidently.

Understanding pvc board 4×8 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard PVC Board (1/2 in.) | Durable, moisture-resistant, versatile | Wall paneling, signage, and displays | Pros: Cost-effective, easy to work with. Cons: Limited thickness options. |

| Reversible PVC Panel | Smooth on one side, wood grain on the other | Interior and exterior trim, decorative elements | Pros: Aesthetic versatility, easy installation. Cons: May require special fasteners for certain applications. |

| Solid PVC Sheet (3/4 in.) | Thicker and sturdier, ideal for heavy-duty use | Structural applications, cabinetry, and furniture | Pros: Greater impact resistance, long-lasting. Cons: Higher cost compared to thinner options. |

| Lightweight PVC Board | Reduced weight for easier handling | Temporary structures, event setups | Pros: Easy to transport and install. Cons: Less durable for long-term applications. |

| Specialty PVC Board | Customizable finishes and colors available | Branding, custom signage, and artistic projects | Pros: Tailored solutions for unique projects. Cons: Longer lead times and potentially higher costs. |

What are the Characteristics of Standard PVC Board (1/2 in.)?

Standard PVC boards are widely recognized for their durability and moisture resistance, making them suitable for various applications including wall paneling and signage. With a thickness of 1/2 inch, they offer a balance between sturdiness and manageability, allowing for easy cutting and installation. B2B buyers should consider the cost-effectiveness of these boards, especially for large-scale projects, while noting that their limited thickness may restrict their use in some structural applications.

How Does the Reversible PVC Panel Differ from Other Options?

Reversible PVC panels feature a smooth side and a wood grain finish on the opposite side, providing aesthetic flexibility for both interior and exterior applications. These panels are often utilized in trim work and decorative elements, appealing to buyers looking for visually appealing solutions. The ease of installation is a significant advantage, though buyers should be aware that specific fasteners may be needed for optimal performance in outdoor settings.

Why Choose Solid PVC Sheets (3/4 in.) for Heavy-Duty Applications?

Solid PVC sheets, typically 3/4 inch thick, are designed for heavy-duty applications that require enhanced impact resistance and durability. These sheets are ideal for structural uses, cabinetry, and furniture, making them a preferred choice for commercial environments where longevity is critical. While they offer superior performance, the higher cost may be a consideration for budget-conscious buyers.

What Advantages Do Lightweight PVC Boards Offer?

Lightweight PVC boards are specifically designed for ease of handling and transportation, making them ideal for temporary structures and event setups. Their reduced weight facilitates quick installation and relocation, which can be advantageous for B2B buyers involved in dynamic projects. However, potential buyers should weigh the trade-off between ease of use and durability, as these boards may not withstand long-term exposure to harsh conditions.

How Can Specialty PVC Boards Enhance Unique Projects?

Specialty PVC boards allow for customizable finishes and colors, catering to businesses seeking tailored solutions for branding, signage, or artistic endeavors. These boards can significantly enhance the visual appeal of a project, making them an attractive option for creative applications. However, buyers should be prepared for longer lead times and potentially higher costs, as custom orders often require additional processing.

Key Industrial Applications of pvc board 4×8

| Industry/Sector | Specific Application of pvc board 4×8 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Architecture | Wall paneling and cladding in commercial buildings | Durable, moisture-resistant, and low maintenance solution | Ensure compliance with local building codes and standards |

| Signage & Advertising | Indoor and outdoor signage fabrication | Lightweight and weather-resistant, ideal for outdoor use | Verify color stability and UV resistance for longevity |

| Hospitality & Retail | Decorative interior finishes in hotels and stores | Enhances aesthetic appeal while providing durability | Look for customizable options and quick delivery times |

| Food Processing | Wall coverings in processing areas | Easy to clean and sanitize, maintaining hygiene standards | Confirm food safety compliance and resistance to chemicals |

| Marine & Outdoor | Boat interiors and outdoor furniture applications | Resistant to saltwater and UV rays, ensuring longevity | Consider weight and ease of installation for marine applications |

How is PVC Board 4×8 Used in Construction & Architecture?

In the construction and architecture sector, PVC board 4×8 is primarily utilized for wall paneling and cladding in commercial buildings. Its toughness and resistance to moisture make it an ideal material for both interior and exterior applications. International buyers, particularly from regions with high humidity or rainfall, such as parts of Africa and South America, will find that PVC boards help mitigate the risks of rot and decay associated with traditional materials. Compliance with local building codes is crucial, so sourcing from reputable manufacturers that can provide certifications is essential.

What Role Does PVC Board 4×8 Play in Signage & Advertising?

In the signage and advertising industry, PVC board 4×8 is favored for its lightweight yet durable characteristics, making it suitable for both indoor and outdoor signage. Its weather-resistant properties ensure that signs maintain their visual appeal even in harsh conditions, which is particularly important in sunny regions like the Middle East. B2B buyers should prioritize suppliers who offer UV-stable options to prevent fading and discoloration over time, ensuring that their branding remains vibrant and effective.

How is PVC Board 4×8 Beneficial for Hospitality & Retail?

Within the hospitality and retail sectors, PVC board 4×8 serves as a decorative finish for interiors, enhancing the aesthetic appeal of hotels and retail spaces. Its low maintenance requirements and resistance to wear make it a cost-effective choice for businesses looking to maintain a polished appearance. Buyers should consider sourcing options that allow for customization in design and color to align with their branding, as well as fast delivery times to meet project deadlines.

Why is PVC Board 4×8 Important in Food Processing?

In food processing facilities, PVC board 4×8 is used for wall coverings due to its ease of cleaning and sanitization, which is critical for maintaining hygiene standards. Its non-porous surface minimizes the risk of bacterial growth, making it suitable for environments where cleanliness is paramount. International buyers should ensure that the PVC boards meet food safety compliance standards and are resistant to various cleaning chemicals commonly used in the industry.

How is PVC Board 4×8 Utilized in Marine & Outdoor Applications?

For marine and outdoor applications, PVC board 4×8 is used in boat interiors and outdoor furniture due to its resistance to saltwater and UV rays. This durability ensures that products made from PVC can withstand the rigors of outdoor exposure without degrading over time. Buyers in coastal regions or those involved in marine construction should consider the weight of the material and its ease of installation, as these factors can significantly impact project efficiency and overall performance.

3 Common User Pain Points for ‘pvc board 4×8’ & Their Solutions

Scenario 1: Difficulty in Sourcing Quality PVC Boards for Specific Applications

The Problem:

B2B buyers often struggle to find high-quality PVC boards that meet specific project requirements. In regions such as Africa and the Middle East, where sourcing reliable materials can be challenging, companies may encounter issues with inconsistent product quality, leading to project delays and increased costs. Additionally, the absence of standardized specifications can result in miscommunication between suppliers and buyers, causing further complications in procurement.

The Solution:

To overcome these challenges, B2B buyers should establish clear specifications for the PVC boards they require, including thickness, color, and durability standards. Conducting thorough research on suppliers and leveraging online platforms that provide product reviews can help ensure the quality of the materials sourced. Additionally, forming partnerships with local distributors who understand the regional market can facilitate better communication and supply chain efficiency. Buyers should also request product samples before placing large orders, allowing them to assess the material’s quality firsthand and make informed purchasing decisions.

Scenario 2: Installation Challenges with PVC Board 4×8 Panels

The Problem:

Installation of PVC board panels can be a daunting task for contractors unfamiliar with the material’s properties. Many buyers face issues with cutting, fastening, and sealing the boards, leading to improper installations that compromise the integrity and aesthetics of the final product. This is particularly true in regions where skilled labor is scarce, and workers may not have the experience necessary to handle PVC materials effectively.

The Solution:

To address installation challenges, B2B buyers should invest in training sessions for their teams on how to work with PVC boards. Providing detailed installation guides that outline best practices can significantly reduce errors. It is also advisable to use standard woodworking tools, as PVC boards are designed to be user-friendly. Additionally, recommending the use of weather-resistant fasteners, such as stainless steel or hot-dipped galvanized screws, can enhance durability, particularly in outdoor applications. Collaborating with experienced contractors who specialize in PVC installations can also yield better results.

Scenario 3: Managing Cost Fluctuations and Budget Constraints

The Problem:

B2B buyers frequently encounter cost fluctuations in PVC board pricing, which can significantly impact project budgets. In regions like South America and Europe, where economic factors can cause sudden price changes, companies may struggle to maintain profitability. This unpredictability can lead to difficult decisions about project scopes or material quality, ultimately affecting project timelines and client satisfaction.

The Solution:

To manage cost fluctuations effectively, B2B buyers should adopt a proactive approach to procurement by establishing long-term contracts with suppliers. This strategy can lock in prices and reduce the impact of market volatility. Additionally, buyers should explore bulk purchasing options or cooperative buying groups, which can yield significant savings. Implementing a robust budgeting process that includes a contingency fund for unexpected costs can also provide financial flexibility. Finally, regularly reviewing supplier performance and market trends can equip buyers with the insights necessary to make timely and strategic purchasing decisions, ensuring projects remain on budget and on schedule.

Strategic Material Selection Guide for pvc board 4×8

When selecting materials for PVC boards measuring 4×8, it’s essential to consider various factors that influence their performance, cost, and suitability for specific applications. Below is an analysis of four common materials used in the production of PVC boards, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of PVC Boards?

1. Rigid PVC (Polyvinyl Chloride)

Rigid PVC is one of the most commonly used materials for PVC boards. It exhibits excellent durability, impact resistance, and a high degree of chemical stability. Rigid PVC boards can withstand temperatures ranging from -40°C to 60°C, making them suitable for various environmental conditions. They are also resistant to corrosion, making them ideal for applications in humid or chemically aggressive environments.

Pros:

– High durability and impact resistance.

– Excellent weather resistance, suitable for outdoor use.

– Low maintenance and easy to clean.

Cons:

– Can be more expensive than other materials.

– Limited flexibility, which may restrict certain applications.

Impact on Application:

Rigid PVC is commonly used in construction, signage, and furniture applications. Its resistance to moisture and chemicals makes it a preferred choice in environments where exposure to harsh conditions is expected.

Considerations for International Buyers:

Buyers from regions like Europe and the Middle East should ensure compliance with local standards such as DIN and ASTM. Additionally, understanding the local market for rigid PVC can help in assessing cost-effectiveness.

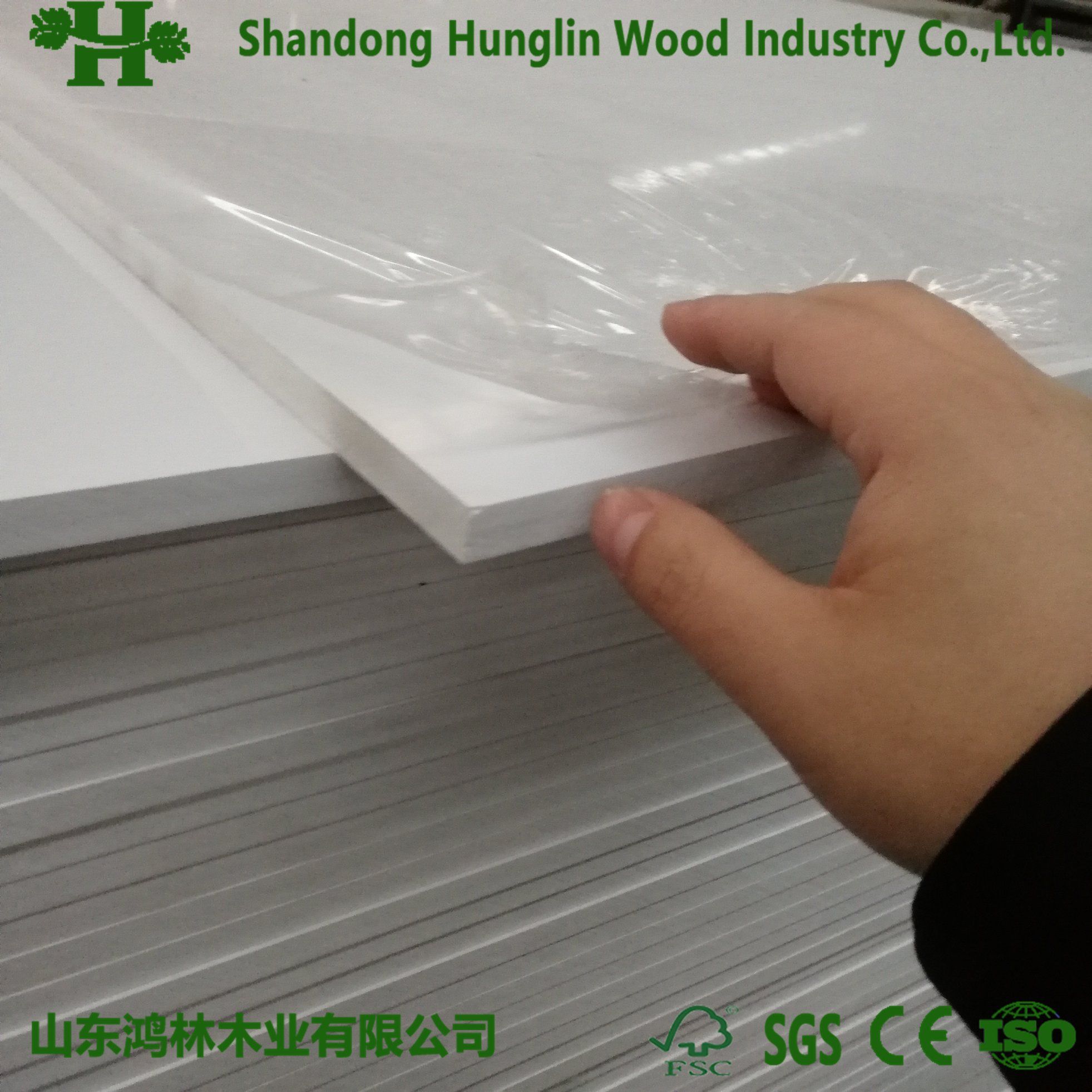

2. Foam PVC

Foam PVC boards are lightweight and versatile, making them ideal for a variety of applications. They are manufactured by expanding the PVC material, resulting in a board that is easy to handle and install. Foam PVC typically has a lower density than rigid PVC, which can be advantageous in specific applications.

Pros:

– Lightweight, making transportation and installation easier.

– Good insulation properties and sound absorption.

– Cost-effective for large-scale projects.

Cons:

– Less durable than rigid PVC, particularly in high-impact scenarios.

– Limited temperature resistance, typically up to 50°C.

Impact on Application:

Foam PVC is often used in interior applications such as wall cladding, displays, and signage. Its lightweight nature allows for easy installation in various settings.

Considerations for International Buyers:

Buyers should be aware of the varying standards for foam PVC in different regions, particularly in terms of fire safety and environmental regulations.

3. PVC Composite

PVC composite boards combine PVC with other materials, such as wood fibers or minerals, to enhance specific properties. These boards are designed to provide improved strength and stability, making them suitable for demanding applications.

Pros:

– Enhanced strength and durability compared to standard PVC.

– Better thermal stability, suitable for a wider range of temperatures.

– Aesthetic appeal due to the ability to mimic natural materials.

Cons:

– Higher manufacturing complexity, which can increase costs.

– May require specialized installation techniques.

Impact on Application:

PVC composite boards are often used in outdoor applications, such as decking and fencing, where durability and aesthetics are crucial.

Considerations for International Buyers:

Compliance with local building codes and environmental regulations is essential, especially in markets with stringent sustainability requirements.

4. Recycled PVC

Recycled PVC boards are made from post-consumer or post-industrial waste, offering an eco-friendly alternative to virgin PVC. They maintain many of the properties of traditional PVC while reducing environmental impact.

Pros:

– Environmentally friendly, reducing landfill waste.

– Cost-effective due to lower material costs.

– Retains many properties of standard PVC, including durability.

Cons:

– Potential variability in quality and performance.

– Limited availability in some regions.

Impact on Application:

Recycled PVC is suitable for various applications, including construction and landscaping, where sustainability is a priority.

Considerations for International Buyers:

Buyers should verify the sourcing and quality of recycled materials to ensure compliance with local regulations and standards.

Summary Table of Material Selection for PVC Board 4×8

| Material | Typical Use Case for pvc board 4×8 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Rigid PVC | Signage, construction, furniture | High durability and impact resistance | More expensive than other materials | Medium |

| Foam PVC | Interior cladding, displays | Lightweight and cost-effective | Less durable, limited temperature resistance | Low |

| PVC Composite | Decking, fencing | Enhanced strength and aesthetic appeal | Higher manufacturing complexity | High |

| Recycled PVC | Construction, landscaping | Environmentally friendly | Variability in quality | Medium |

This comprehensive analysis provides B2B buyers with actionable insights into the selection of materials for PVC boards, emphasizing the importance of understanding the specific requirements and standards relevant to their markets.

In-depth Look: Manufacturing Processes and Quality Assurance for pvc board 4×8

What Are the Main Stages of the Manufacturing Process for PVC Board 4×8?

The manufacturing process of PVC board 4×8 involves several critical stages that ensure the final product meets industry standards for durability, versatility, and performance. The primary stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves the selection of high-quality PVC resin as the primary raw material. The resin is combined with additives such as stabilizers, lubricants, and colorants to enhance its properties and performance. Precise measurements and thorough mixing are essential to ensure a uniform consistency that will affect the board’s strength and durability.

-

Forming: The mixed material is then subjected to a forming process. This typically involves extrusion, where the PVC mixture is heated and forced through a die to create a continuous sheet. The thickness and width can be adjusted to meet specifications, such as the 1/2 inch thickness and 4 ft width of the PVC board. During this stage, temperature and pressure control are critical to achieving the desired properties.

-

Assembly: Once the PVC sheets are formed, they may undergo additional processing, such as cutting to the required size (4 ft x 8 ft) and edge trimming. Depending on the manufacturer, some boards may be laminated or reinforced to enhance their structural integrity, particularly for applications requiring additional strength.

-

Finishing: The final stage involves surface treatments that may include polishing, coating, or printing. These treatments not only enhance the aesthetic appeal of the PVC boards but also improve their resistance to environmental factors such as moisture and UV light. A thorough inspection is performed during this stage to ensure that the boards are free from defects and meet quality standards.

How Is Quality Assurance Implemented in PVC Board Manufacturing?

Quality assurance (QA) is a vital component of the manufacturing process, ensuring that the final products meet both international and industry-specific standards. B2B buyers should be familiar with the various QA measures in place.

-

International Standards Compliance: Many manufacturers adhere to ISO 9001, an international standard that outlines requirements for a quality management system (QMS). Compliance with ISO 9001 indicates that the manufacturer maintains consistent quality in production, which is crucial for B2B buyers seeking reliable suppliers.

-

Industry-Specific Certifications: Depending on the application of the PVC boards, additional certifications may be relevant. For instance, CE marking is essential for products sold in the European Economic Area, indicating conformity with health, safety, and environmental protection standards. Other certifications may include API for products used in the oil and gas industry.

-

Quality Control Checkpoints: Quality control (QC) processes are implemented at various checkpoints during production:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified quality standards.

– In-Process Quality Control (IPQC): Continuous monitoring during manufacturing helps identify and rectify issues in real-time, reducing waste and improving efficiency.

– Final Quality Control (FQC): The finished products undergo a thorough inspection to ensure they meet dimensional, aesthetic, and performance specifications before being packaged and shipped.

What Common Testing Methods Are Used to Ensure Quality?

B2B buyers should be aware of common testing methods employed during the QC process to verify the performance and durability of PVC boards.

-

Mechanical Testing: This includes tensile strength tests, impact resistance tests, and flexural tests to assess the board’s physical properties. Such tests help ensure that the boards can withstand various stresses and environmental conditions.

-

Thermal Testing: Thermal stability tests evaluate how well the PVC boards maintain their properties under temperature fluctuations. This is crucial for applications in regions with extreme climates.

-

Chemical Resistance Testing: Since PVC boards may be used in environments where they are exposed to chemicals, testing their resistance to various substances is vital. This ensures the longevity and safety of the boards in their intended applications.

How Can B2B Buyers Verify Supplier Quality Control?

When sourcing PVC boards, particularly for international markets, B2B buyers should take steps to verify the quality control measures of their suppliers.

-

Supplier Audits: Conducting regular audits of the manufacturing facilities can provide insight into the processes and standards adhered to. This includes reviewing production records, quality management systems, and compliance with international standards.

-

Quality Assurance Reports: Requesting detailed quality assurance reports from suppliers can help buyers understand the QC processes in place, including results from testing and inspections.

-

Third-Party Inspections: Engaging third-party inspection agencies to evaluate the manufacturing processes and quality control measures can provide an unbiased assessment. This is particularly beneficial for buyers in regions where local regulations may differ significantly from international standards.

What Nuances Should International B2B Buyers Consider for Quality Control?

B2B buyers from diverse regions, such as Africa, South America, the Middle East, and Europe, should consider several nuances when evaluating quality control processes.

-

Cultural and Regulatory Differences: Understanding local manufacturing practices and regulatory requirements is crucial. Buyers should familiarize themselves with the specific certifications and standards required in their target markets, such as CE in Europe or local compliance regulations in African countries.

-

Logistical Considerations: The supply chain dynamics can influence quality control. Buyers should ensure that suppliers have robust logistics strategies in place to maintain product integrity during transportation, particularly for long-distance shipments.

-

Communication: Establishing clear communication channels with suppliers can help address any quality concerns promptly. B2B buyers should engage in regular discussions about quality expectations and any changes in manufacturing processes.

In summary, the manufacturing processes and quality assurance practices for PVC board 4×8 are multifaceted, requiring diligent attention to detail from material selection to final inspection. By understanding these processes and implementing thorough verification measures, B2B buyers can ensure they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pvc board 4×8’

When sourcing PVC board 4×8, an organized approach is essential for ensuring that you procure high-quality materials that meet your business requirements. This guide provides a comprehensive checklist to streamline your sourcing process, ensuring you make informed decisions that align with your operational needs.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the specifications for the PVC board you need. Consider factors such as thickness, color, and surface finish.

– Thickness Options: Common thicknesses include 1/2 inch and 3/4 inch, which impact durability and application suitability.

– Color and Finish: White is prevalent for aesthetic reasons, but you may require specific finishes depending on your application.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in PVC boards. This step is crucial for ensuring that you partner with reliable manufacturers.

– Industry Reputation: Look for suppliers with a solid track record in your region, particularly those with positive reviews from international buyers.

– Certifications: Verify that suppliers hold relevant certifications, such as ISO standards, which indicate adherence to quality management practices.

Step 3: Evaluate Product Quality

Assess the quality of the PVC boards offered by potential suppliers. Quality assurance directly affects the longevity and performance of your materials.

– Sample Requests: Always request samples to evaluate the material firsthand, checking for factors such as impact resistance and surface finish.

– Testing Standards: Inquire about the testing procedures employed by the supplier to ensure compliance with industry standards.

Step 4: Confirm Availability and Lead Times

Understanding product availability and lead times is essential for planning your procurement strategy effectively.

– Stock Levels: Ensure the supplier can meet your order volume and has sufficient stock to avoid delays.

– Production Lead Times: Discuss production schedules to align your project timelines with the supplier’s capabilities.

Step 5: Negotiate Pricing and Terms

Engage in discussions about pricing, payment terms, and delivery conditions. Effective negotiation can lead to better deals and long-term partnerships.

– Bulk Discounts: Inquire about discounts for larger orders, which can significantly reduce your overall costs.

– Payment Flexibility: Understand the payment options available, including credit terms that may help manage cash flow.

Step 6: Verify Logistics and Shipping Options

Logistics play a vital role in the procurement process, especially for international transactions.

– Shipping Methods: Discuss available shipping options and their associated costs, ensuring they align with your budget and timelines.

– Customs and Duties: Be aware of any import duties or customs regulations that may apply to your shipment to avoid unexpected expenses.

Step 7: Establish a Quality Control Process

After selecting a supplier, implement a quality control process to monitor the materials received.

– Inspection Protocols: Develop a checklist for inspecting the PVC boards upon arrival, ensuring they meet your specifications.

– Feedback Loop: Create a feedback mechanism for continuous improvement in product quality and supplier performance.

By following this checklist, you can ensure a systematic approach to sourcing PVC board 4×8, leading to informed decisions that bolster your business operations.

Comprehensive Cost and Pricing Analysis for pvc board 4×8 Sourcing

What are the Key Cost Components in PVC Board 4×8 Sourcing?

When sourcing PVC board 4×8, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The raw material cost is influenced by the type and quality of PVC used. Higher-quality or specialized PVC formulations may increase costs but offer enhanced durability and performance.

-

Labor: Labor costs will vary based on the region of production and local wage standards. Countries with lower labor costs can provide a competitive edge in pricing.

-

Manufacturing Overhead: This includes costs associated with facilities, utilities, and administrative expenses. Efficient manufacturing processes can reduce overhead, allowing for more competitive pricing.

-

Tooling: The cost of tools and machinery necessary for production can be significant, especially for custom orders. Investment in advanced tooling can lead to better quality and efficiency.

-

Quality Control (QC): Implementing stringent QC measures ensures that the product meets specified standards, but it also adds to the overall cost. Buyers should consider the value of quality assurance when evaluating suppliers.

-

Logistics: Shipping costs can vary greatly depending on the shipping method, distance, and any customs duties applicable in the destination country. Understanding the logistics landscape can help in forecasting total costs.

-

Margin: Suppliers will factor in their profit margins, which can differ based on their operational model and market position.

How Do Price Influencers Affect PVC Board 4×8 Pricing?

Several factors can influence the pricing of PVC boards, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often attract discounts, as suppliers are willing to reduce prices for bulk purchases. Understanding MOQ policies can help negotiate better terms.

-

Specifications and Customization: Custom specifications can significantly impact pricing. Standard sizes and materials are typically less expensive than custom solutions, so buyers should evaluate their needs carefully.

-

Quality and Certifications: Products that meet specific quality standards or have relevant certifications may come at a premium. Certifications can assure buyers of quality but also increase costs.

-

Supplier Factors: The reliability and reputation of the supplier can affect pricing. Established suppliers may charge higher prices due to their brand value and track record of quality.

-

Incoterms: The chosen Incoterms (International Commercial Terms) can influence total costs by determining who is responsible for various logistics costs, such as shipping and insurance.

What Are Effective Buyer Tips for PVC Board 4×8 Sourcing?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, here are some actionable tips:

-

Negotiate Wisely: Always approach negotiations with a clear understanding of your budget and the market rates. Be prepared to discuss volume discounts and long-term partnerships for better pricing.

-

Focus on Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes purchase price, shipping, installation, and maintenance costs. Sometimes, a higher upfront cost may result in long-term savings.

-

Understand Pricing Nuances: Be aware of seasonal fluctuations in pricing and demand. For instance, prices may rise during peak construction seasons or due to global supply chain disruptions.

-

Research Local Market Conditions: Different regions may have unique pricing structures due to local demand, tariffs, and import regulations. Understanding these nuances can provide leverage in negotiations.

Disclaimer on Indicative Prices

Prices for PVC board 4×8 can vary significantly based on the factors mentioned above. While indicative pricing may be available from various suppliers, it is crucial to obtain tailored quotes to reflect your specific requirements and conditions. Always perform due diligence to ensure that pricing aligns with your project’s needs and market realities.

Alternatives Analysis: Comparing pvc board 4×8 With Other Solutions

When considering materials for construction or manufacturing projects, it’s essential for B2B buyers to evaluate various alternatives to find the best fit for their specific applications. The PVC board 4×8 is a popular choice due to its durability and versatility, but there are other viable options worth exploring. This analysis compares PVC board 4×8 with two alternatives: Medium Density Fiberboard (MDF) and Plywood.

| Comparison Aspect | PVC Board 4×8 | Medium Density Fiberboard (MDF) | Plywood |

|---|---|---|---|

| Performance | High impact resistance, moisture-proof | Good for indoor use, less durable | Strong, but susceptible to moisture |

| Cost | Moderate (e.g., $77.83 per sheet) | Lower (e.g., $30-$50 per sheet) | Variable (e.g., $33-$100 per sheet) |

| Ease of Implementation | Easy to cut and install with standard tools | Easy to work with, but requires sealing | Requires special tools for cutting |

| Maintenance | Low maintenance, resistant to rot and insects | Moderate, prone to swelling if exposed | Moderate, needs sealing against moisture |

| Best Use Case | Outdoor and high-moisture environments | Indoor furniture and cabinetry | Structural applications, flooring, and furniture |

What are the Advantages and Disadvantages of Medium Density Fiberboard (MDF)?

MDF is a manufactured wood product made from wood fibers combined with adhesive. Its smooth surface makes it ideal for painting and veneering, which is advantageous for interior applications. However, while it is cost-effective and easy to work with, MDF is not suitable for outdoor use due to its susceptibility to moisture, which can lead to swelling and degradation. This makes MDF a better choice for indoor furniture and cabinetry, where aesthetics are prioritized over durability.

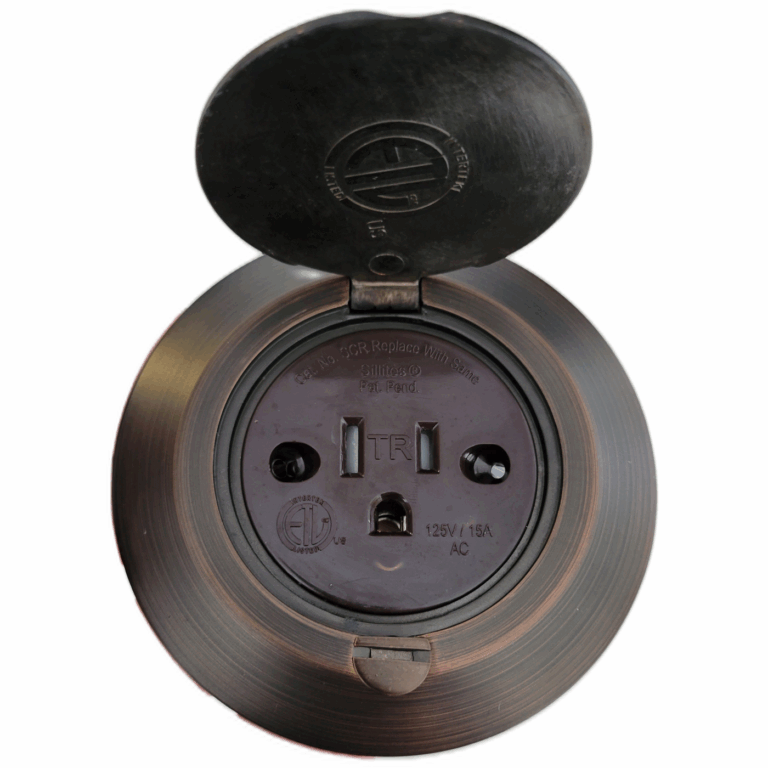

Illustrative image related to pvc board 4×8

How Does Plywood Compare to PVC Board 4×8?

Plywood consists of thin layers of wood veneer glued together, offering great strength and structural integrity. It is widely used in construction and furniture making. Plywood is versatile and can be used for both indoor and outdoor applications, depending on the grade. However, it requires careful sealing and maintenance to prevent moisture damage, especially in high-humidity environments. While plywood can be less expensive than PVC board initially, the long-term maintenance and potential for rot can make it a less favorable option for projects requiring durability.

Conclusion: How Can B2B Buyers Choose the Right Solution for Their Needs?

When selecting a material for construction or manufacturing projects, B2B buyers should weigh the specific requirements of their application against the characteristics of each alternative. PVC board 4×8 excels in environments where moisture resistance and durability are critical, making it ideal for outdoor applications. In contrast, MDF is a cost-effective solution for indoor projects, while plywood provides a strong, versatile option for structural needs. By understanding the performance, cost implications, and maintenance requirements of each alternative, buyers can make informed decisions that align with their project goals and budget constraints.

Essential Technical Properties and Trade Terminology for pvc board 4×8

What Are the Key Technical Properties of PVC Board 4×8?

When sourcing PVC board 4×8 for various applications, understanding its technical specifications is crucial for making informed purchasing decisions. Here are some essential properties to consider:

-

Material Grade: PVC boards are typically categorized by their material grade, which indicates their quality and suitability for specific applications. Higher grades offer better impact resistance and durability. For instance, high-density PVC boards are preferred for outdoor uses due to their resistance to weathering, while lower grades might suffice for indoor applications.

-

Thickness: The thickness of PVC boards, such as the standard 1/2 inch (12 mm), affects their rigidity and load-bearing capacity. Thicker boards are generally more robust and can withstand greater physical stress, making them ideal for structural applications. Buyers should assess the thickness required based on the intended use, whether for wall paneling, cabinetry, or outdoor signage.

-

Surface Finish: The surface finish of PVC boards can vary, typically ranging from smooth to textured. A smooth finish is often preferred for applications requiring easy cleaning and aesthetic appeal, while textured surfaces can provide better grip and are used in environments where slip resistance is necessary.

-

Moisture Resistance: One of the standout features of PVC boards is their inherent moisture resistance, making them suitable for humid environments. This property reduces the risk of rot and mold, ensuring longevity. B2B buyers in regions with high humidity, such as parts of Africa and South America, should prioritize this characteristic to ensure product durability.

-

Impact Resistance: PVC boards are known for their toughness and impact resistance. This property is essential for applications in high-traffic areas or where physical impacts are likely. Understanding the impact resistance can help buyers select the right type of board for applications ranging from construction to decorative use.

-

Weight: The weight of PVC boards can influence shipping costs and handling during installation. A lighter board may reduce transportation expenses but must still meet the required strength and durability standards for the intended application.

What Are Common Trade Terms Related to PVC Board 4×8?

Familiarity with industry jargon can streamline communication and negotiation processes. Here are several key terms relevant to purchasing PVC board 4×8:

-

OEM (Original Equipment Manufacturer): This term refers to companies that manufacture products that are sold under another company’s brand. In the context of PVC boards, buyers may source materials from OEMs who provide custom specifications to meet specific project requirements.

-

MOQ (Minimum Order Quantity): MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is vital for B2B buyers to ensure they can meet their project needs without overcommitting resources or inventory.

-

RFQ (Request for Quotation): An RFQ is a formal document issued by a buyer to solicit pricing and terms from suppliers. This process is crucial for B2B transactions, allowing buyers to compare offers and negotiate better terms based on their project’s needs.

-

Incoterms (International Commercial Terms): These are standardized terms used in international trade to define the responsibilities of buyers and sellers. Understanding Incoterms helps B2B buyers clarify shipping responsibilities, risk transfer, and cost allocation, which is especially important when sourcing materials across borders.

-

Lead Time: Lead time refers to the period between placing an order and receiving the product. For B2B buyers, understanding lead times is essential for project planning and ensuring timely delivery of materials.

-

Certification: Certification indicates that a product meets specific industry standards or regulations. For PVC boards, certifications related to fire resistance, environmental impact, and durability can enhance buyer confidence and ensure compliance with local regulations.

By grasping these properties and terms, B2B buyers can enhance their procurement strategies, ensuring they select the right PVC board for their specific needs while navigating the complexities of international trade.

Navigating Market Dynamics and Sourcing Trends in the pvc board 4×8 Sector

What Are the Key Market Trends Driving the PVC Board 4×8 Sector?

The PVC board 4×8 market is experiencing significant growth, driven by various global factors. The increasing demand for lightweight, durable, and moisture-resistant materials in construction and manufacturing sectors is a primary driver. Emerging economies in Africa and South America are witnessing rapid urbanization, leading to a heightened need for sustainable building materials. In contrast, markets in Europe and the Middle East are focusing on high-quality finishes and aesthetic appeal, which PVC boards readily provide due to their versatility.

Illustrative image related to pvc board 4×8

Technological advancements are also reshaping sourcing trends. Digital platforms are streamlining procurement processes, enabling buyers to access a broader range of suppliers and products. Online marketplaces are increasingly popular, allowing B2B buyers to compare prices, specifications, and certifications efficiently. Additionally, the rise of Industry 4.0 is influencing supply chains, with smart technologies enhancing transparency and traceability in sourcing. This trend is particularly important for international buyers seeking reliable partnerships and quality assurance.

How Is Sustainability Influencing Sourcing Decisions for PVC Board 4×8?

Sustainability has become a cornerstone of sourcing decisions in the PVC board sector. As environmental concerns mount, buyers are prioritizing suppliers that demonstrate a commitment to ethical sourcing practices. The production of PVC boards can have environmental impacts, particularly in terms of energy consumption and waste generation. Therefore, companies are increasingly seeking suppliers that utilize recycled materials or implement energy-efficient production methods.

Certifications such as ISO 14001 for environmental management and the Green Seal certification are becoming critical in the decision-making process. These certifications not only indicate a supplier’s commitment to sustainability but also enhance their credibility in the marketplace. For international buyers, particularly in Europe and the Middle East, aligning with suppliers who adhere to stringent environmental standards can also provide a competitive advantage, as these markets increasingly favor eco-friendly products.

What Is the Historical Context of PVC Board Development?

The evolution of PVC boards dates back to the mid-20th century, when polyvinyl chloride was first commercially produced. Initially used primarily in plumbing and electrical applications, the material’s versatility soon led to its adoption in various other sectors, including construction and furniture manufacturing. The introduction of the 4×8 size standard made it easier for builders and contractors to use PVC boards in a wide range of applications, from wall paneling to cabinetry.

Over the decades, advancements in manufacturing technologies have improved the durability and aesthetic qualities of PVC boards, making them a popular alternative to traditional materials like wood and metal. Today, PVC boards are recognized for their resistance to moisture, rot, and insects, making them ideal for both interior and exterior applications. As the demand for sustainable and low-maintenance building materials continues to rise, the PVC board sector is poised for further growth, adapting to the evolving needs of the global market.

Frequently Asked Questions (FAQs) for B2B Buyers of pvc board 4×8

-

How do I ensure the quality of PVC board 4×8 before purchase?

To ensure the quality of PVC board 4×8, request samples from suppliers before placing a bulk order. Conduct visual inspections for defects, such as cracks or inconsistencies in color. Additionally, inquire about their manufacturing processes and quality assurance measures. Look for certifications that indicate compliance with international standards, such as ISO. Finally, consider third-party testing for durability and performance metrics, especially if the boards will be used in demanding environments. -

What is the best application for PVC board 4×8 in commercial settings?

PVC board 4×8 is ideal for various commercial applications, including wall paneling, signage, and cabinetry. Its resistance to moisture makes it particularly suited for environments like restrooms and kitchens where hygiene is crucial. Additionally, it can be used for outdoor applications due to its durability against weathering. When selecting PVC boards, consider factors like thickness and finish to ensure they meet the aesthetic and functional requirements of your project. -

What are the typical minimum order quantities (MOQ) for PVC board 4×8?

Minimum order quantities for PVC board 4×8 can vary widely depending on the supplier and region. Generally, MOQs range from 100 to 500 sheets for bulk orders. It’s advisable to discuss your specific needs with potential suppliers, as some may offer flexibility based on your order size or ongoing business relationship. Consider negotiating better terms if you plan to establish a long-term partnership. -

How can I vet suppliers for PVC board 4×8 internationally?

Vetting suppliers requires a multi-faceted approach. Start by researching their reputation through reviews and testimonials from previous clients. Verify their business licenses and certifications to ensure compliance with international quality standards. Request references and contact them to discuss their experiences. Additionally, consider conducting site visits or using third-party inspection services to assess manufacturing capabilities firsthand. -

What payment terms are typically offered for international orders of PVC board 4×8?

Payment terms for international orders can vary significantly. Common options include letters of credit, advance payments, and payment upon delivery. Many suppliers may offer net 30 or net 60 terms for established relationships. It’s essential to clarify these terms in the contract to avoid misunderstandings. Also, consider the currency of payment, as fluctuations can affect overall costs. -

What customization options are available for PVC board 4×8?

Customization options for PVC board 4×8 may include varying thicknesses, colors, finishes, and sizes. Some suppliers offer printing services for branding or decorative purposes. Discuss your specific requirements with suppliers to explore available options. It’s important to inquire about the lead time for customized orders, as this can affect project timelines. -

What are the logistics considerations when importing PVC board 4×8?

When importing PVC board 4×8, consider factors like shipping methods, customs duties, and delivery timelines. Choose a reliable freight forwarder who can handle documentation and compliance with local regulations. Be aware of the potential for additional costs such as insurance and handling fees. Coordinate with your supplier to ensure the boards are packaged appropriately to minimize damage during transit. -

How do I handle potential disputes with suppliers over PVC board 4×8 orders?

To handle disputes with suppliers, establish clear communication channels and document all agreements in writing. If issues arise, address them promptly with the supplier, providing evidence such as photos or inspection reports. Many suppliers are willing to resolve issues amicably to maintain a good business relationship. If necessary, consider mediation or arbitration as outlined in your contract to resolve disputes without resorting to litigation.

Top 3 Pvc Board 4X8 Manufacturers & Suppliers List

1. ImeCa – PVC Board 1/2 in. 4 ft x 8 ft

2. Laminates & Things – Solid PVC Sheet 4×8

Domain: laminatesandthings.com

Registered: 2000 (25 years)

Introduction: {“product_name”: “SOLID PVC SHEET 4X8 WHITE 3/4 (18MM)”, “sku”: “PVC-SOLID-18MM”, “dimensions”: “4 X 8 – 3/4”, “price”: “$85.00”, “material”: “PVC”, “finish”: “Solid”, “category”: “Laminates & Things”}

3. Ringsend – 1 in. Kleer PVC Sheet

Strategic Sourcing Conclusion and Outlook for pvc board 4×8

In conclusion, the strategic sourcing of 4×8 PVC boards presents a significant opportunity for international B2B buyers across diverse regions, including Africa, South America, the Middle East, and Europe. The durability, moisture resistance, and low maintenance requirements of PVC boards make them an ideal choice for various applications, from construction to interior design. By leveraging reliable suppliers and understanding regional market dynamics, businesses can secure competitive pricing and ensure timely delivery.

Investing in strategic sourcing not only enhances supply chain resilience but also enables companies to innovate and meet customer demands effectively. Establishing strong relationships with manufacturers and distributors can lead to better negotiation terms and access to exclusive products that stand out in the market.

As we look to the future, the demand for sustainable and versatile building materials is expected to grow. International buyers are encouraged to explore partnerships with reputable suppliers to capitalize on this trend. Embrace the advantages of PVC boards and position your business for success in an evolving marketplace. The time to act is now—secure your supply chain and enhance your product offerings today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to pvc board 4×8