A Deep Dive into Power Supply 24Vdc Solution

Introduction: Navigating the Global Market for power supply 24vdc

In today’s global marketplace, sourcing reliable 24V DC power supplies poses a significant challenge for international B2B buyers. With an increasing demand for efficient and versatile power solutions, businesses across Africa, South America, the Middle East, and Europe must navigate a complex landscape of suppliers and product specifications. This guide aims to simplify that process, providing insights into the various types of 24V DC power supplies available, their diverse applications, and essential factors to consider when vetting suppliers.

From industrial automation and LED lighting to telecommunications and medical equipment, the applications for 24V DC power supplies are vast and varied. Understanding the specific requirements of your projects is crucial for making informed purchasing decisions. This guide not only covers the technical specifications of different power supply models but also addresses key considerations such as compliance with international standards, cost-effectiveness, and supplier reliability.

By equipping B2B buyers with comprehensive knowledge and actionable insights, this resource empowers you to confidently select the right 24V DC power supply solutions that meet your operational needs. Whether you’re based in Nigeria, Vietnam, or any other emerging market, this guide will help streamline your sourcing process, ensuring you partner with trustworthy suppliers and optimize your investment in power supply technologies.

Understanding power supply 24vdc Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

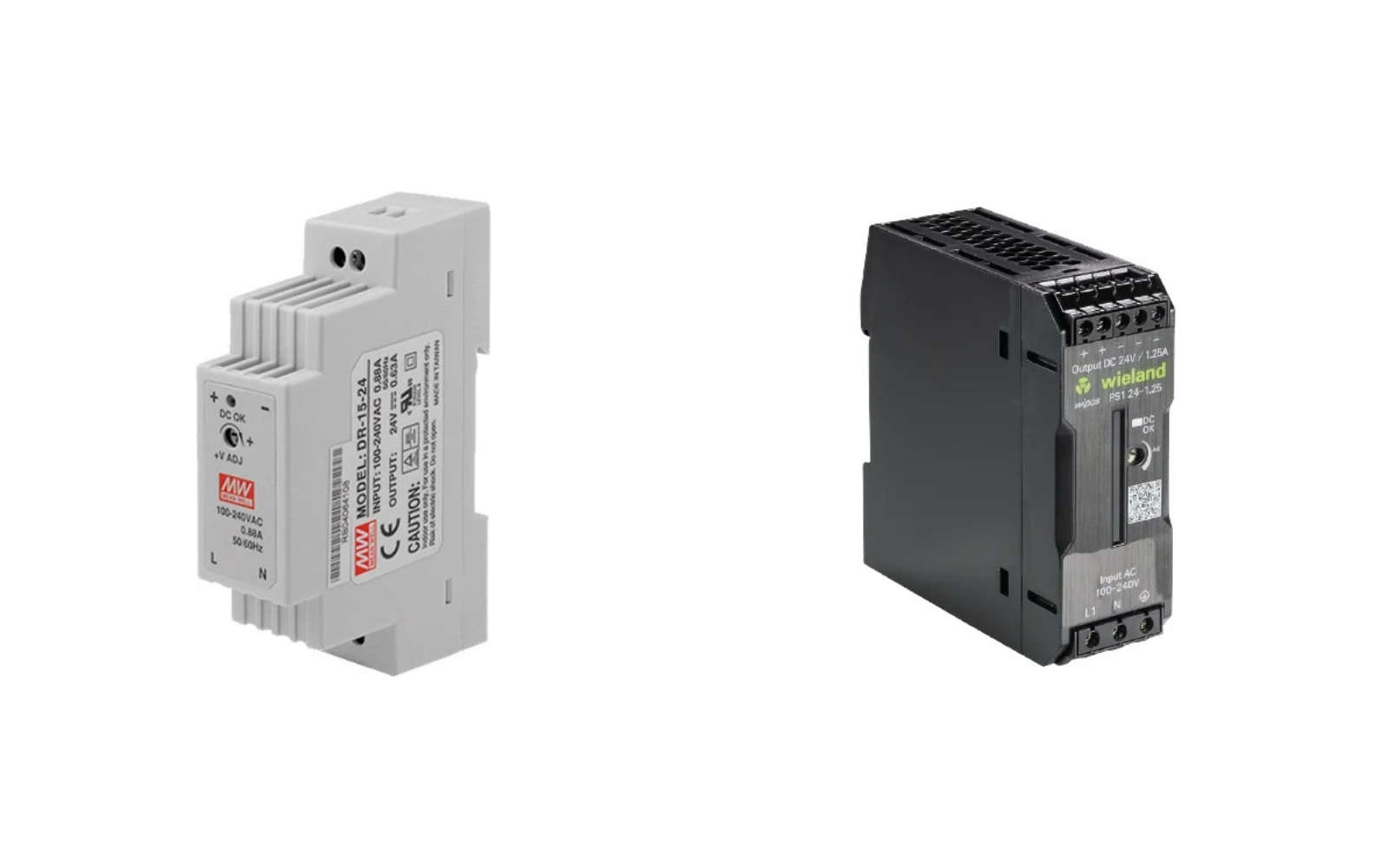

| DIN Rail Power Supply | Compact design, easy installation on DIN rails, often modular. | Industrial automation, control panels | Pros: Space-saving, reliable. Cons: Limited to rail installations. |

| LED Drivers | Specifically designed for LED lighting applications, dimmable options. | Commercial lighting, signage | Pros: Energy-efficient, supports various LED types. Cons: Can be more expensive. |

| Encapsulated Power Supply | Sealed against dust and moisture, ruggedized for harsh environments. | Outdoor applications, transportation | Pros: High durability, suitable for extreme conditions. Cons: Heavier and bulkier. |

| Open Frame Power Supply | Lightweight, cost-effective, and customizable. | Consumer electronics, prototype development | Pros: Low cost, easy to modify. Cons: Requires additional housing for protection. |

| Programmable Power Supply | Offers adjustable voltage and current settings, often with digital interfaces. | R&D, testing labs | Pros: Versatile, suitable for various applications. Cons: More complex to use. |

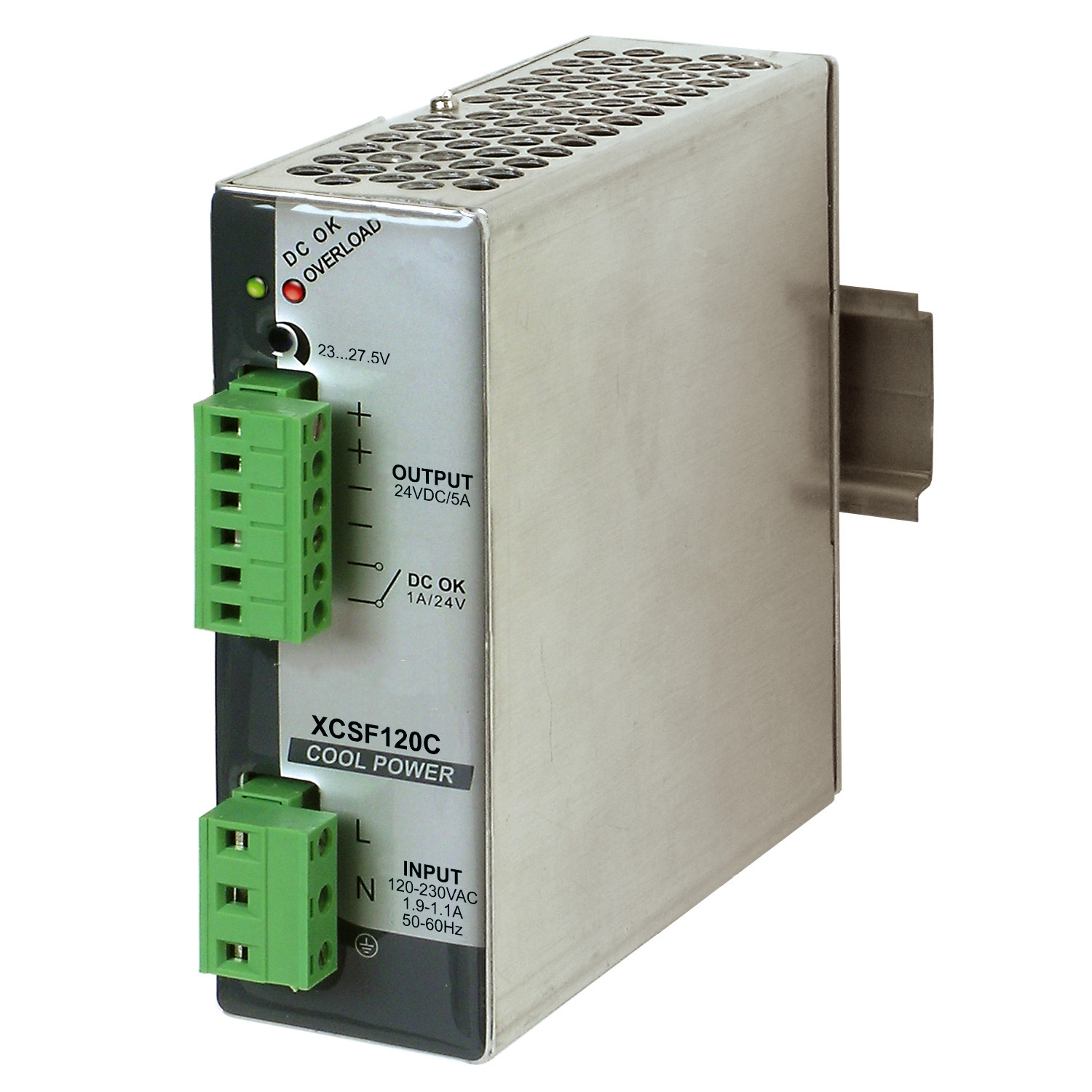

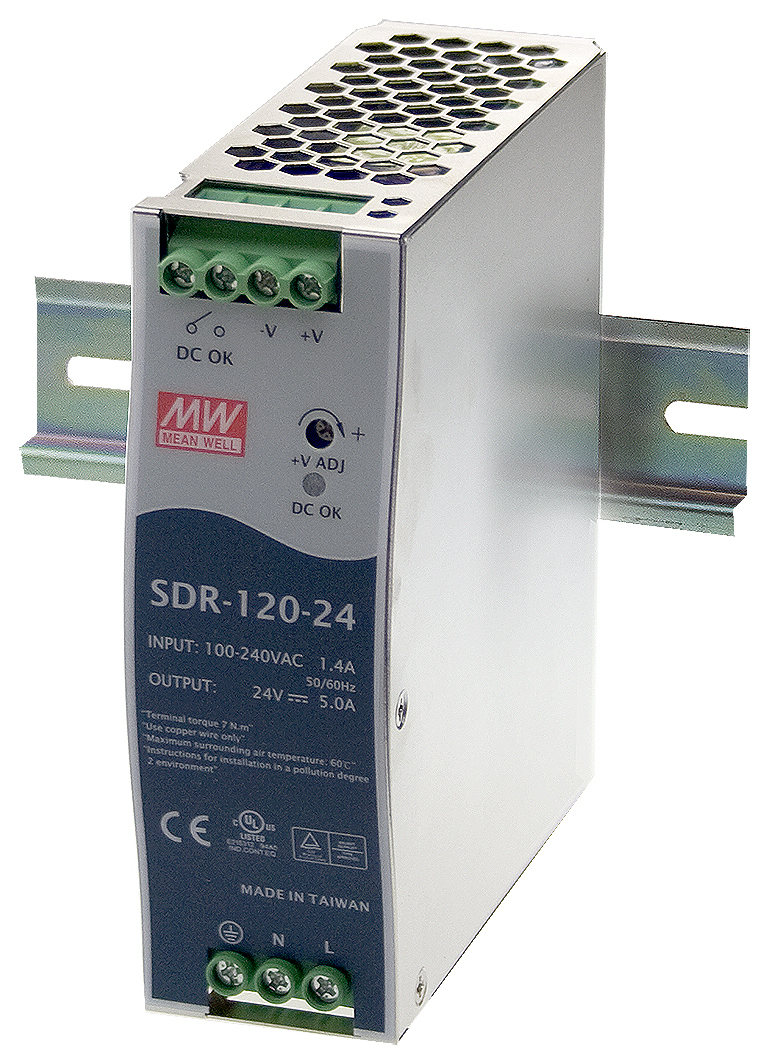

What Are the Characteristics of DIN Rail Power Supplies?

DIN Rail power supplies are designed for easy installation within control cabinets and panels. Their compact size allows for efficient use of space in industrial environments. Typically, these units support a range of input voltages and provide stable output, making them ideal for automation systems. When purchasing, consider the output wattage and the environmental conditions of the installation site, as these factors will influence performance and longevity.

Why Choose LED Drivers for Lighting Solutions?

LED drivers are specialized power supplies that convert electrical input into the correct voltage and current for LED lights. They often include features such as dimming capabilities and thermal management to enhance efficiency. B2B buyers should assess compatibility with existing lighting systems and the specific application requirements, such as outdoor versus indoor use. The investment in a quality LED driver can lead to significant energy savings and longer operational life for lighting systems.

Illustrative image related to power supply 24vdc

What Benefits Do Encapsulated Power Supplies Offer?

Encapsulated power supplies are protected against dust, moisture, and other environmental factors, making them suitable for outdoor and industrial applications. Their rugged design ensures reliability in harsh conditions, such as transportation or outdoor installations. Buyers should evaluate the IP rating for environmental protection and the power output to ensure they meet the demands of their applications. While generally more durable, these units may come at a higher cost due to their protective features.

How Do Open Frame Power Supplies Function?

Open frame power supplies are known for their lightweight and cost-effective designs. They are often used in consumer electronics and prototyping applications due to their customizable nature. However, they require additional housing for protection from environmental factors. Buyers should consider the specific requirements for their applications, including thermal management and safety certifications, as these elements can impact the overall effectiveness and safety of the power supply.

What Are the Use Cases for Programmable Power Supplies?

Programmable power supplies provide flexibility with adjustable voltage and current outputs, making them ideal for research and development environments. They often feature digital interfaces for easy programming and monitoring. When selecting a programmable power supply, buyers should consider the necessary specifications for their testing or experimental setups, as well as the complexity of operation. While they offer versatility, the learning curve and potential higher costs may be considerations for some organizations.

Key Industrial Applications of power supply 24vdc

| Industry/Sector | Specific Application of power supply 24vdc | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Industrial Automation | Control systems for machinery | Enhances operational efficiency and reduces downtime | Reliability, compatibility with existing systems, and safety certifications |

| Renewable Energy | Solar power systems | Supports sustainable energy solutions and reduces costs | Efficiency ratings, environmental certifications, and scalability options |

| Telecommunications | Network equipment power supply | Ensures uninterrupted service and data reliability | Voltage stability, load capacity, and compliance with local regulations |

| Automotive | Electric vehicle charging stations | Facilitates the growth of EV infrastructure | Charging speed, integration with existing systems, and safety features |

| Medical Equipment | Power supply for diagnostic devices | Improves patient safety and device performance | Compliance with medical standards, reliability, and service support |

How is 24V DC Power Supply Used in Industrial Automation?

In industrial automation, 24V DC power supplies are critical for powering control systems that manage machinery operations. These systems often require stable and reliable power to ensure consistent performance. By utilizing 24V DC power supplies, businesses can enhance operational efficiency and minimize downtime, as these power supplies are designed to handle varying loads and provide consistent voltage. Buyers from regions like Africa and South America should prioritize sourcing from manufacturers with proven reliability and compatibility with existing automation systems to avoid disruptions.

Illustrative image related to power supply 24vdc

What Role Does 24V DC Power Supply Play in Renewable Energy?

In renewable energy applications, particularly solar power systems, 24V DC power supplies are utilized to convert and stabilize energy from solar panels. This is essential for battery charging and powering inverters that convert DC to AC for grid use. The use of 24V systems supports sustainable energy solutions, reducing operational costs and reliance on fossil fuels. Buyers in the Middle East and Europe should consider efficiency ratings and environmental certifications when sourcing these power supplies to ensure they meet sustainability goals.

How Does 24V DC Power Supply Ensure Reliability in Telecommunications?

Telecommunications rely heavily on 24V DC power supplies to maintain the functionality of network equipment. These power supplies ensure uninterrupted service, which is crucial for data reliability and customer satisfaction. In regions like Africa and Europe, where network expansion is ongoing, sourcing power supplies that offer voltage stability and sufficient load capacity is essential. Compliance with local regulations and standards is also a key consideration to mitigate risks associated with power outages and equipment failures.

Why is 24V DC Power Supply Important for Electric Vehicle Infrastructure?

The automotive industry increasingly depends on 24V DC power supplies for electric vehicle (EV) charging stations. These power supplies facilitate the growth of EV infrastructure by providing the necessary energy to charge vehicles efficiently. As the demand for electric vehicles rises, businesses in this sector must focus on sourcing power supplies that offer fast charging capabilities and integration with existing systems. Safety features are also critical to ensure user protection during the charging process, especially in developing markets like Nigeria and Vietnam.

How Does 24V DC Power Supply Enhance Medical Equipment Performance?

In the medical field, 24V DC power supplies are essential for powering diagnostic devices and other critical equipment. These power supplies help improve patient safety and device performance by delivering reliable and stable power. For international B2B buyers in this sector, compliance with medical standards is paramount, as is the need for reliable service support to address any operational issues promptly. Sourcing from manufacturers with a strong reputation for quality and reliability can significantly enhance operational outcomes in healthcare settings.

3 Common User Pain Points for ‘power supply 24vdc’ & Their Solutions

Scenario 1: Navigating Supply Chain Delays for 24VDC Power Supplies

The Problem: In today’s global market, B2B buyers often face significant challenges related to supply chain disruptions. For instance, a manufacturer in Nigeria may rely on a specific model of 24VDC power supply from a supplier in China. Unexpected delays due to shipping issues or geopolitical tensions can lead to production halts. This not only affects timelines but can also result in financial losses and dissatisfied customers.

Illustrative image related to power supply 24vdc

The Solution: To mitigate supply chain risks, it’s crucial for businesses to diversify their sourcing strategies. Consider establishing relationships with multiple suppliers across different regions, including local manufacturers. This approach not only provides backup options during disruptions but also allows for quicker turnaround times. Additionally, investing in inventory management solutions can help track stock levels and forecast demand more accurately, ensuring that essential components like 24VDC power supplies are readily available when needed. Regular communication with suppliers about their inventory and lead times can also provide early warnings of potential delays, allowing for proactive adjustments.

Scenario 2: Ensuring Compatibility with Existing Systems

The Problem: A common pain point for B2B buyers is ensuring that new 24VDC power supplies are compatible with existing systems. For example, a company in South America upgrading its manufacturing equipment may find that the new power supplies don’t integrate seamlessly with legacy systems. This can lead to inefficient operations, increased installation costs, and extended downtime.

The Solution: To ensure compatibility, it’s essential to conduct a thorough assessment of the existing systems before making a purchase. Buyers should gather detailed specifications of the current equipment and consult with power supply manufacturers to identify models that match those requirements. Engaging with a technical expert during the selection process can provide insights into potential compatibility issues. Additionally, consider modular power supplies that allow for flexibility and scalability, making it easier to adapt to future technological advancements. Testing the power supply in a controlled environment before full deployment can also help identify any issues that may arise.

Scenario 3: Addressing Performance and Efficiency Concerns

The Problem: Performance efficiency is a critical concern for B2B buyers, especially in industries where energy costs are a significant portion of operational expenses. A company in Europe may experience frequent power fluctuations, leading to inefficient energy usage and overheating of 24VDC power supplies. This not only increases operational costs but can also shorten the lifespan of the equipment.

The Solution: To enhance performance and efficiency, buyers should look for power supplies that feature advanced technologies such as Power Factor Correction (PFC) and thermal management systems. These features help optimize energy consumption and maintain stable output under varying load conditions. Additionally, selecting models with higher efficiency ratings (e.g., 80 Plus certified) can reduce energy costs over time. Regular maintenance and monitoring of power supply performance can also identify potential issues before they escalate, ensuring sustained efficiency. Implementing smart monitoring solutions that provide real-time data on power supply performance can further empower businesses to make informed decisions about upgrades or replacements, ultimately leading to improved operational efficiency.

Strategic Material Selection Guide for power supply 24vdc

What Are the Key Materials Used in 24V DC Power Supplies?

When selecting materials for 24V DC power supplies, it is essential to consider their properties, advantages, disadvantages, and suitability for specific applications. This analysis focuses on four common materials: aluminum, steel, plastic, and copper. Each material offers unique characteristics that can significantly impact performance and compliance with international standards.

How Does Aluminum Perform in 24V DC Power Supplies?

Aluminum is a lightweight and corrosion-resistant material often used in the casing of power supplies. It has excellent thermal conductivity, which helps in dissipating heat generated during operation. This property is crucial for maintaining optimal performance, especially in high-temperature environments.

Pros: Aluminum is durable, lightweight, and cost-effective. Its resistance to corrosion makes it suitable for various environments, including humid and coastal areas.

Cons: While aluminum is generally strong, it can be less durable than steel under extreme mechanical stress. Additionally, the manufacturing process can be more complex due to the need for specialized techniques such as anodizing for enhanced corrosion resistance.

Impact on Application: Aluminum’s thermal properties make it ideal for applications requiring efficient heat dissipation, such as LED drivers and industrial automation systems.

Considerations for International Buyers: Compliance with standards like ASTM and EN is crucial. Buyers from regions like Africa and the Middle East should ensure that the aluminum used meets local environmental and safety regulations.

Illustrative image related to power supply 24vdc

What Role Does Steel Play in Power Supply Construction?

Steel, particularly stainless steel, is another common material used in 24V DC power supplies. It is known for its strength and durability, making it suitable for rugged applications.

Pros: Steel’s high tensile strength allows it to withstand heavy loads and impacts, making it ideal for industrial settings. It is also resistant to deformation and can be easily fabricated.

Cons: Steel is heavier than aluminum, which can be a disadvantage in applications where weight is a concern. Additionally, it is prone to corrosion unless treated, which can increase manufacturing costs.

Illustrative image related to power supply 24vdc

Impact on Application: Steel is often used in environments where mechanical strength is critical, such as in outdoor installations or in industrial machinery.

Considerations for International Buyers: Buyers should be aware of the various grades of steel and their compliance with international standards like JIS and DIN. This is particularly relevant for regions with stringent regulations on material quality.

How Do Plastics Contribute to Power Supply Design?

Plastic materials, such as polycarbonate and ABS (Acrylonitrile Butadiene Styrene), are frequently used for enclosures in 24V DC power supplies. They offer excellent insulation properties and are lightweight.

Pros: Plastics are resistant to corrosion and can be molded into complex shapes, allowing for versatile designs. They are also cost-effective and lightweight, making them suitable for portable applications.

Illustrative image related to power supply 24vdc

Cons: Plastics generally have lower thermal conductivity compared to metals, which can lead to heat buildup if not properly managed. They may also be less durable under extreme conditions.

Impact on Application: Plastics are ideal for consumer electronics and applications where insulation and weight are priorities, such as in portable power supplies.

Considerations for International Buyers: Buyers should ensure that the plastic materials used comply with safety standards such as UL and CE, especially in regions like Europe where compliance is strictly enforced.

What Is the Importance of Copper in Power Supply Systems?

Copper is widely used in the wiring and circuitry of 24V DC power supplies due to its excellent electrical conductivity. This property is essential for minimizing energy loss during transmission.

Pros: Copper’s high conductivity ensures efficient power delivery, reducing the risk of overheating. It is also highly ductile, making it easy to work with during manufacturing.

Cons: Copper is more expensive than aluminum and can be susceptible to corrosion, particularly in certain environments. This may necessitate additional protective measures.

Impact on Application: Copper is critical in applications requiring high current loads, such as industrial automation and heavy machinery.

Considerations for International Buyers: Buyers should consider the copper’s purity and compliance with international standards, as this can affect performance and longevity, particularly in regions with variable environmental conditions.

Summary Table of Material Properties for 24V DC Power Supplies

| Material | Typical Use Case for power supply 24vdc | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Enclosures for LED drivers | Lightweight and corrosion-resistant | Less durable under extreme stress | Medium |

| Steel | Industrial power supplies | High strength and durability | Heavier and prone to corrosion | Medium |

| Plastic | Consumer electronics enclosures | Cost-effective and versatile | Lower thermal conductivity | Low |

| Copper | Wiring and circuitry | Excellent electrical conductivity | Higher cost and corrosion risk | High |

This strategic material selection guide provides B2B buyers with critical insights into the materials used in 24V DC power supplies, helping them make informed decisions that align with their specific application needs and compliance requirements.

Illustrative image related to power supply 24vdc

In-depth Look: Manufacturing Processes and Quality Assurance for power supply 24vdc

What Are the Key Stages in the Manufacturing Process of 24VDC Power Supplies?

The manufacturing process of 24VDC power supplies involves several critical stages, each essential to ensuring product quality and reliability. The main stages typically include material preparation, forming, assembly, and finishing.

-

Material Preparation: This initial stage involves sourcing high-quality raw materials such as transformers, capacitors, and circuit boards. Manufacturers often establish relationships with trusted suppliers to ensure the components meet specific standards. Materials are inspected upon receipt to verify compliance with specifications, which is a critical step in maintaining quality.

-

Forming: In this stage, the prepared materials undergo processes such as cutting, shaping, and soldering. Techniques like surface mount technology (SMT) are commonly used for assembling electronic components onto circuit boards. This stage requires precision to ensure that all components are accurately placed and secured.

-

Assembly: The assembly stage involves integrating various components into a complete power supply unit. This often includes installing the circuit boards into enclosures, connecting wiring, and integrating additional features like cooling systems. Automation is frequently employed to enhance efficiency and consistency during assembly.

-

Finishing: The finishing stage involves the application of protective coatings and the final assembly of the power supply units. This may include conformal coating to protect against moisture and dust, as well as final visual inspections to ensure that the units meet aesthetic and functional standards. The goal of this stage is to prepare the products for shipping while ensuring they are durable and reliable.

What Quality Assurance Measures Are Implemented in 24VDC Power Supply Manufacturing?

Quality assurance (QA) is vital in the manufacturing of 24VDC power supplies to ensure reliability and compliance with international standards. The following QA measures are commonly implemented:

-

International and Industry-Specific Standards: Manufacturers often adhere to international quality management standards such as ISO 9001, which outlines criteria for a quality management system. Additionally, industry-specific certifications like CE (European Conformity), UL (Underwriters Laboratories), and RoHS (Restriction of Hazardous Substances) are crucial for ensuring that products meet safety and environmental regulations.

-

Quality Control Checkpoints: Various quality control checkpoints are established throughout the manufacturing process:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before they are used in production.

– In-Process Quality Control (IPQC): During production, quality checks are performed at critical stages to monitor the manufacturing process and identify any deviations from quality standards.

– Final Quality Control (FQC): After assembly, the final products undergo rigorous testing to ensure they meet performance specifications and safety standards before shipment. -

Common Testing Methods: Various testing methods are employed to validate the quality of 24VDC power supplies. These include:

– Load Testing: Ensures that the power supply can handle specified loads without failure.

– Temperature Testing: Assesses the unit’s performance under extreme temperature conditions.

– Electrical Testing: Confirms voltage outputs and checks for short circuits or other electrical anomalies.

– Environmental Testing: Evaluates the unit’s durability under conditions such as humidity, dust, and vibration.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is crucial to ensuring the reliability of power supply products. Here are some actionable steps:

-

Supplier Audits: Conducting on-site audits of potential suppliers can provide insights into their manufacturing processes and quality control practices. Audits allow buyers to assess compliance with international standards and verify the integrity of quality management systems.

-

Requesting Quality Assurance Reports: Buyers should request and review quality assurance reports from suppliers. These reports often include data on testing results, defect rates, and compliance with standards, providing a clear picture of the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can add an additional layer of assurance. These services can independently verify that suppliers meet the specified quality standards and can provide unbiased reports on product quality.

-

Certifications and Documentation: Buyers should look for certifications that demonstrate a supplier’s adherence to international quality standards. Documentation such as ISO certificates, test reports, and compliance declarations should be readily available and verifiable.

What Are the Nuances of Quality Control for International B2B Buyers?

Understanding the nuances of quality control is particularly important for international B2B buyers. Here are some key considerations:

-

Regulatory Compliance: Different regions have varying regulatory requirements for electronic products. Buyers must ensure that suppliers comply with the specific regulations applicable in their target markets, such as CE marking in Europe or UL certification in North America.

-

Cultural and Operational Differences: Cultural differences can impact manufacturing and quality control practices. Buyers should be aware of these differences and adapt their communication and expectations accordingly to ensure effective collaboration.

-

Supply Chain Transparency: In regions where supply chain transparency may be limited, buyers must take proactive measures to ensure that their suppliers adhere to quality standards. This may involve establishing clear contractual agreements that specify quality expectations and penalties for non-compliance.

-

Long-Term Relationships: Building long-term relationships with trusted suppliers can enhance quality control. Engaging in regular communication, feedback, and collaboration can foster a culture of quality that benefits both parties.

In conclusion, understanding the manufacturing processes and quality assurance measures for 24VDC power supplies is essential for B2B buyers. By focusing on these aspects, buyers can make informed decisions, ensuring that they procure reliable and high-quality products that meet their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘power supply 24vdc’

Introduction

Sourcing a reliable 24V DC power supply is essential for ensuring the efficiency and effectiveness of your electrical systems. This step-by-step checklist is designed for B2B buyers across various regions, including Africa, South America, the Middle East, and Europe, to streamline the procurement process. By following these steps, you can make informed decisions that align with your technical and operational requirements.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications of the power supply you need. Consider factors such as voltage, current rating, and power output to ensure compatibility with your applications. This step is crucial because mismatched specifications can lead to operational failures or increased costs.

- Voltage Requirements: Confirm that the supply is 24V DC.

- Current Rating: Determine the maximum current your application will draw.

Step 2: Research Market Trends and Suppliers

Understanding the market landscape will help you identify potential suppliers and their offerings. Research current trends in the power supply industry, including new technologies, efficiency ratings, and compliance standards. This knowledge will empower you to choose suppliers who are innovative and reliable.

- Trends in Efficiency: Look for suppliers offering high-efficiency models that comply with energy regulations.

- Technological Advancements: Investigate suppliers that provide advanced features, such as remote monitoring and programmable outputs.

Step 3: Evaluate Potential Suppliers

It’s vital to conduct a thorough evaluation of potential suppliers to ensure they meet your business needs. Request company profiles, certifications, and references from other clients, particularly those in similar industries or regions. This will help you gauge their reliability and product quality.

- Check Certifications: Ensure suppliers have relevant certifications such as UL, CE, or ISO to guarantee product safety and quality.

- Request Case Studies: Ask for examples of successful projects that demonstrate their expertise.

Step 4: Assess Product Range and Availability

When selecting a supplier, consider the breadth of their product range and their ability to meet your specific requirements. A diverse product portfolio indicates that the supplier can cater to various applications and adapt to your changing needs.

- Stock Availability: Confirm that the supplier has sufficient stock levels to meet your delivery timelines.

- Customization Options: Look for suppliers that offer customization to tailor products to your specific needs.

Step 5: Verify Supplier Support and Service

After narrowing down your options, evaluate the level of support and service offered by each supplier. Good post-purchase support can significantly enhance your experience and ensure any issues are resolved promptly.

- Technical Support: Ensure the supplier provides access to knowledgeable technical support for installation and troubleshooting.

- Warranty and Returns Policy: Review the warranty offered and understand the returns process in case the product does not meet your expectations.

Step 6: Negotiate Terms and Finalize Purchase

Once you have selected a supplier, engage in negotiations to finalize the terms of your purchase. Discuss pricing, delivery schedules, and payment terms to ensure they align with your budget and operational timelines.

- Bulk Purchase Discounts: Inquire about discounts for bulk orders to maximize your cost efficiency.

- Delivery Terms: Clearly outline delivery expectations to avoid any disruptions in your operations.

Conclusion

By following this checklist, you can streamline the process of sourcing 24V DC power supplies, ensuring that your procurement aligns with both technical specifications and business goals. This proactive approach will help mitigate risks and foster long-term supplier relationships.

Illustrative image related to power supply 24vdc

Comprehensive Cost and Pricing Analysis for power supply 24vdc Sourcing

In the procurement of 24VDC power supplies, understanding the cost structure and pricing dynamics is essential for international B2B buyers. This analysis highlights key cost components, price influencers, and strategic buyer tips to optimize sourcing decisions.

What Are the Key Cost Components in 24VDC Power Supply Manufacturing?

The cost structure of 24VDC power supplies encompasses several components:

-

Materials: The primary materials include semiconductors, capacitors, transformers, and printed circuit boards (PCBs). The choice of components significantly affects the overall cost, with higher-quality materials leading to increased reliability and performance.

-

Labor: Labor costs vary by region and manufacturing complexity. Skilled labor is necessary for assembly and quality control, and labor rates in countries such as China, India, or Vietnam tend to be lower compared to Europe or North America, affecting overall pricing.

-

Manufacturing Overhead: This includes costs associated with factory operation, such as utilities, maintenance, and equipment depreciation. Efficient manufacturing processes can help minimize these costs, thus lowering the final price.

-

Tooling: Custom tooling can be a significant upfront investment, particularly for specialized or high-volume orders. The cost can be amortized over larger orders, making it crucial to consider order volume when negotiating prices.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability and compliance with international standards. While this adds to costs, it can prevent costly returns and enhance customer satisfaction.

-

Logistics: Shipping costs, tariffs, and handling fees must be factored into total costs, especially for international transactions. The choice of Incoterms (e.g., FOB, CIF) can significantly influence the final landed cost.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. This margin can vary based on competition, demand, and supplier reputation.

How Do Volume and Customization Influence Pricing?

-

Volume/MOQ: Suppliers often provide tiered pricing based on order volume. Higher quantities typically lead to lower per-unit costs due to economies of scale. Establishing long-term contracts can also secure better pricing.

-

Specifications and Customization: Custom power supply units designed to meet specific application requirements may incur additional costs. Buyers should weigh the necessity of customization against potential savings from standard models.

-

Materials and Quality Certifications: Higher quality components and certifications (like UL, CE, or RoHS) can increase costs. However, these certifications may be crucial for regulatory compliance in certain markets, particularly in Europe.

What Buyer Tips Should Be Considered for Cost-Efficiency?

-

Negotiation Strategies: Engage suppliers in open discussions about pricing. Leverage quotes from multiple vendors to foster competitive pricing and explore potential discounts for large orders.

-

Total Cost of Ownership (TCO): Assess not just the purchase price but also the TCO, which includes installation, maintenance, and energy consumption over the product’s lifecycle. A slightly higher upfront cost might lead to lower operational costs.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, trade tariffs, and regional demand when sourcing from different countries. For buyers in regions like Africa, South America, and the Middle East, local regulations and import duties can significantly impact pricing.

-

Stay Informed About Market Trends: Monitor industry trends and supplier dynamics. Changes in technology, material costs, and supply chain disruptions can affect pricing strategies.

Conclusion

Understanding the cost structure and pricing influences of 24VDC power supplies is vital for B2B buyers looking to optimize their sourcing strategies. By considering the outlined components, engaging in effective negotiation, and evaluating the total cost of ownership, buyers can make informed decisions that align with their operational needs and budget constraints. Always remember that the prices mentioned may vary, and conducting thorough market research is essential for accurate budgeting.

Alternatives Analysis: Comparing power supply 24vdc With Other Solutions

Exploring Alternative Power Supply Solutions: A Comparison

In the realm of power supply solutions, the 24Vdc power supply stands out as a versatile choice for various applications. However, other alternatives exist that may better suit specific operational needs or constraints. This analysis compares the 24Vdc power supply against two viable alternatives: AC power supplies and battery-operated systems. Each solution has its strengths and weaknesses, which can significantly impact performance and cost-effectiveness.

| Comparison Aspect | Power Supply 24Vdc | AC Power Supply | Battery-Operated Systems |

|---|---|---|---|

| Performance | Reliable voltage output | Variable voltage levels | High portability |

| Cost | Moderate initial cost | Often lower initial cost | Higher total cost over time |

| Ease of Implementation | Simple installation | Requires additional components | Requires charging infrastructure |

| Maintenance | Low maintenance needs | Moderate maintenance | Regular battery replacement |

| Best Use Case | Industrial automation | Residential and commercial | Remote locations, portable devices |

What Are the Pros and Cons of Using an AC Power Supply?

AC power supplies convert alternating current to a specific voltage output. They are typically less expensive than their DC counterparts and can provide power over longer distances without significant loss. However, they may require additional components, such as rectifiers and transformers, to ensure the output is suitable for DC applications. This complexity can lead to higher installation costs and maintenance needs. AC power supplies are best suited for residential and commercial settings where the infrastructure for AC power is already established.

How Do Battery-Operated Systems Compare?

Battery-operated systems offer a high degree of portability and flexibility, making them ideal for remote locations or situations where a constant power supply is not available. They can be easily integrated into mobile devices or temporary installations. However, the total cost can escalate due to the need for regular battery replacements and the potential for reduced performance as batteries discharge. While they excel in applications requiring mobility, their reliance on limited battery life can be a significant drawback for long-term use.

Conclusion: Choosing the Right Power Supply Solution for Your Needs

When selecting a power supply solution, B2B buyers should consider their specific requirements, including application type, budget constraints, and installation environment. The 24Vdc power supply is a robust choice for industrial applications demanding reliability and consistent performance. However, for scenarios where cost efficiency or portability is critical, AC power supplies or battery-operated systems may provide better value. Conducting a thorough analysis of these alternatives will enable buyers to make informed decisions that align with their operational objectives and financial parameters.

Essential Technical Properties and Trade Terminology for power supply 24vdc

What Are the Key Technical Properties of 24VDC Power Supplies?

Understanding the technical specifications of 24VDC power supplies is crucial for B2B buyers. Here are some essential properties that should be considered:

Illustrative image related to power supply 24vdc

-

Output Voltage

The nominal output voltage of 24VDC indicates the power supply’s operational voltage. Consistency in output voltage is vital to ensure the proper functioning of connected devices. Fluctuations can lead to equipment malfunction or damage, which is especially critical in sensitive applications like telecommunications and medical devices. -

Current Rating (Amperage)

This specifies the maximum current the power supply can deliver, typically measured in amperes (A). It is essential to select a power supply with an appropriate amperage rating to match the load requirements of the application. Insufficient current can lead to underperformance, while excessive current can cause overheating and potential failure. -

Efficiency Rating

Efficiency is the ratio of output power to input power, expressed as a percentage. A higher efficiency rating (often 80% or above) is preferred as it indicates less energy waste and lower operational costs. This is particularly important for businesses focused on sustainability and reducing energy expenses. -

Environmental Ratings (IP Ratings)

The Ingress Protection (IP) rating indicates the level of protection against dust and moisture. For instance, an IP67 rating means the device is dust-tight and can withstand immersion in water. This is crucial for applications in harsh environments, such as outdoor installations or industrial settings, where exposure to elements can affect performance and longevity. -

Temperature Range

This specification outlines the operating temperature limits of the power supply. Understanding the temperature range is essential for ensuring reliable operation in varying environmental conditions. Devices operating outside their specified temperature range may experience reduced efficiency or complete failure. -

Form Factor

The physical size and design of the power supply affect installation and compatibility with existing systems. Common form factors include DIN rail mountable, open frame, and enclosed types. Buyers should consider space constraints and installation ease when selecting a power supply.

What Trade Terminology Should B2B Buyers Know for Power Supplies?

Familiarity with industry jargon can facilitate smoother negotiations and procurement processes. Here are some common terms related to power supplies:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships can help buyers identify reliable suppliers and the quality of components used in power supplies. -

MOQ (Minimum Order Quantity)

This term indicates the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers plan their purchases effectively, especially when budget constraints or storage limitations are factors. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and availability for specific products. This is an essential step in the procurement process, allowing buyers to compare costs and terms from different suppliers. -

Incoterms (International Commercial Terms)

These are predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of sellers and buyers in international transactions. Familiarity with Incoterms helps buyers understand shipping costs, risks, and responsibilities, facilitating smoother international trade. -

PFC (Power Factor Correction)

This term refers to techniques used to improve the power factor of a power supply, making it more efficient. A higher power factor indicates better efficiency, which can lead to lower energy costs and compliance with regulatory standards. -

UL Certification

Underwriters Laboratories (UL) certification signifies that a product meets specific safety standards. For power supplies, UL certification can be a critical factor in ensuring compliance with safety regulations, making it an important consideration for buyers focused on quality and reliability.

By understanding these technical properties and terms, B2B buyers can make more informed decisions when sourcing 24VDC power supplies, ultimately enhancing their operations and ensuring the longevity of their investments.

Navigating Market Dynamics and Sourcing Trends in the power supply 24vdc Sector

What Are the Key Market Trends Driving the 24V DC Power Supply Sector?

The global demand for 24V DC power supplies is being propelled by several key drivers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. The increasing adoption of automation in manufacturing and smart technologies in industries such as telecommunications, automotive, and renewable energy is a significant factor. Companies are seeking versatile power solutions that can support various applications, from industrial equipment to consumer electronics. Additionally, the rise in electric vehicle (EV) production, especially in regions like Europe and South America, necessitates reliable power supply systems, further driving the demand for 24V DC solutions.

Moreover, B2B tech sourcing trends indicate a growing preference for suppliers who offer customizable power supplies. Buyers are looking for options that allow for tailored specifications, such as output power, input voltage range, and form factors, to better fit their specific applications. The availability of smart power supplies with integrated monitoring capabilities is also gaining traction, as these features enhance operational efficiency and reduce downtime. As international buyers navigate these dynamics, understanding local regulations and compliance requirements becomes crucial for successful sourcing.

How Does Sustainability Impact the Sourcing of 24V DC Power Supplies?

In today’s B2B landscape, sustainability is not just a trend but a necessity. The environmental impact of manufacturing processes and the lifecycle of products are increasingly scrutinized by buyers. For power supply manufacturers, adopting sustainable practices is essential for meeting the expectations of environmentally-conscious consumers and businesses. This includes utilizing eco-friendly materials, reducing waste during production, and ensuring energy efficiency in product design.

Ethical sourcing has become a priority for many international buyers. Companies are now favoring suppliers that demonstrate a commitment to ethical labor practices and transparent supply chains. Certifications such as ISO 14001 for environmental management and RoHS compliance for hazardous materials are becoming critical benchmarks for evaluating suppliers. Buyers should prioritize partnerships with manufacturers who not only comply with these standards but also actively pursue innovations in sustainability, such as using recyclable materials and developing energy-efficient products.

What Is the Historical Context of the 24V DC Power Supply Industry?

The evolution of the 24V DC power supply industry can be traced back to the early days of electronic devices, where low-voltage power supplies were essential for powering various applications. As technology advanced, the need for more efficient and reliable power sources became evident, leading to the development of more sophisticated power supply units. The introduction of switch-mode power supplies (SMPS) in the late 20th century revolutionized the market, offering higher efficiency and smaller form factors.

In recent years, the focus has shifted towards integrating smart technology into power supplies, allowing for better monitoring and control. This evolution reflects the broader trends in the electronics industry, where connectivity and automation are paramount. As international markets continue to grow, the 24V DC power supply sector is poised for further innovation and expansion, driven by the demands of modern technology and the need for sustainable practices.

Frequently Asked Questions (FAQs) for B2B Buyers of power supply 24vdc

-

How do I select the right 24V DC power supply for my application?

Choosing the right 24V DC power supply involves assessing your specific needs, such as load requirements, environmental conditions, and regulatory standards. Start by determining the total wattage your application requires and select a power supply that can handle that load with some headroom for peak demands. Consider factors like efficiency ratings, dimensions, and mounting options. Additionally, evaluate the input voltage range to ensure compatibility with your power source, and check for certifications that may be necessary for your region or industry. -

What are the common applications for 24V DC power supplies?

24V DC power supplies are widely used in various applications, including industrial automation, telecommunications, LED lighting, and medical devices. They provide reliable power for equipment like sensors, control systems, and data acquisition devices. The versatility of 24V systems makes them suitable for both indoor and outdoor environments, especially when robust and efficient power solutions are required. Understanding the specific demands of your application can help you select the most suitable power supply model. -

What certifications should I look for when purchasing 24V DC power supplies internationally?

When sourcing 24V DC power supplies, it is essential to look for international certifications such as CE, UL, and RoHS, which indicate compliance with safety and environmental standards. Depending on your region, additional certifications may be required, like CCC in China or BIS in India. These certifications not only ensure product safety but also enhance marketability in various regions. Always verify that the supplier can provide documentation for these certifications to avoid compliance issues. -

How can I ensure the reliability of my 24V DC power supply supplier?

To ensure supplier reliability, conduct thorough due diligence, which includes checking their industry reputation, customer reviews, and case studies. Request references from other clients who have purchased similar products. Assess their manufacturing capabilities and quality control processes, including certifications like ISO 9001. It’s also advisable to inquire about their warranty and after-sales support policies, as these can provide insight into their commitment to quality and customer service. -

What customization options are available for 24V DC power supplies?

Many manufacturers offer customization options for 24V DC power supplies, including modified output voltages, form factors, and additional features like remote sensing or built-in fuses. If your application requires specific connectors or mounting configurations, communicate these needs to your supplier. Custom solutions can also involve unique input voltage ranges or environmental ratings, enabling better integration into your systems. Discussing your requirements early in the procurement process can help streamline the customization and delivery. -

What is the typical minimum order quantity (MOQ) for 24V DC power supplies?

Minimum order quantities (MOQs) for 24V DC power supplies can vary significantly based on the manufacturer and the complexity of the product. Generally, MOQs can range from as low as 10 units for standard models to several hundred for customized solutions. When negotiating with suppliers, clarify their MOQ policies and explore options for smaller initial orders or trial runs, especially if you are testing a new product line or market. This flexibility can help mitigate financial risks. -

What payment terms are common when sourcing 24V DC power supplies internationally?

Common payment terms for international transactions include upfront payment, partial payment upon order confirmation, and the balance before shipment. Some suppliers may offer credit terms, especially for established relationships. It’s crucial to negotiate terms that align with your cash flow and procurement strategy. Additionally, consider using secure payment methods such as letters of credit or escrow services to protect your financial interests when dealing with new suppliers. -

How do logistics and shipping impact the procurement of 24V DC power supplies?

Logistics and shipping play a vital role in the timely delivery of 24V DC power supplies. Factors such as shipping method, customs clearance, and lead times can affect your supply chain. Ensure your supplier has experience with international shipping and understands the regulations in your country. Discuss logistics options early in the negotiation process, including potential delays and costs associated with customs duties. A reliable logistics strategy can prevent disruptions in your operations and ensure that you receive the right products on time.

Top 7 Power Supply 24Vdc Manufacturers & Suppliers List

1. TRC – 24V DC Power Supplies

Domain: trcelectronics.com

Registered: 1998 (27 years)

Introduction: {“category”:”24Vdc Power Supplies”,”description”:”Comprehensive selection of 24 Volt DC power supplies from leading manufacturers. Hundreds of models available for immediate shipping. Expert technical and application assistance provided by TRC’s power specialist team.”,”availability”:{“in_stock”:561,”out_of_stock”:446},”country_of_origin”:{“USA”:48,”China”:566,”India”:74,”Philippines”:27,”Thailand…

2. Progressive Automations – PS-10-24-67 Power Supply

Domain: progressiveautomations.com

Registered: 2008 (17 years)

Introduction: {“Model”:”PS-10-24-67″,”Input Voltage”:”100-120 VAC, 50/60Hz”,”Output Voltage”:”24 VDC, 240W”,”Current Rating”:”10A”,”Weather Protection”:”IP67″,”Wire Length”:{“AC”:”40 inches”,”DC”:”11 inches”},”Size”:”9.3 x 2.2 x 4.7 inches”,”Certifications”:[“CE”,”RoHS”],”Unit Weight”:”4.2 lbs”,”Warranty”:”18 Months”,”Price”:{“1-6 units”:”$109.99 USD”,”7-9 units”:”$104.99 USD”,”10-19 units”:”$98.99 USD”,”20+ un…

3. Puls – Dimension C-Series Power Supply

Domain: industrialnetworking.com

Registered: 1998 (27 years)

Introduction: This company, Puls – Dimension C-Series Power Supply, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. McMaster – 24V DC Power Supplies

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – 24V DC Power Supplies, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Puls Power – 24V 10A DIN Rail Power Supply

Domain: products.pulspower.com

Registered: 2000 (25 years)

Introduction: Product Name: 24V 10A DIN Rail Power Supply

Output Voltage: 24 V

Output Current: 10 A

Power: 240 W

Input Voltage Range: AC 100-240 V | DC 110-150 V or AC 380-480 V (for 3-phase)

Efficiency: Up to 95.2%

Dimensions: Various (39x124x117 mm, 48x124x127 mm, 60x124x117 mm, etc.)

Special Features: Conformal coating, EtherCAT, spring clamp terminals, push-in terminals, integrated power supply condition di…

6. Grainger – DC Power Supplies

Domain: grainger.com

Registered: 1994 (31 years)

Introduction: This company, Grainger – DC Power Supplies, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Eaton – Reliable Power Supplies

Domain: eaton.com

Registered: 1996 (29 years)

Introduction: Eaton provides a wide selection of durable and reliable power supplies for 12 and 24 Vdc applications in various sizes and features. These power supplies convert unstable AC input voltage into safe, consistent, and constant DC output voltage.

Strategic Sourcing Conclusion and Outlook for power supply 24vdc

In the evolving landscape of power supply solutions, particularly for 24V DC applications, strategic sourcing emerges as a critical factor for international B2B buyers. Understanding the diverse range of power supply options available—from various wattages to specific certifications—enables organizations to make informed decisions that align with their operational needs and regulatory requirements. By engaging with reliable suppliers who offer comprehensive technical support, buyers can ensure the selection of optimal power supplies that enhance efficiency and performance in their applications.

Moreover, as markets in Africa, South America, the Middle East, and Europe continue to expand, the demand for high-quality, reliable power solutions grows. Buyers must leverage global sourcing strategies to access competitive pricing and a broader selection of products, ultimately driving down costs while increasing reliability.

Looking ahead, the emphasis on sustainability and technological advancement in power supply systems will reshape procurement strategies. Companies are encouraged to stay abreast of industry trends and innovations, ensuring they are well-positioned to adapt to future demands. Now is the time for international buyers to strengthen their sourcing strategies and invest in robust power supply solutions that will support their growth in an increasingly interconnected world.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to power supply 24vdc

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.