A Deep Dive into Potato Spiral Cutter Slicer Solution

Introduction: Navigating the Global Market for potato spiral cutter slicer

In the competitive landscape of the food service industry, sourcing a reliable potato spiral cutter slicer can present a significant challenge for international B2B buyers. As demand for innovative and visually appealing food presentations grows, understanding the diverse range of available slicers becomes crucial. This guide comprehensively addresses the various types of potato spiral cutter slicers on the market, their applications in different culinary settings, and essential factors to consider when vetting suppliers.

From electric models ideal for high-volume operations to manual slicers suited for smaller establishments, each type offers unique benefits tailored to specific business needs. Additionally, we delve into the cost implications, helping you identify budget-friendly options without compromising on quality or performance.

This guide is designed to empower B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Brazil and Saudi Arabia—by providing actionable insights and practical tips. By equipping you with the knowledge to make informed purchasing decisions, we aim to enhance your operational efficiency and product offerings, ultimately leading to increased customer satisfaction and profitability. Let’s embark on this journey to navigate the global market for potato spiral cutter slicers and unlock the potential these tools hold for your business.

Understanding potato spiral cutter slicer Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Spiral Cutter | Hand-operated, portable, simple design | Food stalls, small cafes, home kitchens | Pros: Low cost, easy to use. Cons: Labor-intensive, slower output. |

| Electric Tornado Slicer | Automated, high-speed operation, versatile for various vegetables | Restaurants, catering services, food trucks | Pros: Fast processing, consistent results. Cons: Higher initial investment, requires power source. |

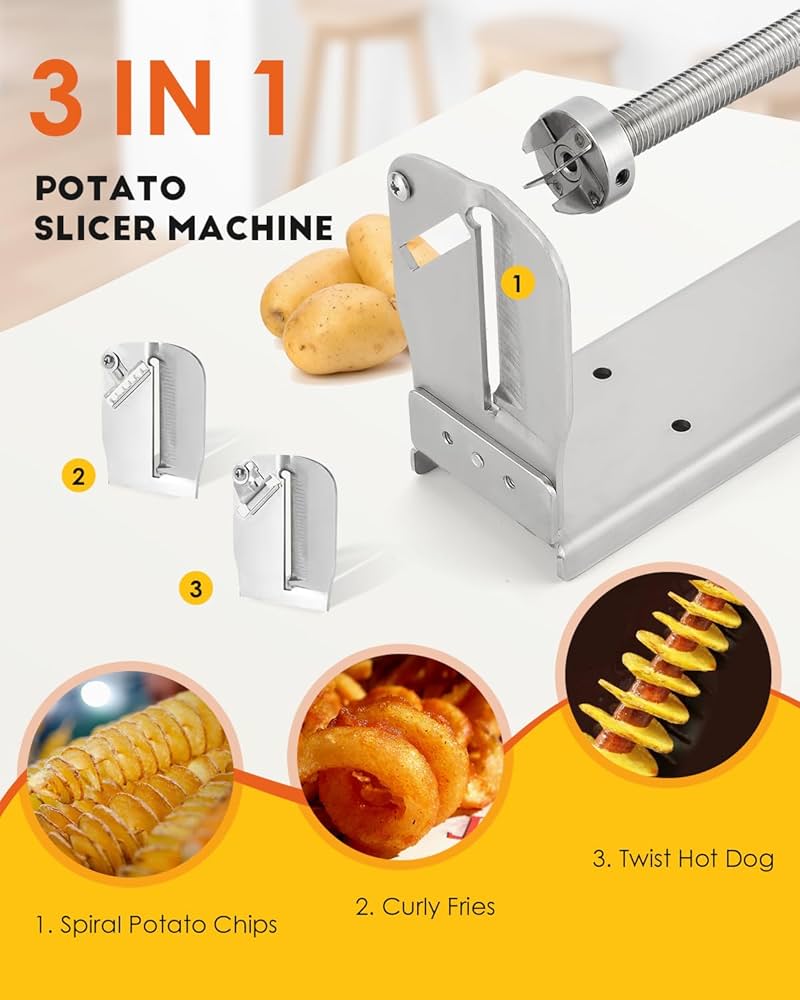

| Spiral Fry™ Potato Cutter | Heavy-duty construction, multiple cutting styles | Bars, lounges, snack shops | Pros: High profit margins, easy to clean. Cons: Bulkier, may require more space. |

| Commercial Potato Slicer | Designed for high volume, robust materials, often multi-functional | Large restaurants, food production facilities | Pros: High efficiency, durable. Cons: Expensive, may need specialized training for use. |

| Compact Countertop Slicer | Space-saving design, suitable for small operations | Small cafes, pop-up restaurants | Pros: Efficient for limited space, affordable. Cons: Limited capacity, may not handle bulk orders. |

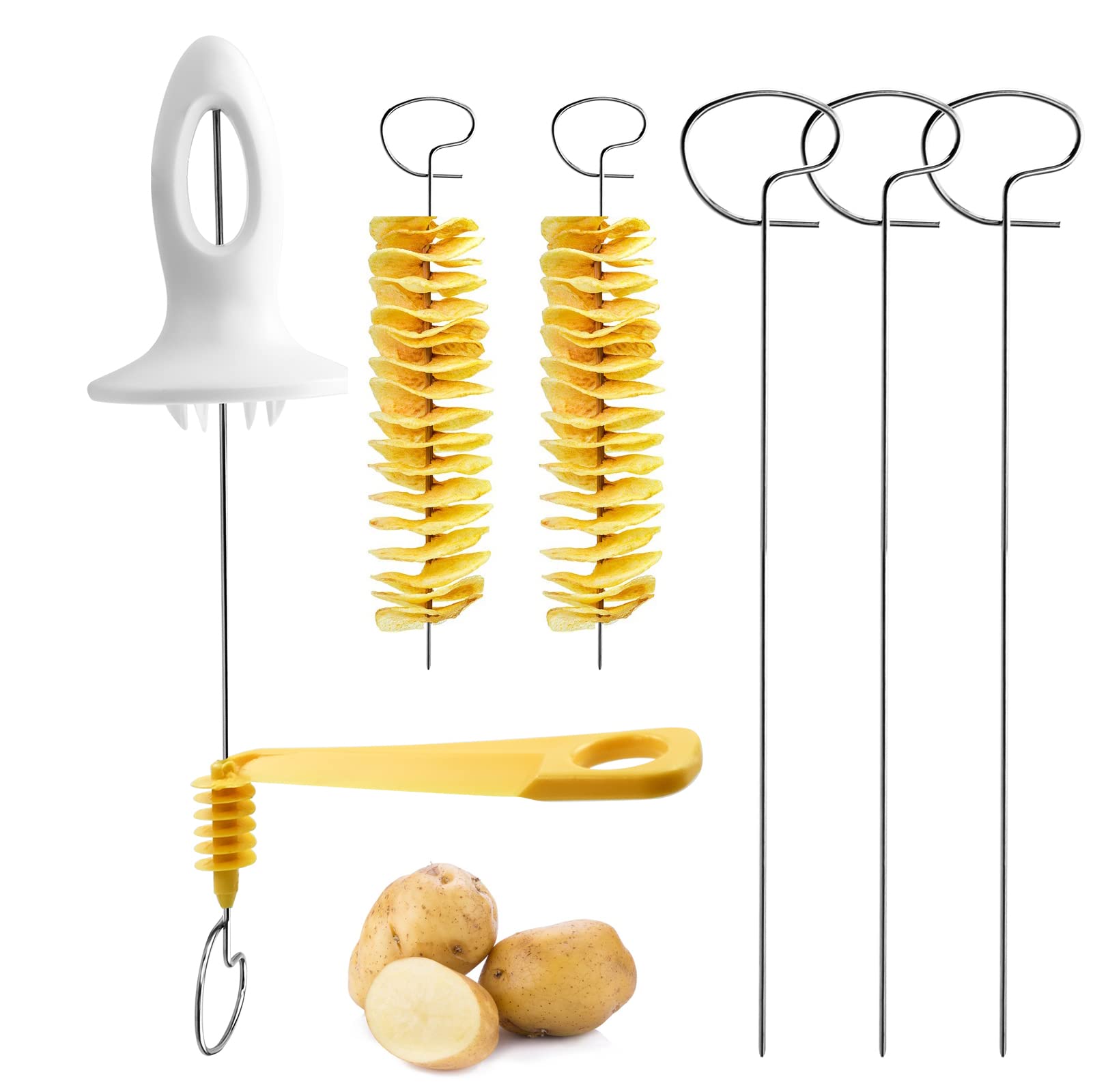

What are the Characteristics of Manual Spiral Cutters?

Manual spiral cutters are basic, hand-operated tools that require physical effort to slice potatoes. Typically made of durable plastic or stainless steel, they are portable and ideal for small-scale operations like food stalls and home kitchens. B2B buyers should consider their ease of use and low cost, but should also be aware of the labor intensity and slower output compared to electric options.

How Do Electric Tornado Slicers Enhance Food Preparation?

Electric tornado slicers automate the spiral cutting process, allowing for high-speed output and consistency. They can handle various vegetables, making them versatile for different culinary applications. These machines are particularly suited for restaurants and catering services that require quick service. While they offer significant efficiency, buyers should consider the higher upfront costs and the need for a reliable power source.

Why Choose Spiral Fry™ Potato Cutters for Profitability?

The Spiral Fry™ potato cutter is designed for heavy-duty use, enabling businesses to create multiple styles of cuts, which can enhance menu offerings. Ideal for bars and snack shops, this machine allows for high profit margins due to low food costs and appealing presentation. While it is easy to clean and maintain, buyers need to consider its larger footprint and potential space requirements in their establishments.

Illustrative image related to potato spiral cutter slicer

What Benefits Do Commercial Potato Slicers Offer?

Commercial potato slicers are built for high-volume operations, making them perfect for large restaurants and food production facilities. These machines are often multi-functional, providing various cutting styles and impressive durability. While they significantly enhance productivity, the investment can be substantial, and buyers may need to ensure staff are trained in their operation to maximize efficiency.

How Can Compact Countertop Slicers Fit into Small Operations?

Compact countertop slicers are designed for space-constrained environments, making them ideal for small cafes and pop-up restaurants. They provide efficient slicing capabilities without the bulk of larger machines. While they are affordable and easy to use, buyers should be aware that their capacity may be limited, which could affect service speed during peak hours.

Key Industrial Applications of potato spiral cutter slicer

| Industry/Sector | Specific Application of Potato Spiral Cutter Slicer | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Service & Catering | Creating unique spiral potato appetizers and snacks | Increases menu diversity and customer appeal | Durability, ease of cleaning, and energy efficiency |

| Retail Food Vendors | Selling spiral-cut potatoes at food markets | High profit margins and quick preparation | Portability, speed of operation, and maintenance support |

| Hospitality & Events | Catering for events with visually appealing dishes | Enhances presentation and customer satisfaction | Customization options and compliance with health standards |

| Snack Food Manufacturing | Mass production of spiral potato snacks | Streamlined operations and reduced labor costs | Production capacity, safety certifications, and reliability |

| Restaurants & Cafés | Incorporating spiral-cut vegetables into meals | Offers innovative side dishes and increases sales | Versatility for different vegetables and consistent cut quality |

How Can Food Service & Catering Businesses Benefit from Potato Spiral Cutters?

In the food service and catering industry, potato spiral cutters are instrumental in creating unique appetizers and snacks that enhance menu offerings. By providing visually appealing spiral-cut potatoes, businesses can attract customers looking for innovative dining experiences. The ability to prepare these snacks quickly and efficiently means that catering services can maintain high-quality standards while managing large events. Buyers should consider the durability and ease of cleaning of the equipment to ensure long-term use in busy environments.

What Advantages Do Retail Food Vendors Gain from Using Spiral Cutters?

Retail food vendors can significantly benefit from potato spiral cutters by offering customers a variety of spiral-cut potato snacks at food markets and festivals. These machines facilitate quick preparation, allowing vendors to serve more customers in less time, ultimately leading to higher profit margins. Portability is a key consideration for vendors, as they often need to transport their equipment to different locations. Additionally, vendors should seek machines that are easy to maintain and provide reliable performance throughout busy service periods.

Illustrative image related to potato spiral cutter slicer

How Do Hospitality & Events Leverage Potato Spiral Cutters for Enhanced Presentation?

In the hospitality sector, potato spiral cutters are used to create visually striking dishes for events and gatherings. This equipment allows catering teams to produce spiral-cut potatoes that serve as eye-catching garnishes or appetizers, enhancing the overall dining experience. The aesthetic appeal of these dishes can lead to increased customer satisfaction and repeat business. Buyers in this sector should prioritize customization options to fit various event themes and ensure compliance with local health and safety standards.

Why Are Snack Food Manufacturers Turning to Spiral Cutters?

Snack food manufacturers are increasingly adopting potato spiral cutters to streamline the mass production of spiral potato snacks. These machines help reduce labor costs and improve production efficiency, allowing businesses to meet growing consumer demand for unique snack options. When sourcing equipment, manufacturers should focus on production capacity, ensuring that the machines can handle their output requirements while maintaining safety certifications for food production.

How Can Restaurants & Cafés Innovate Their Menus with Spiral-Cut Vegetables?

Restaurants and cafés can use potato spiral cutters to incorporate spiral-cut vegetables into their dishes, offering customers a novel twist on traditional sides. This innovation not only boosts menu diversity but also helps restaurants stand out in a competitive market. Buyers should look for machines that are versatile enough to handle various vegetables, ensuring consistent cut quality to maintain presentation standards across different dishes.

Illustrative image related to potato spiral cutter slicer

3 Common User Pain Points for ‘potato spiral cutter slicer’ & Their Solutions

Scenario 1: Difficulty in Achieving Consistent Cuts and Presentation

The Problem: Many B2B buyers, particularly in the food service industry, struggle with ensuring that their potato spiral cutter slicers produce consistent and uniform cuts. Inconsistent slicing not only affects the visual appeal of dishes but also impacts cooking times and customer satisfaction. For businesses that rely on quick service and high-volume sales, such as food trucks or casual dining establishments, this inconsistency can lead to wasted ingredients and dissatisfied customers.

The Solution: To address this issue, buyers should prioritize sourcing potato spiral cutter slicers that feature adjustable cutting thickness settings and high-quality stainless steel blades. When evaluating equipment, look for models that allow for precise depth adjustments, ensuring uniformity in every spiral cut. Furthermore, implementing staff training on how to properly load and operate the machine can significantly improve consistency. Regular maintenance, including blade sharpening and cleaning, will also help maintain cutting precision over time. Establishing a quality control process, where the first few products are checked for consistency before serving, can further enhance customer satisfaction.

Scenario 2: High Maintenance and Downtime Concerns

The Problem: A common concern for B2B buyers is the maintenance and potential downtime associated with potato spiral cutter slicers. Many businesses experience frequent breakdowns due to inadequate maintenance protocols, leading to interruptions in service and loss of revenue. This is particularly critical for businesses operating in high-demand environments, such as fairs or busy restaurants, where operational efficiency is paramount.

The Solution: Buyers can mitigate maintenance issues by investing in robust, commercial-grade slicers that are designed for high-volume use. Look for features such as easy disassembly for cleaning and maintenance, as well as durable construction that can withstand frequent use. Establishing a regular maintenance schedule, including routine inspections and timely blade replacements, will prolong the equipment’s lifespan and minimize unexpected breakdowns. Additionally, sourcing from reputable suppliers that offer warranties and support services can provide peace of mind and quick resolutions when issues arise.

Illustrative image related to potato spiral cutter slicer

Scenario 3: Limited Versatility for Diverse Menu Items

The Problem: B2B buyers often face limitations with potato spiral cutter slicers that only cater to one type of product, restricting menu creativity. In markets where consumers seek variety, having equipment that can only produce spiral-cut potatoes can hinder a business’s ability to innovate and meet customer demands. This is particularly relevant for establishments aiming to diversify their offerings with various snacks or vegetable options.

The Solution: To enhance versatility, buyers should consider multi-functional potato spiral cutter slicers that can accommodate a range of vegetables beyond just potatoes, such as zucchinis, carrots, or cucumbers. When evaluating potential equipment, look for slicers that come with interchangeable blades or attachments that allow for different cut styles, such as ribbons or spirals. This flexibility not only aids in menu diversification but also helps in optimizing inventory management by utilizing various vegetables that may be in surplus. Moreover, incorporating seasonal vegetables into the menu can attract a wider customer base and promote sustainability. By demonstrating versatility in offerings, businesses can create signature dishes that stand out in the competitive market.

Strategic Material Selection Guide for potato spiral cutter slicer

What Are the Key Materials Used in Potato Spiral Cutter Slicers?

When selecting a potato spiral cutter slicer, the choice of materials significantly impacts performance, durability, and overall cost. Here, we analyze four common materials used in the construction of these slicers: stainless steel, aluminum, plastic, and carbon steel. Each material has distinct properties that can influence the decision-making process for international B2B buyers.

How Does Stainless Steel Perform in Potato Spiral Cutter Slicers?

Key Properties: Stainless steel is known for its excellent corrosion resistance, high strength, and ability to withstand high temperatures. It typically has a temperature rating of up to 500°F (260°C) and is resistant to various food acids, making it ideal for food processing equipment.

Pros & Cons: The durability of stainless steel ensures a long lifespan, reducing the need for frequent replacements. However, it tends to be more expensive than other materials, which can increase the initial investment cost. Manufacturing complexity is moderate, as stainless steel requires specialized equipment for cutting and shaping.

Impact on Application: Stainless steel is compatible with various food media and is easy to clean, which is essential in food safety compliance. For international buyers, it is crucial to ensure that the stainless steel used meets standards such as ASTM A240 or DIN 1.4301.

What Advantages Does Aluminum Offer for Potato Spiral Cutter Slicers?

Key Properties: Aluminum is lightweight and has good thermal conductivity, making it suitable for applications where heat dissipation is necessary. It is also resistant to corrosion, although not as robust as stainless steel.

Pros & Cons: The primary advantage of aluminum is its lower cost and ease of manufacturing, which can lead to reduced production times. However, it is less durable than stainless steel and can warp under high pressure or temperature, potentially affecting the slicer’s performance.

Impact on Application: Aluminum is suitable for less demanding environments but may not be ideal for heavy-duty use. International buyers should consider compliance with standards like ASTM B221, especially in regions where food safety regulations are stringent.

Why Choose Plastic for Potato Spiral Cutter Slicers?

Key Properties: Plastic materials, particularly high-density polyethylene (HDPE) and polycarbonate, offer good resistance to chemicals and moisture. They are lightweight and can be molded into complex shapes.

Pros & Cons: The cost-effectiveness of plastic makes it an attractive option for budget-conscious buyers. However, plastics may not withstand high temperatures and can degrade over time, especially when exposed to UV light or harsh cleaning chemicals.

Impact on Application: Plastic is suitable for low-volume applications or temporary setups, but it may not meet the durability requirements for high-traffic environments. Buyers in regions like Africa and South America should ensure that any plastic components comply with local food safety standards.

Illustrative image related to potato spiral cutter slicer

What Role Does Carbon Steel Play in Potato Spiral Cutter Slicers?

Key Properties: Carbon steel is known for its exceptional hardness and edge retention. It is often used for the blades of slicers due to its ability to maintain a sharp edge.

Pros & Cons: While carbon steel can produce high-quality cuts, it is prone to rust and corrosion if not properly maintained. This can lead to higher maintenance costs over time. Additionally, the manufacturing process can be more complex due to the need for heat treatment.

Impact on Application: Carbon steel is best suited for applications where blade sharpness is critical, but buyers must consider the need for regular maintenance. Compliance with standards like JIS G4051 is essential for international buyers to ensure product safety.

Summary Table of Material Selection for Potato Spiral Cutter Slicers

| Material | Typical Use Case for potato spiral cutter slicer | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Heavy-duty, long-lasting slicers | Excellent durability and corrosion resistance | Higher initial cost | High |

| Aluminum | Lightweight, budget-friendly slicers | Cost-effective and easy to manufacture | Less durable under high pressure | Medium |

| Plastic | Low-volume, temporary applications | Lightweight and chemical resistant | Not suitable for high temperatures | Low |

| Carbon Steel | High-performance blades | Superior sharpness and edge retention | Prone to rust and requires maintenance | Medium |

This analysis provides valuable insights for international B2B buyers looking to select the most appropriate materials for potato spiral cutter slicers, considering factors such as performance, cost, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for potato spiral cutter slicer

What Are the Main Stages of Manufacturing Potato Spiral Cutter Slicers?

The manufacturing process of potato spiral cutter slicers involves several critical stages that ensure the final product meets quality and performance standards. Understanding these stages is essential for B2B buyers who prioritize reliability and efficiency in their equipment.

1. Material Preparation

The first step in manufacturing involves sourcing high-quality raw materials, primarily stainless steel, which is favored for its durability and resistance to corrosion. Suppliers often procure materials that meet international standards to ensure longevity and safety in food contact. Additionally, non-toxic plastics may be used for components like handles or bases. Material testing is conducted to verify compliance with standards such as FDA and EU regulations, ensuring that all materials are safe for food use.

2. Forming Techniques

Once the materials are prepared, the forming process begins. This typically involves techniques such as:

-

Stamping and Cutting: Stainless steel sheets are stamped into specific shapes using high-precision dies. This stage includes cutting the blades and other critical components that will form the main body of the cutter.

-

Machining: CNC (Computer Numerical Control) machining is employed to achieve precise dimensions on components like blades, ensuring they can withstand the rigors of daily use. Machining also allows for intricate designs that enhance the aesthetic appeal of the slicer.

-

Injection Molding: For non-metal components, injection molding techniques are used to create durable plastic parts. This process allows for mass production while maintaining consistent quality.

3. Assembly Process

The assembly stage involves putting together the various components to form the final product. Skilled technicians typically perform this process to ensure that each part fits perfectly and operates smoothly. Key assembly steps include:

-

Blade Installation: Blades are attached to the main body with precision, ensuring they are secure and can operate effectively.

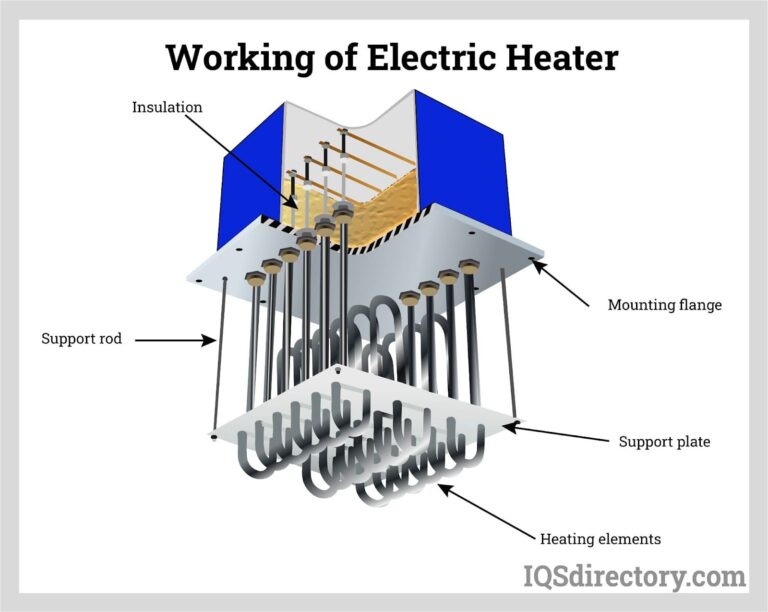

-

Electrical Assembly: For electric models, wiring and electrical components are installed. This step requires adherence to safety regulations, including insulation and proper grounding.

-

Quality Checks: During assembly, initial quality checks (IQC) are conducted to ensure each component meets the specified standards before moving to the next stage.

4. Finishing Touches

The finishing stage includes polishing, painting, or coating the slicers to enhance their appearance and protect against rust and wear. Techniques such as electroplating or powder coating are often used to provide a durable finish that is also visually appealing. Additionally, thorough cleaning is performed to remove any residues from the manufacturing process, ensuring the product is ready for food contact.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance is a vital aspect of the manufacturing process for potato spiral cutter slicers. Buyers should be aware of various international standards and industry-specific certifications that can indicate product reliability and safety.

International Standards

-

ISO 9001: This standard focuses on quality management systems, ensuring that manufacturers consistently produce products that meet customer and regulatory requirements. Certification to ISO 9001 indicates a commitment to quality and continuous improvement.

-

CE Marking: For products sold in Europe, CE marking signifies compliance with health, safety, and environmental protection standards. It is crucial for B2B buyers in Europe to verify that their suppliers have CE certification.

Industry-Specific Certifications

-

FDA Compliance: In the United States, products that come into contact with food must comply with FDA regulations. Manufacturers should provide documentation proving their products meet these requirements.

-

Food Safety Certifications: Certifications like HACCP (Hazard Analysis Critical Control Points) ensure that the manufacturing process adheres to food safety standards, which is particularly important for B2B buyers in the food service industry.

How Are Quality Control Checkpoints Implemented?

Quality control checkpoints are integral to the manufacturing process, ensuring that each potato spiral cutter slicer meets the desired specifications.

Illustrative image related to potato spiral cutter slicer

Incoming Quality Control (IQC)

During the IQC phase, raw materials are inspected for defects or inconsistencies before they enter the production line. This stage may include:

- Material Testing: Conducting tests on incoming materials to ensure they meet required standards.

- Supplier Audits: Regular audits of suppliers to assess their quality control processes and material sourcing practices.

In-Process Quality Control (IPQC)

While the product is being assembled, IPQC measures are taken to monitor the manufacturing process. This can involve:

- Dimensional Inspections: Using tools like calipers and gauges to ensure parts are manufactured to the correct specifications.

- Functional Testing: Testing components to verify that they operate correctly before full assembly.

Final Quality Control (FQC)

The FQC stage occurs after assembly and finishing, where the final product undergoes comprehensive testing, including:

Illustrative image related to potato spiral cutter slicer

- Performance Testing: Assessing the slicer’s cutting efficiency and durability under simulated use conditions.

- Safety Inspections: Ensuring that electrical components meet safety standards and that the product is safe for use.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial to ensure the reliability of potato spiral cutter slicers.

Conducting Supplier Audits

One of the most effective ways to assess a supplier’s quality control is through on-site audits. Buyers should consider:

- Scheduling Regular Audits: Establishing a routine schedule for audits to ensure ongoing compliance with quality standards.

- Evaluating Processes: Reviewing the manufacturer’s processes, documentation, and adherence to quality control measures.

Requesting Quality Reports

Buyers should not hesitate to request quality assurance reports from suppliers. These reports can provide insights into:

- Test Results: Documentation of performance testing and compliance with industry standards.

- Certification Copies: Proof of compliance with ISO, CE, or other relevant standards.

Engaging Third-Party Inspectors

Utilizing third-party inspection services can offer an unbiased assessment of a supplier’s quality control practices. This can include:

- Pre-shipment Inspections: Ensuring that products meet specifications before shipment.

- Random Sampling: Conducting tests on randomly selected units to verify quality consistency.

What Nuances Should International B2B Buyers Be Aware Of?

When sourcing potato spiral cutter slicers, international buyers must navigate various nuances in quality control and certification. Understanding these factors can facilitate smoother procurement processes.

Regional Certification Requirements

Different regions may have specific certification requirements. For example, while CE marking is essential in Europe, buyers in the Middle East may prioritize compliance with local standards. Buyers should familiarize themselves with these regional differences to ensure compliance.

Language and Documentation Barriers

Language differences can pose challenges in understanding quality assurance documentation. B2B buyers should consider:

- Translating Key Documents: Ensuring that critical quality assurance documents are available in a language that is understandable to all stakeholders involved in the procurement process.

- Clear Communication: Establishing clear communication channels with suppliers to address any questions regarding quality control practices.

Conclusion

Understanding the manufacturing processes and quality assurance standards for potato spiral cutter slicers is essential for international B2B buyers. By familiarizing themselves with the key stages of manufacturing, relevant certifications, and quality control checkpoints, buyers can make informed decisions that ensure they procure reliable and efficient equipment for their operations. Engaging in thorough supplier verification practices further enhances the assurance of quality, paving the way for successful business relationships.

Illustrative image related to potato spiral cutter slicer

Practical Sourcing Guide: A Step-by-Step Checklist for ‘potato spiral cutter slicer’

Introduction

This sourcing guide serves as a practical checklist for B2B buyers seeking to procure potato spiral cutter slicers. Whether you are operating in the food service industry or retailing kitchen equipment, understanding the nuances of sourcing these machines is crucial. This guide will help you navigate the procurement process effectively, ensuring you select a product that meets your operational needs and quality standards.

Step 1: Define Your Technical Specifications

Begin by outlining the technical specifications you require for your potato spiral cutter slicer. Consider factors such as the machine’s capacity, blade types, and power requirements.

- Capacity: Determine how many potatoes the slicer can handle at once, which is essential for high-volume operations.

- Blade Type: Choose between manual and electric options, as well as the variety of cuts available (spiral, ribbon, etc.).

Step 2: Research Market Trends and Applications

Investigate current market trends surrounding potato spiral cutter slicers to understand what features are in demand. This knowledge will guide you in making an informed purchasing decision.

- Popular Applications: Identify how these machines are utilized in various settings—food trucks, restaurants, or home kitchens.

- Consumer Preferences: Pay attention to the types of snacks that are trending, such as spiral fries or vegetable garnishes, which can influence your selection.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it is crucial to conduct thorough evaluations. Look for suppliers with a solid reputation and experience in the industry.

- Company Profiles: Request detailed information about their business history, product offerings, and customer service policies.

- References: Seek testimonials or case studies from other buyers in similar markets to assess reliability and product performance.

Step 4: Verify Supplier Certifications

Confirm that potential suppliers have the necessary certifications and compliance with international standards. This step is vital for ensuring product quality and safety.

- Quality Certifications: Look for ISO certifications or other relevant industry standards that demonstrate a commitment to quality.

- Safety Compliance: Ensure that the equipment adheres to local and international safety regulations, which can vary by region.

Step 5: Request Product Samples or Demonstrations

Whenever possible, request samples or arrange for a demonstration of the potato spiral cutter slicer. This hands-on experience can provide valuable insights into the product’s functionality.

- Operational Testing: Evaluate the machine’s ease of use, speed, and consistency in producing the desired cuts.

- Durability Assessment: Inspect the build quality and materials used, as these factors will affect the machine’s longevity in your operations.

Step 6: Negotiate Terms and Pricing

Once you have selected a supplier, engage in negotiations regarding pricing, delivery timelines, and warranty terms. Clear agreements can prevent misunderstandings down the line.

- Volume Discounts: Inquire about bulk purchase discounts or special pricing for long-term contracts.

- Return Policies: Understand the return and warranty policies in case the equipment does not meet your expectations.

Step 7: Finalize the Purchase and Monitor Performance

After concluding negotiations, finalize your purchase and set up a system for monitoring the slicer’s performance in your operations.

- Regular Maintenance: Establish a routine for cleaning and maintaining the equipment to ensure its efficiency and longevity.

- Performance Metrics: Track usage and output quality to gauge the slicer’s effectiveness and make adjustments as needed.

By following these steps, B2B buyers can confidently navigate the sourcing process for potato spiral cutter slicers, ensuring they make informed decisions that align with their business goals.

Illustrative image related to potato spiral cutter slicer

Comprehensive Cost and Pricing Analysis for potato spiral cutter slicer Sourcing

What Are the Key Cost Components for Potato Spiral Cutter Slicers?

When sourcing potato spiral cutter slicers, understanding the cost structure is essential. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly impacts the cost. Stainless steel is commonly used for blades and frames due to its durability and resistance to corrosion, but it can be more expensive than plastic alternatives. Buyers should consider the trade-off between initial costs and long-term durability.

-

Labor: Labor costs vary by region and can influence the overall pricing. In countries with higher wages, such as those in Europe, labor can account for a larger share of the cost compared to regions with lower wage standards.

-

Manufacturing Overhead: This encompasses utilities, rent, and equipment depreciation. Efficient manufacturing processes can help reduce these costs, allowing suppliers to offer competitive pricing.

-

Tooling: The initial investment in molds and dies for production can be significant, especially for custom designs. This cost is often spread across production runs, making it crucial to discuss minimum order quantities (MOQs) with suppliers.

-

Quality Control (QC): Ensuring that products meet specified standards incurs additional costs. Suppliers with robust QC processes may charge more, but this can result in fewer defects and returns.

-

Logistics: Shipping costs can vary widely depending on the destination and shipping method. For international buyers, understanding Incoterms is vital to clarify who bears responsibility for shipping and customs duties.

-

Margin: Suppliers typically add a markup to cover their costs and ensure profitability. Buyers should be aware of typical margins in the industry, which can help in negotiations.

How Do Price Influencers Affect Potato Spiral Cutter Slicer Costs?

Several factors influence the pricing of potato spiral cutter slicers, impacting the final cost for buyers.

-

Volume/MOQ: Suppliers often offer better pricing for larger orders due to economies of scale. Buyers should assess their needs and negotiate MOQs to optimize costs.

-

Specifications and Customization: Custom features or specific design requirements can lead to higher costs. Buyers should clearly define their specifications to avoid unexpected expenses.

-

Materials and Quality Certifications: Higher-quality materials and certifications (e.g., food safety standards) can increase costs but may be necessary for compliance in specific markets. Understanding the market requirements in regions like Africa, South America, and Europe can guide purchasing decisions.

-

Supplier Factors: The supplier’s reputation, experience, and production capabilities can affect pricing. Established suppliers may charge more but offer reliability and better service.

-

Incoterms: International buyers should familiarize themselves with Incoterms to understand shipping responsibilities, which can influence overall costs.

What Are Effective Buyer Tips for Cost-Efficient Sourcing?

For B2B buyers, particularly in Africa, South America, the Middle East, and Europe, effective strategies can enhance cost efficiency in sourcing potato spiral cutter slicers.

-

Negotiation: Always negotiate pricing and terms with suppliers. Building a relationship can lead to better deals and potential discounts for repeat orders.

-

Total Cost of Ownership (TCO): Consider not only the purchase price but also the long-term costs associated with maintenance, parts, and operational efficiency. A cheaper initial price may not always result in lower TCO.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and potential tariffs when importing equipment. Understanding local market conditions can provide insights into fair pricing.

-

Supplier Evaluation: Assess potential suppliers based on their production capabilities, lead times, and customer service. A supplier with a strong track record can save costs in the long run through reliability and support.

Disclaimer on Indicative Prices

Prices for potato spiral cutter slicers can vary widely based on specifications, volume, and supplier factors. It is essential for buyers to conduct thorough market research and engage in direct discussions with suppliers to obtain accurate pricing that reflects their specific needs and circumstances.

Alternatives Analysis: Comparing potato spiral cutter slicer With Other Solutions

Exploring Alternative Solutions to Potato Spiral Cutter Slicers

In the competitive landscape of food processing equipment, businesses often seek alternatives to specialized tools like the potato spiral cutter slicer. Understanding the various options available allows B2B buyers to make informed decisions based on performance, cost, and specific use cases. Below, we compare the potato spiral cutter slicer against two viable alternatives: the Electric Tornado Slicer and the Spiral Fry Potato Cutter.

| Comparison Aspect | Potato Spiral Cutter Slicer | Electric Tornado Slicer | Spiral Fry Potato Cutter |

|---|---|---|---|

| Performance | Produces uniform spiral cuts quickly | Versatile; can cut various vegetables | Creates multiple styles of cuts efficiently |

| Cost | Moderate, often under $100 | Higher initial investment, around $200 | Similar to Tornado Slicer, approximately $150 |

| Ease of Implementation | Simple, manual operation | Requires electrical setup; straightforward | Manual operation; easy to use but needs physical strength |

| Maintenance | Low maintenance; occasional blade sharpening | Moderate; needs cleaning and occasional part replacement | Low; easy to clean and maintain |

| Best Use Case | Ideal for outdoor events and snack vendors | Suitable for restaurants and catering businesses | Great for bars and lounges, high-volume output |

What Are the Advantages and Disadvantages of the Electric Tornado Slicer?

The Electric Tornado Slicer offers significant versatility as it can cut not just potatoes but also other vegetables like zucchini and carrots. This multi-functional capability makes it a valuable asset in various culinary settings, particularly in restaurants and catering services where diverse menu options are a must. The electric model allows for faster production, accommodating high-demand environments. However, its higher cost and dependency on electricity can be drawbacks, especially for mobile vendors or those in regions with unstable power supply.

How Does the Spiral Fry Potato Cutter Compare?

The Spiral Fry Potato Cutter stands out for its ability to produce a range of cuts, including spiral, ribbon, and wavy fries. This adaptability enables businesses to cater to evolving consumer preferences and create visually appealing dishes that enhance customer experience. Its manual operation requires minimal setup and is portable, making it suitable for both indoor and outdoor settings. However, the physical effort required to operate the manual mechanism may deter some users, particularly in high-volume situations.

Conclusion: How Can B2B Buyers Choose the Right Solution for Their Needs?

Choosing the right cutting solution hinges on several factors, including operational requirements, budget constraints, and the specific culinary applications intended. For businesses focused on outdoor events or snack sales, a potato spiral cutter slicer may provide the perfect balance of cost-effectiveness and performance. On the other hand, restaurants aiming for versatility might find the Electric Tornado Slicer more beneficial despite its higher price. Meanwhile, establishments looking to offer a variety of fry styles could opt for the Spiral Fry Potato Cutter. Ultimately, assessing the unique needs of the business will guide buyers to the most suitable equipment for their operations.

Essential Technical Properties and Trade Terminology for potato spiral cutter slicer

What Are the Key Technical Properties of a Potato Spiral Cutter Slicer?

When selecting a potato spiral cutter slicer, understanding its technical specifications is crucial for ensuring that the equipment meets operational needs and quality standards. Here are some essential properties:

1. Material Grade

The material used in the construction of the potato spiral cutter slicer is vital. Most high-quality slicers are made from stainless steel, which offers corrosion resistance, durability, and ease of cleaning. This is especially important for B2B buyers in food service industries, where hygiene and longevity are paramount. Stainless steel components ensure that the equipment can withstand frequent use without degrading.

2. Voltage and Power Rating

Potato spiral cutter slicers typically come with varying voltage and power ratings, such as 110V or 220V. It’s essential for buyers to select a model compatible with their local electrical supply to ensure optimal performance. Understanding the power rating (measured in watts or amps) helps assess the slicer’s efficiency and capability to handle different volumes of production, which is crucial for businesses with varying demand levels.

3. Cutting Thickness

The cutting thickness of the spiral slicer, often specified in millimeters or inches, directly affects the product’s presentation and culinary applications. Most slicers offer adjustable thickness settings, which allow for versatility in preparing dishes. For B2B buyers, the ability to customize the thickness can enhance menu offerings and appeal to different customer preferences.

Illustrative image related to potato spiral cutter slicer

4. Production Capacity

This specification refers to the amount of product the slicer can handle within a given time frame, typically measured in pounds or kilograms per hour. A higher production capacity is essential for businesses that cater to large crowds, such as restaurants or food vendors. Understanding this metric helps buyers evaluate whether the equipment can meet their operational demands efficiently.

5. Ease of Cleaning and Maintenance

Equipment designed with easy disassembly and cleaning features is essential for maintaining hygiene standards. Slicers that can be easily rinsed or have removable parts significantly reduce labor costs associated with cleaning and maintenance, making them more attractive to B2B buyers who prioritize operational efficiency.

What Are Common Trade Terminology and Concepts Related to Potato Spiral Cutter Slicers?

Navigating the B2B landscape requires familiarity with industry-specific terminology. Here are some common terms that buyers should know:

Illustrative image related to potato spiral cutter slicer

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of potato spiral cutter slicers, buyers may source equipment directly from OEMs to ensure quality and compatibility with their business needs.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers, as it can affect inventory management and overall costs. Suppliers often set MOQs based on production costs and logistics.

3. RFQ (Request for Quotation)

An RFQ is a formal document that a buyer sends to potential suppliers to request pricing and terms for specific quantities of products. For buyers of potato spiral cutter slicers, issuing an RFQ can lead to better pricing and terms through competitive bidding.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in shipping goods. Understanding these terms is crucial for B2B transactions, especially when importing equipment from overseas. They clarify aspects like shipping costs, risks, and delivery responsibilities.

5. Lead Time

Lead time refers to the duration from placing an order to receiving the product. In the food service industry, where timing can be critical, knowing the lead time for potato spiral cutter slicers helps businesses plan their inventory and service offerings more effectively.

By comprehending these technical properties and trade terminologies, B2B buyers can make informed decisions that align with their operational goals and market demands.

Navigating Market Dynamics and Sourcing Trends in the potato spiral cutter slicer Sector

What Are the Key Market Dynamics and Trends in the Potato Spiral Cutter Slicer Sector?

The potato spiral cutter slicer market is experiencing significant growth, driven by the rising popularity of street food and quick-service restaurants (QSRs) globally. The convenience of creating visually appealing food items such as spiral fries is a key driver for this trend. In regions like Africa and South America, where street food culture is robust, the demand for versatile food preparation equipment, including potato spiral cutters, is on the rise. Furthermore, the Middle East and Europe are witnessing an influx of these devices in culinary settings, with buyers increasingly seeking innovative equipment to enhance their menu offerings.

Technological advancements are also influencing the market. Electric and automated potato spiral slicers are becoming more prevalent, offering efficiency and consistency in food preparation. International buyers are increasingly looking for equipment that not only meets their operational needs but also aligns with modern kitchen technology trends. Additionally, the integration of smart technologies, such as IoT-enabled devices that track usage and maintenance schedules, is gaining traction among B2B buyers aiming to optimize their operational efficiency.

The market is also seeing a shift towards compact and portable designs, catering to the growing trend of food trucks and mobile kitchens. As culinary entrepreneurs in regions like Brazil and Saudi Arabia seek to maximize space and versatility, lightweight and easy-to-clean models are becoming essential. Overall, international B2B buyers should focus on suppliers that offer innovative, efficient, and versatile potato spiral cutters to stay competitive in this dynamic market landscape.

Illustrative image related to potato spiral cutter slicer

How Important Is Sustainability and Ethical Sourcing in the Potato Spiral Cutter Slicer Industry?

Sustainability and ethical sourcing are increasingly becoming critical considerations for B2B buyers in the potato spiral cutter slicer sector. With growing awareness of environmental issues, businesses are under pressure to adopt sustainable practices throughout their supply chains. This includes sourcing materials that are environmentally friendly and ensuring that manufacturing processes minimize waste and carbon footprints. Buyers should prioritize suppliers who demonstrate a commitment to sustainability through certifications such as ISO 14001, which focuses on effective environmental management systems.

Moreover, the use of recyclable and non-toxic materials in the production of potato spiral cutters is gaining importance. This not only appeals to eco-conscious consumers but also aligns with regulatory trends that favor sustainable practices. For instance, the growing trend of ‘green’ certifications can enhance brand reputation and customer loyalty, particularly in markets where consumers are willing to pay a premium for environmentally responsible products.

Ethical sourcing also involves ensuring fair labor practices within the supply chain. International buyers should seek out manufacturers who uphold ethical labor standards, ensuring that workers are treated fairly and compensated appropriately. This commitment to ethical sourcing not only mitigates risks associated with reputational damage but also fosters a more resilient supply chain, ultimately benefiting all stakeholders involved.

How Has the Potato Spiral Cutter Slicer Evolved Over Time?

The evolution of the potato spiral cutter slicer reflects broader trends in food preparation and culinary innovation. Initially, these devices were simple manual tools, primarily used in home kitchens for casual cooking. Over time, as the demand for visually appealing food options surged, particularly in the fast-food sector, manufacturers began to innovate. The introduction of electric models revolutionized the industry, allowing for faster, more efficient slicing that meets the needs of commercial kitchens.

Today’s potato spiral cutters not only feature advanced cutting technology but also incorporate safety mechanisms and easy-to-clean designs, catering to the high standards of food safety and hygiene. This evolution is significant for B2B buyers, as it underscores the importance of investing in high-quality, reliable equipment that can adapt to changing consumer preferences and operational demands. As the market continues to evolve, staying abreast of these developments will be essential for businesses looking to leverage the popularity of spiral-cut food items.

Frequently Asked Questions (FAQs) for B2B Buyers of potato spiral cutter slicer

-

How do I select the right potato spiral cutter slicer for my business needs?

When selecting a potato spiral cutter slicer, consider factors such as volume capacity, slicing speed, and the types of cuts available. Evaluate whether you need a manual or electric model based on your production requirements. Additionally, assess the machine’s build quality, such as stainless steel components for durability, and ease of cleaning. It’s also beneficial to look at customer reviews and seek out suppliers who offer warranties and reliable customer support. -

What are the most common applications for potato spiral cutter slicers in the food industry?

Potato spiral cutter slicers are primarily used to create visually appealing snacks like spiral fries and twisted potato chips, which are popular in fast-food outlets, food trucks, and fairs. These machines can also be used to slice other vegetables, making them versatile for menu options. Utilizing these slicers can enhance the presentation of dishes, allowing restaurants to attract customers with unique offerings that stand out. -

What is the typical minimum order quantity (MOQ) for potato spiral cutter slicers?

The MOQ for potato spiral cutter slicers can vary by supplier, typically ranging from 5 to 50 units for bulk orders. Factors influencing MOQ include manufacturing capabilities, customization requests, and shipping logistics. It’s advisable to communicate directly with suppliers to negotiate MOQs that suit your business needs, especially if you are testing a new product line or entering a new market. -

How can I ensure the quality of potato spiral cutter slicers before making a purchase?

To ensure quality, request samples or demonstrations from suppliers before committing to a purchase. Additionally, check for certifications that indicate compliance with international safety and quality standards. Customer testimonials and case studies can provide insight into the slicer’s performance in real-world applications. Establishing a quality assurance process, including inspections and testing upon receipt, can also help maintain high standards. -

What payment terms are generally accepted for international purchases of potato spiral cutter slicers?

Payment terms for international transactions often include options such as letters of credit, wire transfers, and escrow services. Many suppliers may require a deposit upfront, with the balance due upon shipment or delivery. It is essential to clarify payment methods and terms during negotiations to ensure alignment with your financial processes and to mitigate risks associated with international trade. -

What are the logistics considerations when importing potato spiral cutter slicers?

When importing, consider shipping methods, customs duties, and delivery times. Air freight is faster but more expensive, while sea freight is cost-effective for bulk orders but takes longer. Ensure your supplier provides the necessary documentation for customs clearance, and factor in any additional costs, such as import taxes or tariffs, that may apply based on your country’s regulations. -

Can I customize potato spiral cutter slicers to meet my specific business requirements?

Many suppliers offer customization options, such as adjusting the size, voltage specifications, or additional features tailored to your operational needs. Discuss your specific requirements with potential suppliers to explore available customization options. Be sure to inquire about any additional costs or lead times associated with custom orders, as these can affect your overall budget and delivery schedule. -

What after-sales support should I expect from suppliers of potato spiral cutter slicers?

Reliable suppliers typically provide comprehensive after-sales support, including warranty coverage, maintenance guidelines, and troubleshooting assistance. Check if the supplier offers replacement parts and easy access to customer service for inquiries. A good after-sales service is crucial for ensuring that your equipment remains operational and meets your business demands over time.

Top 2 Potato Spiral Cutter Slicer Manufacturers & Suppliers List

1. Reddit – DIY Potato Spiral Machine

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: This company, Reddit – DIY Potato Spiral Machine, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Nemco – Spiral Fry™ Potato Cutter

Domain: nemco.com

Registered: 1996 (29 years)

Introduction: {“Model”:”55050AN”,”Product Name”:”Spiral Fry™ Potato Cutter”,”Key Features”:[“Turns potatoes into spiral fries”,”Holds up to a 70-count potato”,”Easy-action drive screw for operation”,”No peeling required”,”Preset drive depth protects blades”,”Heavy-duty construction for durability”,”Mounts securely on any flat surface”,”Easily removable for quick cleanup”],”Profitability”:”Per serving food cost …

Strategic Sourcing Conclusion and Outlook for potato spiral cutter slicer

In today’s competitive food service market, strategic sourcing of potato spiral cutter slicers can significantly enhance operational efficiency and profitability. By investing in high-quality, durable machines, businesses can meet growing consumer demand for unique and visually appealing food offerings. The ability to produce popular snacks like spiral fries not only attracts customers but also allows for impressive profit margins—often exceeding 500% on individual servings.

Moreover, with versatile options available—ranging from manual to electric models—buyers can select equipment that aligns with their specific operational needs and budget constraints. The importance of sourcing from reputable suppliers who offer robust warranties and customer support cannot be overstated, as these factors contribute to long-term satisfaction and reduced downtime.

As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe explore their options, it is crucial to evaluate suppliers based on quality, service, and adaptability to local market trends. By making informed sourcing decisions now, businesses can position themselves to thrive in the evolving culinary landscape. Embrace the opportunity to elevate your offerings and drive profitability by integrating potato spiral cutter slicers into your operations today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to potato spiral cutter slicer