A Deep Dive into Portable Case Solution

Introduction: Navigating the Global Market for portable case

In today’s fast-paced global economy, sourcing the right portable case can pose a significant challenge for international B2B buyers. Whether you are looking to protect sensitive equipment during transportation or ensure the safe storage of valuable items, the variety of options available can be overwhelming. This guide aims to simplify the process by providing comprehensive insights into the diverse types of portable cases, their applications across various industries, and essential considerations for supplier vetting.

From rugged cases designed for extreme conditions to sleek, professional designs suitable for corporate environments, understanding the nuances of each type will empower you to make informed purchasing decisions. Additionally, we will delve into cost factors, material choices, and customization options that can enhance your procurement strategy. This guide is tailored specifically for buyers in Africa, South America, the Middle East, and Europe, including key markets like Nigeria and Saudi Arabia, ensuring that your unique regional needs and logistical challenges are addressed.

By equipping you with the knowledge to navigate the complexities of the portable case market, this resource will facilitate smarter investments, enhance operational efficiency, and ultimately contribute to your business’s success in an increasingly competitive landscape. Explore the essential elements of portable case sourcing to gain a strategic advantage in your procurement efforts.

Understanding portable case Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Gun & Ammo Cases | Designed for firearms, often with custom foam inserts | Military, law enforcement, hunting | Pros: High protection, customizable; Cons: Limited to specific use cases. |

| Camera Cases | Shockproof, waterproof, and often padded for lenses | Photography, videography, broadcasting | Pros: Excellent protection for delicate equipment; Cons: Can be bulky and heavy. |

| Laptop Cases | Designed for portability and protection of laptops | IT, education, field service | Pros: Lightweight, often includes additional storage; Cons: May lack extreme durability. |

| Travel Cases | Lightweight, often with wheels and expandable storage | Business travel, logistics, personal use | Pros: Easy transport, versatile; Cons: Less robust than hard cases. |

| Drone Cases | Custom-fitted for drones with compartments for accessories | Aerial photography, surveying, inspections | Pros: Tailored for specific drone models; Cons: Can be expensive and may not fit all drones. |

What are the Key Characteristics of Gun & Ammo Cases?

Gun and ammo cases are specifically engineered to accommodate firearms and ammunition, often featuring high-density foam inserts that provide a snug fit for each item. These cases are built to withstand harsh conditions, making them ideal for military, law enforcement, and hunting applications. When purchasing, B2B buyers should consider the case’s security features, such as locks and tamper-proof designs, and ensure compliance with local regulations regarding firearm storage.

How Do Camera Cases Protect Valuable Equipment?

Camera cases are designed with shock-absorbent materials and waterproof features to safeguard sensitive photographic equipment. They often include customizable foam interiors to securely hold cameras, lenses, and accessories. These cases are essential for professionals in photography and broadcasting who need reliable protection during transport. Buyers should evaluate the weight, size, and configuration options to ensure they meet their specific needs while considering the potential for bulkiness during travel.

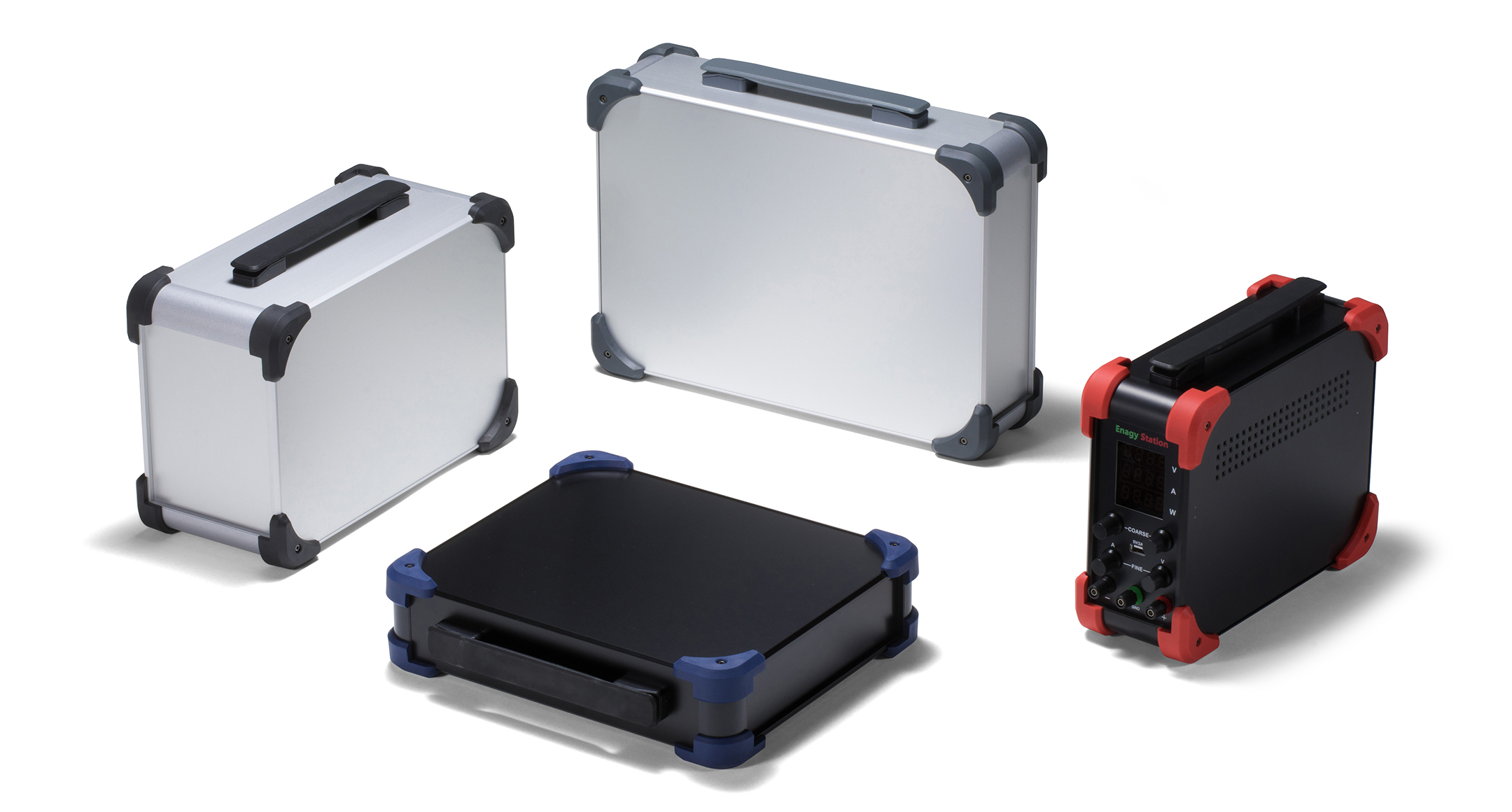

Illustrative image related to portable case

What Makes Laptop Cases Suitable for Business Use?

Laptop cases prioritize portability and protection, often incorporating features such as padded compartments and additional pockets for accessories. These cases are widely used in IT, education, and field service sectors where professionals frequently transport their devices. Buyers should assess factors like weight, material durability, and additional storage capabilities to ensure the case aligns with their operational requirements while providing adequate protection.

Why Choose Travel Cases for Logistics and Business Travel?

Travel cases are designed for ease of transport, often featuring wheels and telescoping handles. They offer expandable storage options, making them versatile for business travel and logistics. While they are generally lighter than hard cases, buyers should be aware that they may not provide the same level of durability. It’s crucial to evaluate the case’s material quality and construction to ensure it can withstand frequent handling and travel.

What Are the Benefits of Using Drone Cases?

Drone cases are tailored to fit specific drone models, providing compartments for the drone itself and its accessories, such as batteries and controllers. They are particularly beneficial for businesses involved in aerial photography, surveying, and inspections. When purchasing, B2B buyers should consider the case’s weight, ease of transport, and waterproofing features to protect their investment in high-value equipment.

Key Industrial Applications of portable case

| Industry/Sector | Specific Application of Portable Case | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace & Defense | Transporting sensitive equipment | Ensures equipment protection during transit, reducing damage risks and costs. | Durability, waterproofing, and compliance with military standards. |

| Medical & Healthcare | Storing and transporting medical devices | Protects equipment from contamination and damage, ensuring reliability in critical situations. | Sterilization options, ease of cleaning, and secure compartments. |

| Photography & Media | Carrying cameras and accessories | Safeguards expensive gear, providing easy access and organization for professionals. | Custom foam inserts, lightweight materials, and portability. |

| Industrial Equipment | Transporting tools and machinery parts | Streamlines logistics, reducing downtime and improving operational efficiency. | Size specifications, weight limits, and ruggedness for harsh environments. |

| Telecommunications | Protecting sensitive electronics | Minimizes risk of damage during transport, maintaining functionality and performance. | Temperature resistance, impact resistance, and customization options. |

How Are Portable Cases Used in the Aerospace & Defense Sector?

In the aerospace and defense sector, portable cases are essential for transporting sensitive equipment such as avionics, communications gear, and military hardware. These cases provide robust protection against environmental hazards, preventing damage from moisture, dust, and impact during transit. Buyers in this sector must prioritize cases that meet rigorous military specifications, ensuring durability and reliability. Additionally, sourcing cases with customizable interiors can accommodate various equipment sizes and configurations, which is crucial for international logistics.

What Role Do Portable Cases Play in the Medical & Healthcare Industry?

Portable cases in the medical and healthcare industry are designed to store and transport critical medical devices, such as diagnostic equipment and surgical instruments. These cases protect against contamination and physical damage, ensuring that medical professionals have reliable tools in emergencies. Buyers should consider cases with sterilization capabilities and secure compartments to prevent movement during transport. Additionally, lightweight and easy-to-clean materials are essential for maintaining hygiene standards in healthcare settings, particularly in regions with varying health regulations.

Illustrative image related to portable case

Why Are Portable Cases Important for Photography & Media Professionals?

For photographers and media professionals, portable cases serve as protective gear for expensive cameras, lenses, and accessories. These cases not only safeguard equipment from physical damage but also provide organizational features that facilitate quick access during shoots. When sourcing cases, buyers should look for options with customizable foam inserts to secure gear effectively and lightweight materials for ease of transport. Given the diverse environments photographers operate in, waterproof and weather-resistant features are also valuable considerations.

How Do Portable Cases Enhance Efficiency in Industrial Equipment Transport?

In industries dealing with heavy machinery and tools, portable cases are crucial for the safe transport of equipment parts. These cases streamline logistics by providing organized storage that reduces downtime caused by lost or damaged items. Buyers need to ensure that the cases meet specific size and weight requirements for easy handling and transport. Additionally, rugged designs that can withstand harsh environments are vital for maintaining the integrity of the equipment during transit, particularly in remote locations.

What Benefits Do Portable Cases Offer to Telecommunications Companies?

Telecommunications companies utilize portable cases to protect sensitive electronic equipment, such as routers and communication devices, during transport. These cases minimize the risk of damage from impacts and environmental conditions, ensuring that technology remains functional and effective. When sourcing, companies should focus on cases that offer temperature and impact resistance, as well as options for customization to fit specific equipment needs. This is particularly important in regions where equipment may be exposed to extreme weather conditions during transportation.

Illustrative image related to portable case

3 Common User Pain Points for ‘portable case’ & Their Solutions

Scenario 1: Navigating the Harsh Environment

The Problem: B2B buyers operating in rugged or unpredictable environments, such as those in the oil and gas, construction, or mining industries, often face significant challenges in protecting sensitive equipment. These environments expose gear to extreme temperatures, moisture, dust, and impacts. The stakes are high; if equipment is damaged, it can lead to costly downtime and loss of productivity. Buyers may struggle to find a portable case that meets the required standards for durability while also being lightweight and easy to transport.

The Solution: To address these concerns, buyers should prioritize sourcing portable cases that are specifically designed for extreme conditions. Look for cases made from high-impact materials that are both waterproof and dustproof, such as those with an IP67 rating. Additionally, consider cases that offer customizable foam interiors. This ensures that equipment fits snugly and is cushioned against shocks. When selecting a supplier, verify their reputation for providing rugged solutions and inquire about product testing in real-world environments. Lastly, educate staff on the importance of proper handling and storage of cases to maximize their lifespan and effectiveness in protecting valuable equipment.

Scenario 2: The Challenge of Customization

The Problem: Many industries require specialized equipment that varies in size and shape, from medical devices to technical instruments. A common pain point for B2B buyers is finding a portable case that can accommodate these unique requirements. Off-the-shelf solutions often fall short, leading to inadequate protection or inefficient use of space within the case. This can result in damaged equipment or difficulty in transportation, which ultimately affects operational efficiency.

The Solution: The ideal approach is to partner with manufacturers that offer customizable portable cases. Buyers should seek options that allow for tailored internal layouts, such as adjustable dividers or bespoke foam inserts that conform to the specific contours of their equipment. Collaborating with a supplier that has a strong design team can help ensure that the case not only fits the equipment perfectly but also facilitates ease of access and organization. During the selection process, request prototypes or samples to test the fit and usability. This investment in customization will pay off by enhancing protection and making transportation more efficient.

Scenario 3: Managing Logistics and Costs

The Problem: For B2B buyers engaged in international trade or multi-site operations, managing logistics and cost is paramount. Portable cases are often a significant expense, and improper selection can lead to increased shipping costs or damage during transit. Furthermore, buyers may experience frustration with suppliers who do not provide transparent pricing or who impose unexpected fees for modifications or shipping.

The Solution: To mitigate these issues, buyers should adopt a comprehensive procurement strategy that includes evaluating total cost of ownership (TCO) rather than just initial pricing. This means considering factors such as durability, potential for damage during transport, and any additional costs related to modifications or custom features. Engage with suppliers who are transparent about their pricing structure and who offer bulk purchasing options for better rates. Additionally, leverage technology such as inventory management systems to track case usage and performance over time. This data can guide future purchasing decisions and help optimize logistics to reduce costs associated with shipping and handling.

By addressing these common pain points with thoughtful solutions, B2B buyers can enhance their operations, protect their investments, and ensure that their portable cases meet the demands of their specific industries.

Strategic Material Selection Guide for portable case

What Are the Key Properties of Common Materials Used in Portable Cases?

When selecting materials for portable cases, understanding the properties and performance characteristics of each option is crucial. Here, we analyze four common materials: Polypropylene, Aluminum, Polycarbonate, and ABS (Acrylonitrile Butadiene Styrene). Each material has unique attributes that make it suitable for different applications, particularly for international B2B buyers.

Illustrative image related to portable case

How Does Polypropylene Perform in Portable Case Applications?

Polypropylene is a thermoplastic polymer known for its lightweight and flexible properties. It offers excellent chemical resistance and can withstand temperatures ranging from -20°C to 100°C. This material is particularly advantageous for cases that may encounter harsh environments, such as those used in the agricultural or chemical sectors.

Pros: Polypropylene is cost-effective and easy to mold, making it suitable for mass production. Its lightweight nature reduces shipping costs, which is particularly beneficial for international buyers in regions like Africa and South America.

Cons: While durable, polypropylene can become brittle at lower temperatures and may not provide the same level of impact resistance as other materials.

Impact on Application: It is ideal for applications requiring chemical compatibility but may not be suitable for heavy-duty protection against impacts.

Considerations for International Buyers: Buyers should ensure compliance with local regulations regarding material safety and environmental impact. Polypropylene is often accepted under international standards such as ASTM and ISO.

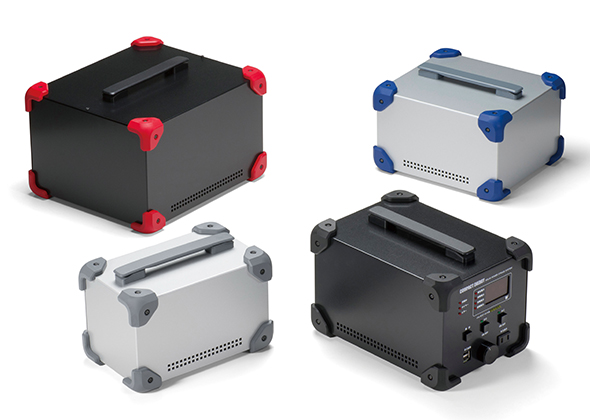

What Advantages Does Aluminum Offer for Portable Cases?

Aluminum is a metal known for its strength-to-weight ratio, corrosion resistance, and durability. It can handle extreme temperatures and pressures, making it suitable for high-performance applications, including military and aerospace.

Pros: Aluminum cases are robust and provide excellent protection against physical impacts and environmental conditions. They are also aesthetically pleasing, which can be a selling point for luxury brands.

Illustrative image related to portable case

Cons: The primary downside is the higher cost compared to plastics and the potential for dents and scratches, which may require additional finishes for aesthetic purposes.

Impact on Application: Aluminum is suitable for high-value equipment, such as electronics or sensitive instruments, where protection is paramount.

Considerations for International Buyers: Buyers in regions with high humidity or salt exposure, such as the Middle East, should look for anodized or coated aluminum options to enhance corrosion resistance.

How Does Polycarbonate Compare in Terms of Durability and Performance?

Polycarbonate is a high-performance thermoplastic known for its exceptional impact resistance and clarity. It can withstand temperatures from -40°C to 120°C, making it suitable for a variety of environments.

Pros: Its high impact resistance makes it ideal for protecting sensitive equipment. Additionally, polycarbonate is lightweight, which helps reduce shipping costs.

Cons: While polycarbonate is strong, it can be more expensive than polypropylene and may scratch easily unless treated with a protective coating.

Impact on Application: This material is ideal for applications requiring transparency, such as cases for cameras or medical devices.

Considerations for International Buyers: Ensure that polycarbonate cases meet local safety standards, as some regions may have specific regulations regarding plastic materials.

What Role Does ABS Play in Portable Case Manufacturing?

ABS is a thermoplastic known for its toughness and impact resistance. It performs well across a range of temperatures, from -20°C to 80°C, making it versatile for various applications.

Pros: ABS is relatively inexpensive and can be easily molded into complex shapes, which is advantageous for custom case designs. Its durability makes it suitable for everyday use.

Cons: While it offers decent impact resistance, ABS is not as strong as aluminum or polycarbonate, making it less suitable for high-stress environments.

Impact on Application: ABS is often used for consumer electronics and tools, where moderate protection is sufficient.

Considerations for International Buyers: Buyers should verify that ABS cases comply with international safety standards, especially in markets with stringent regulations.

Summary Table of Material Selection for Portable Cases

| Material | Typical Use Case for portable case | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polypropylene | Chemical transport cases | Lightweight and cost-effective | Brittle at low temperatures | Low |

| Aluminum | Military and aerospace equipment | High durability and corrosion resistance | Higher cost, prone to scratches | High |

| Polycarbonate | Camera and medical device cases | Excellent impact resistance | More expensive, scratches easily | Med |

| ABS | Consumer electronics and tools | Easy to mold and cost-effective | Moderate impact resistance | Low |

This material selection guide provides insights into the properties, advantages, and limitations of various materials used in portable cases. By understanding these factors, international B2B buyers can make informed decisions that align with their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for portable case

What Are the Main Stages of Manufacturing Portable Cases?

Manufacturing portable cases involves several key stages that ensure the final product meets both functional and aesthetic requirements. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with selecting high-quality materials suited for the intended use of the case. Common materials include high-density polyethylene (HDPE), polypropylene, and aluminum. These materials are chosen for their durability, waterproof properties, and lightweight characteristics. Once selected, materials are cut and shaped into manageable sizes for the subsequent stages.

-

Forming: This stage often involves techniques such as injection molding or rotational molding, depending on the complexity and design of the case. For instance, injection molding is commonly used for plastic cases, where molten plastic is injected into a mold to create the desired shape. For metal cases, processes like stamping or CNC machining may be employed to achieve precision and strength.

-

Assembly: After the individual components are formed, they are assembled to create the portable case. This may involve attaching handles, latches, and any internal padding or dividers. Automated assembly lines are often used for mass production, ensuring consistency and efficiency. In smaller batches, skilled labor may be employed for more intricate assembly tasks.

-

Finishing: The final stage includes surface treatments such as painting, powder coating, or applying protective seals to enhance durability and aesthetics. This stage may also involve quality checks to ensure that all components fit correctly and that the case meets the design specifications.

How Is Quality Assurance Implemented in Portable Case Manufacturing?

Quality assurance (QA) in the manufacturing of portable cases is crucial to ensure that products meet international standards and customer expectations. Several QA methodologies and international standards guide this process.

-

International Standards: Many manufacturers adhere to ISO 9001, a standard that sets out criteria for a quality management system (QMS). This standard helps organizations ensure they meet customer and regulatory requirements consistently. Other relevant certifications may include CE marking for compliance within the European market and API standards for cases used in oil and gas applications.

-

Quality Control Checkpoints: Effective quality control involves multiple checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): This initial check involves inspecting raw materials for quality and compliance with specifications before they enter the production line.

– In-Process Quality Control (IPQC): During the manufacturing process, regular inspections ensure that production techniques adhere to set standards and that any defects are identified early.

– Final Quality Control (FQC): This final inspection assesses the completed product against specifications and performance requirements, ensuring that the portable case is ready for market. -

Common Testing Methods: Various testing methods are employed to validate product durability and functionality. These may include:

– Drop Tests: To assess the case’s ability to withstand impacts.

– Waterproof Tests: To ensure that the case can protect its contents from moisture.

– Temperature and Pressure Tests: For cases designed for extreme environments, ensuring they maintain structural integrity under varying conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to ensure product reliability and compliance with local regulations.

-

Supplier Audits: Conducting audits of suppliers can help buyers assess their manufacturing processes and quality control measures. Audits may focus on the supplier’s adherence to international standards and their internal QA practices.

-

Quality Reports: Requesting regular quality reports from suppliers can provide insights into their QC processes and the results of various tests conducted on their products. These reports should detail the methodologies used and any corrective actions taken in response to identified issues.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased evaluation of the supplier’s manufacturing capabilities and product quality. These inspections can occur at various stages of production and can be particularly valuable for buyers who cannot physically visit the manufacturing facility.

What Are the Quality Control Nuances for International Buyers?

International buyers must be aware of specific nuances related to quality control when sourcing portable cases from different regions.

-

Regulatory Compliance: Different countries have varying regulations regarding product safety and quality. Buyers must ensure that the portable cases comply with the regulations of their respective markets. For example, European buyers will require CE marking, while those in the Middle East may need compliance with GCC standards.

-

Cultural Differences in Quality Standards: Understanding cultural attitudes towards quality can help buyers navigate supplier relationships. Some regions may prioritize cost over quality, while others might have stringent quality expectations. Establishing clear communication about quality expectations is vital.

-

Supply Chain Considerations: The complexity of international supply chains can introduce risks related to quality. Buyers should consider the entire supply chain, from material sourcing to final delivery, ensuring that quality standards are maintained at every stage.

Conclusion

For B2B buyers in diverse regions, understanding the manufacturing processes and quality assurance protocols for portable cases is critical. By familiarizing themselves with these aspects, buyers can make informed purchasing decisions, ensuring that they receive products that meet their specific needs and comply with international quality standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘portable case’

To assist B2B buyers in procuring portable cases effectively, this practical sourcing guide outlines a step-by-step checklist. By following these guidelines, buyers can ensure they select the right cases for their needs while minimizing risks associated with procurement.

Step 1: Define Your Technical Specifications

Clearly outline the specifications required for your portable cases. Consider factors such as size, weight, materials, and intended use. For example, if the cases need to be waterproof or impact-resistant, specify these requirements upfront to filter out unsuitable options.

- Material Considerations: Choose durable materials like polypropylene or aluminum for enhanced protection.

- Size Requirements: Ensure the dimensions align with the items being stored or transported.

Step 2: Identify Your Target Market and Use Cases

Understanding your target market is crucial. Different regions may have unique requirements based on climate, usage scenarios, and regulations. For example, cases for the Middle East may need to withstand high temperatures, while those for Europe might focus on aesthetic appeal.

- Use Case Analysis: Determine if the cases will be used for industrial, travel, or protective purposes.

- Regional Preferences: Research any specific compliance or regulatory standards relevant to your target market.

Step 3: Evaluate Potential Suppliers

Before making a purchase, vet potential suppliers thoroughly. Investigate their reputation, product quality, and customer service history. Request detailed company profiles, case studies, and references from buyers in similar industries.

- Request Samples: Ask for samples to assess the quality and suitability of the cases.

- Assess Certifications: Verify that suppliers hold relevant certifications that ensure product quality and safety.

Step 4: Compare Pricing Structures

Analyze the pricing structures offered by different suppliers. Take into account not only the initial purchase price but also factors such as shipping costs, import duties, and potential discounts for bulk purchases.

- Total Cost of Ownership: Calculate the overall cost, including maintenance and replacement, to make an informed decision.

- Negotiation Opportunities: Leverage quotes from multiple suppliers to negotiate better terms.

Step 5: Review Warranty and Return Policies

A strong warranty and flexible return policy are essential for mitigating risk. Ensure that the supplier offers a clear warranty that covers defects and provides options for returns or exchanges if the product does not meet specifications.

- Warranty Duration: Look for warranties that cover a reasonable period, reflecting the supplier’s confidence in their product.

- Return Conditions: Understand the terms under which returns are accepted to avoid unexpected costs.

Step 6: Conduct a Trial Order

Before committing to a large order, place a trial order to evaluate the supplier’s reliability and the product’s performance in real-world conditions. This step can help identify any unforeseen issues before scaling up your procurement.

Illustrative image related to portable case

- Performance Testing: Use the trial order to assess durability and functionality under typical usage conditions.

- Feedback Loop: Gather input from end-users to gauge satisfaction and identify any potential areas for improvement.

Step 7: Establish a Long-Term Relationship

Building a long-term relationship with your chosen supplier can lead to better pricing, priority service, and ongoing support. Regularly communicate your needs and feedback to strengthen this partnership.

- Feedback Mechanism: Set up regular check-ins to discuss product performance and any future needs.

- Collaboration Opportunities: Explore possibilities for custom solutions or co-development of new products tailored to your requirements.

By following this checklist, B2B buyers can navigate the complexities of sourcing portable cases effectively, ensuring they select the right products to meet their operational needs while fostering beneficial supplier relationships.

Comprehensive Cost and Pricing Analysis for portable case Sourcing

What Are the Key Cost Components in Portable Case Manufacturing?

Understanding the cost structure of portable cases is essential for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts pricing. High-quality, durable materials such as polypropylene, aluminum, or specialized foams will generally lead to higher costs. Buyers should assess the balance between material quality and required functionality.

-

Labor: Labor costs vary by region and can influence overall pricing. In regions with higher labor costs, such as Europe, the final price may be higher compared to suppliers in regions with lower labor costs, such as parts of Africa or South America.

-

Manufacturing Overhead: This includes costs related to factory operations, utilities, and maintenance. Efficient manufacturing processes can reduce overhead, which can be beneficial for price competitiveness.

-

Tooling: Initial tooling costs for molds and production equipment can be significant, especially for custom designs. This cost is often spread over the volume of cases produced, making it crucial for buyers to consider volume when negotiating prices.

-

Quality Control (QC): Implementing robust QC measures ensures product reliability but adds to the overall cost. Buyers should inquire about the QC processes to understand their impact on pricing.

-

Logistics: Shipping and handling costs vary based on distance, volume, and chosen shipping methods. International buyers should account for potential tariffs and customs fees as part of their logistics costs.

-

Margin: Suppliers will include a profit margin in their pricing. This margin can vary significantly between manufacturers based on their market positioning, brand reputation, and operational efficiencies.

What Influences Pricing for Portable Cases in B2B Transactions?

Several factors can influence the pricing of portable cases, particularly for international B2B buyers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically result in lower per-unit costs due to economies of scale. Buyers should negotiate MOQs to maximize their cost-effectiveness.

-

Specifications and Customization: Customized cases or those with specific features (like waterproofing or additional compartments) can significantly increase costs. Buyers should assess whether customization is necessary for their applications.

-

Material Quality and Certifications: High-quality materials often come with certifications (e.g., ISO, military standards) that can add to costs. Buyers must weigh the benefits of certified products against their budgets.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge a premium for their brand, while emerging suppliers might offer competitive pricing to gain market share.

-

Incoterms: The agreed-upon Incoterms (International Commercial Terms) dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms can help buyers avoid unexpected costs.

How Can International Buyers Optimize Their Purchasing Strategy?

For international buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, optimizing purchasing strategies is crucial:

-

Effective Negotiation: Engage suppliers in negotiations, particularly regarding volume discounts and payment terms. Building a relationship can also yield better pricing over time.

-

Focus on Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the TCO, which includes maintenance, durability, and potential replacement costs. Investing in higher-quality cases may reduce long-term expenses.

-

Understand Pricing Nuances: Be aware that pricing structures may vary significantly across regions. Factors such as currency fluctuations, local economic conditions, and trade agreements can impact costs.

-

Research and Compare Suppliers: Conduct thorough research to identify multiple suppliers and compare their offerings. This can provide leverage in negotiations and help identify the best value for money.

-

Stay Informed on Market Trends: Keep abreast of industry trends and innovations that may affect material costs or introduce new products that better meet your needs.

Disclaimer

The prices referenced are indicative and may vary based on market conditions, supplier negotiations, and specific order requirements. Always consult with multiple suppliers to obtain accurate quotes tailored to your specific needs.

Alternatives Analysis: Comparing portable case With Other Solutions

When considering solutions for transporting and protecting valuable equipment or items, the portable case is a popular choice among businesses. However, it is essential to explore alternative solutions that may better fit specific operational needs. This analysis will compare the portable case against two viable alternatives: custom foam inserts and padded bags. Each option presents unique strengths and weaknesses that cater to different requirements.

| Comparison Aspect | Portable Case | Custom Foam Inserts | Padded Bags |

|---|---|---|---|

| Performance | High durability and impact resistance. | Provides tailored protection but may lack robustness. | Moderate protection; suitable for lighter items. |

| Cost | Higher upfront investment. | Variable costs based on customization. | Generally lower cost; budget-friendly. |

| Ease of Implementation | Simple; ready-to-use designs available. | Requires measurement and design work. | Easy to pack and unpack. |

| Maintenance | Low maintenance; durable materials. | May require replacement if foam degrades. | Moderate; fabric may wear out over time. |

| Best Use Case | Ideal for sensitive electronics and high-value items. | Best for specific shapes and delicate equipment. | Suitable for casual use and lightweight items. |

How Does a Portable Case Perform Compared to Custom Foam Inserts?

Custom foam inserts are designed to fit specific equipment shapes, providing excellent protection against shock and vibration. They are particularly beneficial for companies needing tailored solutions for specialized tools or sensitive instruments. However, the customization process can be time-consuming and may not offer the same level of durability as a portable case. Additionally, the cost can vary significantly based on the complexity of the design, potentially leading to budget overruns.

What Are the Advantages and Disadvantages of Using Padded Bags Instead of Portable Cases?

Padded bags present a more economical option for transporting lighter items. They are typically made from fabric and feature cushioning to protect against minor impacts. The primary advantage of padded bags is their lightweight and flexible nature, making them easy to carry and store. However, they do not provide the same level of protection as portable cases, particularly for fragile or high-value items. Over time, the fabric may wear down, compromising the bag’s protective capabilities.

Making the Right Choice: How Can B2B Buyers Select the Best Solution for Their Needs?

When selecting the right solution for transporting equipment, B2B buyers should assess their specific needs, including the nature of the items being transported, the frequency of use, and budget constraints. For high-value or fragile items, a portable case is often the best choice due to its durability and protective features. On the other hand, if the items are less sensitive or the budget is tight, padded bags or custom foam inserts may suffice. Ultimately, the decision should align with the operational requirements and long-term goals of the business, ensuring that the chosen solution provides adequate protection while optimizing costs.

Essential Technical Properties and Trade Terminology for portable case

What Are the Key Technical Properties of Portable Cases?

Understanding the technical properties of portable cases is essential for B2B buyers to make informed purchasing decisions. Here are critical specifications that define the quality and functionality of these products:

1. Material Grade

Portable cases are commonly made from materials such as polypropylene, polyethylene, or aluminum. The material grade significantly impacts the case’s durability, weight, and resistance to environmental factors. For instance, high-grade polypropylene is lightweight yet robust, making it ideal for frequent transport. Buyers should consider the material grade to ensure it aligns with their intended use, especially in industries like electronics or medical equipment where protection is paramount.

2. IP Rating (Ingress Protection)

The IP rating indicates the case’s resistance to dust and water. It is defined by two digits: the first denotes solid particle protection, and the second indicates liquid ingress protection. An IP67 rating, for example, means the case is dust-tight and can withstand immersion in water up to 1 meter for 30 minutes. For businesses operating in harsh environments, selecting a case with a suitable IP rating is crucial for safeguarding valuable equipment.

3. Temperature Tolerance

Temperature tolerance specifies the range within which the case can protect its contents from extreme heat or cold. This specification is vital for industries like pharmaceuticals or food services, where temperature-sensitive items must be stored and transported safely. Understanding the temperature tolerance can help buyers select cases that maintain product integrity throughout their supply chain.

Illustrative image related to portable case

4. Weight Capacity

Each portable case comes with a specified weight capacity, which indicates how much load it can carry without compromising its structural integrity. This property is particularly important for businesses transporting heavy equipment or sensitive materials. Selecting a case with an appropriate weight capacity ensures that it can handle the demands of transportation while minimizing the risk of damage.

5. Customization Options

Many manufacturers offer customization options such as foam inserts, color choices, and branding capabilities. These features allow businesses to tailor cases to their specific needs, enhancing functionality and promoting brand visibility. Customization can also improve the protection of delicate items, ensuring they fit snugly within the case.

What Are Common Trade Terms Used in the Portable Case Industry?

Navigating the portable case market requires familiarity with specific jargon and trade terms. Here are some essential terms that B2B buyers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the portable case industry, understanding OEM relationships can help buyers identify quality manufacturers and assess the reliability of the products they are sourcing.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers looking to manage inventory costs and ensure they are not overcommitting to stock that may not sell quickly.

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price proposals from suppliers. This term is vital for B2B buyers who wish to compare pricing across multiple vendors, ensuring they receive competitive rates for their portable case needs.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for transportation costs, insurance, and risk during shipping. Familiarity with Incoterms helps buyers mitigate risks associated with international logistics.

5. Lead Time

Lead time refers to the period between placing an order and receiving the product. Understanding lead times can help businesses plan their inventory and ensure they have the necessary cases available when needed, particularly in industries with tight deadlines.

By grasping these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring that they select portable cases that meet their specific requirements while navigating the complexities of international trade effectively.

Illustrative image related to portable case

Navigating Market Dynamics and Sourcing Trends in the portable case Sector

What Are the Current Market Dynamics and Key Trends in the Portable Case Sector?

The portable case market is experiencing significant growth, driven by a surge in demand for protective solutions across various industries. Key drivers include the increasing need for secure transportation of valuable equipment, especially in sectors such as photography, military, and medical services. The rise of e-commerce and global trade is also contributing to this demand, as businesses seek durable and reliable packaging solutions for shipping and logistics.

Emerging technologies are reshaping sourcing trends in the portable case sector. The integration of smart technologies—such as RFID tracking and IoT connectivity—into portable cases is gaining traction. These innovations enhance security and inventory management, appealing to B2B buyers in diverse regions, including Africa, South America, the Middle East, and Europe. Additionally, customization options are becoming more prevalent, allowing businesses to tailor cases to specific requirements, thereby improving operational efficiency.

International B2B buyers are increasingly focused on sourcing from manufacturers that offer robust quality assurance processes. As competition intensifies, buyers are prioritizing suppliers who can provide detailed product specifications and certifications. The trend towards local sourcing is also notable, as companies aim to reduce lead times and logistical costs while supporting regional economies.

How Is Sustainability Influencing Sourcing Decisions in the Portable Case Market?

Sustainability is a pivotal consideration for B2B buyers in the portable case sector. As environmental concerns rise, businesses are seeking to minimize their ecological footprint. This shift is prompting manufacturers to adopt eco-friendly practices and materials in their production processes. The use of recyclable materials and the implementation of energy-efficient manufacturing methods are becoming essential criteria for many buyers.

Ethical sourcing is another critical factor influencing purchasing decisions. Buyers are increasingly interested in understanding the supply chain transparency of their suppliers. Companies that demonstrate commitment to ethical labor practices and sustainable sourcing often enjoy a competitive advantage. Certifications such as ISO 14001 (Environmental Management) and FSC (Forest Stewardship Council) are becoming vital indicators of a manufacturer’s dedication to sustainability.

Moreover, the demand for ‘green’ certifications is rising, as consumers and businesses alike are more aware of their purchasing impact. B2B buyers are now more inclined to partner with suppliers who can provide evidence of sustainable practices, as this not only aligns with corporate social responsibility initiatives but also enhances brand reputation in the market.

What Is the Historical Context of the Portable Case Sector for B2B Buyers?

The portable case sector has evolved significantly over the past few decades. Initially, cases were primarily designed for military and industrial applications, focusing on durability and protection. However, as technology advanced, the need for portable cases expanded into various consumer markets, including photography, electronics, and travel.

The introduction of lightweight, impact-resistant materials in the 1990s marked a turning point, allowing for the creation of cases that not only provided robust protection but also enhanced portability. This evolution has been particularly beneficial for B2B buyers, who now have access to a broader range of options tailored to specific needs.

Today, the market reflects a combination of innovation and customization, with manufacturers continuously adapting to the changing demands of businesses worldwide. This historical context underscores the importance of understanding market dynamics and trends for B2B buyers looking to make informed sourcing decisions in the portable case sector.

Illustrative image related to portable case

Frequently Asked Questions (FAQs) for B2B Buyers of portable case

-

How do I choose the right portable case for my products?

Selecting the right portable case involves assessing the specific needs of your products, including size, weight, and fragility. Consider the materials used in the case; options like polyethylene or aluminum offer varying levels of durability and protection. Additionally, think about the case’s intended use—whether for shipping, storage, or travel—and ensure it meets any industry-specific regulations. Consulting with suppliers about customizable features such as foam inserts or dividers can also enhance protection and organization. -

What are the benefits of using customized portable cases for my business?

Customized portable cases can significantly enhance brand visibility and product protection. They allow for tailored dimensions and interior designs that fit your products snugly, reducing movement during transport. Custom branding options, such as logos or colors, can help reinforce your brand identity. Furthermore, bespoke cases often come with specific features that cater to your product’s needs, which can improve customer satisfaction and reduce damage during shipping. -

What factors should I consider when sourcing a portable case supplier internationally?

When sourcing a portable case supplier, consider their reputation, production capabilities, and compliance with international quality standards. It’s crucial to evaluate their experience in your industry and their ability to provide references or case studies. Additionally, assess their communication responsiveness and willingness to accommodate customization requests. Understanding the supplier’s logistics capabilities, including shipping options and lead times, will also help ensure timely delivery. -

What is the typical minimum order quantity (MOQ) for portable cases?

Minimum order quantities (MOQ) for portable cases can vary widely depending on the supplier and the complexity of the customization. Generally, MOQs can range from as few as 50 to several hundred units. It’s advisable to discuss your specific needs with potential suppliers and negotiate terms that work for both parties. Some suppliers may offer flexibility for first-time orders or smaller businesses, while others may require higher quantities to justify production costs. -

How can I ensure the quality of portable cases before making a large purchase?

To ensure quality, request samples before committing to a large order. Evaluate the materials, construction, and overall design of the samples to ensure they meet your standards. Additionally, inquire about the supplier’s quality assurance processes, including any certifications they hold, such as ISO. Conducting a factory visit or third-party inspection can provide further assurance of their manufacturing capabilities and adherence to quality standards. -

What payment terms should I expect when purchasing portable cases internationally?

Payment terms for international purchases typically vary by supplier and can include options such as upfront payment, partial payments, or payment upon delivery. Common methods include wire transfers, letters of credit, and PayPal, depending on the transaction size. It’s essential to clarify payment terms during negotiations and ensure they align with your cash flow capabilities. Consider using escrow services for larger orders to mitigate risks associated with international transactions. -

How do I handle logistics and shipping for portable cases from overseas suppliers?

Managing logistics for international shipping involves coordinating with your supplier and freight forwarder to determine the best shipping method based on cost, time, and reliability. Be aware of any import duties, taxes, and customs regulations that may apply to your shipment. It’s advisable to use a reputable logistics provider familiar with your region’s requirements. Consider insurance for high-value shipments to protect against loss or damage during transit. -

What are common uses for portable cases across various industries?

Portable cases are utilized in numerous industries, including electronics, medical, military, and entertainment. They serve to protect sensitive equipment, transport valuable items, and organize tools or materials. For example, in the medical field, portable cases can house medical devices and supplies, while in the tech industry, they often protect laptops and cameras. Understanding the specific applications within your industry can guide your selection of features and design for optimal functionality.

Top 6 Portable Case Manufacturers & Suppliers List

1. Pelican – Durable Cases for Every Need

Domain: pelican.com

Registered: 1996 (29 years)

Introduction: {“categories”: [“Gun & Ammo Cases”, “Camera Cases”, “Vehicle Cases”, “Travel Cases”, “Micro Cases”, “Drone Cases”, “Laptop Cases”, “Long Cases”, “Carry-On Cases”, “Overlanding Cases”, “Wine & Spirit Cases”], “sizes”: {“Small Cases”: {“length”: “12 inches”, “recommended_for”: [“memory cards”, “phones”, “tools”]}, “Medium Cases”: {“length”: “12 – 22 inches”, “recommended_for”: [“cameras”, “travel”, …

2. Procase – Hard Cases for Tablets and Phones

Domain: procase.com

Registered: 2000 (25 years)

Introduction: All Hard Case – Procase

**Product Categories:**

– Tablets:

– iPad (various models including iPad Pro, iPad Air, iPad Mini)

– Samsung Galaxy Tab (various models)

– Lenovo Tab

– Amazon Kindle

– Other Tablets

– Phones:

– iPhone (various models including iPhone SE, iPhone 11)

– Samsung Galaxy Phones (various models)

– Google Pixel

– LG

– Huawei

– Laptops:

– MacBook (various mo…

3. Cases by Source – BudCase

Domain: shop.casesbysource.com

Registered: 2000 (25 years)

Introduction: Carrying Case options include: Blow Molded Cases, Heavy Duty Waterproof Cases, Medium Duty Carrying Cases, Mobile Electronics Cases, Telescoping Cases, Wheeled Carrying Cases. Key products include: 1. BudCase – interior: 12.5” x 8.99” x 5.13” – $31.19 2. Modi 1083 Molded Soft Case – interior: 10.75” x 8.68” x 3.44” – $24.80 3. Modi 15135 Molded Soft Case – interior: 15.13” x 13.88” x 4.75’…

4. CaseCruzer – GunCruzer and WineCruzer

Domain: casecruzer.com

Registered: 2007 (18 years)

Introduction: CaseCruzer offers a variety of reusable carrying and shipping cases designed for protection and mobility during travel. Key products include: 1. **GunCruzer** – Trusted by law enforcement and military for safe storage and transport of firearms, including handgun and rifle cases. 2. **WineCruzer** – The Portable Wine Cellar™ protects wine bottles from temperature fluctuations, breakage, and spillag…

5. Condition1 – Waterproof Hard Cases

Domain: condition1.com

Registered: 2005 (20 years)

Introduction: This company, Condition1 – Waterproof Hard Cases, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Freefly – Astro Compact Travel Case

Domain: store.freeflysystems.com

Registered: 2011 (14 years)

Introduction: {‘name’: ‘Astro Compact Travel Case’, ‘price’: ‘$795.00’, ‘sku’: ‘910-00842’, ‘availability’: ‘In stock, ships within 1 business day’, ‘features’: [‘Tough, lockable SKB case’, ‘Built in wheels and extendable handle’, ‘Custom closed-cell foam insert fits: Astro (with 2x SL8s installed), Pilot Pro LR1 Payload (with accessory module installed), 2x SL8 chargers, 2x spare props, 3x hex drivers’, ‘Dual …

Strategic Sourcing Conclusion and Outlook for portable case

What Are the Key Takeaways for Strategic Sourcing of Portable Cases?

As the demand for portable cases continues to grow across various sectors, strategic sourcing becomes crucial for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. Emphasizing quality, durability, and customization options is vital for companies seeking to protect valuable assets. Buyers should prioritize suppliers that offer robust warranties and exceptional customer service, ensuring their investment is safeguarded over time.

How Can Buyers Leverage Strategic Sourcing for Competitive Advantage?

Effective strategic sourcing allows businesses to optimize their supply chains and enhance their competitive edge. By engaging with reputable manufacturers who understand local market needs, buyers can access tailored solutions that meet specific requirements. Additionally, leveraging technology and data analytics can streamline procurement processes, leading to cost efficiencies and improved product selection.

What’s Next for International B2B Buyers in the Portable Case Market?

Looking ahead, international buyers should remain proactive in exploring innovative materials and designs that cater to evolving market demands. Establishing long-term partnerships with suppliers who demonstrate sustainability practices and adaptability will be key to navigating future challenges. Embrace the opportunity to invest in high-quality portable cases that not only protect assets but also enhance your brand’s reputation. Engage with trusted suppliers today to secure your position in this dynamic market.

Illustrative image related to portable case

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.