A Deep Dive into Poly Wrapper Solution

Introduction: Navigating the Global Market for poly wrapper

Navigating the complexities of sourcing poly wrappers can be a daunting task for international B2B buyers, especially in diverse markets such as Africa, South America, the Middle East, and Europe. With the increasing demand for efficient packaging solutions that meet both functional and aesthetic requirements, businesses must carefully evaluate their options. This guide addresses key challenges, including identifying the right types of poly wrappers, understanding their various applications, and vetting suppliers to ensure quality and compliance.

Throughout this comprehensive resource, readers will gain insights into the different types of poly wrapping materials available, from crystal clear food wraps ideal for retail settings to robust polyolefin shrink films that enhance product security. We will also delve into the cost considerations associated with various packaging solutions and provide actionable strategies for sourcing the best products to meet your business needs.

By the end of this guide, B2B buyers will be empowered to make informed purchasing decisions, equipped with the knowledge to navigate the global poly wrapper market effectively. Whether you are based in Nigeria, Brazil, or any other region, our insights will help streamline your procurement process and enhance your packaging strategy, ultimately contributing to your business’s success.

Understanding poly wrapper Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Crystal Clear Poly Food Wraps | Made from BOPP material, food-safe, visually appealing | Food packaging, gift wrapping | Pros: Attractive display; protects food freshness. Cons: Limited durability for heavy items. |

| Flat Pack Polywrapper | Servo motor technology, quick changeover, versatile | Packaging napkins, tissues, and small items | Pros: High efficiency; suitable for various products. Cons: Initial investment can be high. |

| Poly-Ply™ Plastic Pipeline Wrap | 3-ply construction, chemical and bacteria resistant | Industrial applications, pipeline protection | Pros: Strong barrier; flexible for irregular shapes. Cons: Niche use; might not suit all buyers. |

| Shrink Wrap | Provides complete package closure, moisture resistant | Retail packaging, security applications | Pros: Enhances product security; attractive presentation. Cons: Requires heat application; may not be eco-friendly. |

| Printed Poly Bagging | Customizable prints, effective for branding | Retail, soft goods packaging | Pros: Enhances brand visibility; cost-effective. Cons: Limited protection for fragile items. |

What Are the Characteristics of Crystal Clear Poly Food Wraps?

Crystal Clear Poly Food Wraps are designed primarily for food packaging, utilizing BOPP material that not only ensures food safety but also allows for a visually appealing presentation. This type of wrap is ideal for businesses that want to showcase their products, such as bakeries or gift shops. When purchasing, consider the size variations available and the potential need for bulk buying to reduce costs.

How Does the Flat Pack Polywrapper Enhance Packaging Efficiency?

The Flat Pack Polywrapper is characterized by its servo motor technology, which allows for continuous product control and rapid changeover between different packaging tasks. This makes it particularly useful for businesses that require versatility in packaging small items like napkins and tissues. Buyers should evaluate the machine’s throughput capabilities and compatibility with existing production lines to maximize efficiency.

Why Choose Poly-Ply™ Plastic Pipeline Wrap for Industrial Applications?

Poly-Ply™ Plastic Pipeline Wrap stands out due to its 3-ply construction, which offers excellent mechanical strength and resistance to chemicals and bacteria. This wrapper is specifically designed for industrial applications, such as protecting pipelines and fittings. When considering this product, businesses should assess the specific environmental conditions it will face and ensure it meets their durability requirements.

What Are the Benefits of Using Shrink Wrap in Retail Packaging?

Shrink Wrap is widely used in retail for its ability to provide complete package closure and protect products from moisture and dirt. This type of packaging is particularly effective for high-value items, enhancing security and presentation. Buyers should consider the heat application process required and evaluate whether the environmental impact of shrink film aligns with their sustainability goals.

How Can Printed Poly Bagging Boost Brand Visibility?

Printed Poly Bagging allows businesses to customize their packaging with branding elements, making it a powerful marketing tool. This type of packaging is commonly used for retail and soft goods, offering a cost-effective solution that enhances brand visibility. When purchasing, companies should focus on the quality of printing and the material’s durability to ensure it meets their packaging needs.

Key Industrial Applications of poly wrapper

| Industry/Sector | Specific Application of poly wrapper | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food & Beverage | Packaging of baked goods and fresh produce | Enhances product visibility and freshness, reduces spoilage | Food safety certifications, clarity of material, size options |

| Manufacturing | Wrapping of metal components for corrosion protection | Extends product life, reduces maintenance costs | Thickness and durability of the material, resistance to chemicals |

| Retail | Security packaging for high-value items | Deters theft, enhances product presentation | Custom branding options, material strength, ease of sealing |

| Pharmaceuticals | Protection of medical supplies and devices | Maintains sterility, ensures compliance with regulations | Compliance with health regulations, barrier properties, size specifications |

| Textiles & Apparel | Bagging of garments and soft goods | Prevents contamination, enhances presentation | Custom sizes, printed options for branding, durability of bags |

How is Poly Wrapper Utilized in the Food & Beverage Industry?

In the food and beverage sector, poly wrappers are essential for packaging baked goods, sandwiches, and fresh produce. These wrappers maintain product freshness and visibility, allowing consumers to see the contents while protecting them from contamination. For international buyers, especially in regions like Africa and South America, sourcing food-safe materials with proper certifications is crucial. The availability of various sizes and thicknesses also helps accommodate diverse product ranges, ensuring optimal preservation and presentation.

What Role Does Poly Wrapper Play in Manufacturing for Metal Components?

Poly wrappers are commonly used in manufacturing to protect metal components from corrosion during storage and transport. By providing a moisture and chemical barrier, these wrappers extend the life of metal products, reducing the need for costly maintenance. Buyers from the Middle East and Europe must consider the material’s thickness and durability to ensure it meets specific environmental conditions. Additionally, sourcing options that offer tailored sizes for unique components can enhance operational efficiency.

How is Poly Wrapper Essential for Retail Security Packaging?

In the retail sector, poly wrappers serve a crucial role in securing high-value items such as cosmetics and electronics. These wrappers deter theft and provide an attractive presentation for display. B2B buyers should prioritize materials that offer both strength and aesthetic appeal, as well as options for custom branding. Sourcing considerations include the ability to create tamper-evident seals, which are increasingly important in ensuring product integrity and consumer trust.

What Benefits Does Poly Wrapper Provide in Pharmaceuticals?

The pharmaceutical industry relies on poly wrappers for packaging medical supplies and devices, maintaining sterility throughout the supply chain. These wrappers are designed to comply with strict health regulations and provide essential barrier properties against contaminants. International buyers should focus on sourcing materials that meet specific regulatory standards, ensuring safety and efficacy. Additionally, the ability to customize sizes and designs can cater to unique packaging needs for various medical products.

How is Poly Wrapper Utilized in Textiles & Apparel Packaging?

In the textiles and apparel industry, poly wrappers are employed for bagging garments and soft goods. This application prevents contamination during shipping and storage while enhancing product presentation at retail outlets. For B2B buyers, sourcing durable and customizable wrappers is important, as they may require specific sizes or printed designs for branding purposes. Furthermore, ensuring that the material is breathable can help maintain the quality of the textiles, particularly in humid climates often found in regions like Africa and South America.

3 Common User Pain Points for ‘poly wrapper’ & Their Solutions

Scenario 1: Inconsistent Quality Across Suppliers

The Problem: B2B buyers often face challenges with the inconsistent quality of poly wrappers from different suppliers. This can lead to issues such as inadequate sealing, tears during transport, or not meeting food safety standards, especially for businesses in the food industry. Buyers are left grappling with the potential loss of product integrity, which can harm their reputation and lead to financial losses. The variability in quality can also result in increased waste and operational inefficiencies, as teams must frequently inspect and test incoming materials.

The Solution: To combat quality inconsistencies, B2B buyers should establish stringent quality control criteria when selecting suppliers. This involves conducting thorough audits of potential suppliers’ production processes and materials. Buyers should request samples and test them under real-world conditions to ensure they meet their specific requirements. Establishing long-term partnerships with suppliers who demonstrate reliability in quality can also be beneficial. By implementing a robust supplier evaluation process, businesses can ensure they receive high-quality poly wrappers consistently, reducing waste and improving their operational efficiency.

Scenario 2: Difficulty in Sourcing the Right Size and Type

The Problem: Many businesses encounter challenges when trying to source poly wrappers that fit their product specifications. With various sizes, materials, and types available, it can be overwhelming for buyers to identify the right solution. This issue is particularly pronounced in industries such as food and pharmaceuticals, where packaging needs to meet strict regulatory standards. Inadequate sizing can lead to packaging that is either too loose, risking contamination, or too tight, which can damage the product.

The Solution: To address sizing challenges, buyers should conduct a thorough analysis of their products and packaging requirements. Creating a detailed specification sheet that outlines dimensions, material types, and any regulatory compliance needs can streamline the sourcing process. Additionally, engaging with suppliers who offer customizable solutions can be advantageous. Many manufacturers now provide the option to create bespoke poly wrappers tailored to specific product dimensions. This proactive approach not only ensures the right fit but also enhances product safety and presentation.

Scenario 3: Environmental Concerns and Sustainability Issues

The Problem: As global awareness of environmental issues grows, many B2B buyers are grappling with the sustainability of their packaging solutions. Poly wrappers, traditionally seen as less eco-friendly due to their plastic composition, can lead to negative perceptions among consumers and stakeholders. Buyers are increasingly pressured to find alternatives that reduce their environmental footprint while still meeting functional needs, leading to a dilemma in balancing cost, performance, and sustainability.

The Solution: To navigate sustainability concerns, businesses should explore poly wrappers made from biodegradable or recycled materials. Engaging with suppliers who prioritize eco-friendly practices can help align packaging choices with corporate social responsibility goals. Additionally, buyers can consider implementing a take-back program for used packaging to promote recycling and reduce waste. Educating stakeholders on the benefits of sustainable packaging can also enhance brand image and customer loyalty. By proactively sourcing sustainable poly wrappers and adopting environmentally friendly practices, companies can mitigate their impact and contribute to a more sustainable future.

Strategic Material Selection Guide for poly wrapper

What Are the Key Properties of Common Materials Used for Poly Wrappers?

When selecting materials for poly wrappers, it is essential to consider various factors such as performance properties, cost, and suitability for specific applications. Below, we analyze four common materials used in poly wrapping, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

How Does Polyethylene (PE) Perform as a Poly Wrapper Material?

Polyethylene (PE) is one of the most widely used materials for poly wrappers due to its versatility and cost-effectiveness. It exhibits excellent chemical resistance and is suitable for a range of temperatures, making it ideal for both food and non-food applications. PE is lightweight and can be produced in various thicknesses, typically ranging from 1.4 mil to 1.6 mil.

Pros:

– Durability: PE is resistant to moisture and chemicals, ensuring product integrity during storage and transport.

– Cost-Effective: Generally lower in cost compared to other materials, making it an attractive option for bulk purchases.

– Manufacturing Simplicity: Easy to process and can be produced in various sizes and shapes.

Cons:

– Environmental Concerns: PE is not biodegradable, raising sustainability issues.

– Limited Temperature Resistance: While it performs well at moderate temperatures, it may not withstand extreme heat or cold.

Considerations for International Buyers:

Compliance with local regulations regarding food safety and environmental impact is crucial. Buyers should ensure that PE products meet standards such as ASTM or DIN, particularly in regions like Europe and South America.

What Advantages Does Polypropylene (PP) Offer for Poly Wrapping?

Polypropylene (PP) is another popular choice for poly wrappers, particularly in food packaging. It is known for its clarity and strength, making it an excellent option for products requiring visibility and protection.

Pros:

– High Clarity: Provides excellent visibility for packaged products, enhancing shelf appeal.

– Chemical Resistance: Offers strong resistance to solvents and chemicals, making it suitable for various applications.

– Reusability: PP wraps can be reused, contributing to sustainability efforts.

Cons:

– Higher Cost: Generally more expensive than PE, which may impact budget considerations for large orders.

– Processing Complexity: Requires more sophisticated manufacturing techniques, potentially leading to longer lead times.

Considerations for International Buyers:

In regions like Africa and the Middle East, where food safety is paramount, ensuring compliance with local health regulations is essential. Buyers should also consider the availability of PP and its production capabilities in their region.

How Does Polyvinylidene Chloride (PVDC) Compare as a Poly Wrapper Material?

PVDC is a specialized material often used for applications requiring high barrier properties, particularly in food packaging. Its unique composition provides excellent moisture and oxygen barrier capabilities, extending product shelf life.

Pros:

– Superior Barrier Properties: Effectively protects against moisture and oxygen, making it ideal for perishable goods.

– Chemical Resistance: Resistant to a wide range of chemicals, ensuring product safety.

Cons:

– Cost: Typically more expensive than PE and PP, which may deter budget-conscious buyers.

– Environmental Impact: Like PE, PVDC is not biodegradable, raising sustainability concerns.

Considerations for International Buyers:

PVDC compliance with food safety standards is critical, especially in regions with stringent regulations like Europe. Buyers should also consider the material’s recyclability and disposal methods.

What Are the Benefits of Using BOPP (Biaxially Oriented Polypropylene)?

BOPP is a type of polypropylene that has been stretched in both the machine and transverse directions, providing enhanced strength and clarity. It is commonly used in packaging for food items, gifts, and retail products.

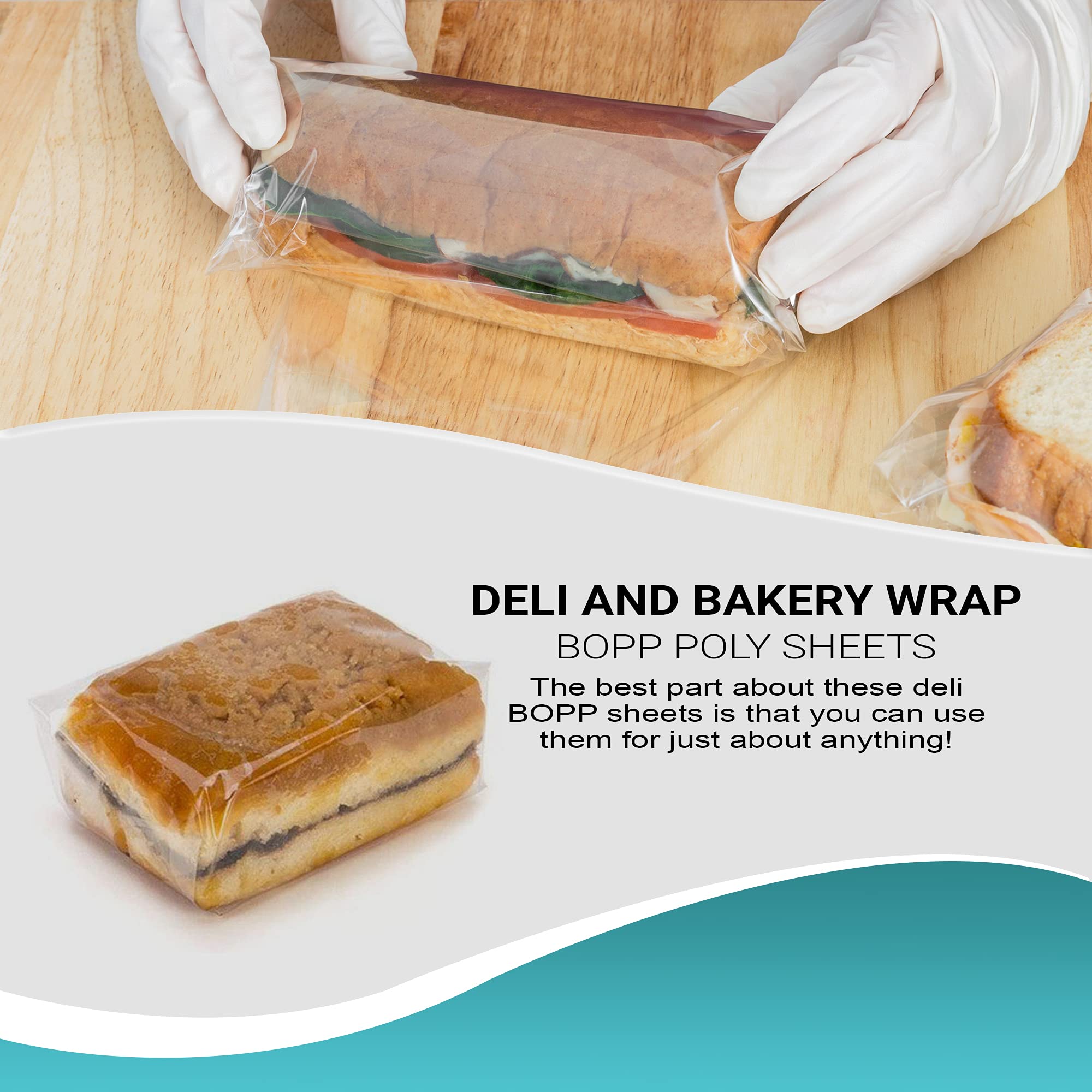

Illustrative image related to poly wrapper

Pros:

– High Strength: Offers excellent tensile strength, making it suitable for heavy-duty applications.

– Clarity and Printability: Provides a clear view of the product while allowing for high-quality printing.

Cons:

– Cost: More expensive than standard polypropylene, which could affect pricing strategies.

– Limited Temperature Resistance: While it performs well under normal conditions, it may not be suitable for extreme temperatures.

Considerations for International Buyers:

BOPP products should comply with local packaging standards, particularly in regions like South America and Africa, where regulations may vary significantly.

Summary of Material Selection for Poly Wrappers

| Material | Typical Use Case for poly wrapper | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene (PE) | General packaging, food and non-food items | Cost-effective and durable | Environmental concerns; limited temperature resistance | Low |

| Polypropylene (PP) | Food packaging, high-visibility products | High clarity and chemical resistance | Higher cost; processing complexity | Medium |

| Polyvinylidene Chloride (PVDC) | High-barrier food packaging | Superior moisture and oxygen barrier | Higher cost; environmental impact | High |

| BOPP | Retail and gift packaging | High strength and printability | Higher cost; limited temperature resistance | Medium |

This guide provides an overview of the strategic material selection for poly wrappers, enabling international B2B buyers to make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for poly wrapper

What Are the Main Stages in the Manufacturing Process of Poly Wrappers?

The manufacturing of poly wrappers involves several critical stages, each essential for ensuring that the final product meets quality and performance standards.

-

Material Preparation: The process begins with the selection of high-quality raw materials, primarily polyethylene (PE) or polypropylene (PP), which are chosen based on the intended application of the wrapper. These materials are then subjected to a thorough quality inspection to confirm they meet industry specifications.

-

Forming: Once the materials are prepared, they undergo extrusion, where plastic pellets are melted and formed into thin sheets or films. This process allows for customization of thickness, width, and properties, depending on the end-use requirements. The extruded films are then cooled and wound onto rolls for easy handling.

-

Assembly: In this stage, the poly film is cut and shaped into specific dimensions according to customer specifications. This may involve folding, sealing, or additional processes like printing for branding purposes. Advanced machinery, such as servo-driven flat pack polywrappers, ensures precision in alignment and speed, reducing material waste and improving efficiency.

-

Finishing: The final stage includes quality checks, packaging, and labeling. The finished poly wrappers are rolled or stacked and prepared for shipment. At this point, additional features like perforations or tamper-evident seals may be added, depending on customer needs.

How Is Quality Assurance Implemented in Poly Wrapper Production?

Quality assurance (QA) is paramount in the manufacturing of poly wrappers, ensuring that the products comply with both international and industry-specific standards.

-

International Standards: Many manufacturers adhere to ISO 9001, a quality management system standard that helps organizations ensure they meet customer and regulatory requirements consistently. Compliance with this standard signifies a commitment to quality and continuous improvement.

-

Industry-Specific Standards: Depending on the application, poly wrappers may also need to meet specific industry standards, such as CE marking for products sold in the European Economic Area or API standards for oil and gas applications. These certifications can enhance marketability and ensure compliance with local regulations.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet predefined specifications.

– In-Process Quality Control (IPQC): During production, regular checks are performed to monitor the manufacturing process and detect any deviations from quality standards.

– Final Quality Control (FQC): Before shipping, the finished products undergo thorough testing to confirm they meet all specifications and standards.

What Common Testing Methods Are Used in Poly Wrapper Quality Assurance?

Testing methods for poly wrappers are designed to assess various properties, including strength, clarity, and chemical resistance. Common methods include:

- Tensile Strength Testing: This evaluates the maximum amount of tensile (pulling) stress that the poly wrapper can withstand before breaking.

- Elongation Testing: Measures how much the material can stretch before it breaks, which is crucial for applications requiring flexibility.

- Thickness Measurement: Ensures that the film meets specified thickness standards, which can impact durability and performance.

- Clarity Testing: Assesses the transparency of the film, especially important for food packaging where visibility is essential.

- Chemical Resistance Testing: Determines how well the wrapper withstands exposure to various chemicals, particularly for industrial applications.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial to ensure product reliability. Here are actionable steps:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing facilities, processes, and quality control measures in place. This firsthand observation can reveal a lot about a supplier’s commitment to quality.

-

Quality Assurance Reports: Request detailed quality assurance reports that outline the testing methods used, results of recent quality checks, and compliance with relevant standards. These documents provide transparency into the supplier’s quality management system.

-

Third-Party Inspections: Engage third-party inspection agencies to perform independent evaluations of the supplier’s products and processes. These organizations can provide unbiased assessments and certifications that bolster trust.

-

Certification Verification: Ensure that the supplier holds relevant certifications (e.g., ISO, CE) and check their validity. This can often be done through the issuing bodies or relevant industry associations.

What Are the Quality Control and Certification Nuances for International B2B Buyers?

Navigating quality control and certification nuances is essential for B2B buyers in different regions. For instance:

-

Regional Standards: Understand that different markets may have unique standards and regulations. For example, the European Union has stringent regulations regarding food safety and packaging materials, which may not apply in other regions.

-

Documentation Requirements: Buyers should familiarize themselves with the necessary documentation for importing poly wrappers into their respective countries, including certificates of compliance and safety data sheets.

-

Cultural Considerations: Building relationships with suppliers who understand local market needs can facilitate smoother transactions and better compliance with regional standards.

-

Sustainability Certifications: Given the increasing global focus on sustainability, buyers should also consider suppliers who have certifications related to environmental management, such as ISO 14001, which can enhance their brand reputation.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing poly wrappers, ensuring they receive products that meet their quality expectations and regulatory requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘poly wrapper’

This guide is designed to assist B2B buyers in efficiently sourcing poly wrappers, ensuring that you make informed decisions that align with your business needs. Poly wrappers are essential for various applications, including food packaging, product security, and moisture protection. By following this checklist, you can streamline your procurement process and select the best supplier for your requirements.

Step 1: Define Your Technical Specifications

Understanding the specific requirements for your poly wrappers is crucial. Consider the type of products you will be wrapping, the environment they will be stored in, and any regulatory standards that must be met.

- Material Type: Determine whether you need polyethylene (PE), polypropylene (PP), or a specialized film.

- Thickness and Size: Specify the required thickness (e.g., 1.4 mil to 1.6 mil for PE) and dimensions based on your product sizes.

Step 2: Identify Your End Use Requirements

Different applications demand different types of poly wrappers. Clearly identifying how you intend to use the wrappers will guide your sourcing decisions.

- Food Safety: If the wrappers are for food items, ensure they are food-safe and compliant with local regulations.

- Durability Needs: For items requiring protection from moisture or chemicals, choose a material that offers the necessary resistance.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s essential to conduct thorough evaluations. This helps ensure you are partnering with a reliable source that can meet your needs consistently.

- Request Documentation: Ask for company profiles, certifications, and case studies to verify their credibility.

- Seek References: Contact other buyers in similar industries to gauge their satisfaction with the supplier’s products and services.

Step 4: Request Samples

Always request samples before making a bulk purchase. This allows you to assess the quality and suitability of the wrappers for your specific applications.

- Quality Assessment: Check the clarity, thickness, and flexibility of the samples to ensure they meet your standards.

- Compatibility Testing: Test the samples with your products to confirm that they provide adequate protection and presentation.

Step 5: Negotiate Pricing and Terms

Once you have identified potential suppliers and evaluated their samples, it’s time to discuss pricing and terms.

- Bulk Discounts: Inquire about pricing structures for bulk orders, as many suppliers offer significant discounts for larger quantities.

- Payment Terms: Ensure the payment terms are favorable and align with your cash flow needs.

Step 6: Verify Compliance and Certifications

Ensure that your chosen supplier adheres to relevant industry standards and regulations. This is especially critical in food packaging and other regulated industries.

Illustrative image related to poly wrapper

- Industry Certifications: Look for certifications such as ISO, FDA compliance for food-grade materials, or other relevant quality assurances.

- Sustainability Practices: If sustainability is important to your brand, check if the supplier follows eco-friendly practices in their production processes.

Step 7: Establish a Clear Communication Plan

Finally, set up a communication plan with your supplier to facilitate smooth transactions and address any potential issues proactively.

- Regular Updates: Schedule regular check-ins to discuss order statuses, potential delays, or changes in specifications.

- Feedback Loop: Create a channel for providing feedback on product quality and service to ensure continuous improvement.

By following these steps, you can ensure a successful sourcing process for poly wrappers, leading to better product presentation, protection, and overall business efficiency.

Comprehensive Cost and Pricing Analysis for poly wrapper Sourcing

Understanding the cost structure and pricing dynamics for poly wrapper sourcing is essential for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis breaks down the key components of costs, identifies price influencers, and provides actionable buyer tips to enhance negotiation power and cost efficiency.

What Are the Key Cost Components in Poly Wrapper Sourcing?

The cost structure for poly wrappers comprises several critical components:

-

Materials: The primary raw materials used in poly wrappers include polyethylene (PE) and polypropylene (PP). The price of these materials can fluctuate based on global oil prices and availability, impacting overall costs.

-

Labor: Labor costs can vary significantly by region, affecting production costs. In countries with lower labor costs, such as some areas in Africa and South America, buyers may find more competitive pricing.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help reduce overhead, leading to lower prices for buyers.

-

Tooling: Initial tooling costs for custom designs can be significant, especially for unique specifications or high-volume orders. These costs are typically amortized over larger production runs, making it advantageous for buyers to negotiate higher volumes.

-

Quality Control (QC): Ensuring the quality of poly wrappers is paramount, especially for food and pharmaceutical applications. QC processes add to the cost but are essential for compliance with safety standards.

-

Logistics: Shipping costs can vary based on distance, mode of transportation, and destination. Buyers should consider logistics in their total cost calculations, as these can significantly affect the final price.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks. This margin can be negotiable based on order size and relationship strength.

What Influences Pricing for Poly Wrappers?

Several factors can influence the pricing of poly wrappers:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for bulk discounts, reducing the per-unit cost. Buyers should assess their needs and negotiate MOQ terms.

-

Specifications and Customization: Custom sizes, colors, or features can increase costs. Buyers should weigh the benefits of customization against potential price increases.

-

Material Quality and Certifications: Higher quality materials or certifications (e.g., food safety certifications) can lead to higher prices. Buyers need to ensure that the quality aligns with their end-use requirements.

-

Supplier Factors: The reputation, reliability, and location of suppliers can affect pricing. Established suppliers with a proven track record may charge more, but they often provide better service and quality assurance.

-

Incoterms: The terms of shipment (e.g., FOB, CIF) can impact pricing and risk allocation. Understanding these terms is crucial for effective cost management.

How Can Buyers Negotiate for Better Pricing?

To secure favorable pricing, buyers should consider the following strategies:

-

Understand Total Cost of Ownership: Evaluate not just the upfront cost but the long-term implications of sourcing decisions, including maintenance, durability, and performance over time.

-

Build Relationships with Suppliers: Establishing a strong rapport with suppliers can facilitate better pricing negotiations. Consider long-term partnerships rather than one-off transactions.

-

Leverage Market Knowledge: Stay informed about market trends, material costs, and competitor pricing. This knowledge can provide leverage during negotiations.

-

Be Clear on Specifications: Clearly define your requirements to avoid misunderstandings that can lead to increased costs. Provide detailed specifications to receive accurate quotes.

-

Explore Alternative Suppliers: Don’t hesitate to source from multiple suppliers to compare pricing and terms. This can also create competitive pressure, potentially leading to better offers.

In conclusion, understanding the comprehensive cost structure and pricing dynamics of poly wrappers is vital for B2B buyers. By recognizing key cost components, price influencers, and employing effective negotiation strategies, buyers can optimize their sourcing processes and achieve cost-efficient solutions tailored to their specific needs. As always, prices can vary widely, and it’s essential to consult suppliers for the most accurate and up-to-date pricing information.

Alternatives Analysis: Comparing poly wrapper With Other Solutions

In the world of packaging solutions, selecting the right method can significantly impact operational efficiency, product safety, and overall cost-effectiveness. Poly wrappers are popular for their versatility and effectiveness in protecting products. However, there are several alternatives that may also serve various business needs effectively. This analysis compares poly wrappers with two viable alternatives: shrink wrapping and paper packaging.

| Comparison Aspect | Poly Wrapper | Shrink Wrapping | Paper Packaging |

|---|---|---|---|

| Performance | Excellent clarity and protection; versatile for various products | Provides a tight seal and excellent moisture protection | Eco-friendly; good for lightweight items |

| Cost | Moderate cost with bulk options | Generally lower cost for materials but higher machinery investment | Typically lower costs; varies based on type |

| Ease of Implementation | Easy to implement in existing systems | Requires specialized machinery for efficiency | Easy to use; minimal machinery needed |

| Maintenance | Low maintenance; occasional replacements needed | Moderate maintenance for machinery | Low maintenance; biodegradable options available |

| Best Use Case | Ideal for food, gifts, and retail items | Best for securing high-value items or irregular shapes | Suitable for lightweight products and eco-conscious brands |

What Are the Advantages and Disadvantages of Shrink Wrapping Compared to Poly Wrappers?

Shrink wrapping utilizes heat to conform the film tightly around the product, providing a secure seal that protects against moisture and dirt. This method is particularly advantageous for high-value items or products with irregular shapes, ensuring they remain intact during transport and storage. However, the initial investment in machinery can be higher, and the process may require more maintenance. Additionally, while shrink wrap is effective in securing products, it may not offer the same visual appeal as poly wrappers, which allow customers to see the product clearly.

How Does Paper Packaging Compare to Poly Wrappers?

Paper packaging is an eco-friendly alternative that appeals to consumers increasingly concerned about sustainability. It is versatile and can be used for a wide range of products, making it suitable for businesses targeting environmentally conscious markets. However, paper does not provide the same level of moisture and dirt protection as poly wrappers, which may compromise product integrity, especially in food applications. Furthermore, paper packaging may require more effort to secure products adequately, and its strength can vary significantly depending on the type of paper used.

Conclusion: How Should B2B Buyers Choose the Right Packaging Solution?

When selecting a packaging solution, B2B buyers should consider several factors, including the nature of their products, target market preferences, and operational capabilities. Poly wrappers are ideal for businesses needing visual appeal and flexibility, particularly in the food and retail sectors. In contrast, shrink wrapping is better suited for high-value items requiring maximum protection, while paper packaging appeals to eco-conscious brands looking to minimize their environmental footprint. Ultimately, evaluating the unique needs of your business will guide you in choosing the most effective packaging solution.

Essential Technical Properties and Trade Terminology for poly wrapper

What Are the Key Technical Properties of Poly Wrappers?

Understanding the technical specifications of poly wrappers is essential for businesses involved in packaging. Here are several critical properties that impact performance, cost, and suitability for various applications.

1. Material Grade

Poly wrappers are commonly made from materials like Polyethylene (PE) and Polypropylene (PP). The choice of material affects the wrapper’s durability, flexibility, and clarity. For instance, BOPP (Biaxially Oriented Polypropylene) is widely used for food packaging due to its excellent moisture barrier properties and transparency, allowing consumers to see the product inside.

2. Thickness

The thickness of the poly wrapper is measured in mils (thousandths of an inch). Typical thickness ranges from 0.8 mil to 1.6 mil, depending on the intended use. A thicker wrapper may offer better puncture resistance and durability, making it ideal for heavy or sharp-edged products. Conversely, a thinner wrapper can reduce material costs and is suitable for lightweight items.

3. Clarity and Transparency

The optical clarity of poly wrappers is crucial for retail packaging, especially in food and gift sectors. Crystal clear wraps enhance product visibility, which can significantly influence consumer purchasing decisions. For B2B buyers, ensuring that the packaging showcases the product effectively can lead to better sales outcomes.

4. Temperature Resistance

Poly wrappers must withstand varying temperature conditions during storage and transport. For instance, some wrappers are designed to remain flexible in cold environments, while others can endure higher temperatures without losing integrity. This property is essential for businesses that deal with perishable goods or products that require specific storage conditions.

5. Chemical Resistance

Poly wrappers are often exposed to various chemicals, especially in industrial applications. A good wrapper should resist degradation from oils, solvents, and other substances to maintain product integrity. This resistance is vital for companies in sectors such as food processing or chemicals, where contamination could lead to severe consequences.

6. Barrier Properties

The effectiveness of a poly wrapper in protecting its contents from moisture, gases, and light is measured by its barrier properties. High-barrier films are essential for preserving food freshness or protecting sensitive electronics. B2B buyers must consider these properties when selecting wrappers to ensure their products remain safe and effective during storage and transportation.

Illustrative image related to poly wrapper

What Common Trade Terms Should B2B Buyers Know About Poly Wrapping?

Familiarity with industry jargon is crucial for effective communication and negotiation in the B2B space. Here are some essential terms related to poly wrapping.

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of poly wrappers, an OEM might supply the machinery used for wrapping, impacting cost and production efficiency.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is critical for B2B buyers to ensure they meet the supplier’s requirements while optimizing inventory levels and reducing excess stock.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting a quote for specific products or services. This process is vital for buyers to compare prices, terms, and conditions from multiple suppliers, ensuring they make informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers regarding the transportation of goods. Understanding these terms is essential for international B2B transactions, as they clarify who is responsible for shipping costs, insurance, and risk during transit.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. For poly wrappers, shorter lead times can enhance supply chain efficiency, allowing businesses to respond quickly to market demands.

6. Customs Duty

Customs duty is a tax imposed on imports and exports. B2B buyers should be aware of the customs duties applicable to poly wrappers, as this can significantly affect overall costs when sourcing from international suppliers.

Illustrative image related to poly wrapper

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions, ensuring they select the right poly wrappers for their specific needs and optimize their packaging strategies.

Navigating Market Dynamics and Sourcing Trends in the poly wrapper Sector

What Are the Key Trends and Market Dynamics in the Poly Wrapper Sector?

The poly wrapper sector is currently experiencing a wave of transformation driven by several global factors. One of the most significant drivers is the increasing demand for packaging solutions that enhance product visibility while ensuring protection against moisture and contaminants. This trend is particularly relevant for international B2B buyers in regions such as Africa, South America, the Middle East, and Europe, where diverse consumer preferences necessitate adaptable packaging options.

Emerging technologies, including automation and advanced materials, are reshaping sourcing strategies. For instance, the integration of servo motors in packaging machinery, such as the Flat Pack Polywrapper, enhances operational efficiency by reducing mechanical wear and facilitating quicker changeovers. Buyers are increasingly seeking suppliers who offer machinery compatible with a variety of materials, including polyethylene and polypropylene, to meet specific product requirements.

Additionally, the rise of e-commerce is prompting businesses to focus on packaging solutions that ensure product integrity during transit. As a result, poly wrappers that provide tamper resistance and security features are becoming more desirable. B2B buyers must stay informed about these dynamics to make strategic sourcing decisions that align with market demands and consumer expectations.

How Important Is Sustainability and Ethical Sourcing in the Poly Wrapper Industry?

Sustainability is becoming an essential consideration for B2B buyers in the poly wrapper sector. The environmental impact of packaging materials is under scrutiny, prompting many businesses to seek alternatives that minimize ecological footprints. Polypropylene and polyethylene, commonly used in poly wrappers, are recyclable, but the adoption of biodegradable and compostable materials is gaining traction. This shift is particularly relevant for buyers in regions with stringent environmental regulations or growing consumer demand for sustainable products.

Ethical sourcing is equally important. Buyers should prioritize suppliers who maintain transparent supply chains and adhere to fair labor practices. Certifications such as ISO 14001 for environmental management and the Forest Stewardship Council (FSC) certification for sustainable sourcing can serve as indicators of a supplier’s commitment to ethical practices.

Illustrative image related to poly wrapper

Investing in sustainable and ethically sourced poly wrappers not only helps businesses comply with regulations but also enhances brand reputation. As consumers increasingly favor environmentally responsible companies, B2B buyers must align their sourcing strategies with these values to remain competitive in the global marketplace.

What Has Been the Evolution of the Poly Wrapper Sector?

The poly wrapper industry has evolved significantly over the past few decades, driven by advancements in materials science and changing consumer preferences. Initially, poly wrappers were primarily used for basic packaging needs, offering limited functionality. However, the introduction of more durable materials and innovative designs has expanded their applications across various sectors, including food service, retail, and industrial packaging.

In the late 20th century, the focus shifted towards enhancing product visibility and protection, leading to the development of crystal clear BOPP (Biaxially Oriented Polypropylene) films. These films not only provided a sleek appearance but also improved product shelf life by offering moisture and contamination barriers.

As sustainability concerns grew, the industry began to pivot towards eco-friendly alternatives, such as biodegradable poly wrappers, responding to both regulatory pressures and consumer demand. Today, the poly wrapper sector is characterized by a blend of advanced technology, sustainability, and design innovation, making it a dynamic field for B2B buyers seeking versatile packaging solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of poly wrapper

-

How do I choose the right poly wrapper for my products?

Selecting the right poly wrapper involves evaluating your product’s size, shape, and specific packaging requirements. Consider the material type, such as polyethylene or polypropylene, which affects durability and clarity. Additionally, assess the thickness and dimensions available to ensure they meet your needs. If your products require visibility, opt for crystal clear options. For food items, ensure the selected wraps are food-safe and comply with local regulations. It’s also beneficial to request samples from suppliers to test compatibility with your product before making a bulk purchase. -

What are the key benefits of using poly wrappers in my business?

Poly wrappers offer numerous advantages, including moisture and dirt protection, which is essential for preserving product quality during storage and transport. They are lightweight, reducing shipping costs, and are available in various sizes and thicknesses to suit different applications. Additionally, poly wrappers can enhance product visibility while providing a professional appearance. Their versatility makes them suitable for a range of industries, including food, retail, and manufacturing, allowing businesses to maintain efficiency and customer satisfaction. -

What customization options are available for poly wrappers?

Many suppliers offer customization options for poly wrappers, including printing your logo or branding on the wrap. You can also choose specific sizes, thicknesses, and colors to match your brand identity or product requirements. Some manufacturers may provide options for eco-friendly materials if sustainability is a priority for your business. Discussing your needs with potential suppliers can help you identify the best customization options available, ensuring your packaging aligns with your brand’s goals and market demands. -

What is the minimum order quantity (MOQ) for poly wrappers?

Minimum order quantities for poly wrappers can vary significantly between suppliers and depend on the type of wrap and customization options. Typically, MOQs can range from a few hundred to several thousand units. It’s crucial to clarify MOQ during initial discussions with suppliers to ensure it aligns with your purchasing capabilities. For smaller businesses, consider negotiating with suppliers for lower MOQs or exploring options for bulk purchasing to reduce overall costs. -

How do I vet potential suppliers for poly wrappers?

When vetting suppliers, check their industry reputation and customer reviews. Request references from other businesses that have purchased from them. Assess their production capabilities, including quality control processes, to ensure they can meet your specifications. Additionally, inquire about their compliance with international standards and regulations. Visiting the supplier’s facility, if feasible, can provide valuable insights into their operations and help establish trust in their ability to deliver quality products. -

What are the payment terms typically offered by suppliers?

Payment terms can vary, but most suppliers offer options such as net 30, net 60, or even net 90 days, depending on your relationship and order size. Some may require a deposit upfront, especially for custom orders. It’s essential to discuss and agree on payment terms before finalizing the order to avoid any misunderstandings. Additionally, consider discussing options for credit terms if you anticipate regular purchases, which can improve cash flow management for your business. -

How can I ensure quality assurance (QA) for my poly wrappers?

To ensure quality assurance, request samples from suppliers before placing large orders. Establish clear specifications for material, size, and performance standards in your contract. Inquire about the supplier’s QA processes, including inspections and testing protocols. Consider implementing a third-party inspection service, particularly for large shipments, to verify that the products meet your quality requirements. Regular communication with your supplier during the production process can also help address any potential issues proactively. -

What logistics considerations should I keep in mind when sourcing poly wrappers internationally?

When sourcing poly wrappers internationally, consider shipping times, customs regulations, and potential tariffs that may affect costs. Work with suppliers who have experience in exporting to your region, as they can provide guidance on necessary documentation and compliance. Additionally, evaluate shipping options to determine the most cost-effective and timely method for delivery. It may also be beneficial to establish a reliable logistics partner who can assist with freight forwarding and customs clearance to streamline the process.

Top 7 Poly Wrapper Manufacturers & Suppliers List

1. ClearBags – Poly Wraps & Packaging Solutions

Domain: clearbags.com

Registered: 1999 (26 years)

Introduction: Poly Wraps for Retail, Food & Gift Packaging. US Customer Service since 1992. Various types of bags including Flap Seal Bags, No Flap Bags, Protective Closure Bags, Rice Paper Pouches, Stand Up Pouches, Zipper Barrier Bags, Side Gusset Bags, Flat Bottom Gusset Bags, Clear Flat Heat Seal Bags, Kraft Flat Heat Seal Bags. Options for Eco-friendly, Compostable, Child Resistant, and Food Safe Packaging…

2. ULINE – Stretch Wrap Solutions

Domain: uline.com

Registered: 1995 (30 years)

Introduction: Stretch Wrap, Pallet Wrap & Stretch Film in Stock – ULINE. Products include Econo-Wrapper®, Mini-Wrap, Goodwrappers®, Machine Length Stretch Wrap, Tinted Stretch Wrap, Opaque Stretch Wrap, Stretch Wrap Dispensers, Stretch Wrap Machines, Pre-Stretched Wrap, New Tech Stretch Wrap, Netting, Top Sheeting, and Stretch Wrap Cutters.

3. TrentonCorp – Poly-Ply™ Plastic Pipeline Outerwrap

Domain: trentoncorp.com

Registered: 1996 (29 years)

Introduction: {‘name’: ‘Poly-Ply™ Plastic Pipeline Outerwrap’, ‘description’: ‘Poly-Ply is a multi-layer version of plastic wrap that helps keep a separation between the tape and the soil. It consists of three membranes of .5-mil clear, 50 gauge, clear, polyvinylidene chloride plastic, high-cling membranes, wound together as a single sheet. It provides a mechanical and electrical barrier over Temcoat™ or #1 Wax…

4. Wraptite – Bulk Polyethylene Bags

Domain: wraptite.com

Registered: 2004 (21 years)

Introduction: Wraptite Poly Bags: Your source for bulk polyethylene bags. Available products include: 2 mil Reclosable Bags, 4 Mil Reclosable Bags, 6 Mil Bags, Slider Bags, Produce Bags, Re-Sealable Poly Bags, 2 Mil Specimen Transfer Bag, Amber Bags, Parts Recloseable Bags, and Flat Poly Bags.

5. Denso – Poly-Wrap Compression Film

Domain: densona.com

Registered: 1996 (29 years)

Introduction: Denso Poly-Wrap is a high performance outerwrap compression film used as a compression film for Denso Glass Outerwrap and as a protective layer over Denso Petrolatum Tape Systems. Key features include superior holding force, excellent prestretch with no film breaks, aggressive cling to self, maximum performance metallocene resins, excellent conformability, and a thick 200 gauge (2 mil) material.

6. US Packaging & Wrapping – Poly Sheeting

Domain: uspackagingandwrapping.com

Registered: 2011 (14 years)

Introduction: Poly Sheeting is available in widths up to 20 feet and comes in clear and black options. It is made from low-density polyethylene and is commonly used as a vapor barrier or drop cloth. Thicknesses range from 2 mils to 6 mils. Clear polyethylene sheeting is available in 2 mil (200 ft per roll), 4 mil, and 6 mil (100 ft per roll). Black polyethylene sheeting is opaque, protects from UV rays, and is …

7. Bagcraft – Poly-Wax Sandwich Wraps and Basket Liners

Domain: bagcraft.com

Registered: 1998 (27 years)

Introduction: {“product_name”:”Poly-Wax Sandwich Wraps and Basket Liners”,”features”:[“Superior grease and moisture protection”,”Improved heat retention vs standard paper wraps”,”Coated with Poly-Wax on one side of the sheet”,”Innovative 5-in-one print design for inventory and cost reduction”],”items”:[{“item_number”:”300367″,”description”:”Poly Wax Paper Wrap & Basket Liner Yellow”,”dimensions”:”12 x 12″,”case…

Strategic Sourcing Conclusion and Outlook for poly wrapper

As international markets continue to evolve, the demand for efficient and versatile packaging solutions like poly wrappers is on the rise. The strategic sourcing of poly wrappers offers businesses a unique opportunity to enhance product visibility, ensure food safety, and maintain freshness—all critical factors for customer satisfaction. By investing in high-quality materials such as BOPP and PE, companies can not only improve the presentation of their goods but also reduce waste and enhance sustainability efforts.

Moreover, leveraging advanced packaging machinery can streamline operations, resulting in cost savings and improved productivity. Suppliers equipped with innovative technologies, such as servo-controlled wrappers, can provide the flexibility needed to adapt to varying production requirements, making them invaluable partners in your supply chain.

Looking ahead, international B2B buyers—particularly from Africa, South America, the Middle East, and Europe—should prioritize strategic sourcing of poly wrappers as a critical component of their growth strategy. By aligning with reliable suppliers and embracing sustainable practices, businesses can enhance their competitiveness in a rapidly changing global marketplace. Take action today to evaluate your packaging solutions and explore partnerships that can drive your success forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to poly wrapper

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.