A Deep Dive into Poly Bush Solution

Introduction: Navigating the Global Market for poly bush

In today’s competitive landscape, sourcing high-quality poly bushes can be a daunting task for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. With varying standards, production methods, and market dynamics, the challenge lies not only in finding durable and reliable products but also in navigating a complex supply chain. This comprehensive guide demystifies the global market for poly bushes, offering insights into different types, applications, and key factors to consider when selecting suppliers.

Within these pages, you will find detailed information on the various applications of poly bushes across industries, from automotive to commercial vehicles. We delve into the nuances of material quality, performance expectations, and the latest innovations in polyurethane technology. Additionally, our guide provides actionable strategies for vetting suppliers, understanding pricing structures, and estimating total cost of ownership, ensuring that you make informed purchasing decisions.

By empowering B2B buyers with the knowledge needed to evaluate options effectively, this guide serves as an essential resource. Whether you’re located in Saudi Arabia, Vietnam, or elsewhere, you’ll gain the tools to navigate the complexities of the poly bush market confidently, ultimately leading to better product choices and improved operational efficiency.

Understanding poly bush Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Poly Bush | Durable polyurethane, designed for OEM replacements | Automotive repair, fleet maintenance | Pros: Enhanced durability; Cons: May be costlier than rubber alternatives. |

| High-Performance Bush | Increased stiffness, optimized for performance | Motorsports, high-performance vehicles | Pros: Improved handling; Cons: Can lead to a harsher ride. |

| Off-Road Bush | Enhanced resistance to extreme conditions | Off-road vehicles, commercial trucks | Pros: Superior durability; Cons: Heavier than standard options. |

| Adjustable Poly Bush | Customizable stiffness, adaptable for various applications | Specialty vehicles, racing applications | Pros: Versatile for different setups; Cons: More complex installation. |

| Heavy-Duty Bush | Reinforced design for heavy loads | Industrial machinery, heavy-duty vehicles | Pros: Exceptional load-bearing capacity; Cons: Limited availability. |

What Are the Characteristics of Standard Poly Bushes?

Standard poly bushes are engineered from high-quality polyurethane, offering a significant upgrade over traditional rubber bushes. They are designed to be direct replacements for Original Equipment Manufacturer (OEM) components, ensuring compatibility across various vehicle makes and models. B2B buyers should consider the longevity and reduced maintenance costs associated with these products, making them ideal for automotive repair shops and fleet maintenance providers. However, the initial investment may be higher than that of rubber alternatives, which could affect budget-conscious buyers.

Why Choose High-Performance Bushes for Motorsports?

High-performance bushes are tailored for motorsports and high-performance vehicles, featuring increased stiffness and precision. These bushes enhance vehicle handling and responsiveness, making them essential for racing applications. B2B purchasers in the automotive sector, particularly those involved in motorsports, should weigh the benefits of improved performance against the potential for a harsher ride quality. The investment in these bushes often pays off in terms of competitive advantage on the track.

What Advantages Do Off-Road Bushes Offer?

Off-road bushes are specifically designed to withstand extreme conditions, including harsh terrains and heavy loads. Their robust construction provides superior resistance to wear and tear, making them ideal for off-road vehicles and commercial trucks. B2B buyers in sectors such as construction and agriculture should consider these bushes for their durability and performance in challenging environments. However, the increased weight compared to standard options may be a consideration for some applications.

How Do Adjustable Poly Bushes Enhance Versatility?

Adjustable poly bushes offer the unique advantage of customizable stiffness, allowing businesses to tailor their suspension systems for specific applications. This flexibility makes them suitable for specialty vehicles and racing scenarios where performance requirements may vary. B2B buyers should evaluate the complexity of installation and potential for increased maintenance, as the adaptability comes at the cost of needing more precise adjustments. However, the versatility can significantly enhance vehicle performance in various settings.

Why Are Heavy-Duty Bushes Essential for Industrial Applications?

Heavy-duty bushes are designed for industrial machinery and heavy-duty vehicles, featuring a reinforced construction that supports exceptional load-bearing capacity. These bushes are critical for applications where equipment is subjected to significant stress and strain. B2B buyers in industries such as logistics and construction should prioritize these bushes for their reliability and performance under demanding conditions. However, limited availability may pose a challenge for some buyers, necessitating careful sourcing strategies.

Key Industrial Applications of poly bush

| Industry/Sector | Specific Application of poly bush | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Suspension systems for commercial vehicles | Enhanced durability, improved handling, and ride comfort | Quality certifications (e.g., ISO9001), compatibility with various vehicle models |

| Construction Machinery | Bushings for excavators and loaders | Increased operational efficiency and reduced maintenance costs | Resistance to harsh environments, custom sizing options |

| Agriculture Equipment | Bushings for tractors and harvesters | Improved performance and longevity of machinery | Availability of specific configurations for different models |

| Aerospace | Vibration dampening components for aircraft | Enhanced safety and comfort for passengers and crew | Compliance with aviation standards and certifications |

| Marine | Bushings for boat trailers and marine vehicles | Increased reliability and performance in marine environments | Corrosion resistance and adaptability to marine conditions |

How is Poly Bush Used in the Automotive Sector?

In the automotive industry, poly bush is primarily used in the suspension systems of commercial vehicles. These polyurethane bushes replace traditional rubber components, offering superior durability and performance. They help improve vehicle handling, reduce vibrations, and enhance ride comfort, which is essential for businesses relying on transportation. Buyers should prioritize sourcing poly bush products that are ISO9001 certified to ensure quality and compatibility across various vehicle models.

What Role Does Poly Bush Play in Construction Machinery?

In construction machinery, poly bush components are utilized in excavators and loaders to withstand heavy loads and harsh working conditions. The durability of polyurethane bushes minimizes wear and tear, leading to reduced downtime and lower maintenance costs. For international buyers, especially in regions with challenging terrains, sourcing bushings that are resistant to environmental stressors and can be custom-sized for specific machinery is critical.

How is Poly Bush Beneficial for Agriculture Equipment?

For agriculture equipment such as tractors and harvesters, poly bush plays a vital role in enhancing performance and extending the life of machinery. The use of polyurethane bushes mitigates the impact of vibrations and shocks during operations, leading to smoother functioning and improved productivity. Buyers in the agricultural sector should look for suppliers that offer specific configurations compatible with various machinery models to ensure optimal performance.

Why is Poly Bush Important in the Aerospace Industry?

In aerospace applications, poly bush is used as vibration dampening components within aircraft. These bushes contribute to passenger comfort and safety by minimizing vibrations and noise. Compliance with stringent aviation standards is paramount for suppliers in this sector. International buyers must ensure that sourced poly bush products meet all necessary certifications to maintain safety and reliability in aviation operations.

How Does Poly Bush Enhance Performance in Marine Applications?

In the marine industry, poly bush is critical for applications such as boat trailers and marine vehicles. These bushes enhance reliability and performance by providing a stable connection that can withstand the corrosive marine environment. Buyers should focus on sourcing poly bush products that offer corrosion resistance and are designed to adapt to various marine conditions, ensuring longevity and dependable performance in challenging settings.

3 Common User Pain Points for ‘poly bush’ & Their Solutions

Scenario 1: Navigating Quality Assurance Challenges in Poly Bush Sourcing

The Problem: B2B buyers often face significant challenges when sourcing poly bushes, particularly regarding product quality and reliability. This is especially true for companies operating in regions with varying manufacturing standards, such as parts from different countries. The risk of receiving inferior products can lead to operational inefficiencies, increased maintenance costs, and dissatisfied customers, ultimately affecting the bottom line. Buyers may feel overwhelmed by the abundance of suppliers and the lack of consistent quality assurance protocols.

The Solution: To mitigate quality assurance concerns, B2B buyers should prioritize sourcing from manufacturers with recognized certifications, such as ISO 9001. This accreditation indicates that the supplier adheres to strict quality management standards, which can significantly reduce the risk of subpar products. Buyers should also request detailed product specifications and test reports to ensure that the poly bushes meet industry standards for durability and performance. Establishing a close relationship with suppliers can facilitate better communication about product quality and enable buyers to conduct regular audits or inspections of the manufacturing process. Additionally, seeking references or case studies from other companies that have successfully sourced poly bushes can provide reassurance and insights into the supplier’s reliability.

Scenario 2: Addressing Compatibility Issues with Poly Bush Installations

The Problem: Compatibility issues often arise when B2B buyers attempt to install poly bushes in various vehicle models or machinery. This can lead to frustration and downtime, particularly if the bushes do not fit correctly or require excessive modifications. Such scenarios can result in costly labor expenses and potential damage to the vehicle or machinery, causing further delays and dissatisfaction among clients.

The Solution: To address compatibility challenges, buyers should invest time in thorough research before purchasing poly bushes. This includes consulting detailed product catalogs and ensuring that the selected bushes are specifically designed for their vehicle make and model. Utilizing advanced filtering tools on supplier websites can streamline this process. Additionally, buyers should engage with technical support teams offered by manufacturers, who can provide invaluable insights into the correct applications and installation techniques. For complex installations, investing in professional training or workshops for maintenance staff can also enhance installation accuracy and efficiency, minimizing the likelihood of future compatibility issues.

Scenario 3: Managing the Cost Implications of Poly Bush Maintenance

The Problem: B2B buyers frequently encounter challenges with the ongoing maintenance costs associated with poly bushes. While these components are generally more durable than their rubber counterparts, improper selection or lack of maintenance can lead to premature wear and tear, resulting in unexpected expenses. Businesses may struggle to balance the need for quality parts with budget constraints, particularly in competitive markets where profit margins are tight.

The Solution: To effectively manage maintenance costs, B2B buyers should adopt a proactive approach to poly bush selection and upkeep. This begins with investing in high-quality polyurethane bushes that are specifically engineered for longevity and performance in demanding environments. Buyers should also implement a regular maintenance schedule that includes inspections and timely replacements based on usage patterns. Establishing partnerships with suppliers can lead to bulk purchasing discounts and loyalty programs that reduce overall costs. Furthermore, educating staff on the signs of wear and proper maintenance procedures can extend the lifespan of poly bushes, ensuring that businesses get the most value from their investment while minimizing unplanned expenditures.

Strategic Material Selection Guide for poly bush

What Are the Key Properties of Common Materials Used for Poly Bush?

When selecting materials for poly bushes, it is essential to consider their properties to ensure optimal performance in various applications. The most common materials include polyurethane, rubber, nylon, and PTFE (Teflon). Each material has unique characteristics that can impact durability, cost, and suitability for specific environments.

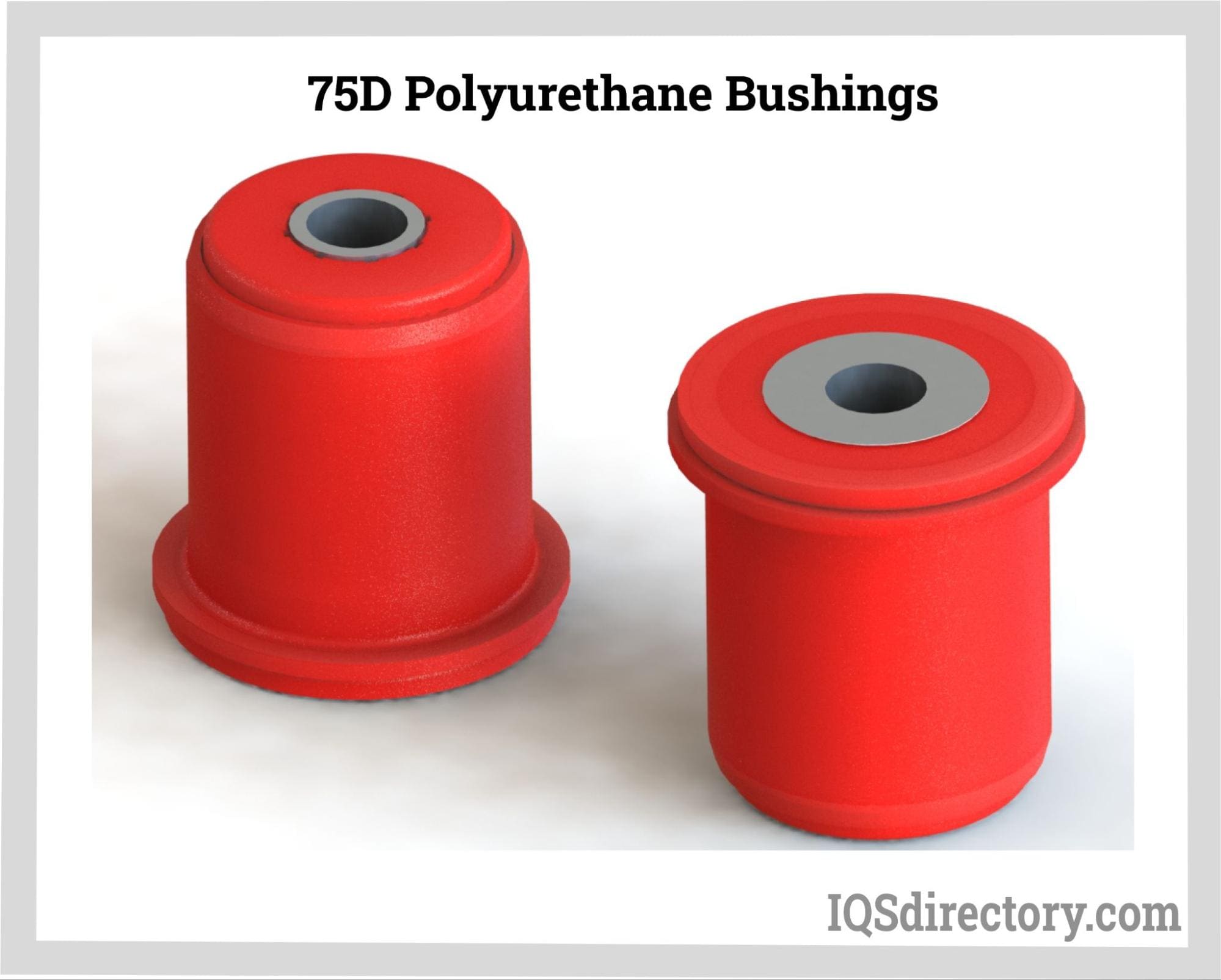

How Does Polyurethane Perform in Poly Bush Applications?

Polyurethane is widely recognized for its excellent mechanical properties, including high tensile strength and resistance to wear and tear. It can withstand a temperature range of -30°C to 80°C and has good pressure resistance. This material is particularly effective in applications where flexibility and durability are critical, such as automotive suspension systems.

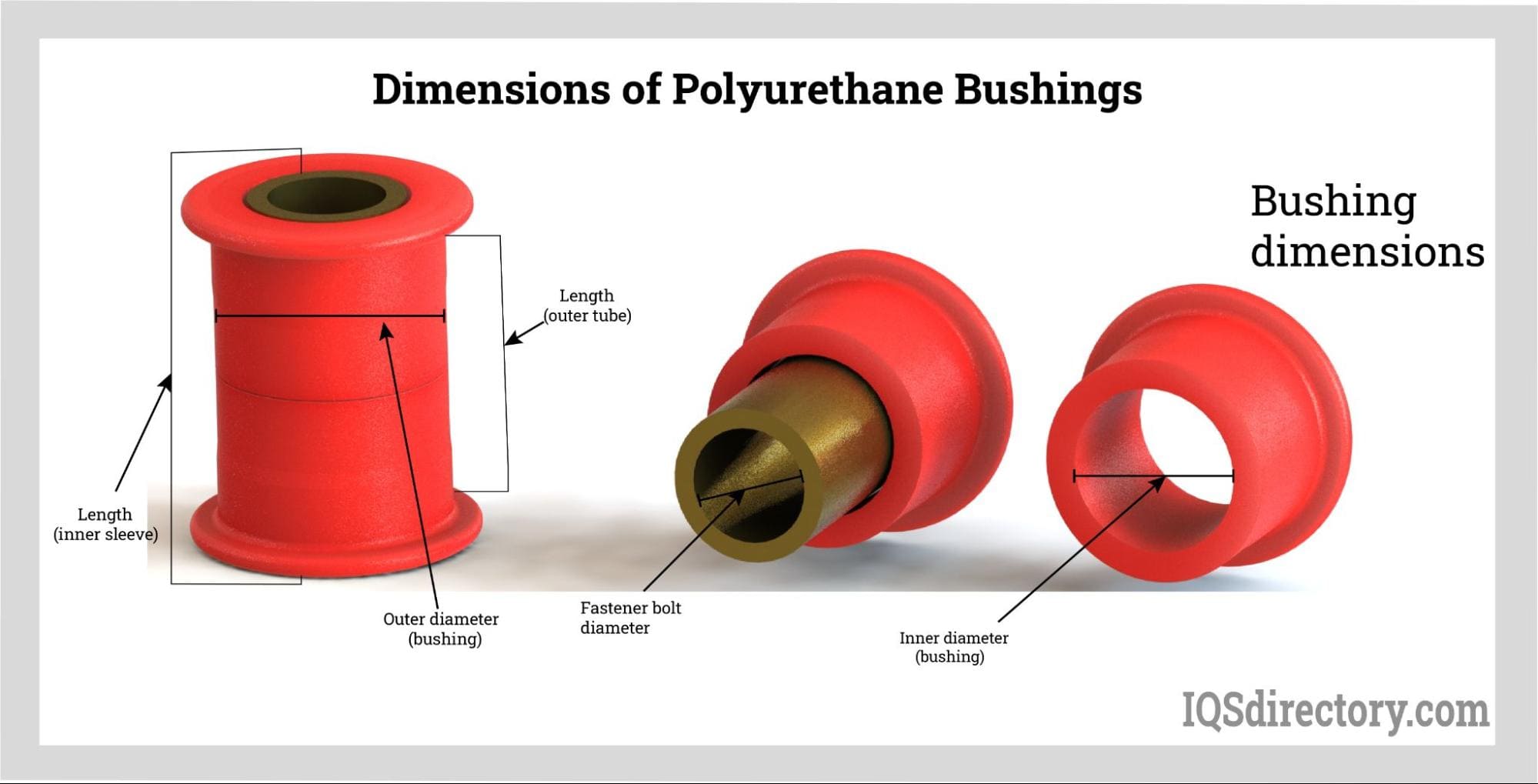

Illustrative image related to poly bush

Pros: Polyurethane offers superior durability and longevity compared to traditional rubber. It also provides better handling and comfort in vehicles, making it a preferred choice for performance applications.

Cons: The manufacturing process for polyurethane can be more complex and costlier than other materials. Additionally, it may not be suitable for extreme temperature environments beyond its specified range.

Impact on Application: Polyurethane is compatible with various media, including oils and fuels, making it versatile for automotive and industrial applications. However, international buyers should ensure compliance with local standards, such as ASTM or DIN, to meet regulatory requirements.

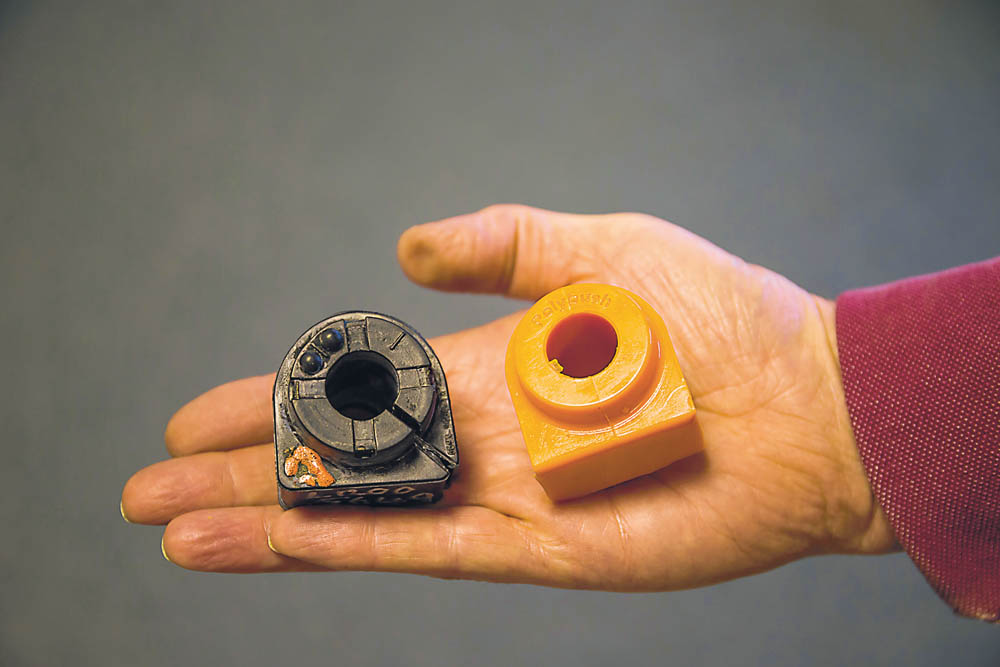

What Are the Advantages of Rubber as a Material for Poly Bush?

Rubber is a traditional choice for suspension bushes due to its inherent elasticity and ability to absorb shocks. It generally performs well under a temperature range of -40°C to 100°C and offers good corrosion resistance.

Pros: Rubber is cost-effective and easy to manufacture, making it a popular option for mass production. Its shock-absorbing properties contribute to a smoother ride in vehicles.

Cons: While rubber provides decent durability, it is prone to degradation over time, especially when exposed to harsh environmental conditions, such as UV light and ozone. This can lead to reduced performance and increased maintenance costs.

Impact on Application: Rubber is compatible with many automotive fluids, but its longevity can be compromised in extreme conditions. Buyers from regions with harsh climates should consider this when selecting rubber-based products.

Illustrative image related to poly bush

How Does Nylon Compare for Use in Poly Bush Applications?

Nylon is another material used for poly bushes, known for its strength and resistance to abrasion. It can withstand temperatures ranging from -40°C to 120°C and has good chemical resistance, making it suitable for various industrial applications.

Pros: Nylon is lightweight, which can contribute to overall vehicle performance. It also has a lower coefficient of friction, reducing wear on components.

Cons: The cost of nylon can be higher than rubber and polyurethane, and it may not provide the same level of shock absorption. Additionally, nylon can be less flexible, which may limit its application in certain suspension systems.

Impact on Application: Nylon’s compatibility with various chemicals makes it suitable for use in different environments. International buyers should verify compliance with relevant standards to ensure product reliability.

What Role Does PTFE Play in Poly Bush Applications?

PTFE, commonly known as Teflon, is renowned for its exceptional chemical resistance and low friction properties. It can operate effectively within a temperature range of -200°C to 260°C, making it suitable for extreme environments.

Illustrative image related to poly bush

Pros: PTFE is highly resistant to corrosion and wear, making it ideal for applications exposed to aggressive chemicals. Its low friction properties enhance performance in dynamic applications.

Cons: The primary drawback of PTFE is its cost, which is generally higher than other materials. Additionally, its mechanical strength is lower compared to polyurethane and rubber, which may limit its use in high-load applications.

Impact on Application: PTFE is compatible with a wide range of media, including acids and solvents. Buyers should ensure that products meet international standards to avoid compliance issues.

Summary Table of Material Selection for Poly Bush

| Material | Typical Use Case for poly bush | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyurethane | Automotive suspension systems | Superior durability and performance | Higher manufacturing complexity and cost | High |

| Rubber | General automotive applications | Cost-effective and good shock absorption | Prone to degradation in harsh conditions | Low |

| Nylon | Industrial applications and lightweight vehicles | Lightweight and low friction | Higher cost and less flexibility | Medium |

| PTFE | Extreme environment applications | Exceptional chemical resistance and low friction | High cost and lower mechanical strength | High |

This strategic material selection guide provides valuable insights for international B2B buyers looking to optimize their poly bush applications. By considering the properties, advantages, and limitations of each material, buyers can make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for poly bush

What Are the Main Stages of the Manufacturing Process for Poly Bush?

The manufacturing process of polyurethane bushes, commonly known as poly bushes, involves several key stages that ensure high-quality end products. These stages include material preparation, forming, assembly, and finishing.

Material Preparation

The first step involves selecting high-grade polyurethane materials that meet specific performance criteria, such as hardness, resilience, and temperature resistance. The materials are often tested for chemical composition and physical properties to ensure they can withstand the rigors of automotive applications. Proper storage conditions are crucial to prevent material degradation.

Forming Techniques

Once the materials are prepared, they undergo various forming techniques. The most common methods include compression molding, injection molding, and casting. Compression molding involves placing the polyurethane material into a heated mold where it is compressed to form the desired shape. Injection molding, on the other hand, allows for more complex geometries by injecting the heated material into a mold under pressure. Casting is typically used for larger components that require a more intricate design.

Assembly Processes

After forming, the individual components may require assembly. This could involve adding metal inserts for increased durability or integrating other materials to enhance performance. Assembly processes are often automated to improve consistency and reduce labor costs.

Illustrative image related to poly bush

Finishing Touches

The final stage includes finishing processes such as trimming, surface treatment, and quality inspections. Trimming ensures that any excess material is removed, while surface treatments can enhance the aesthetic appeal and protect against environmental factors. This stage is critical for ensuring that the final product meets all specifications and performance standards.

How Is Quality Assurance Managed in Poly Bush Manufacturing?

Quality assurance (QA) is a vital aspect of the manufacturing process for poly bushes, ensuring that products meet both customer expectations and international standards. The following components outline how QA is typically managed.

International Standards and Certifications

Reputable manufacturers often adhere to international standards such as ISO 9001, which focuses on quality management systems. Achieving ISO 9001 certification demonstrates a commitment to continuous improvement, efficiency, and customer satisfaction. Additionally, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may be relevant, depending on the application of the poly bushes.

Quality Control Checkpoints

Quality control involves several checkpoints throughout the manufacturing process. These include:

- Incoming Quality Control (IQC): At this stage, raw materials are inspected for quality and compliance with specifications before they enter the production line.

- In-Process Quality Control (IPQC): Continuous monitoring occurs during the manufacturing process to detect and address any deviations from quality standards in real-time.

- Final Quality Control (FQC): After production, the finished products undergo rigorous testing to ensure they meet all performance and safety requirements.

Common Testing Methods for Poly Bushes

Testing methods can include tensile strength tests, hardness tests, and fatigue tests to assess the durability and performance of the poly bushes. Manufacturers may also conduct environmental testing to ensure that the products can withstand extreme temperatures, chemicals, and UV exposure.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control measures is crucial for ensuring product reliability and performance.

Supplier Audits and Reports

Conducting supplier audits is an effective way to evaluate the quality management systems in place. Audits should assess compliance with international standards and the effectiveness of the QA processes. Requesting detailed quality reports can also provide insights into the supplier’s performance history, including defect rates and corrective actions taken.

Third-Party Inspections

Engaging third-party inspection agencies can add an extra layer of assurance. These independent entities can conduct inspections at various stages of the manufacturing process, providing unbiased assessments of quality and compliance. This is particularly important for international buyers who may not have the ability to perform on-site inspections.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various quality control nuances when sourcing poly bushes. These include understanding regional standards, cultural differences in quality perceptions, and logistical challenges.

Regional Standards and Compliance

Different regions may have specific standards that affect the quality of poly bushes. For example, compliance with EU regulations may differ significantly from those in the Middle East or Africa. It is essential for buyers to familiarize themselves with these regulations to ensure that the products they purchase will meet local requirements.

Cultural Differences in Quality Expectations

Cultural perceptions of quality can vary widely, impacting expectations and negotiations. Buyers should engage in clear communication with suppliers to align on quality standards, performance expectations, and testing protocols.

Logistical Considerations

Logistics can also affect quality assurance. Delays in shipping or handling can lead to damage or degradation of products. Ensuring that suppliers have robust logistics and handling processes can mitigate these risks, allowing for a smoother procurement process.

Conclusion

Understanding the manufacturing processes and quality assurance measures for poly bushes is essential for B2B buyers aiming to procure high-quality products. By focusing on the stages of manufacturing, the importance of quality control, and the nuances of international sourcing, buyers can make informed decisions that enhance their supply chain efficiency and product performance. Engaging with reputable suppliers who demonstrate a commitment to quality can lead to long-term partnerships and successful outcomes in various markets worldwide.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘poly bush’

In the competitive landscape of automotive components, sourcing high-quality polyurethane suspension bushes—commonly referred to as “poly bushes”—is essential for enhancing vehicle performance and durability. This guide provides a structured approach for B2B buyers to ensure they make informed decisions when procuring poly bushes for their operations.

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s crucial to clearly outline your technical requirements. Identify the specific vehicle models and types of suspension systems that require poly bushes, as well as the desired performance characteristics, such as durability, load capacity, and resistance to environmental factors. This will streamline your search and ensure you find products that meet your precise needs.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers of poly bushes. Utilize industry directories, trade shows, and online marketplaces to compile a list of manufacturers. Focus on suppliers with a proven track record in producing high-quality polyurethane products and those that cater to your specific geographical regions, such as Africa or South America, where local support may be beneficial.

Step 3: Verify Supplier Certifications

Ensure that your shortlisted suppliers possess relevant certifications, such as ISO9001. These certifications indicate that the supplier adheres to international quality management standards, which is crucial for ensuring the reliability and performance of the products you intend to purchase. Request documentation to verify these certifications and assess their commitment to quality.

Illustrative image related to poly bush

Step 4: Request Product Samples

Before making a bulk purchase, request samples of the poly bushes from your chosen suppliers. Testing samples allows you to evaluate the material quality, fit, and performance firsthand. Consider conducting tests in real-world conditions to determine how the products hold up under stress and whether they meet your specifications.

Step 5: Assess Supplier Support and Service

Evaluate the level of customer support and service provided by potential suppliers. Good communication and responsiveness are vital for a successful partnership. Inquire about their technical support, warranty policies, and return procedures. A supplier that offers robust post-purchase support can significantly enhance your experience and help resolve any issues that may arise.

Step 6: Compare Pricing and Payment Terms

Once you have vetted suppliers and assessed their offerings, compare pricing structures and payment terms. Look for transparency in pricing, including any hidden costs such as shipping and handling fees. Understanding the payment terms—whether upfront, upon delivery, or with credit options—can also impact your cash flow and purchasing decisions.

Step 7: Finalize Your Order and Establish a Relationship

After selecting the most suitable supplier, proceed with finalizing your order. Maintain clear communication regarding delivery timelines and any specific requirements you may have. Building a strong relationship with your supplier can lead to better pricing, priority service, and access to new product developments in the future.

By following these steps, B2B buyers can confidently navigate the sourcing process for poly bushes, ensuring they select the right products that enhance vehicle performance and meet their operational needs.

Comprehensive Cost and Pricing Analysis for poly bush Sourcing

What Are the Key Cost Components in Poly Bush Manufacturing?

Understanding the cost structure of poly bush sourcing is essential for B2B buyers aiming to make informed purchasing decisions. The main components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: The primary input for poly bushes is high-quality polyurethane, which varies in price depending on its specifications and sourcing. Buyers should consider the quality of materials as it directly affects durability and performance.

-

Labor: Labor costs encompass wages for skilled workers involved in the manufacturing process. This varies by region and can significantly impact overall costs, particularly in countries with higher labor rates.

-

Manufacturing Overhead: This includes all indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help minimize these expenses.

-

Tooling: The initial investment in tooling is crucial for production efficiency. Custom tooling may be required for specialized designs, which can increase upfront costs but lead to better long-term savings.

-

Quality Control: Ensuring that poly bushes meet specific performance standards involves rigorous quality control processes, which can add to the cost. ISO certifications, such as ISO 9001, can further influence pricing due to the additional quality assurance measures implemented.

-

Logistics: Shipping and transportation costs are vital, especially for international buyers. Factors like distance, shipping method, and customs duties can significantly affect the total cost.

-

Supplier Margin: This is the profit margin added by suppliers, which can vary widely based on brand reputation, product quality, and service level.

How Do Pricing Influencers Affect Poly Bush Costs?

Several factors influence the pricing of poly bushes, impacting how buyers should approach negotiations:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their needs to maximize savings.

-

Specifications and Customization: Custom designs or specialized materials will incur additional costs. Buyers should clearly define their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Higher quality materials and relevant certifications can drive up prices but are essential for ensuring durability and performance.

-

Supplier Factors: The reliability and reputation of the supplier play a critical role in pricing. Established suppliers may charge a premium but often provide better quality assurance and customer service.

-

Incoterms: Understanding Incoterms is essential for international transactions. They define the responsibilities of buyers and sellers regarding shipping, insurance, and duties, which can significantly impact total costs.

What Negotiation Strategies Can Buyers Use for Cost-Efficiency?

B2B buyers should employ various strategies to enhance cost-efficiency when sourcing poly bushes:

-

Research and Benchmarking: Before negotiations, conduct market research to understand the average prices for poly bushes in your region. This information can empower you during discussions.

-

Volume Discounts: Leverage bulk purchasing to negotiate lower prices. Suppliers are often willing to provide discounts for larger orders.

-

Long-term Relationships: Building long-term relationships with suppliers can lead to better pricing and service over time. Regular communication and commitment can foster trust and loyalty.

-

Total Cost of Ownership (TCO): Consider the TCO rather than just the upfront price. Evaluate factors like longevity, maintenance, and performance to assess the real value of the product over time.

-

Flexibility in Specifications: If possible, remain flexible regarding product specifications. This can open up opportunities for cost reductions, especially if alternative materials or designs are acceptable.

What Pricing Nuances Should International Buyers Consider?

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of specific pricing nuances:

-

Currency Fluctuations: Exchange rates can impact pricing, so buyers should monitor currency trends and consider purchasing in stable currencies.

-

Import Duties and Taxes: Understand the import duties and taxes applicable in your region, as these can add significant costs to your purchase.

-

Shipping and Delivery Times: International shipping can introduce delays. Ensure that suppliers can meet your timelines to avoid potential operational disruptions.

-

Cultural Differences: Different regions may have varying negotiation styles. Understanding cultural nuances can enhance communication and lead to more favorable outcomes.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on market conditions, supplier agreements, and other factors. Always consult with suppliers for the most accurate pricing tailored to your specific needs.

Alternatives Analysis: Comparing poly bush With Other Solutions

Exploring Alternatives to Poly Bush: A Comprehensive Comparison

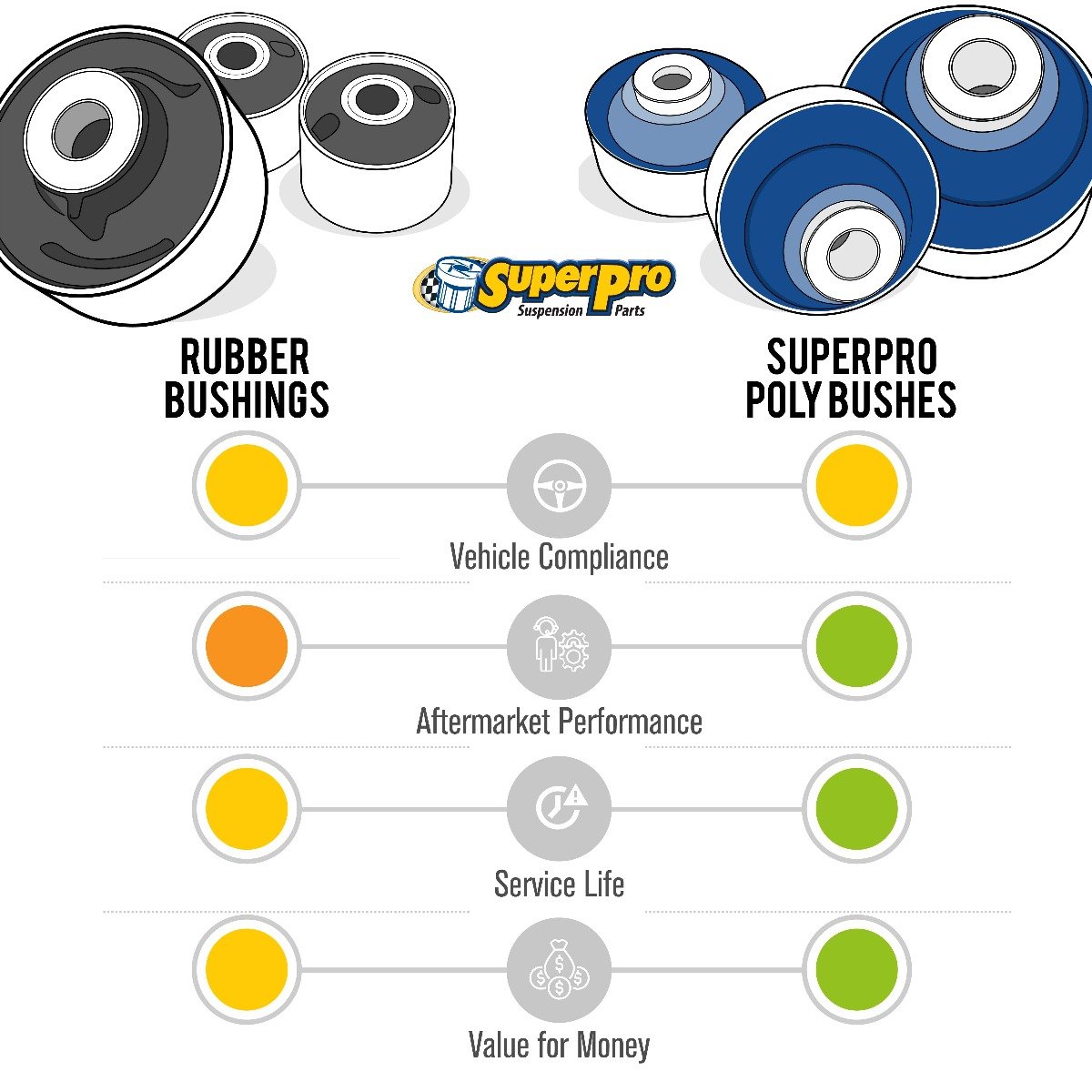

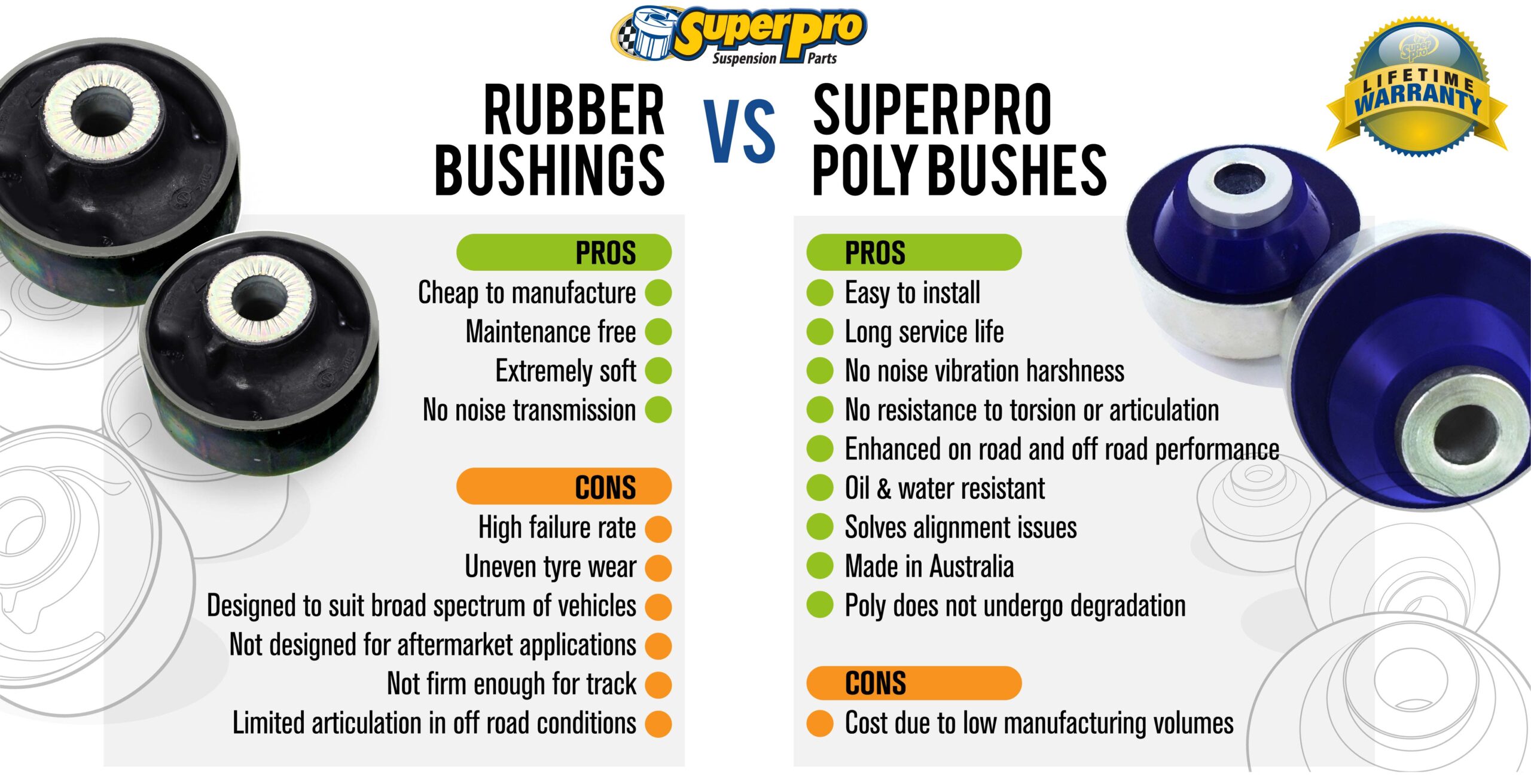

When evaluating suspension solutions for vehicles, particularly in the B2B sector, it’s essential to consider various alternatives to Poly Bushes. Each solution offers distinct advantages and disadvantages based on performance, cost, and implementation. Below, we compare Poly Bushes with two viable alternatives: Rubber Bushes and Metal Bushes.

| Comparison Aspect | Poly Bush | Rubber Bushes | Metal Bushes |

|---|---|---|---|

| Performance | Superior durability and handling; reduced noise and vibration | Good comfort but prone to wear over time | Excellent rigidity and strength; less comfort |

| Cost | Moderate to high initial cost; long-term savings due to durability | Lower initial cost; frequent replacements can add up | High initial investment; lower long-term maintenance |

| Ease of Implementation | Requires specific installation techniques; may need professional help | Easy to install; often a direct replacement | Typically requires specialized tools and skills |

| Maintenance | Low maintenance; lasts longer than alternatives | Moderate; needs regular checks and replacements | Low maintenance but may require periodic inspections |

| Best Use Case | Ideal for performance vehicles and heavy-duty applications | Suitable for regular passenger vehicles | Best for heavy machinery and off-road vehicles |

What Are the Advantages and Disadvantages of Rubber Bushes?

Rubber bushes are a common alternative due to their lower cost and ease of installation. They provide a comfortable ride and are generally effective for standard vehicles. However, their performance deteriorates over time, particularly under heavy loads or extreme conditions. The frequent need for replacements can lead to higher long-term costs, making them less ideal for businesses looking for durability and performance longevity.

How Do Metal Bushes Compare to Poly Bush?

Metal bushes are known for their strength and rigidity, making them suitable for high-performance applications where load-bearing is crucial. They provide minimal flex, which can enhance handling in certain scenarios. However, the trade-off is often a harsher ride quality and increased noise. Additionally, their installation can be more complicated and may require specialized tools, which can add to the overall cost and time of setup.

Making the Right Choice for Your Business Needs

Selecting the appropriate suspension solution involves assessing your specific operational requirements. Poly Bushes are ideal for businesses that prioritize performance, durability, and long-term savings, especially in demanding environments. Rubber bushes might suit budget-conscious buyers with standard vehicle needs, while metal bushes appeal to those requiring maximum strength for heavy-duty applications.

In conclusion, understanding the strengths and weaknesses of each alternative allows B2B buyers to make informed decisions that align with their operational goals, ensuring optimal performance and cost-effectiveness in the long run.

Essential Technical Properties and Trade Terminology for poly bush

What Are the Key Technical Properties of Poly Bush?

Polybushes are engineered components made from high-quality polyurethane, renowned for their durability and performance in automotive applications. Understanding the essential technical properties of poly bushes can significantly influence purchasing decisions and enhance operational efficiency.

1. Material Grade

Polybushes are typically manufactured from various grades of polyurethane, with hardness ratings often specified in Shore A durometer. Common grades include 40A, 55A, and 70A. The chosen grade affects the bush’s resilience, flexibility, and vibration-damping properties, making it crucial for applications requiring specific handling characteristics. For B2B buyers, selecting the appropriate material grade ensures optimal performance for their specific vehicle models and driving conditions.

2. Tolerance Levels

Precision in manufacturing tolerances is vital for the effective performance of poly bushes. Tolerances refer to the allowable variations in dimensions during the production process. Tight tolerances ensure proper fitment and function, minimizing the risk of premature wear or failure. Buyers should prioritize suppliers who adhere to strict tolerance specifications, as this impacts the overall reliability of the suspension system.

3. Load Capacity

Load capacity indicates the maximum weight a poly bush can withstand without deformation or failure. This property is especially important for commercial vehicles that experience heavy loads and dynamic forces. Understanding the load capacity helps buyers ensure that the selected poly bushes can handle the demands of their specific applications, leading to improved safety and performance.

4. Chemical Resistance

Polybushes are often exposed to various environmental factors, including oils, fuels, and road salt. A high level of chemical resistance is essential for maintaining the integrity of the bushes over time. B2B buyers should inquire about the chemical resistance properties of the polyurethane used, as this can significantly affect the longevity and reliability of the components, particularly in harsh conditions.

5. Temperature Range

The operating temperature range of poly bushes is crucial for their performance. Most polyurethane bushes can withstand temperatures from -30°C to +80°C, although some specialized grades may offer broader ranges. Understanding the temperature limits ensures that the bushes will perform optimally under varying environmental conditions, reducing the likelihood of thermal degradation.

What Are Common Trade Terms Related to Poly Bush Products?

Navigating the purchasing process for poly bushes requires familiarity with specific industry terminology. Here are some essential trade terms that B2B buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to the company that manufactures components that are used in the assembly of vehicles. Buyers often seek OEM poly bushes to ensure compatibility and performance similar to the original parts. Understanding the difference between OEM and aftermarket parts is crucial for making informed purchasing decisions.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers as it can affect inventory management and cash flow. Negotiating MOQ terms can lead to better pricing and supply chain efficiency, particularly for larger orders.

Illustrative image related to poly bush

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and availability for specific products. This process allows buyers to compare offers from different manufacturers, facilitating informed decision-making. Providing detailed specifications in an RFQ can help ensure accurate quotes.

4. Incoterms (International Commercial Terms)

Incoterms are a series of pre-defined commercial terms published by the International Chamber of Commerce (ICC) that clarify the responsibilities of buyers and sellers in international transactions. Understanding these terms is vital for B2B buyers engaged in global trade, as they determine who is responsible for shipping, insurance, and tariffs.

5. TPE (Thermoplastic Elastomer)

TPE refers to a class of polymers that have both thermoplastic and elastomeric properties. While not all poly bushes are made from TPE, understanding this term can help buyers recognize the advantages of using flexible materials in suspension applications, such as improved durability and performance.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing poly bushes, ensuring they meet their operational needs and enhance vehicle performance.

Illustrative image related to poly bush

Navigating Market Dynamics and Sourcing Trends in the poly bush Sector

What Are the Key Drivers Influencing the Poly Bush Market Today?

The global poly bush market is currently shaped by several key drivers, including the increasing demand for high-performance automotive components and the rise of electric vehicles (EVs). As automotive manufacturers shift towards EVs, the need for durable and lightweight materials like polyurethane has surged. This trend is particularly significant in regions such as Europe and the Middle East, where stringent emissions regulations are prompting innovation in vehicle design and component sourcing.

Emerging B2B tech trends, such as the integration of digital supply chain solutions and advanced analytics, are revolutionizing sourcing strategies. International buyers can now leverage platforms that offer real-time data on supplier performance and inventory management, enhancing their decision-making processes. Additionally, the growth of e-commerce in B2B transactions simplifies the procurement of poly bush products, allowing buyers from Africa and South America to access a broader range of suppliers and products seamlessly.

Furthermore, the poly bush sector is experiencing a shift towards customization, with suppliers offering tailored solutions that meet specific performance requirements. This trend is essential for buyers looking to optimize vehicle handling and comfort, as customized poly bushes can significantly enhance the driving experience.

How Is Sustainability and Ethical Sourcing Impacting the Poly Bush Sector?

Sustainability has become a pivotal concern in the poly bush industry, as buyers increasingly prioritize environmentally friendly practices. The environmental impact of traditional rubber bushes—often derived from non-renewable resources—has prompted a shift towards polyurethane alternatives, which are not only more durable but also less harmful to the environment.

Ethical sourcing is gaining traction as consumers demand transparency in supply chains. Buyers in Africa, South America, the Middle East, and Europe are more inclined to partner with suppliers who prioritize ethical practices, including fair labor conditions and minimal environmental impact. Certifications such as ISO 14001 and green materials labels can enhance a supplier’s credibility, making them more attractive to conscientious buyers.

Moreover, the adoption of sustainable manufacturing processes—such as recycling old poly bush materials—can reduce waste and lower the carbon footprint associated with production. Buyers are encouraged to seek out suppliers who are committed to these practices, ensuring that their sourcing aligns with global sustainability goals.

How Has the Poly Bush Industry Evolved Over Time?

The poly bush industry has undergone significant evolution over the past few decades. Initially, traditional rubber bushes dominated the market due to their widespread availability and cost-effectiveness. However, the limitations of rubber in terms of durability and performance led to the exploration of polyurethane as a viable alternative.

Illustrative image related to poly bush

As manufacturers began to recognize the superior properties of polyurethane—such as resistance to wear, heat, and environmental factors—the demand for poly bushes surged. This transition has been particularly evident in the automotive sector, where performance and reliability are paramount. Today, the poly bush market is characterized by innovation, with continual advancements in material science leading to the development of high-performance products tailored to meet the evolving needs of international B2B buyers.

In summary, understanding these market dynamics, sustainability considerations, and the historical context of poly bushes can empower international buyers to make informed sourcing decisions that not only enhance their product offerings but also align with broader environmental and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of poly bush

-

How do I determine the right poly bush for my vehicle?

To select the appropriate poly bush for your vehicle, first, identify the make, model, and year of your vehicle, as compatibility can vary significantly. Consult your vehicle’s service manual or a trusted parts catalog to find specifications for suspension components. Additionally, consider the driving conditions and desired performance characteristics, such as improved handling or comfort. Engaging with a reputable supplier who can provide expertise and product recommendations based on your specific requirements is essential. -

What are the advantages of using polyurethane bushes over rubber?

Polyurethane bushes offer several benefits compared to traditional rubber bushes, including enhanced durability, resistance to wear, and improved handling performance. They are less prone to degradation from oil, heat, and environmental factors, leading to a longer lifespan. Additionally, poly bushes provide better response and feedback during driving, resulting in a more enjoyable and controlled driving experience. For those prioritizing performance, comfort, and longevity, polyurethane is the superior choice. -

What minimum order quantities (MOQ) should I expect when sourcing poly bushes?

Minimum order quantities for poly bushes can vary significantly between manufacturers and suppliers. Typically, MOQs may range from a few units to several hundred, depending on production capabilities and the specific type of bush. When engaging with suppliers, inquire about their MOQs to find a balance between your needs and their production thresholds. Smaller businesses may negotiate lower MOQs, especially if they are willing to pay higher prices per unit. -

What payment terms are commonly offered by suppliers of poly bushes?

Payment terms can vary widely among suppliers, but common practices include advance payment, net 30, or net 60 terms. Many suppliers may require a deposit upfront for larger orders, with the remaining balance due upon shipment or delivery. It’s advisable to discuss payment options during negotiations, as some suppliers may offer flexibility based on your relationship and order size. Always ensure that payment terms are clearly outlined in your contract to avoid disputes later. -

How do I ensure quality when sourcing poly bushes internationally?

To ensure quality when sourcing poly bushes, select suppliers who hold recognized quality certifications, such as ISO9001. Request product samples to evaluate the materials and manufacturing processes firsthand. Additionally, consider conducting factory audits or relying on third-party inspection services before finalizing orders. Engaging with suppliers who provide detailed product specifications and testing results can also help assure you of the quality and performance of their products. -

What logistics considerations should I keep in mind when importing poly bushes?

Logistics considerations for importing poly bushes include understanding shipping options, lead times, and customs regulations in your destination country. Choose a reliable freight forwarder experienced in handling automotive parts to navigate these complexities. Factor in potential delays due to customs clearance, and ensure you have the necessary documentation, such as invoices and certificates of origin. Also, consider warehousing solutions if you need to manage inventory effectively. -

How can I customize poly bushes for specific applications?

Customization of poly bushes is often possible through direct consultation with manufacturers. Discuss your specific application requirements, such as stiffness levels, sizes, and design features, to determine if the supplier can accommodate your needs. Some manufacturers may offer bespoke solutions for unique applications, but minimum order quantities and additional costs may apply. Be clear about your expectations and ensure that all specifications are documented to avoid misunderstandings. -

What are the common challenges faced when sourcing poly bushes internationally?

Common challenges in sourcing poly bushes internationally include language barriers, differing quality standards, and logistical complexities. Time zone differences can complicate communication and lead to delays in decision-making. Additionally, varying regulations regarding automotive parts can create compliance issues. To mitigate these challenges, establish clear communication channels, engage local representatives if necessary, and conduct thorough research on potential suppliers to ensure they meet your quality and regulatory standards.

Top 2 Poly Bush Manufacturers & Suppliers List

1. Demon Tweeks – Polybush Suspension Solutions

Domain: demon-tweeks.com

Registered: 1999 (26 years)

Introduction: This company, Demon Tweeks – Polybush Suspension Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Polybush – Poly Bushings Kit For LR3 And LR4

Domain: roverparts.com

Registered: 1996 (29 years)

Introduction: {“product_name”: “Poly Bushings Kit For LR3 And LR4”, “price”: “$621.95”, “item_number”: “9746O”, “manufacturer”: “Polybush”, “availability”: “In Stock”, “shipping”: “Ships Today”, “fits”: [“LR3 / Discovery 3 V8 4.4L (2005 – 2009)”, “LR3 / Discovery 3 V6 4.0L (2005 – 2009)”, “LR4 / Discovery 4 V8 5.0 Liter (2010 – 2013)”, “LR4 / Discovery 4 V6 3.0 Liter (2014 – 2016)”], “material”: “Polyurethane”,…

Strategic Sourcing Conclusion and Outlook for poly bush

How Can Strategic Sourcing Enhance Your Poly Bush Procurement?

In conclusion, strategic sourcing of poly bushes is essential for businesses seeking quality, durability, and improved performance in their vehicle suspension systems. By partnering with reputable suppliers like Polybush, companies can ensure they receive ISO9001-certified products that meet the highest standards of manufacturing and customer service. The positive feedback from users highlights the significant benefits of poly bushes, including enhanced handling, comfort, and longevity—key factors that can lead to increased customer satisfaction and reduced maintenance costs.

International B2B buyers from regions such as Africa, South America, the Middle East, and Europe must prioritize sourcing strategies that emphasize reliability and quality. As the demand for high-performance automotive components continues to grow, aligning with trusted manufacturers will position businesses to capitalize on this trend.

Looking ahead, the global automotive landscape is evolving, and the need for innovative solutions will only intensify. Engage with suppliers who can offer not only superior products but also expert guidance to navigate the complexities of sourcing. Take proactive steps now to secure your supply chain and enhance your competitive edge in the market.

Illustrative image related to poly bush

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.