A Deep Dive into Pellets Machine Maker Solution

Introduction: Navigating the Global Market for pellets machine maker

In the competitive landscape of the global market, sourcing the right pellets machine maker can pose significant challenges for B2B buyers. From ensuring quality and efficiency to navigating diverse supplier landscapes, the stakes are high. This comprehensive guide addresses these challenges head-on, offering insights into various types of pellet mills, their applications across industries, and best practices for vetting suppliers. Whether you are in Africa, South America, the Middle East, or Europe—regions experiencing a growing demand for biomass and feed production—this resource is tailored to empower your purchasing decisions.

Our guide delves into the intricacies of pellet mill technologies, including electric, diesel, and PTO-driven options, highlighting their suitability for different materials and production scales. We will also cover the critical aspects of cost analysis, maintenance considerations, and the latest innovations in pelletizing technology. By equipping international B2B buyers with actionable insights and a clear understanding of market dynamics, this guide aims to facilitate informed decisions that enhance operational efficiency and drive profitability.

As you navigate the complexities of sourcing pellet machines, let this guide serve as your trusted companion in making strategic investments that align with your business goals.

Understanding pellets machine maker Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electric Pellet Mills | High efficiency, low operational cost, various power options | Animal feed, wood pellets, biomass | Pros: Eco-friendly, consistent output. Cons: Limited by power availability in remote areas. |

| Diesel-Powered Pellet Mills | Flexibility in remote locations, robust design | Agriculture, construction materials | Pros: High mobility, suitable for off-grid use. Cons: Higher fuel costs and emissions. |

| PTO Driven Pellet Mills | Connects to tractors, ideal for farms | Agricultural feed production | Pros: Cost-effective, utilizes existing machinery. Cons: Requires compatible tractor. |

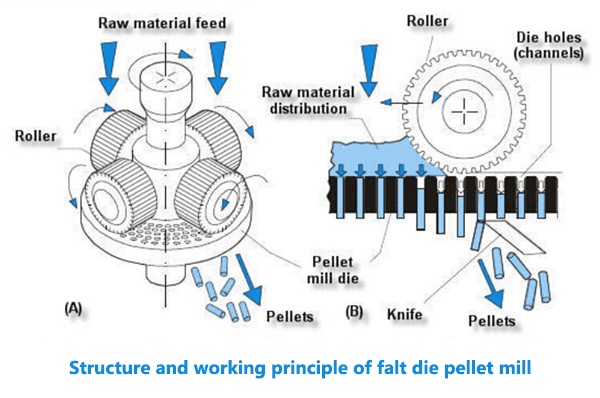

| Flat Die Pellet Mills | Customizable die sizes, suitable for small to medium production | Specialty feeds, recycling applications | Pros: Versatile, lower initial investment. Cons: Slower output compared to ring die mills. |

| Ring Die Pellet Mills | High capacity, designed for continuous operation | Large-scale animal feed, biomass processing | Pros: High efficiency, large output. Cons: Higher initial investment and maintenance costs. |

What Are Electric Pellet Mills and Their Suitability for B2B Buyers?

Electric pellet mills are known for their energy efficiency and low operational costs. They typically come with various power options, making them suitable for different production scales. Ideal for applications in animal feed production and wood pellet manufacturing, these mills are especially advantageous for businesses looking to minimize their environmental footprint. When considering an electric pellet mill, buyers should assess local electricity availability, as remote areas may face limitations that could affect operations.

Why Choose Diesel-Powered Pellet Mills for Flexibility?

Diesel-powered pellet mills offer the advantage of mobility and can operate in remote locations without relying on electricity. This makes them an excellent choice for agricultural applications, especially in regions where access to power is inconsistent. While they provide high flexibility, buyers should consider the ongoing fuel costs and emissions associated with diesel engines. Furthermore, understanding local regulations regarding emissions can help businesses avoid potential compliance issues.

How Do PTO Driven Pellet Mills Benefit Agricultural Operations?

PTO (Power Take-Off) driven pellet mills connect directly to tractors, making them an efficient choice for agricultural settings. They allow farmers to utilize existing machinery, reducing the need for additional investments. These mills are particularly beneficial for producing animal feed on-site, which can lead to cost savings and enhanced feed quality. However, buyers must ensure compatibility with their tractors and evaluate the overall efficiency of their operations before purchase.

What Are the Advantages of Flat Die Pellet Mills for Specialized Applications?

Flat die pellet mills are designed for versatility, allowing businesses to customize die sizes for various applications, from specialty animal feeds to recycling processes. They are particularly suited for small to medium production runs, making them ideal for niche markets. The lower initial investment can be appealing for startups or smaller enterprises, but buyers should be aware that these mills may have slower output rates compared to their ring die counterparts.

Why Are Ring Die Pellet Mills Considered the Workhorses of Large-Scale Production?

Ring die pellet mills are engineered for high-capacity production and continuous operation, making them the preferred choice for large-scale animal feed and biomass processing. Their robust design ensures efficiency and durability, capable of handling significant output requirements. However, potential buyers should weigh the higher initial investment and maintenance costs against the long-term productivity gains. Understanding the specific production needs and operational capabilities is crucial for making an informed purchasing decision.

Key Industrial Applications of pellets machine maker

| Industry/Sector | Specific Application of pellets machine maker | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Animal Feed Production | Custom feed formulation using locally sourced ingredients | Enhances animal health and reduces feed costs through tailored nutrition | Consider local ingredient availability, mill capacity, and power type |

| Biomass Energy | Conversion of agricultural waste into energy pellets | Reduces waste disposal costs and generates renewable energy sources | Evaluate feedstock types, pellet durability, and energy efficiency |

| Plastics Recycling | Pelletizing plastic waste for reuse in manufacturing | Minimizes environmental impact and creates new revenue streams | Assess compatibility with various plastics and required processing capacity |

| Fertilizer Production | Processing organic waste into nutrient-rich pellets | Improves soil health and reduces reliance on chemical fertilizers | Focus on moisture content, pellet size, and nutrient retention |

| Hops and Brewing | Pelletizing hops for efficient storage and brewing processes | Enhances flavor retention and shelf life of hops in brewing | Consider pellet quality, size consistency, and production volume needs |

How is ‘pellets machine maker’ utilized in animal feed production?

In the animal feed industry, pellets machine makers are essential for creating customized feed formulations that cater to specific livestock nutritional needs. By using locally sourced ingredients, businesses can optimize their feed blends, improving animal health and reducing overall costs. For international buyers, especially in regions like Africa and South America, it’s crucial to consider the availability of local ingredients and the mill’s capacity to handle varying volumes. Power type (electric, diesel, etc.) also plays a significant role depending on the infrastructure in place.

What role do pellets machine makers play in biomass energy production?

Pellets machine makers are pivotal in converting agricultural waste, such as crop residues and forestry byproducts, into energy pellets. This process not only mitigates waste disposal costs but also contributes to sustainable energy production. For buyers in the Middle East and Europe, evaluating the types of feedstock they have access to is essential, as is the durability of the pellets produced. Energy efficiency is another critical factor, as it impacts the overall profitability of the biomass energy venture.

How do pellets machine makers facilitate plastics recycling?

In the plastics industry, pellets machine makers enable the recycling of plastic waste by transforming it into reusable pellets for manufacturing. This process significantly reduces environmental impact while creating new revenue opportunities for businesses. For buyers in South America and Africa, understanding the compatibility of pellet mills with various types of plastics and the required processing capacity is vital. Additionally, the ability to handle different plastic grades can influence the effectiveness of recycling operations.

How are pellets machine makers utilized in fertilizer production?

Pellets machine makers are instrumental in processing organic waste into nutrient-rich fertilizer pellets, which can enhance soil health and reduce dependency on chemical fertilizers. This application is particularly valuable in regions with agricultural economies, such as parts of Europe and Africa. Buyers should prioritize moisture content, pellet size, and nutrient retention capabilities when sourcing equipment, as these factors directly affect the quality and effectiveness of the fertilizer produced.

What advantages do pellets machine makers provide in hops and brewing?

In the brewing industry, pellets machine makers are used to pelletize hops, which improves storage efficiency and enhances flavor retention during the brewing process. This method ensures that brewers can maintain the quality of hops over time, which is crucial for producing high-quality beer. For buyers in regions like Germany, where brewing is a significant industry, it’s essential to consider pellet quality, size consistency, and production volume needs to meet market demands effectively.

3 Common User Pain Points for ‘pellets machine maker’ & Their Solutions

Scenario 1: Navigating Production Capacity Limitations

The Problem: A prominent challenge faced by B2B buyers is determining the right pellet mill to meet their production capacity needs. Buyers often find themselves overwhelmed by varying specifications and performance metrics, leading to uncertainty about whether the equipment will efficiently handle their desired output. For instance, a feed producer in South America may require a mill capable of processing large volumes of raw materials to meet regional demand, but without clear guidance on machine capabilities, they risk purchasing equipment that falls short of their operational goals.

The Solution: To effectively address this challenge, buyers should engage with pellet machine makers who offer detailed consultations and tailored recommendations based on specific production needs. It’s vital to request performance metrics such as throughput rates, die sizes, and the types of materials each model can handle. Additionally, buyers should consider investing in scalable solutions, such as modular systems that can grow with their business. For example, a manufacturer could start with a smaller model and expand to a multi-mill installation as demand increases. Collaboration with manufacturers that provide robust customer support and training will also ensure optimal machine utilization from the outset.

Scenario 2: Managing Maintenance and Downtime Costs

The Problem: Maintenance and operational downtime can significantly impact the profitability of businesses relying on pellet mills. A common concern for buyers is the lack of accessible information regarding maintenance protocols and the potential costs associated with equipment failure. For instance, a biomass facility in Europe may experience unexpected downtime due to mechanical issues, which not only halts production but also incurs additional repair costs and lost revenue.

The Solution: To mitigate these risks, B2B buyers should prioritize sourcing pellet mills from manufacturers that emphasize durability and reliability in their designs. It’s advisable to inquire about warranty terms and the availability of replacement parts to ensure quick repairs. Additionally, implementing a proactive maintenance schedule that includes regular inspections and training staff on basic troubleshooting can greatly reduce the likelihood of serious malfunctions. Buyers might also consider investing in predictive maintenance technologies, which utilize data analytics to foresee potential equipment failures before they occur, ultimately saving time and money.

Scenario 3: Ensuring Compliance with Environmental Regulations

The Problem: As global sustainability standards become increasingly stringent, businesses face pressure to comply with environmental regulations. Buyers in regions like Africa and the Middle East may struggle to find pellet mills that not only produce high-quality pellets but also adhere to local and international environmental guidelines. This scenario creates anxiety, as non-compliance can lead to heavy fines and damage to a company’s reputation.

The Solution: To navigate this regulatory landscape, B2B buyers should partner with pellet mill manufacturers that are well-versed in environmental standards and can provide equipment certified for compliance. Engaging in discussions about emissions output, energy consumption, and waste management practices is crucial. Buyers should also consider machinery that features energy-efficient designs and utilizes sustainable materials in its operation. Conducting thorough due diligence by reviewing case studies or seeking testimonials from other compliant operations can further assure buyers that their investment aligns with both production goals and regulatory requirements. Additionally, leveraging expert consultants can provide insights into local regulations, helping businesses adapt their operations accordingly.

Strategic Material Selection Guide for pellets machine maker

What Are the Key Materials Used in Pellet Mills and Their Properties?

When selecting materials for pellet mills, it’s essential to consider their properties, advantages, and limitations. Here, we analyze four common materials used in the construction of pellet mills: Carbon Steel, Stainless Steel, Cast Iron, and Aluminum. Each material has distinct characteristics that can impact the performance and longevity of the machines, as well as their suitability for specific applications.

How Does Carbon Steel Perform in Pellet Mill Applications?

Key Properties: Carbon steel is known for its high tensile strength and durability, making it suitable for heavy-duty applications. It can withstand high temperatures and pressures, which is vital for the pelleting process. However, it is prone to corrosion if not properly coated or maintained.

Pros & Cons: The primary advantage of carbon steel is its cost-effectiveness and strength, making it a popular choice for many manufacturers. However, its susceptibility to rust and corrosion can lead to increased maintenance costs and reduced lifespan if used in humid or corrosive environments.

Impact on Application: Carbon steel is typically used in the structural components of pellet mills, such as frames and housings. It is compatible with a wide range of feedstocks, including wood and agricultural waste.

Considerations for International Buyers: Buyers should ensure that the carbon steel used meets local standards like ASTM or DIN, particularly in regions with strict regulations on material quality. In markets like Germany and Saudi Arabia, compliance with these standards is crucial for operational efficiency.

What Role Does Stainless Steel Play in Pellet Mill Manufacturing?

Key Properties: Stainless steel is renowned for its corrosion resistance and ability to withstand high temperatures. It is non-reactive, making it ideal for processing food-grade materials.

Pros & Cons: The main advantage of stainless steel is its durability and resistance to rust, which extends the lifespan of the equipment. However, it is significantly more expensive than carbon steel, which may deter some buyers.

Impact on Application: Stainless steel is often used in parts that come into direct contact with the feedstock, such as die plates and rollers, ensuring that the final product remains uncontaminated. This is particularly important for industries focused on food and animal feed production.

Considerations for International Buyers: Buyers in regions like Europe and the Middle East should verify that the stainless steel used complies with international food safety standards, such as those set by the FDA or EFSA.

How Does Cast Iron Compare in Pellet Mill Design?

Key Properties: Cast iron is known for its excellent wear resistance and ability to absorb vibrations, which can enhance the operational stability of pellet mills. However, it is heavier and more brittle than other materials.

Pros & Cons: The advantage of cast iron is its durability and ability to withstand high levels of wear, making it suitable for heavy-duty applications. The downside is its weight, which can complicate transportation and installation.

Impact on Application: Cast iron is commonly used in the construction of die housings and other components that require stability and durability under heavy loads.

Illustrative image related to pellets machine maker

Considerations for International Buyers: Buyers should be aware of the specific grades of cast iron used and ensure they meet local manufacturing standards. In regions with varying quality standards, such as South America, this can be particularly important.

Why Choose Aluminum for Pellet Mills?

Key Properties: Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It is less robust than steel but is often chosen for its ease of machining and lower weight.

Pros & Cons: The primary advantage of aluminum is its lightweight nature, which can reduce shipping costs. However, it may not be suitable for high-load applications due to its lower strength compared to steel.

Impact on Application: Aluminum is often used in components that require precision machining, such as certain die and roller designs, where weight savings can enhance performance.

Considerations for International Buyers: Buyers should consider the specific alloy of aluminum used and its compliance with international standards, particularly in regions like Africa, where material sourcing may vary.

Summary Table of Material Selection for Pellet Mills

| Material | Typical Use Case for pellets machine maker | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Structural components (frames, housings) | Cost-effective and strong | Prone to corrosion | Low |

| Stainless Steel | Contact parts (die plates, rollers) | Corrosion-resistant and durable | Higher cost | High |

| Cast Iron | Die housings and heavy-duty components | Excellent wear resistance | Heavy and brittle | Medium |

| Aluminum | Precision parts (die designs) | Lightweight and easy to machine | Lower strength under heavy loads | Medium |

This strategic material selection guide provides a comprehensive overview for international B2B buyers, enabling informed decisions based on material properties, applications, and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for pellets machine maker

What Are the Main Stages in the Manufacturing Process of Pellets Machines?

The manufacturing process of pellet machines is a complex operation that encompasses several key stages: material preparation, forming, assembly, and finishing. Each stage is crucial in ensuring the final product meets the rigorous standards expected in international markets.

Material Preparation: What Raw Materials Are Needed?

The process begins with the selection and preparation of raw materials, typically including steel, cast iron, and specialized alloys. Manufacturers often source high-grade materials to ensure durability and performance. The materials undergo treatments such as heat treatment to enhance their mechanical properties, making them suitable for high-stress environments. This stage may also involve cutting and machining components to specific dimensions, ensuring compatibility with other machine parts.

How Is the Forming Process Executed?

The forming process is where the core components of the pellet machine, such as the die and rollers, are produced. Advanced techniques like CNC (Computer Numerical Control) machining are employed to create precise and complex shapes. This precision is essential for ensuring that the pellets produced are uniform in size and density, directly affecting the quality of the end product. Additionally, manufacturers may utilize forging or casting methods for larger components, enhancing strength and longevity.

What Happens During Assembly?

Once the individual parts are manufactured, they are meticulously assembled. This stage involves fitting components together, including the drive systems, feeders, and control panels. Quality assurance practices are integral at this point, as misalignments or improper fittings can lead to operational inefficiencies. Automated systems may assist in assembly to increase speed and accuracy, but skilled technicians typically oversee the process to ensure that every machine meets the specified operational standards.

How Is the Finishing Stage Carried Out?

The finishing stage involves surface treatments such as painting, coating, or polishing to protect against wear and corrosion. This not only enhances the aesthetic appeal of the machines but also extends their lifespan. Final inspections are conducted to ensure that all components are functioning correctly and that the machine adheres to the desired specifications before it is packaged and shipped to customers.

What Quality Control Measures Are Implemented in Pellet Machine Manufacturing?

Quality control (QC) is a critical aspect of pellet machine manufacturing, ensuring that products meet international standards and customer expectations. Key QC measures include adherence to international standards like ISO 9001, as well as industry-specific certifications such as CE and API.

What International Standards Should B2B Buyers Look For?

ISO 9001 is a widely recognized standard that outlines requirements for a quality management system (QMS). Manufacturers with ISO 9001 certification demonstrate a commitment to quality, consistency, and customer satisfaction. CE marking indicates compliance with European health, safety, and environmental protection standards, which is crucial for buyers in Europe. For buyers in sectors like oil and gas, API certification may also be relevant, indicating that products meet rigorous industry standards.

What Are the Key QC Checkpoints During Production?

Quality control checkpoints are strategically placed throughout the manufacturing process to catch defects early. These include:

- Incoming Quality Control (IQC): Inspection of raw materials upon arrival to ensure they meet specified quality standards.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing to detect any deviations from production standards.

- Final Quality Control (FQC): A thorough examination of the finished product to ensure it meets all specifications and is ready for shipment.

Which Testing Methods Are Commonly Used?

Testing methods employed in the QC process include:

- Dimensional Inspection: Utilizing precision measuring tools to confirm that parts conform to specifications.

- Performance Testing: Running the machines under simulated conditions to verify operational efficiency and output quality.

- Material Testing: Conducting hardness and tensile strength tests to confirm the integrity of raw materials.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is essential for ensuring product reliability. Here are some effective strategies:

What Role Do Audits and Reports Play?

Buyers should request documentation of the manufacturer’s quality management practices, including audit reports and certifications. Regular audits by external parties can provide an objective assessment of a supplier’s adherence to quality standards. Additionally, manufacturers should be willing to share their internal QC reports, detailing the results of inspections and tests conducted throughout the production process.

Illustrative image related to pellets machine maker

How Can Third-Party Inspections Enhance Buyer Confidence?

Engaging third-party inspection services can offer an additional layer of assurance. These independent entities can perform random checks on production lines, assess compliance with industry standards, and verify that QC measures are being effectively implemented. This is particularly important for buyers in regions like Africa and South America, where local regulations may vary widely.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers from different regions must be aware of specific quality control nuances that can affect their purchasing decisions. For instance, European buyers may prioritize CE marking, while buyers in the Middle East may look for compliance with local industry standards. Understanding these regional differences is crucial for ensuring that the equipment meets local regulatory requirements and operational expectations.

In conclusion, the manufacturing processes and quality assurance measures employed by pellet machine makers play a pivotal role in delivering reliable, high-performance equipment to international markets. By understanding these processes and how to verify supplier quality, B2B buyers can make informed decisions that align with their operational needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pellets machine maker’

When sourcing a pellets machine maker, it’s essential to follow a systematic approach to ensure you acquire equipment that meets your operational needs while also delivering value for money. This checklist serves as a practical guide for international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Understanding your specific requirements is crucial before initiating the procurement process. Define the type of pellets you intend to produce (e.g., wood, animal feed, biomass) and the expected production capacity. This clarity will help you communicate effectively with suppliers and ensure that the machines you consider align with your operational needs.

Illustrative image related to pellets machine maker

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable manufacturers and suppliers of pellet mills. Look for companies with a proven track record in the industry, especially those known for their quality and reliability. Utilize online platforms, trade shows, and industry publications to compile a list of potential suppliers.

Step 3: Evaluate Supplier Certifications and Standards

Before engaging with a supplier, verify their certifications and adherence to international standards. This step is vital to ensure that the equipment meets safety, environmental, and quality standards. Look for certifications like ISO 9001, which indicates a commitment to quality management practices.

Step 4: Assess Machine Specifications and Features

When reviewing different pellet mills, compare their specifications and features. Key aspects to consider include:

– Power Source: Identify whether you need electric, diesel, or gasoline-powered machines based on your local energy availability and costs.

– Die Sizes: Ensure the mills can accommodate various die sizes to meet your product diversity.

– Durability and Build Quality: Examine the materials used in construction to gauge longevity and reliability.

Illustrative image related to pellets machine maker

Step 5: Request and Analyze Quotes

Once you’ve shortlisted potential suppliers, request detailed quotes. Compare pricing but also consider what is included in the offer, such as warranties, after-sales service, and delivery times. This comprehensive analysis will help you make an informed decision.

Step 6: Seek Customer References and Reviews

Before finalizing your supplier, ask for references from previous customers. Inquire about their experiences, focusing on machine performance, customer service, and support. Online reviews can also provide insights into the supplier’s reputation in the market.

Step 7: Negotiate Terms and Conditions

Once you’ve selected a supplier, engage in negotiations to finalize the terms of purchase. Discuss payment terms, delivery schedules, and installation support. Clear agreements will help prevent misunderstandings and ensure a smooth procurement process.

Illustrative image related to pellets machine maker

By following this checklist, B2B buyers can navigate the complexities of sourcing a pellets machine maker with confidence, ensuring they choose a solution that enhances their production capabilities and drives business growth.

Comprehensive Cost and Pricing Analysis for pellets machine maker Sourcing

Understanding the cost structure and pricing strategies for sourcing pellet machines is crucial for international B2B buyers, especially those in Africa, South America, the Middle East, and Europe. This analysis will delve into the key components of costs, the factors influencing pricing, and provide actionable insights to facilitate effective negotiations and purchasing decisions.

What Are the Key Cost Components in Pellet Machine Manufacturing?

Materials: The primary cost driver in pellet machine production is the raw materials used. High-quality steel, for instance, is essential for durability and performance, contributing significantly to the overall material costs. The choice of materials can also affect the machine’s ability to handle different types of feedstock, which can be a deciding factor for buyers.

Labor and Manufacturing Overhead: Labor costs vary widely by region and can significantly impact the final price of the machine. Countries with higher labor costs, such as those in Western Europe, may see higher prices. Additionally, manufacturing overhead, including utilities, rent, and administrative expenses, is typically factored into the pricing.

Tooling and Quality Control (QC): Advanced tooling and stringent QC processes ensure the machines meet specific performance and safety standards, particularly for buyers needing certifications for compliance. This adds to the cost but is often necessary for buyers targeting high-performance markets.

Illustrative image related to pellets machine maker

Logistics: Transportation and shipping costs can be substantial, especially for international buyers. The chosen shipping method (air vs. sea) and the distance from the manufacturing site to the buyer’s location can influence overall costs. Import duties and taxes must also be considered as part of the logistics expense.

Margin: Manufacturers typically apply a margin that reflects their business model and market positioning. Established brands may have higher margins due to perceived quality and reliability, while newer or lesser-known suppliers may offer lower prices to gain market share.

What Factors Influence Pellet Machine Pricing?

Volume and Minimum Order Quantity (MOQ): Pricing can be significantly influenced by the volume of machines ordered. Larger orders often qualify for bulk discounts, making it more cost-effective for buyers. Understanding the MOQ can help buyers negotiate better terms.

Specifications and Customization: Customization requests, such as specific die sizes or additional features, can lead to increased costs. Buyers should be clear about their requirements upfront to avoid unexpected price increases.

Material Quality and Certifications: Machines built with higher-grade materials or those that meet specific industry certifications will typically command higher prices. Buyers should assess the long-term benefits of investing in certified machines against their budget constraints.

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established manufacturers with a track record of quality may charge more, but they often provide better after-sales support and warranty services.

Incoterms: The chosen Incoterm (International Commercial Terms) affects pricing by defining responsibilities for shipping, insurance, and tariffs. Buyers should be well-versed in these terms to understand their cost obligations fully.

What Are Some Effective Buyer Tips for Negotiating Pellet Machine Prices?

Negotiate Wisely: Buyers should approach negotiations with a clear understanding of their needs and market prices. Being informed about competitor offerings can provide leverage in discussions.

Consider Total Cost of Ownership (TCO): Beyond the initial purchase price, buyers should evaluate the TCO, which includes maintenance, operational costs, and potential savings from efficiency. A more expensive machine may offer lower operational costs, leading to savings over its lifespan.

Understand Pricing Nuances for International Purchases: Buyers from regions like Africa and South America should consider currency fluctuations and their impact on pricing. Additionally, understanding local regulations and compliance requirements can prevent unforeseen costs.

Request Multiple Quotes: Obtaining quotes from several suppliers can provide insights into market pricing and help buyers identify the best value proposition.

Conclusion

Sourcing pellet machines involves a complex interplay of cost components and pricing influences. By understanding these elements and employing strategic negotiation techniques, international B2B buyers can make informed purchasing decisions that align with their operational needs and budget constraints. As always, it is advisable to verify indicative prices and ensure clarity on all terms before finalizing any agreements.

Alternatives Analysis: Comparing pellets machine maker With Other Solutions

Understanding Alternative Solutions to Pellets Machine Makers

In the competitive landscape of biomass processing and material densification, various solutions exist alongside traditional pellets machine makers. These alternatives cater to diverse production needs, operational scales, and resource availability. This analysis aims to provide B2B buyers with comparative insights into the effectiveness, cost-efficiency, and application suitability of pellets machine makers versus other viable solutions.

Comparison Table

| Comparison Aspect | Pellets Machine Maker | Alternative 1: Hammer Mill | Alternative 2: Briquette Press |

|---|---|---|---|

| Performance | High output for various materials, consistent pellet quality | Versatile for coarse grinding, lower output | Efficient for high-density briquettes, good for certain materials |

| Cost | Mid to high-range investment, varies by model and capacity | Generally lower initial cost, but higher operational costs | Mid-range investment, additional costs for conditioning materials |

| Ease of Implementation | Requires setup and calibration, generally user-friendly | Simpler installation, less training needed | Moderate complexity, requires understanding of material properties |

| Maintenance | Regular maintenance needed for optimal performance | Low maintenance, but wear on hammers | Moderate maintenance, depends on material used |

| Best Use Case | Ideal for producing animal feed, wood pellets, and biomass | Best for grinding grains and raw materials | Suitable for producing fuel briquettes and compacting waste |

Pros and Cons of Alternatives

Hammer Mill:

Hammer mills are a popular alternative to pellet mills, particularly for their versatility in grinding various raw materials. They excel in producing coarse particles, making them suitable for animal feed production and biomass processing. However, while they have a lower initial investment cost, they may incur higher operational costs due to energy consumption and wear on the hammers. Additionally, they require less technical knowledge to operate, making them accessible for smaller operations.

Briquette Press:

Briquette presses offer an efficient solution for densifying biomass and waste materials into high-density briquettes, which are particularly valuable for energy production. They are well-suited for materials like agricultural residues and wood chips. While their initial investment is generally within a mid-range budget, the conditioning of materials before briquetting can add to operational costs. The complexity of operation may require more technical knowledge, particularly in understanding the properties of the materials being processed.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the right solution for biomass processing or feed production, B2B buyers should consider their specific operational needs, budget constraints, and the types of materials they intend to process. Pellets machine makers are ideal for high-volume, consistent pellet production, while hammer mills provide flexibility for various raw materials. Briquette presses, on the other hand, are advantageous for energy-focused applications where high-density output is critical. Evaluating these aspects will help businesses make informed decisions that align with their production goals and resource capabilities.

Essential Technical Properties and Trade Terminology for pellets machine maker

When exploring the realm of pellet machine manufacturing, understanding key technical properties and industry-specific terminology is essential for B2B buyers. This knowledge aids in making informed purchasing decisions and optimizing operational efficiency.

What Are the Essential Technical Properties of Pellet Machines?

1. Material Grade

The material grade of a pellet machine refers to the quality of the steel used in its construction. High-grade steel, such as stainless steel or hardened alloy, is preferred for its durability and resistance to wear and corrosion. For B2B buyers, investing in machines made from superior materials ensures longevity and reduced maintenance costs, ultimately leading to higher operational efficiency.

2. Power Rating

Power rating, typically measured in horsepower (hp), indicates the machine’s capacity to process various materials. Different applications require specific power ratings; for instance, wood pellets might need higher power than feed pellets. Understanding the power requirements helps buyers select machines that align with their production goals, preventing underperformance or operational bottlenecks.

3. Die Size

The die size of a pellet machine affects the diameter of the pellets produced. Common sizes range from 4mm to 12mm, with various options available for different applications. For buyers, selecting the appropriate die size is critical as it impacts pellet quality, production rate, and suitability for specific markets, whether for animal feed, biomass, or other materials.

4. Production Capacity

Production capacity is the maximum output of pellets a machine can produce in a given time frame, often measured in tons per hour. Understanding the production capacity is vital for buyers to ensure that their investment meets their operational demands. A mismatch can lead to increased operational costs or lost revenue opportunities.

5. Efficiency Rating

Efficiency ratings reflect how effectively a pellet machine converts raw materials into finished pellets. Higher efficiency reduces energy consumption and raw material waste, which is crucial for cost-effective operations. Buyers should evaluate efficiency ratings to optimize their production processes and minimize expenses.

What Are Common Trade Terms in Pellet Machinery?

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of pellet machines, understanding OEM relationships helps buyers identify reputable manufacturers who provide quality equipment and support.

2. MOQ (Minimum Order Quantity)

MOQ signifies the smallest quantity of a product that a supplier is willing to sell. For pellet machinery, knowing the MOQ helps buyers plan their purchases effectively, ensuring they meet supplier requirements while optimizing inventory levels.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for a specific product or service. For B2B buyers, issuing an RFQ allows them to compare offers and negotiate better terms, ensuring they receive competitive pricing for pellet machines.

4. Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Understanding these terms, such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight), is crucial for B2B buyers to clarify shipping costs, risks, and delivery responsibilities when purchasing pellet machinery from global suppliers.

5. Turnkey Solutions

Turnkey solutions refer to fully integrated systems provided by manufacturers, where the entire process, from design to installation, is managed by the supplier. For buyers, opting for turnkey solutions can simplify the procurement process, ensuring that all components work seamlessly together and reducing the time to market.

In conclusion, a thorough understanding of the essential technical properties and industry terminology related to pellet machines equips B2B buyers with the knowledge to make informed decisions, optimize procurement strategies, and enhance operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the pellets machine maker Sector

What Are the Current Market Dynamics and Key Trends in the Pellets Machine Maker Sector?

The pellets machine maker sector is experiencing robust growth, driven by increasing demand for sustainable fuel sources and efficient waste management solutions. Globally, the shift towards renewable energy and biofuels is a significant catalyst. This demand is particularly pronounced in regions like Africa, South America, the Middle East, and Europe, where countries are investing heavily in alternative energy infrastructures. For instance, nations such as Germany and Saudi Arabia are championing biomass technologies to meet their energy needs while reducing carbon footprints.

Emerging technologies such as automation, IoT (Internet of Things), and advanced analytics are revolutionizing the sourcing landscape. Manufacturers are increasingly adopting smart pellet mills equipped with sensors that monitor performance metrics, thereby enhancing operational efficiency and reducing downtime. Moreover, the integration of AI in predictive maintenance is allowing companies to anticipate machine failures, which can save significant costs and improve productivity.

International B2B buyers are also seeking suppliers who offer customizable solutions tailored to specific needs, whether for animal feed, biomass, or recycling. This trend is indicative of a broader move towards more personalized and flexible manufacturing processes, allowing companies to adapt quickly to changing market demands.

How Is Sustainability Shaping Sourcing Trends in the Pellets Machine Maker Sector?

Sustainability is at the forefront of the pellets machine maker sector, influencing everything from sourcing to production processes. As environmental concerns rise, international buyers are increasingly prioritizing equipment that minimizes waste and maximizes energy efficiency. Pellet mills that can convert agricultural residues, forestry by-products, and even industrial waste into high-quality pellets are gaining traction, highlighting the importance of circular economy practices.

Ethical sourcing is another key factor in the decision-making process for B2B buyers. Companies are now more inclined to partner with manufacturers who demonstrate a commitment to sustainable practices, such as using certified materials and adhering to environmental regulations. Certifications like ISO 14001 (Environmental Management) and FSC (Forest Stewardship Council) are increasingly becoming prerequisites in supplier evaluations.

Moreover, as regulations around carbon emissions tighten globally, businesses in regions like Europe are compelled to adopt greener technologies. This shift not only ensures compliance but also enhances brand reputation among eco-conscious consumers, making sustainability a pivotal component of competitive strategy.

What Is the Historical Context of the Pellets Machine Maker Sector?

The history of the pellets machine maker sector dates back to the early 20th century when the need for efficient processing of agricultural and industrial waste emerged. Initially, the technology focused on producing animal feed pellets, which allowed farmers to maximize nutritional delivery while minimizing storage costs. Over the decades, advancements in engineering and materials science have significantly enhanced the performance and efficiency of pellet mills.

By the late 20th century, the sector saw a shift towards biomass energy as an alternative to fossil fuels, particularly in Europe and North America. This evolution was spurred by growing environmental awareness and the need for sustainable energy sources. As a result, modern pellet mills are now designed to handle a variety of feedstocks, including wood, straw, and even plastic waste, reflecting the industry’s adaptability to changing market demands.

Today, the pellets machine maker sector stands at a crossroads, with technology and sustainability driving its future. Manufacturers are expected to continue innovating to meet the diverse needs of global markets while adhering to stringent environmental standards.

Frequently Asked Questions (FAQs) for B2B Buyers of pellets machine maker

-

How do I choose the right pellet mill for my business needs?

When selecting a pellet mill, consider factors such as the type of materials you will process (biomass, animal feed, etc.), the desired production capacity, and the power source (electric, diesel, or gasoline). Evaluate the machine’s die size options, as different sizes impact pellet quality and production rates. It’s also essential to assess the manufacturer’s reputation, customer support, and whether they offer customization options to meet your specific requirements. -

What is the best pellet mill for biomass production?

For biomass production, a flat die pellet mill is often recommended due to its efficiency in handling various feedstocks like wood, agricultural residues, and even plastics. Look for models with a robust construction and high torque capabilities, which can handle tough materials. Additionally, consider mills that allow for scalability, enabling you to increase production capacity as your business grows. Always check for warranties and after-sales support as well. -

What are the typical payment terms when sourcing pellet mills internationally?

Payment terms can vary significantly based on the supplier and the nature of the transaction. Common terms include a deposit (usually 30-50%) upfront, with the balance due upon shipment or before delivery. For larger orders, suppliers may offer more flexible payment options or financing. Always negotiate terms upfront and ensure they are clearly outlined in your contract to avoid misunderstandings later. -

How do I vet pellet mill suppliers for reliability and quality?

To vet suppliers, start by reviewing their industry experience and customer testimonials. Request references from previous clients, particularly those in your region, to gauge satisfaction levels. Check if they adhere to international quality standards and certifications. Additionally, consider visiting their manufacturing facility or arranging for a third-party inspection to assess quality control processes firsthand. -

What is the minimum order quantity (MOQ) for pellet mills?

MOQs can vary significantly by supplier and the type of equipment. Some manufacturers may offer single units for small businesses, while others may require bulk orders to ensure cost-effectiveness. It’s advisable to discuss your needs with the supplier directly, as they may be willing to accommodate smaller orders, especially for new partnerships or in markets where they are looking to expand. -

What logistics considerations should I keep in mind when importing pellet mills?

When importing pellet mills, consider shipping methods, customs duties, and local regulations. Ensure that your supplier provides all necessary documentation, including commercial invoices and packing lists, to facilitate customs clearance. Also, evaluate the shipping costs and delivery timelines, as these can impact your operational planning. Partnering with a logistics expert familiar with international trade can streamline the process. -

How can I ensure quality assurance (QA) for the pellet mills I purchase?

Implementing a QA process starts with setting clear specifications with your supplier regarding materials, production processes, and performance standards. Request samples or trial runs before placing large orders. Additionally, consider third-party QA inspections to validate compliance with international standards. Establishing a clear communication channel with your supplier for ongoing support and feedback can further enhance product quality. -

What are the warranty and after-sales support options for pellet mills?

Warranty terms can vary by manufacturer, but most reputable suppliers offer warranties ranging from one to three years on their equipment. During the warranty period, they typically cover repairs or replacement of defective parts. After-sales support is crucial; inquire about the availability of technical assistance, spare parts supply, and training for your staff on equipment operation and maintenance to ensure optimal performance.

Top 3 Pellets Machine Maker Manufacturers & Suppliers List

1. PelletMasters – Pellet Mills, Hammer Mills, and Grinders

Domain: pelletmasters.com

Registered: 2008 (17 years)

Introduction: PelletMasters offers a range of Pellet Mills, Hammer Mills, and Grinders for various applications including wood, animal feed, and fertilizer production. Key product details include: 1. Pellet Mills for Wood: – Single Phase Electric Powered – Three Phase Electric Powered – Diesel Powered – PTO Driven – Die sizes range from 3mm to 12mm, with a standard 6mm die included. 2. Pellet Mills for Feed and…

2. One CPM – Pellet Mills

Domain: onecpm.com

Registered: 2013 (12 years)

Introduction: Pellet Mills: Built to the highest standards for efficiency and safety. Key models include: CL Series (granular solution), 1100 Series (smallest production-scale), 3000 Series (compact workhorse), 7700 Series (intermediate level), 7900 Series (gentle giant), 9000 Series (high output), 9900 Series (largest ring-die), Pioneer Series (varied die sizes), and PM Series (for animal feed, aqua feed, and …

3. eBay – Pellet Mill Machines

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Pellet Mill for sale on eBay includes various models and specifications. Key products include: 1. Feed Pellet Mill Machine 4mm Disc 3Head Roller, 220V, priced at $1,192.86. 2. Chicken Feed Pellet Mill Machine 2mm, 220V, 3kw, priced at $760.46. 3. TECHTONGDA Household Electric Animal Feed Pellet Machine, 220V, 3mm, priced at $838.86. 4. 6mm Chicken Feed Pellet Duck Mill Machine, 220V, priced at $1,…

Strategic Sourcing Conclusion and Outlook for pellets machine maker

As the global market for pellet production continues to evolve, strategic sourcing has become paramount for businesses seeking to enhance operational efficiency and reduce costs. By investing in high-quality pellet mills tailored to specific production needs—whether for wood, animal feed, or biomass—companies can significantly improve their output while minimizing waste. Notably, understanding the diverse options available, from electric to diesel-powered machines, enables businesses to select equipment that aligns with their operational capabilities and regional energy resources.

For international B2B buyers in Africa, South America, the Middle East, and Europe, the focus should be on leveraging local expertise and supplier relationships to ensure optimal sourcing. Engaging with manufacturers that offer turnkey solutions can streamline the implementation process, allowing businesses to focus on scaling production and maximizing profitability.

Looking ahead, the demand for sustainable and efficient pellet production is set to rise. Companies that embrace innovation and invest in advanced pelletizing technologies will be well-positioned to capture emerging market opportunities. Now is the time to act—evaluate your sourcing strategy, connect with reputable pellet machine makers, and prepare to lead in a competitive landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.