A Deep Dive into Paint Conveyor Systems Solution

Introduction: Navigating the Global Market for paint conveyor systems

In an increasingly competitive global market, sourcing reliable paint conveyor systems can present significant challenges for international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe. As manufacturers strive for efficiency and quality in their finishing processes, the need for tailored conveyor solutions that address unique operational requirements becomes paramount. This guide delves into the diverse landscape of paint conveyor systems, exploring various types—ranging from overhead to belt systems—and their specific applications in industries such as automotive, aerospace, and custom fabrication.

Throughout this comprehensive resource, buyers will gain insights into the critical factors influencing their purchasing decisions, including supplier vetting, cost considerations, and the importance of compliance with industry standards. By understanding the nuances of different conveyor technologies and their operational impacts, B2B buyers can navigate the complexities of the market with confidence.

Whether you are in Nigeria seeking advanced powder coating solutions or in Germany looking for efficient wet spray systems, this guide equips you with the knowledge to make informed choices. Empowering your procurement strategy with actionable insights, we aim to enhance your operational efficiency and overall product quality in an ever-evolving industrial landscape.

Understanding paint conveyor systems Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Overhead Conveyor | Enclosed track design prevents contamination; suitable for high-temperature environments. | Automotive, furniture, and metal finishing | Pros: Space-efficient; minimizes overspray. Cons: Higher initial investment. |

| Belt Conveyor | Ground-level operation; designed for heavy items; often used in manual assembly lines. | Food processing, packaging, and assembly lines | Pros: Easy access; versatile for various weights. Cons: Limited to heavier items. |

| Dip Line Conveyor | Immerses parts in paint; ensures uniform coating; ideal for intricate shapes. | Aerospace, industrial equipment, and metal parts | Pros: Consistent finishes; efficient for complex shapes. Cons: Requires more space. |

| Powder Coating Conveyor | Specialized for powder coating applications; can handle high temperatures. | Automotive, appliance, and furniture industries | Pros: Durable finish; eco-friendly. Cons: Higher operational costs. |

| Electrocoating System | Uses electrical current for coating; suitable for water-based paints; ensures even coverage. | Automotive and electronic component manufacturing | Pros: High-quality finish; efficient use of materials. Cons: Requires specialized equipment. |

What Are the Key Characteristics of Overhead Conveyors?

Overhead conveyors are distinguished by their enclosed track design, which protects the internal components from paint overspray and contaminants. They are particularly suitable for high-temperature environments, making them ideal for automotive and furniture finishing lines. When considering an overhead conveyor, B2B buyers should evaluate their production space, the weight and size of the items to be transported, and the specific finishing processes required. These systems are generally more expensive upfront but can lead to significant savings in operational efficiency.

How Do Belt Conveyors Operate in Industrial Settings?

Belt conveyors operate at ground level and are designed to transport heavy items efficiently. Commonly used in food processing and assembly lines, they allow for easy manual access, making them versatile for various applications. When purchasing a belt conveyor, buyers should consider the weight capacity, the materials involved, and the overall layout of the facility. While they offer flexibility and ease of use, they are limited to handling heavier items and may require more frequent maintenance due to wear and tear.

What Advantages Do Dip Line Conveyors Offer?

Dip line conveyors are specifically designed to immerse parts in paint, ensuring a uniform coating across complex shapes. This makes them invaluable in industries like aerospace and industrial equipment manufacturing. Buyers should assess the space requirements and the potential need for additional equipment, such as drying or curing systems. The consistent finishes provided by dip line conveyors can significantly enhance product quality, although they do require more floor space than other conveyor types.

Illustrative image related to paint conveyor systems

Why Choose Powder Coating Conveyors?

Powder coating conveyors are engineered to handle the high temperatures associated with powder coating processes. They are commonly used in automotive and appliance manufacturing due to their ability to deliver a durable and eco-friendly finish. When selecting a powder coating conveyor, B2B buyers must consider the operational costs, maintenance needs, and the specific requirements of their production line. While they are more expensive, the long-lasting finish and lower environmental impact can justify the investment.

What Are the Benefits of Electrocoating Systems?

Electrocoating systems utilize an electrical current to ensure an even coating of water-based paints. This technology is particularly effective for automotive and electronic component manufacturing, where high-quality finishes are essential. Buyers should look into the compatibility of their existing equipment with electrocoating systems and the specific finishing requirements of their products. While the initial setup can be costly, the efficiency and material savings often lead to a favorable return on investment over time.

Key Industrial Applications of paint conveyor systems

| Industry/Sector | Specific Application of paint conveyor systems | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Automated spray painting of vehicle components | Increases throughput and ensures uniform paint coverage | Compatibility with different vehicle sizes and shapes |

| Aerospace | Electrocoating for aircraft parts | Provides corrosion resistance and lightweight finishes | Compliance with aviation standards and regulations |

| Furniture Manufacturing | Powder coating for wood and metal furniture | Enhances durability and aesthetic appeal | Ability to handle various shapes and sizes |

| Industrial Equipment | Dip coating for heavy machinery components | Ensures even coverage and protection from wear | Temperature tolerance and chemical resistance |

| Construction | Coating of structural steel and aluminum frames | Increases lifespan and reduces maintenance costs | Durability against environmental factors and coatings |

How Are Paint Conveyor Systems Used in the Automotive Industry?

In the automotive sector, paint conveyor systems facilitate automated spray painting of vehicle components, ensuring a consistent finish while maximizing production efficiency. These systems can handle various shapes and sizes of parts, making them suitable for diverse vehicle models. For international buyers, especially in regions like Nigeria and Germany, sourcing systems that comply with local regulations and can accommodate high-volume production is crucial. Additionally, systems that minimize overspray and waste can significantly enhance profitability.

Illustrative image related to paint conveyor systems

What Role Do Paint Conveyor Systems Play in Aerospace Manufacturing?

Aerospace manufacturers utilize paint conveyor systems for electrocoating aircraft parts, which provides a durable finish resistant to corrosion and environmental wear. This process is essential for meeting stringent aviation safety standards. Buyers from the Middle East and Europe should consider systems that are not only compliant with international aerospace regulations but also capable of delivering lightweight coatings that do not compromise structural integrity. The ability to integrate with existing assembly lines is another key requirement.

How Are Paint Conveyor Systems Beneficial in Furniture Manufacturing?

In furniture manufacturing, paint conveyor systems, particularly those designed for powder coating, enhance the durability and aesthetic appeal of wood and metal pieces. These systems allow for efficient handling of awkwardly shaped items, ensuring even coverage and reducing labor costs. Buyers in South America and Africa should prioritize sourcing systems that can accommodate various materials and finishes while ensuring compliance with local environmental regulations regarding paint emissions.

How Do Paint Conveyor Systems Improve Coating Processes for Industrial Equipment?

For industrial equipment, paint conveyor systems are often employed in dip coating applications, which provide uniform coverage and protection against wear and corrosion. This is critical for maintaining the longevity and reliability of heavy machinery components. International buyers must evaluate the thermal and chemical resistance of the systems, especially when dealing with high-temperature processes. Additionally, considering the space requirements for installation and the ability to integrate with existing workflows is vital for optimizing operational efficiency.

Why Are Paint Conveyor Systems Important in Construction Applications?

In the construction sector, paint conveyor systems are used for coating structural steel and aluminum frames, significantly extending the lifespan of these materials. By providing a protective layer that withstands environmental factors, businesses can reduce maintenance costs and improve safety. Buyers from various regions should focus on sourcing systems that offer durability against harsh weather conditions and that comply with local building codes. Furthermore, understanding the specific coating types suitable for different materials is essential for effective procurement.

3 Common User Pain Points for ‘paint conveyor systems’ & Their Solutions

Scenario 1: Inconsistent Paint Quality Leads to Increased Waste

The Problem: B2B buyers often face the challenge of inconsistent paint application on products moving through conveyor systems. This inconsistency can result from various factors, including equipment malfunctions, improper conveyor speed, or inadequate integration with paint booths. The consequence is significant: defective products that require rework or disposal, leading to wasted materials and increased production costs.

The Solution: To mitigate this issue, it is crucial to invest in high-quality conveyor systems that are specifically engineered for paint applications. When sourcing paint conveyor systems, prioritize options that feature precision control over speed and paint flow. Additionally, consider systems that provide real-time monitoring capabilities to track paint application consistency. By integrating these systems with automated paint booths designed for your specific process—be it powder coating, wet spray, or electrocoating—you can ensure a uniform application. Regular maintenance and calibration of equipment can also help sustain paint quality, reducing waste and improving overall efficiency.

Scenario 2: Equipment Downtime Due to Contamination

The Problem: Another common pain point for B2B buyers is equipment downtime caused by contamination from paint overspray or chemical buildup. Contaminants can lead to mechanical failures, increased maintenance costs, and production delays, which ultimately affect profitability. This is particularly problematic in high-volume environments where every minute of downtime translates directly into lost revenue.

Illustrative image related to paint conveyor systems

The Solution: To combat contamination issues, select paint conveyor systems with enclosed tracks, such as those offered by leading manufacturers. Enclosed track systems protect critical components from paint and chemical overspray, reducing the risk of contamination. Furthermore, implementing a routine cleaning schedule that aligns with your production cycles can prevent buildup and extend the lifespan of your equipment. Additionally, consider using specialized coatings for your conveyor system that resist chemical corrosion and are easy to clean. Investing in proper training for your staff on maintenance and cleaning procedures can also play a significant role in minimizing downtime.

Scenario 3: Limited Flexibility in Production Layout

The Problem: Many B2B buyers encounter difficulties when their production layout needs to adapt to new product lines or changing market demands. Traditional conveyor systems often lack the flexibility to accommodate various product shapes and sizes or to reroute materials efficiently, leading to bottlenecks and inefficiencies in the workflow.

The Solution: To enhance flexibility, look for modular conveyor systems that allow for easy reconfiguration and expansion. Systems like power-and-free conveyors enable products to be routed to different stations without stopping the entire line, facilitating a smoother workflow. When specifying your conveyor system, include features that support multiple configurations, such as adjustable track heights and curves that fit your available space. Additionally, consulting with engineering experts who understand your specific operational needs can help tailor a system that can quickly adapt to changes in production requirements. By investing in a flexible conveyor solution, you can significantly improve your operational agility and responsiveness to market demands.

Illustrative image related to paint conveyor systems

Strategic Material Selection Guide for paint conveyor systems

What Are the Key Materials Used in Paint Conveyor Systems?

When selecting materials for paint conveyor systems, it is essential to consider their properties, advantages, disadvantages, and compatibility with specific applications. Here, we analyze four common materials used in the construction of paint conveyor systems: steel, aluminum, plastic, and stainless steel.

How Does Steel Perform in Paint Conveyor Systems?

Steel is a widely used material in paint conveyor systems due to its strength and durability. It typically has a high temperature rating, making it suitable for environments where heat is a factor, such as in ovens used for curing paint. Steel’s corrosion resistance can be enhanced through coatings or galvanization, but it may still be susceptible to rust if not properly maintained.

Pros: Steel offers excellent strength and load-bearing capacity, making it ideal for heavy-duty applications. It is also relatively cost-effective compared to other materials.

Illustrative image related to paint conveyor systems

Cons: The primary drawback of steel is its weight, which can complicate installation and increase transportation costs. Additionally, without protective coatings, it can corrode, leading to increased maintenance needs.

For international buyers, particularly in regions like Africa and South America, compliance with local standards (e.g., ASTM) and the availability of protective coatings are crucial considerations.

What Advantages Does Aluminum Offer for Paint Conveyor Systems?

Aluminum is favored for its lightweight properties and resistance to corrosion, making it an excellent choice for overhead conveyor systems. It can withstand moderate temperatures and is often used in environments where weight reduction is critical.

Pros: The main advantage of aluminum is its low weight, which simplifies installation and reduces energy consumption during operation. It also has inherent corrosion resistance, which minimizes maintenance.

Cons: However, aluminum may not be suitable for very high-temperature applications or heavy loads, as it can deform under stress. Its cost is generally higher than that of steel.

International buyers should consider the availability of aluminum in their region and any specific certifications required for use in industrial applications.

Why Is Plastic a Viable Option for Paint Conveyor Systems?

Plastic materials, such as high-density polyethylene (HDPE) or polyvinyl chloride (PVC), are increasingly used in paint conveyor systems, particularly for components like rollers and guides. These materials are lightweight and resistant to chemicals, making them suitable for various paint applications.

Pros: Plastic components are resistant to corrosion and chemicals, which is advantageous in environments where paint overspray is common. They are also lightweight, leading to easier handling and installation.

Cons: The primary limitation of plastic is its lower load-bearing capacity compared to metals, which may restrict its use in heavy-duty applications. Additionally, plastics can be more susceptible to wear and tear over time.

Illustrative image related to paint conveyor systems

For international buyers, understanding the specific grades of plastic that meet local standards is essential to ensure compatibility with the intended application.

How Does Stainless Steel Compare in Paint Conveyor Systems?

Stainless steel is renowned for its corrosion resistance and hygienic properties, making it ideal for applications requiring high cleanliness, such as in food processing or medical equipment. It can withstand high temperatures and is durable enough for various industrial applications.

Pros: The key advantage of stainless steel is its superior resistance to corrosion and staining, which prolongs the lifespan of the conveyor system. It also maintains structural integrity under varying temperatures.

Illustrative image related to paint conveyor systems

Cons: The main drawback is its higher cost compared to other materials like carbon steel and aluminum. It can also be more challenging to work with due to its hardness.

For international buyers, particularly in Europe, compliance with standards such as DIN for stainless steel is critical, and understanding the specific grades suitable for their applications is essential.

Summary Table of Material Selection for Paint Conveyor Systems

| Material | Typical Use Case for paint conveyor systems | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Heavy-duty applications | Excellent strength and load-bearing | Susceptible to corrosion without coatings | Medium |

| Aluminum | Lightweight overhead systems | Low weight reduces energy consumption | Not suitable for high temperatures or heavy loads | High |

| Plastic | Rollers and guides in various applications | Corrosion and chemical resistance | Lower load-bearing capacity | Medium |

| Stainless Steel | Hygienic applications in food/medical sectors | Superior corrosion resistance | Higher cost and harder to work with | High |

This guide serves as a foundational resource for international B2B buyers looking to make informed decisions on material selection for paint conveyor systems, ensuring compatibility with their operational needs and compliance with regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for paint conveyor systems

What Are the Main Stages in the Manufacturing Process of Paint Conveyor Systems?

The manufacturing process for paint conveyor systems is a multi-stage operation that requires precision and attention to detail. Each stage plays a crucial role in ensuring the final product meets industry standards and customer expectations.

Material Preparation: What Materials Are Used and Why?

The first stage involves the selection and preparation of materials. Common materials include steel, aluminum, and various plastics, chosen for their durability and resistance to chemicals and high temperatures. Steel is often used for structural components due to its strength, while aluminum may be selected for lighter applications. Proper treatment processes, such as galvanization or powder coating, are applied to prevent corrosion, ensuring longevity in harsh environments.

Forming: How Are Components Shaped for Optimal Performance?

Following material preparation, the forming stage begins. This typically involves cutting, bending, and welding the selected materials into specific shapes that will fit together to form the conveyor system. Advanced techniques such as laser cutting and CNC machining may be utilized to ensure high precision. The choice of forming technique can impact the efficiency and effectiveness of the paint application process, as well as the overall operational reliability of the conveyor system.

Assembly: What Techniques Ensure a Seamless Build?

The assembly stage brings together all formed components into a complete conveyor system. This process often employs both manual and automated methods, depending on the complexity and size of the system. Key techniques include bolting, welding, and the use of rivets, which ensure robust connections between parts. During assembly, attention is paid to alignment and functionality, as any misalignment can lead to operational issues during the paint application process.

Finishing: What Processes Enhance Durability and Performance?

Finishing is the final stage of manufacturing and is critical for protecting the conveyor system from wear and tear. Various finishing techniques are employed, including powder coating, wet painting, and electrocoating. Each method provides different levels of protection against chemicals, heat, and physical abrasion. The finishing process not only enhances aesthetics but also ensures that the conveyor system can withstand the rigors of paint application environments.

How Is Quality Assurance Integrated into Paint Conveyor Systems Manufacturing?

Quality assurance (QA) is a vital component of the manufacturing process, ensuring that every conveyor system meets international standards and customer specifications. Various QA checkpoints and international standards guide this process.

What International Standards Should B2B Buyers Be Aware Of?

For B2B buyers, understanding the relevant international standards is essential. ISO 9001 is a widely recognized standard that focuses on quality management systems and continuous improvement. Compliance with this standard indicates a commitment to quality and customer satisfaction.

Additionally, industry-specific certifications such as CE marking (for products sold in the European Economic Area) and API standards (for products used in the petroleum and natural gas industry) provide further assurance of quality. Buyers from regions such as Africa, South America, the Middle East, and Europe should verify these certifications during the supplier selection process.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control is typically divided into three main checkpoints: Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified requirements. Any defective materials are rejected, preventing downstream issues.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, regular inspections are conducted to monitor the quality of the work being performed. This includes verifying dimensions, checking for weld integrity, and ensuring that assembly processes adhere to specifications.

-

Final Quality Control (FQC): Before shipment, a comprehensive inspection of the finished product is performed. This includes functional testing to ensure the conveyor operates as intended, as well as visual inspections for surface finishes and overall construction quality.

What Testing Methods Are Commonly Used in Quality Assurance?

Various testing methods are employed to verify the quality and performance of paint conveyor systems. These methods may include:

Illustrative image related to paint conveyor systems

- Load Testing: Ensures the conveyor can handle the specified weight limits without failure.

- Operational Testing: Involves running the conveyor to assess its performance under normal operating conditions.

- Corrosion Resistance Testing: Evaluates how well the conveyor system resists environmental factors that could lead to deterioration.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must take proactive steps to ensure that suppliers adhere to rigorous quality control standards. Here are some strategies to verify QC practices:

-

Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. Buyers should request access to audit reports to assess compliance with international standards.

-

Request Documentation: Suppliers should provide documentation related to their quality management systems, including certifications and process descriptions. This transparency is crucial in building trust.

-

Third-Party Inspections: Engaging third-party inspection services can offer an independent assessment of the supplier’s quality control practices. This can be particularly beneficial for international buyers who may not be able to visit suppliers in person.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers face unique challenges when it comes to quality control. Factors such as cultural differences, language barriers, and varying local regulations can complicate the QC process. Buyers should be aware of these nuances and may consider the following:

-

Cultural Sensitivity: Understanding cultural differences can improve communication and collaboration with suppliers. This is particularly relevant in regions like Africa and the Middle East, where business practices may differ significantly.

-

Local Regulations: Familiarize yourself with local regulations that may affect product compliance and quality standards. This knowledge is essential for ensuring that imported conveyor systems meet local requirements.

-

Building Relationships: Establishing strong relationships with suppliers can facilitate better quality control practices. Regular communication and feedback can help ensure that both parties are aligned on quality expectations.

In summary, a thorough understanding of the manufacturing processes and quality assurance practices for paint conveyor systems is crucial for B2B buyers. By focusing on these areas, buyers can make informed decisions and select suppliers that meet their specific needs, ensuring high-quality outcomes in their operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘paint conveyor systems’

Introduction

When sourcing paint conveyor systems, B2B buyers must navigate a complex landscape of options to ensure they select the right equipment for their specific needs. This checklist serves as a practical guide to help you systematically evaluate your requirements, assess suppliers, and ultimately make an informed purchasing decision. Following these steps will streamline your procurement process and enhance the efficiency of your operations.

Illustrative image related to paint conveyor systems

Step 1: Define Your Technical Specifications

Begin by clearly outlining the technical requirements for your paint conveyor system. This includes the weight, size, and shape of the items you will be conveying, as well as the type of finishing processes you will employ, such as powder coating, wet spray, or electrocoating.

– Considerations: Identify the materials (metal, wood, plastic) and the environmental conditions (temperature, humidity) that your conveyor will be exposed to.

Step 2: Assess Your Space and Layout

Evaluate the physical space available for installation. The configuration of your facility will dictate whether you need a floor-level or overhead conveyor system.

– Tips: Measure the height, width, and length of the area where the conveyor will be installed to ensure it fits within your operational workflow. Consider potential obstructions from existing equipment.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough due diligence. Request company profiles, case studies, and references from buyers in similar industries or regions.

– What to Look For: Assess their experience in your specific application and verify their compliance with industry standards (e.g., OSHA, NFPA). A reputable supplier should provide documented evidence of successful projects.

Illustrative image related to paint conveyor systems

Step 4: Inquire About Customization Options

Different manufacturing processes may require specific conveyor configurations. Inquire if the supplier offers customization options tailored to your operational needs.

– Important Features: Look for flexibility in conveyor design, such as the ability to accommodate various product sizes and shapes or integrate with existing production lines.

Step 5: Request Detailed Proposals and Quotes

Once you have shortlisted potential suppliers, request comprehensive proposals that detail the specifications, pricing, and timelines for installation.

– Key Elements: Ensure the proposals include warranty information, maintenance services, and any additional costs related to installation or training for your staff.

Step 6: Verify Supplier Support and Maintenance Services

Assess the level of ongoing support and maintenance the supplier offers post-installation. A strong support system can minimize downtime and enhance productivity.

– What to Ask: Inquire about their response times for service requests, availability of replacement parts, and training programs for your employees.

Step 7: Review and Finalize Contracts

Before finalizing your purchase, review the contract thoroughly. Pay close attention to payment terms, delivery schedules, and conditions for warranty claims.

– Best Practices: Ensure that all verbal agreements are documented and clarify any ambiguous terms to avoid potential disputes in the future.

Illustrative image related to paint conveyor systems

By following this checklist, B2B buyers can make well-informed decisions when sourcing paint conveyor systems, ensuring they select equipment that meets their operational needs while optimizing efficiency and productivity.

Comprehensive Cost and Pricing Analysis for paint conveyor systems Sourcing

Understanding the cost structure and pricing dynamics of paint conveyor systems is essential for international B2B buyers. This analysis highlights the components that contribute to the overall cost, the factors influencing pricing, and practical tips for optimizing procurement.

What Are the Key Cost Components of Paint Conveyor Systems?

The cost of paint conveyor systems can be broken down into several critical components:

-

Materials: The choice of materials significantly impacts cost. High-quality steel for structural components, specialized coatings for corrosion resistance, and durable conveyor belts all contribute to the overall expense. The complexity of the paint system—whether it’s a simple belt conveyor or a sophisticated power-and-free system—also affects material costs.

-

Labor: Labor costs include both the assembly and installation of the conveyor systems. Skilled labor is often required for custom installations, especially for complex systems that integrate with existing workflows.

-

Manufacturing Overhead: This encompasses factory expenses, utilities, and administrative costs. Efficient manufacturing processes can help reduce overhead, impacting the final pricing.

-

Tooling: Custom tooling required for specific designs or modifications can add to initial costs. Standardized designs typically incur lower tooling expenses.

-

Quality Control (QC): Rigorous testing and quality assurance measures are essential, particularly for systems that must operate reliably in demanding environments. QC processes can add to both time and costs but are crucial for ensuring product longevity and performance.

-

Logistics: Shipping and transportation costs vary based on the destination and the complexity of the system. International buyers should consider customs duties and potential tariffs, which can influence the total landed cost.

-

Margin: Suppliers typically add a markup to cover their costs and ensure profitability. Understanding supplier margins can help buyers negotiate more effectively.

What Influences the Pricing of Paint Conveyor Systems?

Several factors can influence the pricing of paint conveyor systems:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to discounts. Buyers should assess their needs carefully to take advantage of economies of scale.

-

Specifications and Customization: Custom solutions tailored to specific operational needs can significantly raise costs. Buyers must weigh the benefits of customization against their budget constraints.

-

Material Quality and Certifications: Systems made from high-grade materials or those that meet specific industry certifications tend to be pricier. However, investing in quality can lead to lower maintenance costs and a longer lifespan.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more but offer better service, warranty, and support.

-

Incoterms: Understanding the shipping terms is critical. Different Incoterms can lead to variations in pricing, as they dictate who is responsible for shipping costs, insurance, and tariffs.

How Can Buyers Negotiate and Optimize Costs?

-

Leverage Volume Discounts: When placing orders, consider bundling purchases to qualify for volume discounts. This strategy can lead to significant savings.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider long-term operational costs, including maintenance, energy consumption, and potential downtime. A slightly higher upfront cost may result in lower TCO.

-

Understand Pricing Nuances in International Markets: Buyers from Africa, South America, the Middle East, and Europe should be aware of local market conditions, including currency fluctuations and regional demand, which can impact pricing.

-

Negotiate Terms: Don’t hesitate to negotiate terms that can lead to better pricing. Discussing payment terms, delivery schedules, and warranty provisions can create a more favorable deal.

-

Request Detailed Quotes: When seeking quotes, ask for itemized breakdowns of costs. This transparency can help identify areas for negotiation and clarify the value offered by different suppliers.

Conclusion

Investing in paint conveyor systems involves careful consideration of various cost components and pricing influences. By understanding these dynamics, B2B buyers can make informed decisions that align with their operational needs and budget constraints. While indicative prices can provide a starting point, thorough market research and supplier engagement are essential for achieving the best value.

Alternatives Analysis: Comparing paint conveyor systems With Other Solutions

Exploring Alternatives to Paint Conveyor Systems for Industrial Applications

In the realm of industrial painting and finishing processes, selecting the right system is crucial for optimizing workflow, ensuring product quality, and managing costs. While paint conveyor systems are widely recognized for their efficiency and effectiveness in transporting items through various stages of painting, other alternatives exist that may be better suited to specific operational needs. This analysis will compare paint conveyor systems with two notable alternatives: manual painting methods and robotic painting systems.

| Comparison Aspect | Paint Conveyor Systems | Manual Painting Methods | Robotic Painting Systems |

|---|---|---|---|

| Performance | High throughput and consistency | Variable quality and speed | High precision and repeatability |

| Cost | Higher initial investment | Lower upfront costs, but higher labor costs | High initial cost, but lower long-term labor costs |

| Ease of Implementation | Requires space and setup | Minimal setup, but requires skilled labor | Complex setup and programming |

| Maintenance | Moderate, with specialized parts | Low, but dependent on workforce skill | High, with regular software updates and maintenance |

| Best Use Case | High-volume production runs | Custom, low-volume applications | High precision applications, complex shapes |

Detailed Breakdown of Alternatives

Manual Painting Methods

Manual painting methods involve skilled workers applying paint directly to products using brushes, rollers, or spray guns. This approach provides flexibility, allowing workers to adapt techniques based on the specific needs of each piece. However, the reliance on human skill introduces variability in quality and efficiency. This method is best suited for custom jobs or low-volume production where precision and artistry are paramount. While initial costs are lower due to minimal equipment needs, the ongoing labor costs can accumulate, making it less economical for larger operations.

Illustrative image related to paint conveyor systems

Robotic Painting Systems

Robotic painting systems utilize automated robots to apply paint with high precision and repeatability. These systems are especially advantageous for complex parts and high-volume production, ensuring uniform coverage and minimizing waste. Although the initial investment can be substantial, the long-term savings in labor and material costs can offset this expense. However, implementing robotic systems requires significant setup and programming, which may pose challenges for facilities without prior automation experience. Regular maintenance and updates are necessary to keep these systems running optimally.

Conclusion: Making the Right Choice for Your Business Needs

When considering the best solution for your painting and finishing processes, it is essential to evaluate your specific operational requirements. Paint conveyor systems offer high efficiency and consistency for large-scale operations, while manual methods provide flexibility for custom projects. On the other hand, robotic systems deliver unmatched precision for complex applications but come with higher upfront costs. B2B buyers should assess factors such as production volume, product complexity, available space, and budget constraints to determine the most suitable painting solution for their business. By aligning the chosen method with operational needs, businesses can enhance productivity, ensure quality, and achieve a competitive edge in the market.

Essential Technical Properties and Trade Terminology for paint conveyor systems

What Are the Key Technical Properties of Paint Conveyor Systems?

Understanding the technical specifications of paint conveyor systems is crucial for B2B buyers to ensure compatibility with their production lines and to maximize operational efficiency. Here are several essential properties to consider:

1. Material Grade

The material grade of conveyor components (such as steel, aluminum, or stainless steel) is fundamental to the system’s durability and resistance to corrosion. For paint conveyor systems, materials must withstand exposure to chemicals and high temperatures, especially in environments like spray booths or ovens. High-grade materials also contribute to lower maintenance costs and longer operational lifespans.

2. Load Capacity

Load capacity refers to the maximum weight a conveyor can handle while maintaining its performance. It is vital for B2B buyers to evaluate the weight of the items being transported, as exceeding the load limit can lead to system breakdowns or inefficiencies. Knowing the load capacity ensures that the conveyor can accommodate the specific needs of your production line, whether for lightweight components or heavier machinery parts.

Illustrative image related to paint conveyor systems

3. Temperature Tolerance

Conveyors used in paint applications often operate in environments with elevated temperatures, particularly in curing ovens. The temperature tolerance indicates the maximum temperature the conveyor can withstand without degradation. Systems with higher temperature tolerances are essential for maintaining efficiency and ensuring that the paint curing process is not compromised, which can affect the quality of the finished product.

4. Speed and Efficiency

The speed of a conveyor system impacts the overall productivity of the manufacturing process. Buyers should consider the speed settings available and how they align with production requirements. Efficient conveyors reduce downtime and ensure a continuous flow of materials, which is critical for meeting production deadlines.

5. System Configuration

The configuration of a conveyor system (overhead, floor-mounted, or hybrid) affects how well it integrates into existing workflows. Overhead conveyors are particularly useful in paint applications as they save floor space and minimize the risk of contamination from overspray. Buyers should evaluate the available space and the specific layout of their facilities to choose the most effective configuration.

Illustrative image related to paint conveyor systems

6. Maintenance Requirements

Understanding the maintenance needs of a conveyor system is crucial for operational planning. Some systems may require more frequent inspections and part replacements than others, impacting labor costs and downtime. Buyers should consider systems designed for ease of maintenance, which can enhance productivity and reduce long-term operational costs.

What Are Common Trade Terms Used in Paint Conveyor Systems?

Familiarizing oneself with industry terminology is essential for effective communication and negotiation in the B2B landscape. Here are some key terms related to paint conveyor systems:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM specifications is important for buyers to ensure compatibility and quality in replacement parts or new systems.

2. MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a supplier is willing to sell. Knowing the MOQ is critical for budget planning and inventory management, especially for buyers looking to scale their operations.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. This term is essential for buyers to initiate the procurement process and compare offers from different vendors.

4. Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with these terms helps buyers understand shipping responsibilities, risks, and costs associated with the procurement of conveyor systems.

5. Lead Time

Lead time is the amount of time from placing an order to receiving it. For B2B buyers, understanding lead times is crucial for project planning and ensuring that production schedules are not disrupted.

6. Customization

Customization refers to the ability to modify conveyor systems to meet specific operational needs. Buyers should assess the level of customization offered by suppliers to ensure the conveyor system aligns perfectly with their production requirements.

Understanding these technical properties and industry terms can empower B2B buyers to make informed decisions when selecting paint conveyor systems, ultimately enhancing production efficiency and product quality.

Navigating Market Dynamics and Sourcing Trends in the paint conveyor systems Sector

What Are the Current Market Dynamics and Key Trends in the Paint Conveyor Systems Sector?

The global market for paint conveyor systems is experiencing significant transformation driven by several factors. Key trends include the adoption of automation and Industry 4.0 technologies, which enhance operational efficiency and reduce labor costs. For B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding these advancements is crucial for making informed sourcing decisions. The demand for customized solutions tailored to specific production needs is also on the rise, allowing manufacturers to optimize their workflows and improve product quality.

Emerging technologies, such as IoT-enabled conveyor systems, are facilitating real-time monitoring and predictive maintenance, which can significantly reduce downtime. Buyers are increasingly looking for suppliers who can provide integrated solutions that combine conveyor systems with advanced paint application technologies, including powder coating and electrocoating. Moreover, sustainability is becoming a central theme, with businesses seeking systems that minimize waste and energy consumption. The ability to adapt to diverse production environments, whether for automotive, aerospace, or custom fabrication industries, is also a driving force behind sourcing decisions.

How Does Sustainability and Ethical Sourcing Impact the Paint Conveyor Systems Sector?

Sustainability is no longer just a buzzword; it has become a critical factor in sourcing decisions for paint conveyor systems. Environmental considerations include minimizing the carbon footprint of manufacturing processes and ensuring that materials used in conveyor systems are recyclable or sourced from sustainable practices. B2B buyers are increasingly aware of the environmental impact of their supply chains, and they prefer suppliers that prioritize eco-friendly solutions.

Ethical sourcing is equally important, as companies strive to ensure that their suppliers adhere to fair labor practices and responsible sourcing of materials. Certifications such as ISO 14001 (Environmental Management) and other green certifications are becoming essential for suppliers aiming to prove their commitment to sustainability. Additionally, using low-VOC (volatile organic compound) paints and coatings contributes to healthier working environments and compliance with regulatory standards. By choosing suppliers that prioritize sustainability, buyers can enhance their corporate responsibility initiatives while also benefiting from improved operational efficiencies and reduced long-term costs.

What Is the Brief Evolution of Paint Conveyor Systems and Its Relevance for B2B Buyers?

The evolution of paint conveyor systems can be traced back to the early 20th century when assembly line manufacturing began to take hold. Initially, these systems were simple belt conveyors, but as technology advanced, so did the complexity and efficiency of the systems. The introduction of overhead conveyors allowed for more versatile layouts and improved space utilization in manufacturing facilities.

Over the decades, the integration of automation and advanced coating technologies has transformed the paint finishing process. Today, systems are designed not only for efficiency but also for flexibility, accommodating various types of finishes and substrates. For B2B buyers, understanding this evolution is critical for recognizing the capabilities of modern conveyor systems and how they can be leveraged to meet specific production needs. As industries continue to innovate, staying informed about the latest advancements will empower buyers to make strategic sourcing decisions that align with their operational goals.

Illustrative image related to paint conveyor systems

Frequently Asked Questions (FAQs) for B2B Buyers of paint conveyor systems

-

How do I select the right paint conveyor system for my manufacturing needs?

Selecting the right paint conveyor system involves assessing several critical factors, including the size, weight, and shape of the items to be painted, as well as the specific finishing process required (e.g., powder coating, wet spray, or electrocoating). Consider the physical space available for installation and whether overhead or floor-level systems are more suitable. Additionally, evaluate the quality of the finish needed and the operational environment, such as temperature and the presence of chemicals. Engaging with a supplier for a tailored consultation can streamline this selection process. -

What types of paint conveyor systems are available for different applications?

There are several types of paint conveyor systems designed for various applications. Overhead conveyors are ideal for lightweight items and complex layouts, while floor-based belt conveyors are suited for heavier loads. Systems can be tailored for specific processes such as powder coating, wet spray, or dip coating. Customization options may include enclosed tracks to prevent overspray and contamination. Selecting the right system ensures optimal efficiency and quality in the painting process, catering to your industry’s unique requirements. -

What are the typical payment terms for purchasing paint conveyor systems?

Payment terms for paint conveyor systems can vary significantly depending on the supplier and the scale of the order. Common practices include a deposit upon order confirmation, followed by the balance due prior to shipping or upon installation. For large projects, phased payments based on project milestones may be negotiated. It’s essential to clarify payment terms upfront, including any financing options or discounts for early payment, to align with your budgetary constraints and cash flow management. -

How can I ensure quality assurance (QA) for paint conveyor systems?

To ensure quality assurance for paint conveyor systems, request detailed specifications and certifications from suppliers, such as compliance with industry standards like OSHA and NFPA. Conduct regular inspections and audits during manufacturing to monitor adherence to quality benchmarks. Additionally, consider suppliers that offer warranties and post-installation support, ensuring any issues can be addressed promptly. Establishing a solid QA process minimizes risks and enhances the reliability of the systems in your production line. -

What should I consider when vetting suppliers for paint conveyor systems?

When vetting suppliers, focus on their experience, reputation, and customer feedback within your specific industry. Verify certifications and compliance with international standards to ensure safety and quality. Assess their capacity for customization and support services, including installation and maintenance. Additionally, consider their geographic location and logistics capabilities to ensure timely delivery and service. Engaging in discussions with previous clients can also provide insights into the supplier’s reliability and after-sales support. -

What are the logistics considerations for importing paint conveyor systems internationally?

Logistics for importing paint conveyor systems involve several key factors, including shipping methods, customs regulations, and import duties specific to your country. Ensure that the supplier provides all necessary documentation, such as bills of lading, invoices, and compliance certificates, to facilitate smooth customs clearance. Consider working with a logistics partner experienced in international trade to navigate potential challenges and optimize delivery timelines. Additionally, factor in lead times for both manufacturing and shipping to align with your production schedules. -

What are the minimum order quantities (MOQ) for paint conveyor systems?

Minimum order quantities (MOQ) for paint conveyor systems vary by supplier and the complexity of the system being ordered. Some manufacturers may have flexible MOQs for standard models, while custom systems may require larger orders to justify production costs. It’s advisable to discuss MOQs during initial negotiations and explore options for scaling orders over time. Understanding the supplier’s policies can help you plan your procurement strategy and manage inventory effectively. -

How can I customize a paint conveyor system to meet my specific operational needs?

Customizing a paint conveyor system involves working closely with suppliers to define your operational requirements, such as load capacity, speed, layout, and the type of finishing process. Discuss potential modifications like track configurations, component materials, and automation features that enhance efficiency and integration with existing systems. Request prototypes or simulations to visualize the system’s functionality before full-scale production. A collaborative approach ensures the final solution is tailored to optimize your workflow and meet production goals.

Top 7 Paint Conveyor Systems Manufacturers & Suppliers List

1. PACLINE – Conveyor Systems for Paint and Finishing

Domain: pacline.com

Registered: 1996 (29 years)

Introduction: PACLINE offers a variety of conveyor systems for paint and finishing operations, including solutions for powder coating, wet spray, dip line, and E-coat applications. Key features include:

– Enclosed track design to prevent contaminants from affecting conveyor components.

– PAC-MAX™ high-capacity conveyor can be inverted or installed sideways to avoid contact with painted parts.

– PAC-TRAK™ towlin…

2. Eisenmann – VarioMover

Domain: eisenmann.com

Registered: 1996 (29 years)

Introduction: Conveyor System – Eisenmann GmbH

1. **VarioMover**: Automated guided vehicle for car body coating processes. Configurable as PaintMover (skidless transport) or StoreMover (scalable storage). Load capacity: 1,500 kg. Omnidirectional movement, 360-degree safety with LiDAR, compatible with various batteries, 93% recharging efficiency.

2. **PaintMover**: Driverless transport of car bodies through co…

3. Spray-Tech – Paint Line Conveyor Systems

Domain: spraytech.com

Registered: 1996 (29 years)

Introduction: Paint Line Conveyor Systems from Spray-Tech are designed for efficiency, consistency, and quality in various operations. They cater to high-volume manufacturers, mid-sized facilities, and specialty operations with flexible layouts. With over 65 years of engineering experience, these systems integrate seamlessly with paint booths, ovens, and washers, providing a complete automated finishing solutio…

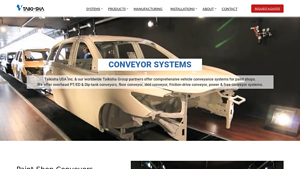

4. Taikisha USA Inc. – Vehicle Conveyance Systems

Domain: taikisha-na.com

Registered: 2024 (1 years)

Introduction: Taikisha USA Inc. offers comprehensive vehicle conveyance systems for paint shops, including overhead PT/ED & Dip-tank conveyors, floor conveyors, skid conveyors, friction-drive conveyors, and power & free conveyor systems. They provide design/build services for conveyor systems used in industrial painting systems across various industries such as automotive, heavy trucking, aerospace, and more. K…

5. RW Conveyor – Finishing Line Conveyors

Domain: rwconveyor.com

Registered: 2002 (23 years)

Introduction: Finishing Line Conveyors include monorail, power, and free conveyor solutions designed for flexibility, reliability, and customization. They cater to various applications from simple paint line conveyors to large-scale robotic systems. Key offerings include: Standard (Monorail) Systems – cost-effective, follow one path, powered manually or by a continuous chain; Power & Free Systems – overhead sys…

6. Material Flow – Overhead Conveyor Systems

Domain: materialflow.com

Registered: 1998 (27 years)

Introduction: Overhead Conveyor Systems for Paint and Finish Lines by Material Flow. Options include Econo Conveyor, Gregory Adams, Jervis Webb, Litton Conveyors, Pacline, Rapid Overhead, RW Richards, Wilcox, Saferail, Unibilt, Zig-Zag. Features include replacement track, replacement chain, replacement motors, light duty overhead, light duty push line, manual lines, paint lines, powered lines, power & free line…

7. Hi-Colo – Paint and Finishing Line Conveyors

Domain: m.hi-colo.com

Registered: 2012 (13 years)

Introduction: {“product_name”: “Paint and Finishing Line Conveyors”, “model”: “Paint and Finishing Line Conveyors”, “item_specifics”: {“origin”: “Original China”, “use”: “Chain transportation”, “customized”: “yes”, “delivery_time”: “10 days”}, “description”: “Overhead conveyor systems can be manual, powered or more sophisticated power and free type; in all cases your overhead conveyor systems will improve the p…

Strategic Sourcing Conclusion and Outlook for paint conveyor systems

In the dynamic landscape of industrial manufacturing, the strategic sourcing of paint conveyor systems is essential for optimizing production efficiency and ensuring high-quality finishes. Key considerations include selecting the appropriate conveyor type based on product size, weight, and finishing requirements, as well as understanding the environmental conditions that impact the longevity and performance of these systems. Leveraging advanced technologies such as overhead conveyors and dip lines can significantly enhance operational workflows while minimizing maintenance costs.

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, the emphasis on tailored solutions becomes increasingly important. Investing in robust, compliant, and customized conveyor systems not only boosts productivity but also aligns with global standards for safety and quality.

As the market continues to evolve, embracing innovations in paint conveyor systems will be crucial. Buyers are encouraged to engage with suppliers who can offer comprehensive solutions that meet their unique operational needs. By prioritizing strategic sourcing, companies can position themselves for sustained growth and competitive advantage in an ever-changing industrial landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.